Innovative Method for Determining Young’s Modulus of Elasticity in Products with Irregular Shapes: Application on Peanuts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Design and Statistical Analysis Using RSM

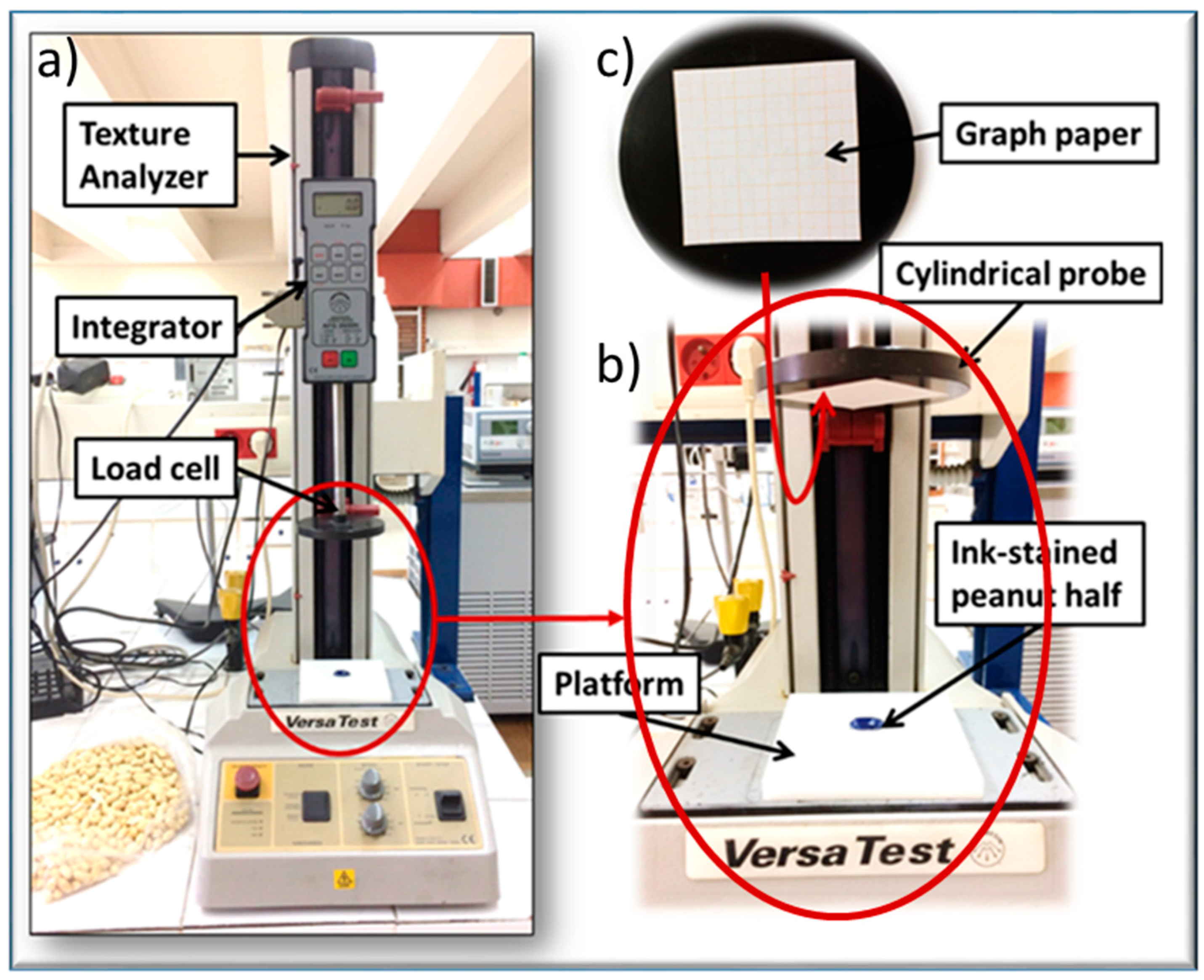

2.3. Compression Test

3. Results and Discussion

3.1. Contact Surface Determined by the Blueprint

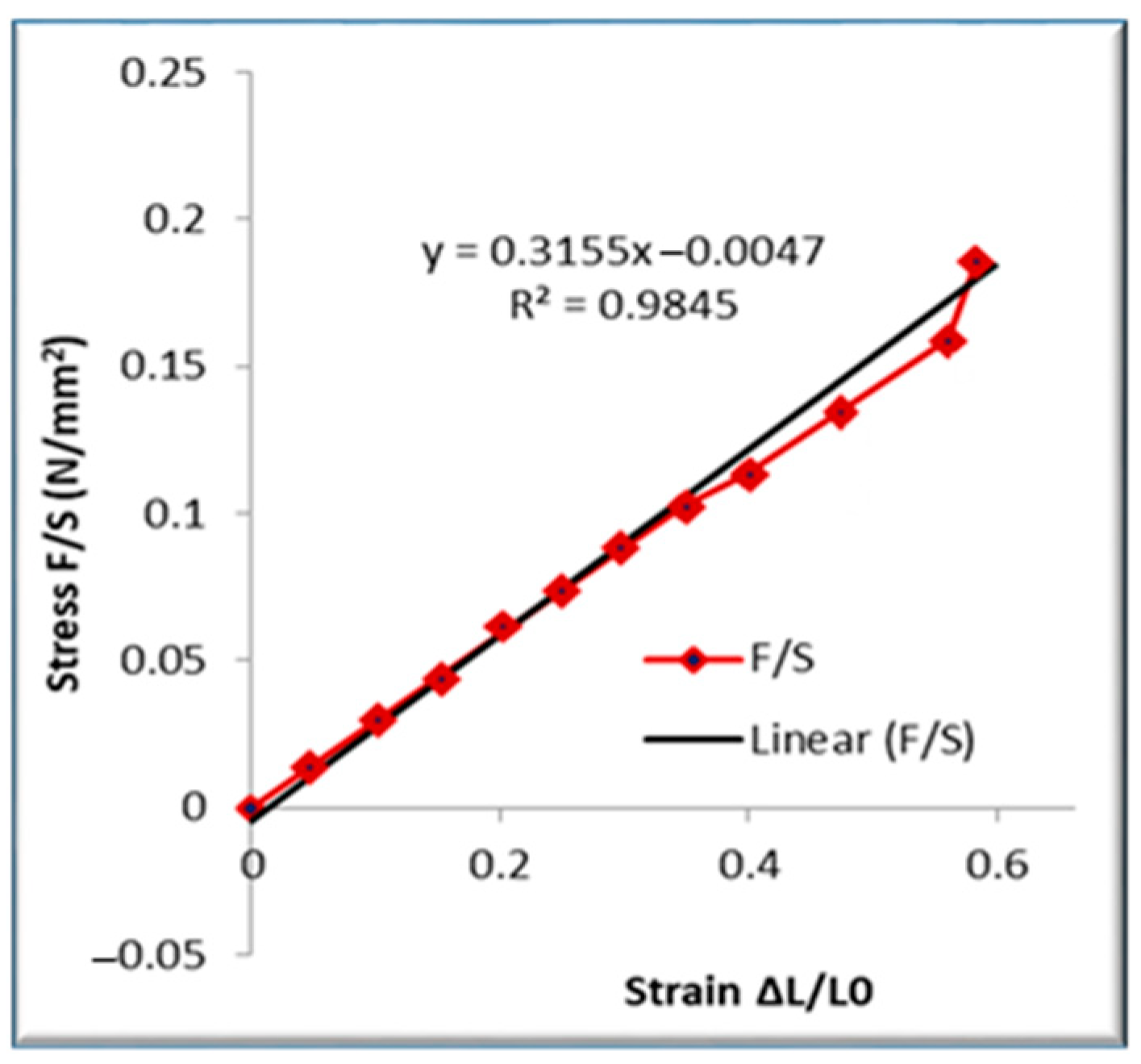

3.2. Stress–Strain Curves and Results of Young’s Modulus of Elasticity

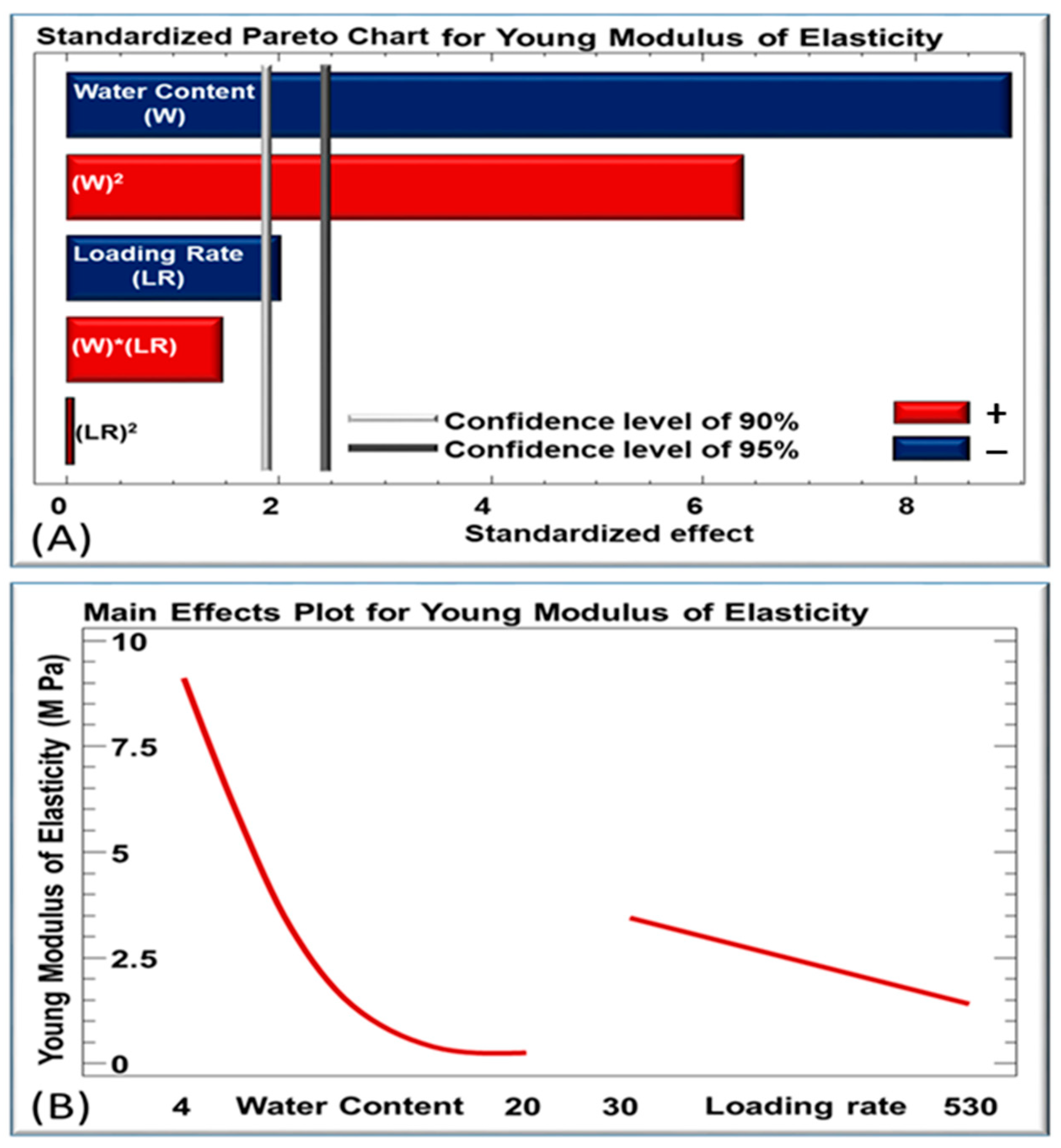

3.3. Significance of the Operating Parameters

3.4. Model Fitting and Regression Equation

3.5. Analysis of Variance for Young’s Modulus of Elasticity

3.6. Main Effects of the Operating Parameters

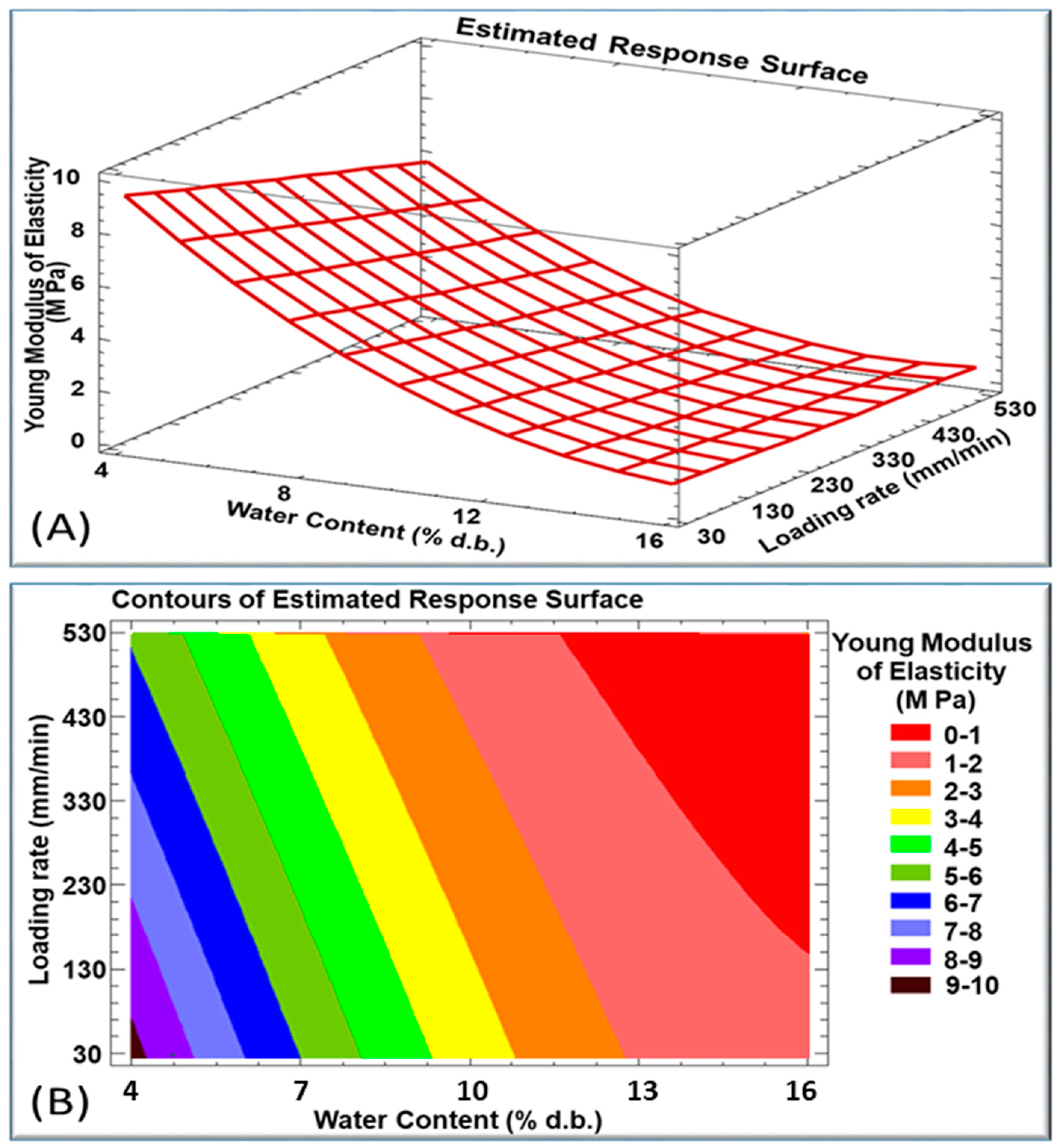

3.7. Estimated Response Surface, Iso–Response Curves and Optimization of Young’s Modulus of Elasticity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, Y.T.; Qie, Y.H.; Dai, S. A New Calculation Method of In-Plane Elastic Properties Analytical Model for Novel Nested Honeycomb with Negative Poisson’s Ratio and Enhanced Young’s Modulus. Eur. J. Mech. A/Solids 2023, 97, 104847. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Yu, Q.; Petzold, A.; Thurn-Albrecht, T.; Glüge, R.; Altenbach, H.; Androsch, R. Young’s Modulus of the Different Crystalline Phases of Poly (L-Lactic Acid). J. Mech. Behav. Biomed. Mater. 2023, 137, 105546. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.W.W.; Teulon, J.M.; Kaur, H.; Godon, C.; Pellequer, J.L. Nano-Structural Stiffness Measure for Soft Biomaterials of Heterogeneous Elasticity. Nanoscale Horiz. 2022, 8, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Shahverdiloo, M.R.; Zare, S. Experimental Study of Normalized Confining Pressure Effect on Young’s Modulus in Different Rock Types. Arab. J. Geosci. 2023, 16, 55. [Google Scholar] [CrossRef]

- Duroy, A.L.; Basset, O.; Brusseau, E. Virtual Fields Based-Method for Reconstructing the Elastic Modulus in Quasi-Static Ultrasound Elastography. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022. [Google Scholar] [CrossRef]

- Bartolozzi, G.; Pierini, M.; Orrenius, U.; Baldanzini, N. An Equivalent Material Formulation for Sinusoidal Corrugated Cores of Structural Sandwich Panels. Compos. Struct. 2013, 100, 173–185. [Google Scholar] [CrossRef]

