An Experimental Study on the Impact of the Particle Size and Proportion of Composite Proppant on the Conductivity of Propped Fractures in Coalbed Methane Reservoirs following Pulverized Coal Fines Infiltration

Abstract

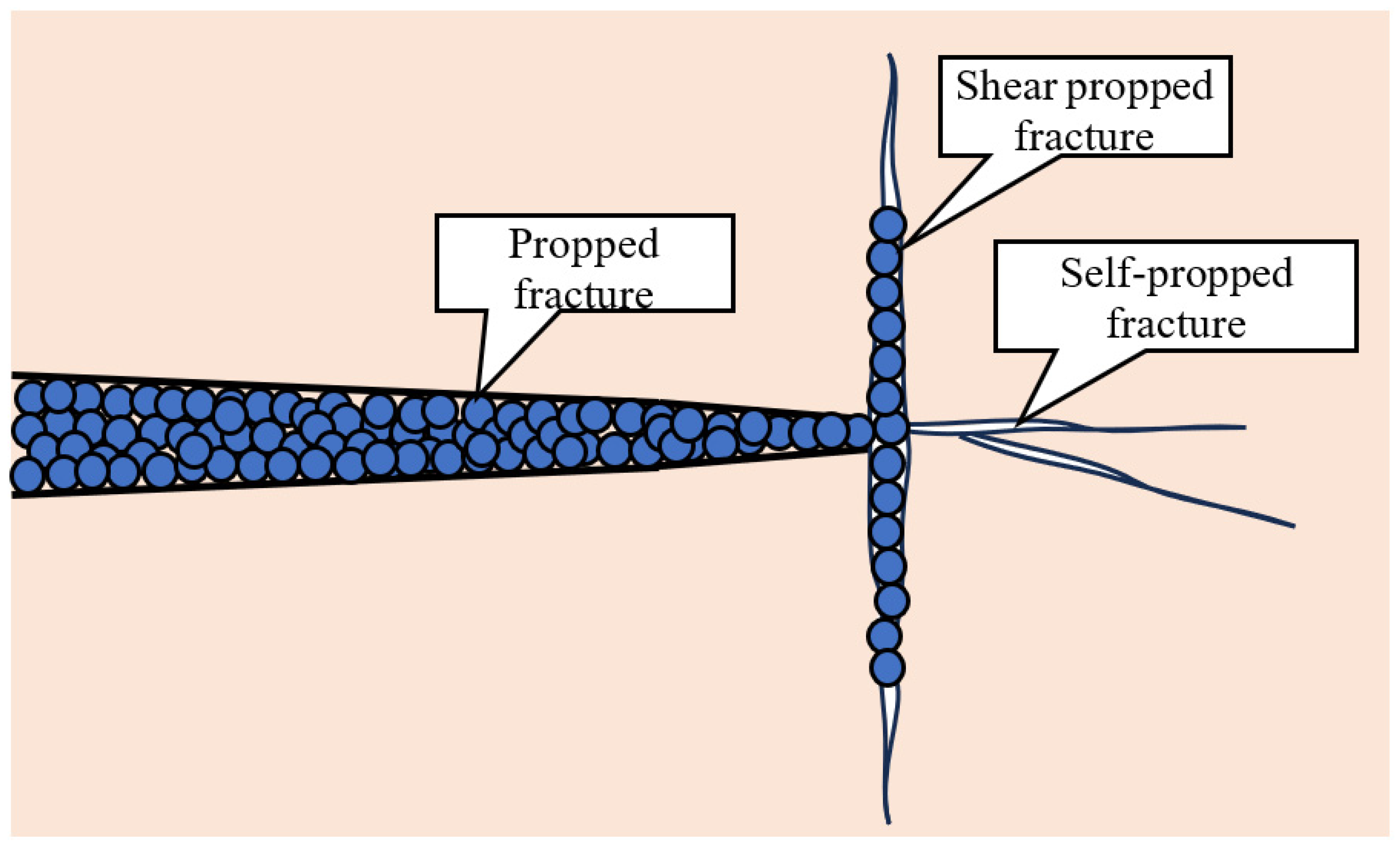

1. Introduction

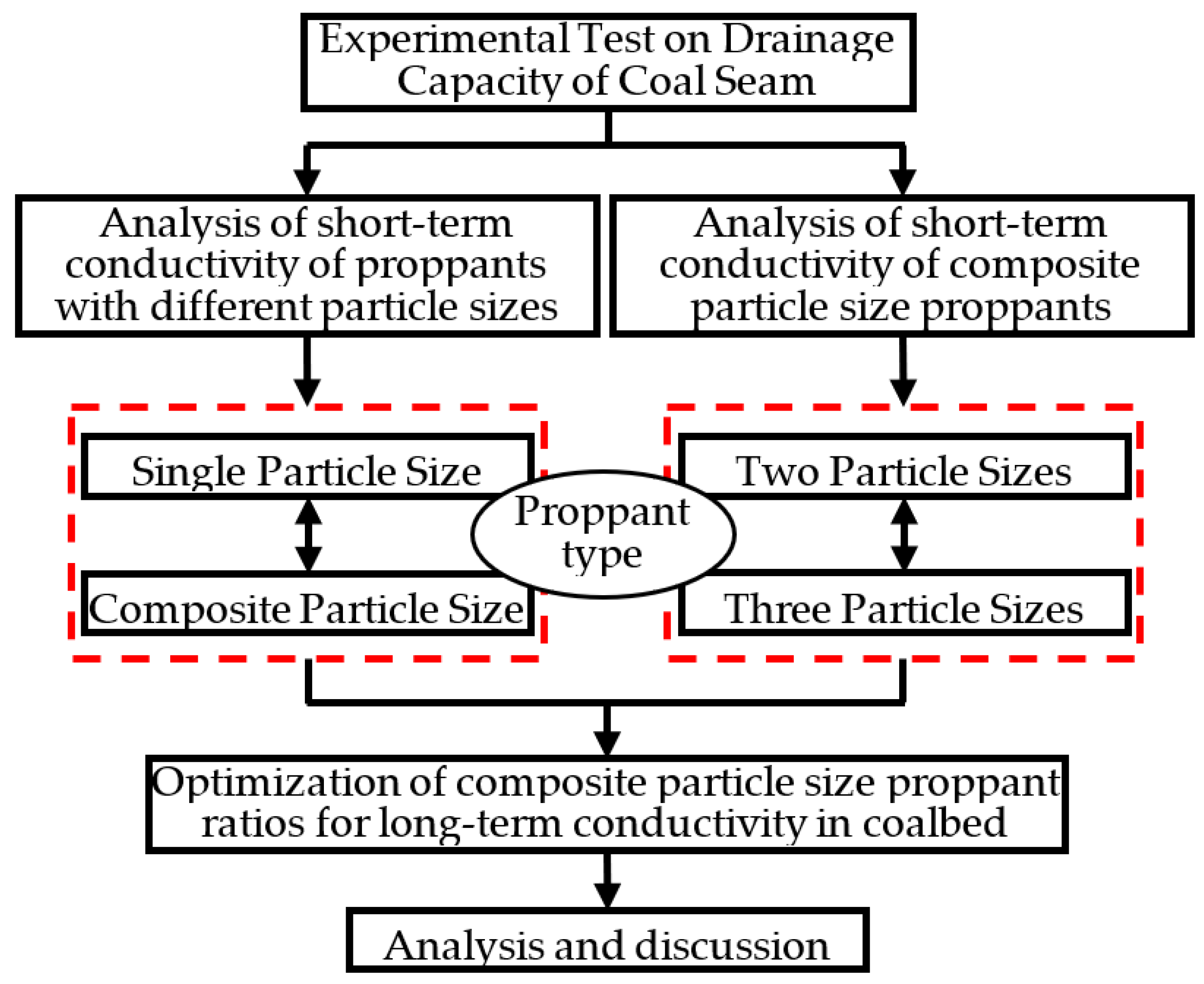

2. Experimental Study on Conductivity of Coalbed Propped Fractures

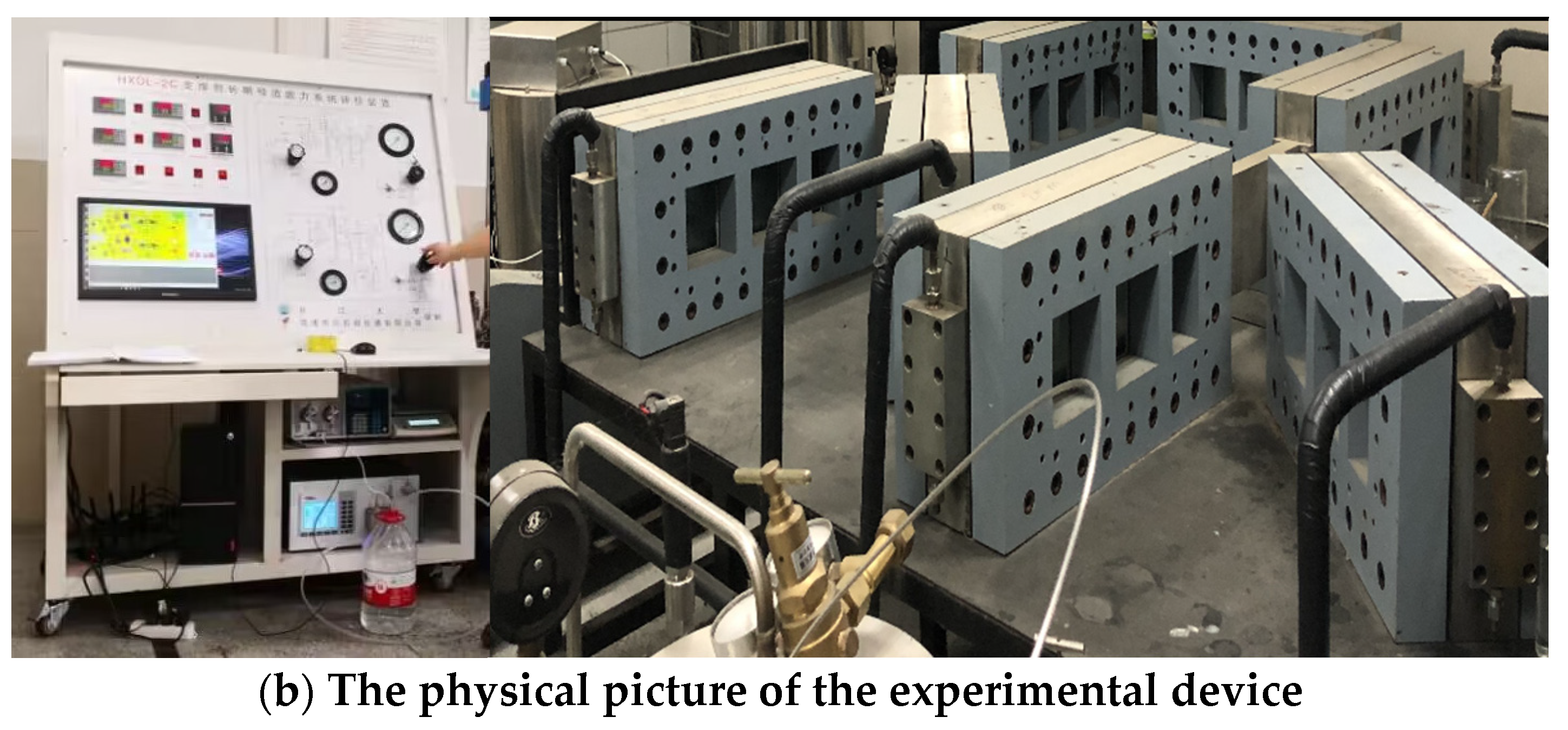

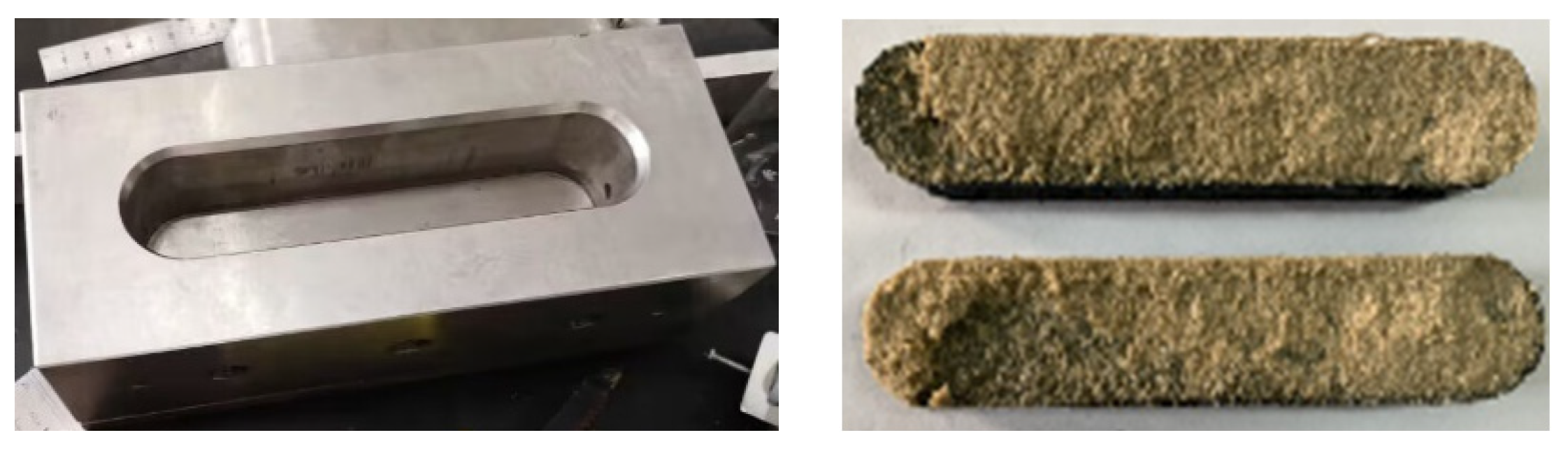

2.1. Experimental Apparatus

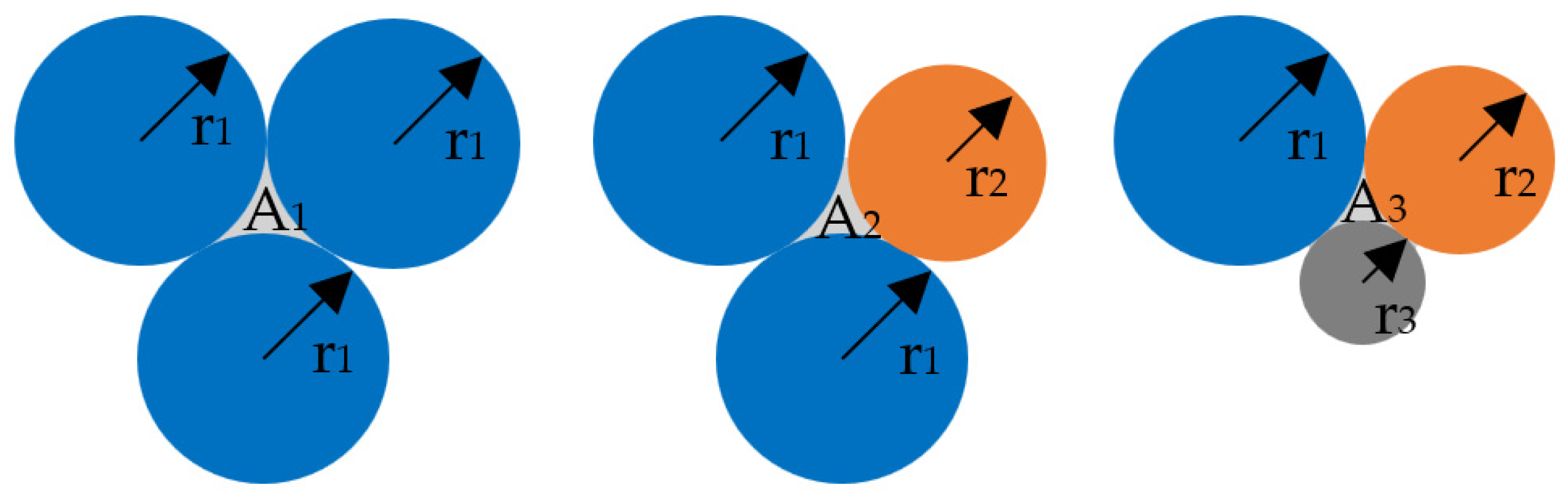

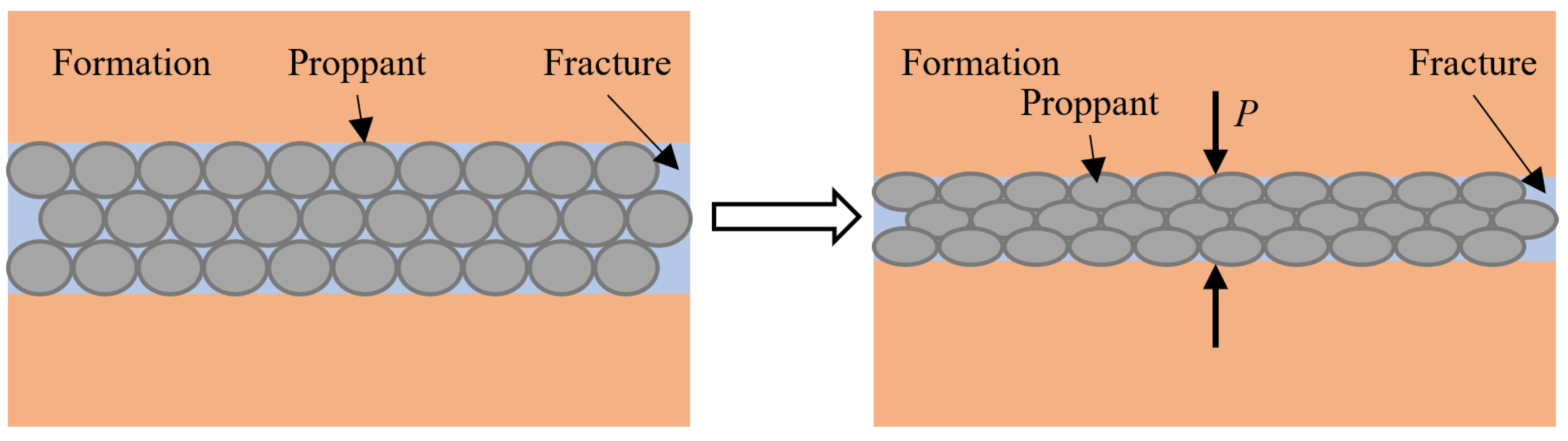

2.2. Experimental Principles

2.3. Experimental Preparation

2.3.1. Experimental Materials

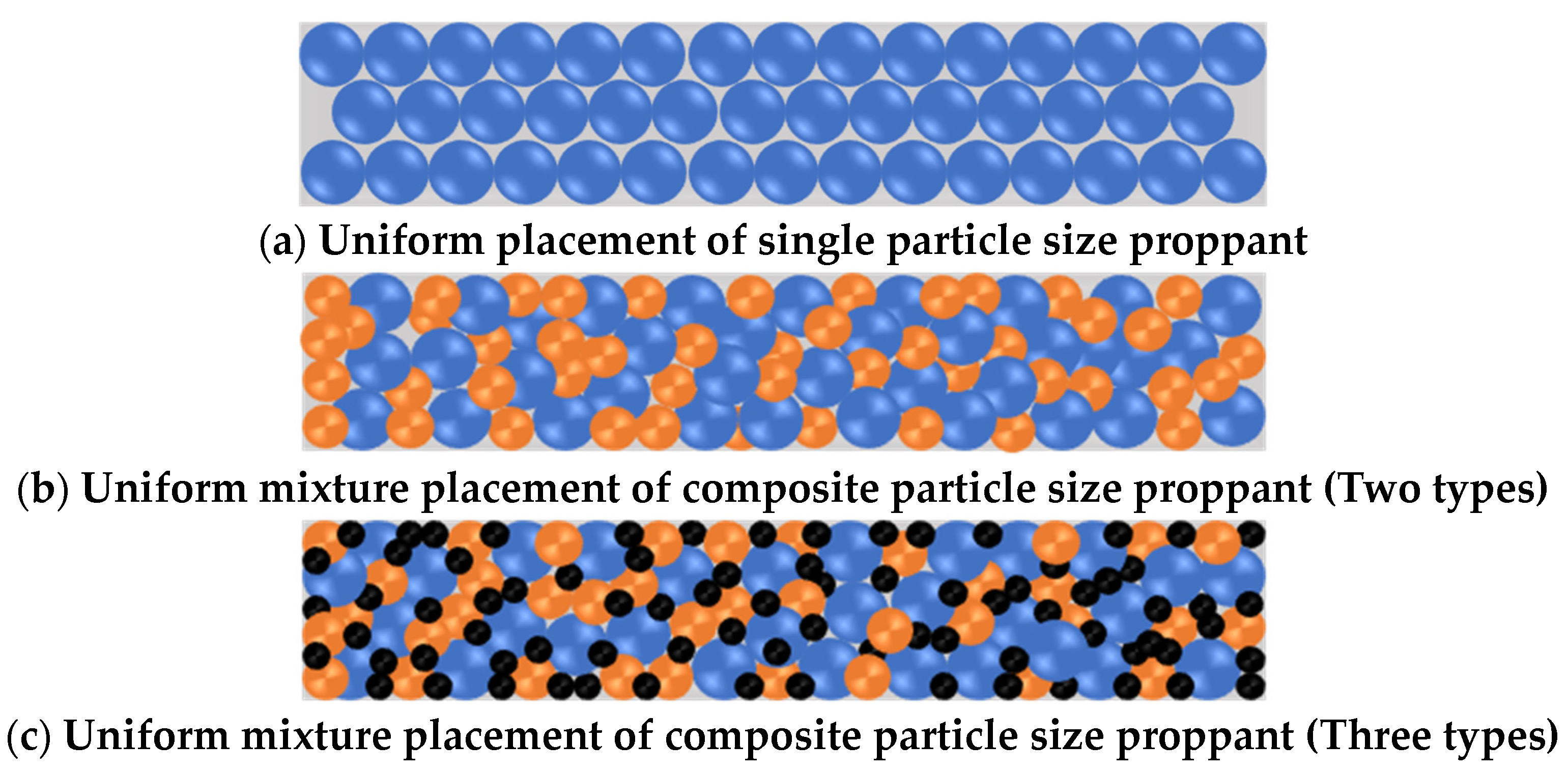

2.3.2. Design of Proppant Placement Patterns

