Coal Structure Recognition Method Based on LSTM Neural Network

Abstract

1. Introduction

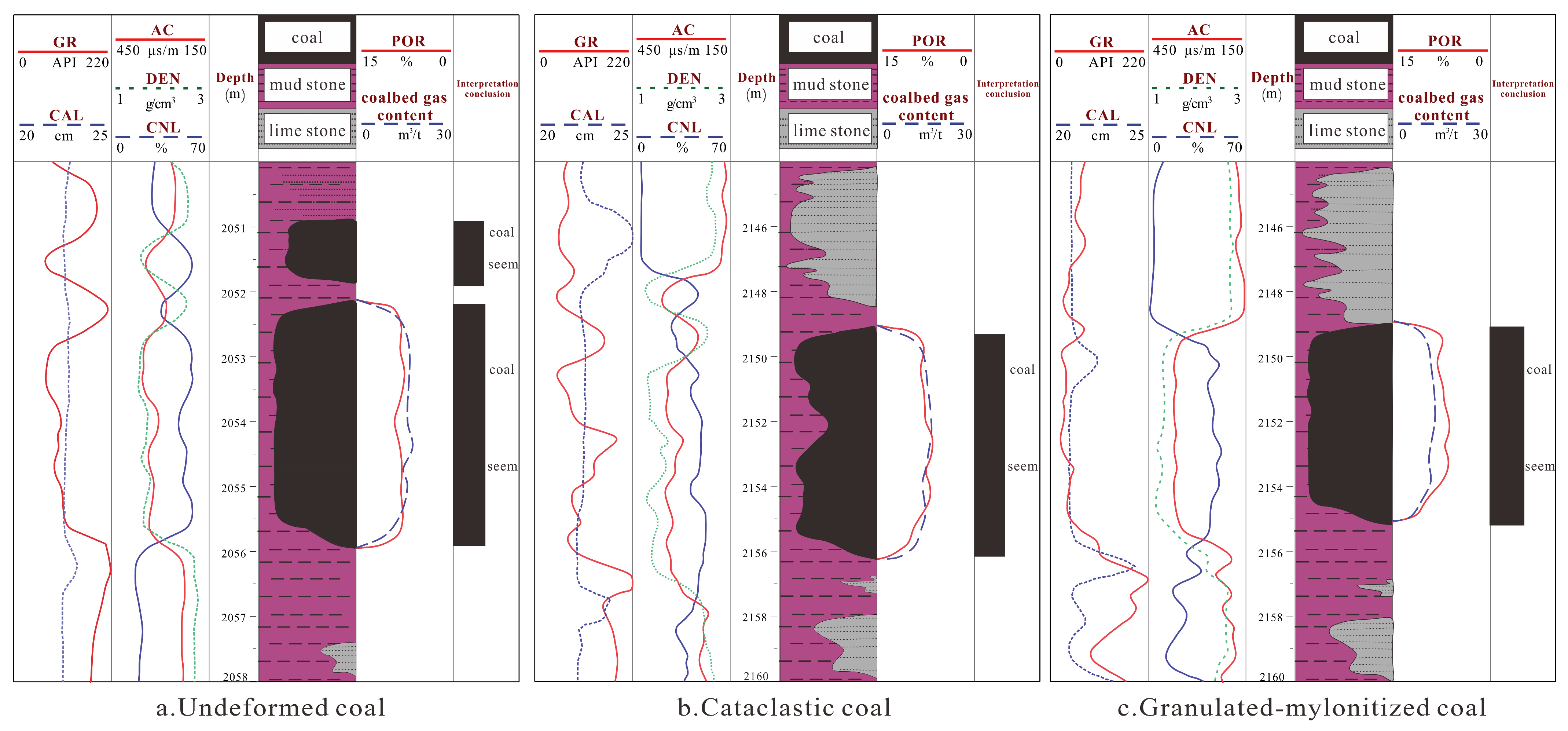

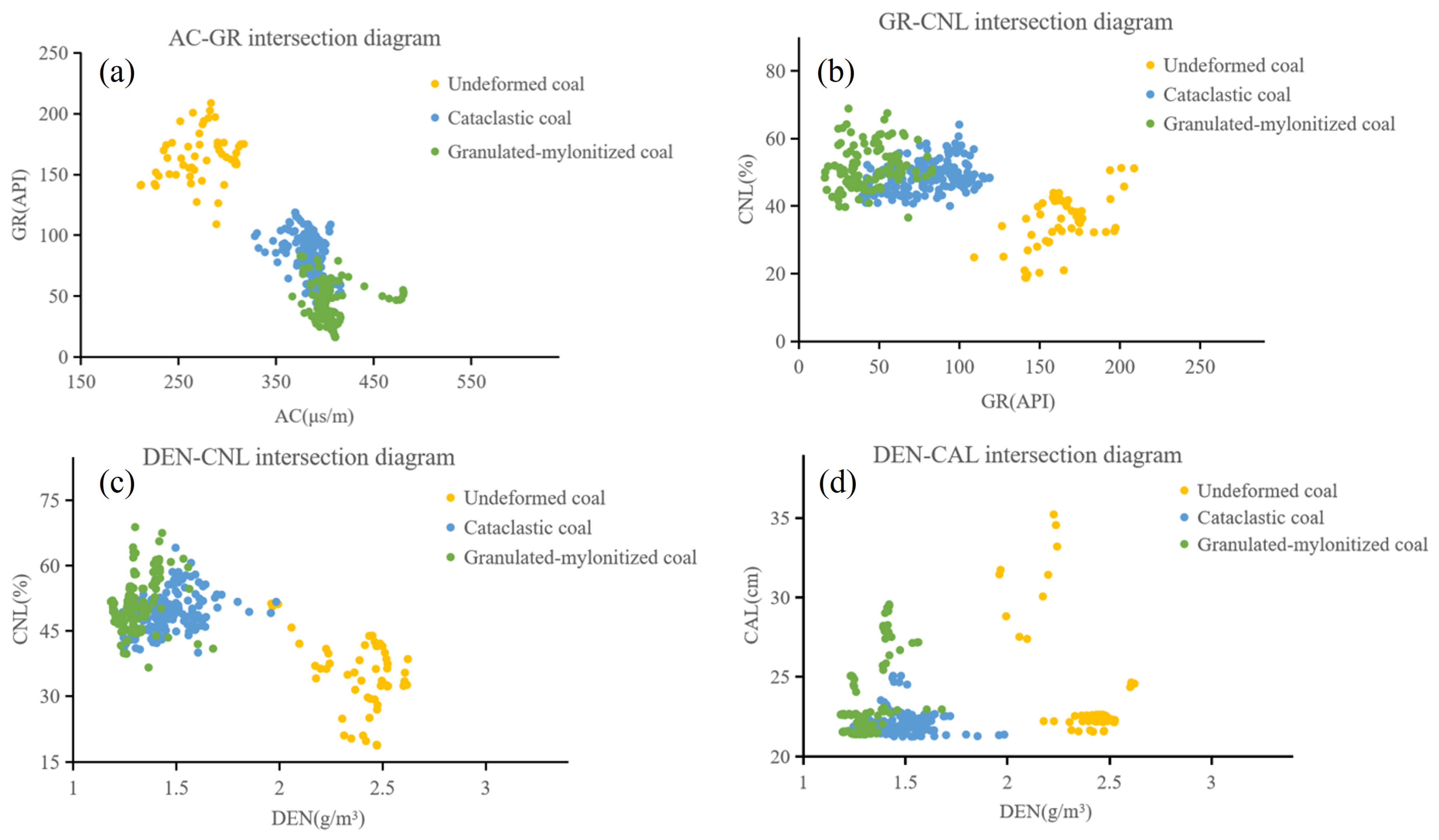

2. Logging Response Characteristics of Coal Structure

2.1. Coal Structure Division

- (1)

- Undeformed coal: This coal structure remains largely intact, characterized by angular, massive forms with no significant displacement. The coal and rock exhibit well-developed bedding, cleating, and high hardness, with no substantial signs of structural deformation.

- (2)

- Cataclastic coal: This type has undergone moderate structural damage, exhibiting lenticular block formations with noticeable relative displacement. The original layered structure is largely disrupted, with clear exogenous fractures crossing through the coal and rock clefts, leading to a local lenticular appearance.

- (3)

- Granulated-mylonitized coal: This type shows more severe structural damage compared to cataclastic coal, often appearing lumpy or fragmented into granulated pieces. The bedding structure is minimal, and the coal layers exhibit unconformity contacts with significant secondary fracturing. The coal is highly friable, frequently breaking into granular fragments and powder.

