Characteristics and Geological Impact Factors of Coalbed Methane Production in the Taiyuan Formation of the Gujiao Block

Abstract

1. Introduction

2. Geological Background

3. Characteristics of Production

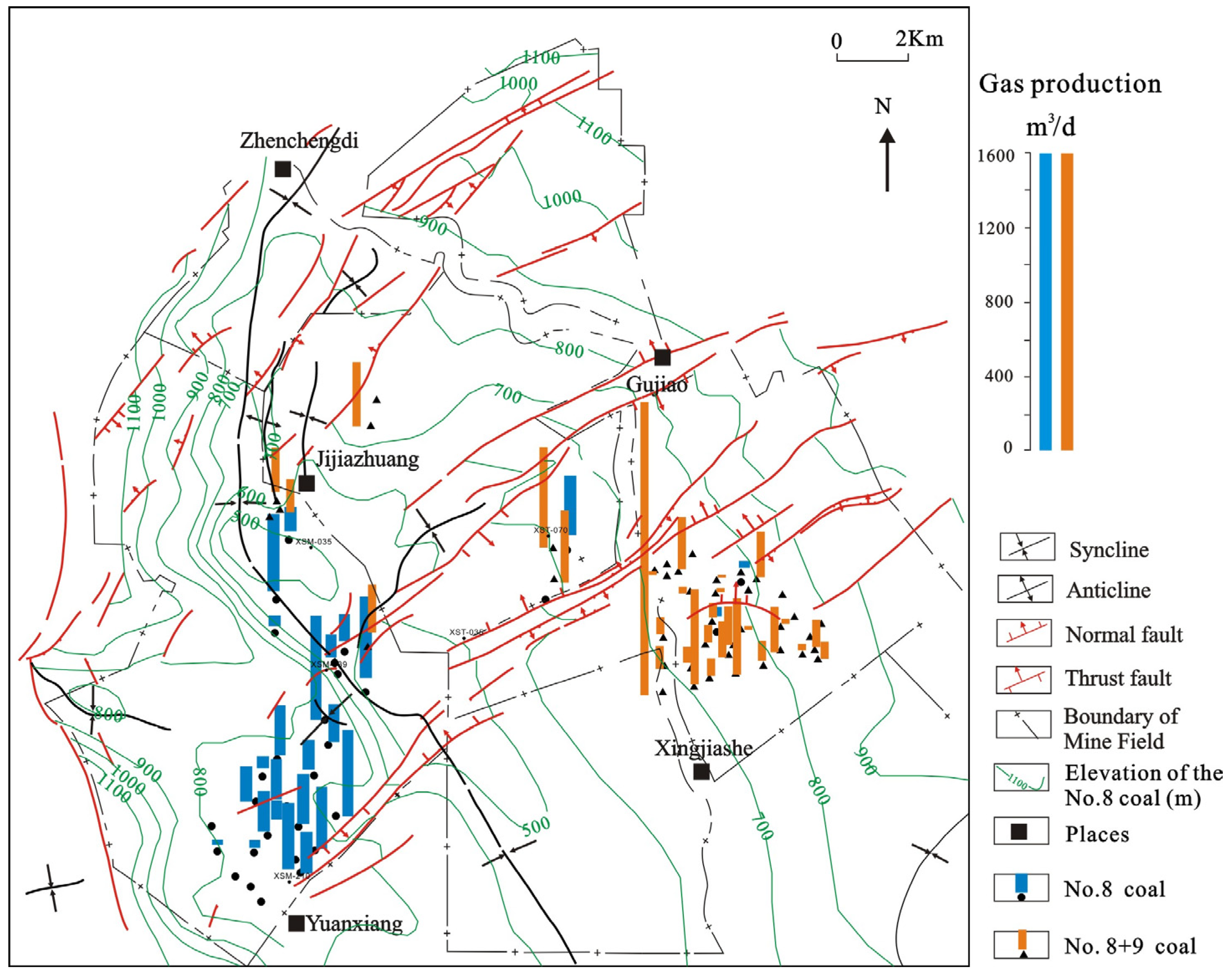

3.1. Gas Production Characteristics

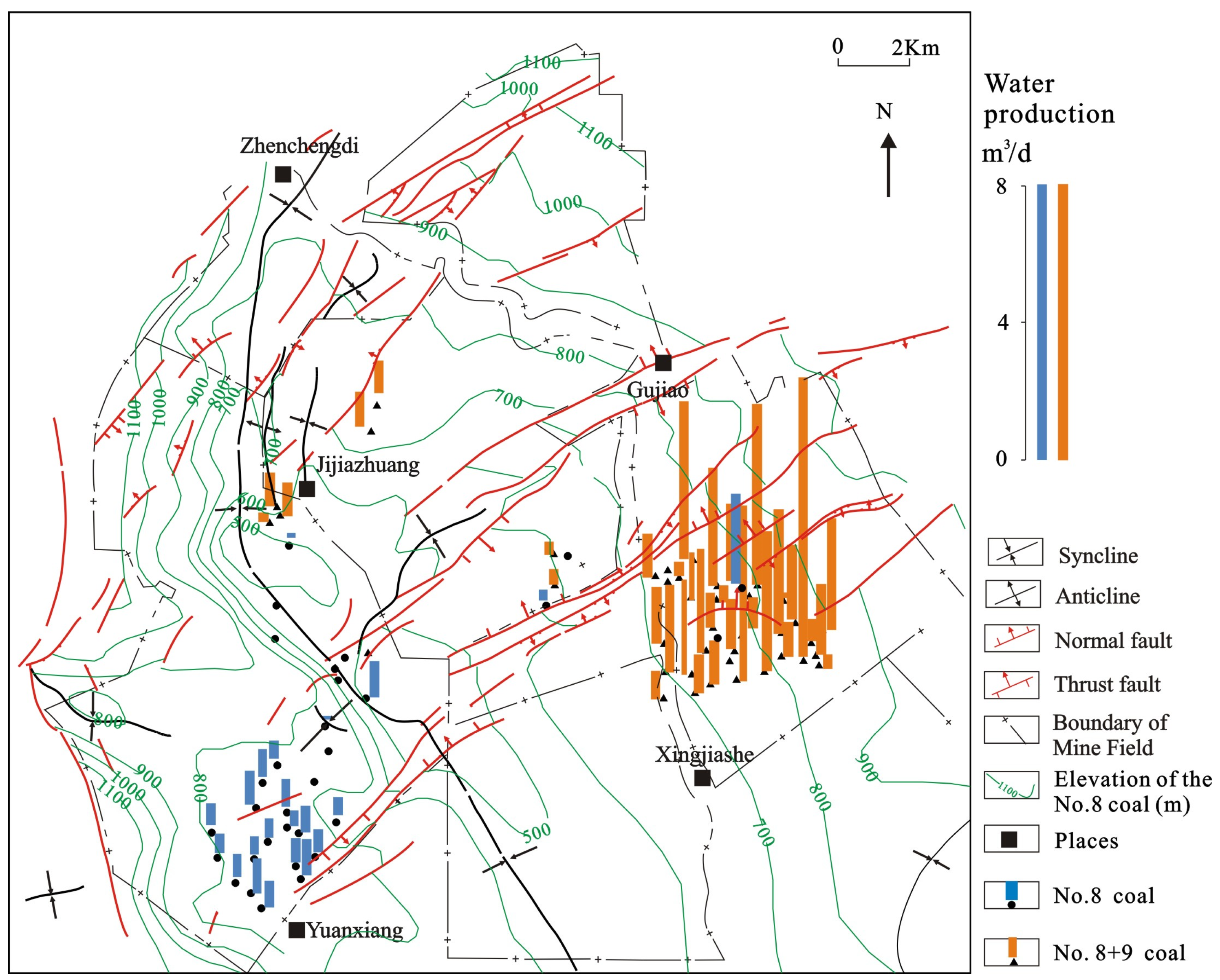

3.2. Water Production Characteristics

4. Geological Impact Factors

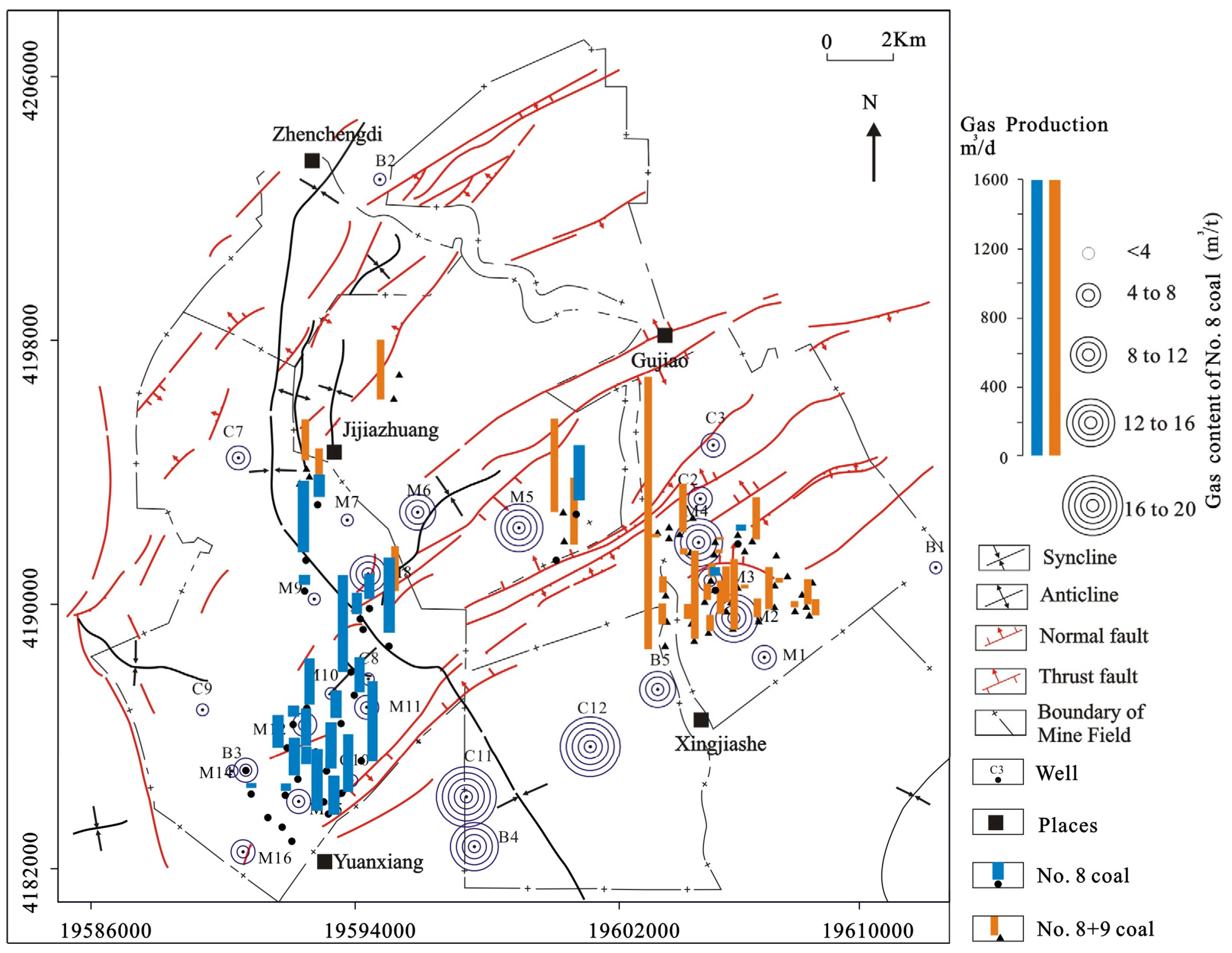

4.1. Tectonic

4.2. Hydrochemistry and Hydrodynamic

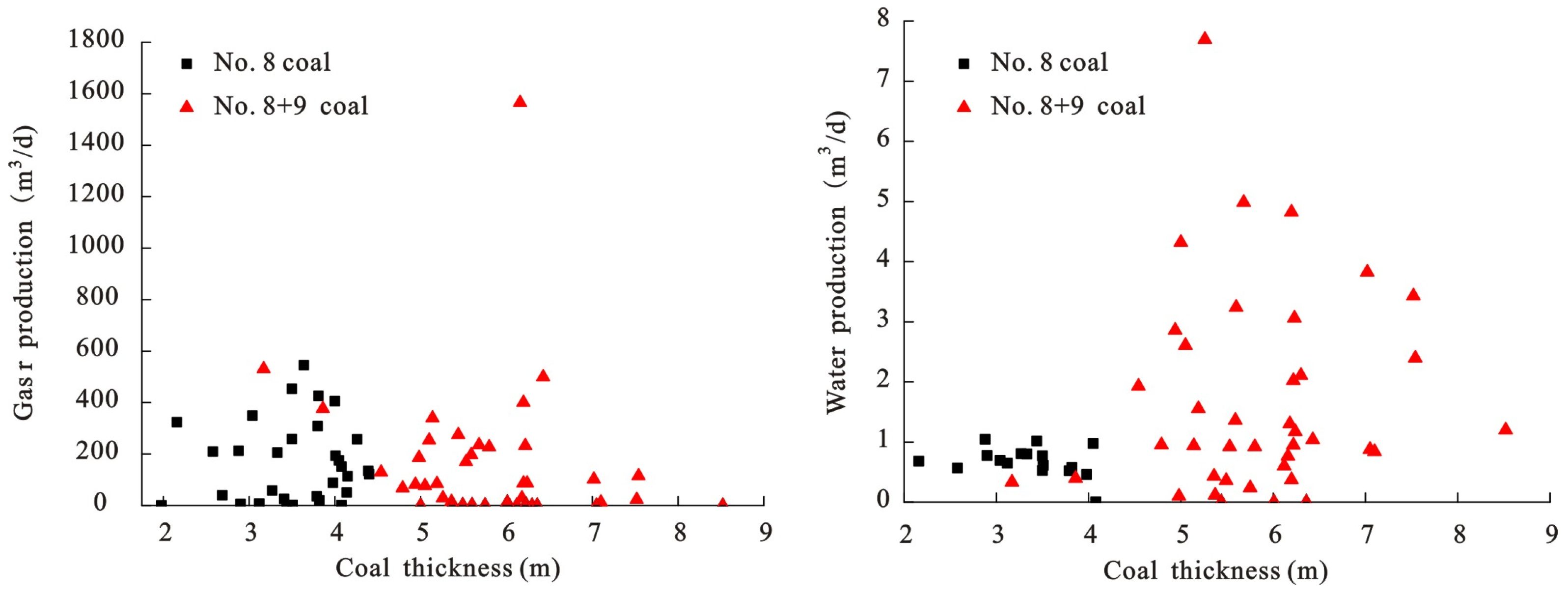

4.3. Coal Thickness

4.4. Buried Depth

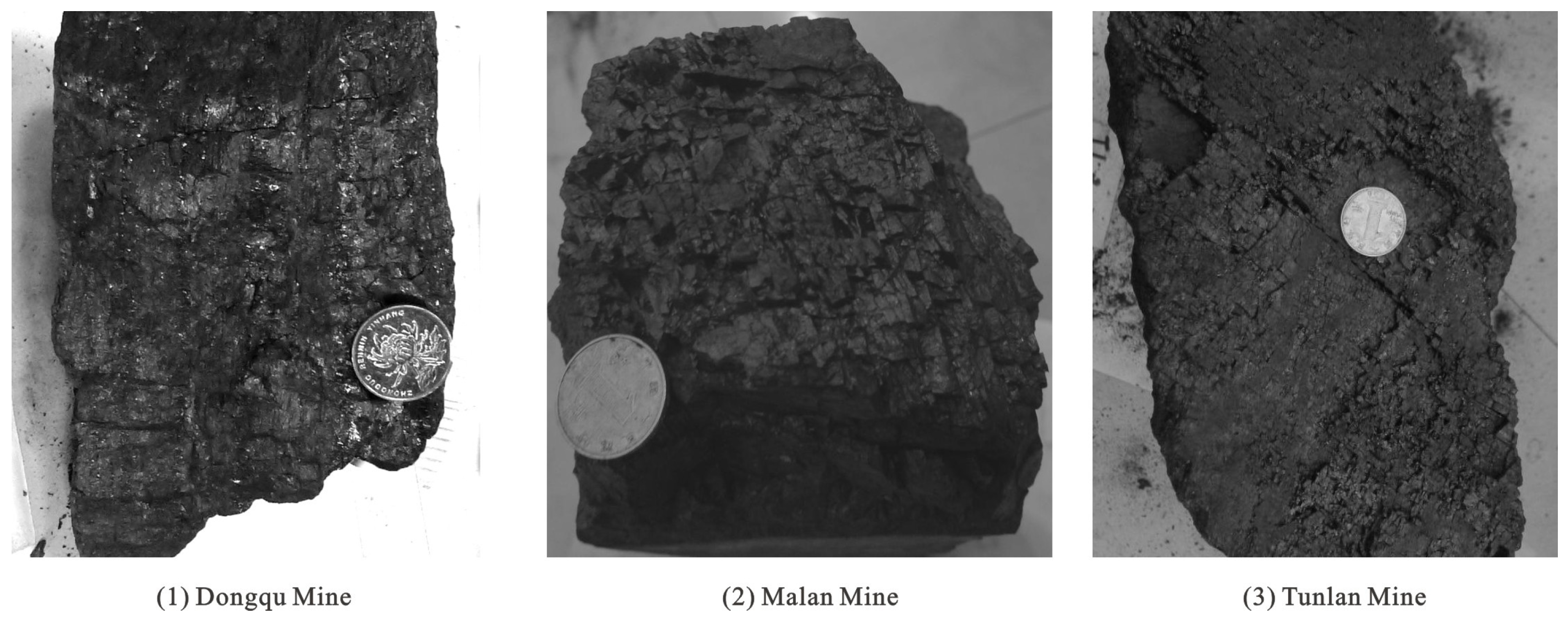

4.5. Porosity and Permeability

4.6. Gas Content and Desorption Characteristics

5. Development Suggestions

6. Conclusions

- (1)

- Coalbed methane resources are abundant in Gujiao Block and the exploration degree is high. The average gas production in this region is less than 1000 m3/d, and that for some wells is even less than 200 m3/d. The average water production is less than 10 m3/d, and that for some wells is even less than 1 m3/d. These wells can be classified as low-gas-production and low-water-production wells.

- (2)

