Microstructure Characteristics and Elevated-Temperature Wear Mechanism of FeCoCrNiAl High-Entropy Alloy Prepared by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Laser Experimental Parameters

2.2. Microstructure and Hardness Test

2.3. Elevated Friction and Wear Test

3. Results

3.1. Phase Analysis of the Coating

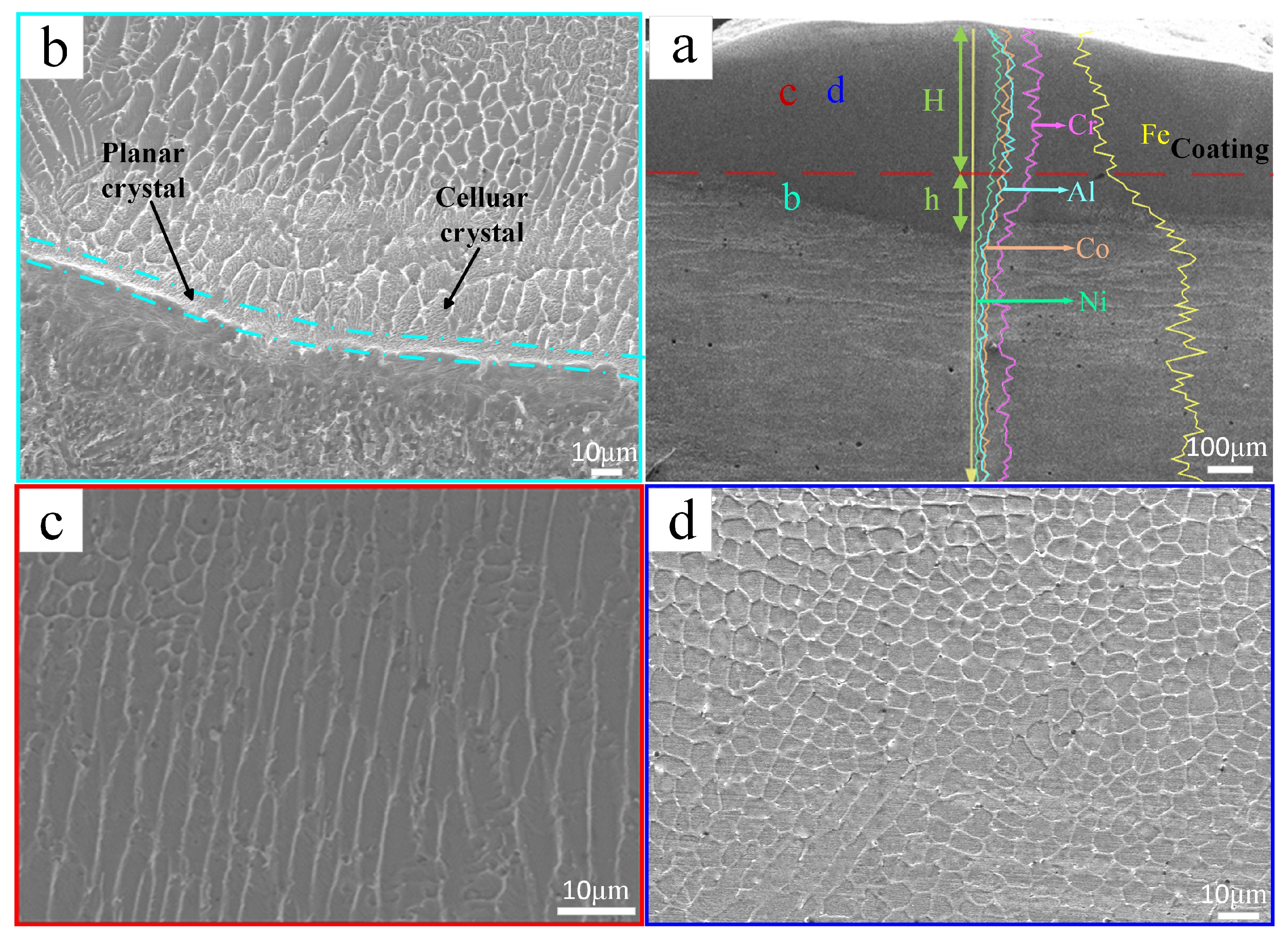

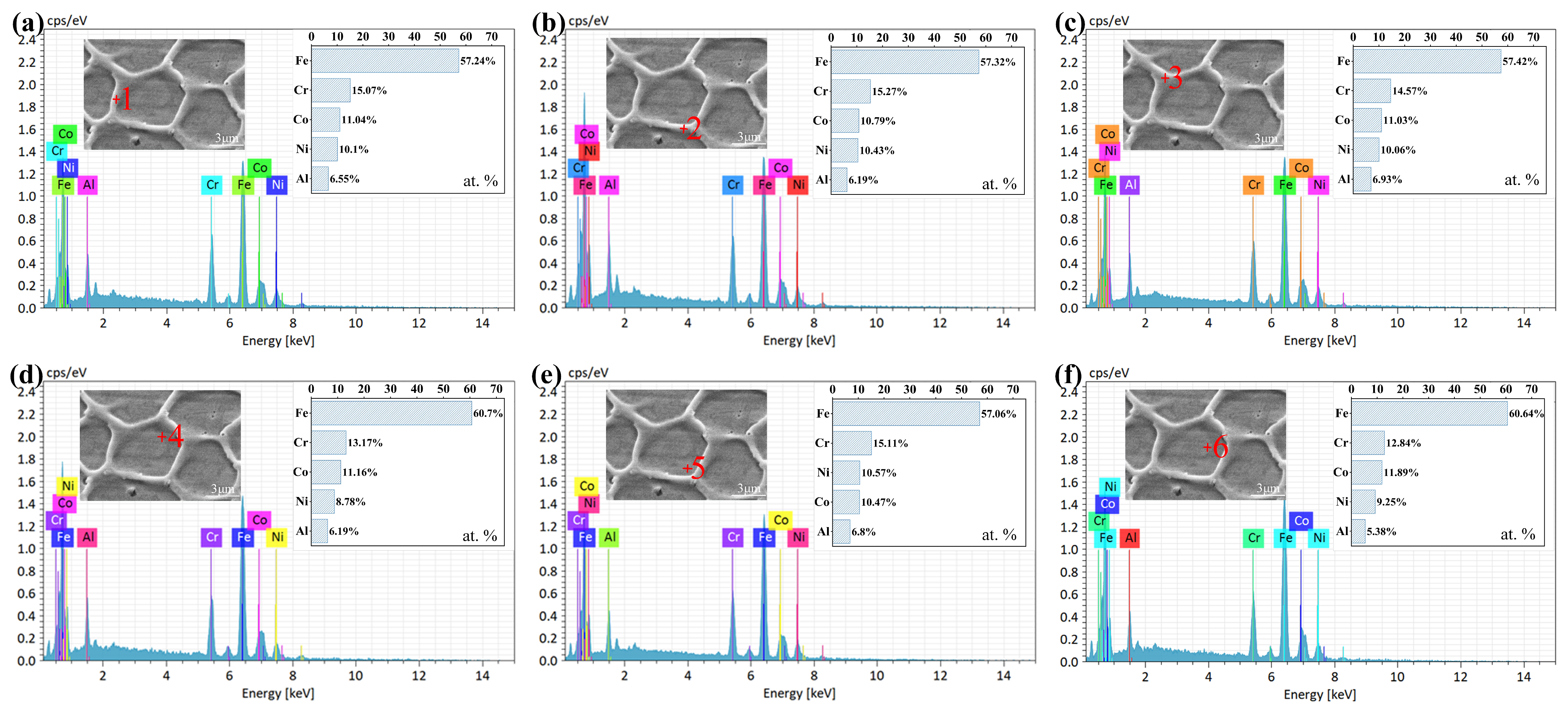

3.2. Microstructure Analysis of the Coating

3.3. Microhardness Analysis of the Coating

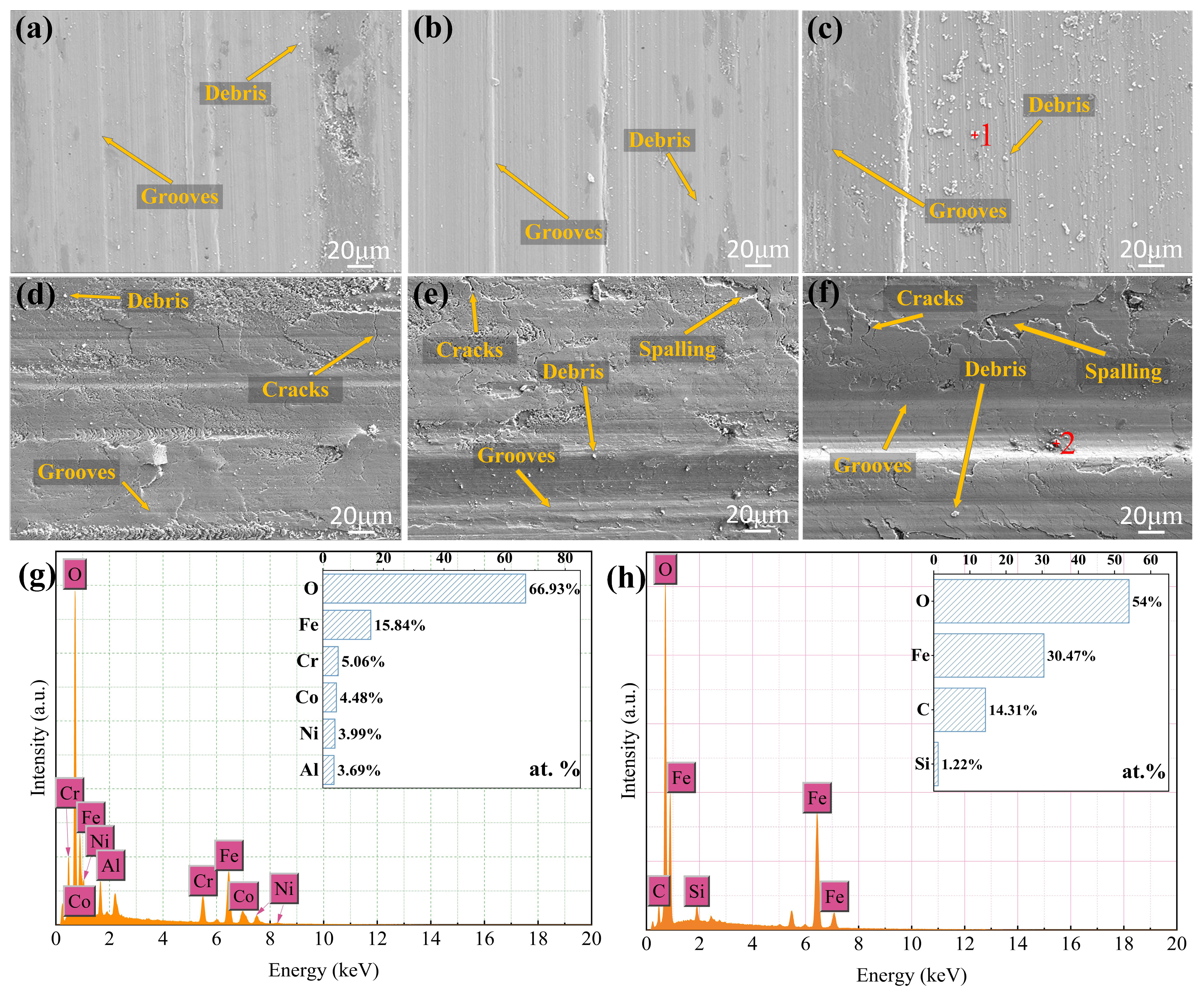

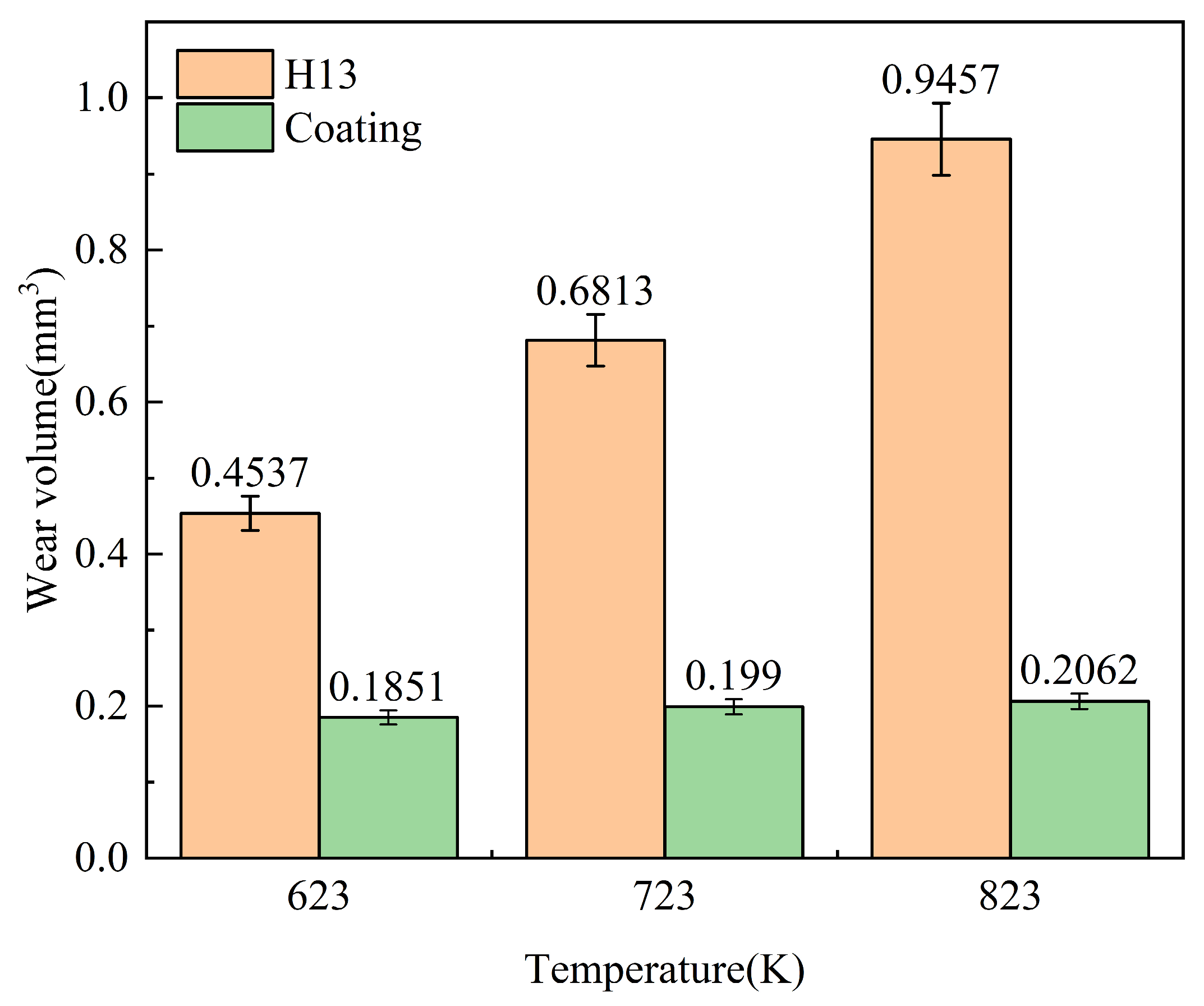

3.4. Elevated-Temperature Wear Resistance Analysis of the Coating

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.F.; Li, J.Q.; Wang, L.Z.; Chen, C.Y.; Wang, X.; Zhao, F. Study on modification of primary carbides and improvement of properties in H13 steel by CeO2 nanoparticles addition. J. Mater. Res. Technol. 2023, 27, 7685–7694. [Google Scholar] [CrossRef]

- Ding, H.G.; Liu, T.; Wei, J.B.; Chen, L.L.; Cao, F.Y.; Zhang, B.S.; Luo, R.; Cheng, X.N. Microstructure and tempering softening mechanism of modified H13 steel with the addition of Tungsten, Molybdenum, and lowering of Chromium. Mater. Des. 2022, 224, 111317. [Google Scholar] [CrossRef]

