Exergy-Based Improvements of Sustainable Aviation Fuels: Comparing Biorefinery Pathways

Abstract

1. Introduction

2. Materials and Methods

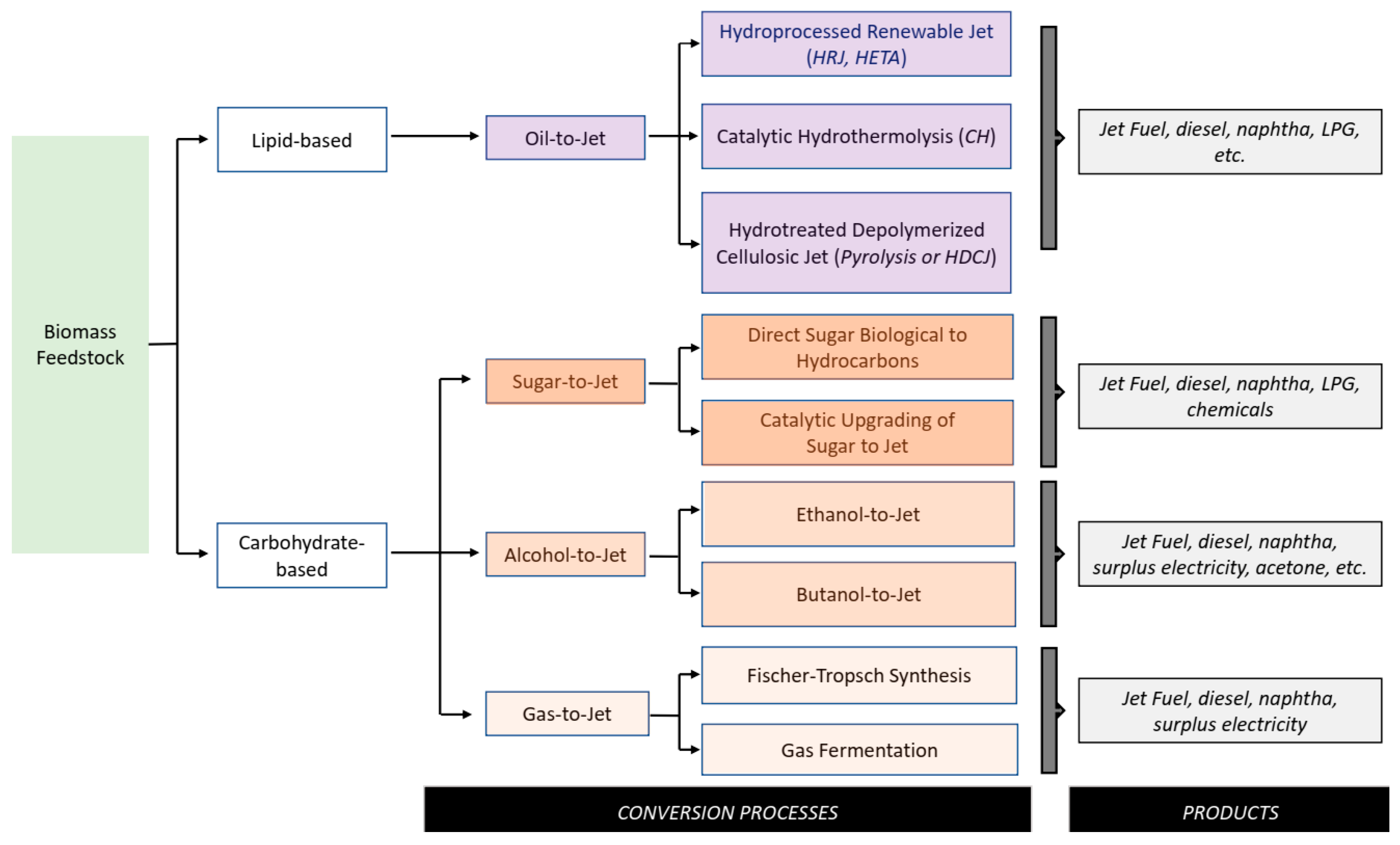

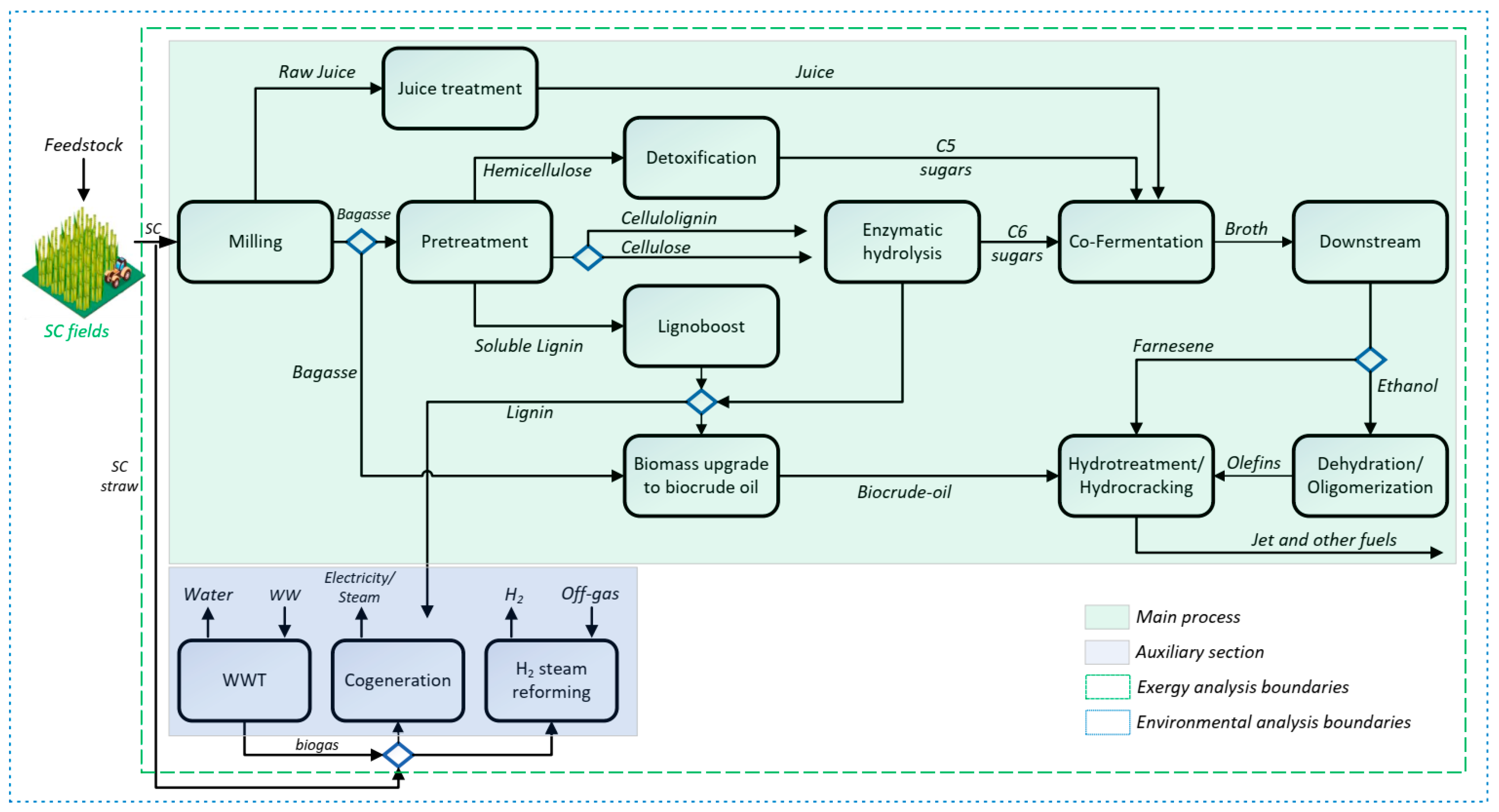

2.1. Production Technologies and Processing Conditions

2.2. Exergy Assessment

Exergy Balance

- Exergy efficiency: The exergy efficiency for the biorefinery pathways is determined by the ratio between the sum of exergy products and the sum of exergy resources as given in Equation (4) [19].

- Irreversibility rate: The irreversibility rate was found by applying the exergy balance expression introduced in Equation (3).The specific exergy values [15] of the inputs considered were 5130 kJ/kg (SC), 16,725 kJ/kg (straw), and 9667 kJ/kg (SCbagasse). Concerning the exergy of the products, the values adopted in the simulations of the analyzed plants were 17,479 kJ/kg (sugar) and 27,042 kJ/kg (bioethanol). The specific chemical exergies are usually close to their lower heating value (LHV) for fuels in reference conditions of temperature and pressure (T0 and P0). The relation between bCH and LHV values for several fossils is mainly given in Szargut et al. [9], and for bio-based raw materials in Silva Ortiz et al. [8]. Table A6 shows the standard chemical exergy (bCH) per resource adopted. The technological comparisons carried out in Section 3.2 are based on the exergy efficiency calculations of each scenario, where the exergy of the products and the inputs are established based on the relation between bCH and LHV values.

