Judgment Basis and Mechanical Analysis of Current Collector Failure in the Winding Process of a Lithium-Ion Battery

Abstract

:1. Introduction

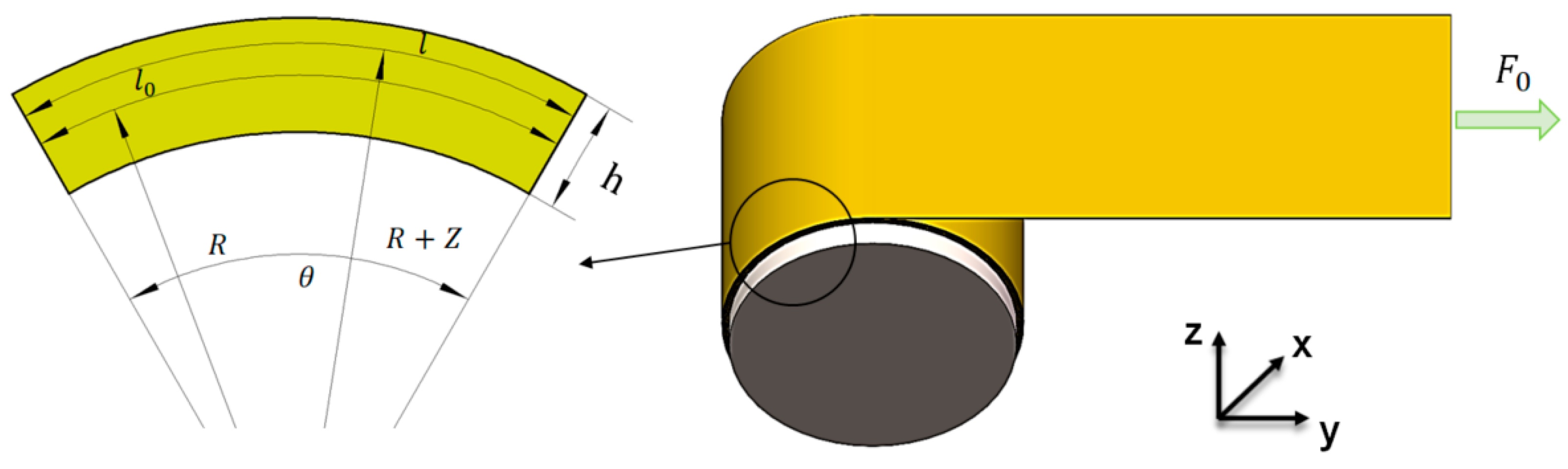

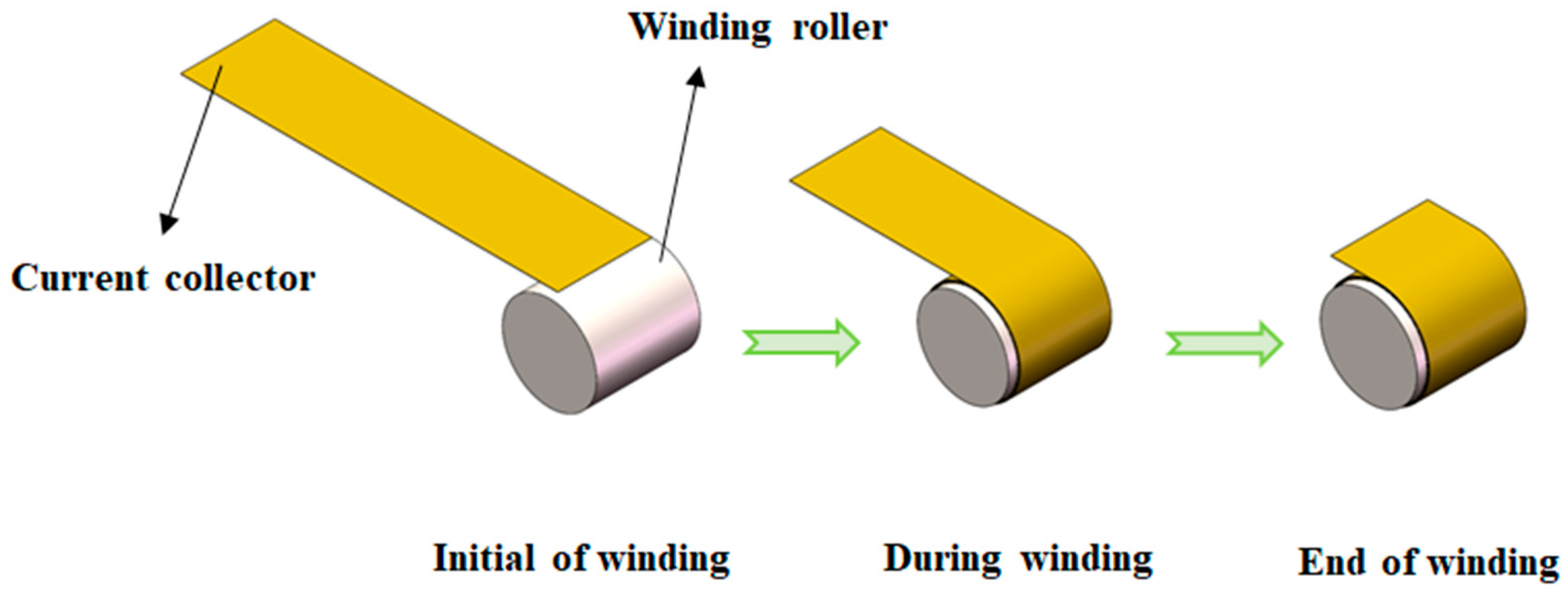

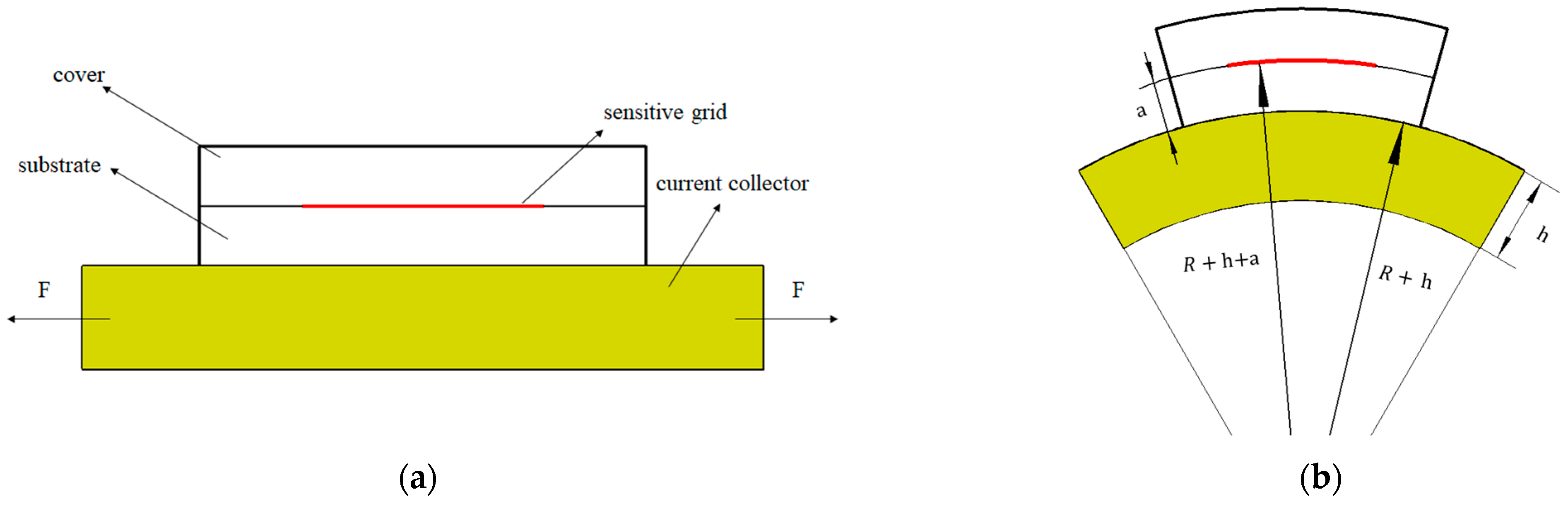

2. The Criterion for Determining Current