- A series of large faults developed in the central and eastern part of the study area, and CBM wells nearby produce more water, but less gas. The salinity of the water discharged from the CBM wells ranges from 810.34 to 3115.48 mg/L and increases from north to south. This trend is the same as that of gas content distribution. Coal thickness and buried depth have little effect on gas production, but have some effects on water production. The endogenous fracture system in coal reservoirs is extremely developed and the porosity and permeability of reservoirs are low, which is not conducive to the migration and recovery of coalbed methane. The adsorption capacity of coal samples is strong. However, due to the continuous uplift and erosion from the middle Yanshanian to the Himalayan region, it is not conducive to the preservation and enrichment of coalbed methane. In addition, a series of large faults and the broken coal structure in this region lead to the escape of a large amount of coalbed methane.

- (3)

- In the southern study area, the Xingjiashe area is located in the core of the syncline, and the fault is not developed. The groundwater in this area is retained, which is conducive to the enrichment and preservation of CBM. This area may be a favorable area for CBM mining.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.H. Analysis on the present situation and prospect of CBM exploration and development in Gujiao. World Nonferrous Met. 2017, 7, 95–96+98. [Google Scholar]

- Yan, T.; He, S.; Bai, Y.; He, Z.; Liu, D.; Zeng, F.; Chen, X.; Fu, X. A study on the heterogeneity characteristics of geological controls on coalbed methane accumulation in Gujiao coalbed methane field, Xishan Coalfield, China. Geofluids 2021, 2021, 6629758. [Google Scholar] [CrossRef]

- Qin, Y.; Yuan, L.; Hu, Q.T.; Ye, J.P.; Hu, A.M.; Shen, B.H.; Cheng, Y.P.; He, X.Q.; Zhang, S.A.; Li, G.F.; et al. Status and Development Orientation of Coal Bed Methane Exploration and Development Technology in China. Coal Sci. Technol. 2012, 40, 1–6. [Google Scholar]

- Liu, H.L.; Wang, H.Y.; Zhao, G.L.; Li, G.Z.; Yang, F.; Liu, H.J. Influence of the tectonic thermal events in Yanshan Epoch on coalbed methane enrichment and high productivity in Xishan Coal Field in Taiyuan. Nat. Gas Ind. 2005, 25, 29–32, (In Chinese with an English abstract). [Google Scholar]

- Wang, B.; Jiang, B.; Guo, Z.B.; Liu, H.L.; Wang, H.Y.; Li, G.Z.; Zhao, Q. Coalbed methane reservoir-forming characteristics of Xishan coalfield, Qinshui basin. Nat. Gas Geosci. 2007, 18, 565–567, (In Chinese with an English abstract). [Google Scholar]