2.2. Logging Response Characteristics of Different Coal Structures

3. LSTM Neural Network Model for Coal Structure Recognition

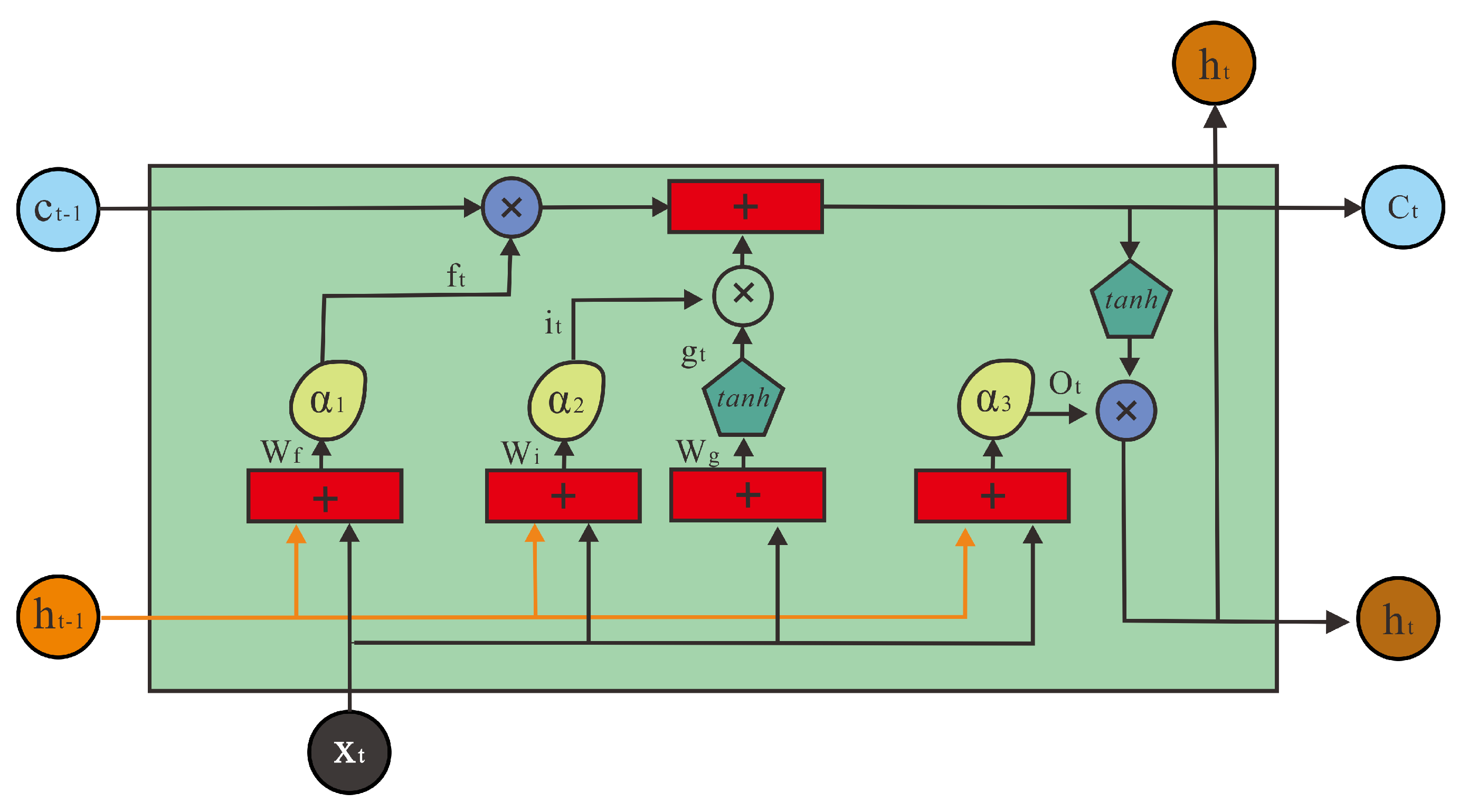

3.1. Basic Principle of LSTM Neural Network

3.2. Logging Data Preprocessing

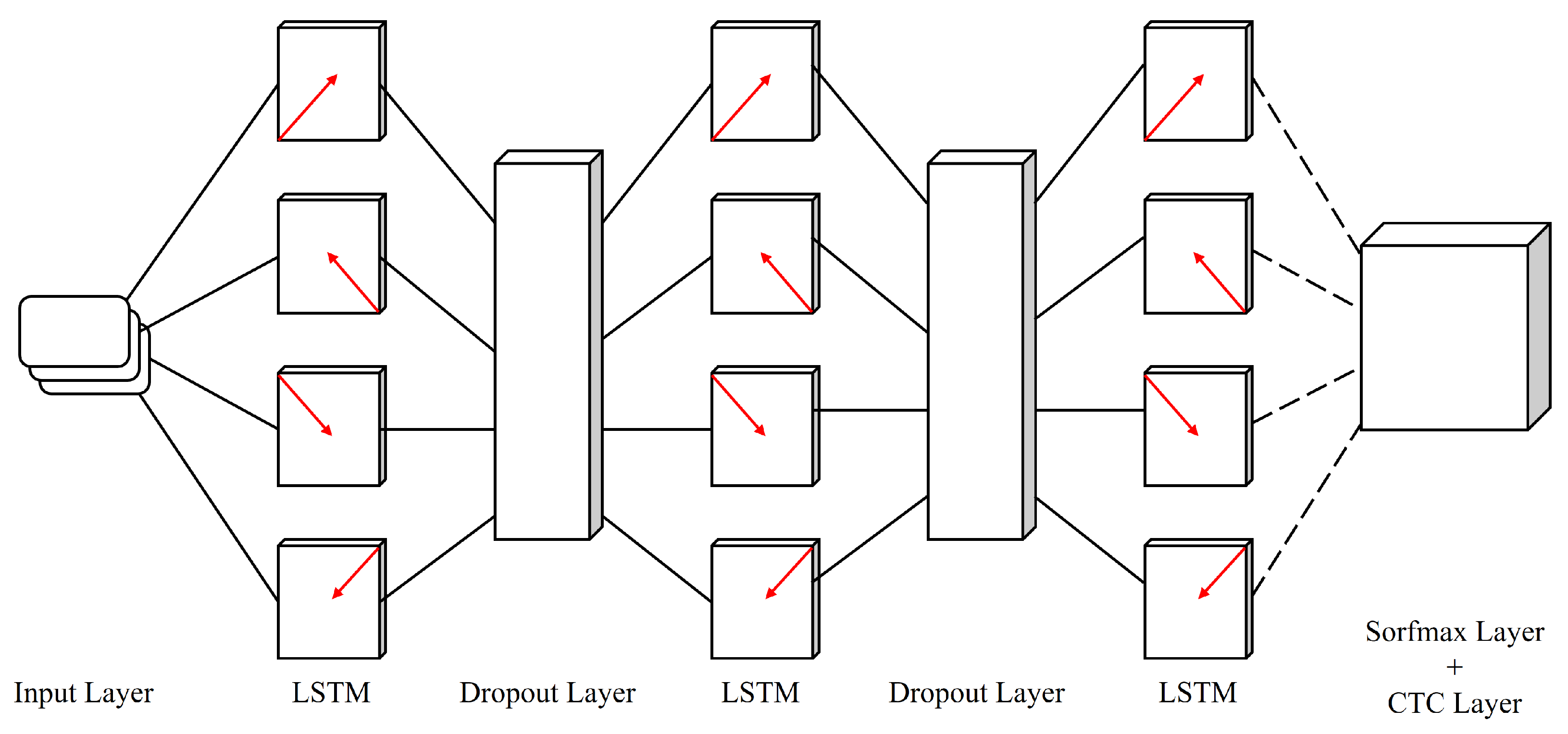

3.3. Construction and Training of Coal Structure Recognition Model Based on LSTM Neural Network

- Normalize the three-dimensional seismic attribute data and sample a result set for backup;

- Perform feature learning on the sample data set;

- Train the LSTM model, using the lower layer output as input for the upper layer;

- After feature learning and training, obtain a trained feature representation model;

- Fine-tune the parameters in the top layer using the BPTT algorithm from front to back;

- Use Softmax as a regression classifier to output the probability of the prediction results;

- Compute the cross-entropy loss of the model and optimize it iteratively using a gradient-based algorithm to achieve the best model.

