1. Introduction

The development of horizontal well technology has yielded significant economic benefits for oilfield operations. By increasing the contact area with the reservoir, horizontal wells enhance oil recovery [

1]. However, reservoir heterogeneity can result in bottom water breakthroughs, leading to challenges in the efficient development of horizontal wells in bottom water reservoirs [

2]. In response to this issue, inflow control device (ICD) water control completion technology emerged in the 1990s. ICD technology mitigates bottom water coning by regulating the influx of reservoir fluid into the wellbore. Its widespread implementation in oilfields has effectively suppressed the rate of water cut rise in horizontal wells, extending the period of water-free oil production. However, as the water cut increases and the reservoir enters a high water cut period, the water control efficacy of ICDs diminishes. To address this challenge, AICDs have emerged as a new generation of water control completion technology. AICD technology automatically adjusts in response to changes in the water cut during reservoir fluid production after bottom water breakthrough, achieving a production pressure difference, balanced liquid production profile [

3], and delayed bottom water coning, ultimately enhancing oil recovery [

4]. AICDs can be classified into different types based on internal structures, and this paper focuses on flow channel AICD water control completion technology. It is important to note that careful pre-production design is critical for the water control effectiveness of both ICDs and AICDs [

5].

AICD technology is primarily classified into two types: floating disc and runner type. The floating disc type of AICD has been successfully deployed in over 200 oil wells. The disc regulates inflow by adjusting the flow rate based on the viscosity and flow rate of the fluid. As the water cut in the horizontal well increases, the flow rate also rises significantly, resulting in a substantial pressure difference. In response, the floating disc moves upwards, reducing the flow rate and effectively inhibiting bottom water coning [

6].

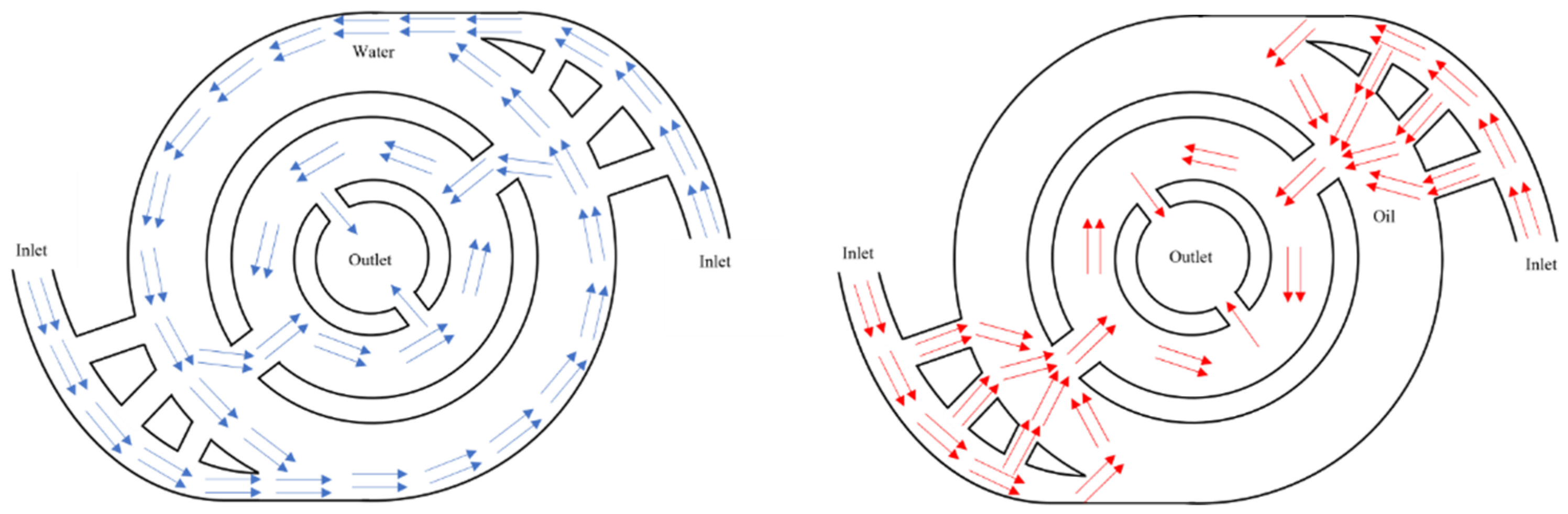

The Fluidic Diode is another variant of AICD, where oil and water enter from the inlets on both sides and exit from the nozzle in the middle. Due to the higher viscosity of the oil phase, it tends to take a shorter path to the nozzle compared to the water phase. This discrepancy in path lengths leads to a significant pressure drop, resulting in reduced flow through the AICD [

7]. The operational mechanism underlying the Fluidic Diode AICD hinges on exploiting fluid properties. When a high-viscosity fluid traverses the Fluidic Diode AICD, it directly proceeds towards the outlet via the radial channel. Conversely, a low-viscosity fluid follows a path through the tangential channel before reaching the outlet. The internal structure of the Fluidic Diode AICD will restrict the unnecessary fluid (water or gas), and simultaneously facilitate the required fluid (oil) so as to control the water. The flow laws of different fluids entering the Fluidic Diode AICD are shown in the

Figure 1.