- Wang, G.; Qin, Y.; Xie, Y.W.; Shen, J.; Zhao, L.; Huang, B.; Zhao, W.Q. Coalbed methane system potential evaluation and favourable area prediction of gujiao blocks, Xishan Coalfield, based on multi-level fuzzy mathematical analysis. J. Pet. Sci. Eng. 2018, 160, 136–151. [Google Scholar] [CrossRef]

- Wang, G.; Qin, Y.; Xie, Y.W.; Wang, Z.W.; Wang, B.Y.; Wang, Q.; Zhang, X.Y. Cyclic Characteristics of the Physical Properties of Key Strata in CBM Systems Controlled by Sequence Stratigraphy―An Example from the Gujiao Block. Acta Geol. Sin. (Engl. Ed.) 2020, 94, 444–455. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, Z.; Bai, J.P.; Liu, D.H.; Tian, Y.D. Source apportionment of produced-water and feasibility discrimination of commingling CBM production from wells in Southern Qinshui Basin. J. China Coal Soc. 2014, 39, 1892–1898. [Google Scholar]

- Qin, Y.; Shen, J.; Shen, Y.L. Joint mining compatibility of superposed gasbearing systems: A general geological problem for extraction of three natural gases and deep CBM in coal series. J. China Coal Soc. 2016, 41, 14–23, (In Chinese with an English Abstract). [Google Scholar]

- Li, Z.; Liu, D.; Wang, Y.; Si, G.; Cai, Y.; Wang, Y. Evaluation of multistage characteristics for coalbed methane desorption-diffusion and their geological controls: A case study of the northern Gujiao Block of Qinshui Basin, China. J. Pet. Sci. Eng. 2021, 204, 108704. [Google Scholar] [CrossRef]

