Abstract

Joining similar or dissimilar materials has recently become a hot topic in industries. In this study, an adhesive technique was used to join plastic materials produced by additive manufacturing (3D printing) with metal materials. The effects of the type of material that forms the joint pairs on the joint strength were investigated. In addition, a case study was carried out on the “rubber-metal buffer” part, which is a rubber industry product. The “rubber-metal buffer” part, traditionally produced by vulcanization, was re-manufactured by changing the body material and production technique. Samples were produced from Tough PLA and TPU materials using a 3D printer at 80% and 100% fill rates. Adhesive joints were made by bonding dissimilar (Tough PLA/Galvanized steel, TPU/Galvanized steel, Tough PLA/TPU) and similar materials (Tough PLA/Tough PLA, TPU/TPU, Galvanized steel/Galvanized steel) using Loctite 9466 adhesive. The mechanical properties of the joints were determined using tensile and hardness tests, and then the damage mechanisms were examined. The highest strength value in similar material pairs (3D printed) was found in Tough PLA/Tough PLA joints (4 MPa). In dissimilar material pairs, the highest strength value was determined to be Tough PLA/Galvanized steel (4.17 MPa). As a result, it was found that TPU and Tough PLA materials produced by 3D printing can be used as an alternative to rubber.

1. Introduction

The production of multi-material structures, which can provide high load-carrying capacity and weight reduction by joining different materials, has become popular today. Due to these advantages, joining polymer and metal parts, especially in the automotive and aviation industries, is of interest [1,2]. There are several joining methods, such as mechanical fastening and adhesive bonding, that can be used to achieve successful metal/polymer bonding [3,4,5]. The chemical and physical properties of the materials to be joined [6], as well as the processing durations, health effects, cost, and bond strengths of the joining processes are very different from each other [7]. It may not be appropriate to adapt the results and evaluations obtained by joining similar materials (single-material) to the joining of dissimilar materials. Proper design of dissimilar material joint pairs and knowing the loads they will be subjected to are necessary to explain the actual strength of the joint at the application area [8]. For example, it is difficult to join materials with different melting temperatures, such as metals and polymers, using methods that require heat. The fact that the materials have different chemical and physical properties further increases this difficulty [4]. Adhesive bonding is often used in joining such material pairs. It is also a preferred application because it has advantages such as being lightweight and sealing [9,10,11,12]. There are several factors that affect the success of this application. The surface treatments of the materials to be bonded, the selection of the adhesive, the amount of compression pressure, environmental conditions (temperature, corrosion, etc.), the load to which the joints will be subjected, and the competence of the person applying the adhesive are variables that can change the process results. Despite the complexity of the adhesive bonding application, it enables the joining of different materials without mechanical fastening or creating a weld zone, which causes stress concentrations in the structures. At the same time, it prevents galvanic and crevice corrosion between two different materials [13].

There are various studies on the bonding of dissimilar materials. Kah et al. [14] summarized the information obtained from research and reviews on the methods used to join different materials. Their study has helped to better understand bonding techniques. In a similar study, Meschut et al. [15] presented their laboratory observations on the joining of steel/aluminum material, which is a multi-material structure, using experimental data.

Jun et al. [16] created metal/polymer joint pairs using micro/nanostructured aluminum and acrylonitrile butadiene styrene (ABS). They applied a new method, direct bonding, in which the organic solvent Chloroform was used. Joints were tested by single-lap shear and T-peel tests. In this method, it was observed that the shear strength was highly correlated with surface roughness.

Aliakbari et al. [17] studied epoxy formulations containing phenolic resin, recycled tire particles, and clay nanoplatelets for metal-polymer applications. The effects of adding these additives in certain ratios on the tensile strength, Young’s modulus, and toughness of the epoxy adhesives were investigated. They found that adding 50% by weight of phenolic resin, 10% by weight of recycled tire particles, and 2% by weight of clay nanoplatelets resulted in an increase of about 39% in the single-lap joint shear strength compared to the plain epoxy adhesive.

Dantas et al. [18] investigated a flexible tubular metal-polymer adhesive joint in their study. They used different design configurations to evaluate the effect of the production procedure on the joint performance in terms of surface treatment and geometric parameters of the adhesive layer.