- Li, C.D.; Qiu, F.; Yang, H.Y.; Chang, F.; Li, T.Y.; Zhang, H.; Jiang, Q.C. Role and mechanism of innovative addition process of trace nano-TiCp in microstructure manipulation and significant mechanical properties enhancement of H13 steels. J. Mater. Process. Technol. 2023, 311, 117819. [Google Scholar] [CrossRef]

- Berrais, A.; Boudebane, A.; Labaiz, M.; Montagne, A.; Lemboub, S.; Touhami, M.Z.; Ourdjini, A. Analysis of wear of a nitrided AISI H13 hot work tool steel in an aluminum hot extrusion process. Wear 2023, 514–515, 204587. [Google Scholar] [CrossRef]

- Wang, Y.J.; Jia, Z.; Ji, J.J.; Wei, B.L.; Heng, Y.B.; Liu, D.X. Determining the wear behavior of H13 steel die during the extrusion process of pure nickel. Eng. Fail. Anal. 2022, 134, 106053. [Google Scholar] [CrossRef]

- Ding, H.G.; Cheng, X.N.; Liu, T.; Cao, F.Y.; Chen, L.L.; Luo, R.; Zhang, Y.X.; Zhang, B.S. Microstructure and high-temperature tensile behavior of spray-formed modified 2000MPa H13 hot work die steel with 0.5wt % carbon. Mater. Sci. Eng. A 2022, 842, 143102. [Google Scholar] [CrossRef]

- Zou, J.X.; Wu, A.M.; Dong, C.; Hao, S.Z.; Liu, Z.M.; Ma, H.T. Oxidation protection of AISI H13 steel by high current pulsed electron beam treatment. Surf. Coat. Technol. 2004, 183, 261–267. [Google Scholar] [CrossRef]

- Neto, N.D.C.; Brune, R.; Luo, A.A.; Brancaleon, P.; Korenyi-both, A.L.; Midson, S.P.; Kaufman, M.J. Towards lube-free aluminum high pressure die casting using duplex AlCrN physical vapor deposition coatings. J. Mater. Res. Technol. 2023, 24, 7409–7426. [Google Scholar] [CrossRef]

- Shakib, S.E.; Babakhani, A.; Torbati, M.K. Nanomechanical assessment of tribological behavior of TiN/TiCN multi-layer hard coatings deposited by physical vapor deposition. J. Mater. Res. Technol. 2023, 25, 1344–1354. [Google Scholar] [CrossRef]

- Farid, M.A.; Amir, A.Z.; Maryam, A.Z.; Narguess, N.; Ramin, A. Plasma-enhanced chemical vapor deposition of TiB2 and TiBN hard coatings using BBr3. Tribol. Int. 2023, 179, 108137. [Google Scholar]

- Arulvel, S.; Winfred, R.D.D.; Akshat, J.; Jayakrishna, K.; Mridul, S. Laser processing techniques for surface property enhancement: Focus on material advancement. Surf. Interfaces 2023, 42, 103293. [Google Scholar]

- Li, Y.F.; Zhang, J.; Huang, X.H.; Liu, J.; Deng, L.J.; Han, P.Y. Influence of laser power on microstructure evolution and properties of laser cladded FeNiCoCrMo HEA coatings. Mater. Today Commun. 2023, 35, 105615. [Google Scholar] [CrossRef]

- Cai, Y.C.; Chen, Y.; Manladan, S.M.; Zhen, L.; Gao, F.; Li, L. Influence of dilution rate on the microstructure and properties of FeCrCoNi high-entropy alloy coating. Mater. Des. 2018, 142, 124–137. [Google Scholar] [CrossRef]

- Cao, S.L.; Liang, J.; Zhou, J.S.; Wang, L.G. Microstructure evolution and wear resistance of in-situ nanoparticles reinforcing Fe-based amorphous composite coatings. Surf. Interfaces 2020, 21, 100652. [Google Scholar] [CrossRef]

