Study on the Dynamic Characteristics of the Impact Loads in a Near-Wall Double-Cavitation Bubble Collapse

Abstract

1. Introduction

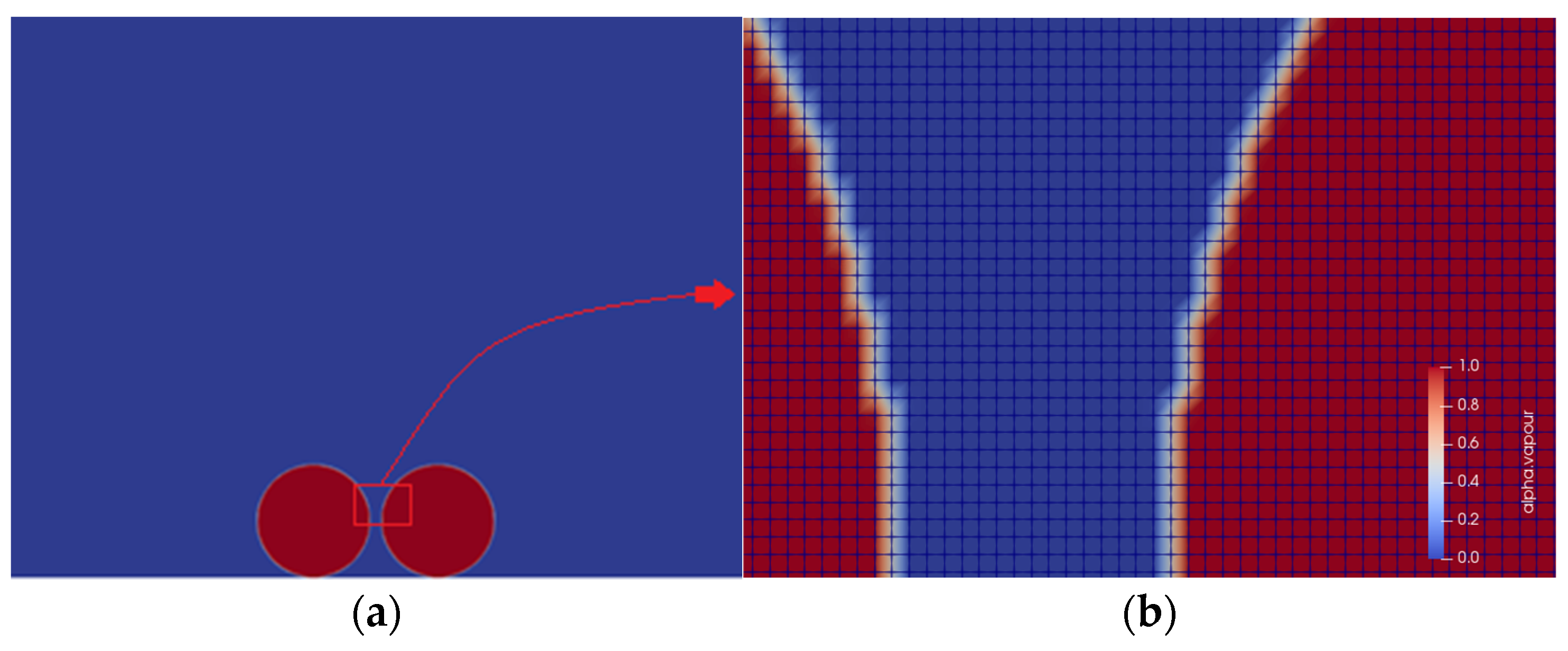

2. Materials and Methods

Verification of Grid Independence

3. Results

3.1. Experimental Validation of the Calculation Results of the Double-Cavitation Bubble Collapse Process

3.2. Velocity and Pressure Analysis of the Double-Cavitation Bubble Collapse Process

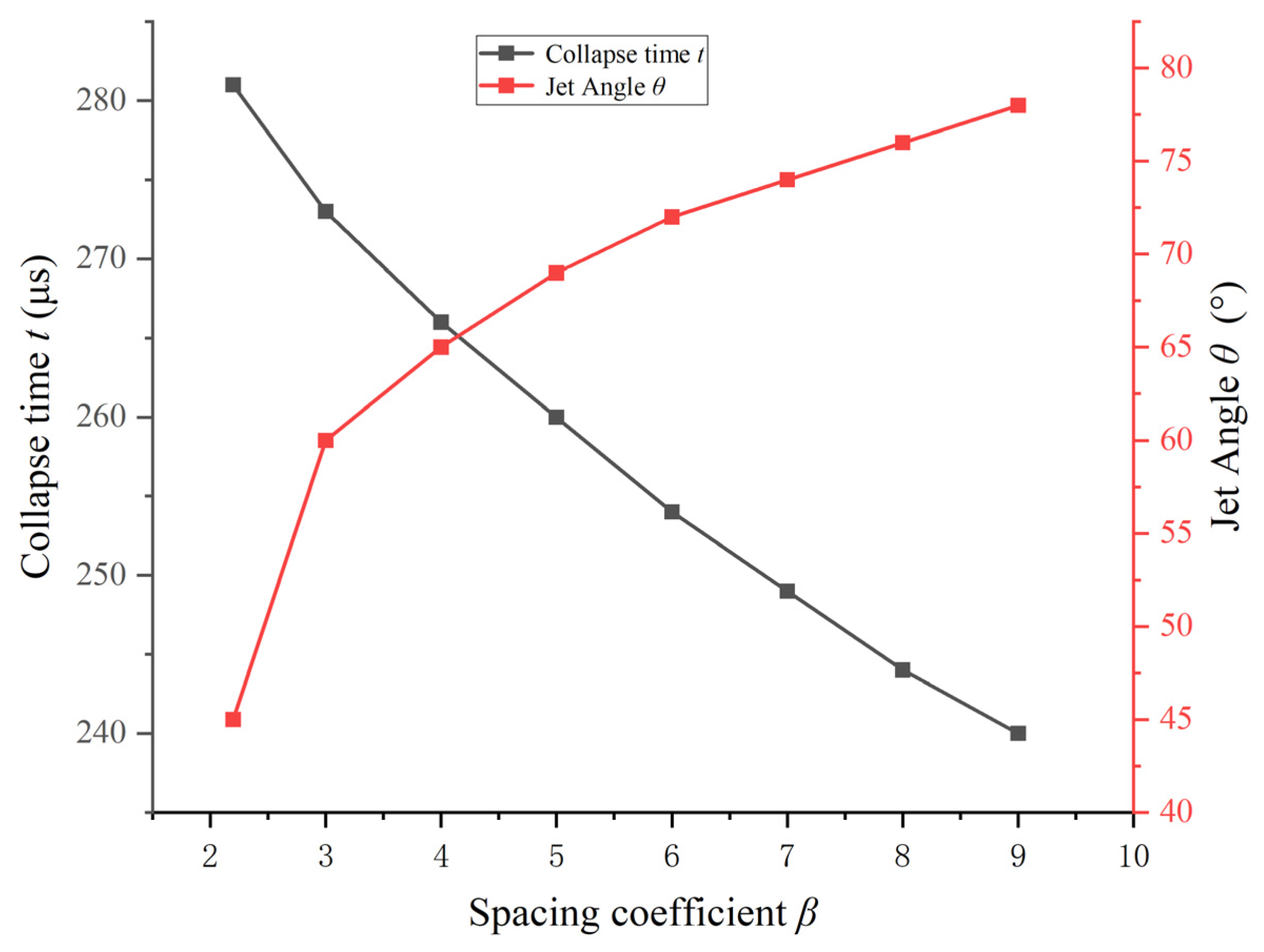

