Numerical Simulation Study of a Pusher Feed Classifier Based on RNG-DPM Method

Abstract

1. Introduction

2. Materials and Methods

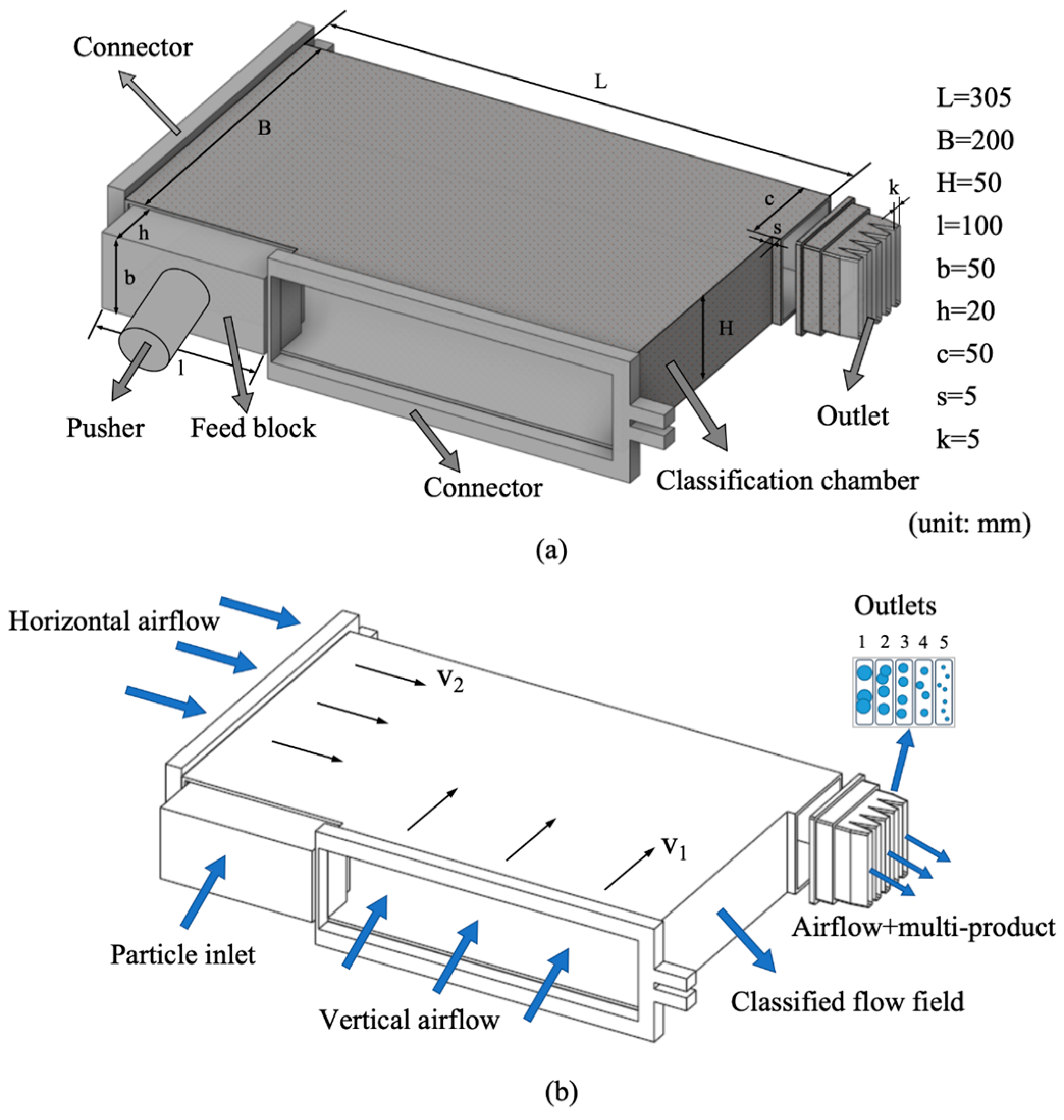

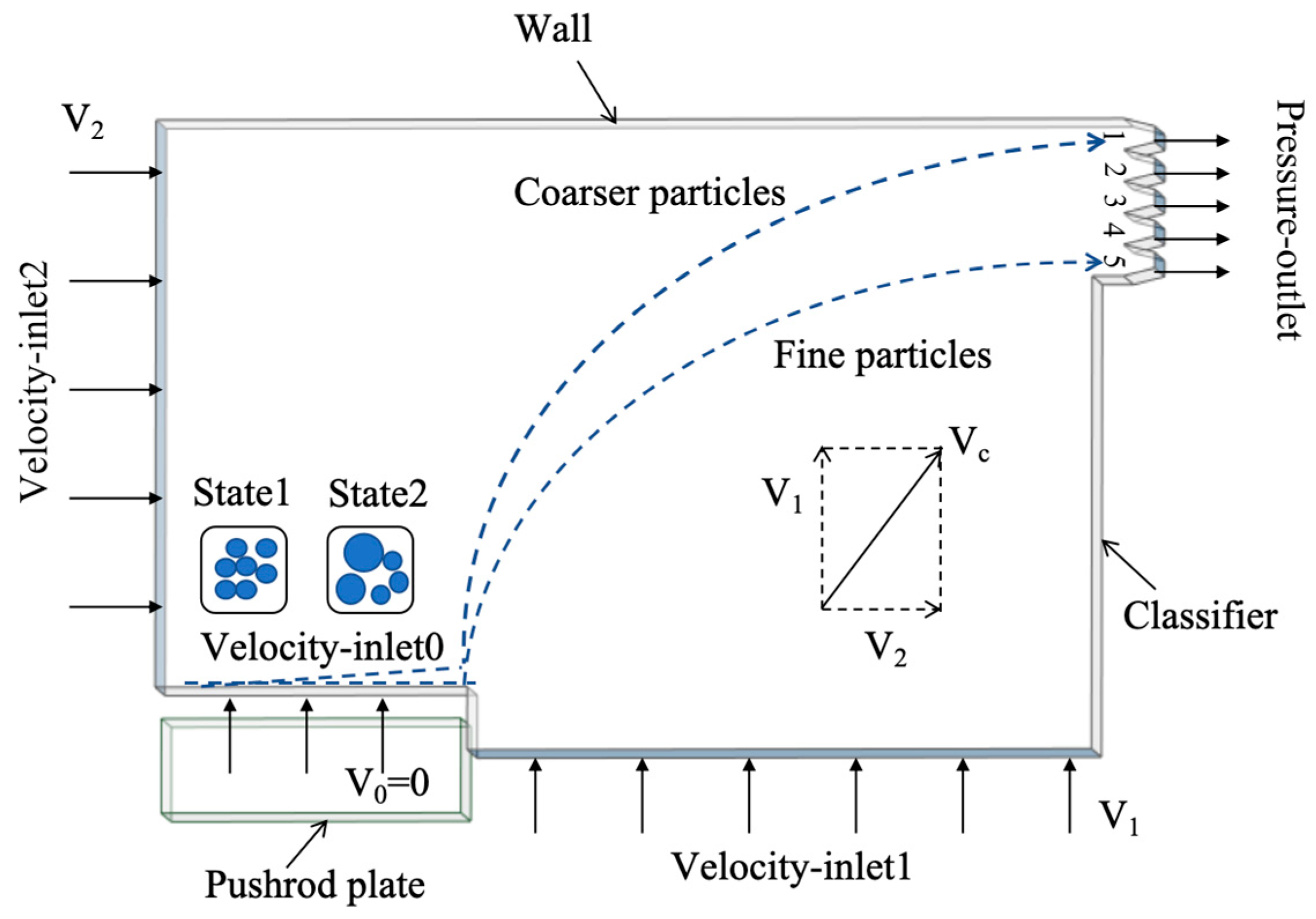

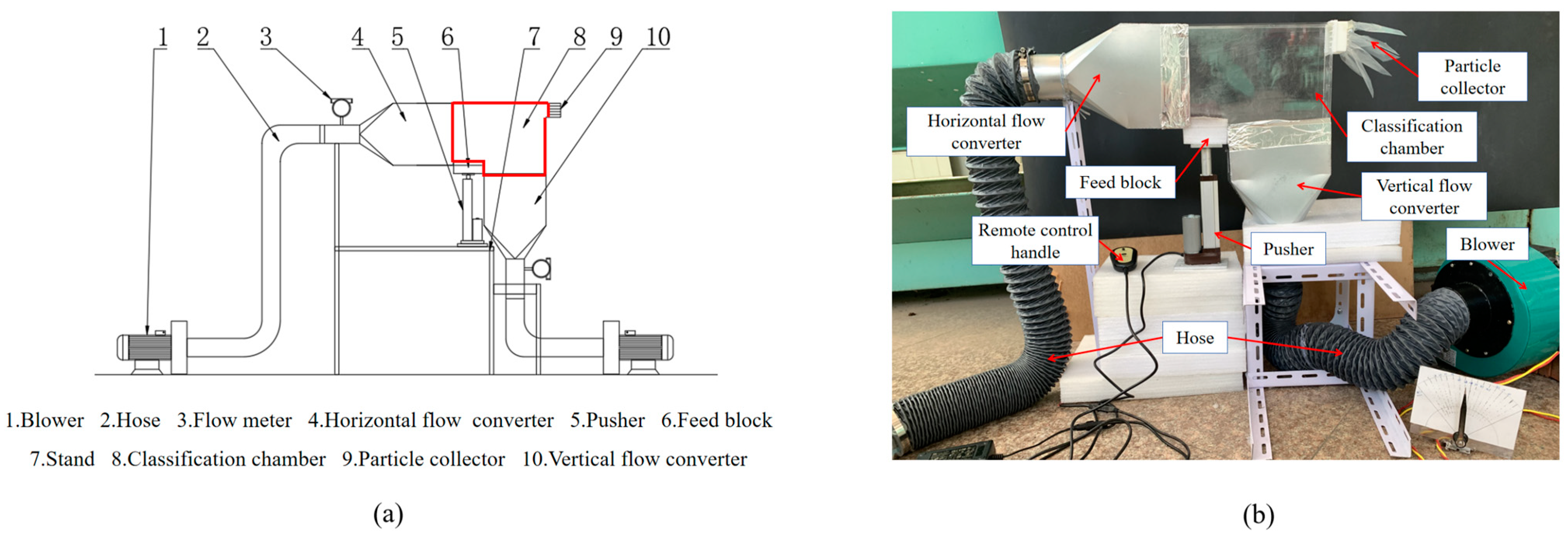

2.1. Design of Pusher Feed Classifier

2.2. Mathematical Model

2.2.1. Geometric Modeling and Meshing

2.2.2. RNG - Turbulence Model

2.2.3. Particle Phase Model

2.3. Simulation Boundary Conditions and Parameter Settings

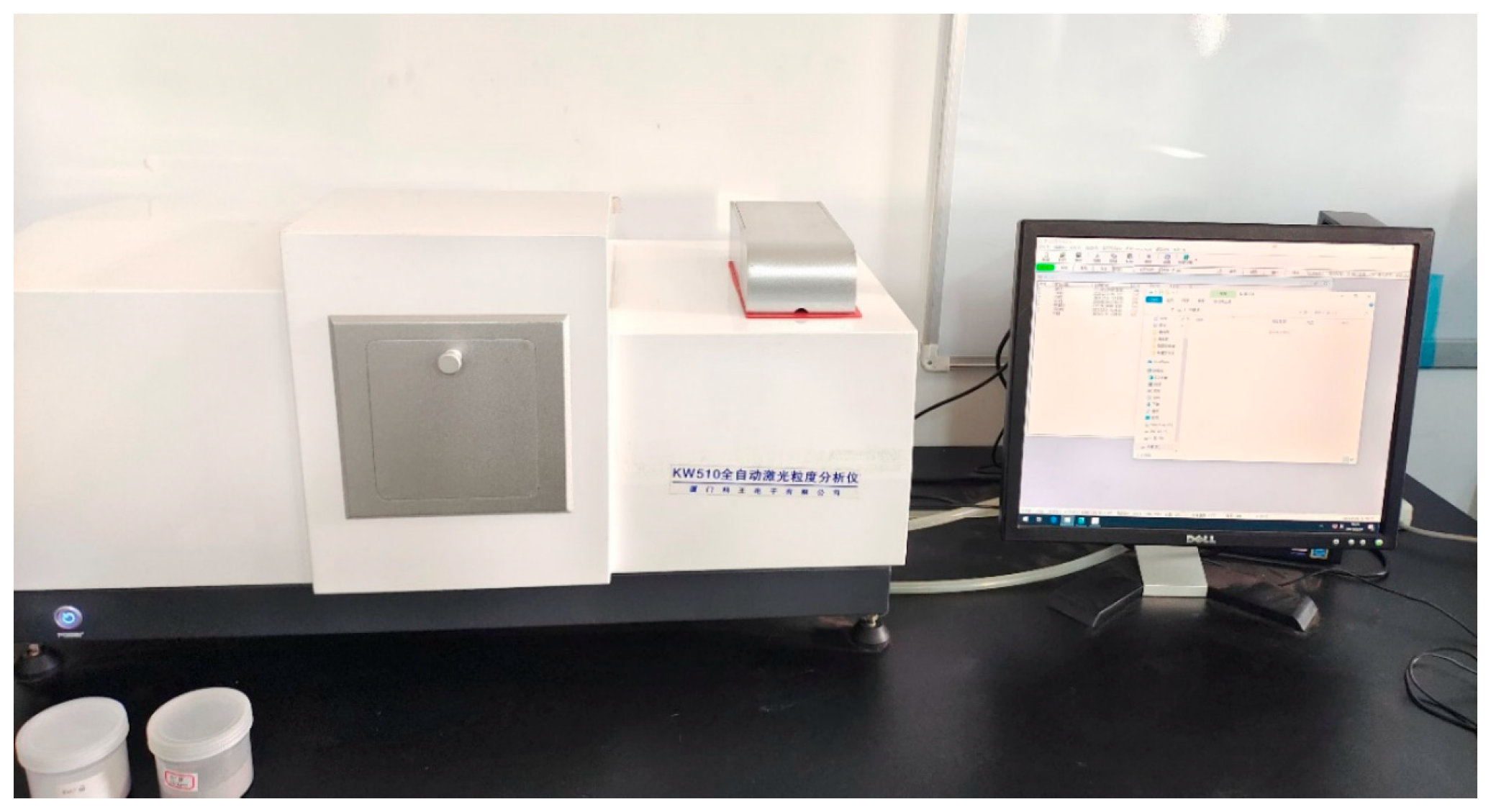

2.4. Classification Experiment

3. Results and Discussion

3.1. Characterization of the Classified Flow Field