Collector Fracture Failure

3. Finite Element Analysis

4. Experimental Testing Method

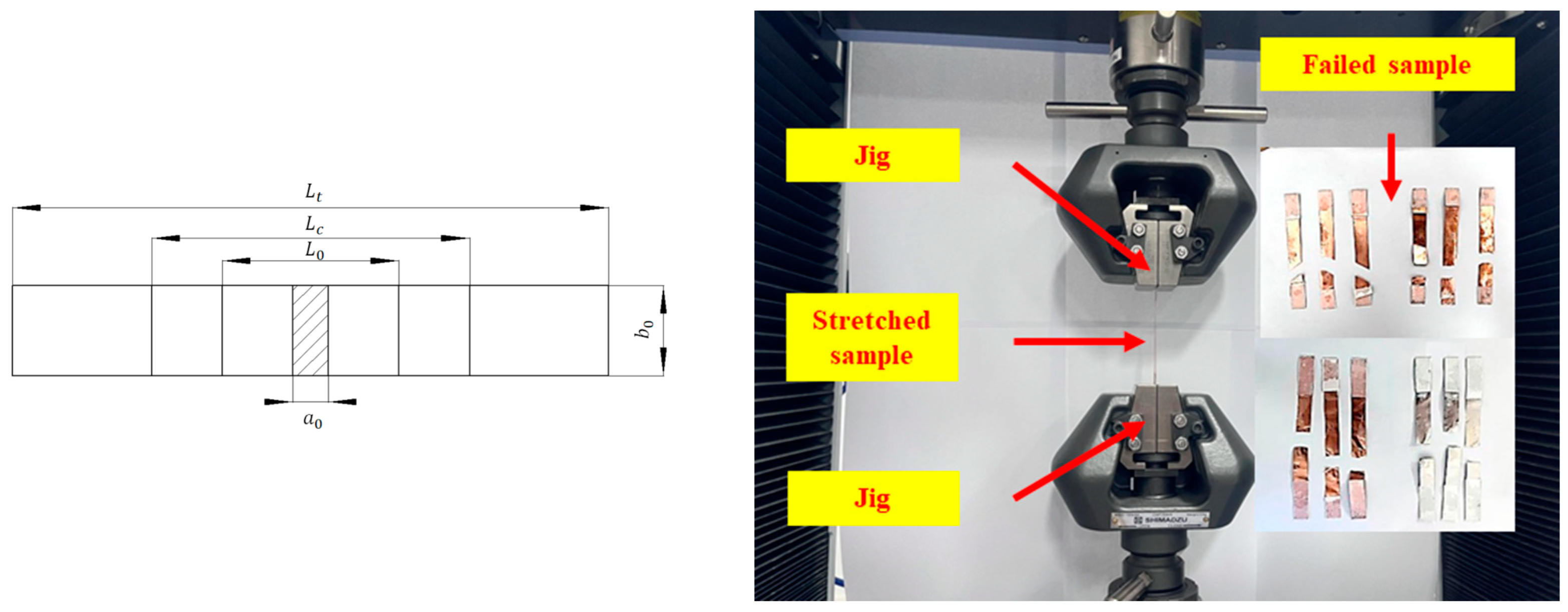

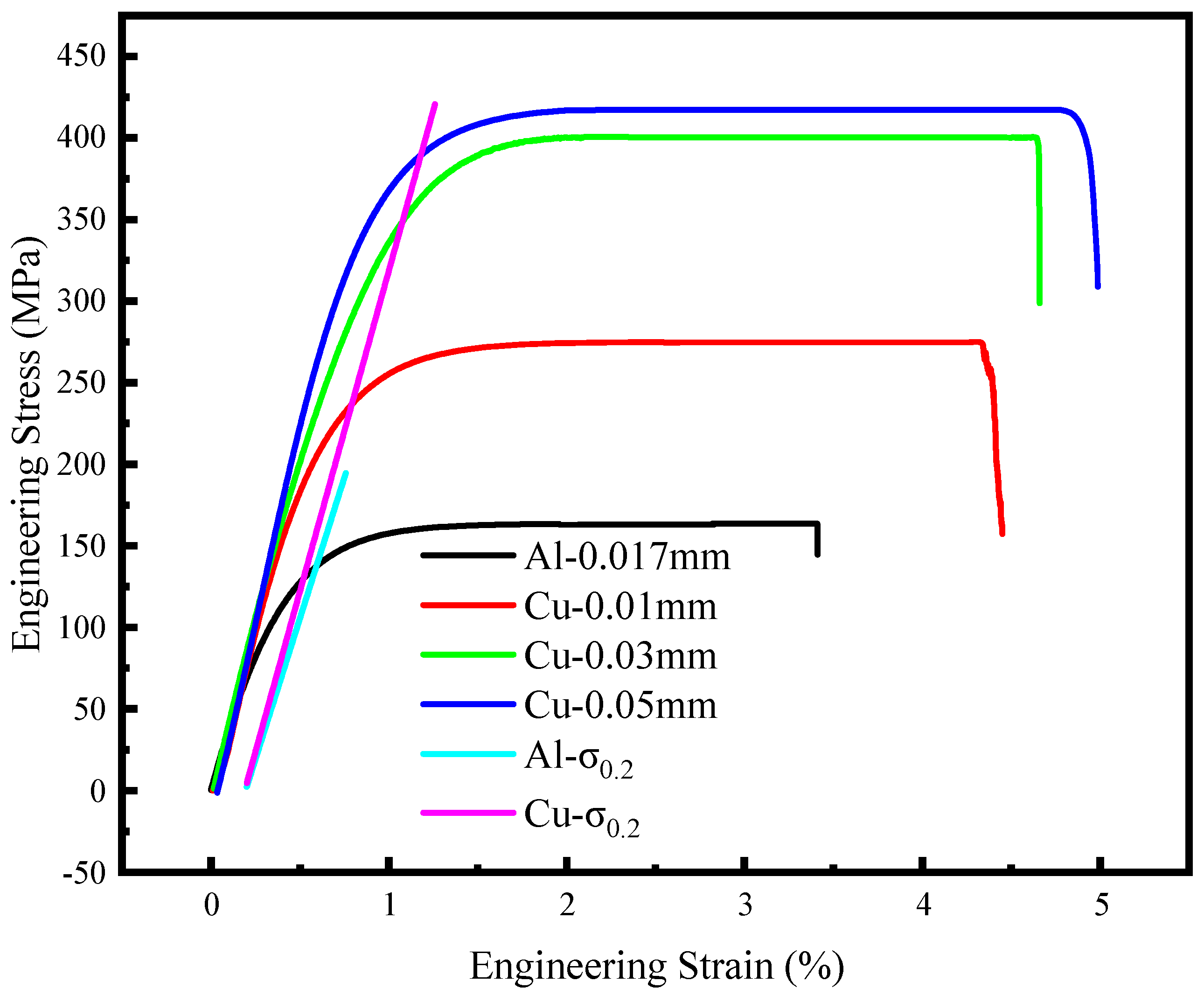

