Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts

Abstract

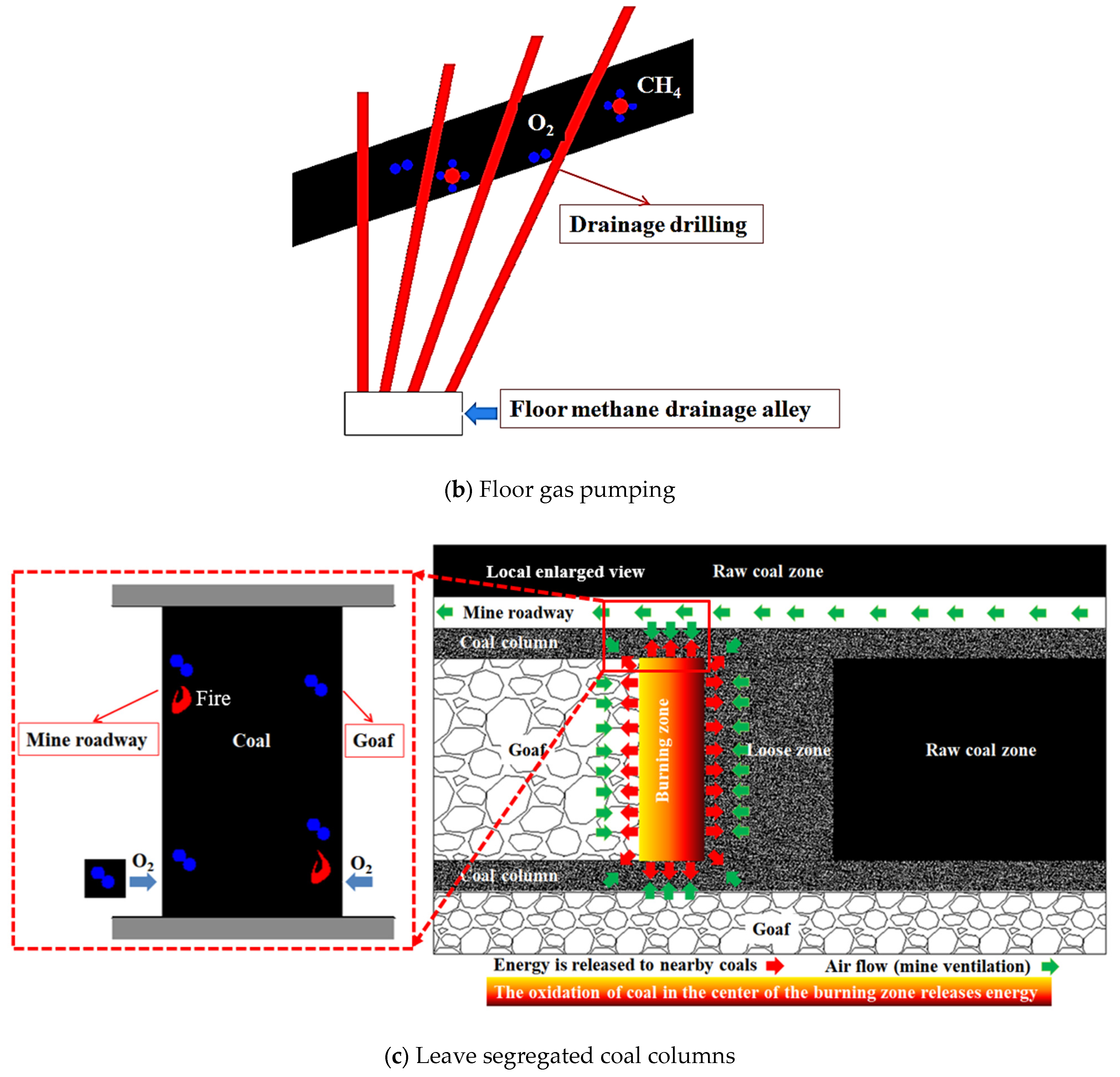

1. Introduction

2. Classification Index of Coal and Gas Outbursts

- (1)

- Strength index

- (2)

- Time indicators

- (3)

- Energy indicators

- (4)

- Deformation index

- (5)

- Comprehensive indicators

3. Test Equipment and Methods

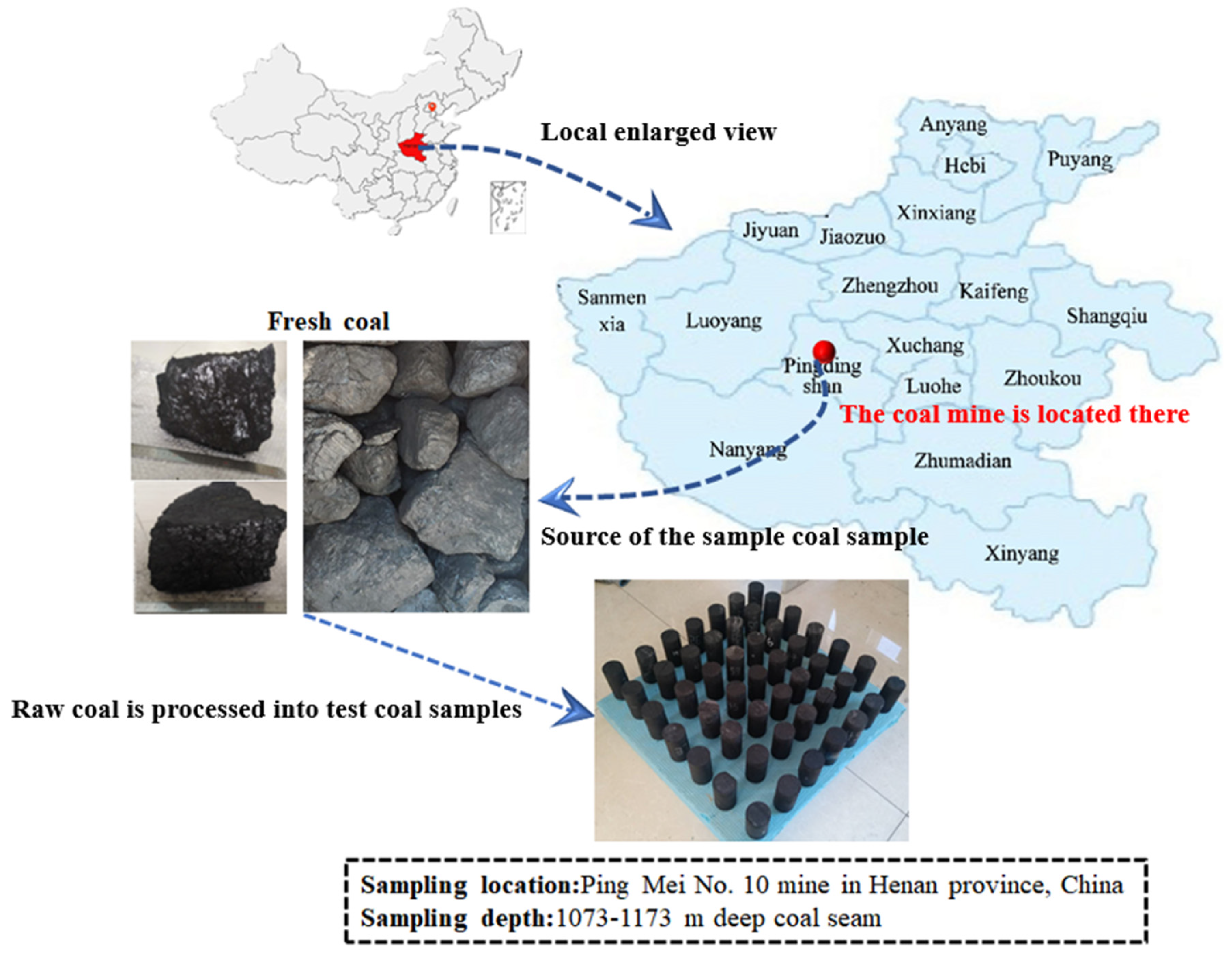

3.1. Specimen Preparation

3.2. Test Protocol

- (1)

- The retrieved coal block was cored using an electric drilling core machine, and the coal was processed into standard specimens for testing using a cutting and smoothing-integrated machine and a double-end face grinding machine.

