Abstract

Shale reserves have become an ever-increasing component of the world’s energy map. The optimal design of multi-well multi-stage fracturing (MMF) treatments is essential to the economic development of such resources. However, optimizing MMF treatments is a complex process. It requires geomechanical simulation, reservoir simulation, and automatic optimization. In this work, an integrated workflow is proposed to optimize MMF treatments in an unconventional reservoir, and the net present value (NPV) of reserves was treated as the objective function. The forward model consists of two submodels: a hydraulic fracturing model and a reservoir simulation model. The stochastic simplex approximation gradient (StoSAG) is used with the steepest ascent algorithm to maximize the NPV function. The computational results show that optimizing the fracture design can achieve a 20% higher NPV than that obtained with the field reference case. The drainage area of the optimal design is larger than that of the initial design. The maximum gas production rate increases from 23.75 MMSCF/day to 34.43 MMSCF/day and the maximum oil production rate increases from 497 STB/day to 692 STB/day. Therefore, new optimization paths can accelerate fracture design and help increase well production. This paper innovatively proposes a coupled workflow that can reduce the waste of manpower and improve the optimization results.

1. Introduction

Multi-well multi-stage fracturing (MMF) is an indispensable technique in developing unconventional resources economically [1]. Productivity can be dramatically increased by enlarging the contact area with reservoirs. However, MMF is a costly, resource-intensive, and potentially environmentally dangerous procedure. The costs of MMF consist of horizontal drilling costs, completion costs, and fracturing costs. The optimal design of MMF can maximize the net present value (NPV). The design variables include: (a) wellbore placement and lateral length; (b) completion strategies; (c) fracture spacing and fracture number; and (d) fracture geometry and conductivity [2].

Three kinds of methods have been applied to optimize MMF treatments. The first method refers to the single simulation of multiple fracture propagation. Wu and Olson developed a geo-mechanical simulator based on the simplified 3D displacement discontinuity method (DDM). Taking fluid partition as the objective function, they optimized the diameter and the number of perforations of each cluster with fixed fracture number and fracture spacing [3]. Li and Zhang derived the coupled geomechanics and fluid-heat-flow model to simulate a complex fracture network based on the finite element method and finite volume method. Taking the total hydraulically fractured area as the objective function, they optimized the following three parameters: (1) well spacing with fixed fracture number and fracture spacing of each well, (2) fracture spacing with fixed well spacing and stage length during simultaneous multifracture treatments, and (3) fracturing sequence with fixed fracture parameters [4]. Wang et al. built a fully coupled flow and mechanics model to simulate multiple fracture propagation based on the extended finite element method (XFEM). They took the fracture network area as the objective function and optimized the injection rate with fixed fracture spacing and number [5]. Liu et al. introduced a nonplanar fracture propagation model based on XFEM and optimized fracture spacing in sequentially and simultaneously fractured horizontal wells [6]. Liao et al. first investigated fracture propagation, when a horizontal wellbore is not co-linear, with the minimum horizontal principal stress [7]. Zhang et al. proposed a hybrid numerical approach combining the XFEM and phase-field model [8]. The fracture propagation in a naturally fractured formation can be characterized. By coupling the fracture propagation model and the proppant transportation model, Yang et al. developed a dynamic hydraulic fracturing model that considers proppant transport, proppant settling, and fracture propagation. In terms of single fracture, they optimized the proppant pumping schedule to improve the uniform proppant distribution within fractures [2]. Temporarily plugging staged fracturing in a horizontal well is simulated using a modified pore pressure cohesive zone model. The fracture propagation results of TPSF, influenced by the stress difference, cluster spacing, and number of perforation clusters, are presented [9].

The second category refers to performing reservoir simulation with given fracture geometry (i.e., fracture length, width, height, and conductivity) and comparing the production rate or NPV. Cipolla et al. evaluated the effects of fracture spacing, proppant distribution, and fracture conductivity on good performance based on a reservoir simulation study. They pointed out that adequate primary fracture conductivity, small fracture spacing, and large proppants typically improve Barnet horizontal wells’ recovery [10]. Based on reservoir simulation, Sahai et al. optimized horizontal well spacing concerning uniform/non-uniform fracture half-length and fracture spacing. Their study indicates that the longest repeated fracture half-length determines the optimal well number, while non-uniform fracturing spacing has negligible effects [11]. Saputelli et al. optimized fracture numbers with fixed horizontal well length based on reservoir simulation for a tight oil reservoir. Their study assumed known permeability, natural fracture distribution, and stress orientation. Moreover, they compared the optimization results between open-hole and cased completion [12]. Xu et al. proposed the fracturing design optimization surface considering the heterogeneity, hydraulic fracture turning, and induced secondary fracture. The relationships between fracturing treatment parameters and three optimization goals, including uniform fracture propagation, SRV, and NPV maximization, are investigated [13]. Yu and Sepehrnoori combined fracture-propagation modeling and reservoir simulation to optimize fracture numbers within a given stage length for shale gas reservoirs. They not only considered the nonplanar-fracture geometry with varying fracture width and permeability along fracture length, but also considered gas slippage, gas diffusion, and gas desorption effects [14,15].