- Pang, X.M.; Jiang, J.X.; Zhao, D.Y.; Zhou, J.X. Study of wide temperature range and hard protective La2O3 doped cermet based single-layer solar selective absorbing coating by laser cladding. Surf. Interfaces 2021, 27, 101544. [Google Scholar] [CrossRef]

- Xue, K.N.; Lu, H.F.; Luo, K.Y.; Cui, C.Y.; Yao, J.H.; Xing, F.; Lu, J.Z. Effects of Ni25 transitional layer on microstructural evolution and wear property of laser clad composite coating on H13 tool steel. Surf. Coat. Technol. 2020, 402, 126488. [Google Scholar] [CrossRef]

- Lu, H.F.; Xue, K.N.; Xu, X.; Luo, K.Y.; Xing, F.; Yao, J.H.; Lu, J.Z. Effects of laser shock peening on microstructural evolution and wear property of laser hybrid remanufactured Ni25/Fe104 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 291, 117016. [Google Scholar] [CrossRef]

- Lu, J.Z.; Xue, K.N.; Lu, H.F.; Xing, F.; Luo, K.Y. Laser shock wave-induced wear property improvement and formation mechanism of laser cladding Ni25 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 296, 117202. [Google Scholar] [CrossRef]

- Rajeev, G.P.; Kamaraj, M.; Srinivasa, R.B. Hardfacing of AISI H13 tool steel with Stellite 21 alloy using cold metal transfer welding process. Surf. Coat. Technol. 2017, 326, 63–71. [Google Scholar]

- Debapriya, P.K.; Gopinath, M.; Ashish, K.N. Effect of scan strategy and heat input on the shear strength of laser cladded Stellite 21 layers on AISI H13 tool steel in as-deposited and heat treated conditions. Surf. Coat. Technol. 2020, 384, 125331. [Google Scholar]

- Wang, G.S.; Fan, G.H.; Geng, L.; Hu, W.; Huang, Y.D. Microstructure evolution and mechanical properties of TiB2/Cu composites processed by equal channel angular pressing at elevated temperature. Mater. Sci. Eng. A 2013, 571, 144–149. [Google Scholar] [CrossRef]

- Tran, V.N.; Yang, S.; Phung, T.A. Microstructure and properties of Cu/TiB2 wear resistance composite coating on H13 steel prepared by in-situ laser cladding. Opt. Laser Technol. 2018, 108, 480–486. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Zheng, K.Y.; Yu, X.H.; Wang, L.J.; Yao, S.Y.; Qi, Q. Effect of particles size of TiC on oxidation resistance of in-situ TiC/Ni composite. Heliyon 2023, 9, 18220. [Google Scholar] [CrossRef]

- Wang, G.Y.; Zhang, J.Z.; Shu, R.Y.; Yang, S. High temperature wear resistance and thermal fatigue behavior of Stellite-6/WC coatings produced by laser cladding with Co-coated WC powder. Int. J. Refract. Met. Hard Mater. 2019, 81, 63–70. [Google Scholar] [CrossRef]

- Shu, F.Y.; Zhang, B.L.; Liu, T.; Sui, S.H.; Liu, Y.X.; He, P.; Liu, B.; Xu, B.S. Effects of laser power on microstructure and properties of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coatings. Surf. Coat. Technol. 2019, 358, 667–675. [Google Scholar] [CrossRef]

- Li, Z.T.; Jing, C.N.; Feng, Y.; Wu, Z.L.; Lin, T.; Zhao, J.R. Microstructure evolution and properties of laser cladding Nb containing eutectic high entropy alloys. Int. J. Refract. Met. Hard Mater. 2023, 110, 105992. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Guo, Z.H.; Li, Z.Y.; He, R.; Wang, G.P. Effect of laser energy densities on the phase composition change in laser-cladded AlCoCrNbMo high-entropy alloy coatings. Mater. Today Commun. 2023, 37, 107152. [Google Scholar] [CrossRef]

- Takebayashi, S.; Kunieda, T.; Yoshinaga, N.; Ushioda, K.; Ogata, S. Comparison of the Dislocation Density in Martensitic Steels Evaluated by Some X-ray Diffraction Methods. ISIJ Int. 2010, 50, 875–882. [Google Scholar] [CrossRef]