- (2)

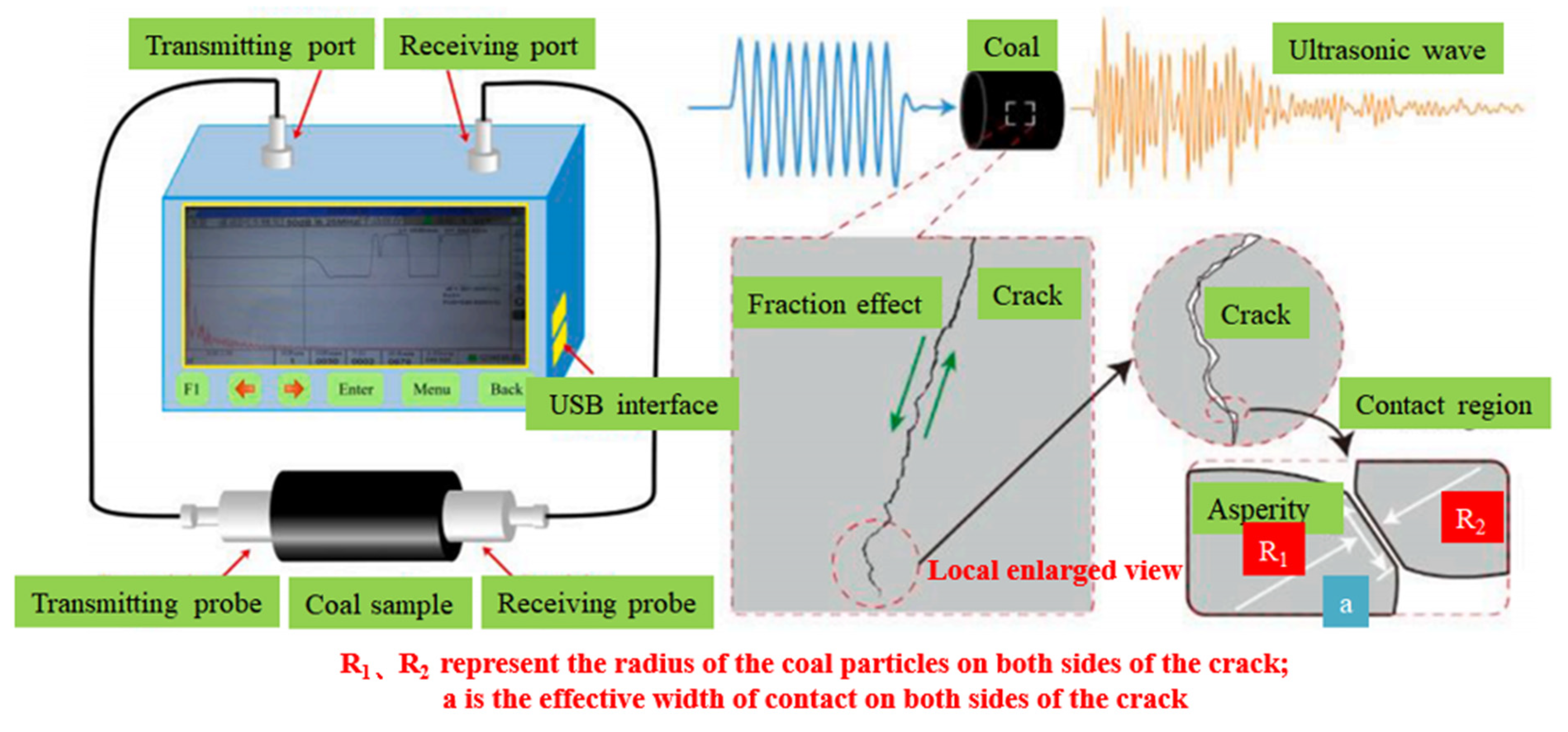

- Since the coal block in the sampling process was in a water-drenched state, the coal needed to be dried in a drying box (maintained at a constant temperature of 50 °C) for 6 h. The resulting coal samples were denoted by MY1–MY53. To reduce the discreteness of the test results, the coal was screened using an HC-U7 nonmetallic ultrasonic detector. The screened coal samples were grouped such that there were no fewer than three in each group.

- (3)

- The screened specimens were packed in a sealed plastic bag and placed in the same environment for later use.

- (4)

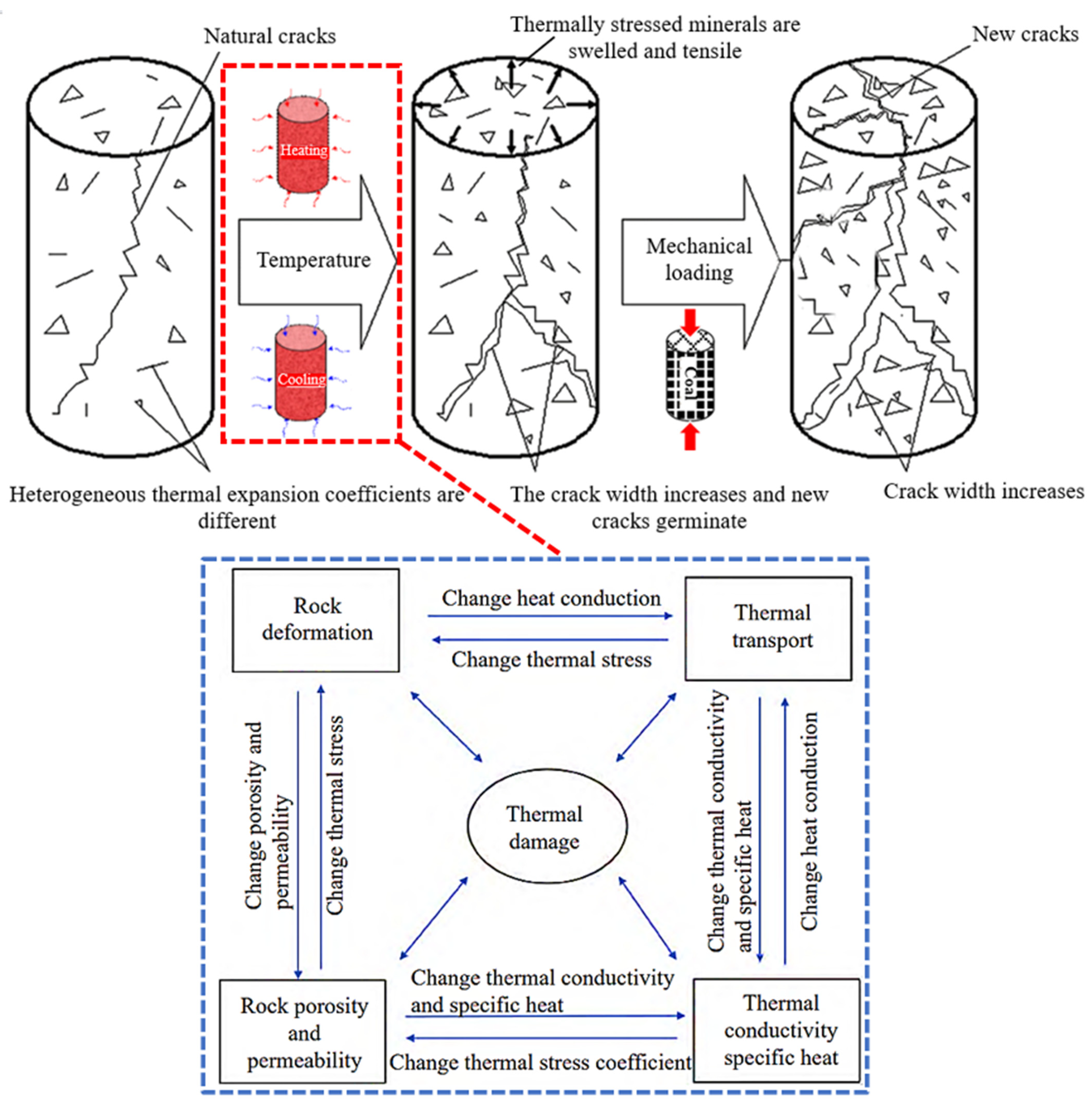

- Thermal damage to the coal (50–300 °C) was induced using an electric blower drying oven, where the coal was heated to the target temperature at a rate of 1 °C/s. The coal used in the test was placed in a drying box for thermal damage for 2 h, and the specimen was removed and placed in a well-ventilated position in the laboratory until it cooled to room temperature.

- (5)

- When the specimen reached room temperature, its mass and volume were measured, and its wave velocity was tested using an HC-U7 ultrasonic detector. Before the ultrasonic wave velocity test, the ultrasonic sensor was coupled with butter at both ends of the coal sample, tested individually, and recorded.