3.3. Relationship between the Cavitation Bubble Spacing Coefficient and the Collapse Time and Jet Angle

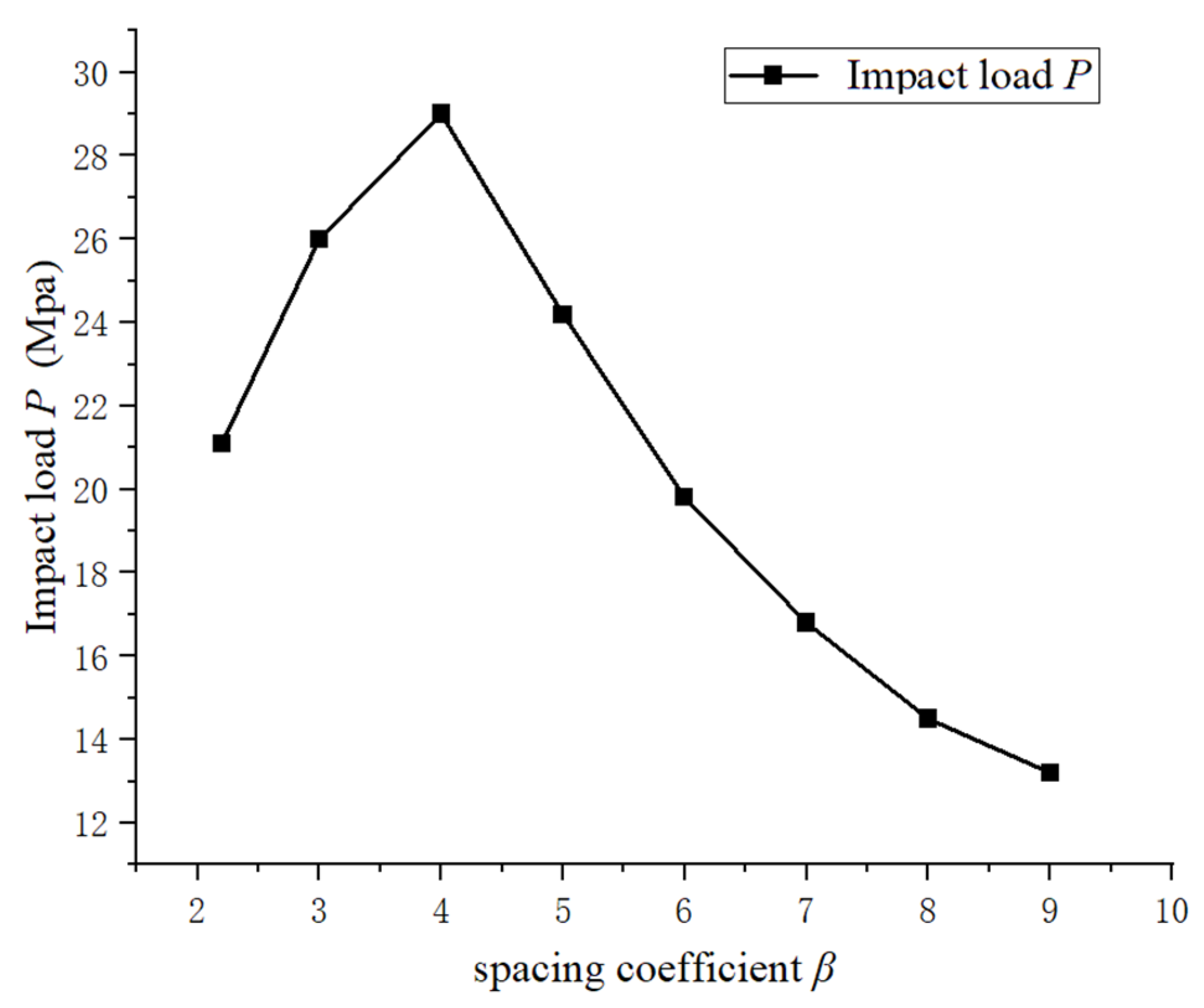

3.4. Relationship between the Cavitation Bubble Spacing Coefficient and the Wall Impact Load

3.5. Relationship between the Near-Wall Coefficient and the Collapse Time and Jet Angle

3.6. Relationship between the Near-Wall Coefficient and the Wall Impact Load

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kan, K.; Binama, M.; Chen, H.; Zheng, Y.; Zhou, D.; Su, W.; Muhirwa, A. Pump as turbine cavitation performance for both conventional and reverse operating modes: A review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Binama, M.; Kan, K.; Chen, H.-X.; Zheng, Y.; Zhou, D.; Su, W.-T.; Muhirwa, A.; Ntayomba, J. Flow instability transferability characteristics within a reversible pump turbine (RPT) under large guide vane opening (GVO). Renew. Energy 2021, 179, 285–307. [Google Scholar] [CrossRef]