- Shao, X.J.; Tang, D.Z.; Wang, C.F.; Shang, D.Z.; Sun, Y.B.; Xu, H. Productivity mode and control factors of coalbed methane wells: A case from Hancheng region. J. China Coal Soc. 2013, 38, 271–276, (In Chinese with an English Abstract). [Google Scholar]

- Kaiser, W.R.; Hamilton, D.S.; Scott, A.R.; Tyler, R.J.; Finley, R.J. Geological and hydrological controls on the producibility of coalbed methane. J. Geol. Soc. 1994, 151, 417–420. [Google Scholar] [CrossRef]

- Sang, S.X.; Liu, H.H.; Li, Y.M.; Li, M.X.; Li, L. Geological controls over coal-bed methane well production in southern Qinshui basin. Procedia Earth Planet. Sci. 2009, 1, 917–922. [Google Scholar] [CrossRef]

- Pashin, J.C. Variable gas saturation in coalbed methane reservoirs of the Black Warrior Basin: Implications for exploration and production. Int. J. Coal Geol. 2010, 82, 135–146. [Google Scholar] [CrossRef]

- Tao, S.; Tang, D.Z.; Xu, H.; Lv, Y.M.; Zhao, X.L. Analysis on influence factors of coalbed methane wells productivity and development proposals in southern Qinshui Basin. J. China Coal Soc. 2011, 36, 194–198. [Google Scholar]

- Zhang, P.H.; Liu, Y.H.; Wang, Z.X.; Liu, N.N. Geological Factors of Production Control of CBM Well in South Qinshui Basin. Nat. Gas Geosci. 2011, 22, 909–914. [Google Scholar]

- Lv, Y.M.; Tang, D.Z.; Xu, H.; Luo, H.H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96, 93–108. [Google Scholar] [CrossRef]

- Zhao, S.L.; Zhu, Y.M.; Cao, X.K.; Wang, H.M.; Zhou, Y. Control Mechanism and Law of Geological Structure Affected to Production Capacity of Coal Bed Methane Well. Coal Sci. Technol. 2012, 9, 108–111. [Google Scholar]

- Liu, S.Q.; Sang, S.X.; Li, M.X.; Liu, H.H.; Huang, H.Z.; Zhang, J.F.; Xu, H.J. Key geologic factors and control mechanisms of water production and gas production divergences between CBM wells in Fanzhuang block. J. China Coal Soc. 2013, 38, 277–283. [Google Scholar]

- Tao, S.; Tang, D.Z.; Xu, H.; Gao, L.J.; Fang, Y. Factors controlling high-yield coalbed methane vertical wells in the Fanzhuang Block, Southern Qinshui Basin. Int. J. Coal Geol. 2014, 134, 38–45. [Google Scholar] [CrossRef]

- Li, T.; Wu, C.F.; Liu, Q. Characteristics of coal fractures and the influence of coal facies on coalbed methane productivity in the South Yanchuan Block, China. J. Nat. Gas Sci. Eng. 2015, 22, 625–632. [Google Scholar] [CrossRef]

- Shen, J.; Qin, Y.; Li, Y.P.; Yang, Y.H.; Ju, W.; Yang, C.L.; Wang, G. In situ stress field in the FZ Block of Qinshui Basin, China: Implications for the permeability and coalbed methane production. J. Pet. Sci. Eng. 2018, 170, 744–754. [Google Scholar] [CrossRef]

- Kang, J.Q.; Fu, X.H.; Gao, L.; Liang, S. Production profile characteristics of large dip angle coal reservoir and its impact on coalbed methane production: A case study on the Fukang west block, southern Junggar Basin, China. J. Pet. Sci. Eng. 2018, 171, 99–114. [Google Scholar] [CrossRef]

- Su, X.; Wang, Q.; Feng, Y.; Wang, X.; Ji, C. Low-Yield Genesis of Coalbed Methane Stripper Wells in China and Key Technologies for Increasing Gas Production. ACS Omega 2022, 7, 3262–3276. [Google Scholar] [CrossRef]

- Pan, S.; Cheng, B. Sedimentary Environment of Taiyuan Xishan Coal Basin; Coal Industry Publishing House: Beijing, China, 1987. (In Chinese) [Google Scholar]

- Colmenares, L.B.; Zoback, M.D. Hydraulic fracturing and wellbore completion of coalbed methane wells in the Powder River Basin, Wyoming: Implications for water and gas production. AAPG Bull. 2007, 91, 51–67. [Google Scholar] [CrossRef]

- Chen, Z.H.; Wang, Y.B.; Yang, J.S.; Wang, X.H.; Chen, Y.P.; Zhao, Q.B. Influencing factors on coalbed methane production of single well: A case of Fanzhuang Block in the south part of Qinshui Basin. Acta Pet. Sin. 2009, 30, 409. [Google Scholar]

- Ayers, W.B. Coalbed gas systems, resources, and production and a review of contrasting cases from the San Juan and Powder River basins. AAPG Bull. 2002, 86, 1853–1890. [Google Scholar]

- Cai, Y.D.; Liu, D.M.; Yao, Y.; Li, J.Q.; Qiu, Y.K. Geological controls on prediction of coalbed methane of No. 3 coal seam in Southern Qinshui Basin, North China. Int. J. Coal Geol. 2011, 88, 101–112. [Google Scholar] [CrossRef]

- Song, Y.; Liu, H.L.; Hong, F.; Qin, S.F.; Liu, S.B.; Li, G.Z.; Zhao, M.J. Syncline reservoir pooling as a general model for coalbed methane (CBM) accumulations: Mechanisms and case studies. J. Pet. Sci. Eng. 2012, 88, 5–12. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Yan, T.T. Geological and hydrogeological controls on the accumulation of coalbed methane in the Weibei field, southeastern Ordos Basin. Int. J. Coal Geol. 2014, 121, 148–159. [Google Scholar] [CrossRef]

