NMR-Based Analysis of Fluid Occurrence Space and Imbibition Oil Recovery in Gulong Shale

Abstract

1. Introduction

2. Experiment Apparatus and Materials

2.1. Experiment Apparatus

2.2. Experiment Materials

3. Experimental Principle and Method

3.1. Experimental Principle

3.2. Experimental Method

3.2.1. Measurement of Permeability in Shale Core

3.2.2. Saturation of Shale Core with Kerosene

3.2.3. Porosity Measurement and Correction

3.2.4. Shale Imbibition Experiment

3.2.5. NMR Testing

4. Result and Discussion

4.1. Analysis of Porosity and Permeability

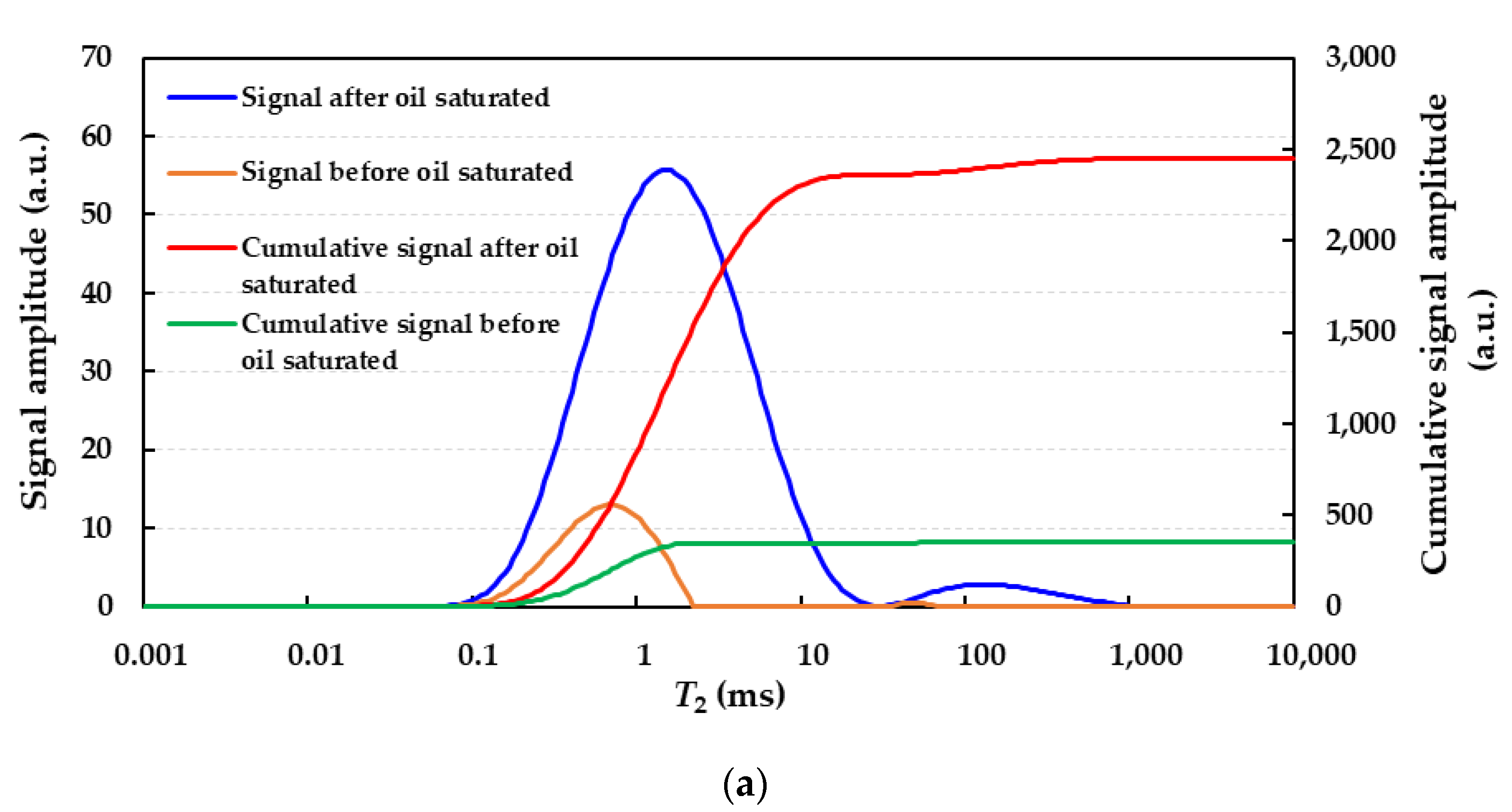

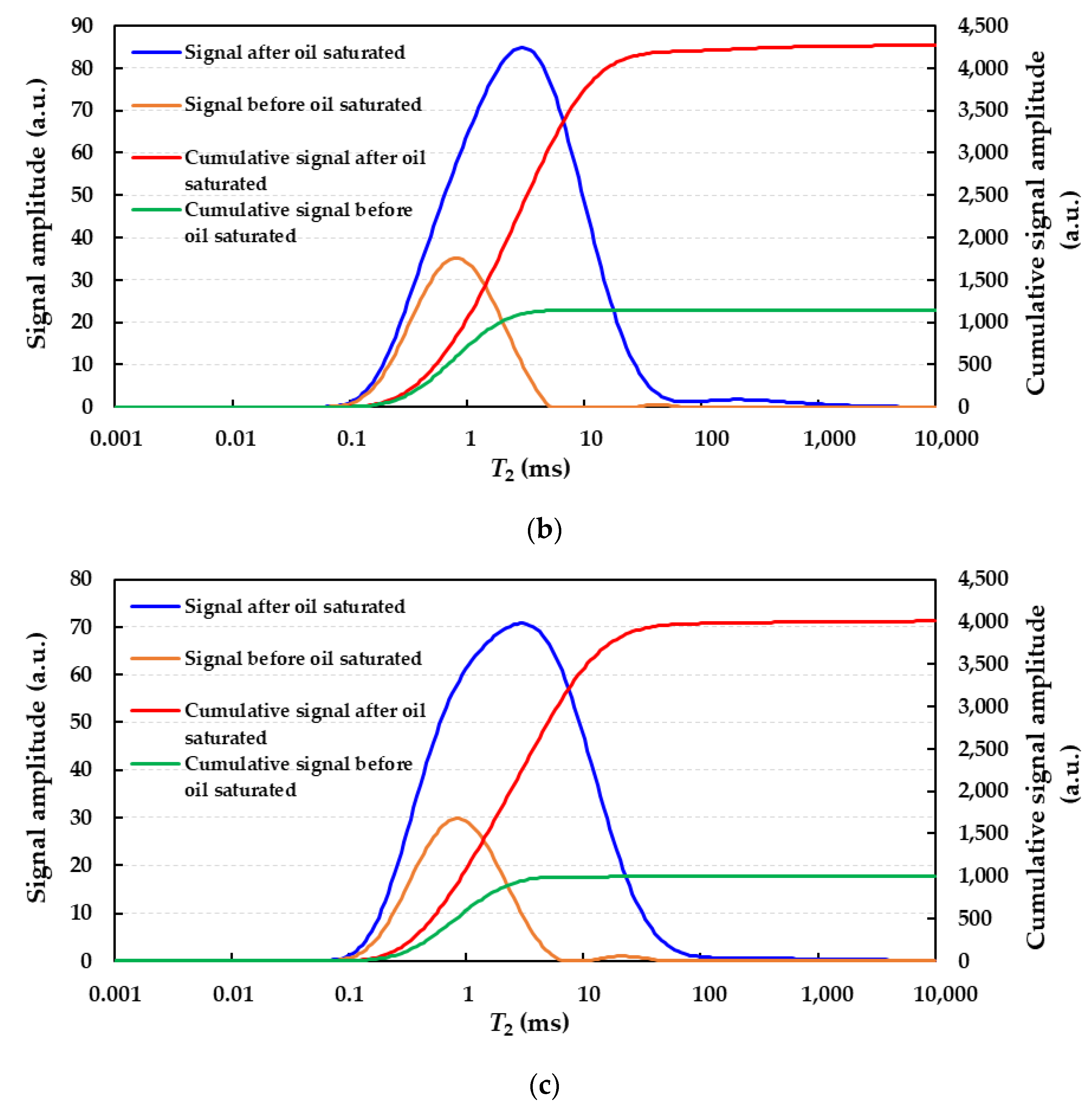

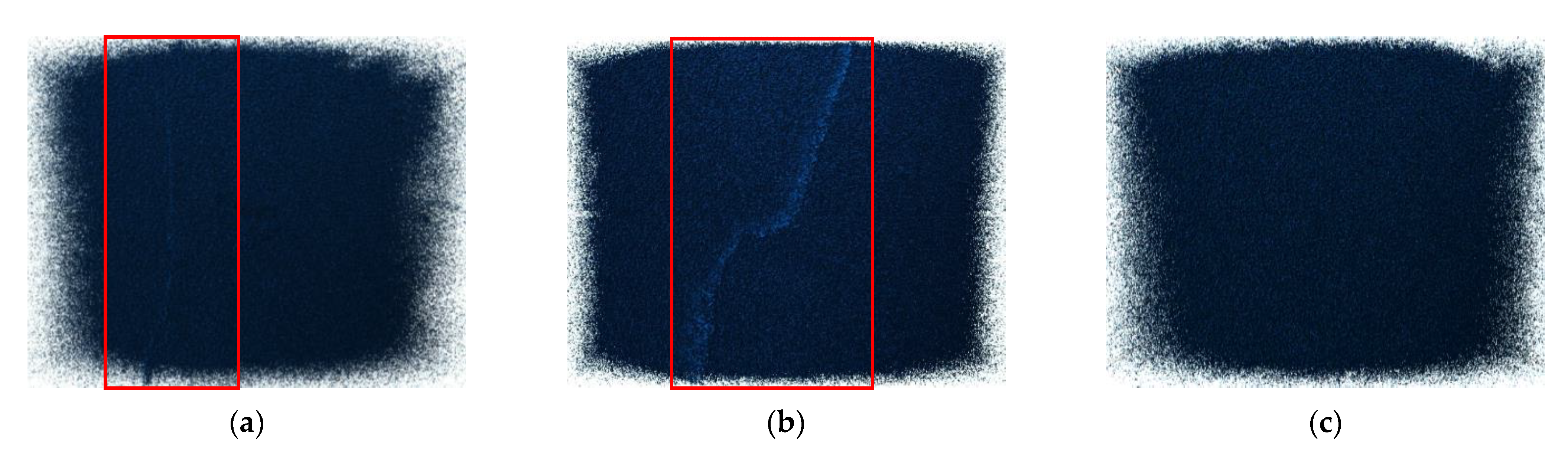