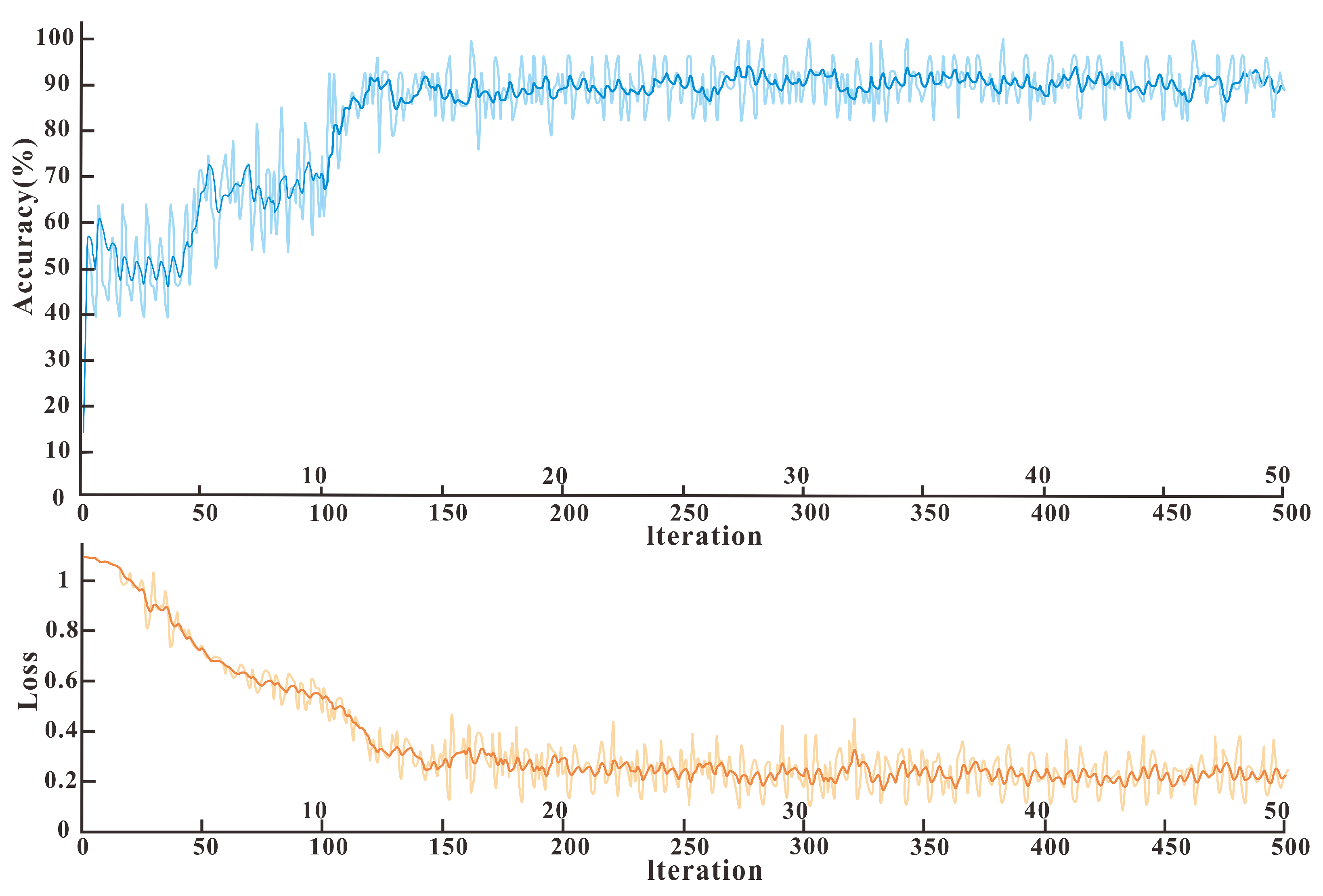

3.4. Verification of Coal Structure Recognition Results and Accuracy

4. Discussion

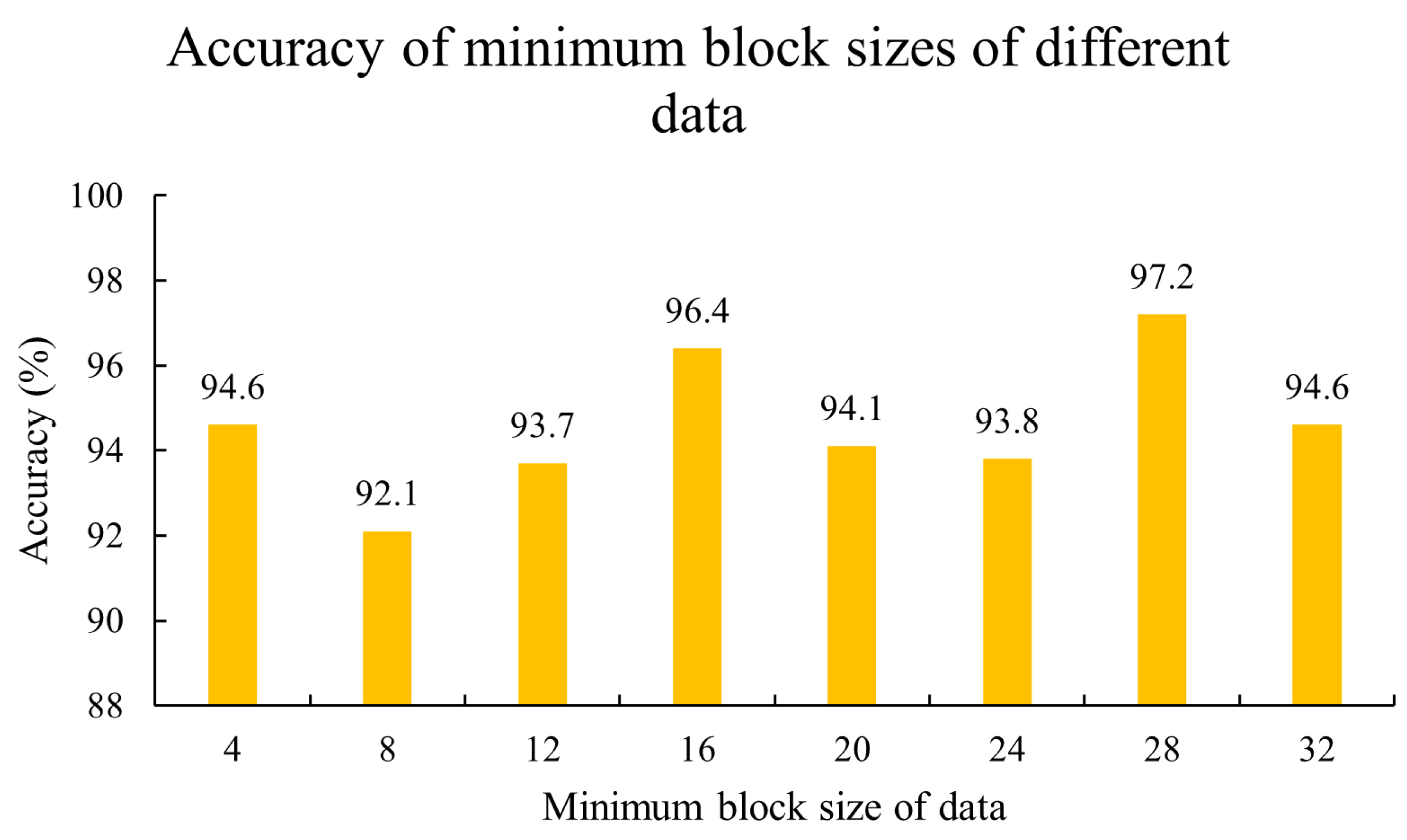

4.1. Parameter Analysis of LSTM Network Model

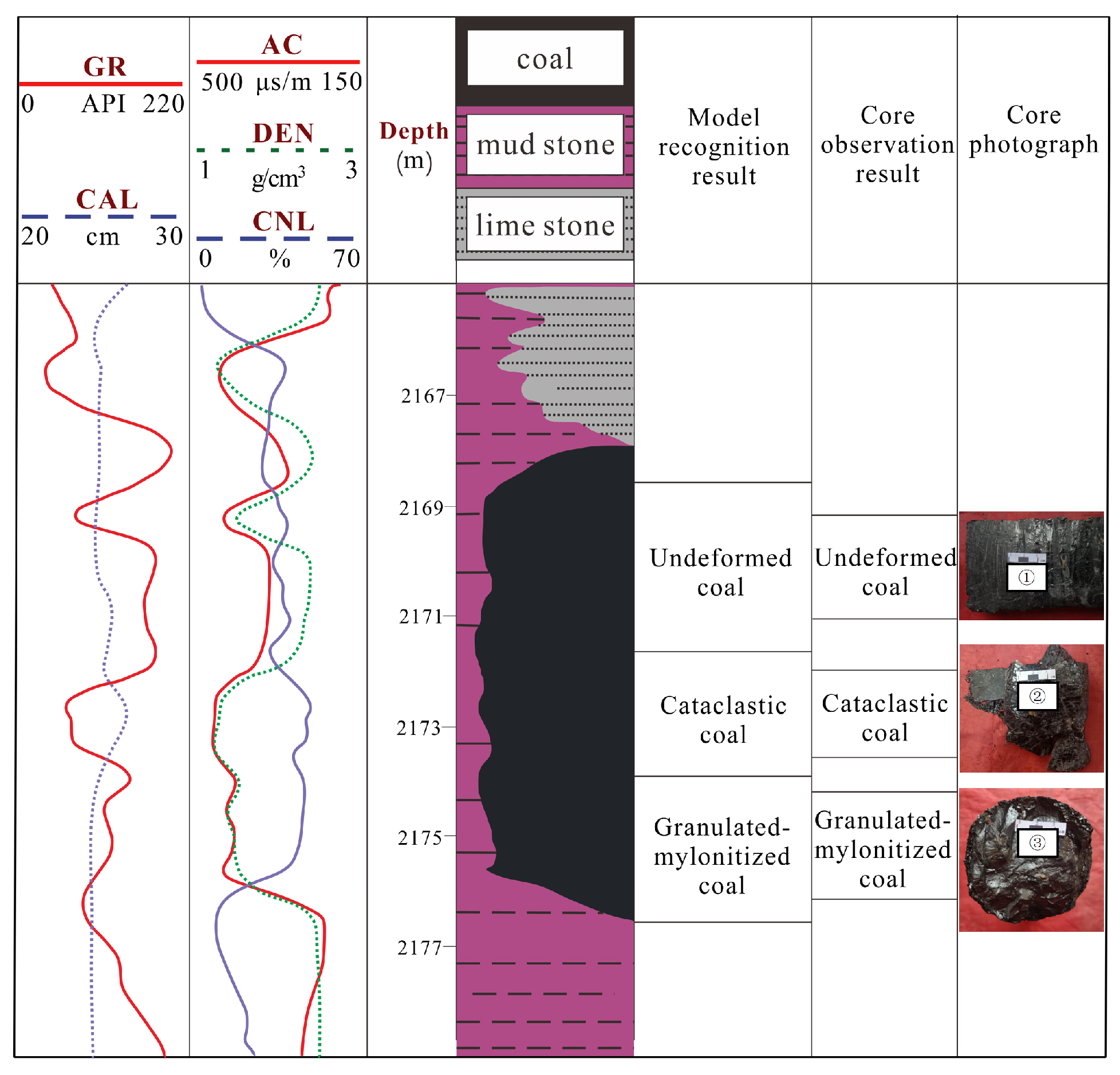

4.2. Model Reliability Analysis

- (1)

- The No. 1 coal core, located at a burial depth of 2170 to 2171.875 m with a length of 1.875 m, is classified as undeformed coal.

- (2)

- The No. 2 coal core, situated at a depth of 2172.625 to 2173.625 m and measuring 1 m in length, is identified as cataclastic coal.

- (3)

- The No. 3 coal core, buried between 2174.625 and 2175.875 m, has a length of 1.2 m and is classified as granulated-mylonitized coal.

4.3. Distribution Characteristics of Coal Structures

5. Conclusions

- (1)

- Based on the analysis of coal core data from the Benxi Formation in Area A of the Ordos Basin and the observed challenges posed by granulated and mylonitized coal on coalbed methane extraction, the coal structure in Area A is classified into three distinct types: (1) undeformed coal, which displays minimal structural disruption, characterized by angular blocky masses; (2) cataclastic coal, which shows moderate structural damage, forming lenticular blocks with visible fractures; (3) granulated-mylonitized coal, which has undergone significant deformation, resulting in granular fragments with unconformable contacts with adjacent layers and extensive secondary fracturing.

- (2)