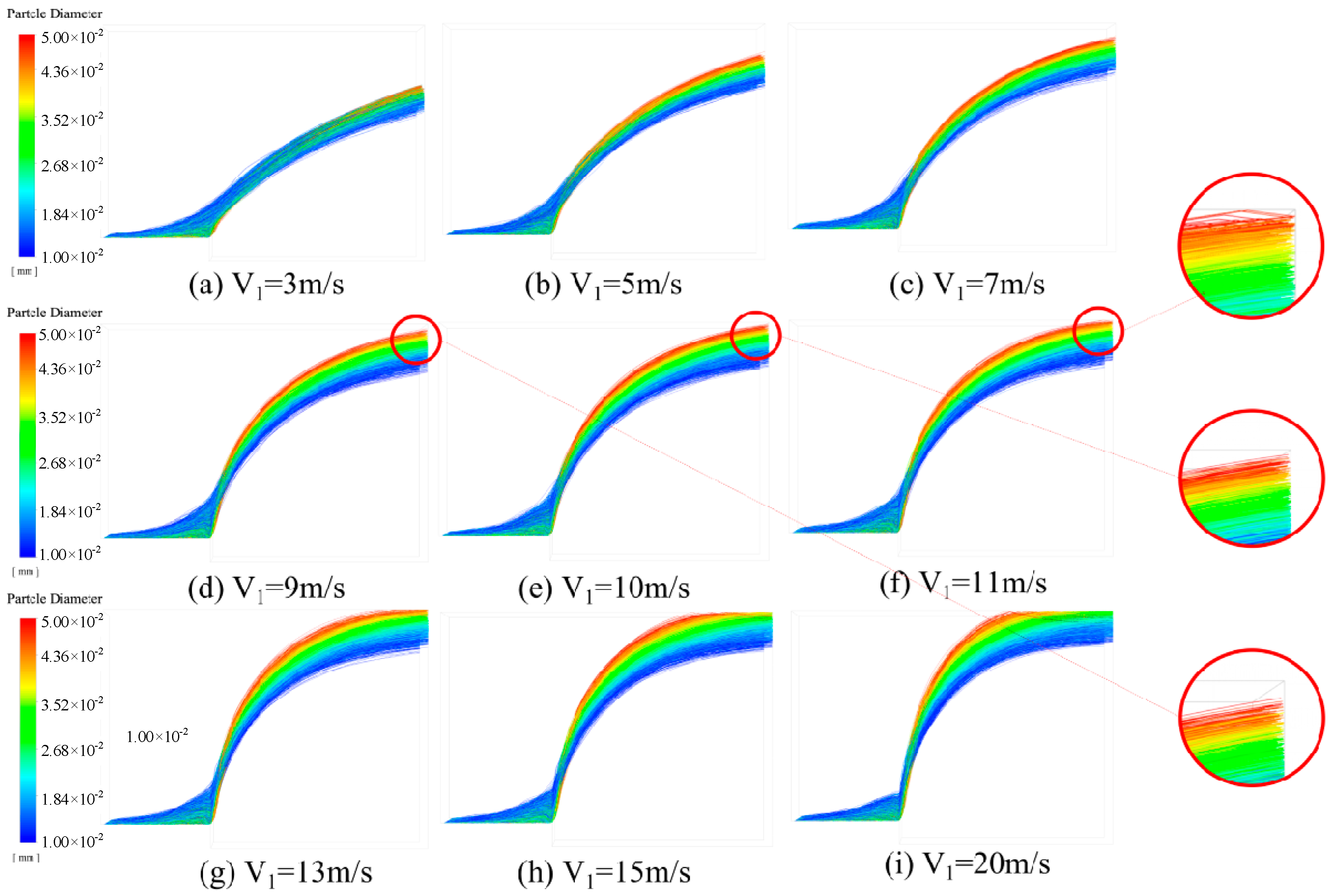

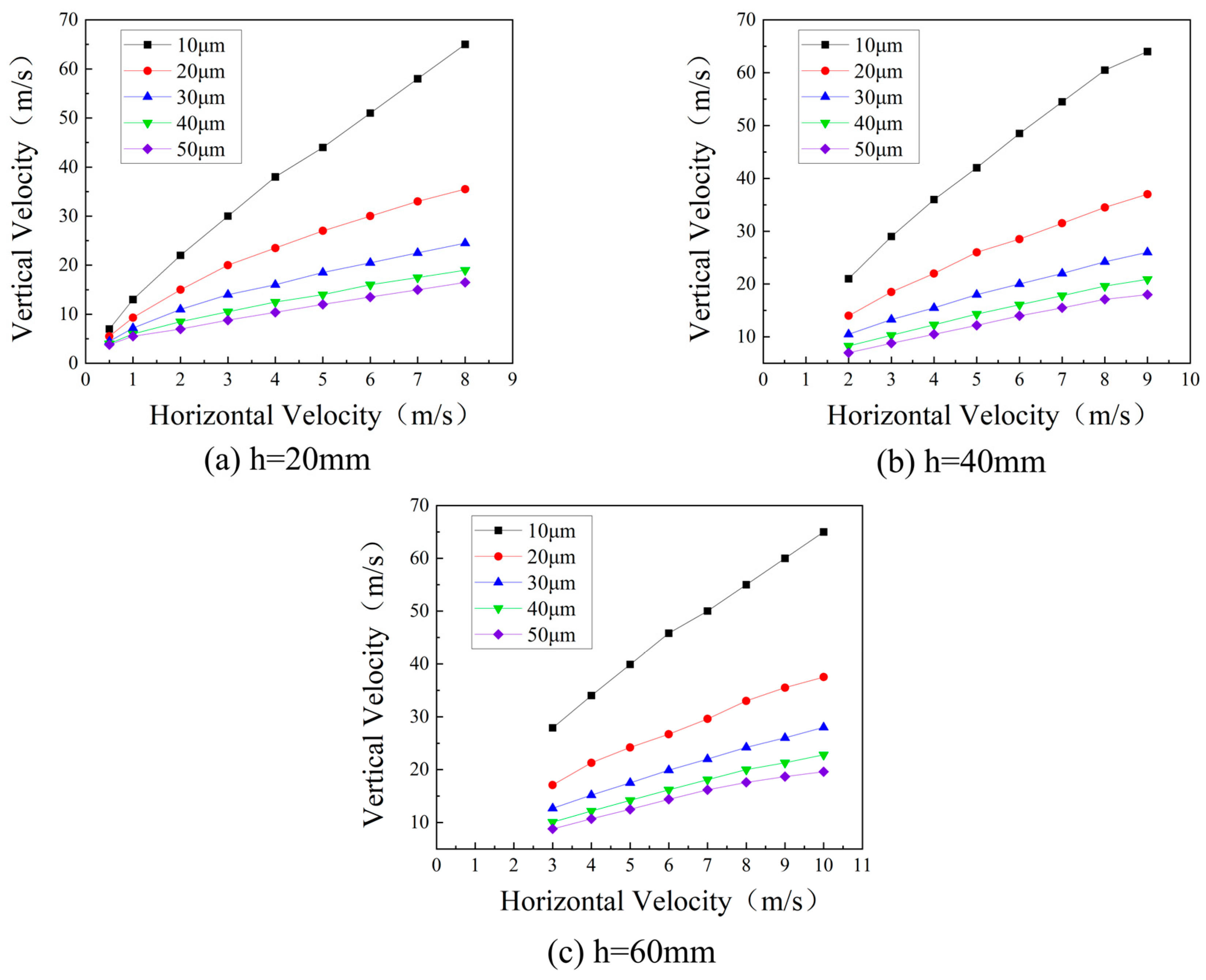

3.2. The Effect of Particle Classification under Different Velocity Matching

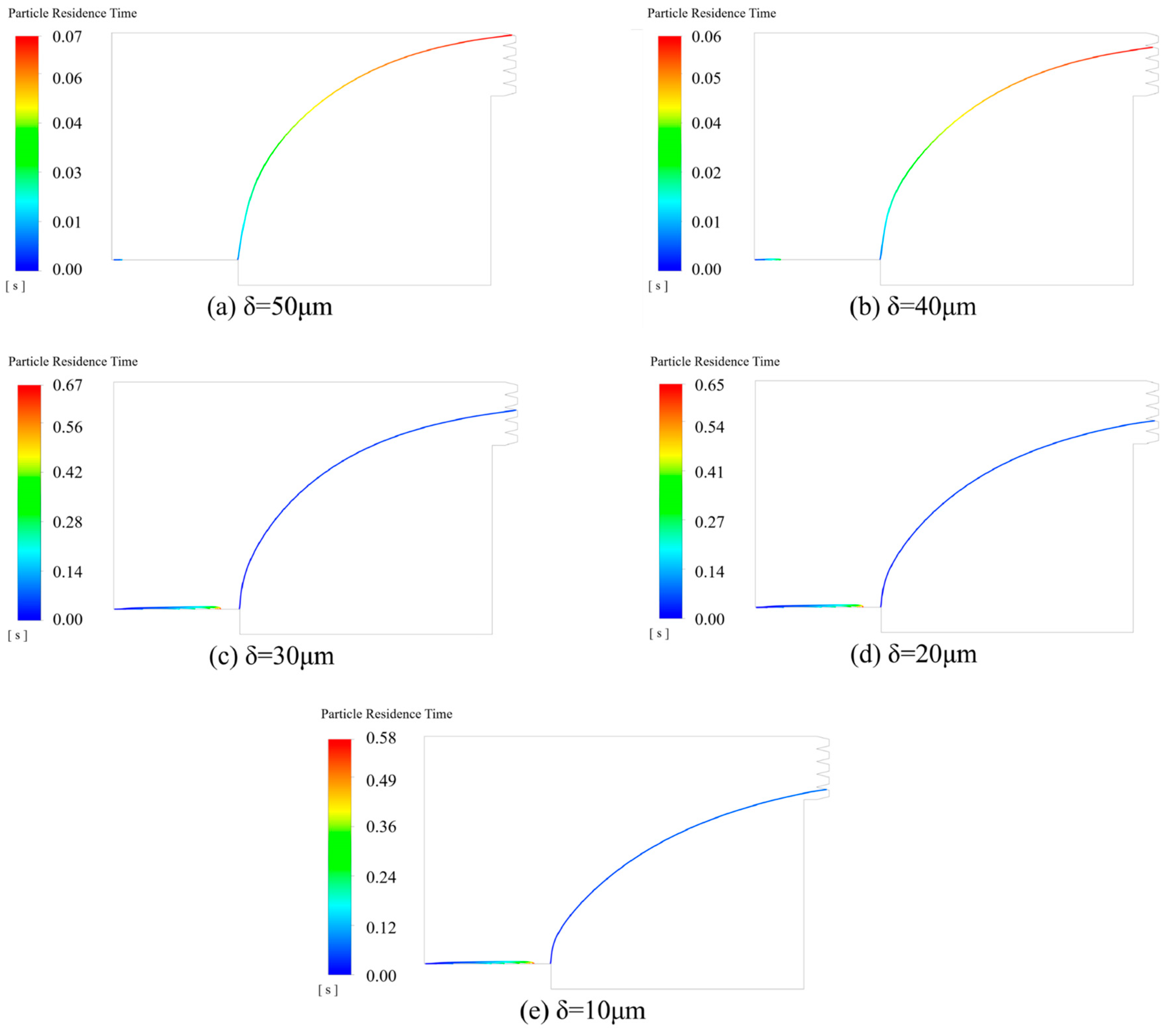

3.3. Trajectories of Particles of Different Sizes

3.4. Outlet Particle Size Distribution

3.5. Experimental Results Analysis

4. Conclusions

- The pusher feed classifier has a stable classified flow field and a better classification effect when V2 is 1/3–1/5 of V1. When V2 = 3 m/s and V1 = 10 m/s, it has the best classification effect. With the increase in feed depth, the energy consumption for fine particle classification decreases.