- (6)

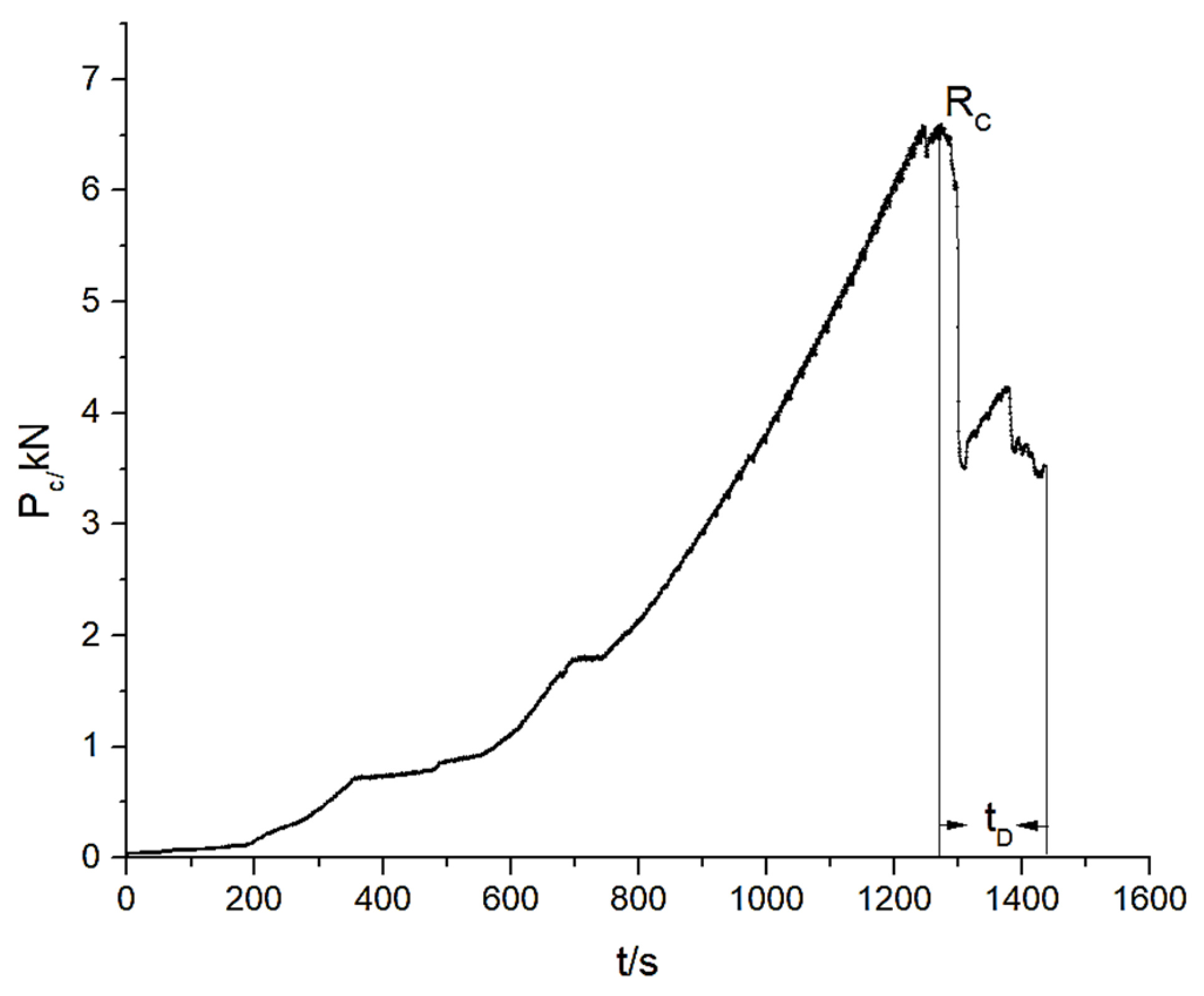

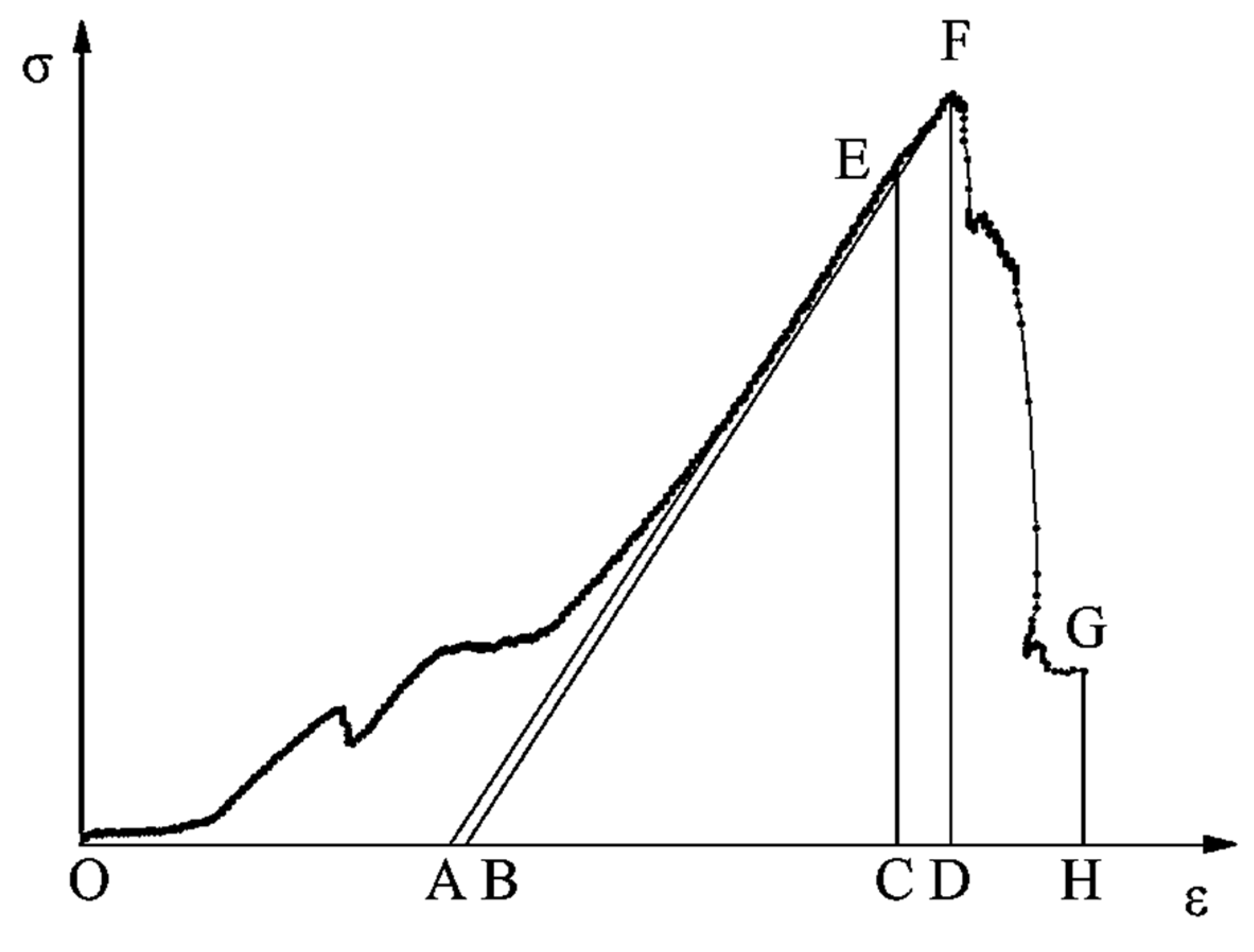

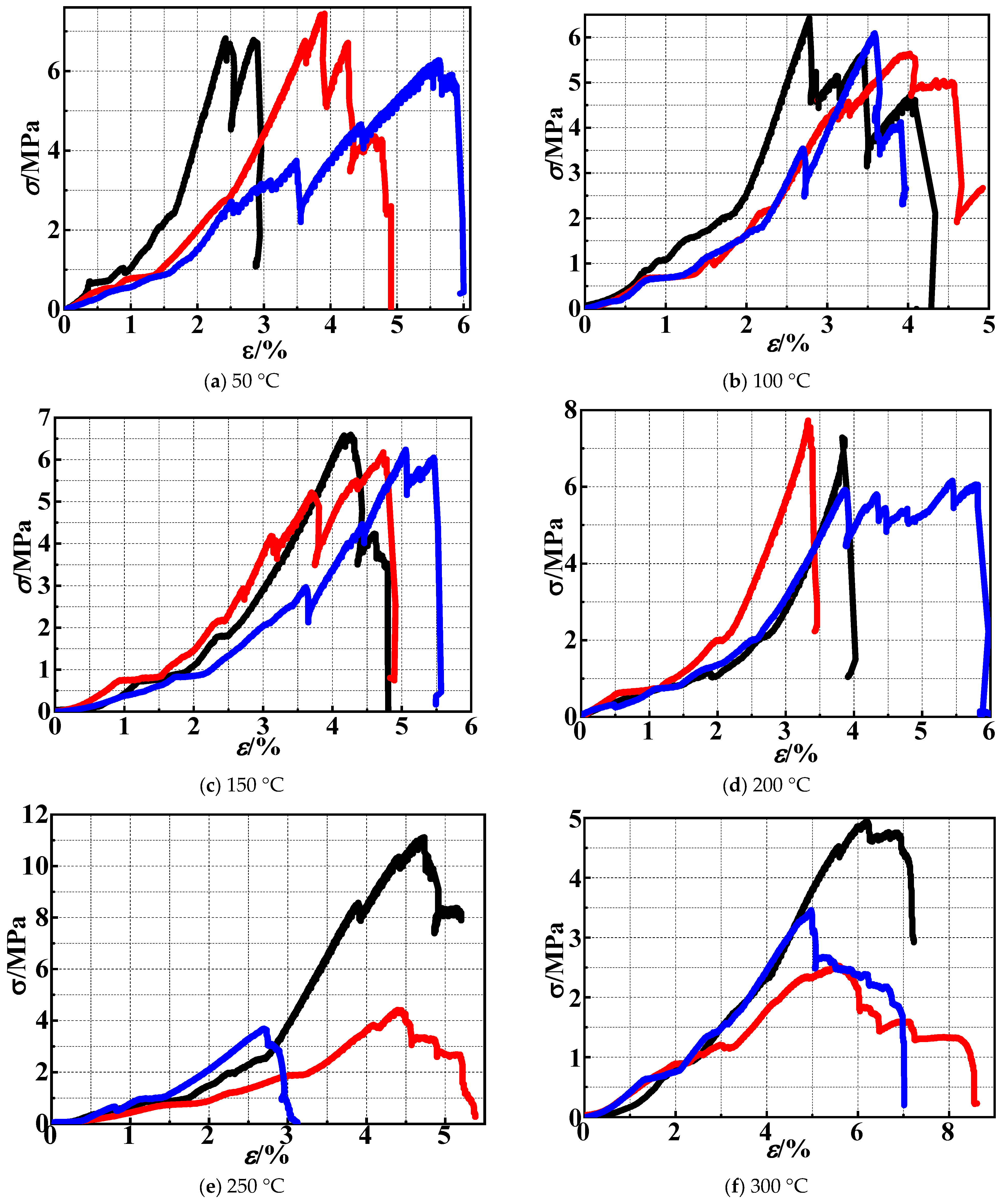

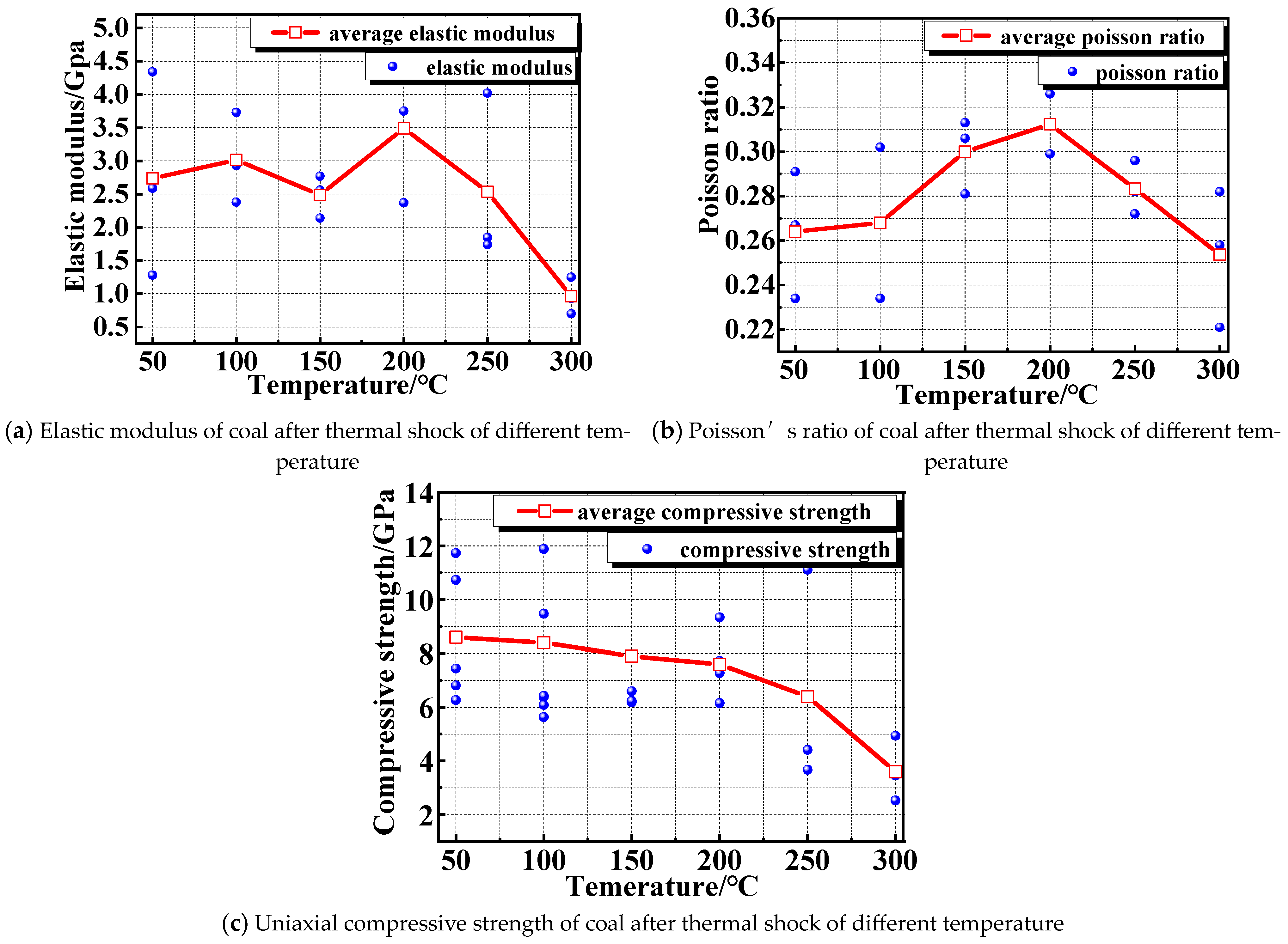

- After thermal damage, the six groups of coal specimens were subjected to uniaxial compression tests at a loading rate of 0.001 mm/s until they lost their bearing capacity. The stress, strain, time, and other related parameters were recorded until the coal was damaged, and the full stress–strain curve was plotted. The transverse and longitudinal strains of the coal were obtained using a stress–strain gauge to determine the Poisson’s ratio of the coal at different temperatures.

- (7)