4.1. Tensile Testing of Lithium-Ion Battery Current Collectors

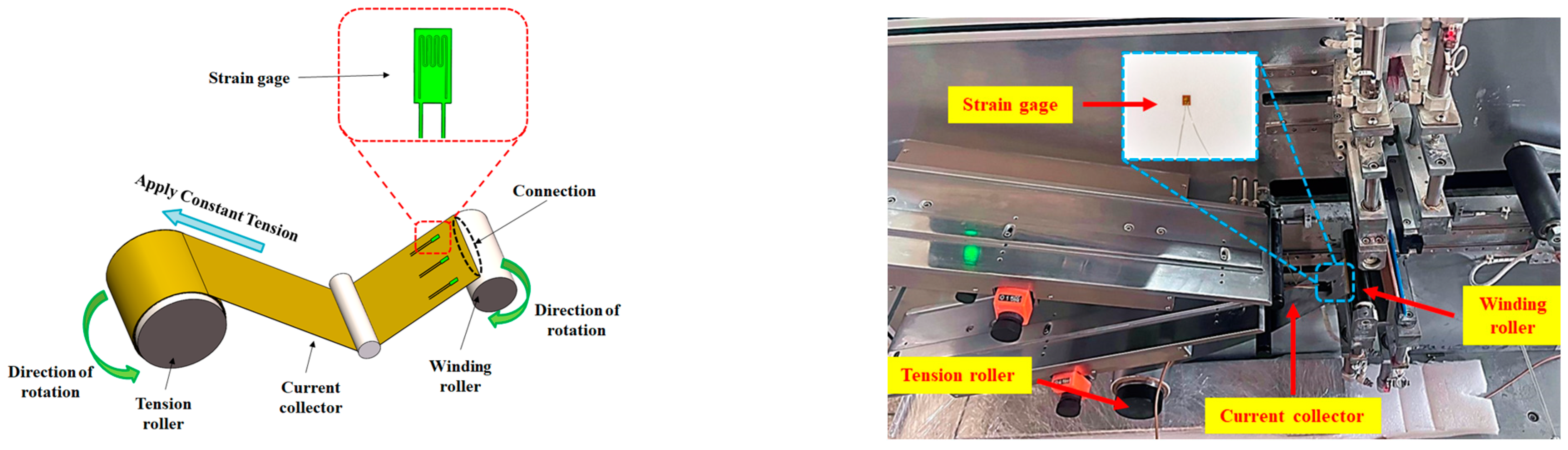

4.2. Winding Stress Testing of Lithium-Ion