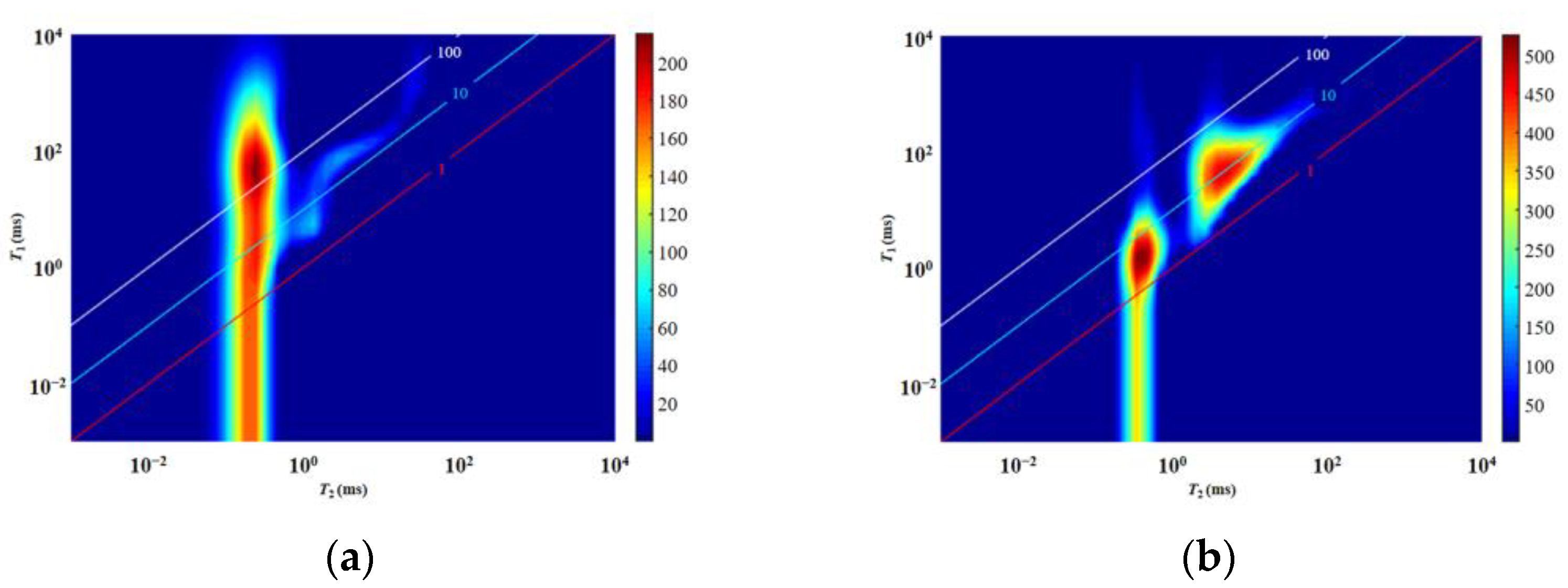

4.2. Fluid Occurrence Space Analysis

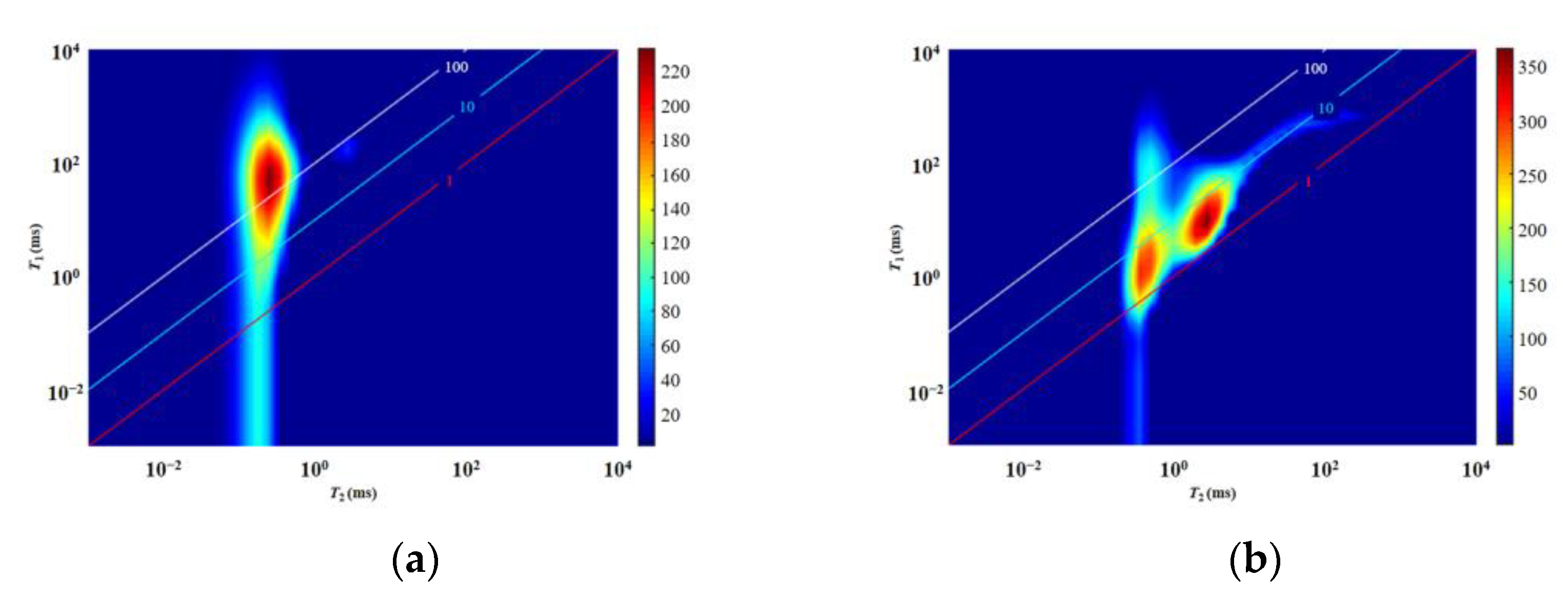

4.3. Analysis of the Imbibition Effect

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, C.; Dong, D.; Wang, Y.; Li, X.; Huang, J.; Wang, S.; Guan, Q.; Zhang, C.; Wang, H.; Liu, H. Shale Gas in China: Characteristics, Challenges and Prospects (II). Petrol. Explor. Develop. 2016, 43, 182–196. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Q.; Qi, L.; Xue, Z.; Cao, X.; Liu, Z. Evaluation technology and practice of continental shale oil development in China. Petrol. Explor. Develop. 2022, 49, 1098–1109. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Fu, X.; Lyu, Y.; Sun, X.; Gong, L.; Bai, Y. Petrological characteristics and shale oil enrichment of lacustrine fine-grained sedimentary system: A case study of organic-rich shale in first member of Cretaceous Qingshankou Formation in Gulong Sag, Songliao Basin, NE China. Petrol. Explor. Develop. 2018, 45, 884–897. [Google Scholar] [CrossRef]

- Li, C.; Yan, W.; Wu, H.; Han, T.; Zheng, J.; Jun, Y.; Zhou, F.; Xu, H. Calculation of oil saturation in clay-rich shale reservoirs: A case study of Qing 1 Member of Cretaceous Qingshankou Formation in Gulong Sag, Songliao Basin, NE China. Petrol. Explor. Develop. 2023, 49, 1351–1363. [Google Scholar] [CrossRef]

- Hua, G.; Wu, S.; Zhang, J.; Liu, R.; Guan, M.; Cai, Y.; Li, M.; Zhang, S. Laminar Structure and Reservoir Quality of Shales with High Clay Mineral Content in the Qingshankou Formation, Songliao Basin. Energies 2022, 15, 6132. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Fu, X.; Bai, Y.; Bai, L.; Jia, M.; He, B. Lithofacies and depositional setting of a highly prospective lacustrine shale oil succession from the Upper Cretaceous Qingshankou Formation in the Gulong sag, northern Songliao Basin, northeast China. AAPG Bull. 2019, 103, 405–432. [Google Scholar] [CrossRef]

- Niu, D.; Li, Y.; Zhang, Y.; Sun, P.; Wu, H.; Fu, H.; Wang, Z. Multi-scale classification and evaluation of shale reservoirs and ‘sweet spot’ prediction of the second and third members of the Qingshankou Formation in the Songliao Basin based on machine learning. J. Pet. Sci. Eng. 2022, 216, 110678. [Google Scholar] [CrossRef]

- Li, S.; Li, S.; Guo, R.; Zhou, X.; Wang, Y.; Chen, J.; Zhang, J.; Hao, L.; Ma, X.; Qiu, J. Occurrence State of Soluble Organic Matter in Shale Oil Reservoirs from the Upper Triassic Yanchang Formation in the Ordos Basin, China: Insights from Multipolarity Sequential Extraction. Nat. Resour. Res. 2021, 30, 4379–4402. [Google Scholar] [CrossRef]

- Sun, L.; Liu, H.; He, W.; Li, G.; Zhang, S.; Zhu, R.; Jin, X.; Meng, S.; Jiang, H. An analysis of major scientific problems and research paths of Gulong shale oil in daqing oilfield, NE China. Petrol. Explor. Develop. 2021, 48, 527–540. [Google Scholar] [CrossRef]