The two optimization methods above are restricted to parametric sensitivity analysis with a single variable [16]. The two methods suffer from the following drawbacks. Firstly, sensitivity analysis is tedious, time-consuming, and non-automatic. Secondly, the optimization methods may reach a local optimal scenario. Therefore, the optimization method of the third category was proposed, which refers to coupling reservoir simulation with optimization methods to optimize MMF design. Holt combined reservoir simulation and a gradient-based optimization algorithm to optimize the displacement and number of fracturing stages with fixed wellbore length [17]. Ma et al. applied a hierarchical optimization framework to optimize horizontal well placement and uneven fracture spacing simultaneously. Genetic algorithm (GA), discrete simultaneous perturbation stochastic approximation (DSPSA), and finite difference (FD) were used in the study [18]. Recently, Rammay and Awotunde implemented differential evolution (DE) on reservoir simulation to optimize hydraulic fracturing parameters and horizontal well length. The fracture parameters, including fracture half-length, amount of proppant, and fracture spacing, are also optimized using the same method [19]. Xu et al. optimized the horizontal placement, fracture spacing, fracture conductivity, and the angle between the wellbore and fracture by coupling the embedded discrete fracture model (EDFM) and intelligent algorithms. The EDFM is capable of dealing with a complex fracture network [20]. The response surface methodology (RSM) and analysis of variance (ANOVA) are introduced to optimize the demulsification of water in heavy crude oil emulsions [21]. Wang and Chen applied a generalized differential evolution (GDE) algorithm to optimize well spacing, fracture spacing, fracture length, and fracture conductivity [22]. An optimization based on the third category methods can automatically compare the results of different designs and provide better optimization design. However, these studies applied uniform properties for all fractures and thus neglected the effects of varying fracture length and fracture width induced by fracture interaction on production performance.

In this work, an integral workflow is proposed to optimize MMF design. The proposed workflow combines fracture propagation modeling, reservoir simulation, and an intelligent algorithm. A geomechanical simulator is developed based on the displacement discontinuity method (DDM), which considers stress shadow effects, to model the fracture propagation process. Then, the overall fracture configuration and corresponding apertures generated from the geomechanical simulator are used as inputs into the CMG’s GEM (the Compositional and Unconventional Simulator developed by Computer Modelling Group LTD). The GEM uses a logarithmically spaced, locally refined, dual-permeability (LS-LR-DK) grid system to simulate fluid flow. The fractures are explicitly gridded, while CMG’s GEM allows for the consideration of a dual-permeability reservoir through the DK model. The combination of the geomechanical simulation and CMG’s GEM represents the complete forward model to calculate the NPV for any given set of optimization variables. The stochastic simplex approximation gradient (StoSAG) is used with the steepest ascent algorithm to maximize the NPV function. Finally, a conceptual model is calculated, and the optimization results robustly verify the feasibility of the integral workflow.

2. Methodology

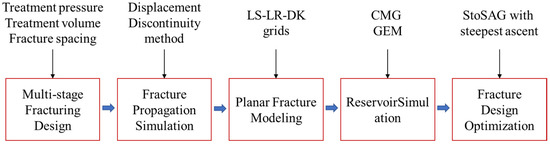

2.1. Introduction of the Workflow

As shown in Figure 1, the workflow begins with determining the design variables, which are treatment fluid volume, treatment pressure, and fracturing spacing. Then, the displacement discontinuity method (DDM) simulates multiple fracture propagation and obtains the overall fracture geometry. After that, a planar fracture model with logarithmically spaced local grid refinement is applied to simulate fluid flow within or around the resultant fractures, and reservoir simulation is performed in CMG’s GEM. Lastly, the steepest ascent algorithm combined with a simplex stochastic gradient is implemented to find the optimal design variables.

Figure 1.

Flow diagram of the integral workflow.

2.2. Optimization Problem

In this work, the net present value (NPV) of recoverable reserves is applied to evaluate the performance of different MMF designs. The NPV function is defined by:

where u is the D-dimensional vector containing all design variables. In the following conceptual case, the design variables include the treatment volume of each stage, the treatment pressure of each stage, and the fracture spacing of each well. In Equation (1), n denotes the nth time step of the simulation; Nt is the total number of time steps; △tn represents the length of the nth time step; b is the discount rate; ro and rg denote the selling price of oil and gas (in units of USD/STB and USD/MSCF, respectively); cw is the unit cost of the produced water purification (in the unit of USD/STB); and , , and , denote the average oil production rate, average gas production rate, and average water production rate of the jth horizontal well at the nth time step (in units of STB/day, MSCF/day, and STB/day), respectively. Cdrilling, and Ccompletion denote drilling costs and completion costs in USD.

The MMF optimization problem is defined as:

subject to:

where ui is the ith component of the design variable vector, and and are the lower and upper bounds for ui, respectively.

To improve the scaling of the optimization problem, all the design variables were scaled to the domain [0, 1] by mapping ui to vi using the following equation:

where vi denotes the transformed design variable corresponding to the variable, ui.

2.3. Cost Function

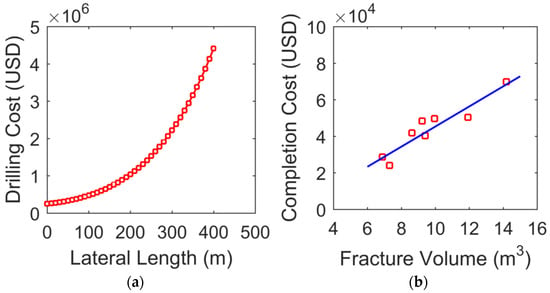

The cost function is affected by many factors, including operation cost, material cost, equipment investment, staff cost, etc. To simplify the optimization process, we considered the cost terms associated with optimization variables. The other cost terms are considered as a constant number and are not involved in the optimization process. The NPV function includes the drilling cost item and completion cost item. It is hard to derive the analytical cost function due to a large number of influencing factors. This work obtains the drilling cost function and the completion cost function based on the field data through regression methods. In this work, drilling cost is defined as a regression function of the lateral length and the horizontal well:

where Llateral denotes the lateral length of the horizontal well, m.