Liu et al. [19] have bonded composite-to-aluminium and aluminium-to-aluminium materials using polyurethane and epoxy adhesives. They examined the shear strength and stiffness of single-lap joints with different bonding thicknesses. They found that the variation in bonding thickness had a significant effect on the bond strength when the joint was made using polyurethane adhesive, whereas the bond strength of epoxy adhesive joints was less sensitive to bonding thickness.

Epoxy adhesives are commonly preferred for bonding metals and polymers due to their high stiffness, crack-filling ability, and low shrinkage [20]. Therefore, in this study, both single-material (Galvanized steel/Galvanized steel, TPU/TPU, and Tough PLA/Tough PLA) and bi-material (TPU/Galvanized steel, Tough PLA/Galvanized steel) joints bonded with an epoxy adhesive were investigated. The thermoplastic adherends were produced using 3D printers that use the FDM technology, which is an additive manufacturing method. Despite environmental and economic concerns, plastic or plastic-based materials cannot be abandoned. Moreover, as additive manufacturing methods and material diversity improve, it is possible to produce plastic-based parts as end-use parts [21]. However, special thermoset plastics such as rubber cannot be 3D printed. As an alternative, flexible thermoplastic materials such as TPU and TPE are available [22].

In this study, a different manufacturing flowchart was investigated for mass-production products (rubber-metal buffers) that are produced by joining rubber with metal during the vulcanization process. The newly designed production flowchart enables the component to be produced by additive manufacturing and adhesive bonding while adhering to the technical drawing dimensions used in traditional production. One of the most important reasons for using additive manufacturing is its fast and economical prototyping production. 3D printers have become important tools in modeling and prototyping for developing new products or improving existing ones. The aim of this study is to increase the applicability of innovative methods such as additive manufacturing, which has a wide range of materials, instead of traditional methods that require rubber.

2. Materials and Methods

2.1. Materials

In the experiments, two different thermoplastic materials—Tough PLA (Polylactic Acid) and TPU (Thermoplastic Polyurethane)—as well as galvanized steel were used. PLA filament is one of the most commonly used consumables in 3D printers due to its ease of printing and production. There are also various versions of PLA, such as Tough PLA, PLA Plus, and PLA-CF, which have improved mechanical properties, in order to be able to use PLA filaments in advanced engineering applications. PLA is a thermoplastic material produced from organic materials (corn starch and sugar cane) that is safe for human health and biodegradable in nature [23,24,25]. Tough PLA, on the other hand, is more resistant than PLA material under high-impact load. Tough PLA is suitable for sanding and post-processing [26,27]. Biodegradable thermoplastic polyurethane (TPU) is called a copolymer due to its two-phase microstructure consisting of hard and soft parts [28,29]. TPU filaments have low heat resistance but high tensile strength and wear resistance. In addition to being lightweight, TPUs are recyclable and environmentally friendly materials [28,30].

The other material used in the study is galvanized steel (DX51D+Z quality galvanized steel (EN 10346:2015)). Galvanized steels have a wide range of applications, including light industry, household appliances, kitchenware, construction, and the automotive industry, due to their high resistance to corrosion. The technical properties of the materials used in the study are given in Table 1, and the chemical composition of galvanized steel is given in Table 2. The mechanical properties of galvanized steel material are based on the values provided by the manufacturer.

Table 1.

Technical properties of the materials used.

Table 2.

Chemical composition of galvanized steel (weight %).

2.2. Preparation of Samples

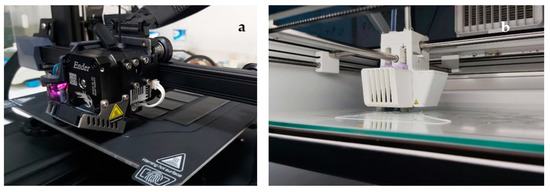

In the experiments, Ender 3S1 and Ultimaker S5 printers were used to print TPU and Tough PLA filaments (Figure 1). The solid models of the parts used (according to standard sample sizes) were modeled in three dimensions using the Fusion 360 program, the slicing process was carried out using the Cura program, and then the printing process was completed. The parameters used for the part printing in three-dimensional printers are given in Table 3.