- Liu, X.T.; Lei, W.B.; Ma, L.J.; Liu, J.; Liu, J.L.; Cui, J.Z. On the microstructures, phase assemblages and properties of Al0.5CoCrCuFeNiSix high-entropy alloys. J. Alloys Compd. 2015, 630, 151. [Google Scholar] [CrossRef]

- Zhu, J.M.; Fu, H.M.; Zhang, H.F.; Wang, A.M.; Li, H.; Hu, Z.Q. Synthesis and properties of multiprincipal component AlCoCrFeNiSix alloys. Mater. Sci. Eng. A. 2010, 527, 7210–7214. [Google Scholar] [CrossRef]

- Tan, X.D.; Xu, Y.B.; Yang, X.L.; Wu, D. Microstructure properties relationship in a one-step quenched and partitioned steel. Mater. Sci. Eng. 2014, 589, 101–111. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Microstructural characterization of AISI431 martensitic stainless steel laser-deposited coatings. J. Mater. Sci. 2011, 46, 3405–3414. [Google Scholar] [CrossRef]

- Sun, W.Q.; Zhang, D.Q.; Chen, X.; Zhang, J.Q.; Jia, Y.J. Effect of the scanning speed of laser cladding on microstructure and mechanical properties of WC/Ni composite coatings. J. Mech. Sci. Technol. 2022, 36, 679–687. [Google Scholar] [CrossRef]

- Gao, Y.L.; Jiang, S.; Bai, S.C.; Jie, M.; Zhang, D.D.; Liu, Y. Microstructure and Mechanical Properties of FeCoCrNiAl + WC Composite Coating Formed by Laser Cladding on H13. Coatings 2024, 14, 1259. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | V | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.32–0.45 | 0.80–1.20 | 0.20–0.50 | 4.75–5.50 | 1.10–1.75 | 0.80–1.20 | ≤0.03 | ≤0.03 | Bal. |

| High-Entropy Alloy | Fe | Co | Cr | Ni | Al |

|---|---|---|---|---|---|

| wt.% | 22.12 | 23.34 | 20.60 | 23.25 | 10.69 |

| Laser Power | Scanning Speed | Overlap Rate | Spot Diameter | Shielding Gas | Shielding Gas Flow |

|---|---|---|---|---|---|

| 1200 W | 240 mm/min | 30% | 3 mm | argon | 5 L/h |

| Phases | a (Å) | ε | ξ | b (Å) | ρ (cm−2) |

|---|---|---|---|---|---|

| Fe–Cr | 2.910 | 1.118 × 10−2 | 0.648 | 2.518 | 9.534 × 1015 |

| Fe–Ni | 3.630 | 2.562 × 10−3 | 0.533 | 3.144 | 4.146 × 1015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Bai, S.; Kou, G.; Jiang, S.; Liu, Y.; Zhang, D. Microstructure Characteristics and Elevated-Temperature Wear Mechanism of FeCoCrNiAl High-Entropy Alloy Prepared by Laser Cladding. Processes 2024, 12, 2228. https://doi.org/10.3390/pr12102228

Gao Y, Bai S, Kou G, Jiang S, Liu Y, Zhang D. Microstructure Characteristics and Elevated-Temperature Wear Mechanism of FeCoCrNiAl High-Entropy Alloy Prepared by Laser Cladding. Processes. 2024; 12(10):2228. https://doi.org/10.3390/pr12102228

Chicago/Turabian StyleGao, Yali, Sicheng Bai, Guangpeng Kou, Shan Jiang, Yu Liu, and Dongdong Zhang. 2024. "Microstructure Characteristics and Elevated-Temperature Wear Mechanism of FeCoCrNiAl High-Entropy Alloy Prepared by Laser Cladding" Processes 12, no. 10: 2228. https://doi.org/10.3390/pr12102228

APA StyleGao, Y., Bai, S., Kou, G., Jiang, S., Liu, Y., & Zhang, D. (2024). Microstructure Characteristics and Elevated-Temperature Wear Mechanism of FeCoCrNiAl High-Entropy Alloy Prepared by Laser Cladding. Processes, 12(10), 2228. https://doi.org/10.3390/pr12102228