- Research indicates that undeformed coal is characterized by a low density, low radioactivity, and high acoustic transit time. Specifically, the density (DEN) ranges from 1.96 to 2.62 g/cm3, the gamma ray (GR) value is typically over 100 API, and the acoustic transit time (AC) ranges from 210.9 to 316.8 μs/m. In comparison, the density (DEN) of the cataclastic structure ranges from 1.23 to 1.98 g/cm³, with a gamma ray (GR) of 38.6 to 118.8 API, and an acoustic transit time (AC) of 328.1 to 416.2 μs/m. For the granulated-mylonitized structure, the density (DEN) ranges from 1.18 to 1.67 g/cm3, the gamma ray (GR) ranges from 16.2 to 82.2 API, and the acoustic transit time (AC) is 366.5 to 480.6 μs/m.

- (3)

- This study integrates forgetting gates, input gates, and output gates within the framework of an LSTM neural network to develop a coal structure recognition model. By utilizing five logging curves—CAL, GR, AC, CNL, and DEN—the model significantly improves the accuracy of coal structure identification, achieving an overall accuracy of 85.5%.

- (4)

- The undeformed coal is more developed in the study area, while the development of cataclastic coal and granulated-mylonitized coal is less pronounced. Along the fault trend, the development of cataclastic coal and granulated-mylonitized coal is more prominent, indicating that fault activity influenced the coal structure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yegireddi, S.; Uday Bhaskar, G. Identification of Coal Seam Strata from Geophysical Logs of Borehole Using Adaptive Neuro-Fuzzy Inference System. J. Appl. Geophys. 2009, 67, 9–13. [Google Scholar] [CrossRef]