2.3. Specific CO2 Equivalent Emissions

2.4. Average Unitary Exergy Cost (AUEC)

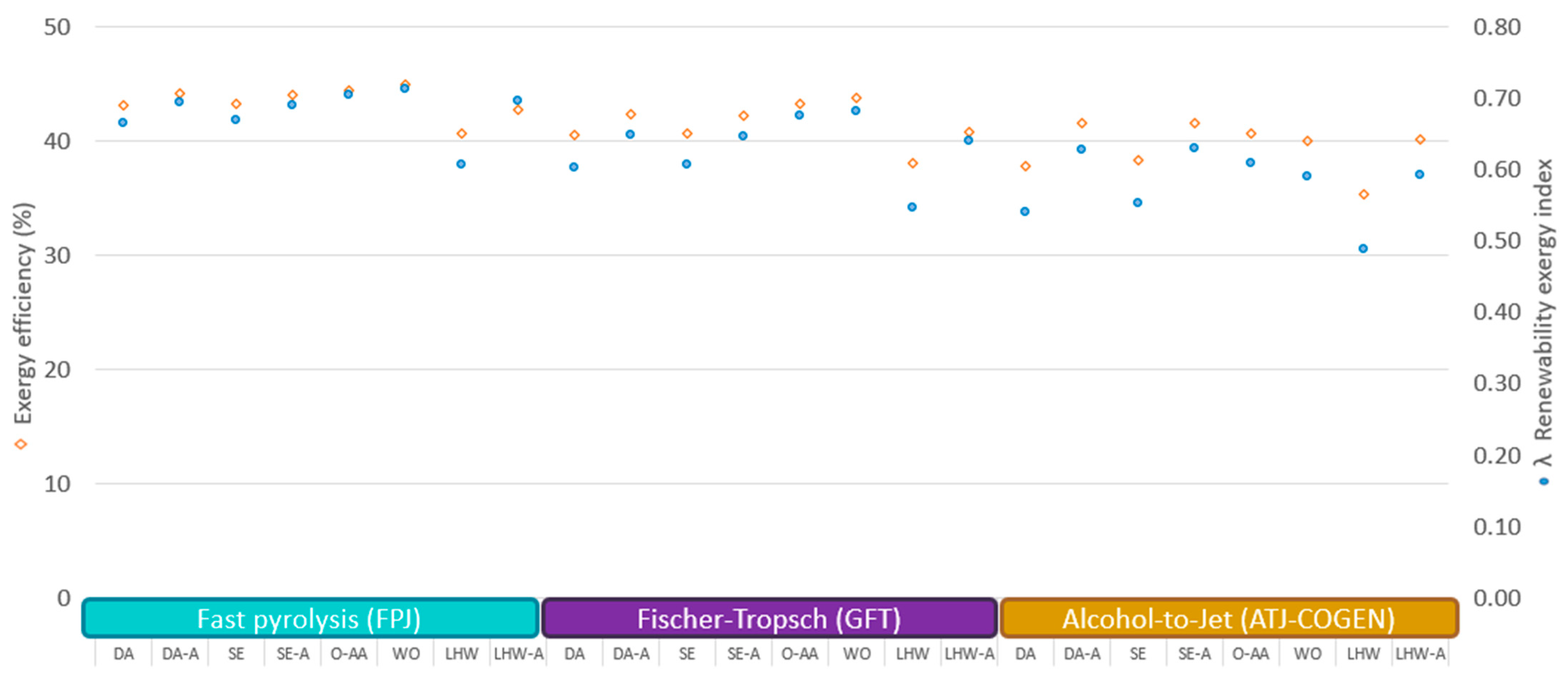

2.5. Renewability Exergy Index

3. Results and Discussion

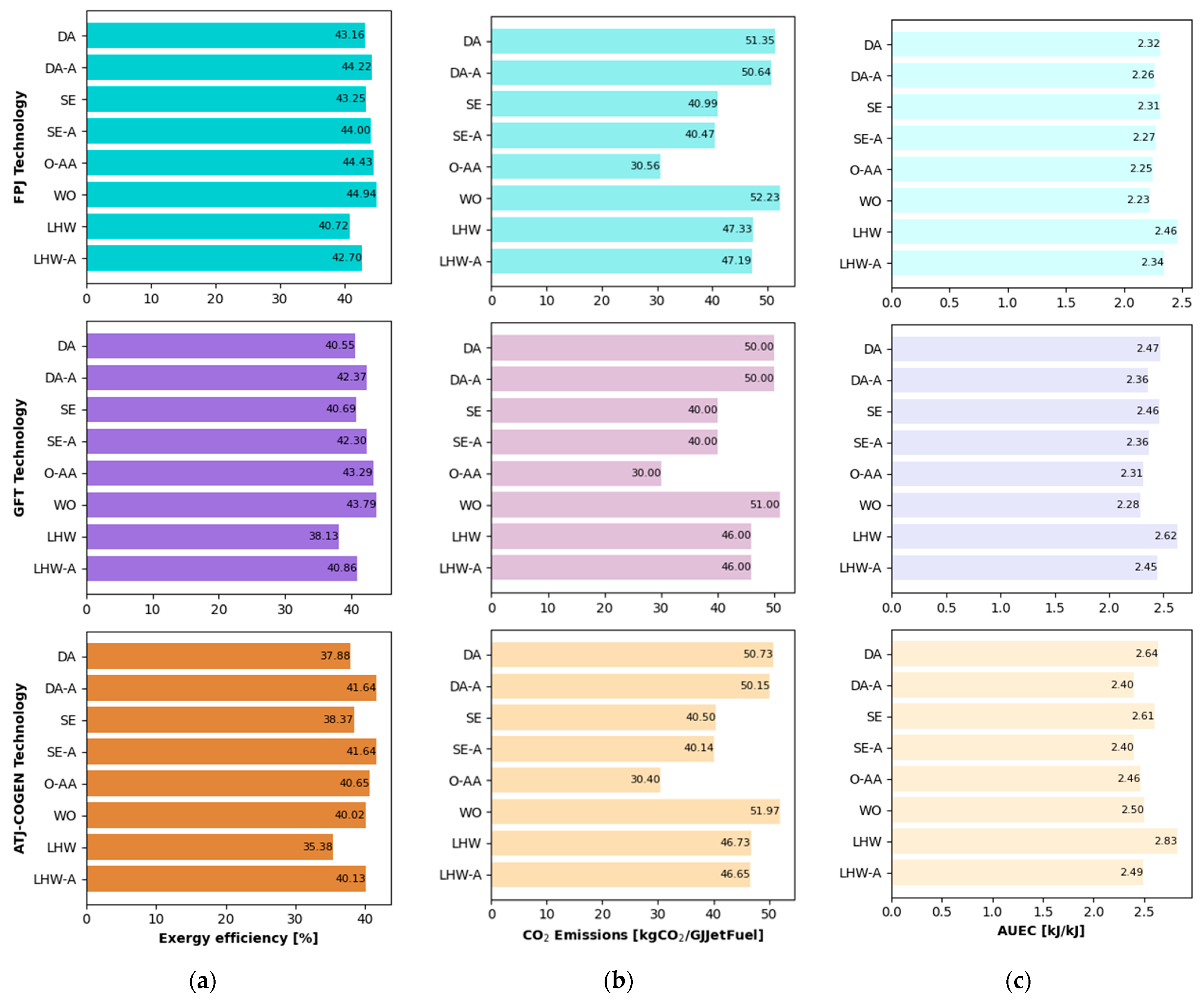

3.1. Sugarcane Biorefineries Performance

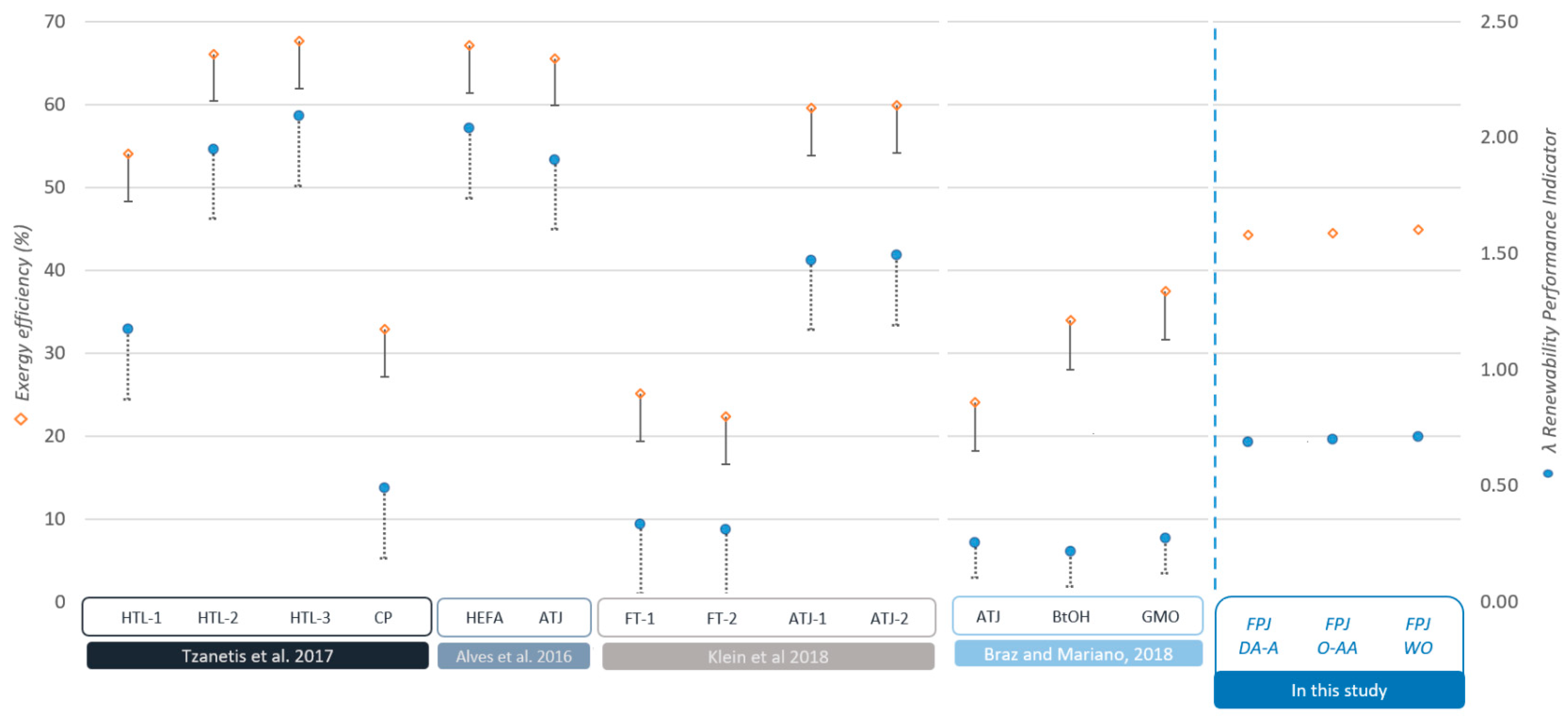

3.2. Benchmark of Renewable Jet Fuel Conversion Routes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AUEC | Average unit exergy cost (kJ/kJ) |

| B | Exergy flow rate (kW) |

| b | Specific exergy (kJ/kg) |

| bch | Standard chemical exergy (kJ/kg) |

| c | Average unit exergy cost (kJ/kJ) |

| CO2EE | Specific CO2 equivalent emissions (exergy base) (kg/GJ) |

| CV | Control volume |

| I | Irreversibility rate (KW or MW) |

| h | Specific enthalpy (kJ/kg) |

| Mass flow rate, (kg/s) | |

| P | Pressure (kPa, bar) |

| Heat rate (kW) | |

| s | Specific entropy (kJ/kg K) |

| t | Temperature, (°C, K) |

| Power, (kW) | |

| x | Mole or mass fraction |

| ηB | Exergy efficiency (%) |

| Abbreviations | |

| ATJ | Alcohol-to-Jjet |

| DSHC | Direct Sugar to Hydrocarbon |

| CORSIA | Carbon Offsetting and Reduction Scheme for International Aviation |

| FT | Fischer-Tropsch |

| LCAF | Lower-Carbon Aviation Fuels |

| HDCJ | Hydrotreated Depolymerized Cellulosic Jet |

| HEFA | Hydroprocessed Esters and Fatty Acids |

| H2SMR | Hydrogen Steam Methane Reforming |