- The pusher feed classifier can classify particles with a particle size of 10–50 μm in five stages. The geometric mean of particle size μg(q0) decreases from outlet 1 to outlet 5. There is particle size overlap between neighboring outlets. Coarse particles have a better classification effect, and fine particles have a more concentrated distribution and better monodispersity.

- The CSR values of the pusher feed classifier from outlet 1 to outlet 5 are 1.24, 0.55, 0.45, 0.39, and 0.15. Under suitable structural and process parameters, the particles can flow from outlet 1 to outlet 5 of the pusher feed classifier, from large to small. Coarse particles at outlet 1 have a better classification effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.P.; Liu, C.Y.; Yang, G.; Chen, L. Orthogonal vortices characteristic performance evaluation and classification mechanism of a horizontal classifier with three rotor cages. Powder Technol. 2022, 404, 117438. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Shen, W. Numerical simulation of particle classification in new multi-product classifier. Chem. Eng. Res. Des. 2022, 177, 484–492. [Google Scholar] [CrossRef]

- Blake, T.R. Assessment of fractional collection efficiency in louvered inertial particle classifiers. Powder Technol. 2017, 311, 432–438. [Google Scholar] [CrossRef]

- Jayarathna, C.K.; Moldestad, B.M.; Britt, M.E.; Tokheim, A. Improved multi-stage cross-flow fluidized bed classifier. Powder Technol. 2019, 342, 621–629. [Google Scholar] [CrossRef]

- Peng, J.; Hui, C.; Zhao, Z.; Fang, Y. Research and optimization of operating parameters of a rotor classifier for calcined petroleum coke. Processes 2024, 12, 603. [Google Scholar] [CrossRef]

- Abohelwa, M.; Benker, B.; Javadi, M.; Wollmann, A.; Weber, A.P. Limitation in the performance of fine powder separation in a turbo air classifier. Processes 2023, 11, 2817. [Google Scholar] [CrossRef]

- Sun, Z.P.; Liang, L.L.; Liu, C.Y.; Yang, G. Structural optimization of vortex finder for a centrifugal air classifier. Chem. Eng. Res. Des. 2021, 166, 220–226. [Google Scholar] [CrossRef]

- Fatahian, H.; Esmaeel, N.; Majid, E.; Ahmadi, G. Novel designs for square cyclone using rounded corner and double-inverted cones shapes. Powder Technol. 2021, 380, 67–79. [Google Scholar] [CrossRef]

- Li, Q.; Mou, X.; Fang, Y. Effects of a guide cone on the flow field and performance of a new dynamic air classifier. Processes 2022, 10, 874. [Google Scholar] [CrossRef]