2.4. Design of Proppant Placement Patterns

3. Analysis of Experimental Results

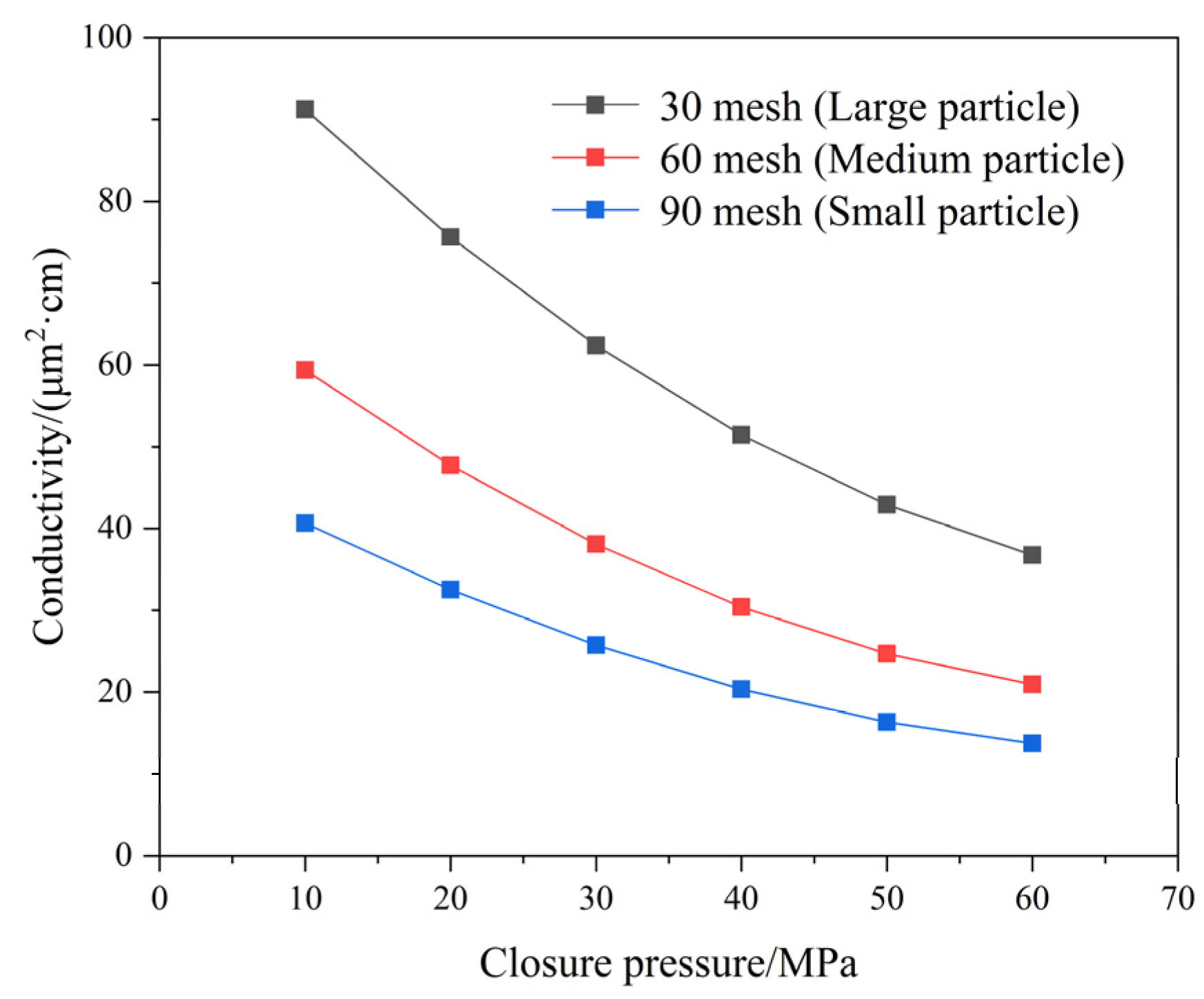

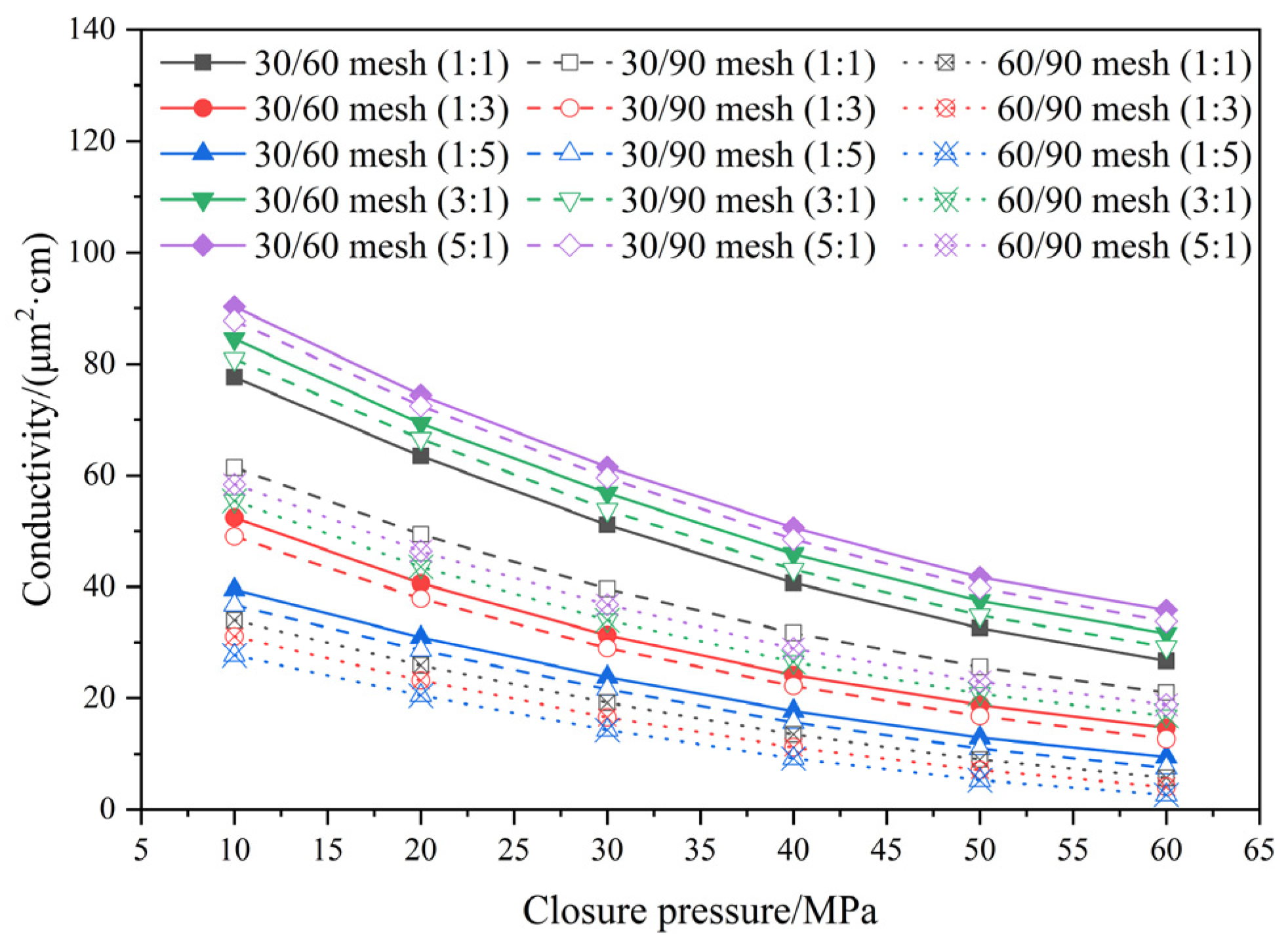

3.1. Influence of Single Particle Size on Short-Term Conductivity of Coalbed Propped Fractures

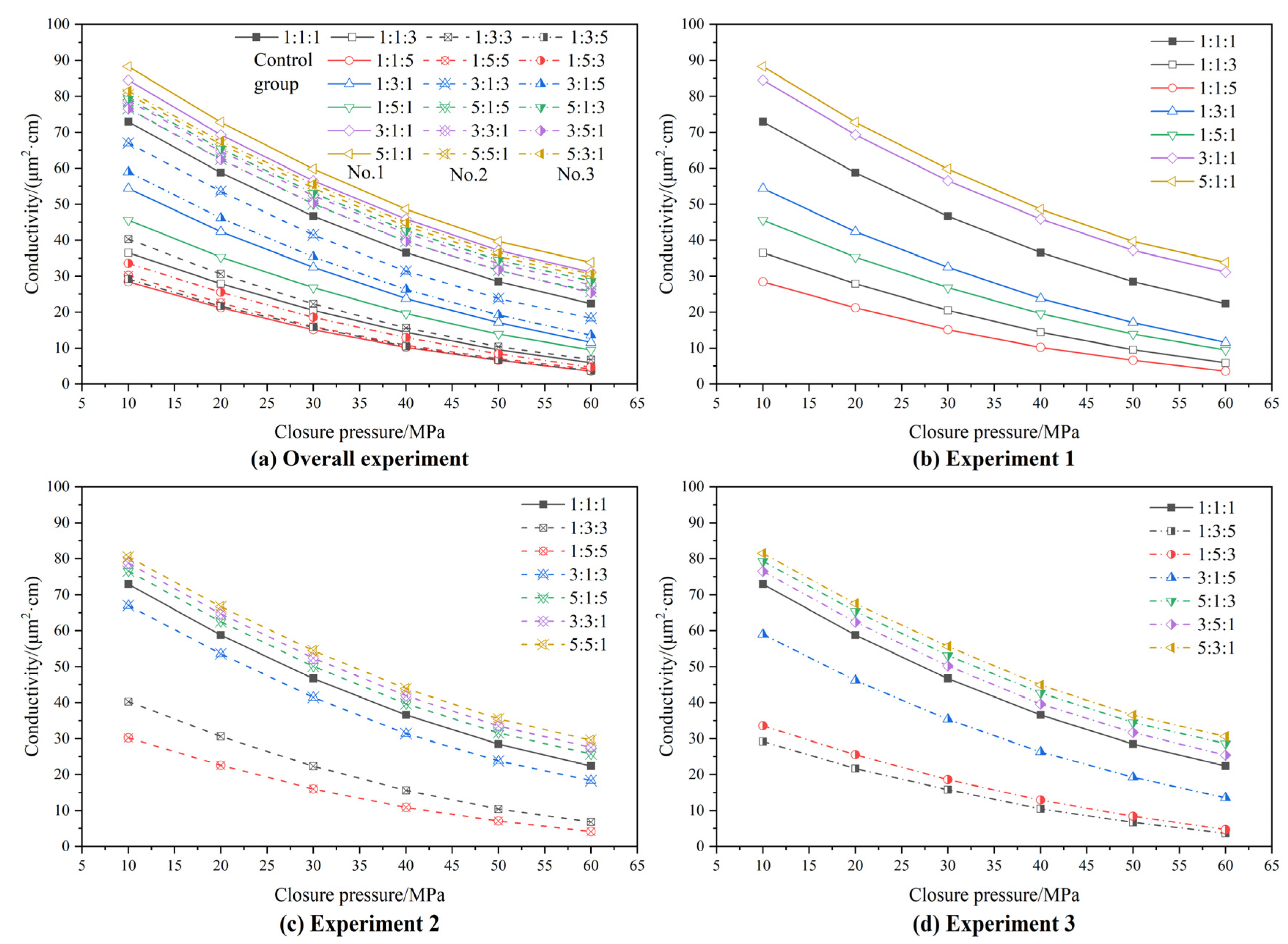

3.2. Influence of Composite Particle Sizes on Short-Term Conductivity of Coalbed Propped Fractures

3.2.1. Influence of Two Particle Sizes Composite Proppant

3.2.2. Influence of Three Particle Sizes Composite Proppant

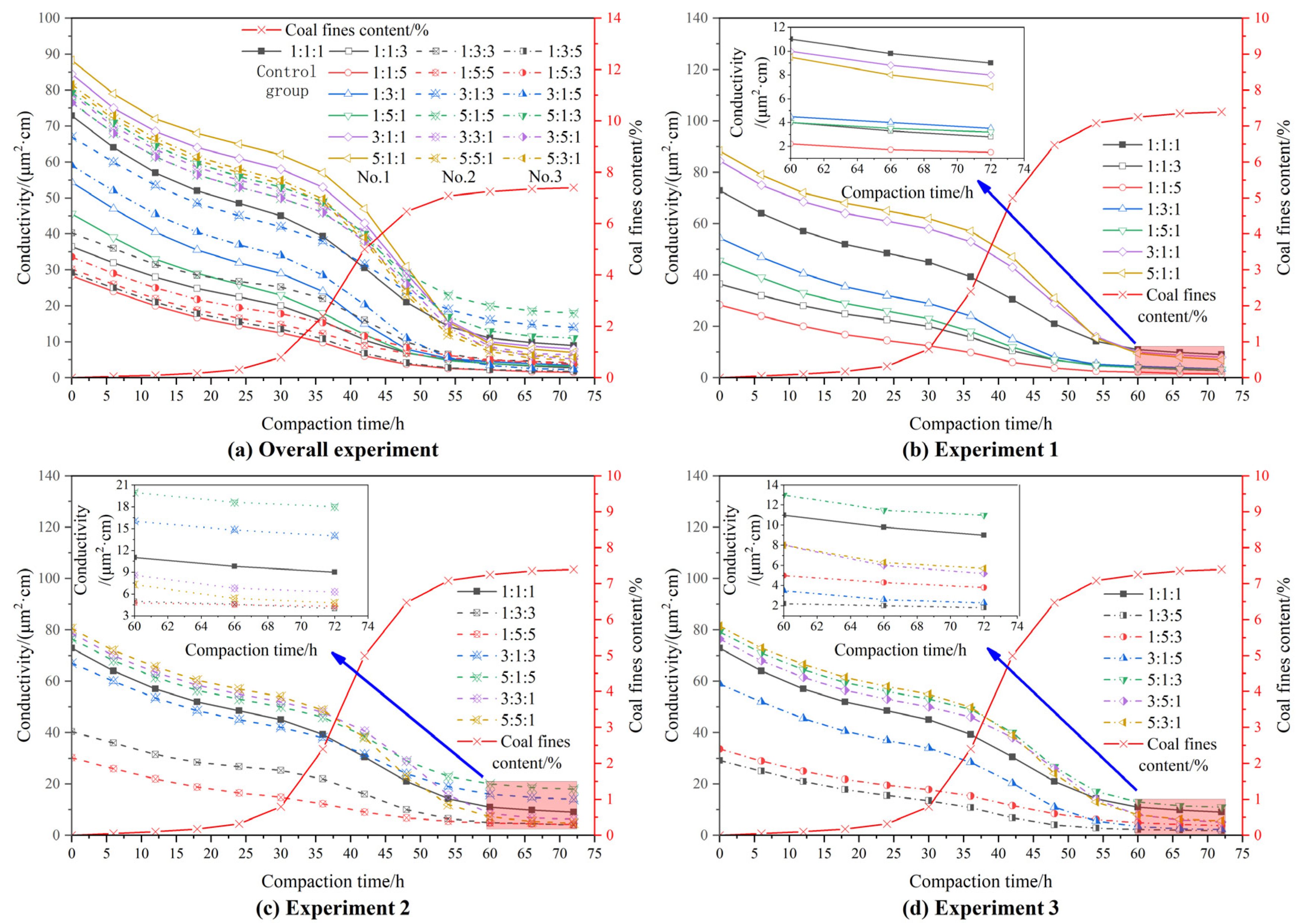

3.3. Influence of Composite Particle Sizes on Long-Term Conductivity of Coalbed Propped Fractures

4. Discussion

5. Conclusions

- (1)