| NREU | Non-Renewable Energy Use |

| GFT | Gasification Fischer-Tropsch |

| GHG | Greenhouse gas emissions |

| GWP | Global Warming Potential |

| SC | Sugarcane |

| PtL | Power-to-Liquid |

| WWT | Wastewater Treatment |

| WtWa | Well-to-Wake |

| Greek symbols | |

| η | efficiency |

| λ | renewability exergy index |

Appendix A

| Unit | Condition | Value | Units |

|---|---|---|---|

| Cleaning and crushing | Water make-up | 0.05 | m3/TC * |

| Fibers separation efficiency | 100 | % | |

| Bagasse moisture | 53.8 | % | |

| Imbibition water | 0.28 | ton/TC | |

| Imbibition water recycling | 100 | % | |

| Liming settling and filtration | Sugars (sucrose, glucose) recovered | 95 | % |

| Phosphoric Acid (H3PO4) | 0.2 | kg/ton SC | |

| Calcium oxide (CaO) | 1 | kg/TC | |

| Flocculant polymer | 2.5 | g/TC | |

| Fraction of soluble solids retained in filter | 65 | % | |

| Fraction of insoluble solids precipitated | 99.7 | % | |

| Washing water | 8.19 | kg/kgsugars | |

| Juice concentration | Pressure in 5th effect | 0.16 | bar |

| Temperature in 1st effect | 115 | °C | |

| Juice solids content to sell | 65 | % | |

| Juice solids content to fermentation | Defined in fermentation with constraints

| ||

| Unit | Condition | Value |

|---|---|---|

| Pump | ΔP (bar) | 4 |

| Dehydration reactor | P (bar)0/T (°C) | 4/375 |