The completion cost (USD) is composed of the cost of purchasing the material (e.g., fracturing fluid or proppant) and the construction costs. The slick water completion cost is defined as a linear regression function of fracture volume (fracture width × fracture height × fracture length):

where Vfrac denotes the fracture volume per stage, m3.

In this work, treatment volume is treated as a design variable instead of the fracture volume. Thus, the relationship between these two items needs to be specified. For the given volume of fracturing fluid, the fracture volume is determined by the fluid leak-off rate. To simply this problem, treatment volume per stage, Qin (m3), is calculated by:

where α denotes the fluid injection coefficient, which is defined as the ratio of the actual fluid injection volume to the fracture volume. The coefficient α is determined by the fluid leak-off rate, which is highly influenced by treatment pressure [23]. Based on the estimation of the fluid injection coefficient for slick water fracturing from Cardium tight formation, the value of α is between 10 and 18, depending on the treatment pressure. The Cardium tight formation located at the Western Canadian Sedimentary Basin (WCSB) is one of the most prolific hydrocarbon-producing zones in North America. More information can be found in reference [22].

2.4. Displacement Discontinuity Method (DDM)

While searching for the optimal design variables, a large number of simulations need to be performed. Thus, the calculation cost of a single simulation should be reduced to facilitate the optimization. Several methods have been applied to simulate fracture propagation. The methods include the finite element method (FEM), the discrete element method (DEM), the extended finite element method (XFEM), and the displacement discontinuity method (DDM). By comparison, DDM presents the highest computational efficiency when dealing with multiple fracture propagation modeling. Only the fracture paths need to be discretized, and the fracture element number determines the dimension of the solution equations. The drawback of DDM is that it can only deal with a homogeneous reservoir. In this work, the model is treated as a homogeneous production zone.

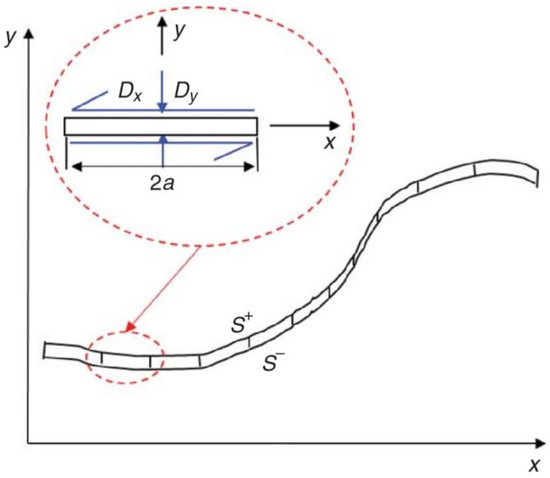

As shown in Figure 2, during fracture propagation, fractures will create an aperture of several millimeters. The fracture surface will squeeze the surrounding rock and create extra stresses (0–10 MPa), which is called the stress shadow effect. The stresses at a point, ξ, within an elastic region are integrals of displacements, △ui, over the boundary, S±, of the fracture region:

where the quantity, Eijk(ξ, η), is the tensor field that represents the influences of a concentrated force at the point, ξ, on displacements at the point, η. u+ and u− denote the displacement of the fracture surface. To solve Equation (8) efficiently, the boundary, S±, is divided into N planar elements. Based on the solution of Kelvin’s problem and the Green’s function approach, the analytical solution of a constant displacement discontinuity element in an infinite elastic solid has been derived successfully. Based on the principle of linear superposition, the stresses at arbitrary points can be calculated by combining the contributions of the displacement discontinuities of all elements.

Figure 2.

Illustration of a 2D boundary with crack-like geometry (S+ and S− denote the boundary of the fracture).

Generally, the boundary conditions of fracture surfaces and the model boundary are defined as stress or displacement conditions. In this paper, Equation (9) defines the remote and local stress boundary conditions [24]:

where pfrac denotes the fluid pressure within the fractures, MPa; denotes the normal stress induced by the remote formation crustal stresses, MPa; denotes the locally applied shear stress acting on fracture elements, MPa; and denotes the remote boundary shear stress induced by the remote formation crustal stresses, MPa; and △σn denotes the fracture net pressure, MPa.

For fracture propagation modeling, the normal and shear stress acting on an ith fracture element are known and are defined as and in Equation (10), respectively. By simultaneously solving the equation system in Equation (10), the shear and normal displacement discontinuities, and , at any element, j, can be computed.

Here, denotes the factors that account for the elastic–mechanical interaction between elements. is the plane-strain, elastic-influence coefficient matrix representing the normal stress at element, I, induced by a shear displacement discontinuity at element, j, and gives the normal stresses at element, i, because of an opening displacement discontinuity at element, j. We can attribute analogous meanings to and .

During hydraulic fracturing, vertical fracture propagation is typically contained by layered stress differences. Thus, the fracture height is finite. In this paper, the 3D aspects of displacement discontinuities induced by finite height fracture can be considered through the 3D correction factor, , derived by Olson [25]:

where dij denotes the distance between the center of the element i and element j, m; h is the fracture height, m; and α and β are empirically determined constants, where α = 1 and β = 2.3.

According to Olson [24], the stress intensity factors at the crack tips determine whether fractures propagate forward. Moreover, the opening mode and sliding shear mode stress intensity factors, KI and KII (MPa·m0.5), determine the fracture propagation direction at the next step. KI and KII can be calculated by use of the normal and shear displacement discontinuities at the crack tip element, Dn and Ds (m), respectively.