- During the short-term conductivity in coalbed fracturing, the influence of coal fines on the conductivity of propped fractures can be neglected due to their low concentration. The conductivity decreases with an increase in the proportion of small particles. Under a closure pressure of 10 MPa, the conductivity of 30/60/90 mesh = 5:1:1 was 59.9 μm2·cm higher than that of 1:1:5. A segmented and uniform placement approach, starting from the tip of the fracture and extending to the near-wellbore region, effectively filled the smaller-scale slip fractures in the distal region and the larger-scale opening fractures near the wellbore, thereby enhancing the conductivity.

- (2)

- In the long-term conductivity in coalbed fracturing, the continuous injection of proppants onto the coal rock fracture surface leads to an increase in coal fines concentration and a significant accumulation of proppant interstices, resulting in an impaired conductivity. To address this issue, it is necessary to appropriately increase the proportion of small particles and adopt a mixed placement approach to balance the particle interstices within the propped fracture. This approach prevents the excessive infiltration of coal fines, while minimizing the impact on long-term conductivity. After a compaction time of 70 h, the conductivity of 30/60/90 mesh = 5:1:5 was 16.5 μm2·cm higher than that of 1:1:5.

- (3)

- In the current experiment, a mixed placement approach was used for the proppant particles, but the potential impact of particle crushing and subsequent particle interstice blockage due to the proppant particles’ compaction on the