- Qin, Y.; Liang, J.S.; Shen, J.; Liu, Y.G.; Wang, C.W. Gas logging shows and gas reservoir types in tight sandstones and shales from southern of Qinshui basin. J. China Coal Soc. 2014, 39, 1559–1565. [Google Scholar]

- Su, X.B.; Lin, X.Y.; Zhao, M.J.; Song, Y.; Liu, S.B. The upper Paleozoic coalbed methane system in the Qinshui basin, China. AAPG Bull. 2005, 89, 81–100. [Google Scholar] [CrossRef]

- Pashin, J.C.; Ward, W.E.; Winston, R.B.; Chandler, R.V.; Bolin, D.E.; Richter, K.E.; Osborne, W.E.; Sarnecki, J.C. Regional Analysis of the Black Creek-Cobb Coalbed Methane Target Interval, Black Warrior Basin, Alabama; Alabama Geological Survey Bulletin: Tusculoosa, AL, USA, 1991. [Google Scholar]

- Jin, Z.K.; Zhang, X.X.; Zhao, K.Z.; Liu, R.H.; Wang, C.S. Control of Late Carboniferous-Early Permian sea level fluctuation on coal reservoir heterogeneity, Taiyuan, Shanxi. Pet. Explor. Dev. 2005, 31, 44–49. [Google Scholar]

- Wang, G.; Qin, Y.; Xie, Y.W. Geochemical Characteristics of Coal in the Taiyuan Formation in the Center and North of the Xishan Coalfield. Energies 2022, 15, 8025. [Google Scholar] [CrossRef]

- Wang, S.W.; Duan, L.X.; Zhang, M.; Chen, L.C.; Zhou, C.M. Coal Reservoir Evaluation Principle Technical Method and Application; China University of Geosciences Press: Wuhan, China, 2012. [Google Scholar]

- Bo, H.; Yong, Q.; Zhang, W.; Zheng, Q.; Shi, S.; Wang, G. Prediction of high-quality coalbed methane reservoirs based on the fuzzy gray model: An investigation into coal seam No. 8 in Gujiao, Xishan, North China. Energy Explor. Exploit. 2020, 38, 1054–1081. [Google Scholar] [CrossRef]

- Tian, L.; Cao, Y.; Chai, X.; Liu, T.; Feng, P.; Feng, H.; Zhou, D.; Shi, B.; Oestreich, R.; Rodvelt, G. Best practices for the determination of low-pressure/permeability coalbed methane reservoirs, Yuwu Coal Mine, Luan mining area, China. Fuel 2015, 160, 100–107. [Google Scholar] [CrossRef]

- Mo, R.H.; Zhao, J.; Wang, Y.F. Current Status and Prospect of Exploration and Development of Gujiao CBM Project. China Coalbed Methane 2012, 5, 3–7. [Google Scholar]

- Peng, C.; Zou, C.; Zhou, T.; Li, K.; Yang, Y.; Zhang, G.; Wang, W. Factors affecting coalbed methane (CBM) well productivity in the Shizhuangnan block of southern Qinshui basin, North China: Investigation by geophysical log, experiment and production data. Fuel 2017, 191, 427–441. [Google Scholar] [CrossRef]

- Zhang, P.H. Characteristics of main reservoir parameters influencing CBM development in China. Nat. Gas Geosci. 2008, 18, 880–884. [Google Scholar]

| CBM Wells of No. 8 + 9 Coal | Thickness (m) | Buried Depth (m) | AG (m3/d) | AW (m3/d) | CBM Wells of No. 8 Coal | Thickness (m) | Buried Depth (m) | AG (m3/d) | AW (m3/d) |