The relationship between pressure drop and flow is a critical factor that characterizes the flow performance of ICDs and AICDs, and it significantly influences their water control effectiveness. To investigate the flow properties of AICDs, Least et al. conducted tests using fluids with viscosities ranging from 1 mPa·s to 1000 mPa·s [

8]. Subsequently, Least et al. analyzed the flow characteristics of the tested ICD and AICD under pressure and temperature conditions representative of the SAGD environment [

9]. Corona et al. measured the multiphase flow performance of a fluidic diode AICD in a light oil reservoir, demonstrating the reliability of fluid diode AICDs as a solution for enhanced oil recovery without the need for moving parts [

10]. Eltazy Eltaher et al. presented a comprehensive elucidation of the characteristic curves associated with Annular Flow Control Devices (AFCC), supported by numerical simulations conducted in heavy oil fields. The findings substantiated the criticality of parameter optimization for AFCC in the context of diverse oil field developments [

11].

Numerical simulation has emerged as a powerful tool for evaluating the production performance of horizontal wells. The pioneering work of Joshi introduced an initial horizontal well productivity analysis model, which served as a foundation for subsequent advancements by Giger and Francois [

12,

13]. Vicente et al. proposed a fully implicit 3D coupling reservoir numerical simulation model enabling dynamic analysis of horizontal wellbore flow [

14]. Valvatne et al. proposed a calculation model for downhole inflow control devices in unconventional wells, which enabled efficient modeling of these complex systems [

15]. Atkinson et al. developed a semi-analytical completion dynamic coupling model based on Inflow Control Devices (ICD), which explicitly accounted for pressure-based inflow behavior of the wellbore, but did not take into account the axial flow direction in the annulus [

16]. Khafiz Muradov et al. emphasized the significance of accounting for annular flow effects in numerical simulations of AFCD. They successfully deduced a realistic representation of annular flow impact through theoretical analysis, providing a straightforward means to incorporate annular flow effects into the reservoir model [

17].

The semi-analytical model represents a promising approach for calculating production dynamics, offering rapid solutions similar to analytical models while capturing instantaneous inflow dynamics. Penmatcha proposed a semi-analytical model in 1998 [

18]. Ozkan et al. (1999) developed an isothermal single-phase reservoir-wellbore coupled analytical model, and examined the distribution of the wellbore flow rate and pressure drop under both steady-state and unsteady-state conditions [

19]. Ouyang et al. conducted investigations on the behavior of single-phase or multi-phase flow in horizontal wellbores, addressing the issue of pressure loss in such scenarios [

20]. Birchenko et al. tackled the problem of inflow control devices in heterogeneous reservoirs. However, they did not consider the influence of the annular space [

21]. Seines et al. established various coupling models between reservoirs and horizontal wells based on semi-analytical models [

22]. Li et al. established a prediction model for inflow profiles of horizontal wells in bottom water gas reservoirs [

23]. Luo et al. introduced a mathematical model for ICD completion of horizontal wells in bottom water reservoirs, incorporating formation heterogeneity, anisotropy, and annular space flow characteristics [

24]. However, this model is limited to ICDs and cannot be readily applied to different completion methods. To address this limitation and accommodate diverse completion methods and inflow control devices from various companies, this paper presents a comprehensive integrated coupling model of horizontal wells in bottom water reservoirs, and the corresponding coupling process.

In light of geological variations and unique development strategies, it is imperative to tailor the well completion design for ICDs/AICDs to the specific geological conditions of individual horizontal wells, to enhance water control efficiency. However, the availability of professional and commercially accessible AICD optimization design software remains limited both domestically and internationally. To address this gap, this study proposes an AICD completion parameter optimization model. Leveraging the integrated coupling model of horizontal wells in bottom water reservoirs, the AICD completion parameters were optimized based on distinct geological conditions, ultimately yielding a scientifically informed completion plan aimed at enhancing oil recovery.

To elucidate the effects of diverse completion parameters on the water control efficacy of AICD water control devices, this study employed node analysis theory and network modeling to establish an integrated coupling model encompassing the bottom water reservoir, annular space, water control valve, and the horizontal wellbore. Additionally, an AICD flow model was devised through experimental investigations. This results in an integrated coupling model of horizontal wells in bottom water reservoirs that caters to different well completion methods. Using a horizontal well as a case study, this paper investigated the impact of various well completion parameters on the water control performance of AICD water control devices, leading to the formulation of an AICD well completion parameter optimization model for optimized design and on-site implementation. The accuracy of the proposed AICD completion parameter optimization model and integrated coupling model of horizontal wells in bottom water reservoirs was confirmed through a production period of verification.

2. Fluidic Diode AICD Flow Model

To establish the AICD flow model, this paper studied the flow principle of AICDs through commercial software, designed the AICD test experimental device independently, and established the AICD characteristic curve model through an experimental test, which provides the theoretical basis for the integrated coupling model of horizontal wells in bottom water reservoirs.

2.1. Flow Principle

The Fluidic Diode AICD was designed with different baffles and scrolls based on the fluid’s inertia force and viscous force, resulting in varying pressure losses. During the production process of horizontal wells in bottom water reservoirs, when oil–water mixed fluid enters the flow diversion channel of the Fluidic Diode AICD, the high viscosity, low density, and low flow velocity of crude oil cause it to enter the center of the valve through the launder. Due to the low viscosity, high density, and high flow velocity of water, it rotates along the circular channel at high speed after passing through the diversion channel, resulting in a significant pressure loss. This phenomenon stabilizes oil production, controls water production, and improves recovery.