- He, W.; Wang, M.; Wang, X.; Meng, Q.; Wu, Y.; Lin, T.; Li, J.; Zhang, J. Pore Structure Characteristics and Affecting Factors of Shale in the First Member of the Qingshankou Formation in the Gulong Sag, Songliao Basin. ACS Omega 2022, 7, 35755–35773. [Google Scholar] [CrossRef]

- Huo, Z.; Hao, S.; Liu, B.; Zhang, J.; Ding, J.; Tang, X.; Li, C.; Yu, X. Geochemical characteristics and hydrocarbon expulsion of source rocks in the first member of the Qingshankou Formation in the Qijia-Gulong Sag, Songliao Basin, Northeast China: Evaluation of shale oil resource potential. Energy Sci. Eng. 2020, 8, 1450–1467. [Google Scholar] [CrossRef]

- Kuila, U.; McCarty, D.K.; Derkowski, A.; Fischer, T.B.; Prasad, M. Total porosity measurement in gas shales by the water immersion porosimetry (WIP) method. Fuel 2014, 117, 1115–1129. [Google Scholar] [CrossRef]

- Lewis, R.; Singer, P.; Jiang, T.; Rylander, E.; Sinclair, S.; Mclin, R.H. NMR T2 distributions in the Eagle Ford shale: Reflections on pore size. In Proceedings of the SPE Unconventional Resources Conference, The Woodlands, TX, USA, 10–12 April 2013. [Google Scholar]

- Birdwell, J.E.; Washburn, K.E. Multivariate analysis relating oil shale geochemical properties to NMR relaxometry. Energy Fuels 2015, 29, 2234–2243. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Chen, G.; Wang, M.; Tian, S.; Guo, Z. A new method for measuring shale porosity with low-field nuclear magnetic resonance considering non-fluid signals. Mar. Pet. Geol. 2019, 102, 535–543. [Google Scholar] [CrossRef]

- Krzyzak, A.T.; Habina-Skrzyniarz, I.; Machowski, G.; Mazur, W. Overcoming the barriers to the exploration of nanoporous shales porosity. Microporous Mesoporous Mater. 2020, 298, 110003. [Google Scholar] [CrossRef]

- Kausik, R.; Fellah, K.; Feng, L.; Freed, D.; Simpson, G. High-and low-field NMR relaxometry and diffusometry of the bakken petroleum system. In Proceedings of the SPWLA 57th Annual Logging Symposium, Reykjavík, Iceland, 25–29 June 2016. [Google Scholar]

- Zhong, J.; Yan, R.; Zhang, H.; Feng, Y.; Liu, X. A decomposition method of nuclear magnetic resonance T2 spectrum for identifying fluid properties. Petrol. Explor. Develop. 2020, 47, 740–752. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z.; Zhou, Y. Application of nuclear magnetic resonance (NMR) in coalbed methane and shale reservoirs: A review. Int. J. Coal Geol. 2020, 218, 103261. [Google Scholar] [CrossRef]

- Washburn, K.E.; Birdwell, J.E. Updated methodology for nuclear magnetic resonance characterization of shales. J. Magn. Reson. 2013, 233, 17–28. [Google Scholar] [CrossRef]

- Kausik, R.; Fellah, K.; Rylander, E.; Singer, P.M.; Lewis, R.E.; Sinclair, S.M. NMR Relaxometry in Shale and Implications for Logging. Petrophysics 2017, 57, 339–350. [Google Scholar]

- Habina, I.; Radzik, N.; Topor, T.; Krzyzak, A.T. Insight into oil and gas-shales compounds signatures in low field H-1 NMR and its application in porosity evaluation. Microporous Mesoporous Mater. 2017, 252, 37–49. [Google Scholar] [CrossRef]

- Liu, B.; Bai, L.; Chi, Y.; Jia, R.; Fu, X.; Yang, L. Geochemical characterization and quantitative evaluation of shale oil reservoir by two-dimensional nuclear magnetic resonance and quantitative grain fluorescence on extract: A case study from the Qingshankou Formation in Southern Songliao Basin, northeast China. Mar. Pet. Geol. 2020, 120, 104481. [Google Scholar]