|---|---|---|---|---|---|---|---|---|---|

| M89-1 | 5.26 | 482.70 | 29.79 | 7.70 | M8-1 | 436.48 | 3.41 | 25.62 | 0.00 |

| M89-2 | 6.20 | 510.89 | 87.10 | 0.37 | M8-2 | 499.93 | 2.69 | 39.07 | 2.59 |

| M89-3 | 6.43 | 450.17 | 499.96 | 1.04 | M8-3 | 600.56 | 1.98 | 0.00 | 0.30 |

| M89-4 | 6.24 | 493.99 | 86.62 | 1.17 | M8-4 | 478.73 | 3.8 | 308.35 | 0.05 |

| M89-5 | 6.20 | 489.72 | 400.14 | 4.82 | M8-5 | 585 | 4.4 | 121.84 | 0.14 |

| M89-6 | 5.05 | 487.70 | 76.43 | 2.61 | M8-6 | 777.49 | 4.39 | 134.77 | 0.00 |

| M89-7 | 7.02 | 472.57 | 101.68 | 3.82 | M8-7 | 715.19 | 4.08 | 0.81 | 0.03 |

| M89-8 | 4.94 | 524.00 | 82.25 | 2.86 | M8-8 | 798.97 | 4.15 | 113.47 | 0.02 |

| M89-9 | 5.59 | 564.73 | 197.55 | 1.36 | M8-9 | 730.87 | 4.14 | 50.64 | 0.00 |

| M89-10 | 6.22 | 492.44 | 232.71 | 0.95 | M8-10 | 849.31 | 4 | 405.49 | 0.00 |

| M89-11 | 4.54 | 565.09 | 129.89 | 1.93 | M8-11 | 791.64 | 3.81 | 425.43 | 1.06 |

| M89-12 | 7.10 | 573.15 | 13.36 | 0.84 | M8-12 | 503.15 | 3.64 | 545.32 | 0.11 |

| M89-13 | 6.12 | 491.89 | 0.00 | 0.60 | M8-13 | 613.79 | 4.01 | 193.11 | 0.00 |

| M89-14 | 4.79 | 451.55 | 67.84 | 0.95 | M8-14 | 531.77 | 4.26 | 257.00 | 0.52 |

| M89-15 | 6.23 | 484.56 | 4.30 | 3.06 | M8-15 | 605.6 | 3.27 | 57.48 | 0.81 |

| M89-16 | 6.16 | 455.93 | 1564.97 | 0.76 | M8-16 | 655.09 | 4.08 | 150.74 | 0.00 |

| M89-17 | 7.54 | 451.86 | 115.36 | 2.39 | M8-17 | 642.9 | 4.05 | 175.23 | 0.98 |

| M89-18 | 5.36 | 560.11 | 15.24 | 0.43 | M8-18 | 707.05 | 3.33 | 205.28 | 0.80 |

| M89-19 | 5.60 | 481.85 | 2.40 | 3.24 | M8-19 | 709.13 | 3.5 | 453.43 | 0.52 |

| M89-20 | 8.52 | 459.88 | 0.00 | 1.20 | M8-20 | 686.99 | 3.98 | 87.78 | 0.46 |

| M89-21 | 6.30 | 487.85 | 0.00 | 2.11 | M8-21 | 547.26 | 3.51 | 2.48 | 0.61 |

| M89-22 | 5.19 | 448.72 | 85.40 | 1.55 | M8-22 | 650.36 | 3.5 | 258.07 | 0.77 |

| M89-23 | 6.18 | 498.14 | 29.17 | 1.30 | M8-23 | 695.95 | 2.58 | 209.19 | 0.57 |

| M89-24 | 5.49 | 511.17 | 2.11 | 0.36 | M8-24 | 577.53 | 3.82 | 20.31 | 0.57 |

| M89-25 | 7.52 | 502.53 | 22.80 | 3.43 | M8-25 | 679.8 | 3.79 | 35.20 | 0.52 |

| M89-26 | 6.22 | 554.34 | 0.00 | 2.02 | M8-26 | 695.8 | 2.16 | 323.11 | 0.68 |

| M89-27 | 5.37 | 498.54 | 0.23 | 0.12 | M8-27 | 702.04 | 3.04 | 348.92 | 0.69 |

| M89-28 | 5.68 | 530.14 | 235.21 | 4.98 | M8-28 | 655.5 | 3.12 | 6.25 | 0.65 |

| M89-29 | 4.98 | 501.89 | 186.25 | 0.10 | M8-29 | 656.04 | 2.88 | 212.21 | 1.04 |

| M89-30 | 6.01 | 463.21 | 11.66 | 0.00 | M8-30 | 618.94 | 3.44 | 1.18 | 1.01 |

| M89-31 | 5.44 | 543.01 | 275.01 | 0.00 | M8-31 | 603.44 | 2.9 | 5.11 | 0.77 |

| M89-32 | 6.36 | 462.07 | 0.00 | 0.00 | |||||

| M89-33 | 5.00 | 474.82 | 0.00 | 4.32 | |||||

| M89-34 | 3.86 | 636.15 | 376.59 | 0.40 | |||||

| M89-35 | 3.17 | 571.50 | 530.60 | 0.33 | |||||

| M89-36 | 7.05 | 447.45 | 0.00 | 0.88 | |||||

| M89-37 | 5.14 | 427.00 | 339.43 | 0.94 | |||||

| M89-38 | 5.10 | 840.41 | 253.57 | ||||||

| M89-39 | 5.75 | 525.55 | 1.40 | 0.24 | |||||

| M89-40 | 5.53 | 490.00 | 170.16 | 0.92 | |||||

| M89-41 | 5.80 | 469.59 | 227.57 | 0.92 |

| Sample | MCQ1 | MCQ2 | MCQ3 | MCQ4 | MCQ5 | MCQ6 | MCQ7 | MCQ8 | MCQ9 | MCQ10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Coal seam | 8 + 9 + 2 | 8 + 9 | 8 + 9 + 2 | 8 | 8 + 9 + 2 | 8 + 9 + 2 | 8 + 9 + 2 | 8 + 9 + 2 | 8 + 9 + 2 | 8 + 9 + 2 |

| PH | 8.1 | 8.4 | 8.4 | 8.6 | 8.2 | 8.5 | 8 | 8.3 | 8.6 | 8.1 |

| Hardness (mg/L) | 73.24 | 31.05 | 44.92 | 27.26 | 62.64 | 24.62 | 56.89 | 27.09 | 18.50 | 52.95 |

| TDS (mg/L) | 2605.99 | 3059.32 | 3115.48 | 2547.92 | 2953.04 | 2538.04 | 2714.76 | 1806.33 | 810.34 | 2192.57 |

| Conductivity (mv) | 2274.20 | 2551.42 | 2571.27 | 2267.46 | 2396.33 | 2164.38 | 2468.02 | 1613.16 | 895.48 | 1808.77 |

| F− (mg/L) | 1.12 | 3.05 | 1.32 | 4.74 | 3.02 | 3.94 | 1.05 | 6.25 | 8.52 | 3.64 |

| Cl− (mg/L) | 202.12 | 178.90 | 161.49 | 109.70 | 103.23 | 51.44 | 338.95 | 107.43 | 151.76 | 71.20 |

| Br− (mg/L) | 1.59 | 1.18 | 0.78 | 0.48 | 1.39 | 0.52 | 3.28 | 0.22 | 0.68 | 0.79 |

| HCO3− (mg/L) | 1720.99 | 2102.04 | 2164.85 | 1666.56 | 2102.04 | 1754.49 | 1666.56 | 1226.89 | 460.61 | 1599.56 |

| SO42− (mg/L) | 0.08 | 1.95 | 2.10 | 7.51 | 0.54 | 1.93 | 0.72 | 24.62 | 11.47 | 0.35 |

| Al3+ (mg/L) | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 |

| Ca2+ (mg/L) | 16.13 | 5.41 | 9.10 | 5.81 | 12.11 | 5.24 | 8.55 | 7.13 | 4.74 | 12.69 |