- Kan, K.; Xu, Y.; Li, Z.; Xu, H.; Chen, H.; Zi, D.; Gao, Q.; Shen, L. Numerical study of instability mechanism in the air-core vortex formation process. Eng. Appl. Comput. Fluid Mech. 2023, 17, 2156926. [Google Scholar] [CrossRef]

- Li, W.; Li, Z.; Qin, Z.; Yan, S.; Wang, Z.; Peng, S. Influence of the solution pH on the design of a hydro-mechanical magneto-hydraulic sealing device. Eng. Fail. Anal. 2022, 135, 106091. [Google Scholar] [CrossRef]

- Liu, L.; Yao, X.; Zhang, A. Numerical analysis of the jet stage of bubble near a solid wall using a front tracking method. J. Phys. Fluids 2017, 29, 012105. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Z. A review of research progress in cavitating bubble boundary interactions. Nucl. Sci. Eng. 2022, 3, 42. [Google Scholar]

- Liu, D.; Liu, S.; Wu, Y.; Xu, H.; Zhang, M. Numerical simulation of turbine cavitation based on modified cavitation mass Transfer equation. J. Eng. Thermophys. 2011, 32, 4. [Google Scholar]

- Lauterborn, B.H.J.W. Experimental investigations of cavitation-bubble collapse in the neighbourhood of a solid boundary. J. Fluid Mech. 1975, 72, 391–399. [Google Scholar] [CrossRef]

- Shima, A.; Takayama, K.; Tomita, Y. Mechanisms of the bubble collapse near a solid wall and the induced impact pressure generation. Rep. Inst. High Speed Mech. Tohoku Univ. 1984, 48, 77–97. [Google Scholar]

- Philipp, A.; Lauterborn, W. Cavitation erosion by single laser-produced bubbles. J. Fluid Mech. 2000, 361, 75–116. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.; Shao, X. Analysis of pressure wave energy in Cavitation process. J. Aerodyn. 2020, 38, 8. [Google Scholar]

- Zhang, M.; Chen, X. Numerical study on the side-wall effect of single steam bubble collapse process. J. Shanghai Jiao Tong Univ. 2014, 48, 7. [Google Scholar]

- Nie, J.; Su, Y.; Yang, G. Numerical simulation of single cavity collapse and cavitation noise. Ordnance Ind. Autom. 2009, 28, 2. [Google Scholar]

- Liu, Y.; Peng, Y. Study on the Collapse Process of Cavitation Bubbles Including Heat Transfer by Lattice Boltzmann Method. J. Mar. Sci. Eng. 2021, 9, 219. [Google Scholar] [CrossRef]

- Gordoa, P.R.; Pickering, A. Ultrasonic Waves in Bubbly Liquids: An Analytic Approach. Mathematics 2021, 9, 1309. [Google Scholar] [CrossRef]

- Mancas, S.C.; Rosu, H.C. Cavitation of spherical bubbles: Closed-form, parametric, and numerical solutions. Phys. Fluids 2016, 28, 022009. [Google Scholar] [CrossRef]

- Ershkov, S.V.; Christianto, V.; Shamin, R.V.; Giniyatullin, A.R. About analytical ansatz to the solving procedure for Kelvin–Kirchhoff equations. Eur. J. Mech. Fluids 2020, 79, 87–91. [Google Scholar] [CrossRef]

- Li, W.; Li, Z.; Han, W.; Li, Y.; Yan, S.; Zhao, Q.; Chen, F. Measured viscosity characteristics of Fe3O4 ferrofluid in magnetic and thermal fields. Phys. Fluids 2023, 35, 012002. [Google Scholar] [CrossRef]

- Li, W.; Li, Z.; Han, W.; Li, Y.; Yan, S.; Zhao, Q.; Gu, Z. Pumping-velocity variation mechanisms of a ferrofluid micropump and structural optimization for reflow inhibition. Phys. Fluids 2023, 35, 052005. [Google Scholar]

- Tomita, Y.; Shima, A.; Ohno, T. Collapse of multiple gas bubbles by a shock wave and induced impulsive pressure. J. Appl. Phys. 1984, 56, 125–131. [Google Scholar] [CrossRef]

- Sagar, H. Dynamics of a cavitation bubble near a solid surface and the induced damage. J. Fluids Struct. 2020, 92, 102799. [Google Scholar] [CrossRef]