Figure 1.

3D printers (a) Ender 3 S1 and (b) Ultimaker S5.

Table 3.

Printing parameters of the samples.

To conduct mechanical testing of Tough PLA and TPU materials, tensile samples were prepared in accordance with the ASTM D608-10 [33,34] standard. The plate dimensions for the adhesive joints are shown in Figure 2a. Galvanized steel material with dimensions of 100 mm × 25 mm × 1.5 mm was used for the experimental studies.

Figure 2.

(a) Adhesive joint plate dimensions and (b) Single lap joint (mm).

2.3. Adhesive Bonding Parameters

Loctite 9466 was chosen as the adhesive. Loctite 9466 is a reinforced 2K-Epoxy adhesive suitable for applications requiring long working time and high bond strength. It can be applied to many surfaces, such as metals, ceramics, and most plastics. The properties of Loctite 9466 brand adhesive are given in Table 4.

Table 4.

Mechanical properties of Loctite EA 9466.

The first step in joining the parts printed on the 3D printer and the steel plates with adhesive is surface preparation. The mechanical abrasion method using 240 SiC sandpaper was used to roughen the galvanized steel and Tough PLA surfaces that the adhesive would contact. TPU materials, on the other hand, are resistant to abrasion, so sanding could not be conducted. Therefore, the TPU plates were used as they were printed from the printer. The view of the joint samples (single lap joint) used in the bonding process is shown in Figure 2b. After the bonding process, all the samples, which were clamped with metal clips (a clamping force), were kept at room temperature for 24 h for one day, and the adhesive was cured.

2.4. Tensile Test and Hardness Measurement

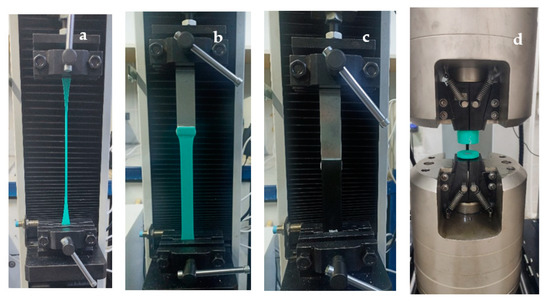

Tensile tests were conducted on the experiment samples produced with the 3D printer. The tensile tests were performed at room temperature using a WDW-5 model universal tensile machine with a capacity of 5 kN (Figure 3a–c). In addition, tensile tests were carried out at two different speeds: 2 mm/min for Tough PLA/Tough PLA, Galvanized steel/Galvanized steel bonding joints and 20 mm/min for TPU bonding joints. Galvanized steel/Galvanized steel bonding joints and samples prepared for the industrial application were subjected to tensile tests using the Besmak tensile machine with a capacity of 200 kN (Figure 3d). Figure 3 shows the elongation of adhesive joints during the tensile testing.

Figure 3.

Examples of elongation during tensile testing. (a) TPU, (b) TPU/Galvanized steel, (c) Tough PLA/Galvanized steel, and (d) Rubber-metal buffer part.

Shore D hardness measurements for Tough PLA and TPU were conducted using a LOYKA D-type shore hardness durometer. The Shore D hardness was measured in a 5-mm-thick square printed with 100% infill. In addition, Table 5 presents the tests used in the study, the test results, and the tables/figures in which they are presented.

Table 5.

Test methods used in the study and the figures/tables in which they are included.

2.5. An Industrial Case Study

In this study, the “rubber-metal buffer” part produced in the rubber industry was studied. Rubber-metal buffers are anti-vibration mounts suitable for damping and isolating vibrations in engines and compressors and storing mechanical components. Rubber-metal buffers can be produced in different shapes and sizes. As a standard, natural rubber with an average body hardness of 55 +/−5 Shore A and metal parts are made of galvanized steel [35,36,37]. The rubber-metal bumper used as a vibration damper is a cylindrical rubber part with an external (male) thread connection on both sides. This type is often used to mount a machine, such as a pump or a fan, to a frame or base. This rubber-metal buffer is resistant to compressive load.