- Hou, H.; Shao, L.; Guo, S.; Li, Z.; Zhang, Z.; Yao, M.; Zhao, S.; Yan, C. Evaluation and Genetic Analysis of Coal Structures in Deep Jiaozuo Coalfield, Northern China: Investigation by Geophysical Logging Data. Fuel 2017, 209, 552–566. [Google Scholar] [CrossRef]

- Juan, T.; Dameng, L.; Yanbin, Y.; Yidong, C. Quantitative Evaluation of Coal Structures with the Aid of Geophysical Logging Data. Int. J. Hybrid Inf. Technol. 2016, 9, 383–392. [Google Scholar] [CrossRef]

- Wu, J.; Tang, D.; Li, S.; Ren, P. Characteristics and influence factors of pore structure of coal reservoirs in theeastern margin of Ordos basin. Coal Geol. Explor. 2017, 45, 58–65. [Google Scholar] [CrossRef]

- Wang, H.; Xiang, J.; Li, C.; Deng, X.; Song, X.; Zhao, Q.; Meng, Y. Influence of Fracturing on a Coal Structure During Coalbed Methane Stimulation. ACS Omega 2024, 9, 5772–5779. [Google Scholar] [CrossRef]

- Kang, H.; Gao, F.; Xu, G.; Ren, H. Mechanical Behaviors of Coal Measures and Ground Control Technologies for China’s Deep Coal Mines—A Review. J. Rock Mech. Geotech. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Chu, Y.; Zhang, D.; Song, S.; Ouyang, K.; Fei, L. Affiliations Experimental Study on the Evolution of Pore Structure of Coal Samples Under Freeze–Thaw. Phys. Fluids 2023, 35, 36602. [Google Scholar] [CrossRef]