| Catalyst used | Heterogeneous, 0.5%La–2%P H-ZSM-5 | |

| Reactor specifications | Multi-tubular fixed bed in a furnace | |

| Decanter (Fraction of components in the gas outlet) | Water ethylene | 1.16% 100% |

| Compressor | ΔP (bar) | 30 |

| Oligomerization reactor butylene synthesis | P (bar)/T (°C) | 30/200 |

| Oligomerization reactorbutylene oligomerization | P (bar)/T (°C) | 89/200 |

| Oligomerization general | Catalyst | Ziegler Natta-type |

| Reactor type | Fixed bed | |

| Compressor of H2 | ΔP (bar) | 30 |

| Hydrogenation reactor and decanter | P (bar)/T (°C) | 30/250 |

| Catalyst | palladium and platinum over GAC | |

| WHSV (h−1) w/w | 3 | |

| Lifetime (years) | 5 | |

| H2 requirement (kg/kg olefins) | 0.05 | |

| H2 excess | 50% of the amount reacted | |

| Steam distillation | Live steam required (kg/kg paraffin) | 0.258 |

| Fraction of compounds in LPG stream | ||

| LPG Naphtha Water | 97% 32% 2.38% | |

| Fraction of compounds in naphtha stream | ||

| LPG Naphtha Water | 3% 62% 0.01% | |

| Unit | Condition | Value |

|---|---|---|

| Lignin dryer | Max. lignin moisture | 8% |

| T final (°C) FPJ | 307 | |

| Air make-up (kg air/kg water evaporated) | 2.605 | |

| Lignin grinder | Diameter of lignin particles (mm) | ≈2 |

| Fast pyrolysis fluidized auger bed | P (bar)/T (°C)/Residence time (s) | 1.5/500/2 |