- Lu, J.; Wang, T.; Li, L.; Yin, Z.; Wang, R.; Fan, X.; Tan, D. Dynamic Characteristics and Wall Effects of Bubble Bursting in Gas-Liquid-Solid Three-Phase Particle Flow. Processes 2020, 8, 760. [Google Scholar] [CrossRef]

- Michna, J.; Rogowski, K. Numerical Study of the Effect of the Reynolds Number and the Turbulence Intensity on the Performance of the NACA 0018 Airfoil at the Low Reynolds Number Regime. Processes 2022, 10, 1004. [Google Scholar] [CrossRef]

- Dang, S. Influence of Impeller Tip Clearance on the Performance of Spiral Mixed-Flow Water Jet Propulsion Pump. Master’s thesis. Lanzhou University of Technology, Lanzhou, China, 2022. [CrossRef]

- Zhang, L.; Yin, Q.; Shao, X. Theoretical and numerical study of bubble collapse in water. Res. Prog. Hydrodyn. Ser. A 2012, 27, 6. [Google Scholar]

- Rayleigh, L. On the pressure developed in a liquid during the collapse of a spherical cavity. Philos. Mag. 1917, 34, 94–98. [Google Scholar] [CrossRef]

- Ma, Y.; Lin, S. Secondary Bjerknes Force and Its Influence on the Radiation Impedance of Coupled Bubbles. Acta Acust. United Acust. 2017, 103, 589–595. [Google Scholar] [CrossRef]

- Doinikov, A.A. Dissipative effects on Bjerknes forces between two bubbles. J. Acoust. Soc. Am. 1998, 102, 747–751. [Google Scholar] [CrossRef]

- Rabaud, D.; Thibault, P.; Raven, J.-P.; Hugon, O.; Lacot, E.; Marmottant, P. Manipulation of confined bubbles in a thin microchannel: Drag and acoustic Bjerknes forces. Phys. Fluids 2011, 23, 042003. [Google Scholar] [CrossRef]

| Case Number | Grid Quantity | |

|---|---|---|

| 1 | 148,800 | 0.11 |

| 2 | 820,800 | 0.095 |

| 3 | 1,359,300 | 0.09 |

| 4 | 2,032,800 | 0.089 |

| 5 | 2,430,000 | 0.089 |

| Cavitation Bubble Spacing Coefficient | β = 3 | β = 4 | β = 5 | β = 6 |

|---|---|---|---|---|

| t = 0 μs |  |  |  |  |

| t = 50 μs |  |  |  |  |

| t = 100 μs |  |  |  |  |

| t = 150 μs |  |  |  |  |

| t = 200 μs |  |  |  |  |

| t = 250 μs |  |  |  |  |

| Cavitation Bubble Spacing Coefficient | β = 7 | β = 8 | β = 9 |

|---|---|---|---|

| t = 0 μs |  |  |  |

| t = 50 μs |  |  |  |

| t = 100 μs |  |  |  |

| t = 165 μs |  |  |  |

| t = 220 μs |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, W.; Xu, Z.; Hao, Y.; Ren, J.; Li, W.; Gu, Z. Study on the Dynamic Characteristics of the Impact Loads in a Near-Wall Double-Cavitation Bubble Collapse. Processes 2023, 11, 1805. https://doi.org/10.3390/pr11061805

Han W, Xu Z, Hao Y, Ren J, Li W, Gu Z. Study on the Dynamic Characteristics of the Impact Loads in a Near-Wall Double-Cavitation Bubble Collapse. Processes. 2023; 11(6):1805. https://doi.org/10.3390/pr11061805

Chicago/Turabian StyleHan, Wei, Zitian Xu, Yingjian Hao, Jiale Ren, Wangxu Li, and Zhenye Gu. 2023. "Study on the Dynamic Characteristics of the Impact Loads in a Near-Wall Double-Cavitation Bubble Collapse" Processes 11, no. 6: 1805. https://doi.org/10.3390/pr11061805

APA StyleHan, W., Xu, Z., Hao, Y., Ren, J., Li, W., & Gu, Z. (2023). Study on the Dynamic Characteristics of the Impact Loads in a Near-Wall Double-Cavitation Bubble Collapse. Processes, 11(6), 1805. https://doi.org/10.3390/pr11061805