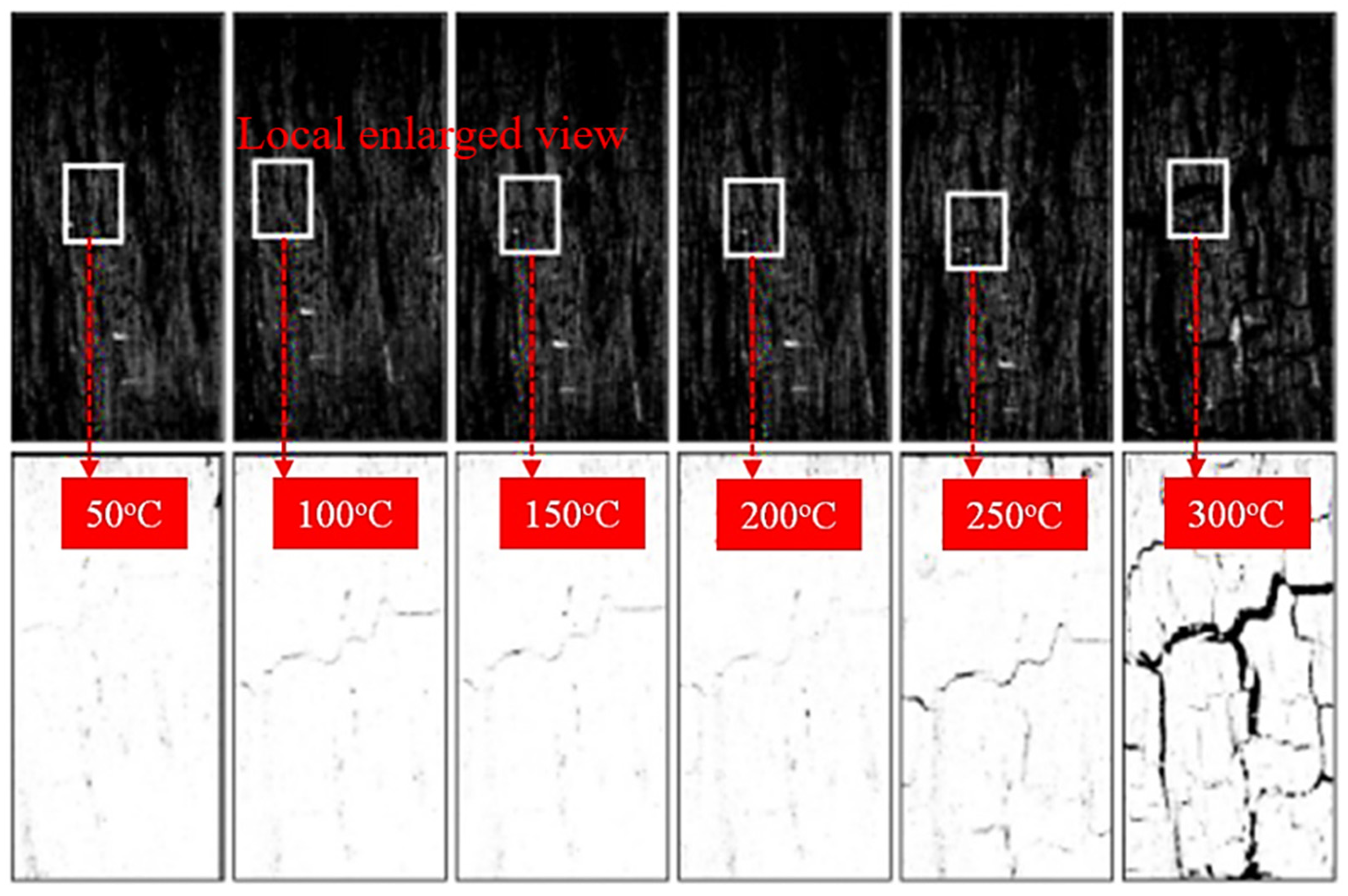

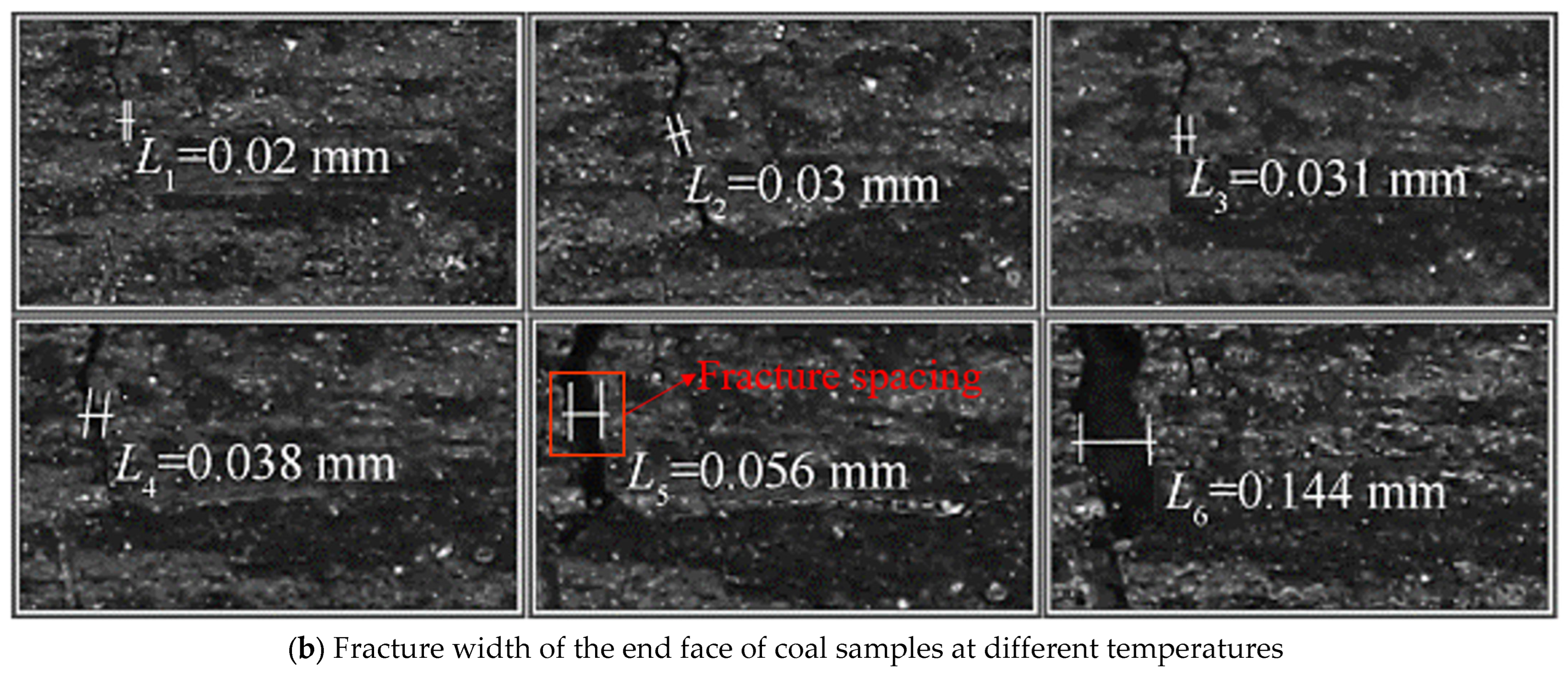

- A control specimen of the coal was selected. Optical measurement and imaging of the meso-crack state were conducted using a 4 K scientific research camera by inducing thermal damage on the control coal specimen, so as to obtain local fracture images, which were finally stitched to plot a microscopic crack map of the end face of the coal. This helped study the crack evolution law of thermally damaged coal. Subsequently, the complex fracture network was quantitatively described by performing a crack analysis on the stitched full-fracture image with the help of Image J software.