Battery Current Collectors

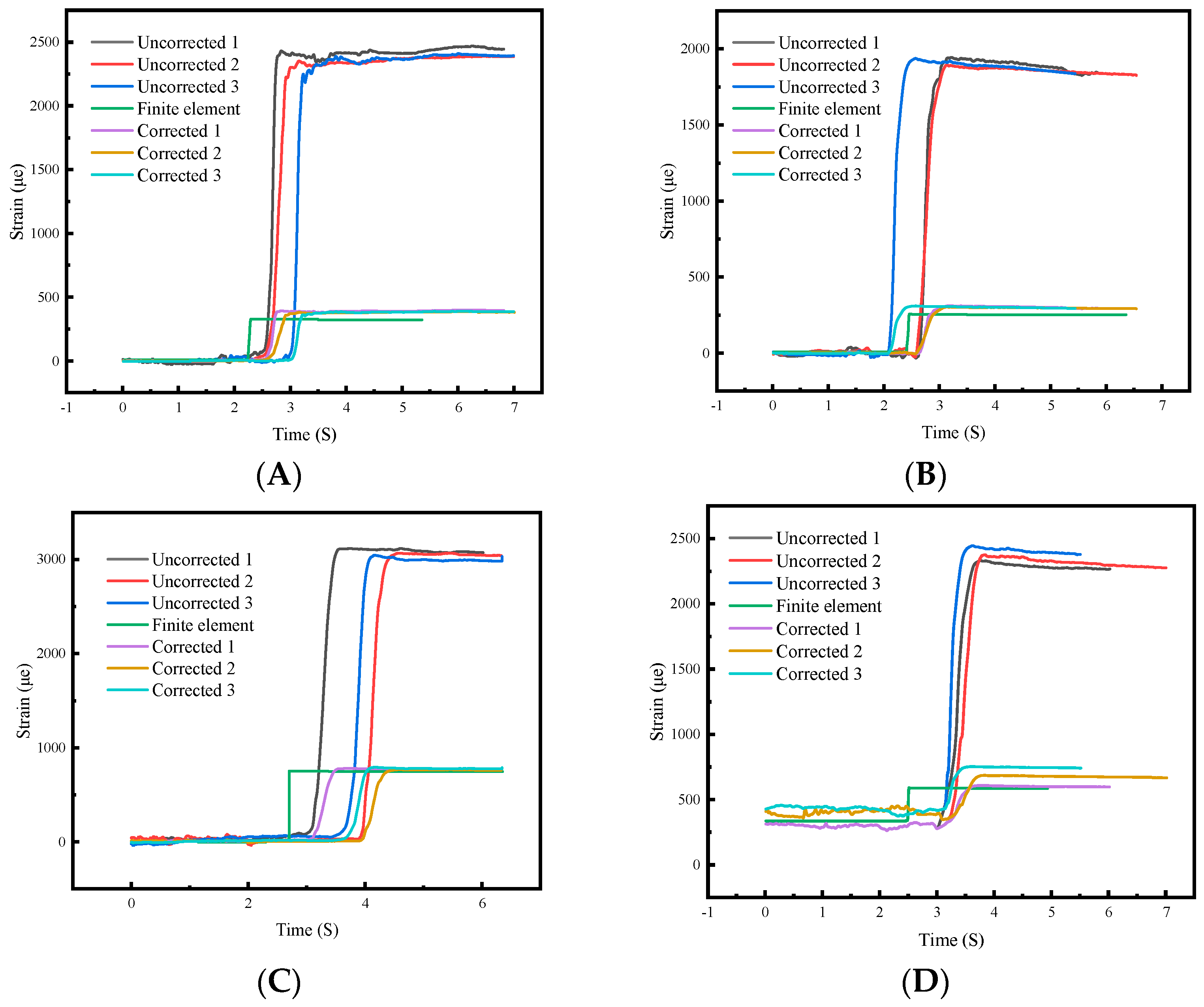

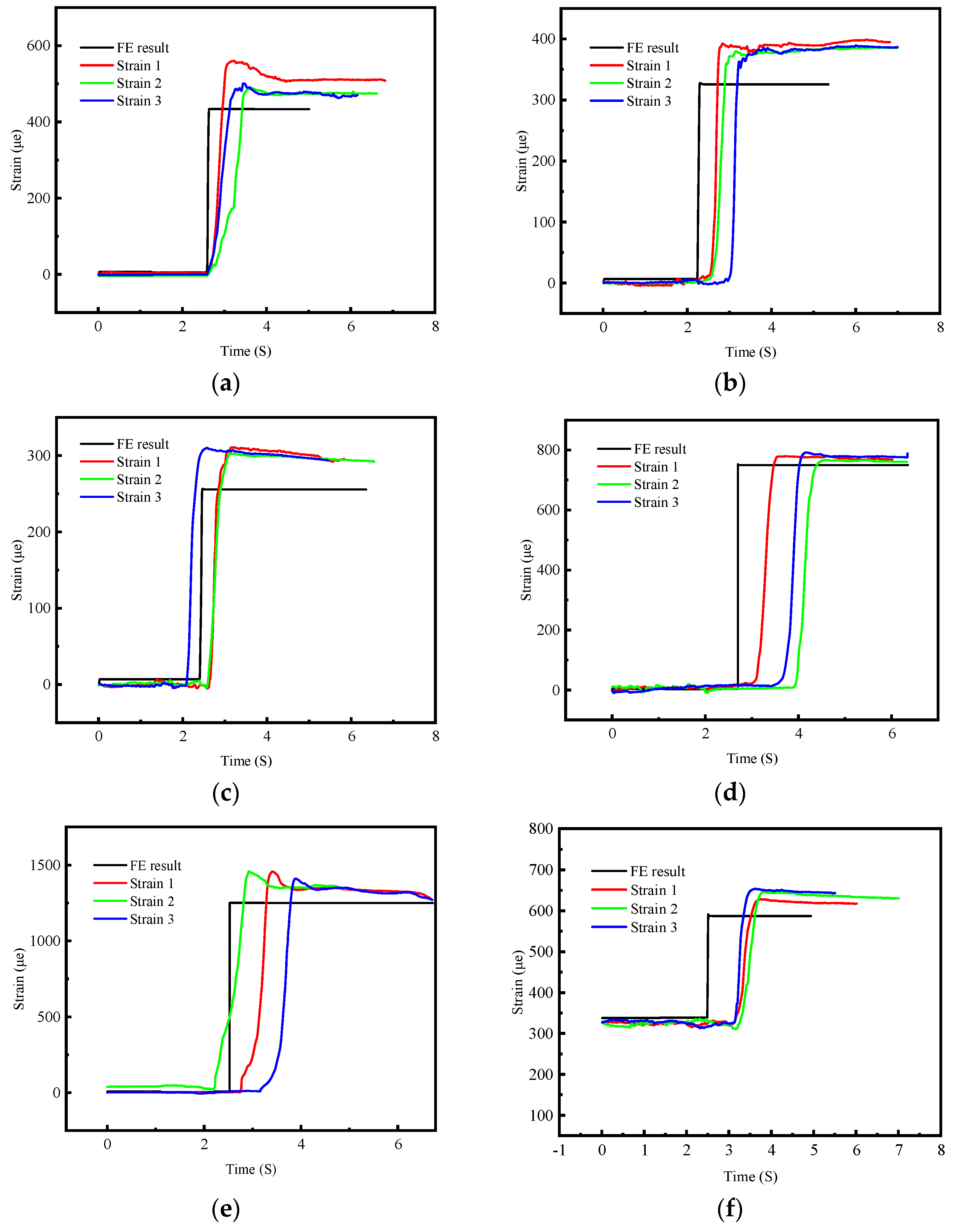

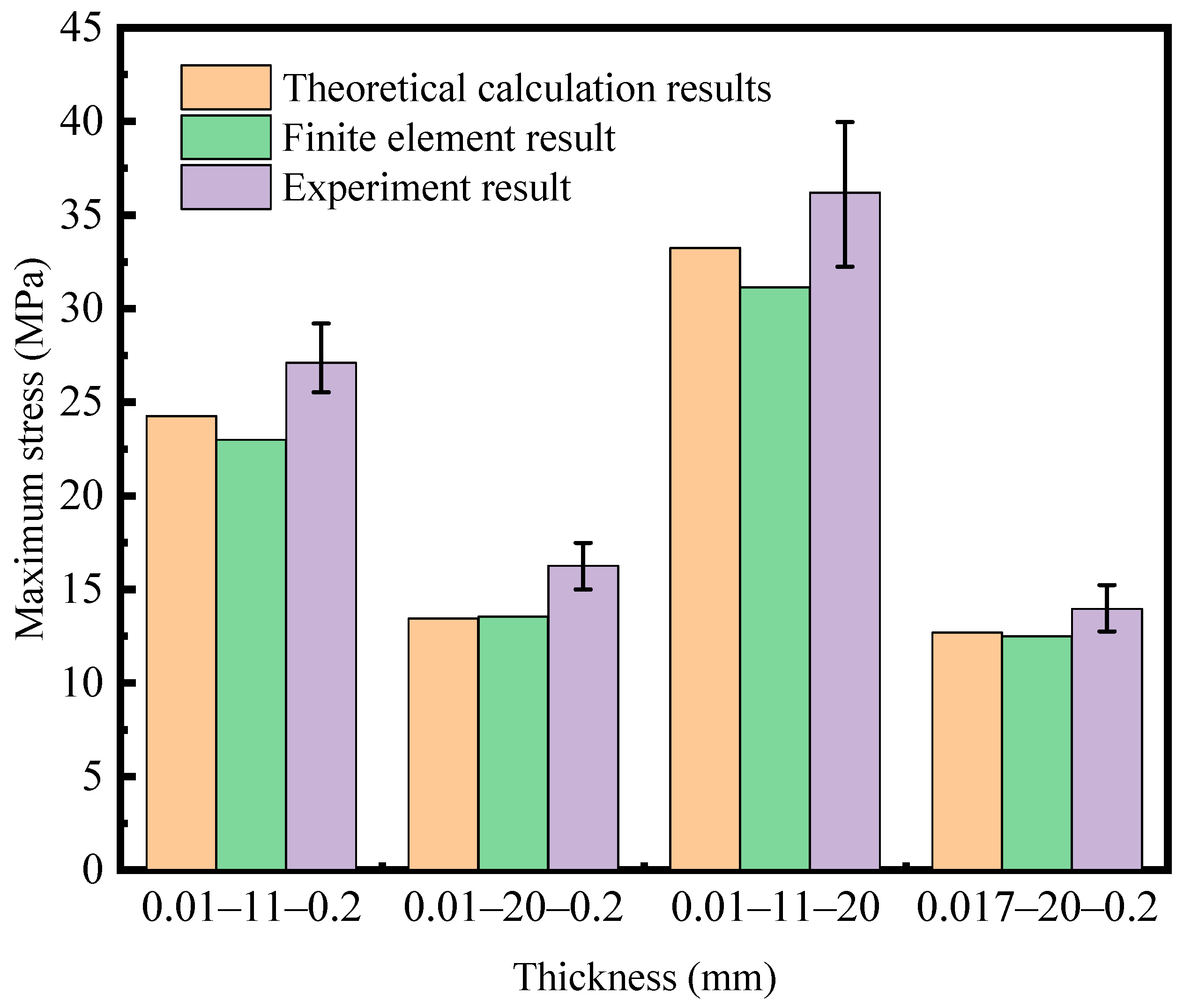

5. Analysis and Discussion

5.1. Analysis and Discussion of Tensile Experiment

5.2. Analysis and Discussion of the Winding Experiment

6. Conclusions

- (1)