| Sand/biomass (kg/kg) | 14.5 | |

| Fluidization gas/lignin (kg/wet kg lignin) | 3 | |

| Cyclone | Solid/gas separation efficiency | 100% |

| Quenching column | Chilled water/inlet stream (kg/kg) | 1.445 |

| Fraction of components in the bio-oil stream | ||

| Phenolics (organic liquid fraction bio-oil) Light ends Water Non-condensable compounds | 100% 49.34% 45.06% 0% | |

| Sand heater/Char combustor | T of gas and sand (°C) | 608 |

| O2 excess (kgO2/kgO2 consumed in char combustion) | 1.2 | |

| Unit | Condition | Value |

|---|---|---|

| Syngas polishing | P (bar)/T (°C) | 25/150 |

| Packing/lignin flowrate (kg/kg dry lignin/day) | 0.853 | |

| Max. H2S concentration (kg/kg clean syngas) | 5.0 × 10−8 | |

| Max. NH3 concentration (kg/kg clean syngas) | 1.0 × 10−5 | |

| H2 SMR | P (bar)/T (°C) | 25/870 |

| Catalyst | Ni and aluminum | |

| Catalyst/H2 synthesized flowrate (kg/kg H2/day) | 0.058 | |

| HP steam/CH4 inlet (mol/mol) | 6 | |

| CH4 concentration in the outlet (%) | 1.5 | |

| T outlet (°C) of cooling water | 300 | |

| Water gas shift | Catalyst | Copper-zinc |

| Catalyst/lignin flowrate (kg/kg/day) | 0.00297 | |

| PSA | H2 recovery efficiency/Purity (%) | 85/100 |

| Packing | 2/3 with activated carbon and 1/3 with molecular sieve | |

| H2/carbon compounds in PSA outlet (mass %) | 0.0136 | |

| FT reactor | P (bar)/T (°C) | 25/200 |

| Catalyst | Cobalt on AlO3 | |

| Catalyst/lignin flowrate (kg/kg/day) | 0.0926 | |

| Separator/Decanter | Water/gas/organic phase separation efficiency | 100% |

| Hydroprocessing | H2 requirementminimum (kg H2/kg waxes) | 0.06 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|---|---|

| pre-treatment | DA | DA | DA | DA | DA | DA | DA | DA | DA |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 43.16 | 40.55 | 37.88 | 20.63 | 19.54 | 15.54 | 22.15 | 19.14 | 16.22 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 91,041 | 85,540 | 79,881 | 43,522 | 41,216 | 32,783 | 46,716 | 40,375 | 34,212 |

| I (KW) | 119,084 | 124,573 | 130,264 | 166,609 | 168,903 | 177,371 | 163,424 | 169,753 | 175,952 |

| AUEC (kJ/kJ) | 2.32 | 2.47 | 2.64 | 4.85 | 5.12 | 6.43 | 4.51 | 5.22 | 6.16 |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | |

| pre-treatment | DA-A | DA-A | DA-A | DA-A | DA-A | DA-A | DA-A | DA-A | DA-A |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 44.22 | 42.37 | 41.64 | 19.44 | 17.59 | 16.86 | 19.44 | 17.60 | 16.86 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 93,282 | 89,383 | 87,827 | 41,011 | 37,113 | 35,557 | 41,011 | 37,113 | 35,557 |

| I (KW) | 116,831 | 120,726 | 122,296 | 169,109 | 173,005 | 174,575 | 169,119 | 173,014 | 174,585 |

| AUEC (kJ/kJ) | 2.26 | 2.36 | 2.40 | 5.14 | 5.68 | 5.93 | 5.14 | 5.68 | 5.93 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | |

| pre-treatment | SE | SE | SE | SE | SE | SE | SE | SE | SE |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 43.25 | 40.69 | 38.37 | 20.43 | 17.87 | 15.55 | 20.43 | 17.88 | 15.55 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 91,215 | 85,825 | 80,910 | 43,088 | 37,698 | 32,783 | 43,088 | 37,698 | 32,783 |

| I (KW) | 118,937 | 124,314 | 129,262 | 167,072 | 172,449 | 177,397 | 167,081 | 172,459 | 177,407 |

| AUEC (kJ/kJ) | 2.31 | 2.46 | 2.61 | 4.89 | 5.59 | 6.43 | 4.89 | 5.59 | 6.43 |

| 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | |

| pre-treatment | SE-A | SE-A | SE-A | SE-A | SE-A | SE-A | SE-A | SE-A | SE-A |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 44.00 | 42.30 | 41.64 | 19.22 | 17.52 | 16.86 | 19.22 | 17.52 | 16.86 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 92,806 | 89,222 | 87,827 | 40,536 | 36,951 | 35,557 | 40,536 | 36,951 | 35,557 |

| I (KW) | 117,323 | 120,904 | 122,312 | 169,602 | 173,183 | 174,591 | 169,608 | 173,189 | 174,596 |

| AUEC (kJ/kJ) | 2.27 | 2.36 | 2.40 | 5.20 | 5.71 | 5.93 | 5.20 | 5.71 | 5.93 |

| 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | |

| pre-treatment | O-AA | O-AA | O-AA | O-AA | O-AA | O-AA | O-AA | O-AA | O-AA |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 44.43 | 43.29 | 40.65 | 20.24 | 19.10 | 16.46 | 20.24 | 19.10 | 16.46 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 93,751 | 91,347 | 85,765 | 42,702 | 40,298 | 34,716 | 42,702 | 40,298 | 34,716 |

| I (KW) | 116,310 | 118,701 | 124,313 | 167,366 | 169,757 | 175,369 | 167,376 | 169,767 | 175,379 |

| AUEC (kJ/kJ) | 2.25 | 2.31 | 2.46 | 4.94 | 5.24 | 6.08 | 4.94 | 5.24 | 6.08 |

| 46 | 47 | 48 | 49 | 50 | 51 | 52 | 53 | 54 | |

| pre-treatment | O-GAC | O-GAC | O-GAC | O-GAC | O-GAC | O-GAC | O-GAC | O-GAC | O-GAC |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 44.44 | 43.29 | 40.65 | 20.24 | 19.10 | 16.46 | 20.24 | 19.10 | 16.46 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 93,751 | 91,347 | 85,765 | 42,702 | 40,298 | 34,716 | 42,702 | 40,298 | 34,716 |