4. Analysis of Test Results

4.1. Load Stress—Strain Curve of Thermally Damaged Coal

4.2. Analysis of the Mechanical Properties of Thermally Damaged Coal from a Mesoscopic Perspective

4.2.1. Analysis of the Influence of Thermal Damage on Coal Mechanical Characteristics and Parameters

4.2.2. Quantitative Analysis of Mesoscopic Thermal Damage Images of Coal Rock

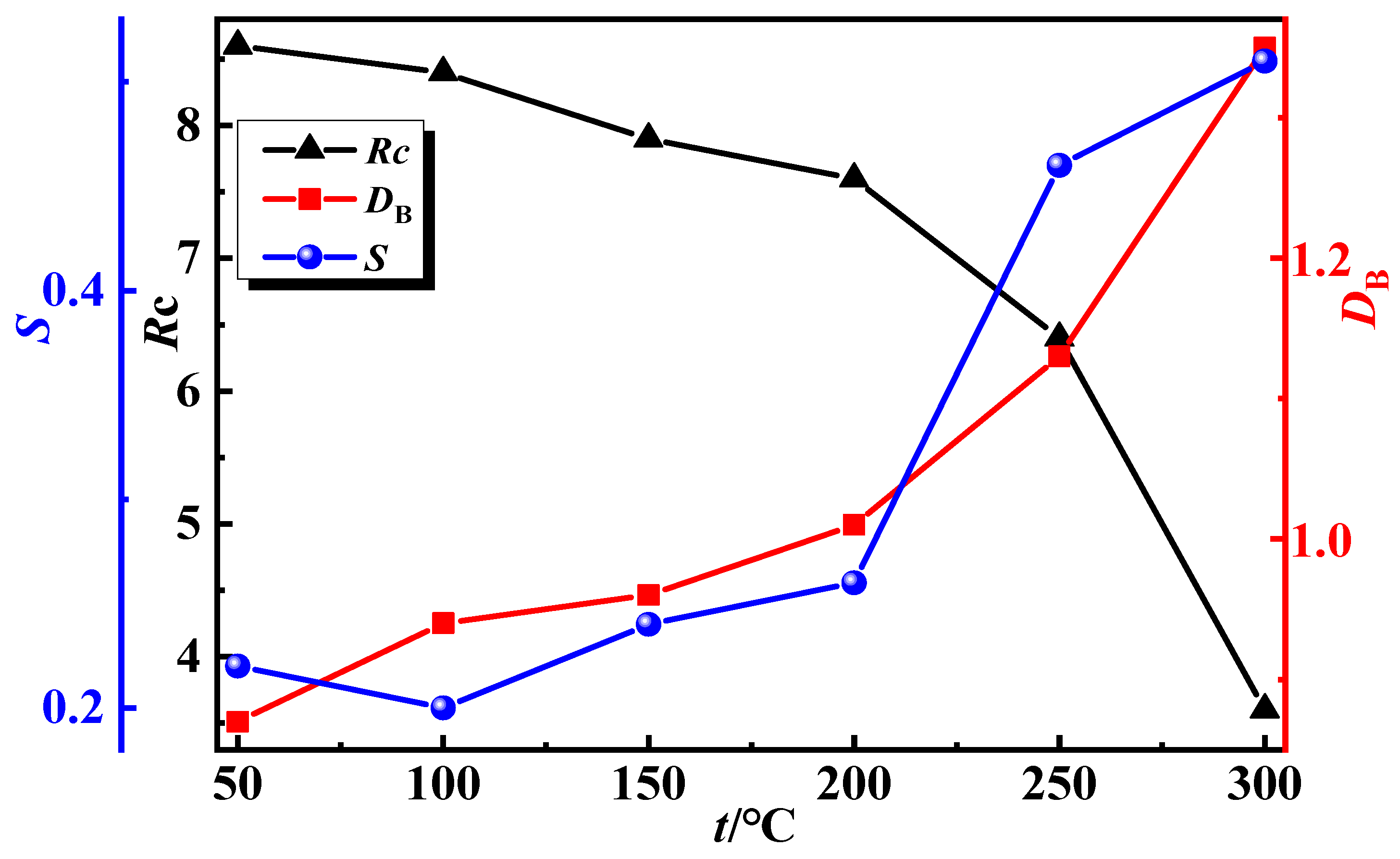

4.2.3. Coal Rock Damage Factors and Meso-Fractal Description

5. Analysis of the Shock Tendency Index of Coal

5.1. Effect of Thermal Damage on the Uniaxial Compressive Strength Index

5.2. Effect of Thermal Damage on Comprehensive Indicators of Coal Shock Tendency

5.2.1. Change Law of Comprehensive Index of the Bursting Liability of Coal Rock

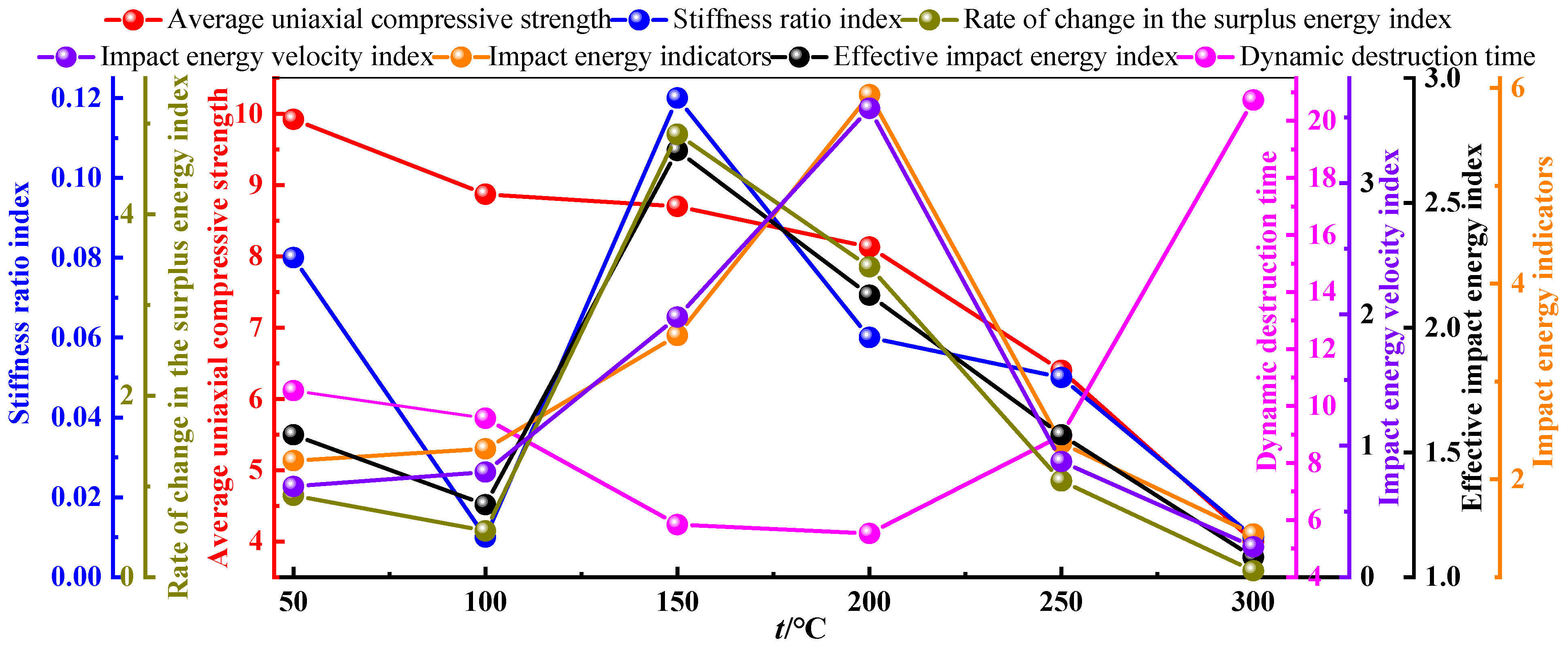

- (1)

- In the temperature range of 50–150 °C, the impact energy index increased slightly to 1.58 times that at 150 °C. The effective impact energy index, surplus energy index change rate, and impact energy velocity index also increased with the increase in temperature, and their distributions increased to 1.73, 5.42, and 2.87 times, with the coal transitioning from weak bursting liability to medium bursting liability.

- (2)

- In the temperature range of 150–200 °C, the impact energy index and the impact energy rate increased with the change in the thermal damage temperature. The impact energy and impact energy velocity indices increased by 71% and 80%, respectively. The effective impact energy index was reduced by 21%, and the rate of change in the surplus energy index was reduced by 30%.

- (3)

- In the temperature range of 200–300 °C, all the indicators decreased significantly with an increase in the temperature, with the coal transitioning from medium-bursting liability to no- bursting liability.

- (4)

- Based on the stiffness ratio index, the normal temperature coal showed a bursting liability, as shown in Figure 18. In the temperature range of 50–100 °C, the bursting liability of the coal specimens was enhanced. In the temperature range of 100–150 °C, the bursting liability weakened. In the temperature range of 150–300 °C, the bursting liability increased.

5.2.2. Comparative Analysis of Shock Propensity Indicators

5.3. Correlation Analysis of Mesoscopic Damage and Energy Response of Thermally Damaged Coal

5.4. Macroscopic Failure State before and after Loading Failure of Thermally Damaged Coal

5.5. Discussion

6. Conclusions

- (1)