- Yang, G.; Tang, S.; Zhang, S.; Huang, W.; Xi, Z.; Li, L.; Li, Y.; Li, J.; Wang, M.; Gong, M. Impacts of Vertical Variation of Different Coal Texture Types on Coalbed Methane Production in Zaoyuan Area of the Shizhuangnan Block, Southern Qinshui Basin, North China. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1617–1624. [Google Scholar] [CrossRef]

- Zhao, F.; Sang, S.; Han, S.; Wu, Z.; Zhang, J.; Xiang, W.; Xu, A. Characteristics and Origins of the Difference Between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block. Energies 2022, 15, 3181. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, Y.; Lyu, S.; Li, J.; Tian, L. Coal Structure Characteristics in the Northern Qinshui Basin and Their Discrimination Method Based on the Particle Size of Drilling Cuttings. ACS Omega 2022, 7, 22956–22968. [Google Scholar] [CrossRef]

- Huang, B.; Qin, Y.; Zhang, W.; Wang, G. Identification of the Coal Structure and Prediction of the Fracturability in the No. 8 Coal Reservoir, Gujiao Block, China. Energy Explor. Exploit. 2018, 36, 204–229. [Google Scholar] [CrossRef]

- Shao, X.; Sun, Y.; Sun, J.; Tang, D.; Xu, H.; Dong, X.; Lü, Y. Log Interpretation for Coal Petrologic Parameters: A Case Study of Hancheng Mining Area, Central China. Pet. Explor. Dev. 2013, 40, 599–605. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, X.; Zeng, L.; Zhang, Y.; Dong, S. Identification of Coal Structures by Semi-Supervised Learning Based on Limited Labeled Logging Data. Fuel 2023, 337, 127191. [Google Scholar] [CrossRef]

- Kumar, T.; Seelam, N.K.; Rao, G.S. Lithology Prediction from Well Log Data Using Machine Learning Techniques: A Case Study from Talcher Coalfield, Eastern India. J. Appl. Geophys. 2022, 199, 104605. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, H.; Xu, H.; Fan, J.; Ding, W. Construction and Application of an Intelligent Prediction Model for the Coal Pillar Width of a Fully Mechanized Caving Face Based on the Fusion of Multiple Physical Parameters. Sustainability 2024, 16, 986. [Google Scholar] [CrossRef]

- Baneshi, M. The Determination of Lithofacies Using an Optimized Neural Network and Well Log Data. Pet. Sci. Technol. 2014, 32, 897–903. [Google Scholar] [CrossRef]

- Chen, Q.; Yao, H.-F.; Chang, S.-L.; Liu, J. Coalbody Structure Classification Method Based on Dual-Lateral and RXO Crossplot Analysis. J. Coal Sci. Eng. 2013, 19, 522–529. [Google Scholar] [CrossRef]

- Lv, F.; Yang, R.; Yi, T.; Gao, W.; Cheng, W.; Yan, Z. A Prediction Model of Coal Structure Based on Logging Parameters in Liupanshui Coalfield, Guizhou, China. Arab. J. Geosci. 2021, 14, 2204. [Google Scholar] [CrossRef]

- Zhao, Z.; Tao, S.; Tang, D.; Chen, S.; Ren, P. A Mathematical Method to Identify and Forecast Coal Texture of Multiple and Thin Coal Seams by Using Logging Data in the Panguan Syncline, Western Guizhou, China. J. Pet. Sci. Eng. 2020, 185, 106616. [Google Scholar] [CrossRef]

- Shi, J.; Zeng, L.; Dong, S.; Wang, J.; Zhang, Y. Identification of Coal Structures Using Geophysical Logging Data in Qinshui Basin, China: Investigation by Kernel Fisher Discriminant Analysis. Int. J. Coal Geol. 2020, 217, 103314. [Google Scholar] [CrossRef]

- Zhou, X.; Zhansong, Z.; Chaomo, Z. Bi-LSTM Deep Neural Network Reservoir Classification Model Based on the Innovative Input of Logging Curve Response Sequences. IEEE Access 2021, 9, 19902–19915. [Google Scholar] [CrossRef]

- Wang, D.; Ni, J.; Du, T. An Image Recognition Method for Coal Gangue Based on ASGS-CWOA and BP Neural Network. Symmetry 2022, 14, 880. [Google Scholar] [CrossRef]

- Keskinsezer, A. Determination of Coal Layers Using Geophysical Well-Logging Methods for Correlation of the Gelik-Zonguldak and Kazpınar-Amasra (Bartın) Coalfields, Turkey. Geomech. Geophys. Geo-Energy Geo-Resour. 2019, 5, 223–235. [Google Scholar] [CrossRef]

- Dailei, Z.; Chong, Z. Inversion of 3D Density Interface with PSO-BP Method. Glob. Geol. 2016, 19, 33–40. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Zhang, K.; Xiao, H.; Xu, H.; Hu, J.; Fan, L. Missing Interpolation Algorithm of Landslide Surface Displacement Monitoring Data Based on Principal Component Analysis and Long Short Term Memory Network. Sci. Technol. Eng. 2023, 23, 11129–11135. [Google Scholar] [CrossRef]

- Wang, Z.; Zuo, R. Mineral Prospectivity Mapping Using a Joint Singularity-Based Weighting Method and Long Short-Term Memory Network. Comput. Geosci. 2022, 158, 104974. [Google Scholar] [CrossRef]

- Bustin, R.M.; Clarkson, C.R. Geological Controls on Coalbed Methane Reservoir Capacity and Gas Content. Int. J. Coal Geol. 1998, 38, 3–26. [Google Scholar] [CrossRef]