conductivity of the proppant pack was not considered. In future studies, the influence of different placement methods on the conductivity and the impact of proppant compressive strength on the particle crushing rate should be taken into account to optimize the experimental results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Santiago, V.; Ribeiro, A.; Johnson, R., Jr.; Hurter, S.; You, Z. Modelling and economic analyses of graded particle injections in conjunction with hydraulically fracturing of coal seam gas reservoirs. SPE J. 2022, 27, 1633–1647. [Google Scholar] [CrossRef]

- Chen, H.; Hu, W.; Liu, Q.; Tian, L.; Men, C.; Zhao, F. Optimization and Application of Segmental Fracturing Parameters for Low-Permeability and Ultra-Low-Permeability Coalbed Methane Horizontal Wells. Coal Technol. 2019, 38, 115–118. [Google Scholar]

- Du, J.; Jiang, J.; Huo, Z.; Shen, Y. Quantitative Evaluation of Fracture Development and Permeability in High-Rank Coalbed Methane Reservoirs. Coal Mine Saf. 2019, 50, 181–184. [Google Scholar]

- Wang, D.; You, Z.; Wang, M.; Li, Q.; Wu, L. Numerical investigation of proppant transport at hydraulic-natural fracture intersection. Powder Technol. 2022, 398, 117123. [Google Scholar] [CrossRef]

- Wang, D.; You, Z.; Johnson, R., Jr.; Wu, L.; Bedrikovetsky, P.; Aminossadati, S.M.; Leonardi, C. Numerical investigation of the effects of proppant embedment on fracture permeability and well production in Queensland coal seam gas reservoirs. Int. J. Coal Geol. 2021, 242, 103689. [Google Scholar] [CrossRef]