The Fluidic Diode AICD possesses an internal structure capable of automatic adjustment in response to the fluid characteristics, rendering it adaptable for water control in diverse oil–water mixing conditions. During the middle and late stages of production in horizontal wells located in reservoirs with bottom water, the implementation of the Fluidic Diode AICD has demonstrated notable effectiveness in delaying the breakthrough time of water.

2.2. Experimental Test

2.2.1. Experimental Facility

To investigate the water control efficacy of the Fluidic Diode AICD, an independent pressure drop test apparatus was designed and developed, as depicted in

Figure 2. The device is equipped with a test fluid inlet and outlet at its two ends. The test fluid was introduced through the valve inlet, passed through the annular channel and flow groove, and eventually entered the oil pipe or casing through the nozzle. By measuring the additional pressure drop before and after passing through the water control components under various test fluids, the pressure difference generated by the Fluidic Diode AICD with different apertures under varying test fluid flow rates could be obtained.

2.2.2. Experimental Sample

To evaluate the performance of the Fluidic Diode AICD in horizontal wells with bottom water reservoirs, the experimental setup involved the formulation of compound fluids by the target layer at the site. This included the preparation of white oil with varying viscosities and compound fluids with different water contents for testing purposes.

2.2.3. Experimental Procedure

The experimental procedure entailed several key steps, including the examination of the experimental device for tightness, the formulation of crude oil compound liquid, pressure drop tests on the Fluidic Diode AICD, and the implementation of cycle tests.

- (a)

Leakage check

The Fluidic Diode AICD was affixed to the experimental platform, followed by the introduction of a predetermined volume of pristine water into the experimental apparatus via the fluid inlet, with the quantity of water injected meticulously recorded. Subsequently, the device outlet was obstructed, and the entire setup was allowed to stand undisturbed for 2 h. If the volume of water remained unchanged after the designated time period, it would signify a superior sealing performance of the Fluidic Diode AICD.

- (b)

Preparation of crude oil compound solution

The compound liquid was formulated by the characteristics of the target reservoir layer. For this experiment, a diverse range of white oils exhibiting varying viscosities, as well as compound liquids featuring distinct water contents, were chosen for testing purposes.

- (c)

Pressure drop test of the flow channel AICD

The pressure drop test of the Fluidic Diode AICD was conducted with meticulous precision. The test liquid was carefully added to the water tank, typically reaching a level of 2/3 of the tank’s capacity. Subsequently, the power pump was activated, and the pressure gauge was monitored while adjusting the frequency converter. Once the pressure reached a stable state, the flow value and pressure difference were accurately measured and recorded. Subsequently, the flow rate was altered using the frequency converter, and the flow value was measured and recorded again after the pressure stabilized. This process was repeated until all the designated pressure measuring points were thoroughly tested.

- (d)

Cyclic testing

Cyclic testing was performed to assess the performance of the Fluidic Diode AICD under varying water content conditions. The water content of the experimental sample was systematically modified, followed by repeating the aforementioned step (c) for pressure drop testing.

2.3. Mathematical Model of Characteristic Curve

The experimental data of the Fluidic Diode AICD were obtained through rigorous experimentation. However, in order to effectively apply the obtained curve in numerical simulations for practical applications, it was imperative to establish a precise mathematical model that accurately described the behavior of the valve. Therefore, a characteristic curve formula for the Fluidic Diode AICD was proposed.

The formula for the characteristic curve of the Fluidic Diode AICD is [

25]:

where Δ

PAICD is the pressure drop across the AICD;

q is volume flow;

ρ is the density of the oil–water mixture;

ρ =

ƒwρw + (1 −

ƒw)

ρo;

μ is the viscosity of the oil–water mixture,

μ =

μo(1−fw) −

μo(fw); and

K is the coefficient of AICD.

In this paper, an AICD flow model considering different AICD aperture sizes is proposed, and the effect of AICD aperture sizes on pressure drop was added to the parameter

K. When the properties of the fluid or the water content changed, the calculation formula of

K was:

where

y is the viscosity index,

aAICD is the AICD control constant,

ρ is the density of the oil–water mixture,

ρcal is the calibrated density,

μ is the viscosity of the oil–water mixture,

μcal is the calibrated viscosity,

ƒw is the water cut,

z is the aperture index, and

D is the aperture of the AICD.

In this study, we adopted Mathiesen’s model as a reference and made necessary refinements. To enhance the applicability of the Autonomous Inflow Control Device (AICD) flow model across a wider range of aperture sizes, we introduced the 1/Dz term into the Mathiesen model.