- Changnv Zeng, H.G.; Wang, Y. Stress-Strain Response of Sheared Wheat Granular Stored in Silos Using Triaxial Compression Tests. Int. Agrophysics 2020, 1, 103–114. [Google Scholar] [CrossRef]

- Shaban, M.; Alibeigloo, A. Gobal Bending Analysis of Corrugated Sandwich Panels with Integrated Piezoelectric Layers. J. Sandw. Struct. Mater. 2018, 22, 1055–1073. [Google Scholar] [CrossRef]

- Bahrami-Novin, N.; Shaban, M.; Mazaheri, H. Flexural Response of Fiber-Metal Laminate Face-Sheet/Corrugated Core Sandwich Beams. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 183. [Google Scholar] [CrossRef]

- Khodabakhshian, R.; Emadi, B. Determination of the Modulus of Elasticity in Agricultural Seeds on the Basis of Elasticity Theory. Middle-East J. Sci. Res. 2011, 7, 367–373. [Google Scholar]

- Kiani, M.; Maghsoudi, H.; Minaei, S. Determination of Poisson’s Ratio and Young’s Modulus of Red Bean Grains. J. Food Process Eng. 2009, 10, 1745–1756. [Google Scholar] [CrossRef]

- Thompson, S.A.; Ross, I.J. Thermal Stresses in Steel Grain Bins Using the Tangent Modulus of Grain. Trans. Am. Soc. Agric. Eng. 1984, 27, 165–168. [Google Scholar] [CrossRef]

- Moya, M.; Ayuga, F.; Guaita, M.; Aguado, P. Mechanical Properties of Granular Agricultural Materials. Trans. ASAE 2002, 45, 1569–1577. [Google Scholar] [CrossRef]

- Kang, Y.S.; Spillman, C.K.; Steele, J.L.; Chung, D.S. Mechanical Properties of Wheat. Trans. ASAE 1995, 38, 573–578. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Abelenda, N.; Vázquez, M.J. Rheological Behaviour of Chestnuts under Compression Test. Int. J. Food Sci. Technol. 2007, 42, 1188–1194. [Google Scholar] [CrossRef]

- Saiedirad, M.H.; Tabatabaeefar, A.; Borghei, A.; Mirsalehi, M.; Badii, F.; Ghasemi-Varnamkhasti, M. Effects of Moisture Content, Seed Size, Loading Rate and Seed Orientation on Force and Energy Required for Fracturing Cumin Seed (Cuminum Cyminum Linn.) under Quasi-Static Loading. J. Food Eng. 2008, 86, 565–572. [Google Scholar] [CrossRef]

- Bamgboye, A.I.; Adejumo, O.I. Mechanical Properties of Roselle (Hibiscus sabdariffa L.) Seeds. Agric. Sci. Res. J. 2011, 1, 178–183. [Google Scholar]