The fracture-propagation direction θ can be obtained by solving Equation (13) based on the maximum circumferential stress theory:

where θ is the counterclockwise positive angle from the in-plane propagation of the fracture ahead of the fracture edge. For pure opening mode (KI > 0 and KII = 0), we would predict the planar fracture propagation angle to be along θ = 0. For pure sliding mode (KI = 0 and KII 0), the strongest possible kink in the fracture direction occurs along θ = ±75° for positive or negative KII, respectively.

2.5. Planar Fracture Model

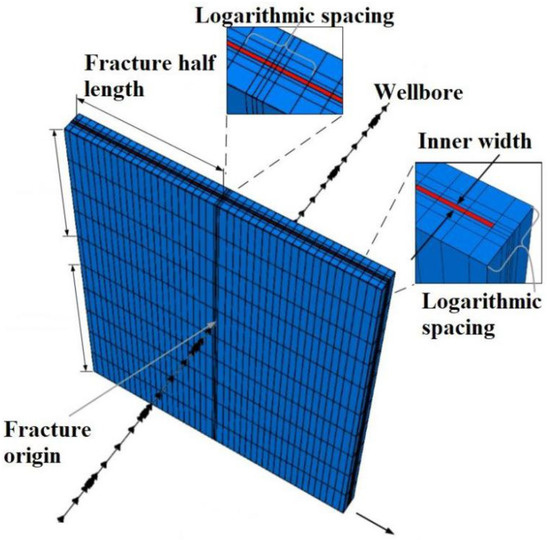

When performing reservoir simulation of MMF, it is important to consider production interference between multiple fractures, non-Darcy flow in fractures, and the variance of fracture length and conductivity between different fractures. CMG’s GEM, a commercial compositional simulator, is selected to perform reservoir simulation as it can consider non-Darcy flow, gas desorption/absorption effects, and the presence of natural fractures. Moreover, logarithmically spaced dual-permeability (DK) refinement LGR grids are applied within the stimulated reservoir volume (SRV). The standard DK girds are applied out of the SRV. Thus, the transient behavior of reservoir fluids from the matrix to fractures can be accurately modeled, and the influences of natural fractures can be considered [26]. Sierra et al. reported that the creation of planar fracture in shale reservoirs is more effective, while a complex fracture network is preferable only for formation with a permeability less than 10−7 μm2 [27]. Fracture configuration is highly influenced by the stress field and natural fracture properties, and the simulation of planar fracture is commonly performed in common fracture software, such as FracPT, Gohfer, and Meyer.

After obtaining the overall fracture configuration with our in-house geomechanical simulator, as shown in Figure 3, the planar fracture model is used in CMG’s GEM to perform reservoir simulation. The planar fracture is perpendicular to the wellbore. The fracture half-length, fracture height, and fracture permeability can be specified in CMG’s GEM.

Figure 3.

Sketch of a single fracture (the red line represents the fracture zone).

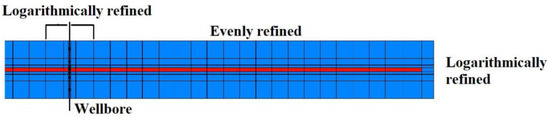

In the planar fracture model, logarithmically spaced local grid refinements are capable of accurately modeling multiple fractures and the transient behavior of gas/oil flow from a tight matrix to fractures. As shown in Figure 4, the grids intersecting with the wellbore are logarithmically refined in both directions to model fluids flowing into the wellbore and fracture more accurately. Other grids are logarithmically refined along the wellbore direction and evenly refined along the fracture length direction. The red fracture zone has a default width of 2 ft in CMG’s GEM, while the actual fracture width ranges from 0 to 10 mm under the ground. To use wide grids in CMG’s GEM to simulate an actual narrow fracture, it is assumed that the fracture conductivity of the actual fracture is equal to that of the red fracture zone used in CMG’s GEM, as shown in Figure 4. The effective permeability of the red fracture zone, keff, can be calculated by:

where kactual is the actual fracture permeability, 10−3 μm2. The actual fracture permeability is determined by the fracture width and proppant distribution. In this work, it is assumed that proppant is uniformly distributed in each whole open fracture. Based on the experimental results, fracture permeability is specified at 100 μm2. denotes the actual fracture width in mm, which is obtained from the geomechanical fracturing simulation. is the width of the red fracture zone, mm. The default value is 2 ft.

Figure 4.

Sketch of a single fracture (the red line represents the fracture zone).

2.6. The Steepest Ascent Algorithm Using StoSAG

The steepest ascent method using the stochastic simplex approximation gradient (StoSAG) is implemented to maximize the NPV function. According to Liu and Reynolds [28], StoSAG generally yields significantly better gradient approximations than the standard ensemble optimization (EnOpt) algorithm. The update equation for the set of optimization variables at iteration l is given by [28]:

where ul denotes the current estimation of the optimum step design vector; ul+1 denotes the updated design vector; αl denotes the step size; and dl denotes the search direction. In this work, the simplex gradient is used as the search direction.

The simplex gradient at iteration l is given by:

where Np is the number of random design variable perturbations, Np = 5; Ne is the number of random geological models, Ne = 1; mk, k = 1, 2, …, Ne, represents the kth reservoir model parameter vectors; and Ul,j,k denotes the random perturbation vector of design variables. The perturbation equals step size times gradient. The step size will change dynamically during each perturbation, and cut in half if the NPV does not increase. After five perturbations for each iteration, the current optimal design variables correspond to the maximum NPV of the five perturbations. In this work, we did not specify the convergence criterion. We specified the number of iterations as 50.