- Gao, C.; Ai, C.; Zhang, B.; Zhang, F. Analysis of Factors Affecting the Flow Conductivity of Coal-Rock Fractures. Contemp. Chem. Ind. 2015, 44, 1632–1633. [Google Scholar]

- Palmer, I.; Moschovidis, Z.A.; Cameron, J.R. Coal Failure and Consequences for Coalbed Methane Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Magill, D.P.; Ramurthy, M.; Halliburton; Jordan, R.; Devon; Nguyen, P. Controlling Coal-fines Production in Massively Cavitated Openhole Coalbed-methane Well. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, QLD, Australia, 18–20 October 2010. [Google Scholar]

- Cao, D.; Yuan, Y.; Wei, Y.; Liu, S.; Li, X.; Wang, Q. Comprehensive Classification Study of Coal Fines Genetic Mechanism and Origin Site. Coal Geol. China 2012, 24, 10–12. [Google Scholar]

- Wei, Y.; Cao, D.; Yuan, Y.; Zhu, X.; Yao, Z.; Zhou, J. Characteristics and controlling factors of pulverized coal during coalbed methane drainage in Hancheng area. J. China Coal Soc. 2013, 38, 1424–1429. [Google Scholar]

- Huang, F.; Dong, C.; Shang, X.; You, Z. Effects of proppant wettability and size on transport and retention of coal fines in proppant packs: Experimental and theoretical studies. Energy Fuels. 2021, 35, 11976–11991. [Google Scholar] [CrossRef]

- Wen, Q.; Wang, Q. Analysis and Discussion on Factors Affecting the Long-Term Flow Conductivity of Proppants. Inn. Mong. Petrochem. Ind. 2003, 3, 101–104. [Google Scholar]

- Hou, B.; Chen, M.; Wang, Z.; Yuan, J.; Liu, M. Hydraulic Fracture Initiation Theory for A Horizontal Well in A Coal Seam. Pet. Sci. 2013, 10, 219–225. [Google Scholar] [CrossRef]

- Wang, M. Developmental Experiment and Numerical Simulation of Coal Bed Methane Considering the Effect of Coal Powder. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2016. [Google Scholar]

- Wang, H.; Lan, W.; Liu, Y.; Zhang, H.; Yu, H. Mathematical model of fluid-solid coupling percolation with coal powder in coal reservoir. Nat. Gas Geosci. 2013, 24, 667–670. [Google Scholar]

- Zhang, F.; Li, M.; Qi, Y.; Zhu, H.; Meng, S. Analysis of pulverized coal migration during CBM production. J. China Univ. Pet. 2015, 39, 86–92. [Google Scholar]

- Li, Y.; Han, W.; Wang, Y.; Meng, S.; Wu, X.; Wang, Z.; Ma, Z.; Liu, D.; Zhao, S. Progress of coal fines agglomeration and settlement mechanism based on high efficiency coalbed methane drainage. Coal Geol. Explor. 2021, 49, 1–12. [Google Scholar]

- Zheng, C.; Bao, J. Research on the Numerical Simulation for Migration Law of Pulverized Coal in Wellbore. Unconv. Oil Gas 2016, 3, 99–103. [Google Scholar]

- Zhang, J.; Zhu, S.; Peng, X.; Deng, P. Tri-phase flow model of coalbed methane-water-solid and numerical simulation study. China Offshore Oil Gas 2022, 34, 117–127. [Google Scholar]

- Liu, Y.; Zhang, S.; Cao, L.; Meng, S.; Zhang, T. Rules of coal powder migration and deposition in the proppant fracture. J. China Coal Soc. 2014, 39, 1333–1337. [Google Scholar]

- Chen, W.; Wang, S.; Qin, Y.; Zhao, W.; Zhao, J.; Yang, J.; Li, R. Migration and control of coal powder in CBM well. J. China Coal Soc. 2014, 39, 416–421. [Google Scholar]

- Zhao, S. Experimental Study on the Influence of Pore Structure on Seepage Characteristics in Tight Sandstone Reservoir. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2021. [Google Scholar]

- Pan, L.; Zhang, S.; Zhang, J.; Lin, X. An experimental study on screening of dispersants for the coalbed methane stimulation. Int. J. Oil Gas Coal Technol. 2015, 9, 437. [Google Scholar] [CrossRef]

- Yang, R.; Huang, Z.; Li, G.; Wei, Y.; Shen, Z. A semi-analytical method for modeling two-phase flow in coalbed methane reservoirs with complex fracture networks. SPE Reserv. Eval. Eng. 2018, 21, 719–732. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, W.; Zhao, P.; Lu, Q.; Fang, H. Numerical well test for well with finite conductivity vertical fracture in coalbed. Appl. Math. Mech. 2014, 35, 729–740. [Google Scholar] [CrossRef]

- Huang, F.; Dong, C.; You, Z.; Shang, X.; You, Z. Detachment of coal fines deposited in fracturing proppants induced by single-phase water flow: Theoretical and experimental analyses. Int. J. Coal Geol. 2021, 239, 103728. [Google Scholar] [CrossRef]

- You, Z.; Wang, D.; Leonardi, C.; Johnson, R., Jr.; Bedrikovetsky, P. Influence of elastoplastic embedment on CSG production enhancement using graded particle injection. APPEA J. 2019, 59, 310–318. [Google Scholar] [CrossRef]

- Cao, K.; Jiang, J.; Guo, L.; Wang, L.; Ma, F.; An, D. Experimental Study on Flow Conductivity of Quartz Sand and Ceramic Composite Proppant. Oil Drill. Prod. Technol. 2016, 38, 684–688. [Google Scholar]

- Li, Y.; Jia, D.; Gao, R.; Gao, C.; Mi, J.; Ai, C. Experimental Study on Long-Term Flow Conductivity of Complex Fractures in Coal and Rock. Nat. Gas Oil 2017, 35, 11+12+94–99. [Google Scholar]

- Liang, T.; Cai, B.; Meng, C.; Zhu, X.; Liu, Y.; Chen, F. Influence of Hydraulic Fracturing Proppant Performance on Flow Conductivity. Fault-Block Oil Gas Field 2021, 28, 403–407. [Google Scholar]

- Zhao, Z.; Wang, D.; Wang, G. Experimental Study on Long-Term Flow Conductivity Variation of Quartz Sand Proppant. Drill. Prod. Technol. 2022, 45, 72–77. [Google Scholar]

- Jin, P.; Wang, X.; Zhang, S.; Wang, L.; Lu, Z. Analysis of Factors Affecting Flow Conductivity of Hydraulic Fracture in Tight Sandstone Reservoirs. Fault-Block Oil Gas Field 2022, 29, 234–238. [Google Scholar]

- Chen, C.; Guo, J.; Lu, Q.; Ci, J. Study and Application of Multiscale Propping Mechanism in Tight Gas Reservoirs. J. Southwest Pet. Univ. 2022, 44, 131–138. [Google Scholar]