- Conducting tensile experiments on commonly used thicknesses of current collectors to obtain their mechanical properties, providing valuable references for practical production.

- (2)

- Revealing the strain mutation mechanism during the winding process of the current collector through finite element analysis and stress–strain testing, quantitatively characterizing the relationship between the stress of the current collector and parameters such as initial tensile stress, winding curvature radius, and current collector thickness.

- (3)

- Establishing criteria for determining the failure of the current collector, providing theoretical foundations for the winding process of lithium batteries.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wei, M.; Ye, M.; Li, J.B.; Wang, Q.; Xu, X.X. State of charge estimation for lithium-ion batteries using dynamic neural network based on sine cosine algorithm. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 241–252. [Google Scholar] [CrossRef]

- Manthiram, A. A reflection on lithium-ion battery cathode chemistry. Nat. Commun. 2020, 11, 9. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Xiong, L.Q.; Li, P.X.; Fu, H.Y.; Hou, Z.C.; Zhu, L.; Li, W.Z. Self-supported CuO nanoflake arrays on nanoporous Cu substrate as high-performance negative-electrodes for lithium-ion batteries. J. Power Sources 2019, 428, 20–26. [Google Scholar] [CrossRef]

- Choi, J.W.; Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 2016, 1, 16013. [Google Scholar] [CrossRef]

- Shao, J.; Lin, C.; Yan, T.; Qi, C.; Hu, Y. Safety Characteristics of Lithium-Ion Batteries under Dynamic Impact Conditions. Energies 2022, 15, 9148. [Google Scholar] [CrossRef]

- Song, X.; Liu, G.; Yue, H.; Luo, L.; Yang, S.; Huang, Y.; Wang, C. A novel low-cobalt long-life LiNi0.88Co0.06Mn0.03Al0.03O2 cathode material for lithium ion batteries. Chem. Eng. J. 2021, 407, 126301. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, D.; Feng, X.; Wang, L.; Ouyang, M. Thermal runaway modeling of large format high-nickel/silicon-graphite lithium-ion batteries based on reaction sequence and kinetics. Appl. Energy 2022, 306, 117943. [Google Scholar] [CrossRef]

- Zhai, P.; Liu, K.; Wang, Z.; Shi, L.; Yuan, S. Multifunctional separators for high-performance lithium ion batteries. J. Power Sources 2021, 499, 229973. [Google Scholar] [CrossRef]

- Chen, C.J.; Zhang, Y.; Li, Y.J.; Kuang, Y.D.; Song, J.W.; Luo, W.; Wang, Y.B.; Yao, Y.G.; Pastel, G.; Xie, J.; et al. Highly Conductive, Lightweight, Low-Tortuosity Carbon Frameworks as Ultrathick 3D Current Collectors. Adv. Energy Mater. 2017, 7, 1700595. [Google Scholar] [CrossRef]

- Chen, M.Y.; Liu, J.H.; Ouyang, D.X.; Wang, J. Experimental investigation on the effect of ambient pressure on thermal runaway and fire behaviors of lithium-ion batteries. Int. J. Energy Res. 2019, 43, 4898–4911. [Google Scholar] [CrossRef]

- Wang, W.W.; Yang, S.; Lin, C.; Shen, W.X.; Lu, G.X.; Li, Y.D.; Zhang, J.J. Investigation of mechanical property of cylindrical lithium-ion batteries under dynamic loadings. J. Power Sources 2020, 451, 227749. [Google Scholar] [CrossRef]

- Zhu, S.; Yang, L.; Fan, J.; Wen, J.; Feng, X.; Zhou, P.; Xie, F.; Zhou, J.; Wang, Y.-N. In-situ obtained internal strain and pressure of the cylindrical Li-ion battery cell with silicon-graphite negative electrodes. J. Energy Storage 2021, 42, 103049. [Google Scholar] [CrossRef]

- Wang, L.; Yin, S.; Xu, J. A detailed computational model for cylindrical lithium-ion batteries under mechanical loading: From cell deformation to short-circuit onset. J. Power Sources 2018, 413, 284–292. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Wang, X.; Hu, D. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies. Appl. Energy 2016, 172, 180–189. [Google Scholar] [CrossRef]