- Balastreire, L.A.; Herum, F.L.; Stevens, K.K.; Blaisdell, J.L. Fracture of Corn Endosperm in Bending: Part 1. Fract. Parameters. Trans. ASAE 1982, 25, 1057–1062. [Google Scholar] [CrossRef]

- Khazaei, J. Determination of Force Required to Pea Pod Harvesting and Mechanical Resistance to Impact. Ph.D. Thesis, Faculty of Biosystem Engineering, University of Tehran, Karaj, Iran, 2002. [Google Scholar]

- Rong, L.; Wang, C.H.; Bathgate, R.G. Fracture Analysis of Cracked Macadamia Nutshells under Contact Load between Two Rigid Plates. J. Agric. Eng 1999, 74, 243–250. [Google Scholar]

- Ojijo, N.K.O.; Kimura, T.; Shimizu, N.; Koaze, H. Viscoelastic Components of Hard-to-Cook Defect in Soybean Cotyledons Subjected to Accelerated Storage. J. Jpn. 2000, 30, 61–72. [Google Scholar]

- Mohsenin, N.N.; Cooper, H.E.; Tukey, L.D. Engineering Approach to Evaluating Textural Factors in Fruits and Vegetables. Trans. ASAE 1963, 6, 85–88. [Google Scholar] [CrossRef]

- Finney, E.E.; Hall, C.W. Elastic Properties of Potatoes. Trans. ASAE 1967, 10, 4–8. [Google Scholar] [CrossRef]

- Shirvani, M.; Ghanbarian, D.; Ghasemi-Varnamkhasti, M. Measurement and Evaluation of the Apparent Modulus of Elasticity of Apple Based on Hookee’s, Hertz’s and Boussinesq’s Theories. Measurement 2014, 54, 133–139. [Google Scholar] [CrossRef]

- Arnold, P.C.; Roberts, A.W. Stress Distributions in Loaded Wheat Grains. J. Agric. Eng. Res. 1966, 11, 38–43. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Gordon and Breach Science Publishers: New York, NY, USA, 1986. [Google Scholar]

- Dinrifo, R.R.; Faborode, M.O. Application of Hertz’s Theory of Contact Stresses to Cocoa Pod Deformation. J. Agric. Eng. Technol. 1993, 1, 63–73. [Google Scholar]

- Burubai, W.A.; Davies, E.; Etekpe, R.M.G.; Daworiye, S.P. Determ. Poisson. ratio elastic Modul. African nutmeg (Monodora myristica). Int. Agrophysics 2008, 22, 99–102. [Google Scholar]

- Timbers, G.E.; Staley, L.M.; Watson, E.L. Determining Modulus Elasticity in Agricultural Products by Loaded Plungers. Agric. Eng. 1965, 46, 274–275. [Google Scholar]

- Emadi, B. Experimental Comparison of Applying Different Theories in Elasticity for Determination of the Elasticity Modulus of Agricultural Produce, Pumpkin Seed as a Case Study. Int. J. Agric. Technol. 2011, 7, 1495–1508. [Google Scholar]

- Arnold, P.C.; Roberts, A.W. Fundamental Aspects of Load-Deformation Behavior of Wheat Grains. Trans. ASAE 1969, 18, 104–108. [Google Scholar]

- Bargale, P.C.; Irudayaraj, J.; Marquis, B. Studies on Rheological Behaviour of Canola and Wheat. J. Agric. Eng. Res. 1995, 61, 267–274. [Google Scholar] [CrossRef]

- Shitanda, D.; Nishiyama, Y.; Koide, S. Compressive Strength Properties of Rough Rice Considering Variation of Contact Area. J. Food Eng. 2002, 53, 53–58. [Google Scholar] [CrossRef]

- Haidar, E.; Lakkis, J.; Karam, M.; Koubaa, M.; Louka, N.; Debs, E. Peanut Allergenicity: An Insight into Its Mitigation Using Thermomechanical Processing. Foods 2023, 12, 1253. [Google Scholar] [CrossRef] [PubMed]

- Nader, J.; Afif, C.; Louka, N. Impact of a Novel Partial Defatting Technology on Oxidative Stability and Sensory Properties of Peanut Kernels. Food Chem. 2021, 334, 127581. [Google Scholar] [CrossRef] [PubMed]

- Nader, J.; Afif, C.; Louka, N. Expansion of Partially Defatted Peanuts by a New Texturizing Process Called “Intensification of Vaporization by Decompression to the Vacuum” (IVDV). Innov. Food Sci. Emerg. Technol. 2017, 41, 179–187. [Google Scholar] [CrossRef]

- Mrad, R.; El Rammouz, R.; Maroun, R.G.; Louka, N. Effect of Intensification of Vaporization by Decompression to the Vacuum as a Pretreatment for Roasting Australian Chickpea: Multiple Optimization by Response Surface Methodology of Chemical, Textural and Color Parameters. J. Food Qual. 2015, 38, 139–152. [Google Scholar] [CrossRef]