| I (KW) | 116,320 | 118,711 | 124,323 | 167,375 | 169,766 | 175,378 | 167,385 | 169,776 | 175,387 |

| AUEC (kJ/kJ) | 2.25 | 2.31 | 2.46 | 4.94 | 5.24 | 6.08 | 4.94 | 5.24 | 6.08 |

| 55 | 56 | 57 | 58 | 59 | 60 | 61 | 62 | 63 | |

| pre-treatment | WO | WO | WO | WO | WO | WO | WO | WO | WO |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 44.94 | 43.79 | 40.02 | 21.15 | 19.99 | 16.22 | 21.15 | 20.00 | 16.22 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 94,808 | 92,370 | 84,408 | 44,612 | 42,174 | 34,212 | 44,612 | 42,174 | 34,212 |

| I (KW) | 115,286 | 117,749 | 125,743 | 165,527 | 167,954 | 175,948 | 165,537 | 167,963 | 175,958 |

| AUEC (kJ/kJ) | 2.23 | 2.28 | 2.50 | 4.73 | 5.00 | 6.16 | 4.73 | 5.00 | 6.16 |

| 64 | 65 | 66 | 67 | 68 | 69 | 70 | 71 | 72 | |

| pre-treatment | LHW | LHW | LHW | LHW | LHW | LHW | LHW | LHW | LHW |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 40.72 | 38.13 | 35.38 | 32.90 | 30.31 | 27.56 | 32.90 | 30.31 | 27.56 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 85,884 | 80,430 | 74,629 | 69,389 | 63,935 | 58,133 | 69,389 | 63,935 | 58,133 |

| I (KW) | 124,231 | 129,671 | 135,508 | 140,733 | 146,174 | 152,011 | 140,742 | 146,183 | 152,020 |

| AUEC (kJ/kJ) | 2.46 | 2.62 | 2.83 | 3.04 | 3.30 | 3.63 | 3.04 | 3.30 | 3.63 |

| 73 | 74 | 75 | 76 | 77 | 78 | 79 | 80 | 81 | |

| pre-treatment | LHW-A | LHW-A | LHW-A | LHW-A | LHW-A | LHW-A | LHW-A | LHW-A | LHW-A |

| technology | ATJ | ATJ | ATJ | DFJ | DFJ | DFJ | DFJ-DA | DFJ-DA | DFJ-DA |

| lignin destination | FPJ | GFT | cogen | FPJ | GFT | cogen | FPJ | GFT | cogen |

| ηB (%) | 42.70 | 40.86 | 40.13 | 18.80 | 16.95 | 16.22 | 18.80 | 16.95 | 16.22 |

| Binputs (KW) | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 | 210,525 |

| Boutputs (KW) | 90,085 | 86,197 | 84,647 | 39,649 | 35,762 | 34,212 | 39,649 | 35,762 | 34,212 |

| I (KW) | 120,014 | 123,898 | 125,463 | 170,459 | 174,343 | 175,908 | 170,469 | 174,353 | 175,917 |

| AUEC (kJ/kJ) | 2.34 | 2.45 | 2.49 | 5.32 | 5.90 | 6.17 | 5.32 | 5.90 | 6.17 |

| Resources (x) | Input/ Output + | GHG (kgCO2/x) | Units (x) | Notes | bCH (kJ/kmol) | bCH (MJ/kg) | |

|---|---|---|---|---|---|---|---|

| From Ecosphere (environment) | Sugarcane * | input | 0.034 | kg | Including transportation, without trash burning, with sugar yield of our process | - | 5.13 |

| SC bagasse * | input | 0.01 | kg | Using the yield of sugars, of sugarcane bagasse/sugarcane | - | 9.67 | |

| Enzyme * | input | 4.09 | kg | kg of enzyme (CH1.57N0.29O0.31S0.007) | 541,376 | 23.73 A | |

| Water ** | input | 0.002 | kg | Estimated from the electricity of a cooling pump with 80% efficiency to cool down 1 kg of chilled water | 900 | 0.05 | |

| Chemicals and others | (CH3)2CO ** | difference between input and output | 2.19 | kg | Acetone liquid | 1,788,500 | 30.85 |

| C2H4O2 ** | input | 1.403 | kg | Acetic acid via methanol carbonylation | 908,000 | 15.30 | |

| CaO ** | input | 0.15 | kg | Lime (100%) | 110,200 | 1.97 | |

| C10H14O2 | input | 3.163 | kg | kg CO2/kg tert-butyl catechol produced from lignin | 5,049,720 | 30.42 B | |

| Na2CO3 ** | input | 0.59 | kg | Sodium carbonate (caustic soda), 50%, Na2CO3 | 41,100 | 0.39 | |

| NaOH ** | input | 1.096 | kg | Analyzing 1 kg ‘Sodium hydroxide, 50% in H2O, production mix, at plant/RER U’ | 74,900 | 1.87 | |

| NH4OH ** | input | 2.089 | kg | Ammonia, liquid, at regional storehouse/kg/RER | 337,900 | 19.84 | |

| H3PO4 ** | input | 1.423 | kg | Commercial phosphoric acid (15%) used has a concentration of 85% by mass | 89,600 | 0.91 | |

| H2SO4 ** | input | 0.124 | kg | Sulfuric acid | 163,400 | 1.67 | |

| SO2 ** | input | 0.44 | kg | Sulfur dioxide, liquid | 313,400 | 4.89 | |

| Waste to landfill | output end life | 0.329 | kg | Disposal, average incineration residue, 0% water, to residual material landfill | - | - | |

| Electricity and Fuels | Electricity | input | 0.486 | kWh | Electricity, production mix RER/kWh/RER | - | - |

| Natural gas | input | 1.422 | kg | Emissions in production from fossil fuels (extraction, transportation, and processing) | 829,457 | 51.70 C | |

| Natural gas (emissions) | output | 2.284 | kg | Combustion of CH4 emissions | - | - | |

| Liquefied petroleum gas (LPG) | input | 2.871/0.139 | kg | Combustion emissions/extraction and processing of LPG, which typically consists of propane (C3H8) or a mixture of propane and butane (C4H10) | 2,483,915 | 45.01 C | |

| Gasoline (C8H18) | input | 2.789/0.503 | kg | Emissions in utilization and production from fossil fuels | 5,413,532 | 47.39 C | |

| Diesel (C12H23) | input | 2.966/0.568 | kg | Emissions in utilization and production from fossil fuels | 7,130,900 | 42.70 D | |

| Jet fuel (transportation) | output | 4.5/17.1 | t.km | São Paulo, by train (150 km), Rio de Janeiro, by train (570 km) | 7,565,100 | 45.30 D |