The rubber used in the body of the product is made of Nitrile-Butadiene rubber (NBR) and Styrene-Butadiene rubber (SBR). The dimensions of the selected vibration-damping block for the study are h: 30 mm, d: 42 mm, m: M8, and l: 15 mm (Figure 4). For this study, in the industrial case sample, the rubber in the body material of the rubber-metal buffer in the traditional design was replaced with materials printed on a 3D printer.

Figure 4.

Technical drawing of rubber-metal buffer part.

The reason for selecting TPU and Tough PLA as experimental materials is that they have good damping properties [38,39,40,41]. In particular, TPU material has the mechanical performance properties of rubber and has the ability to be processed [42].

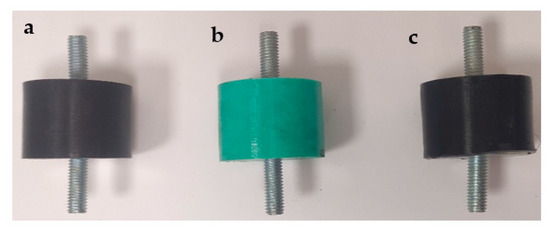

The bonding of 3D-printed parts (galvanized steel and Tough PLA surfaces sanded) with Loctite 9466 epoxy adhesive was performed after surface preparation. Figure 5 shows product images of 3D-printed Tough PLA and TPU (80% and 100%) bodies after being bonded to the metal part made of galvanized steel.

Figure 5.

Rubber-metal buffer parts obtained from 3D printer. (a) Tough PLA, (b) 100% TPU, and (c) 80% TPU.

3. Results and Discussion

3.1. Hardness and Tensile Experiments

Tensile samples were prepared from three samples of Tough PLA and TPU materials, and tensile tests were carried out. The rupture surfaces of the samples are shown in Figure 6. In both Tough PLA and TPU samples, rupture occurred near the jaw. The crack was in the form of a zig-zag progression at an angle of 45°. It was also observed that the amount of elongation in TPU materials was significantly higher than in the Tough PLA material. In particular, the damage process in TPU with 100% infill is similar to the mechanism described by Helfenstein-Didier et al. [43], which involves the elastic recoil of the ruptured layers of the delaminated region, starting with the formation of a Mode I crack and leading to Mode II propagation.

Figure 6.

Broken dog bone specimens (Numbers indicate experiment repetition).

The tensile stress values of Tough PLA and TPU materials measured as a result of the tensile test are given in Figure 7. Ultimate tensile strength (UTS) values for 80% TPU and 100% TPU and Tough PLA were found to be 23.44, 31.79, and 49.19 MPa, respectively. Elongation was 305% in 80% TPU, 460% in 100%TPU, and 4.1% in Tough PLA.

Figure 7.

TPU (80 and 100%) and Tough PLA Ultimate Tensile Stress (MPa) values.

The average shear strength values of adhesive joints are given in Figure 8. When the similar material pairs were examined, it was observed that Tough PLA/Tough PLA joints showed higher shear strength compared to TPU/TPU material pairs. The mechanical properties of the material to be bonded (such as strength and hardness) affect the adhesion mechanism. Since the Tough PLA material has stronger characteristics than TPU, the shear strength of the bond was higher. Similarly, the strength of Galvanized steel/Galvanized steel joints was 25.8 MPa; therefore, it was higher than all other joints.

Figure 8.

Average shear strength values of adhesive joints.

It was observed that the strength of the bonding joints increased when the fill rate of the material increased (from 80% to 100%) in TPU adhesive joints (Figure 8). This is in line with the literature [44] and is due to the fact that the strength of 100% filled printed TPU is higher than that of 80% filled TPU, as indicated in Figure 7.

The surface energies and surface roughness values of the materials to be bonded greatly affect the wettability of the surface with the adhesive [45]. TPU is a low-surface-energy and hydrophobic polymer [46]. Therefore, using the TPU as printed may have caused the TPU/TPU joints to have low strength. In addition, since the surfaces of galvanized steel and Tough PLA were roughened before bonding, the strength of their joints with TPU materials increased. Due to the roughening of the surface, the ability of the adhesive to adhere to the surface has improved. Therefore, TPU/Galvanized Steel and TPU/Tough PLA joints have high strength.