| Mg2+ (mg/L) | 8.01 | 4.26 | 5.39 | 3.09 | 7.87 | 2.80 | 8.63 | 2.25 | 1.62 | 5.16 |

| Na+ (mg/L) | 648.47 | 756.33 | 761.79 | 747.78 | 717.72 | 713.44 | 681.68 | 431.91 | 177.44 | 496.52 |

| K+ (mg/L) | 5.43 | 5.30 | 5.42 | 2.55 | 4.44 | 3.69 | 5.07 | 2.23 | 0.69 | 2.61 |

| δ18O (‰) | −10.62 | −10.78 | −10.26 | −10.57 | −11.66 | −11.34 | −10.05 | −11.08 | −11.77 | −11.22 |

| δD (‰) | −72.48 | −76.05 | −76.60 | −78.68 | −79.29 | −81.23 | −63.73 | −81.63 | −85.84 | −75.99 |

| Sample | D8-1 | D8-2 | M8-1 | T8-1 | T8-2 | X8 | Z8 | D9 | X9-4 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Wellfield | Dognqu | Dognqu | Malan | Tunlan | Tunlan | Xiqu | Zhenchengdi | Dognqu | Xiqu | |

| N2 Porosity (%) | 9.65 | 9.53 | 3.14 | 3.28 | 2.69 | - | - | - | - | |

| N2 Permeability (mD) | 1.14 | 0.19 | 0.89 | 0.31 | 1.31- | - | - | - | - | |

| Mercury injection porosity (%) | 5.72 | 4.07 | 4.3 | 5.22 | 5.19 | 3.67 | 4.2 | 5.62 | 6.04 | |

| Efficiency of mercury withdrawal (%) | 73.5 | 80.7 | 71.1 | 83.3 | 70.2 | 85.1 | 79.2 | 69.38 | 68.67 | |

| Pore ratio (%) | V1 | 17.64 | 16.82 | 25.78 | 20.18 | 10.38 | 10.85 | 20 | 13.54 | 13.45 |

| V2 | 9.22 | 7.48 | 6.8 | 2.98 | 10.84 | 4.07 | 5.63 | 14.79 | 14.86 | |

| V3 | 26.45 | 24.92 | 22.95 | 24.31 | 30.02 | 26.78 | 25.63 | 25 | 29.32 | |

| V4 | 46.69 | 50.78 | 44.48 | 52.52 | 48.76 | 58.31 | 48.73 | 46.46 | 44.18 | |

| Coal maceral (%) | V | 74.92 | 83.77 | 68.14 | 63.7 | 60.33 | 63.82 | 66.56 | 83.3 | 76.88 |

| I | 20.2 | 9.74 | 25.66 | 33.7 | 36.72 | 34.13 | 23.15 | 12.9 | 23.12 | |

| E | 0.65 | 0 | 0.88 | 0.74 | 0.33 | 0.34 | 0.64 | 0.19 | 0 | |

| M | 4.23 | 6.49 | 5.31 | 1.85 | 2.62 | 1.71 | 9.65 | 3.61 | 0 | |

| Ro,max (%) | 1.74 | 1.83 | 1.25 | 1.43 | 1.37 | 1.47 | 1.14 | 2.18 | 1.93 | |

| Sample | Well and Wellfield | Mad(%) | Aad(%) | VL (m3/t) | PL (MPa) | Notes | ||

|---|---|---|---|---|---|---|---|---|

| AD | DAF | AD | DAF | |||||

| M8-1 | Malan | 0.59 | 10.77 | 16.95 | 19.12 | 2.17 | 2.17 | From mine |

| D8-2 | Dongqu | 0.58 | 14.12 | 23.85 | 27.96 | 1.78 | 1.78 | |

| T8-2 | Tunlan | 0.53 | 10.96 | 20.06 | 22.67 | 1.87 | 1.87 | |

| X8 | Xiqu | 0.77 | 5.54 | 19.83 | 21.16 | 2.15 | 2.15 | |

| Z8 | Zhenchengdi | 0.45 | 7.97 | 18.4 | 20.09 | 2.33 | 2.33 | |

| X9-4 | Xiqu | 0.94 | 23.46 | 19.33 | 25.57 | 3.21 | 3.21 | |

| 8 | GJ-03 | 27.91 | 31.14 | 1.63 | 1.63 | Mo [39] | ||

| 9 | GJ-03 | 22.51 | 33.98 | 2.17 | 2.17 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Xie, Y.; Chang, H.; Du, L.; Wang, Q.; He, T.; Zhang, S. Characteristics and Geological Impact Factors of Coalbed Methane Production in the Taiyuan Formation of the Gujiao Block. Processes 2023, 11, 2000. https://doi.org/10.3390/pr11072000

Wang G, Xie Y, Chang H, Du L, Wang Q, He T, Zhang S. Characteristics and Geological Impact Factors of Coalbed Methane Production in the Taiyuan Formation of the Gujiao Block. Processes. 2023; 11(7):2000. https://doi.org/10.3390/pr11072000

Chicago/Turabian StyleWang, Gang, Yiwei Xie, Huizhen Chang, Liqiang Du, Qi Wang, Tao He, and Shuaiyi Zhang. 2023. "Characteristics and Geological Impact Factors of Coalbed Methane Production in the Taiyuan Formation of the Gujiao Block" Processes 11, no. 7: 2000. https://doi.org/10.3390/pr11072000

APA StyleWang, G., Xie, Y., Chang, H., Du, L., Wang, Q., He, T., & Zhang, S. (2023). Characteristics and Geological Impact Factors of Coalbed Methane Production in the Taiyuan Formation of the Gujiao Block. Processes, 11(7), 2000. https://doi.org/10.3390/pr11072000