References

- Prussi, M.; Lee, U.; Wang, M.; Malina, R.; Valin, H.; Taheripour, F.; Velarde, C.; Staples, M.D.; Lonza, L.; Hileman, J.I. CORSIA: The first internationally adopted approach to calculate life-cycle GHG emissions for aviation fuels. Renew. Sustain. Energy Rev. 2021, 150, 111398. [Google Scholar] [CrossRef]

- IATA. Our Commitment to Fly Net Zero by 2050, (n.d.). Available online: https://www.iata.org/en/programs/environment/flynetzero/ (accessed on 18 May 2023).

- Wang, W.-C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- Mupondwa, E.; Li, X.; Tabil, L. Chapter 6—Production of biojet fuel: Conversion technologies, technoeconomics, and commercial implementation. In Biofuels and Biorefining; Castro, F.I.G., Gutiérrez-Antonio, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 157–213. [Google Scholar] [CrossRef]

- de Jong, S.; van Stralen, J.; Londo, M.; Hoefnagels, R.; Faaij, A.; Junginger, M. Renewable jet fuel supply scenarios in the European Union in 2021–2030 in the context of proposed biofuel policy and competing biomass demand. GCB Bioenergy 2018, 10, 661–682. [Google Scholar] [CrossRef]

- Santos, C.I.; Silva, C.C.; Mussatto, S.I.; Osseweijer, P.; van der Wielen, L.A.; Posada, J.A. Integrated 1st and 2nd generation sugarcane bio-refinery for jet fuel production in Brazil: Techno-economic and greenhouse gas emissions assessment. Renew. Energy 2018, 129, 733–747. [Google Scholar] [CrossRef]

- Michailos, S. Process design, economic evaluation and life cycle assessment of jet fuel production from sugar cane residue. Environ. Prog. Sustain. Energy 2017, 37, 1227–1235. [Google Scholar] [CrossRef]

- Gerber, L.; Gassner, M.; Maréchal, F. Systematic integration of LCA in process systems design: Application to combined fuel and electricity production from lignocellulosic biomass. Comput. Chem. Eng. 2011, 35, 1265–1280. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Capaz, R.S.; de Medeiros, E.M.; Falco, D.G.; Seabra, J.E.; Osseweijer, P.; Posada, J.A. Environmental trade-offs of renewable jet fuels in Brazil: Beyond the carbon footprint. Sci. Total. Environ. 2020, 714, 136696. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Motta, I.L.; Filho, R.M.; van der Wielen, L.; Capaz, R.; Seabra, J.; Osseweijer, P.; Posada, J.; de Freitas Gonçalves, M.; Scorza, P.R.; et al. 5.16—Sustainable Aviation Fuels: Production, Use and Impact on Decarbonization. In Comprehensive Renewable Energy, 2nd ed.; Letcher, T.M., Ed.; Elsevier: Oxford, UK, 2022; pp. 348–371. [Google Scholar] [CrossRef]

- Bhatt, A.H.; Zhang, Y.; Milbrandt, A.; Newes, E.; Moriarty, K.; Klein, B.; Tao, L. Evaluation of performance variables to accelerate the deployment of sustainable aviation fuels at a regional scale. Energy Convers. Manag. 2023, 275, 116441. [Google Scholar] [CrossRef]

- Rojas-Michaga, M.F.; Michailos, S.; Cardozo, E.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Sustainable aviation fuel (SAF) production through power-to-liquid (PtL): A combined techno-economic and life cycle assessment. Energy Convers. Manag. 2023, 292, 117427. [Google Scholar] [CrossRef]

- Sacchi, R.; Becattini, V.; Gabrielli, P.; Cox, B.; Dirnaichner, A.; Bauer, C.; Mazzotti, M. How to make climate-neutral aviation fly. Nat. Commun. 2023, 14, 3989. [Google Scholar] [CrossRef]

- Silva Ortiz, P.A.; Filho, R.M.; Posada, J. Mass and Heat Integration in Ethanol Production Mills for Enhanced Process Efficiency and Exergy-Based Renewability Performance. Processes 2019, 7, 670. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes, 1st ed.; Hemisphere: Ipswich, UK, 1988. [Google Scholar]

- Ghannadzadeh, A. Exergy-aided environmental sustainability assessment of an ethylene dichloride–vinyl chloride production process. Chem. Eng. Res. Des. 2018, 130, 109–128. [Google Scholar] [CrossRef]

- Ptasinski, K. Efficiency of Biomass Energy: An Exergy Approach to Biofuels, Power, and Biorefineries; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- de Oliveira Junior, S. Exergy Analysis and Environmental Impact. In Exergy: Production, Cost and Renewability; de Oliveira Junior, S., Ed.; Springer: London, UK, 2013; pp. 281–303. [Google Scholar] [CrossRef]

- Ecoinvent. The Ecoinvent Database, (v 3.9); 2023. Available online: https://ecoinvent.org/database/ (accessed on 20 December 2023).