2.7. Presentation of Fracture Propagation Simulation and Reservoir Simulation

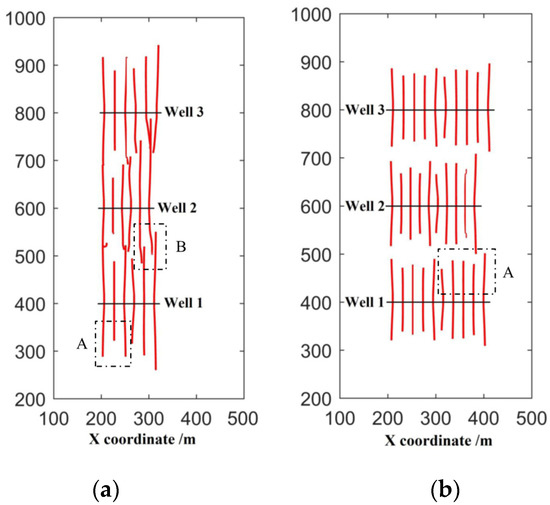

In this study, a geomechanical simulator based on DDM was developed to simulate multiple fracture propagation. Here, two cases with different numbers of fractures per stage are presented. Figure 5 shows that this geomechanical simulator can capture fracture interaction between closely spaced fractures and fracture hit effects between different wells. As shown in Region A in Figure 5, fractures propagate with divergency. This is because of the induced compression stresses from the closely open fractures. In Region B in Figure 5, fractures propagated appealing to each other. This is because of the induced shear stresses from the fracture shear displacements.

Figure 5.

Multiple fracture propagation geometry, showing (a) 3 fractures per stage and (b) 5 fractures per stage(Region A represents the fracture rejection, Region B represents the fracture attraction).

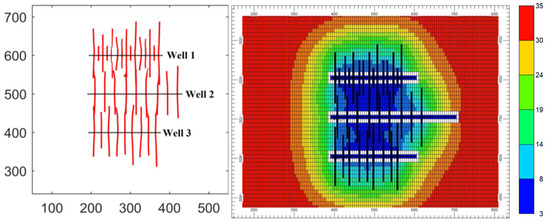

By combining the geomechanical simulator and CMG’s GEM (Figure 6), the fracture configuration of any set of design variables can be input into the reservoir simulation model to perform reservoir simulation. The non-planar fracture paths are discretized to many elements, so that the length is the sum of the elements, and accuracy can be guaranteed. The length of the planar fracture in the simulation is equal to the real length of the non-planar fracture, which can indicate the real contact surface. The NPV can be calculated after obtaining the oil/gas production rates.

Figure 6.

Fracture configuration (ft) and the corresponding pressure profile after reservoir simulation.

3. Case Study

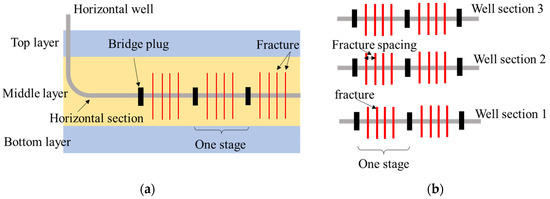

Based on the integral workflow developed above, this section presents a conceptual model and develops a typical shale reservoir with optimized parameters. As shown in Figure 7a, the horizontal well section is drilled in a single layer. The thickness of this layer is set as 20 m, and the effective length of this layer is about 300 m. The property variations of the layer can be neglected due to the small scale. Therefore, the middle layer is considered a homogeneous production zone. The horizontal section of the well is isolated by bridge plugs and stimulated stage by stage. In Figure 7b, three horizontal wells are located in the same middle layer with a certain well spacing. Well spacing is not a design variable and is specified as 200 m. During multi-well multi-stage fracturing (MMF), one horizontal well generally contains 6–15 fracturing stages. In this work, two fracturing stages are considered to save the simulation time. The proposed workflow is also suitable for multiple wells with multiple fracturing stages. Each stage has four fractures. The fracture propagation path is represented by red lines in Figure 5, Figure 6 and Figure 7. The geology properties of the model are simplified. The goal of this part is to verify the effectiveness of the integral methods.

Figure 7.

Sketch of MMF treatment. (a) Side view for one horizontal well; (b) top view for three horizontal well sections.

3.1. Reservoir Properties and Treatment Parameters

The domain of the reservoir is 1000 m × 1200 m. The vertical depth is 2900 m. The thickness of the middle layer is 20 m, and a fracture can be vertically opened through the entire thickness. The effective horizontal minimum stress is 20 MPa, and the effective horizontal maximum stress is 25 MPa. The depth of water–oil contact is 3000 m. The reservoir porosity is 0.11 for matrix and 0.001 for fracture. The permeability of the matrix is 5 × 10−5 μm2, and the effective permeability of fracture is 4 × 10−7 μm2.

The length of the horizontal section equals fracture spacing × 8 because each section has two stages and each stage has four fractures. After the fracture spacing is optimized, the length of the wellbore changes, which indicates that, effectively, the wellbore length is an implicit design variable [29]. In this model, there are three horizontal well sections, and each section has two stages. Thus, there are a total of six stages. The explicit design variables are the treatment fluid volume of each stage (6), the treatment pressure of each stage (6), and the fracturing spacing of each well (3). Therefore, there are 15 design variables. The lower and upper bounds of the treatment pressure per stage are set to 22–28 MPa. The lower and upper bounds of the treatment volume per stage are set to 400–4000 m3. The lower and upper bounds of the fracture spacing are set to 10–60 m. During optimization, each design variable will update between the lower and upper bounds.