- El-Emam, A.; Mahmoud, L.; Zhou, W.D.; Han, C. Performance evaluation of standard cyclone separators by using CFD-DEM simulation with realistic bio-particulate matter. Powder Technol. 2021, 385, 357–374. [Google Scholar] [CrossRef]

- Huang, L.; Yuan, J.L.; Pan, M.; Wu, J.D.; Qiao, J.P.; Jiang, H.S.; Duan, C.L. CFD simulation and parameter optimization of the internal flow field of a disturbed air cyclone centrifugal classifier. Sep. Purif. Technol. 2022, 307, 122760. [Google Scholar] [CrossRef]

- Jayarathna, C.K.; Moldestad, B.M.; Britt, M.E.; Tokheim, L.A. Impact of solids loading and mixture composition on the classification efficiency of a novel cross-flow fluidized bed classifier. Powder Technol. 2019, 336, 30–44. [Google Scholar] [CrossRef]

- Guo, M.; Le, D.K.; Sun, X.; Yoon, J.Y. Multi-objective optimization of a novel vortex finder for performance improvement of cyclone separator. Powder Technol. 2022, 410, 117856. [Google Scholar] [CrossRef]

- Petit, H.A.; Edgardo, F.I. The throat classifier: A novel air classifier for the control of dust in manufactured sands. Powder Technol. 2021, 390, 417–427. [Google Scholar] [CrossRef]

- Prasad, K.; Sachinraj, D.; Awasthi, A.; Mukherjee, A.K.; Ranjan, A. Intermediate size fine coal beneficiation by Reflux ™ Classifier using statistical approach. Powder Technol. 2020, 361, 548–561. [Google Scholar] [CrossRef]

- Wasilewski, M.; Brar, L.S. Effect of the inlet duct angle on the performance of cyclone separators. Sep. Purif. Technol. 2019, 213, 19–33. [Google Scholar] [CrossRef]

- Zhou, J.W.; Shangguan, L.J.; Gao, K.D.; Wang, Y.H.; Hao, Y.X. Numerical study of slug characteristics for coarse particle dense phase pneumatic conveying. Powder Technol. 2021, 392, 438–447. [Google Scholar] [CrossRef]

- Dang, K.L.; Joon, Y.Y. Numerical investigation on the performance and flow pattern of two novel innovative designs of four-inlet cyclone separator. Chem. Eng. Process. Process Intensif. 2022, 150, 107867. [Google Scholar] [CrossRef]

- Li, H.X.; Song, Z.H.; Sun, Z.J.; Zhang, A.Z.; Si, H.B.; Hu, R.G.; Yang, C.Z.; Zhang, S.B.; Jin, L.Y. Operational performance characteristics of an axial double baffles three channels classifier for coarse pulverized coal. Powder Technol. 2022, 400, 117250. [Google Scholar] [CrossRef]

- Banjac, V.; Pezo, L.; Pezo, M.; Vukmirovic, Ð.; Colovic, D.; Fistes, A.; Colovic, R. Optimization of the classification process in the zigzag air classifier for obtaining a high protein sunflower meal-chemometric and CFD approach. Adv. Powder Technol. 2017, 28, 1069–1078. [Google Scholar] [CrossRef]

- Weingerl, U.; Schaflinger, U. Feeding of granular material on conveyer bands or chutes. Powder Technol. 2000, 108, 1–5. [Google Scholar] [CrossRef]

- Hou, D.; Liu, P.; Zhao, Q.; Jiang, L.; Cui, B.; Wei, D. Numerical study on the separation performance of hydro cyclones with different secondary cylindrical section diameters. Processes 2023, 11, 2542. [Google Scholar] [CrossRef]

- Hong, G.Y.; Wang, N.; Cao, Y.X.; Meng, X.J.; Yao, L. Effects of helical fins on the performance of a cyclone separator: A numerical study. Adv. Powder Technol. 2023, 34, 103929. [Google Scholar] [CrossRef]

- Mezhericher, M.; Brosh, T.; Levy, A. Modeling of particle pneumatic conveying using DEM and DPM methods. Part. Sci. Technol. 2011, 29, 197–208. [Google Scholar] [CrossRef]

- Zhang, L.L.; Yan, X.C.; Bo, Z.; Min, H.D.; Yan, F.Y. Numerical simulation on structure optimization of escape-pipe of cyclone separator with downward outlet. Powder Technol. 2022, 411, 17588. [Google Scholar] [CrossRef]

- Guo, M.; Hao, X.; Jiang, P.; Dang, K.L.; Xun, S.; Joon, Y.Y. Numerical investigation on the swirling vortical characteristics of a Stairmand cyclone separator with slotted vortex finder. Powder Technol. 2023, 416, 118236. [Google Scholar] [CrossRef]

- Ahn, S.H.; Ye, X.X.; Zheng, W.W.; Yong, Y.L.; Hong, G.F. Unsteady prediction of cavitating flow around a three dimensional hydrofoil by using a modified RNG - model. Ocean Eng. 2018, 158, 275–285. [Google Scholar] [CrossRef]