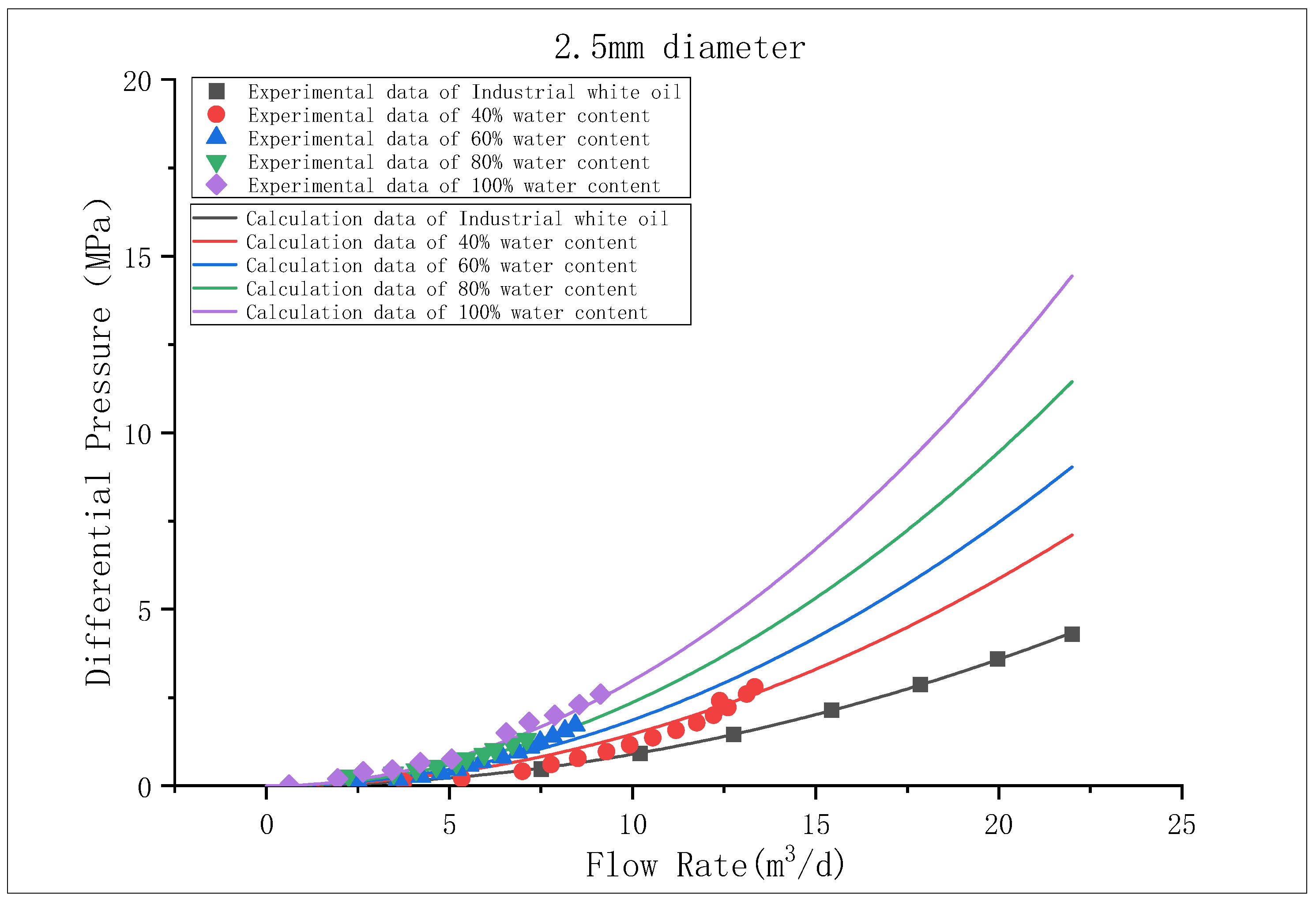

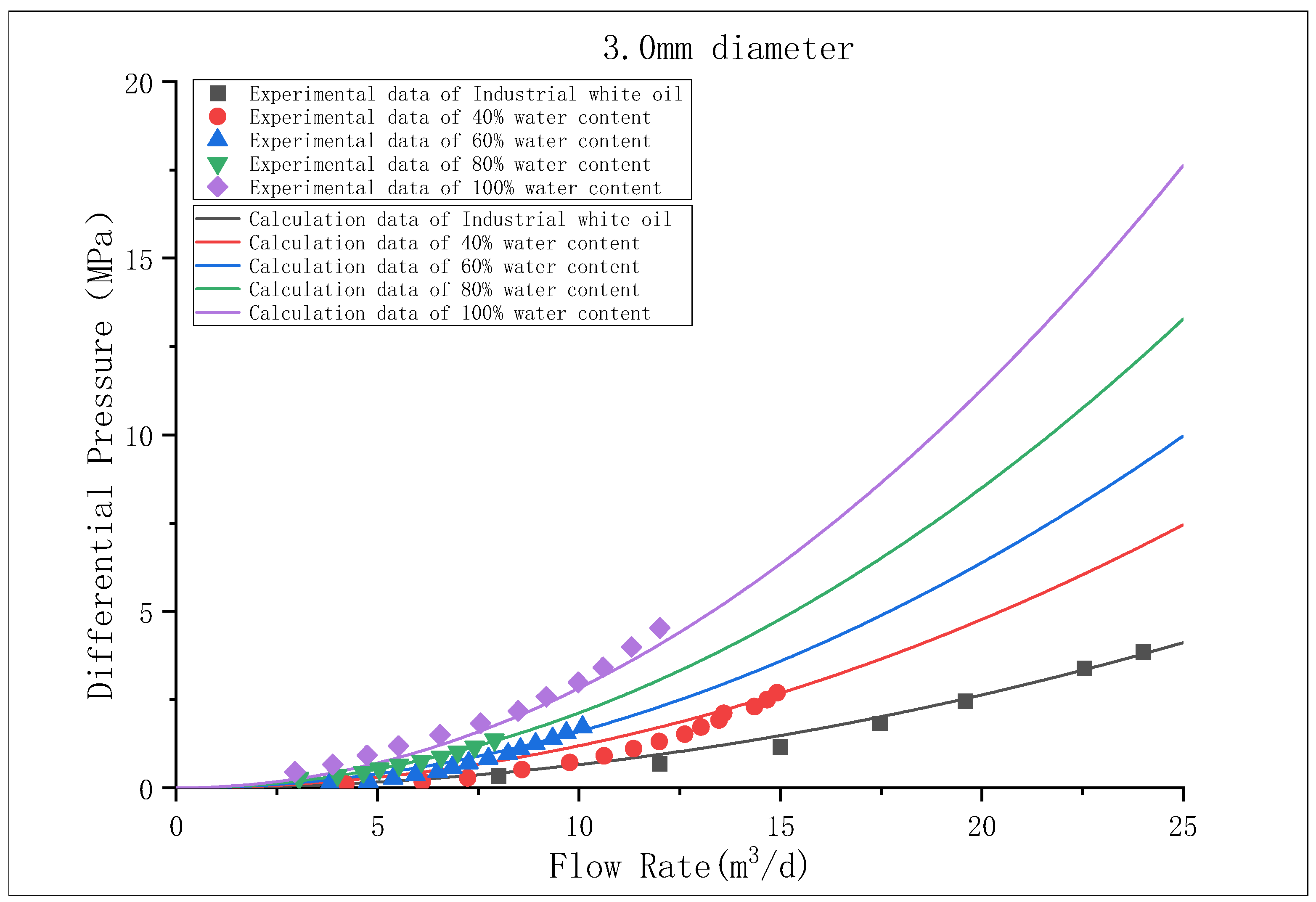

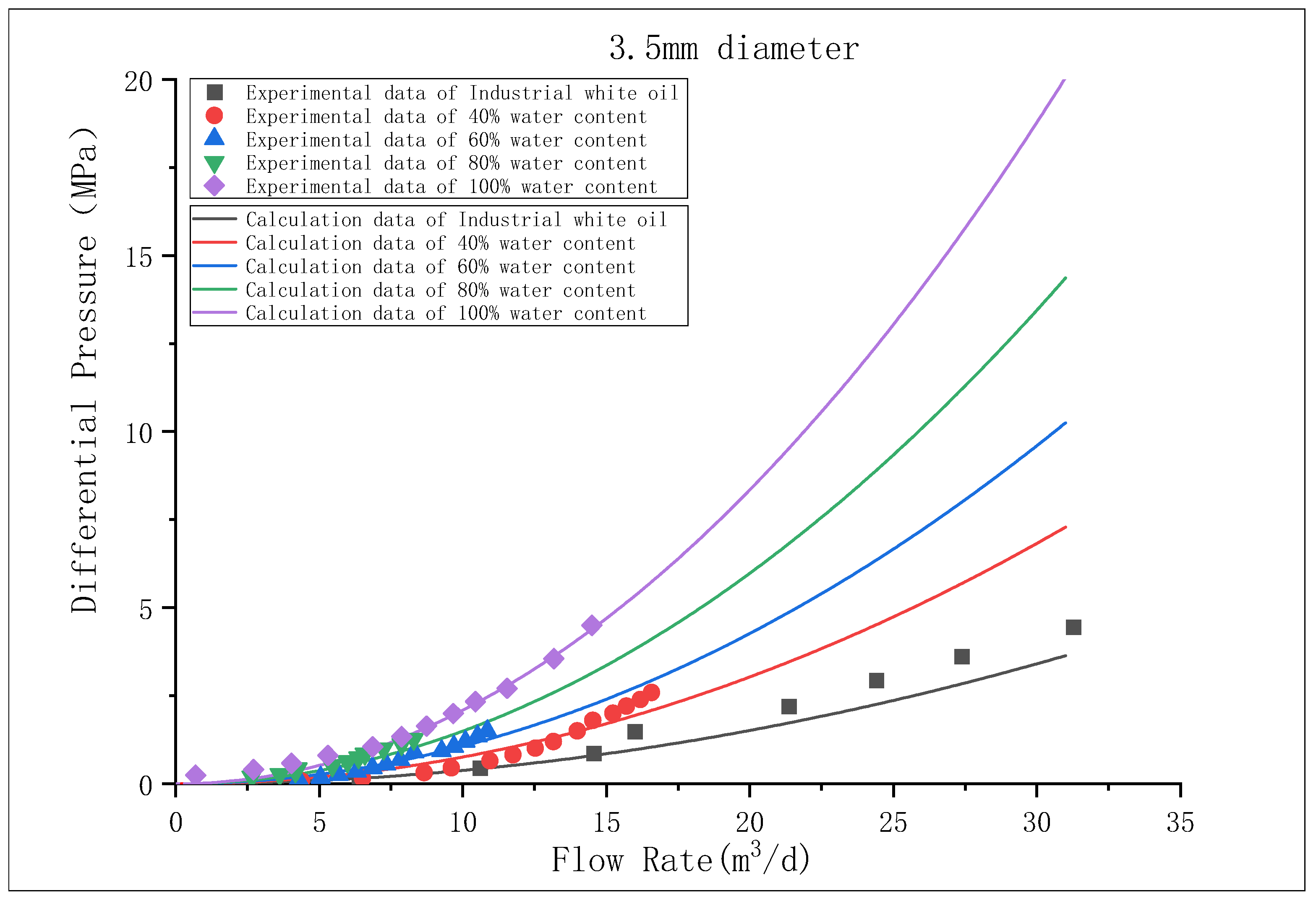

In the experimental investigation, a series of AICDs with varying aperture sizes, namely 2.5 mm, 3 mm, 3.5 mm, and 4 mm, were meticulously tested under diverse conditions, including industrial white oil, compound solutions with water cuts of 40%, 60%, and 80%, and clean water. The resultant relationship curve depicting the flow rate versus pressure difference, which represents the characteristic curve of the Fluidic Diode AICD, is illustrated in

Figure 3,

Figure 4,

Figure 5 and

Figure 6. The experimental results clearly demonstrate that, as the water cut increases, the fluid flow rate through the Autonomous Inflow Control Device progressively diminishes under the same pressure difference. Moreover, it is evident that fluids characterized by elevated water content exhibit a greater pressure drop when subjected to the same flow rate, thereby indicating the remarkable inhibitory efficacy of the Autonomous Inflow Control Device in mitigating fluids with high water content.

The comparative analysis of the flow rate and pressure drop relationship under varying AICD aperture sizes and water contents, as obtained from the aforementioned experiments, was juxtaposed with the characteristic curve of the Fluidic Diode AICD, which was obtained through meticulous fitting procedures. The fitting accuracy, as depicted in

Figure 3,

Figure 4,

Figure 5 and

Figure 6, exceeded 93%. To streamline the model and facilitate the adaptability of the parameters in AICD models with diverse AICD aperture sizes, this paper proposes a simplified AICD flow model. This approach allows for the consistent applicability of the model while minimizing parameter modifications. The Coefficients of the Fluidic Diode AICD characteristic curve are shown in