3.2. Results

The drilling cost is determined by the lateral length of the horizontal well. The lateral length equals fracture spacing times fracture number. The value of the lateral length ranges from 100 to 300 m. The completion cost is determined by the material cost and the pumping cost. In this work, the completion cost is a linear regression function of fracture volume. According to Equations (5) and (6), the drilling and completion costs are shown in Figure 8.

Figure 8.

Drilling and completion cost calculation results. (a) The relationship between the drilling cost and the lateral length; (b) the relationship between the completion cost and the fracture volume.(the red box represents the real data and the blue line represents linear regression function of fracture volume).

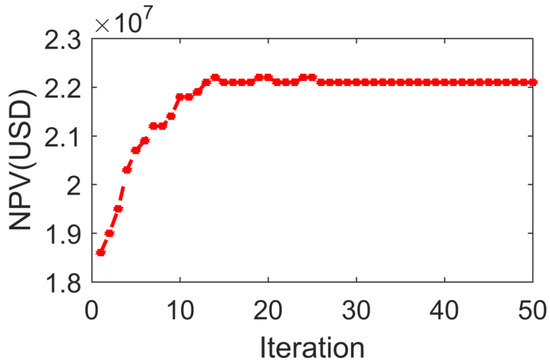

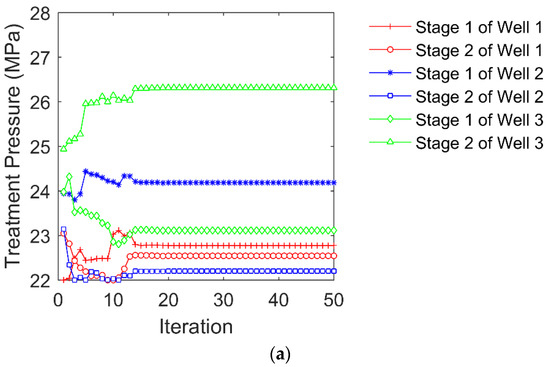

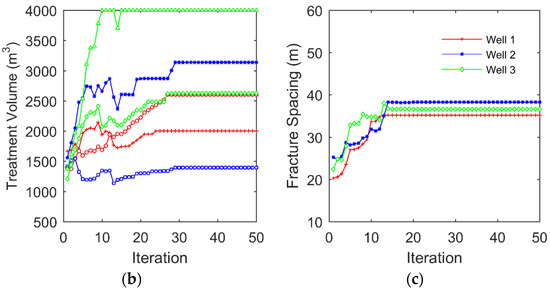

For the MMF optimization of the target wells, the initial conditions are derived from the offset wells. The reservoir properties can be regarded as the same values. Comparing the stimulation effects of the offset wells, the initial design is obtained and a good initial design will reduce the optimization cost. As shown in Figure 9, the maximum NPV is obtained after 30 iterations, and the NPV function increases to 22.06 × 106 USD from 18.6 × 106 USD, with an increasing percentage of 18.6%. Figure 10 presents the updating process of the design variables. It shows that: the treatment pressure of each stage reaches the optimal value after 13 iterations, ranging from 22 MPa to 26 MPa; the treatment volume of each stage reaches the optimal value after 30 iterations, ranging from 1000 to 4000 m3; and the fracture spacing of each well reaches the optimal value after 14 iterations, ranging from 35 to 38 m. Overall, only the treatment volume of the second stage of the second well has the optimal value at the upper bound.

Figure 9.

NPV vs. iteration.

Figure 10.

Design variable updating: (a) for the treatment pressure per stage; (b) for the treatment volume per stage; and (c) for the fracture spacing per well.

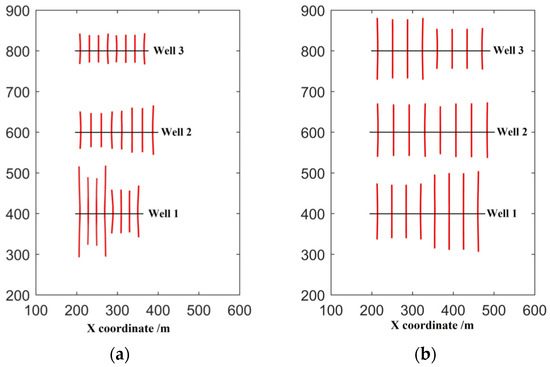

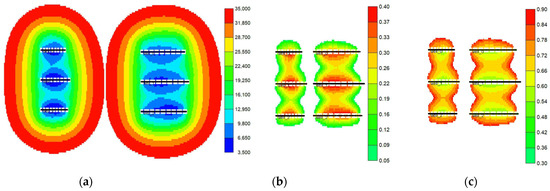

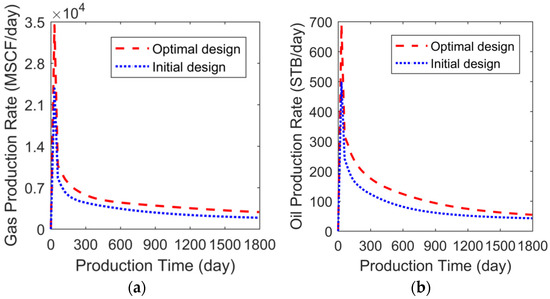

Figure 11 presents the initial and optimal fracture geometry. By comparing the results, we can see that the fracture spacing increases to avoid strong fracture interaction, and the fracture length increases to control larger reservoir volume. As shown in Figure 12, the drainage area of the optimal design is larger than that of the initial design. As shown in Figure 13, comparing the production rate between the initial design and the optimal design, the maximum gas production rate increases from 23.75 MMSCF/day to 34.43 MMSCF/day; the maximum oil production rate increases from 497 STB/day to 692 STB/day.