- Keshavarzi, M.M.; Gilaki, M.; Sahraei, E. Characterization of in-situ material properties of pouch lithium-ion batteries in tension from three-point bending tests. Int. J. Mech. Sci. 2022, 219, 107090. [Google Scholar] [CrossRef]

- Christoph, B.; Wolfgang, S.; Florian, F.; Gregor, G.; Bernhard, L.; Christoph, K.; Christian, E.; Joerg, M.; Hermann, S.; Michael, S. A ‘Microscopic’ Structural Mechanics FE Model of a Lithium-Ion Pouch Cell for Quasi-Static Load Cases. Sae Int. J. Passeng. Cars Mech. Syst. 2013, 6, 1044–1054. [Google Scholar]

- Lai, W.J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery cells under compressive loading conditions. J. Power Sources 2014, 245, 609–623. [Google Scholar] [CrossRef]

- Ali, M.Y.; Lai, W.-J.; Pan, J. Computational models for simulations of lithium-ion battery cells under constrained compression tests. J. Power Sources 2013, 242, 325–340. [Google Scholar] [CrossRef]

- Chen, Y.; Sang, M.; Jiang, W.; Wang, Y.; Zou, Y.; Lu, C.; Ma, Z. Fracture predictions based on a coupled chemo-mechanical model with strain gradient plasticity theory for film electrodes of Li-ion batteries. Eng. Fract. Mech. 2021, 253, 107866. [Google Scholar]

- de Vasconcelos, L.S.; Sharma, N.; Xu, R.; Zhao, K. In-Situ Nanoindentation Measurement of Local Mechanical Behavior of a Li-Ion Battery Cathode in Liquid Electrolyte. Exp. Mech. 2019, 59, 337–347. [Google Scholar] [CrossRef]

- Nakanishi, S.; Suzuki, T.; Cui, Q.; Akikusa, J.; Nakamura, K. Effect of surface treatment for aluminum foils on discharge properties of lithium-ion battery. Trans. Nonferrous Met. Soc. China 2014, 24, 2314–2319. [Google Scholar]

- van Bommel, A.; Divigalpitiya, R. Effect of Calendering LiFePO4 Electrodes. J. Electrochem. Soc. 2012, 159, A1791–A1795. [Google Scholar]

- Zhou, S.; Liu, G.; Ding, N.; Shang, L.; Dang, R.; Zhang, J. Improved performances of lithium-ion batteries by graphite-like carbon modified current collectors. Surf. Coat. Technol. 2020, 399, 126150. [Google Scholar]

- Tao, R.; Liang, Z.; Zhu, S.; Yang, L.; Ma, L.; Song, W.-L.; Chen, H. Mechanical Analysis and Strength Checking of Current Collector Failure in the Winding Process of Lithium-Ion Batteries. Acta Mech. Solida Sin. 2021, 34, 297–306. [Google Scholar]

- Asnafi, N. Springback and fracture in v-die air bending of thick stainless steel sheets. Mater. Des. 2000, 21, 217–236. [Google Scholar]

| Materia | Thickness (mm) | Elastic Modulus (GPa) |

|---|---|---|

| Cu | 0.01 | 53 |

| 0.03 | 55 | |

| 0.05 | 56 | |

| Al | 0.017 | 29 |

| Materia | Thickness (mm) | Roller Diameter (mm) | Initial Tensile Stresses (MPa) |

|---|---|---|---|

| CU | 0.01 | 11 | 0.2 |

| 0.01 | 15 | 0.2 | |

| 0.01 | 20 | 0.2 | |

| 0.01 | 20 | 20 | |

| 0.03 | 20 | 0.2 | |

| 0.05 | 20 | 0.2 | |

| Al | 0.017 | 20 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhao, C.; Du, X.; Zhao, J.; Hu, Y. Judgment Basis and Mechanical Analysis of Current Collector Failure in the Winding Process of a Lithium-Ion Battery. Processes 2023, 11, 2629. https://doi.org/10.3390/pr11092629

Zhang Y, Zhao C, Du X, Zhao J, Hu Y. Judgment Basis and Mechanical Analysis of Current Collector Failure in the Winding Process of a Lithium-Ion Battery. Processes. 2023; 11(9):2629. https://doi.org/10.3390/pr11092629

Chicago/Turabian StyleZhang, Yuxin, Chunhui Zhao, Xiaozhong Du, Jianjun Zhao, and Yijian Hu. 2023. "Judgment Basis and Mechanical Analysis of Current Collector Failure in the Winding Process of a Lithium-Ion Battery" Processes 11, no. 9: 2629. https://doi.org/10.3390/pr11092629

APA StyleZhang, Y., Zhao, C., Du, X., Zhao, J., & Hu, Y. (2023). Judgment Basis and Mechanical Analysis of Current Collector Failure in the Winding Process of a Lithium-Ion Battery. Processes, 11(9), 2629. https://doi.org/10.3390/pr11092629