- Nader, J.; Fawaz, N.; Afif, C.; Louka, N. A Novel Process for Preparing Low-Fat Peanuts: Optimization of the Oil Extraction Yield with Limited Structural and Organoleptic Damage. Food Chem. 2016, 197, 1215–1225. [Google Scholar] [CrossRef]

- Nader, J.; Louka, N. Development of a Novel Technology Entitled “Intensification of Vaporization by Decompression to the Vacuum” (IVDV) for Reconstitution and Texturing of Partially Defatted Peanuts. Innov. Food Sci. Emerg. Technol. 2018, 45, 455–466. [Google Scholar] [CrossRef]

- El-Sayed, A.S.; Yahaya, R.; Wacker, P.; Kutzbach, H.D. Characteristic Attributes of the Peanut (Arachis hypogaea L.) for Its Separation. Int. Agrophys 2001, 15, 225–230. [Google Scholar]

- Khodabakhshian, R.; Fard, M.H.A. Some Engineering Properties of Sunflower Seed and Its Kernel. J. Agric. Sci. Technol. 2010, 4, 37–46. [Google Scholar]

- Özarslan, C. Physical Properties of Sweet Corn Seed (Zea mays saccharata Sturt.). J. Food Eng. 2006, 74, 523–528. [Google Scholar]

- Gorji, A.; Rajabipour, A.; Tavakoli, H. Fracture Resistance of Wheat Grain as a Function of Moisture Content, Loading Rate and Grain Orientation. Aust. J. Crop Sci. 2010, 4, 448–452. [Google Scholar]

- Triveni, R.; Shamala, T.R.; Rastogi, N.K. Optimized Production and Utilization of Exopolysaccharide from Agrobacterium Radiobacter. Process Biochem. 2001, 36, 787–795. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Y.; Thornton, C. A Comparison of Discrete Element Simulations and Experiments for “sandpiles” Composed of Spherical Particles. Powder Technol. 2005, 160, 219–228. [Google Scholar] [CrossRef]

- Yi, S.; Bingjian, D.; Ting, Z.; Bing, H.; Fei, Y.; Rui, Y.; Xiaosong, H.; Yuanying, N.; Quanhong, L. Optimization of Extraction Process by Response Surface Methodology and Preliminary Structural Analysis of Polysaccharides from Defatted Peanut (Arachis hypogaea) Cakes. Carbohydr. Res. 2011, 346, 305–310. [Google Scholar]

- Tiezheng, M.; Qiang, W.; Haiwen, W. Optimization of Extraction Conditions for Improving Solubility of Peanut Protein Concentrates by Response Surface Methodology. LWT Food Sci. 2010, 43, 1450–1455. [Google Scholar]

- Pericin, D.; Radulovic, L.; Trivic, S.; Dimic, E. Evaluation of Solubility of Pumpkin Seed Globulins by Response Surface Method. J. Food Eng. 2008, 84, 591–594. [Google Scholar] [CrossRef]

- Burubai, W.; Akor, A.J.; Igoni, A.H.; Puyate, Y.T. Effects of Temperature and Moisture Content on the Strength Properties of African Nutmeg (Monodora myristica). Int. Agrophysics 2007, 21, 217–223. [Google Scholar]

- Herak, D.; Gurdil, G.; Sedlacek, A.; Dajbych, O.; Simanjuntak, S. Energy Demands for Pressing Jatropha curcas L. Seeds. Biosyst. Eng. 2010, 106, 527–534. [Google Scholar] [CrossRef]

- Carman, K. Some Physical Properties of Lentil Seeds. J. Agric. Eng. 1996, 63, 87–92. [Google Scholar] [CrossRef]

- Henika, R.G. Use of the Surface Response Methodology in Sensory Evaluation. Food Technol. 1982, 36, 96–102. [Google Scholar]

- Molenda, M.; Stasiak, M. Determination of Elastic Constants of Cereal Grains in Uniaxial Compression Test. Int. Agrophys 2002, 16, 61–65. [Google Scholar]

- Stasiak, M.; Molenda, M.; Horabik, J. Determination of Modulus of Elasticity of Cereals and Rapeseeds Using Acoustic Method. J. Food Eng. 2007, 82, 51–57. [Google Scholar] [CrossRef]

- Hemery, Y.M.; Mabille, F.; Martelli, M.R.; Rouau, X. Influence of Water Content and Negative Temperatures on the Mechanical Properties of Wheat Bran and Its Constitutive Layers. J. Food Eng. 2010, 98, 360–369. [Google Scholar] [CrossRef]

- Demir, A.D.; Cronin, K. The Thermal Kinetics of Texture Change and the Analysis of Texture Variability for Raw and Roasted Hazelnuts. Int. J. Food Sci. Technol. 2004, 39, 371–383. [Google Scholar] [CrossRef]