- Silva Ortiz, P.A.; Maréchal, F.; de Oliveira Junior, S. Exergy assessment and techno-economic optimization of bioethanol production routes. Fuel 2020, 279, 118327. [Google Scholar] [CrossRef]

- Lozano, M.; Valero, A. Theory of the exergetic cost. Energy 1993, 18, 939–960. [Google Scholar] [CrossRef]

- Velásquez, H.; De Oliveira, S.; Benjumea, P.; Pellegrini, L. Exergo-environmental evaluation of liquid biofuel production processes. Energy 2013, 54, 97–103. [Google Scholar] [CrossRef]

- Huysman, S.; Schaubroeck, T.; Dewulf, J. Exergy and Cumulative Exergy Use Analysis, in: Sustainability Assessment of Renewables-Based Products; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 141–154. [Google Scholar] [CrossRef]

- Bakshi, B.R. Sustainable Engineering; Cambridge University Press (CUP): Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; Cardoso, T.d.F.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Tzanetis, K.F.; Posada, J.A.; Ramirez, A. Analysis of biomass hydrothermal liquefaction and biocrude-oil upgrading for renewable jet fuel production: The impact of reaction conditions on production costs and GHG emissions performance. Renew. Energy 2017, 113, 1388–1398. [Google Scholar] [CrossRef]

- Alves, C.M.; Valk, M.; de Jong, S.; Bonomi, A.; van der Wielen, L.A.; Mussatto, S.I. Techno-economic assessment of biorefinery technologies for aviation biofuels supply chains in Brazil. Biofuels, Bioprod. Biorefining 2016, 11, 67–91. [Google Scholar] [CrossRef]

- Braz, D.S.; Mariano, A.P. Jet fuel production in eucalyptus pulp mills: Economics and carbon footprint of ethanol vs. butanol pathway. Bioresour. Technol. 2018, 268, 9–19. [Google Scholar] [CrossRef]

- Kotas, T.J. The Exergy Method of Thermal Plant Design; Butterworths: London, UK, 1985. [Google Scholar]

- Wooley, R.J.; Putsche, V. Development of An Aspen Plus Physical Property Database for Biofuels Components; National Renewable Energy Laboratory-NREL: Golden, CO, USA, 1996. Available online: http://www.nrel.gov/docs/legosti/old/20685.pdf (accessed on 20 December 2023).

- Butcher, M.G.; Meyer, P.A.; Hallen, R.T.; Albrecht, K.O.; Clayton, C.K.; Polikarpov, E.; Rappe, K.G.; Jones, S.B.; Magnuson, J.K. Fungal metabolites as precursors to renewable transportation fuels. Fuel 2018, 215, 123–141. [Google Scholar] [CrossRef]

- Arango-Miranda, R.; Hausler, R.; Romero-López, R.; Glaus, M.; Ibarra-Zavaleta, S.P. An Overview of Energy and Exergy Analysis to the Industrial Sector, a Contribution to Sustainability. Sustainability 2018, 10, 153. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Chapter 3—Chemical exergy. In Exergy, 3rd ed.; Dincer, I., Rosen, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 37–60. [Google Scholar] [CrossRef]

| Technology | FPJ | |||||||

|---|---|---|---|---|---|---|---|---|

| Pre-treatment | DA | DA-A | SE | SE-A | O-AA | WO | LHW | LHW-A |

| Exergy efficiency (%) | 43.16 | 44.22 | 43.25 | 44.00 | 44.43 | 44.94 | 40.72 | 42.70 |

| Irreversibility rate (MW) | 119 | 117 | 119 | 117 | 116 | 115 | 124 | 120 |

| AUEC (kJ/kJ) | 2.32 | 2.26 | 2.31 | 2.27 | 2.25 | 2.23 | 2.46 | 2.34 |

| GHG emission (kgCO2/GJJet Fuel) | 51.35 | 50.64 | 40.99 | 40.47 | 30.56 | 52.23 | 47.33 | 47.19 |

| λ | 0.67 | 0.69 | 0.67 | 0.69 | 0.70 | 0.71 | 0.61 | 0.70 |

| Technology | GFT | |||||||

| Pre-treatment | DA | DA-A | SE | SE-A | O-AA | WO | LHW | LHW-A |

| Exergy efficiency (%) | 40.55 | 42.37 | 40.69 | 42.30 | 43.29 | 43.79 | 38.13 | 40.86 |

| Irreversibility rate (MW) | 124 | 120 | 124 | 121 | 118 | 117 | 129 | 123 |

| AUEC (kJ/kJ) | 2.47 | 2.36 | 2.46 | 2.36 | 2.31 | 2.28 | 2.62 | 2.45 |

| GHG emission (kgCO2/GJJet Fuel) | 50.73 | 50.15 | 40.50 | 40.14 | 30.40 | 51.97 | 46.73 | 46.65 |

| λ | 0.60 | 0.65 | 0.61 | 0.65 | 0.67 | 0.68 | 0.55 | 0.64 |

| Technology | ATF (COGEN) | |||||||

| Pre-treatment | DA | DA-A | SE | SE-A | O-AA | WO | LHW | LHW-A |

| Exergy efficiency (%) | 37.88 | 41.64 | 38.37 | 41.64 | 40.65 | 40.02 | 35.38 | 40.13 |

| Irreversibility rate (MW) | 130 | 122 | 129 | 122 | 124 | 126 | 135 | 125 |

| AUEC (kJ/kJ) | 2.64 | 2.40 | 2.61 | 2.40 | 2.46 | 2.50 | 2.83 | 2.49 |

| GHG emission (kgCO2/GJJet Fuel) | 50.00 | 50.00 | 40.00 | 40.00 | 30.00 | 51.00 | 46.00 | 46.00 |

| λ | 0.54 | 0.63 | 0.55 | 0.63 | 0.61 | 0.59 | 0.49 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva Ortiz, P.; de Oliveira, S., Jr.; Mariano, A.P.; Jocher, A.; Posada, J. Exergy-Based Improvements of Sustainable Aviation Fuels: Comparing Biorefinery Pathways. Processes 2024, 12, 510. https://doi.org/10.3390/pr12030510

Silva Ortiz P, de Oliveira S Jr., Mariano AP, Jocher A, Posada J. Exergy-Based Improvements of Sustainable Aviation Fuels: Comparing Biorefinery Pathways. Processes. 2024; 12(3):510. https://doi.org/10.3390/pr12030510

Chicago/Turabian StyleSilva Ortiz, Pablo, Silvio de Oliveira, Jr., Adriano Pinto Mariano, Agnes Jocher, and John Posada. 2024. "Exergy-Based Improvements of Sustainable Aviation Fuels: Comparing Biorefinery Pathways" Processes 12, no. 3: 510. https://doi.org/10.3390/pr12030510

APA StyleSilva Ortiz, P., de Oliveira, S., Jr., Mariano, A. P., Jocher, A., & Posada, J. (2024). Exergy-Based Improvements of Sustainable Aviation Fuels: Comparing Biorefinery Pathways. Processes, 12(3), 510. https://doi.org/10.3390/pr12030510