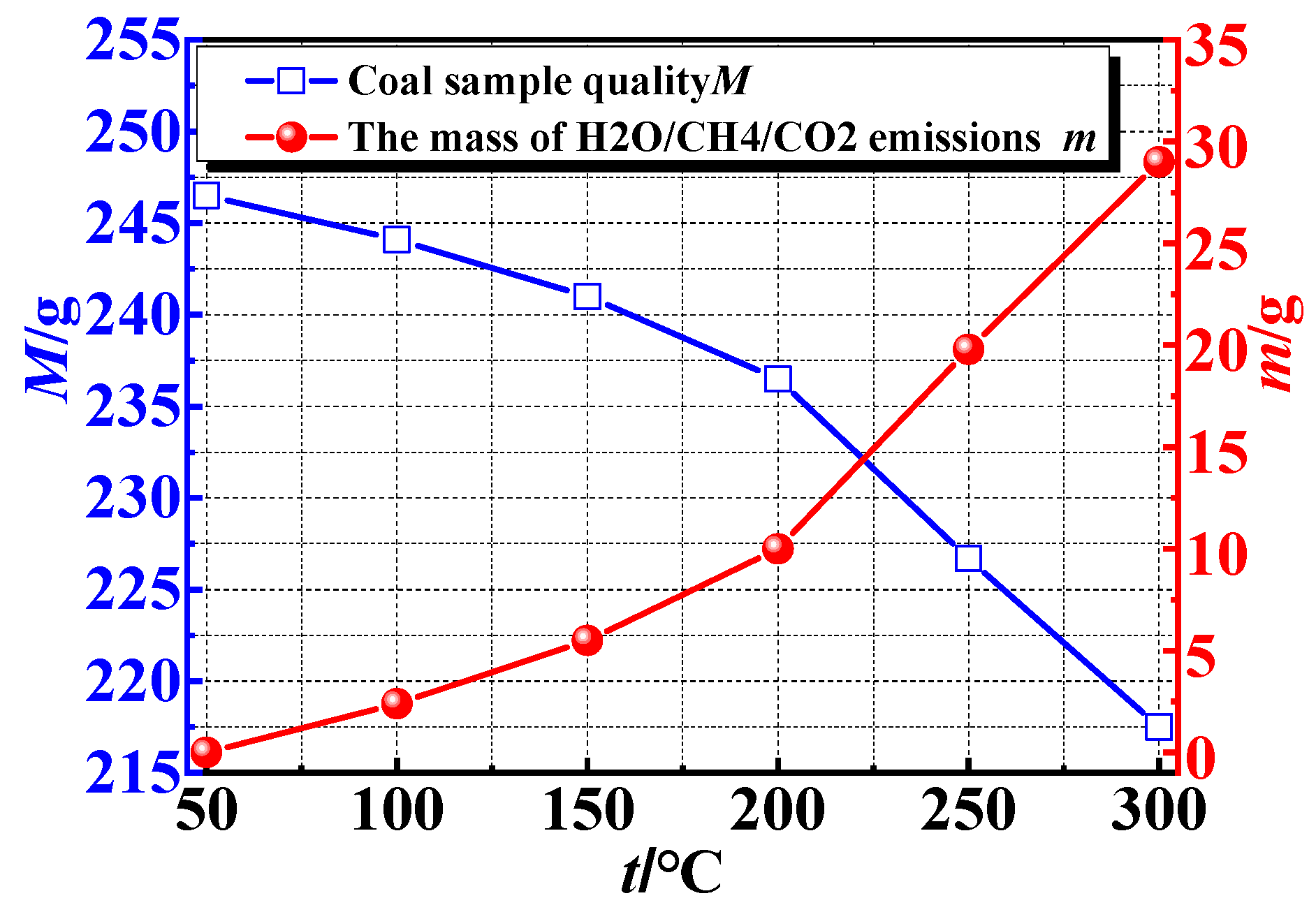

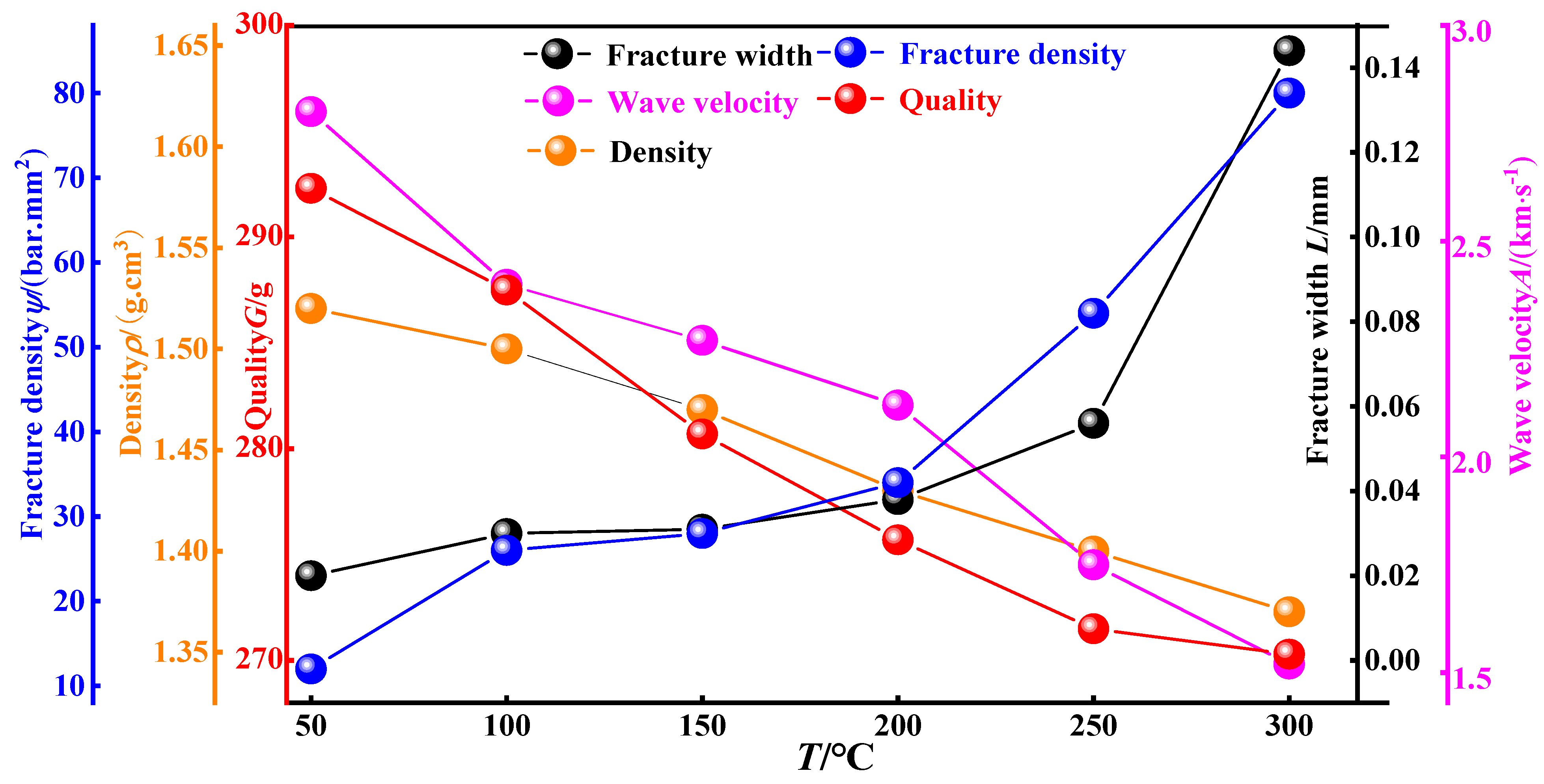

- Wave velocity A, coal mass m, coal density ρ, and temperature θ showed a negative correlation. The fracture width L and fracture density ψ were positively correlated with the temperature θ. In the temperature range of 50–200 °C, the complexity of the meso-structure of the coal body increased, and the variation amplitudes of the fracture width L and coal density ρ were flat. In the temperature range of 200–300 °C, the coal body had the most complex meso-structure, the fracture length was large, the distribution range was wide, the fracture shape was complex, many fractures appeared to penetrate each other, and the fracture distribution was relatively dense.

- (2)

- Thermally induced mesoscopic damage of the coal showed a good positive correlation with the mechanical properties and energy response during thermal loading. The higher the thermal damage temperature, the greater the pore development in the coal, and high-stress zones were easily formed around the pores to superimpose each other, which deteriorated the mechanical properties to a greater extent, and the accumulated strain energy was easily consumed through plastic deformation or rupture.

- (3)

- When the temperature was between 50 and 200 °C, in terms of the failure mode, there were multiple splitting fractures along the axial direction. In the temperature range of 200–300 °C, there were more damage before the coal was not stressed, and a large number of cracks could be visually seen. After loading to failure, the coal came close to the molten state. With the thermal damage temperature exceeding 200 °C, the rupture surfaces of the coal increased in number, the ductility deformation increased, the energy dissipation increased, and the energy release during failure decreased.

- (4)

- The comprehensive impact index of the normal temperature coal showed that it was in a transition state from medium shock to strong impact. With the increase in the thermal damage temperature, the impact energy index first increased, reached a peak at 200 °C, and then gradually decreased. The bursting liability decreased to no impact at 300 °C.

- (5)

- Comparing the six shock tendency indicators, the effective impact energy index, surplus energy index change rate, and impact energy velocity index could accurately reflect real bursting liability. With the increase in the thermal damage temperature, the change laws of the three comprehensive indicators were relatively consistent. When determining the impact risk of coal, it is necessary to combine comprehensive indicators with uniaxial compressive strength. The change law of the bursting liability of coal with temperature, as characterized by the dynamic failure time, was consistent with the impact energy index and impact energy velocity index. The stiffness ratio index ignored the degree of stiffness weakening and the weakening rate after the peak, could not fully grasp the change characteristics before and after the peak, and had a weak correlation with the other indicators.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Chen, C.; Wang, M.; Khandelwal, M. Proposing a novel comprehensive evaluation model for the coal burst liability in underground coal mines considering uncertainty factors. Int. J. Min. Sci. Technol. 2021, 31, 799–812. [Google Scholar] [CrossRef]

- Sun, H.; Liu, X.; Zhang, S.; Nawnit, K. Experimental investigation of acoustic emission and infrared radiation thermography of dynamic fracturing process of hard-rock pillar in extremely steep and thick coal seams. Eng. Fract. Mech. 2020, 226, 106845. [Google Scholar] [CrossRef]

- Litwiniszyn, J. A model for the initiation of coal-gas outbursts. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1985, 22, 39–46. [Google Scholar] [CrossRef]

- Paterson, L. A model for outbursts in coal. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1986, 23, 327–332. [Google Scholar] [CrossRef]

- Hyman, D.M. A Review of the Mechanisms of Gas Outbursts in Coal; U.S. Department of the Interior, Bureau of Mines: Washington, DC, USA, 1987.

- Choi, X.; Wold, M. Study of the Mechanisms of Coal and Gas Outbursts Using a New Numerical Modeling Approach; University of Wollongong: Wollongong, NSW, Australia, 2004. [Google Scholar]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Gao, F.; Zhang, Z.; Wang, S. Experimental investigation of mechanical properties, impact tendency, and brittleness characteristics of coal mass under different gas adsorption pressures. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 131. [Google Scholar] [CrossRef]

- Zhang, C.; Ye, D.; Yang, P.; Wu, S.; Wang, C. Study on Impact Tendency of Coal and Rock Mass Based on Different Stress Paths. Adv. Civ. Eng. 2020, 2020, 8883537. [Google Scholar] [CrossRef]

- Gan, Q.; Xu, J.; Peng, S.; Yan, F.; Wang, R.; Cai, G. Effect of heating on the molecular carbon structure and the evolution of mechanical properties of briquette coal. Energy 2021, 237, 121548. [Google Scholar] [CrossRef]

- Du, T.; Pan, J.; Xia, Y.; Sun, R. Study on the influence of confining pressure and unloading damage on the bursting liability characteristics of coal. Front. Earth Sci. 2023, 11, 1104831. [Google Scholar] [CrossRef]

- Gao, D.; Guo, L.; Wang, F.; Zhang, Z. Study on the Spontaneous Combustion Tendency of Coal Based on Grey Relational and Multiple Regression Analysis. ACS Omega 2021, 6, 6736–6746. [Google Scholar] [CrossRef]

- Liu, S.; Xiao, F.; Li, T.; Zhang, B. Analysis of Impact Tendency and Sensitivity of Fractured Rock with Different Crack Arrest Measures. Sustainability 2022, 14, 13833. [Google Scholar] [CrossRef]

- Hasegawa, H.S.; Wetmiller, R.J.; Gendzwill, D.J. Induced seismicity in mines in Canada–An overview. Pure Appl. Geophys. 1989, 129, 423–453. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.; Wang, E.; Li, Z. Rockburst mechanism in coal rock with structural surface and the microseismic (MS) and electromagnetic radiation (EMR) response. Eng. Fail. Anal. 2021, 124, 105396. [Google Scholar] [CrossRef]

- Qi, Q.; Li, Y.; Zhao, S. Years of development of coal mine impact pressure in China: Establishment and thinking of theoretical and technical system. Coal Sci. Technol. 2019, 47, 1–40. [Google Scholar]

- Wang, X.; Ma, H.; Qi, X.; Gao, K.; Li, S.; Yang, X. Experimental study on the effect of high-temperature oxidation coal mechanical characteristics. PLoS ONE 2022, 17, e0264039. [Google Scholar] [CrossRef]