- Holloway, O.E., Jr.; Wilkins, H. Low-Fat Nuts with Improved Natural Flavor. Am. Pat. 1982, 4, 329. [Google Scholar]

| Coded Values | −1.41421 | −1 | 0 | +1 | +1.41421 | |

|---|---|---|---|---|---|---|

| Experimental parameters | Water Content (% d.b.) | 4.7 | 7 | 12.5 | 18 | 20.3 |

| Loading rate (mm/min) | 37.9 | 100 | 250 | 400 | 462 |

| Run | Water Content (% d.b.) | Loading Rate (mm/min) | |

|---|---|---|---|

| Factorial design | 1 | 7 | 100 |

| 2 | 18 | 100 | |

| 3 | 7 | 400 | |

| 4 | 18 | 400 | |

| Star points | 5 | 4.7 | 250 |

| 6 | 20.3 | 250 | |

| 7 | 12.5 | 37.9 | |

| 8 | 12.5 | 462 | |

| 4 central points | 9 to 12 | 12.5 | 250 |

| Operating Parameters | Contact Surface (mm2) | ΔL (mm) | L0 (mm) | Force (N) | ΔL/L0 | F/K (N/mm2) | E = tg (α) | Average Modulus of Elasticity (MPa) | Standard Deviation | |

|---|---|---|---|---|---|---|---|---|---|---|

| 22 factorial design | Wc = 7%; Lr = 100 mm/min | 27 | 1.47 | 6.52 | 27.8 | 0.22 | 1.03 | 4.58 | 4.20 | ±0.38 |

| 28 | 1.38 | 5.78 | 25.4 | 0.24 | 0.91 | 3.79 | ||||

| 50.5 | 1.55 | 5.33 | 57.3 | 0.29 | 1.13 | 3.90 | ||||

| 33 | 2.28 | 7.04 | 43.8 | 0.32 | 1.33 | 4.09 | ||||

| 39.5 | 1.55 | 6.25 | 45.2 | 0.25 | 1.14 | 4.61 | ||||

| Wc = 18%; Lr = 100 mm/min | 47 | 1.93 | 6.33 | 8.9 | 0.31 | 0.19 | 0.62 | 0.61 | ±0.05 | |

| 21.25 | 1.65 | 7.9 | 3.1 | 0.21 | 0.15 | 0.70 | ||||

| 34.5 | 1.28 | 6.39 | 3.9 | 0.20 | 0.11 | 0.56 | ||||

| 49.5 | 1.83 | 6.5 | 8.6 | 0.28 | 0.17 | 0.62 | ||||

| 49 | 2.02 | 7.23 | 7.8 | 0.28 | 0.16 | 0.57 | ||||

| Wc = 7%; Lr = 400 mm/min | 34.5 | 2.93 | 6.85 | 33.1 | 0.43 | 0.96 | 2.24 | 2.18 | ±0.12 | |

| 27.5 | 2.53 | 6.02 | 25.4 | 0.42 | 0.92 | 2.19 | ||||

| 35 | 2.87 | 5.65 | 35.2 | 0.51 | 1.01 | 1.98 | ||||

| 16 | 2.53 | 5.82 | 15.7 | 0.44 | 0.98 | 2.25 | ||||

| 28.75 | 3.33 | 6.69 | 32.2 | 0.50 | 1.12 | 2.25 | ||||

| Wc = 18%; Lr = 400 mm/min | 35 | 3.33 | 5.71 | 6.5 | 0.58 | 0.19 | 0.32 | 0.30 | ±0.02 | |

| 30.25 | 2.53 | 7.31 | 3.1 | 0.35 | 0.10 | 0.30 | ||||

| 39 | 2.53 | 6.36 | 4.4 | 0.40 | 0.11 | 0.28 | ||||

| 37 | 3.67 | 6.55 | 5.9 | 0.56 | 0.16 | 0.28 | ||||

| 42.25 | 4.40 | 7.06 | 8.6 | 0.62 | 0.20 | 0.33 | ||||

| Axial points | Wc = 4.7%; Lr = 250 mm/min | 12.25 | 1.58 | 6.24 | 20.8 | 0.25 | 1.70 | 6.69 | 6.73 | ±0.37 |

| 6 | 1.83 | 6.36 | 12.2 | 0.29 | 2.03 | 7.05 | ||||

| 20.25 | 1.83 | 7.41 | 35.4 | 0.25 | 1.75 | 7.07 | ||||

| 22.25 | 1.83 | 7.02 | 35.8 | 0.26 | 1.61 | 6.16 | ||||

| 20 | 1.17 | 6.01 | 25.9 | 0.19 | 1.30 | 6.67 | ||||

| Wc = 20.3%; Lr = 250 mm/min | 30.75 | 5.96 | 6.92 | 7.4 | 0.86 | 0.24 | 0.28 | 0.29 | ±0.02 | |

| 27.5 | 2.29 | 6.64 | 2.9 | 0.35 | 0.11 | 0.31 | ||||

| 38 | 2.08 | 6.65 | 3.8 | 0.31 | 0.10 | 0.32 | ||||

| 43.5 | 2.29 | 5.61 | 5.3 | 0.41 | 0.12 | 0.30 | ||||

| 25.75 | 4.08 | 6.79 | 4.2 | 0.60 | 0.16 | 0.27 | ||||

| Wc = 12.5%; Lr = 37.9 mm/min | 33 | 0.93 | 5.65 | 5 | 0.17 | 0.15 | 0.92 | 0.96 | ±0.06 | |