Table 1.

3. Integrated Coupling Mathematical Model

3.1. Assumptions

The reservoir seepage model was established based on the following assumptions:

The reservoir was assumed to have a closed top boundary, driven by bottom water at the bottom boundary, and was considered to be infinite in the horizontal direction with equal thickness in each part, accounting for permeability anisotropy.

The fluid seepage in the reservoir was considered as stable seepage of single-phase incompressible fluid, following Darcy’s law.

The flow in the base pipe, annular space, and automatic phase selection control valve was assumed to be steady-state isothermal oil–water two-phase flow, with incompressible fluids and constant fluid viscosity irrespective of pressure.

The flow process was assumed to be isothermal, with no heat exchange with the external environment.

One-dimensional steady-state flow was assumed in the wellbore.

The oil–water two-phase fluid is assumed to be evenly injected along the AICD holes of the base pipe.

The model considered both oil and water as immiscible phases and assumed that the two-phase seepage followed the same seepage law.

The radial pressure drop of the fluid from the reservoir sand surface to the wellbore annulus was assumed to be negligible in the model.

The model treats the oil-water mixture as a homogeneous mixture.

3.2. Reservoir Flow Model

In this study, it was assumed that the reservoir under investigation was a bottom-water reservoir, with only a two-phase flow of oil and water, without considering the influence of gas. It was further assumed that the composition of each phase fluid flowing into and out of a specific unit remained constant, and the material balance equation was formulated accordingly [