- Lamberson, M.N.; Bustin, R.M. Coalbed Methane Characteristics of Gates Formation Coals, Northeastern British Columbia: Effect of Maceral Composition1. AAPG Bull. 1993, 77, 2062–2076. [Google Scholar] [CrossRef]

- Wang, T.; Deng, Z.; Hu, H.; Ding, R.; Tian, F.; Zhang, T.; Ma, Z.; Wang, D. Pore Structure of Deep Coal of Different Ranks and Its Effect on Coalbed Methane Adsorption. Int. J. Hydrogen Energy 2024, 59, 144–158. [Google Scholar] [CrossRef]

- Kang, L.; Kang, Y.; Liu, N.; Deng, Z.; Zhang, B. Coupling mechanism of formation pressure and coal structure and its influence on gas content. China Min. Mag. 2020, 29, 251–257. [Google Scholar]

- Guo, H.; Cheng, Y.; Ren, T.; Wang, L.; Yuan, L.; Jiang, H.; Liu, H. Pulverization Characteristics of Coal from a Strong Outburst-Prone Coal Seam and Their Impact on Gas Desorption and Diffusion Properties. J. Nat. Gas Sci. Eng. 2016, 33, 867–878. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, Y.; Meng, J. Synthetic Well Logs Generation via Recurrent Neural Networks. Pet. Explor. Dev. 2018, 45, 598–607. [Google Scholar] [CrossRef]

- Hinton, G.E.; Osindero, S.; Teh, Y.-W. A Fast Learning Algorithm for Deep Belief Nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef]

- An, P.; Cao, D. Research and Application of Logging Lithology Identification Based on Deep Learning. Prog. Geophys. 2018, 33, 1029–1034. [Google Scholar] [CrossRef]

- An, P.; Yang, X.; Zhang, M. Porosity Prediction and Application with Multiwell-Logging Curves Based on Deep Neural Network. In SEG Technical Program Expanded Abstracts; SEG: Houston, TX, USA, 2012; pp. 819–823. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, H.; Sun, B.; Ouyang, Z.; Dou, W.; Wang, B.; Lai, P.; Hu, Z.; Luo, B.; Yang, M.; et al. Pore Size Distribution and Fractal Characteristics of Deep Coal in the Daning–Jixian Block on the Eastern Margin of the Ordos Basin. ACS Omega 2024, 9, 32837–32852. [Google Scholar] [CrossRef]

| Coal Structure Type | Degree of Coal Fragmentation | Physical Properties | Fracture Development Characteristics | Typical Core Photograph |

|---|---|---|---|---|

| Undeformed coal | The structure of the coal body is complete, and there is no obvious displacement | Appear black columnar, with a metallic luster, hard texture | Cleft development, rare ectogenesis cracks |  |

| Cataclastic coal | The structure of coal body is relatively complete, showing lenticular block and obvious relative displacement | Appear black columnar, with a metallic luster, hard texture | Cleft is developed and cleaved by exogenous fractures |  |

| Granulated-mylonitized coal | The structure of the coal body was seriously damaged, which was lumpy or broken, and had unconformable contact with the upper and lower layers | Black lump, dim luster, low hardness, easy to twist powder | The coal body is loose and develops a large number of ectogenesis cracks. It is impossible to distinguish the primary cleat or present broken grain and powder |  |

| Coal Structure Type | GR/(API) | DEN/(g/cm3) | AC/(μs/m) | CAL/(cm) | CNL/(%) |

|---|---|---|---|---|---|

| Undeformed structure | 109.2~208.8 | 1.96~2.62 | 210.9~316.8 | 21.5~25.2 | 18.8~51.3 |

| Cataclastic structure | 38.6~118.8 | 1.23~1.98 | 328.1~416.2 | 21.2~30.1 | 40.1~64.1 |

| Granulated-mylonitized structure | 16.2~82.2 | 1.18~1.67 | 366.5~480.6 | 24.3~35.5 | 36.6~68.8 |

| Coal Structure Type | Sample Size of Validation Set | Accurate Recognition Number | The Recognition Accuracy |

|---|---|---|---|

| Undeformed coal | 63 | 57 | 90.5% |

| Cataclastic coal | 86 | 72 | 83.4% |

| Granulated-mylonitized coal | 44 | 36 | 81.8% |

| Total | 193 | 165 | 85.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Chen, C.; Zhang, J.; Hu, F.; He, T.; Wang, X.; Cheng, Q.; He, J.; Zhao, Y.; Zeng, Q. Coal Structure Recognition Method Based on LSTM Neural Network. Processes 2024, 12, 2717. https://doi.org/10.3390/pr12122717

Chen Y, Chen C, Zhang J, Hu F, He T, Wang X, Cheng Q, He J, Zhao Y, Zeng Q. Coal Structure Recognition Method Based on LSTM Neural Network. Processes. 2024; 12(12):2717. https://doi.org/10.3390/pr12122717

Chicago/Turabian StyleChen, Yang, Cen Chen, Jiarui Zhang, Fengying Hu, Taohua He, Xinyue Wang, Qun Cheng, Jiayi He, Ya Zhao, and Qianghao Zeng. 2024. "Coal Structure Recognition Method Based on LSTM Neural Network" Processes 12, no. 12: 2717. https://doi.org/10.3390/pr12122717

APA StyleChen, Y., Chen, C., Zhang, J., Hu, F., He, T., Wang, X., Cheng, Q., He, J., Zhao, Y., & Zeng, Q. (2024). Coal Structure Recognition Method Based on LSTM Neural Network. Processes, 12(12), 2717. https://doi.org/10.3390/pr12122717