- Pang, X.; Wang, G.; Kuang, L.; Zhao, F.; Li, C.; Wang, C.; Zhang, M.; Lai, J. Lamellation fractures in shale oil reservoirs: Recognition, prediction and their influence on oil enrichment. Mar. Pet. Geol. 2022, 148, 106032. [Google Scholar] [CrossRef]

- Wei, J.; Fu, L.; Zhao, G.; Li, B.; Zhao, X.; Wang, A. Sensitivity of shale pore structure to external fluids for Gulong shaleoil reservoir in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 120–129. [Google Scholar]

- Yan, W.; Zhang, Z.; Chen, L.; Zhao, Z.; Wang, W. New evaluating method of oil saturation in Gulong shalebased on NMR technique. Pet. Geol. Oilfield Dev. Daqing 2021, 40, 78–86. [Google Scholar]

- Li, B.; Deng, S.; Liu, Y.; Cao, S.; Jin, D.; Dong, D. Measurement method of movable fluid saturation of Gulong shale oil reservoir in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 130–138. [Google Scholar]

- He, W.; Meng, Q.; Feng, Z.; Zhang, J.; Wang, R. In-situ accumulation theory and exploration &development practice of Gulong shale oil in Songliao Basin. Acta Pet. Sin. 2022, 43, 1–14. [Google Scholar]

- He, W.; Liu, B.; Zhang, J.; Bai, L.; Tian, S.; Chi, Y. Geological Characteristics and Key Scientific and Technological Problems of Gulong Shale Oil in Songliao Basin. Earth Sci. 2023, 48, 49–62. [Google Scholar]

- Wu, X.; Hou, Z.; Yang, Y.; Chen, J.; Wang, H.; Nie, C. Development and performance evaluation for Gulong 1# emulsion system. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 112–119. [Google Scholar]

- Liu, G.; Yang, D.; Mei, X.; Yu, S.; Ma, W.; Fan, X. Method of well-soaking and controlled flowback after large-scalefracturing of Gulong shale oil reserviors in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 147–154. [Google Scholar]

| Core Number | Dry Weight /g | Weight after Saturation /g | Volume of Kerosene /cm3 | Core Volume /cm3 | Porosity /% | Permeability /mD |

|---|---|---|---|---|---|---|

| 1# | 27.22 | 27.895 | 0.84 | 10.47 | 8.06 | 0.422 |

| 2# | 75.786 | 77.218 | 1.79 | 28.43 | 6.30 | 0.235 |

| 3# | 61.794 | 62.951 | 1.45 | 23.44 | 6.17 | 0.080 |

| Core Number | Initial Porosity | NMR Porosity | Porosity of T2 < 0.13 ms | Permeability /mD |

|---|---|---|---|---|

| 1# | 8.06% | 9.40% | 0.14‰ | 0.422 |

| 2# | 6.30% | 8.59% | 0.19‰ | 0.235 |

| 3# | 6.17% | 8.23% | 0.16‰ | 0.080 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Jiang, H.; Liu, M.; Jiang, S.; Wang, Y.; Li, J. NMR-Based Analysis of Fluid Occurrence Space and Imbibition Oil Recovery in Gulong Shale. Processes 2023, 11, 1678. https://doi.org/10.3390/pr11061678

Xu F, Jiang H, Liu M, Jiang S, Wang Y, Li J. NMR-Based Analysis of Fluid Occurrence Space and Imbibition Oil Recovery in Gulong Shale. Processes. 2023; 11(6):1678. https://doi.org/10.3390/pr11061678

Chicago/Turabian StyleXu, Fei, Hanqiao Jiang, Ming Liu, Shuai Jiang, Yong Wang, and Junjian Li. 2023. "NMR-Based Analysis of Fluid Occurrence Space and Imbibition Oil Recovery in Gulong Shale" Processes 11, no. 6: 1678. https://doi.org/10.3390/pr11061678

APA StyleXu, F., Jiang, H., Liu, M., Jiang, S., Wang, Y., & Li, J. (2023). NMR-Based Analysis of Fluid Occurrence Space and Imbibition Oil Recovery in Gulong Shale. Processes, 11(6), 1678. https://doi.org/10.3390/pr11061678