26,

27].

where:

νo is the seepage velocity of oil,

νw is the seepage velocity of water,

Bo is the volume coefficient of oil,

Bw is the volume coefficient of water,

So is the saturation of oil,

Sw is the saturation of water,

qo is the flow rate of oil in the standard state, and

qw is the flow rate of water in the standard state.

Considering the influence of gravity, it can be obtained from Darcy’s law:

where

K is the absolute permeability,

Kro is the relative permeability of oil,

Krw is the relative permeability of water, dimensionless;

μo is the viscosity of oil,

μw is the viscosity of water;

Po is the oil phase pressure,

Pw is the water phase pressure,

ρo is the density of oil,

ρw is the density of water,

g is the gravitational acceleration, and

D is the depth (downward is positive).

Substituting Equation (5) into Equation (3), and Equation (6) into Equation (4), we obtain the seepage equations of the oil phase and water phase:

3.3. Horizontal Wellbore Flow Model

By taking into account the unique characteristics of horizontal wells, the phenomenon of variable mass flow within the horizontal wellbore was fully considered. Continuous injection of fluid into the wellbore results in a friction coefficient of the wellbore wall that differs from that of ordinary circular pipes. Additionally, the radial inflow from the wellbore mixes with the axial flow, leading to the generation of an acceleration pressure drop. Moreover, the horizontal section of the wellbore exhibits fluctuations in elevation, resulting in the generation of a gravity pressure drop. Consequently, the pressure drop in the horizontal wellbore comprises a friction pressure drop, acceleration pressure drop, and gravity pressure drop.