- Pandey, S.; Brar, L.S. On the performance of cyclone separators with different shapes of the conical section using CFD. Powder Technol. 2022, 407, 117629. [Google Scholar] [CrossRef]

- Brar, L.S.; Wasilewski, M. Investigating the effects of temperature on the performance of novel cyclone separators using large-eddy simulation. Powder Technol. 2023, 416, 118213. [Google Scholar] [CrossRef]

- Park, I.H.; Cho, Y.J.; Lee, J.S. Analysis of empirical constant of eddy viscosity by - and RNG - turbulence model in wake simulation. J. Korean Soc. Mar. Environ. Saf. 2019, 25, 344. [Google Scholar] [CrossRef]

- Daryus, A.; Siswantara, A.I.; Darmawan, S.; Gunadi, G.R.; Camalia, R. CFD simulation of turbulent flows in Proto X-3 bioenergy micro gas turbine combustor using STD - and RNG - model for green building application. Int. J. Technol. 2016, 7, 204. [Google Scholar] [CrossRef]

- Javidinejad, A.; Clayton, J.; Vecchio, D.C. FEA Practical Illustration of Mesh-Quality-Results differences between structured mesh and unstructured mesh. ISRN Mech. Eng. 2012, 6, 1–7. [Google Scholar] [CrossRef]

- Raeesh, M.; Devi, T.T. Comparison of Three Turbulence Models in Predicting the Particle Removal Efficiency of a Sedimentation Tank. Recent Adv. Civ. Eng. 2023, 431, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Zakeri, A.; Alizadeh Behjani, M.; Hassanpour, A. Fully coupled CFD-DEM simulation of oil well hole cleaning: Effect of mud hydrodynamics on cuttings transport. Processes 2024, 12, 784. [Google Scholar] [CrossRef]

- Lai, W.; Lu, W.; Chen, C. The new expression of the effectiveness of powder classification. Adv. Powder Technol. 2005, 16, 611–620. [Google Scholar] [CrossRef]

| Mesh Number | Pressure Drops (Pa) |

|---|---|

| 157,725 | 597.13 |

| 270,981 | 647.62 |

| 308,235 | 649.68 |

| 417,399 | 650.23 |

| Grid Quality Evaluation Indicators | Range of Results | Range of Indicators |

|---|---|---|

| Quality | 0.32–1 | 0.3–1 |

| Aspect ratio | 0.4–1 | 0.2–1 |

| Determinant | 0.3–1 | 0.2–1 |

| Equiangle Skewness | 0.4–1 | 0.2–1 |

| Orthogonal Quality | 0.7–1 | 0.2–1 |

| Min angle | 36°–90° | 18°–162° |

| Parameter | Numerical Value |

|---|---|

| Gravitation acceleration (m/s2) | 9.81 |

| Fluid density (kg/m3) | 1.225 |

| Fluid viscosity (kg/m·s) | 1.789 × 10−5 |

| Particle density (kg/m3) | 2350 |

| Outlet | CSR | ||

|---|---|---|---|

| Outlet 1 | 26.7 | 131.2 | 1.24 |

| Outlet 2 | 11.8 | 97.8 | 0.55 |

| Outlet 3 | 9.7 | 81.5 | 0.45 |

| Outlet 4 | 8.4 | 40.7 | 0.39 |

| Outlet 5 | 3.3 | 21.6 | 0.15 |

| Outlet | CSR | ||

|---|---|---|---|

| Outlet 1 | 27.5 | 49.7 | 1.73 |

| Outlet 2 | 18.6 | 42.2 | 1.17 |

| Outlet 3 | 14.7 | 30.4 | 0.92 |

| Outlet 4 | 11.4 | 23.4 | 0.72 |

| Outlet 5 | 10.3 | 15.9 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zou, X.; Ma, Z.; Wu, C.; Li, Y. Numerical Simulation Study of a Pusher Feed Classifier Based on RNG-DPM Method. Processes 2024, 12, 1151. https://doi.org/10.3390/pr12061151

Zhou Y, Zou X, Ma Z, Wu C, Li Y. Numerical Simulation Study of a Pusher Feed Classifier Based on RNG-DPM Method. Processes. 2024; 12(6):1151. https://doi.org/10.3390/pr12061151

Chicago/Turabian StyleZhou, Youhang, Xin Zou, Zhuxi Ma, Chong Wu, and Yuze Li. 2024. "Numerical Simulation Study of a Pusher Feed Classifier Based on RNG-DPM Method" Processes 12, no. 6: 1151. https://doi.org/10.3390/pr12061151

APA StyleZhou, Y., Zou, X., Ma, Z., Wu, C., & Li, Y. (2024). Numerical Simulation Study of a Pusher Feed Classifier Based on RNG-DPM Method. Processes, 12(6), 1151. https://doi.org/10.3390/pr12061151