- Fan, L.; Gao, J.; Wu, Z.; Yang, S.; Ma, G. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl. Therm. Eng. 2018, 140, 505–519. [Google Scholar] [CrossRef]

- Pan, R.; Ma, Z.; Yu, M.; Chao, J.; Ma, Z.; Jia, H.; Li, C. Mechanical properties of spontaneous combustion coal oxidation. J. Coal Sci. Eng. 2021, 46, 2949–2964. [Google Scholar]

- Kong, B.; Li, Z.; Yang, Y.; Liu, Z.; Yan, D. A review on the mechanism, risk evaluation, and prevention of coal spontaneous combustion in China. Environ. Sci. Pollut. Res. 2017, 24, 23453–23470. [Google Scholar] [CrossRef]

- Zheng, C.; Yao, Q.; Shan, C.; Li, Y.; Shang, X.; Li, X.; Li, J. Measurement of uniaxial compression mechanical properties of thermally dried coal by energy and fragmentation characteristic analyses. Measurement 2023, 207, 112363. [Google Scholar] [CrossRef]

- Xiao, W.; Yu, G.; Li, H.; Zhan, W.; Zhang, D. Experimental study on the failure process of sandstone subjected to cyclic loading and unloading after high temperature treatment. Eng. Geol. 2021, 293, 106305. [Google Scholar] [CrossRef]

- Wang, D.K.; Zhang, P.; Liu, S.M.; Wei, J.P.; Yu, C.; Sun, L.T. Experimental study on the evolution characteristics of internal pore structure of coal seam under temperature shock. J. Coal Sci. Eng. 2018, 43, 3395–3403. [Google Scholar]

- Li, L. Study on mesoscopic characteristics of pore fractures during thermal damage of lignite. Saf. Coal Mines 2020, 51, 12–15. [Google Scholar]

- Qi, X.; Ma, H.; Wang, X.; Zhang, Z.; Lyu, Y. Study on the influence of thermal damage on mesoscopic damage and mechanical properties of coal rock. China Saf. Sci. J. 2020, 30, 85–92. [Google Scholar]

- Zhang, H.W.; Wan, Z.J.; Zhou, C.B.; Zhao, Y.X.; Wang, W.; Yang, Y.L.; Teng, T. Analysis of high temperature mechanical characteristics and thermal damage effect of hot dry rock. J. Min. Saf. Eng. 2021, 38, 138–145. [Google Scholar]

- Hu, G.Z.; Wang, C.B.; Xu, J.L.; Wu, X.; Qin, W. Experimental study on impact tendency of hard coal reduced by microwave radiation. J. Coal Sci. Eng. 2021, 46, 450–465. [Google Scholar]

- Zhang, M.; Song, W.; Pan, Y. Study on prevention of ground pressure by water injection in coal seam. China Saf. Sci. J. 2003, 13, 73–76. [Google Scholar]

- Wang, Z.; Hu, Q.; Yin, G. Experimental study on the influence of gas pressure on coal impact index. Int. J. Min. Sci. Technol. 2010, 39, 516–519. [Google Scholar]

- Zhang, G.H.; Ouyang, Z.H.; Qi, Q.X.; Li, H.Y.; Deng, Z.G.; Jiang, J.J. Experimental study on the influence of gas on coal shock tendency. J. Coal Sci. Eng. 2017, 42, 3159–3165. [Google Scholar]

- Song, Z.; Han, P.; Li, W.; Wang, E.; Li, S.; Liu, T.; Ji, P.; Deng, D.; Yang, S. Effect of gas on energy dissipation of impact coal. J. Coal Sci. Eng. 2015, 40, 843–849. [Google Scholar]

- Du, J.; Chen, J.; Pu, Y.; Jiang, D.; Chen, L.; Zhang, Y. Risk assessment of dynamic disasters in deep coal mines based on multi-source, multi-parameter indexes, and engineering application. Process. Saf. Environ. Prot. 2021, 155, 575–586. [Google Scholar] [CrossRef]

- Dou, L.; He, X. Theory and Technology of Impact Mine Pressure Prevention and Control; China University of Mining and Technology Press: Xuzhou, China, 2001. [Google Scholar]

- Zhu, F.; Pan, C.; Guo, R. A new rock-burst tendency index-effective impact energy index. Ground Press. Strat. Control. 2002, 3, 83–84. [Google Scholar]

- Tang, L.; Pan, C.; Wang, W. Residual energy index for analysis of rock-burst tendency. J. Cent. South Univ. Technol. 2002, 33, 129–132. [Google Scholar]

- Jin, L.; Xian, X. Experimental study on coal seam impact tendency and fuzzy comprehensive evaluation. J. Chongqing Univ. 1993, 16, 114–119. [Google Scholar]

- Feng, T.; Xie, X.B.; Wang, W.X.; Pan, C.L. Rock brittleness and brittleness coefficient describing rock burst tendency. Min. Metall. Eng. 2000, 20, 18–19. [Google Scholar]

- Wu, X.; Wang, S.; Zhang, T. New index of coal seam impact tendencies. J. Xi’an Univ. Sci. Technol. 2019, 39, 782–789. [Google Scholar]

- Pan, Y.; Geng, L.; Li, Z. Study on coal seam impact tendency and risk evaluation index. J. Coal Sci. Eng. 2010, 35, 1975–1978. [Google Scholar]

- Lei, H. Mechanics of Mine Rock Mass; Metallurgical Industry Press: Beijing, China, 1983. [Google Scholar]

- Liu, G.; Liu, Z.; Feng, J.; Song, Z.; Liu, Z. Experimental research on the ultrasonic attenuation mechanism of coal. J. Geophys. Eng. 2017, 14, 502–512. [Google Scholar] [CrossRef]

- Liu, L.; Ji, H.; Elsworth, D.; Zhi, S.; Lv, X.; Wang, T. Dual-damage constitutive model to define thermal damage in rock. Int. J. Rock Mech. Min. Sci. 2020, 126, 104185. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, B.; Li, Y. Change Laws of Pore–Fracture Structure of Coal under High-Temperature Steam Shock. ACS Omega 2022, 7, 44298–44309. [Google Scholar] [CrossRef]

- Song, J.; Deng, J.; Zhao, J.; Zhang, Y.; Wang, C.; Shu, C.M. Critical particle size analysis of gas emission under high-temperature oxidation of weathered coal. Energy 2021, 214, 118995. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, W.; Li, X.; Tang, C.; Xu, Q.; Yu, L. Study on mechanical and acoustic emission characteristics of coal-bearing rock system under water-rock action. Int. J. Min. Sci. Technol. 2021, 50, 558–569. [Google Scholar]

- Feng, Z.; Zhao, Y. Micro-CT mesoscopic characteristics of pyrolysis rupture process of coal: Pore fracture evolution. J. Coal Sci. Eng. 2015, 40, 103–108. [Google Scholar]

- Yang, Y.; Zheng, K.; Li, Z.; Li, Z.; Si, L.; Hou, S.; Duan, Y. Experimental study on pore-fracture evolution law in the thermal damage process of coal. Int. J. Rock Mech. Min. Sci. 2019, 116, 13–24. [Google Scholar] [CrossRef]

- Yavuz, H.; Demirdag, S.; Caran, S. Thermal effect on the physical properties of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 94–103. [Google Scholar] [CrossRef]

- Hong, Y.-D.; Lin, B.-Q.; Zhu, C.-J.; Wang, Z.; Liu, J.-Q.; Saffari, P.; Nie, W. Image and ultrasonic analysis-based investigation of coal core fracturing by microwave energy. Int. J. Rock Mech. Min. Sci. 2020, 127, 104232. [Google Scholar] [CrossRef]

- Hassani, F.; Nekoovaght, P.M.; Gharib, N. The influence of microwave irradiation on rocks for micro-waveassisted underground excavation. J. Rock Mech. Geotech. Eng. 2016, 8, 1–15. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Mir-Amal, A.M.; Chernyshev, A.B. Assessment of a Hydrogeological Object’s Distributed Control System Stability. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Saint Petersburg, Russia, 25–28 January 2022; pp. 768–771. [Google Scholar]

- Martirosyan, A.V.; Ilyushin, Y.V. The Development of the Toxic and Flammable Gases Concentration Monitoring System for Coalmines. Energies 2022, 15, 8917. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Qi, X.; Ma, H.; Li, S. Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts. Processes 2023, 11, 1687. https://doi.org/10.3390/pr11061687

Wang X, Qi X, Ma H, Li S. Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts. Processes. 2023; 11(6):1687. https://doi.org/10.3390/pr11061687

Chicago/Turabian StyleWang, Xiaoqi, Xiaohan Qi, Heng Ma, and Shengnan Li. 2023. "Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts" Processes 11, no. 6: 1687. https://doi.org/10.3390/pr11061687

APA StyleWang, X., Qi, X., Ma, H., & Li, S. (2023). Experimental Investigation on the Influence of Temperature on Coal and Gas Outbursts. Processes, 11(6), 1687. https://doi.org/10.3390/pr11061687