In this study, it was assumed that the fluid within the wellbore behaves as a one-dimensional, isothermal, incompressible fluid. To analyze the flow characteristics in the horizontal wellbore, the wellbore was divided into n small segments, each with an equal length of ΔL (m). We assumed that the wall inflow flow rate at the i segment was qi, and the axial flow rate at the wellbore inlet end was Qi. The inner diameter of the wellbore was dw, and the friction coefficient is ƒi.

3.3.1. Friction Pressure Drop

According to Darcy’s formula, the frictional pressure drop of each section of the horizontal well wall is:

where

is the average flow velocity of the

i section fluid, and

ƒi is the friction coefficient of the

i section wall.

Considering the comprehensive influence of borehole wall roughness and radial inflow, the surface friction coefficient of the Ouyang friction factor [

28] was used for correction:

where

ƒo is the wall friction coefficient of the sidewall inflow, and

Rei is the Reynolds number of paragraph

i.

According to the theories of conservation of momentum and energy, the average velocity of the wellbore in the

i section was:

By substituting Formula (18) for Formula (16), the friction pressure drop of section I wellbore can be reduced to:

3.3.2. Acceleration Pressure Drop

The radial inflow of the well wall in each section of the horizontal wellbore leads to changes in the axial flow at the inlet and outlet sections, resulting in variations in fluid momentum along each section. This phenomenon gives rise to the acceleration pressure drop. Based on the momentum theorem, the additional stress resulting from the momentum change in each section of the horizontal well can be calculated as follows:

Next, the acceleration pressure drop of each section can be obtained as:

where Δ

Pc is the acceleration and pressure drop of the first section and

dw is the wellbore diameter.

3.3.3. Gravity Pressure Drop

In the case of non-horizontal horizontal wells, the effect of gravity on the fluid results in a pressure drop along the wellbore. Accordingly, the pressure drop caused by gravity can be mathematically expressed as:

There exists an inclination angle between the heel and toe ends of the horizontal well concerning the horizontal direction. In cases where the horizontal section is inclined in an upward direction, the gravity pressure drop is negative, while it is positive when the horizontal section is inclined in a downward direction. Thus, the magnitude of the gravity pressure drop is primarily determined by the actual trajectory of the horizontal wellbore.

3.4. AICD Flow Model

The AICD flow model was calculated based on the model established above through experiments and fitting calculations. The formula is as follows:

3.5. Model Coupling

This paper proposes a coupling method for different scale flow models based on the node analysis method, which included the porous media flow model, AICD flow model, horizontal wellbore flow model, and wellbore annulus flow model. The three-dimensional space of the reservoir was discretized into grids, with each grid cell center serving as a solution point for conducting node analysis in the near-wellbore region. The schematic diagram of the node analysis is presented below. The resulting integrated coupling model, incorporating the porous media flow model, horizontal wellbore flow model, and wellbore annular flow model, was specifically designed for studying horizontal wells in bottom water reservoirs.

3.6. Packer Optimization

The optimization of AICD well completion parameters will play a critical role in achieving effective water control. Considering the geological variations and development strategies, it is imperative to optimize the design of AICD water control completion plans to ensure scientific plans that enhance oil recovery while effectively mitigating bottom water coning.