Figure 11.

The overall fracture geometry: (a) for the initial design; (b) for the optimal design.

Figure 12.

Profile comparison of the reservoir simulation results between the initial and optimal designs. (a) Pressure profile; (b) gas saturation profile; (c) oil saturation profile.

Figure 13.

Comparison of the production rate between the initial design and the optimal design. (a) Gas production rate comparison; (b) oil production rate comparison.

4. Conclusions

- An integrated workflow is developed to optimize the MMF design in shale reservoirs. The workflow combines the DDM, LS-LR-DK grid system, CMG’s GEM, and the steepest ascent algorithm using the StoSAG search method.

- The DDM method satisfies the computation speed for multiple fracture propagation simulations because only the fracture paths need to be discretized.

- The planar fracture model can accurately model the transient behavior of reservoir fluids from the matrix to fractures. The grids intersecting with the wellbore are logarithmically refined in both directions to model fluids flowing into the wellbore and fracture more accurately.

- The StoSAG search method can efficiently find the optimal solution under high-dimension space. StoSAG generally yields significantly better gradient approximations than the standard ensemble optimization (EnOpt) algorithm.

- The computational results show that the optimization of the fracture design for the conceptual model can achieve a nearly 20% higher NPV score than the one obtained with the field case. This work presents a complete and feasible solution to optimize MMF design.

Author Contributions

Conceptualization, B.W., Y.F. and Z.L.; methodology, B.W., Y.F. and Z.L.; software, B.W., L.L. and Z.L.; validation, B.W., L.L. and Z.L.; formal analysis, B.W., Y.F. and Z.L.; investigation, B.W.; resources, Y.F.; writing—original draft, B.W. and Z.L.; writing—review and editing, B.W., L.L. and Z.L.; visualization, B.W. and Z.L.; supervision, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financially supported by the Research Foundation of China University of Petroleum-Beijing at Karamay (NO. XQZX20210001), National Natural Science Foundation of China (No. 52104011), Natural Science Foundation of Xinjiang Uygur Autonomous Region (NO. 2022D01B77), Karamay Innovative Environment Construction Plan (Innovative talents) project (NO. 20232023hjcxrc0037).

Data Availability Statement

The data is unavailable due to privacy.

Conflicts of Interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

References

- Li, H.; Misra, S. Assessment of Miscible Light-Hydrocarbon-Injection Recovery Efficiency in Bakken Shale Formation Using Wireline-Log-Derived Indices. Mar. Pet. Geol. 2018, 89, 585–593. [Google Scholar] [CrossRef]

- Yang, S.; Siddhamshetty, P.; Kwon, J.S.-I. Optimal Pumping Schedule Design to Achieve a Uniform Proppant Concentration Level in Hydraulic Fracturing. Comput. Chem. Eng. 2017, 101, 138–147. [Google Scholar] [CrossRef]

- Wu, K.; Olson, J.E. Mechanisms of Simultaneous Hydraulic-Fracture Propagation From Multiple Perforation Clusters in Horizontal Wells. SPE J. 2016, 21, 1000–1008. [Google Scholar] [CrossRef]

- Li, S.; Zhang, D. A Fully Coupled Model for Hydraulic-Fracture Growth During Multiwell-Fracturing Treatments: Enhancing Fracture Complexity. SPE Prod. Oper. 2018, 33, 235–250. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Wang, H.; Liu, H.; Wu, H. Comparison of Consecutive and Alternate Hydraulic Fracturing in Horizontal Wells Using XFEM-Based Cohesive Zone Method. J. Pet. Sci. Eng. 2016, 143, 14–25. [Google Scholar] [CrossRef]

- Liu, C.; Wang, X.; Deng, D.; Zhang, Y.; Zhang, Y.; Wu, H.; Liu, H. Optimal Spacing of Sequential and Simultaneous Fracturing in Horizontal Well. J. Nat. Gas Sci. Eng. 2016, 29, 329–336. [Google Scholar] [CrossRef]

- Liao, S.; Hu, J.; Zhang, Y. Investigation on the Influence of Multiple Fracture Interference on Hydraulic Fracture Propagation in Tight Reservoirs. J. Pet. Sci. Eng. 2022, 211, 110160. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, H.; Xu, W.; Lv, C.; Micheal, M.; Shi, F.; Wu, H. A Hybrid Numerical Approach for Hydraulic Fracturing in a Naturally Fractured Formation Combining the XFEM and Phase-Field Model. Eng. Fract. Mech. 2022, 271, 108621. [Google Scholar] [CrossRef]

- Li, J.; Dong, S.; Hua, W.; Li, X.; Guo, T. Numerical Simulation of Temporarily Plugging Staged Fracturing (TPSF) Based on Cohesive Zone Method. Comput. Geotech. 2020, 121, 103453. [Google Scholar] [CrossRef]

- Cipolla, C.L.; Lolon, E.P.; Mayerhofer, M.J.; Warpinski, N.R. Fracture Design Considerations in Horizontal Wells Drilled in Unconventional Gas Reservoirs. In Proceedings of the All Days, The Woodlands, TX, USA, 19 January 2009; SPE: The Woodlands, TX, USA, 2009; p. SPE-119366-MS. [Google Scholar]