| 27 | 1.04 | 6.07 | 4.8 | 0.17 | 0.18 | 1.04 | ||||

| 39 | 0.69 | 5.55 | 4.4 | 0.13 | 0.11 | 0.90 | ||||

| 26.75 | 0.93 | 6.25 | 3.7 | 0.15 | 0.14 | 0.93 | ||||

| 21 | 1.18 | 6.05 | 4.2 | 0.20 | 0.20 | 1.03 | ||||

| Wc = 12.5%; Lr = 462 mm/min | 22.5 | 14.40 | 5.73 | 15.4 | 2.51 | 0.68 | 0.27 | 0.28 | ±0.02 | |

| 54.5 | 3.77 | 5.81 | 10.8 | 0.65 | 0.20 | 0.31 | ||||

| 41 | 3.39 | 6.37 | 6.6 | 0.53 | 0.16 | 0.30 | ||||

| 38 | 2.08 | 5.22 | 4.1 | 0.40 | 0.11 | 0.27 | ||||

| 30 | 2.54 | 6.08 | 3.2 | 0.42 | 0.11 | 0.26 | ||||

| 4 repetitions at the centers of the domains | Wc = 12.5%; Lr = 250 mm/min | 26.5 | 1.83 | 7.48 | 3.3 | 0.25 | 0.12 | 0.51 | 0.47 | ±0.04 |

| 35.5 | 1.38 | 6.31 | 3.4 | 0.22 | 0.10 | 0.44 | ||||

| 52 | 2.29 | 6.23 | 8.9 | 0.37 | 0.17 | 0.47 | ||||

| 40 | 2.75 | 6.2 | 9.1 | 0.44 | 0.23 | 0.51 | ||||

| 45.5 | 1.83 | 5.59 | 6.6 | 0.33 | 0.15 | 0.44 | ||||

| 35.5 | 2.29 | 6.81 | 6.1 | 0.34 | 0.17 | 0.51 | 0.48 | ±0.04 | ||

| 41 | 1.58 | 6.42 | 4.4 | 0.25 | 0.11 | 0.44 | ||||

| 38.5 | 2.29 | 5.65 | 7.8 | 0.41 | 0.20 | 0.50 | ||||

| 31 | 2.08 | 6.02 | 5.4 | 0.35 | 0.17 | 0.50 | ||||

| 29 | 1.63 | 6.02 | 3.4 | 0.27 | 0.12 | 0.43 | ||||

| 33 | 1.58 | 5.83 | 4 | 0.27 | 0.12 | 0.45 | 0.47 | ±0.03 | ||

| 33.25 | 2.04 | 6.09 | 5.4 | 0.34 | 0.16 | 0.48 | ||||

| 48 | 2.50 | 5.28 | 11.2 | 0.47 | 0.23 | 0.49 | ||||

| 63 | 2.04 | 4.9 | 13.2 | 0.42 | 0.21 | 0.50 | ||||

| 43.5 | 2.08 | 5.23 | 7.3 | 0.40 | 0.17 | 0.42 | ||||

| 39.75 | 2.29 | 5.97 | 6.9 | 0.38 | 0.17 | 0.45 | 0.46 | ±0.03 | ||

| 41.25 | 2.04 | 6.13 | 6.7 | 0.33 | 0.16 | 0.49 | ||||

| 42.5 | 2.29 | 6.11 | 6.9 | 0.38 | 0.16 | 0.43 | ||||

| 26.5 | 1.83 | 6.64 | 3.3 | 0.28 | 0.12 | 0.45 | ||||

| 37 | 1.83 | 5.83 | 5.8 | 0.31 | 0.16 | 0.50 |

| Source | Sum of Squares | Df | p-Value |

|---|---|---|---|

| A: Water content | 26.6 | 1 | 0.0001 |

| B: Loading rate | 1.4 | 1 | 0.0908 |

| AA | 13.6 | 1 | 0.0007 |

| AB | 0.73 | 1 | 0.1897 |

| BB | 0.0013 | 1 | 0.9519 |

| R-squared = 95.52 percent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nader, J.; Assaf, J.C.; Debs, E.; Louka, N. Innovative Method for Determining Young’s Modulus of Elasticity in Products with Irregular Shapes: Application on Peanuts. Processes 2023, 11, 2532. https://doi.org/10.3390/pr11092532

Nader J, Assaf JC, Debs E, Louka N. Innovative Method for Determining Young’s Modulus of Elasticity in Products with Irregular Shapes: Application on Peanuts. Processes. 2023; 11(9):2532. https://doi.org/10.3390/pr11092532

Chicago/Turabian StyleNader, Joelle, Jean Claude Assaf, Espérance Debs, and Nicolas Louka. 2023. "Innovative Method for Determining Young’s Modulus of Elasticity in Products with Irregular Shapes: Application on Peanuts" Processes 11, no. 9: 2532. https://doi.org/10.3390/pr11092532

APA StyleNader, J., Assaf, J. C., Debs, E., & Louka, N. (2023). Innovative Method for Determining Young’s Modulus of Elasticity in Products with Irregular Shapes: Application on Peanuts. Processes, 11(9), 2532. https://doi.org/10.3390/pr11092532