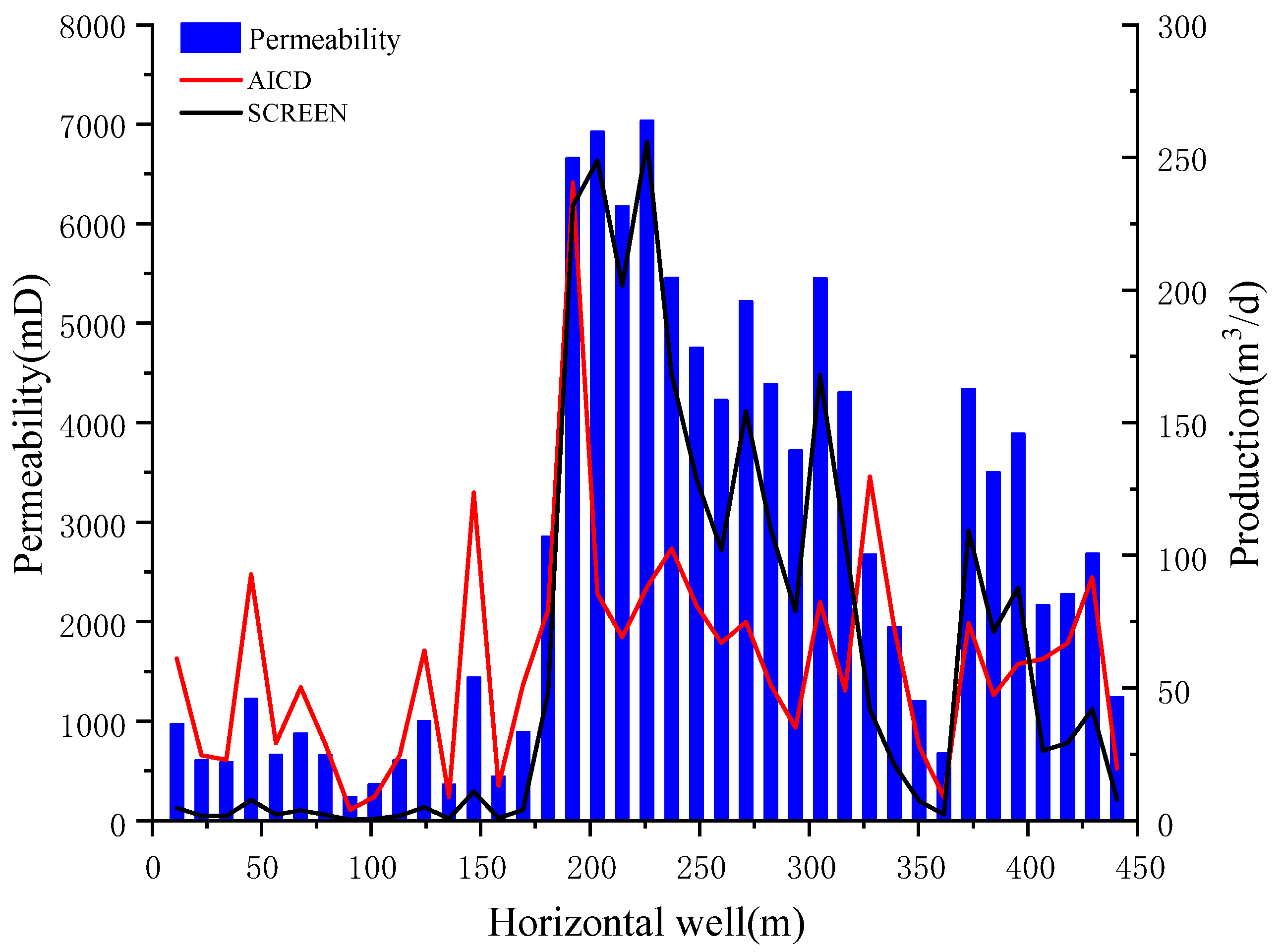

To illustrate the optimization effects of the number of packers, a horizontal well in a bottom water reservoir was selected as an example, and the integrated coupling model of water control and completion devices for horizontal wells in bottom water reservoirs was used for calculations. The permeability distribution is depicted in the

Figure 7.

The quantity of packers employed significantly impacts the water control performance of AICDs. A higher number of packers tends to yield better water control effects, but excessive usage may lead to cost-related concerns and increased operational risks. Thus, there exists an optimal number of packers that can enhance the recovery rate while ensuring project safety. To illustrate this, the integrated coupling model of horizontal wells in bottom water reservoirs was utilized to calculate the influence of different packer quantities on cumulative oil production, using a case well as an example. The calculation results are presented in the

Figure 8 below.

Based on the permeability distribution of the case well’s horizontal section, the analysis of the Figure revealed that an optimal number of 4–6 packers can effectively enhance oil recovery, while also ensuring cost-effectiveness and minimizing running risks. It is noteworthy that the ideal number of packers may vary depending on the reservoir’s permeability characteristics. Thus, optimizing the quantity of packers is of paramount importance in improving water control effectiveness and enhancing reservoir recovery.

4. Applications

By considering a horizontal well in a bottom water reservoir as a case study, the integrated coupling model of horizontal wells in bottom water reservoirs was employed for the calculations. The parameter optimization design was developed using the previously mentioned AICD water control completion parameter optimization design model, and the construction was carried out on-site.

Table 2 presents the essential parameters of the reservoir and fluid, while

Figure 7 illustrates the permeability distribution in the reservoir.

The optimization design of AICD parameters in this study involved the implementation of five packers at specific depths along the wellbore, namely, 2712 m, 2820 m, 2920 m, 2995 m, and 3129 m. After coupling model design optimization, and rigorous testing of production wells, operational performance was assessed under varying aperture sizes of AICDs as well as the number of AICDs employed. Subsequently, to ensure compliance with production allocation and production pressure difference specifications, a final selection was made. Environmental control of the horizontal well was achieved through the installation of 96 valves in total, distributed across six sections along the screen. These valves were 3.5 mm AICD valves, as shown in

Figure 9, which presents the well completion string diagram.

The integrated coupling model of horizontal wells in bottom water reservoirs was simulated and calculated using the integrated coupling model of horizontal wells in bottom water reservoirs. The simulation results were compared with the actual production daily report. The calculation results of the integrated coupling model have a high accuracy rate, as shown in

Figure 10, effectively predicting the production performance of oil wells. The liquid production profile, as shown in

Figure 11, was used for comparative analysis between the screen tube and the AICD liquid production profile. During the advanced stages of oilfield development, particularly in regions characterized by high permeability, it is observed that the flow rate through the screen surpasses that of the AICD. The AICD effectively regulates the flow rate to mitigate the risk of bottom water coning. Simultaneously, upon examining the reservoir water saturation distribution diagram within the same development period (

Figure 12), it is evident that the water saturation levels attributed to the AICD are lower than those observed through the screen in the high permeability formation. This compelling evidence substantiates the commendable efficacy of AICD in effectively preventing bottom water coning. The results indicated that the AICD system effectively controlled the liquid production profile, mitigated the occurrence of bottom water coning, and demonstrated a positive water control effect, aligning with the actual production performance.