- Sahai, V.; Jackson, G.; Rai, R. Effect of Non-Uniform Fracture Spacing and Fracture Half-Length on Well Spacing for Unconventional Gas Reservoirs. In Proceedings of the All Days, London, UK, 10 June 2013; SPE: London, UK, 2013; p. SPE-164927-MS. [Google Scholar]

- Saputelli, L.; Lopez, C.; Chacon, A. Mohammed Soliman Design Optimization of Horizontal Wells with Multiple Hydraulic Fractures in the Bakken Shale. In Proceedings of the Day 2 Wed, Vienna, Austria, 26 February 2014; SPE: Vienna, Austria, 2014; p. D021S018R003. [Google Scholar]

- Xu, S.; Guo, J.; Feng, Q.; Ren, G.; Li, Y.; Wang, S. Optimization of Hydraulic Fracturing Treatment Parameters to Maximize Economic Benefit in Tight Oil. Fuel 2022, 329, 125329. [Google Scholar] [CrossRef]

- Yu, W.; Wu, K.; Sepehrnoori, K. A Semianalytical Model for Production Simulation From Nonplanar Hydraulic-Fracture Geometry in Tight Oil Reservoirs. SPE J. 2016, 21, 1028–1040. [Google Scholar] [CrossRef]

- Yu, W.; Hu, X.; Wu, K.; Sepehrnoori, K.; Olson, J.E. Coupled Fracture-Propagation and Semianalytical Models To Optimize Shale Gas Production. SPE Reserv. Eval. Eng. 2017, 20, 1004–1019. [Google Scholar] [CrossRef]

- Liu, Z.; Forouzanfar, F. Ensemble Clustering for Efficient Robust Optimization of Naturally Fractured Reservoirs. Comput. Geosci. 2018, 22, 283–296. [Google Scholar] [CrossRef]

- Holt, S. Numerical Optimization of Hydraulic Fracture Stage Placement in a Gas Shale Reservoir. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 7 December 2011. [Google Scholar]

- Ma, X.; Gildin, E.; Plaksina, T. Efficient Optimization Framework for Integrated Placement of Horizontal Wells and Hydraulic Fracture Stages in Unconventional Gas Reservoirs. J. Unconv. Oil Gas Resour. 2015, 9, 1–17. [Google Scholar] [CrossRef]

- Rammay, M.H.; Awotunde, A.A. Stochastic Optimization of Hydraulic Fracture and Horizontal Well Parameters in Shale Gas Reservoirs. J. Nat. Gas Sci. Eng. 2016, 36, 71–78. [Google Scholar] [CrossRef]

- Xu, S.; Feng, Q.; Wang, S.; Javadpour, F.; Li, Y. Optimization of Multistage Fractured Horizontal Well in Tight Oil Based on Embedded Discrete Fracture Model. Comput. Chem. Eng. 2018, 117, 291–308. [Google Scholar] [CrossRef]

- Ahmadi, S.; Khormali, A.; Meerovich Khoutoriansky, F. Optimization of the Demulsification of Water-in-Heavy Crude Oil Emulsions Using Response Surface Methodology. Fuel 2022, 323, 124270. [Google Scholar] [CrossRef]

- Wang, S.; Chen, S. Integrated Well Placement and Fracture Design Optimization for Multi-Well Pad Development in Tight Oil Reservoirs. Comput. Geosci. 2019, 23, 471–493. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Ge, H.; Sun, D.; Yu, B. Experimental Study on the Failure Mechanisms in Brittle Shales. ACS Omega 2020, 5, 10382–10394. [Google Scholar] [CrossRef]

- Olson, J.E. Fracture Aperture, Length and Pattern Geometry Development under Biaxial Loading: A Numerical Study with Applications to Natural, Cross-Jointed Systems. SP 2007, 289, 123–142. [Google Scholar] [CrossRef]

- Jon, E. Olson Predicting Fracture Swarms—The Influence of Subcritical Crack Growth and the Crack-Tip Process Zone on Joint Spacing in Rock. Geol. Soc. Lond. Spec. Publ. 2004, 231, 73–88. [Google Scholar] [CrossRef]

- Li, H.; He, J.; Misra, S. Data-Driven In-Situ Geomechanical Characterization in Shale Reservoirs. In Proceedings of the Day 3 Wed, Dallas, TX, USA, 26 September 2018; SPE: Dallas, TX, USA, 2018; p. D032S065R002. [Google Scholar]

- Sierra, L.; Mayerhofer, M.; Jin, C.J. Production Forecasting of Hydraulically Fractured Conventional Low-Permeability and Unconventional Reservoirs Linking the More Detailed Fracture and Reservoir Parameters. In Proceedings of the Day 3 Wed, The Woodlands, TX, USA, 6 February 2013; SPE: The Woodlands, TX, USA, 2013; p. D031S009R005. [Google Scholar]

- Liu, Z.; Reynolds, A.C. History Matching an Unconventional Reservoir with a Complex Fracture Network. In Proceedings of the Day 2 Thu, Galveston, TX, USA, 11 April 2019; SPE: Galveston, TX, USA, 2019; p. D020S002R002. [Google Scholar]

- Wang, T.; Ye, X.; Liu, Z.; Gao, Y.; Zhuang, Z. An Optimized Perforation Clusters Spacing Model Based on the Frictional Shale Layer’s Debonding. Sci. China Phys. Mech. Astron. 2019, 62, 114621. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).