- Zhu, H.; Zhao, F. Influence of Different Particle Size Combination Proppants on Flow Conductivity of Tight Sandstone Reservoirs. Chem. Eng. Des. Commun. 2022, 48, 27–29. [Google Scholar]

- Zhang, H.; Wang, Y.; Yang, H. Study on Factors Affecting Flow Conductivity of Complex Fractures in Coalbed Methane Reservoirs. Coal Mine Saf. 2022, 53, 21–26. [Google Scholar]

- Ren, L.; Hu, Z.; Zhao, J.; Lin, R.; Hu, D.; Li, Z.; Wu, J.; Peng, S. Optimization Design of Deep Shale Gas Fracturing Proppants Based on the Evaluation of Fracture Network Flow Efficiency. Pet. Geol. Oilfield Dev. Daqing 2023, 42, 148–157. [Google Scholar]

- Xiao, F.; Zhang, S.; Li, X.; Wang, F.; Liu, X. Particle Size Combination and Slickwater Carrying Sand Placement Law and Flow Conductivity: A Case Study of Jimsar Shale Oil Reservoir. Pet. Geol. Oilfield Dev. Daqing 2023, 1–8. [Google Scholar]

- Wang, C.; Lu, Y.; Yi, X.; Qiu, X.; Dai, L.; Du, R.; Dong, L. Experimental Study on the Conductivity of Sand Filled Fractures in Coal and Rock. Sci. Technol. Eng. 2013, 13, 10604–10607+10612. [Google Scholar]

- Zou, Y.; Zhang, S.; Zhang, J. Experimental Method to Simulate Coal Fines Migration and Coal Fines Aggregation Prevention in the Hydraulic Fracture. Transp. Porous Media 2014, 101, 17–34. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, Y.; Tian, H.; Li, D.; Zhang, H.; Sun, H.; Wu, X.; Chen, W. Mechanism anlaysis of coal fines damaged to coal reservoirs and prevention countermeasures during fracturing. Coal Sci. Technol. 2015, 43, 84–87. [Google Scholar]

- Liu, Y.; Su, X.; Zhang, S. Influencing characteristics and control of coal powder to proppant fracture conductivity. J. China Coal Soc. 2017, 42, 687–693. [Google Scholar]

- Ahamed, M.; Perera, M. Pressure-dependent flow characteristics of proppant pack systems during well shut-in and the impact of fines invasion. J. Nat. Gas Sci. Eng. 2021, 96, 104251. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, Y.; Zhang, Q.; Zhang, S.; Wang, A.; Cao, D. Physical simulation experiment of the effect of hydro chemical properties on the migration of coal fines in propped fractures. J. China Coal Soc. 2023, 1–11. [Google Scholar]

| Proppant Type | Particle Size/Mesh | Density /(g·cm−3) | Average Particle Size /μm | Roundness/Sphericity | Turbidity |

|---|---|---|---|---|---|

| Ceramic proppant | 30 (Large particle) | 2.31 | 713.26 | 0.9/0.9 | 62.3 |

| 60 (Medium particle) | 2.32 | 376.51 | 0.9/0.9 | 63.5 | |

| 90 (Small particle) | 2.31 | 168.74 | 0.9/0.9 | 61.7 | |

| Industry standard requirements | ≥0.7/≥0.7 | ≤100 | |||

| Experimental Number | 30/60/90 Mesh Uniform Ratio (Control Group) | 30/60/90 Mesh Non-Uniform Ratio (EXPERIMENTAL Group) | Experimental Content |

|---|---|---|---|

| 1 | 1:1:1 | 1:1:3, 1:1:5 1:3:1, 1:5:1 3:1:1, 5:1:1 | The influence of the density of large, medium, or small particles on the conductivity. |

| 2 | 1:3:3, 1:5:5 3:1:3, 5:1:5 3:3:1, 5:5:1 | The impact of uniform ratio of two particle sizes on the conductivity. | |

| 3 | 1:3:5, 1:5:3 3:1:5, 5:1:3 3:5:1, 5:3:1 | The impact of non-uniform ratio of three particle sizes on the conductivity. | |

| Objective | Optimal ratio for the combination of large, medium, and small particles | ||

| Composite Proppant Ratio | Particle Ratio (Large:Medium:Small) | Short-Term Conductivity Ranking | Long-Term Conductivity Ranking |

|---|---|---|---|

| 1:1:1 | 2:1 | 9 | 4 |

| 1:1:3 | 2:3 | 15 | 16 |

| 1:1:5 | 2:5 | 19 | 19 |

| 1:3:1 | 4:1 | 12 | 14 |

| 1:5:1 | 6:1 | 13 | 15 |

| 3:1:1 | 4:1 | 2 | 5 |

| 5:1:1 | 6:1 | 1 | 6 |

| 1:3:3 | 4:3 | 14 | 12 |

| 1:5:5 | 6:5 | 17 | 11 |

| 3:1:3 | 4:3 | 10 | 2 |

| 5:1:5 | 6:5 | 7 | 1 |

| 3:3:1 | 6:1 | 6 | 7 |

| 5:5:1 | 10:1 | 4 | 10 |

| 1:3:5 | 4:5 | 18 | 18 |

| 1:5:3 | 6:3 | 16 | 13 |

| 3:1:5 | 4:5 | 11 | 17 |

| 3:5:1 | 6:3 | 5 | 3 |

| 5:1:3 | 8:1 | 8 | 9 |

| 5:3:1 | 8:1 | 3 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Huang, Z.; Huang, H.; Chen, Q.; Ling, X.; Xin, F.; Kong, X. An Experimental Study on the Impact of the Particle Size and Proportion of Composite Proppant on the Conductivity of Propped Fractures in Coalbed Methane Reservoirs following Pulverized Coal Fines Infiltration. Processes 2023, 11, 2205. https://doi.org/10.3390/pr11072205

Chen Q, Huang Z, Huang H, Chen Q, Ling X, Xin F, Kong X. An Experimental Study on the Impact of the Particle Size and Proportion of Composite Proppant on the Conductivity of Propped Fractures in Coalbed Methane Reservoirs following Pulverized Coal Fines Infiltration. Processes. 2023; 11(7):2205. https://doi.org/10.3390/pr11072205

Chicago/Turabian StyleChen, Qing, Zhiqiang Huang, Hao Huang, Qi Chen, Xingjie Ling, Fubin Xin, and Xiangwei Kong. 2023. "An Experimental Study on the Impact of the Particle Size and Proportion of Composite Proppant on the Conductivity of Propped Fractures in Coalbed Methane Reservoirs following Pulverized Coal Fines Infiltration" Processes 11, no. 7: 2205. https://doi.org/10.3390/pr11072205

APA StyleChen, Q., Huang, Z., Huang, H., Chen, Q., Ling, X., Xin, F., & Kong, X. (2023). An Experimental Study on the Impact of the Particle Size and Proportion of Composite Proppant on the Conductivity of Propped Fractures in Coalbed Methane Reservoirs following Pulverized Coal Fines Infiltration. Processes, 11(7), 2205. https://doi.org/10.3390/pr11072205