When dissimilar material pairs were examined, joints made with TPU/Galvanized Steel pairs provided less strength compared to joints made with Tough PLA/Galvanized Steel pairs. The shear strength of the joints formed by bonding Galvanized steel material with Tough PLA was also higher than the joints formed by other dissimilar materials.

The % elongation values of the adhesive joints are given in Table 6. The highest % elongation value was found in TPU/TPU (100%) joints, and the lowest % elongation value was in Galvanized Steel/Tough PLA joints.

Table 6.

% Elongation values of adhesive joints.

The hardness measurements of the materials used in the experiment are given in Table 7. It was observed that as the filling ratio increased in TPU material, the hardness also increased. TPU is flexible, while Tough PLA is a hard thermoplastic. Therefore, the hardness of Tough PLA was measured as higher than that of TPU.

Table 7.

Hardness measurement values.

3.2. Fracture Surface Images

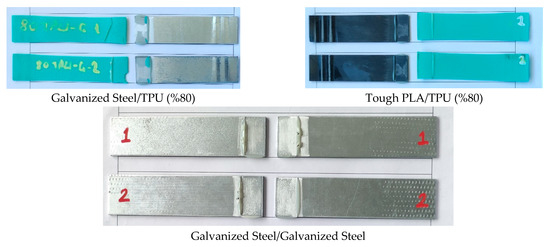

The damage that occurred in the samples as a result of the tensile test are shown in Figure 9. It was observed that there was adherend failure or substrate failure in all material pairs of Tough PLA/Tough PLA and Tough PLA/Galvanized Steel. In the Tough PLA/Galvanized Steel pair, the breakage occurred from the Tough PLA, which has lower strength. It can be said that the load capacity of the adhesive in both joints (Tough PLA/Tough PLA and Tough PLA/Galvanized Steel) is higher than the strength of Tough PLA. The rupture of Tough PLA/Galvanized Steel joints occurred close to the overlap area, while the rupture of Tough PLA/Tough PLA joints occurred near the jaws. TPU/Galvanized steel joints have had both adhesive failure and substrate failure. In TPU/Galvanized steel joints, it is seen that the TPU parts remain in the lap area of the galvanized steel. In joints with 80% TPU, much larger pieces remained on the steel bonding surface compared to joints with 100% TPU. Adhesive failure was observed in all of the other joints, and the parts were broken from the lap area. If the adhesive bond strength is subjected to excessive stress, adhesive failure may occur [47].

Figure 9.

The rupture surfaces of the adhesive joints.

The rubber body material in the rubber-metal buffer product has been re-manufactured from different materials. Tensile test results of rubber and 3D-printed parts with different bodies are shown in Table 8, and the damage to the parts after the tensile test is shown in Figure 10.

Table 8.

Tensile test results of rubber-metal buffer parts.

Figure 10.

Rupture surfaces of buffer parts (rubber-metal and 3D printed).

When the tensile test results of the products were examined, it was observed that the part with a TPU body at 80% filling rate reached the highest shear strength. It is seen that this part takes the damage over the plane where the metal was bonded to the surface, and it ruptured from the body of the part (Figure 10). The part with a TPU body at 100% filling rate showed the lowest bond strength. The part took its damage by the rupture of the metal from the TPU body at the bonded wall or edge. Both the TPU parts at 80% and 100% filling rate had adherend failure and adhesive failure. The rupture failures in the Galvanized Steel/TPU (80%) and Galvanized Steel/TPU (100%) joints, which are given in Figure 9, were the same.

The part with a Tough PLA body showed the second-highest strength. This part had adherend and adhesive failures. The metal part was completely separated from where it was bonded to the body, and the Tough PLA particles on the metal were visible.

Foreseeable and unforeseen defects can occur in bonded joints. In some cases, defects caused by the adhered material—and in some cases by the adhesive material—may cause a change in the mechanical performance of the joints. Factors such as cracks, voids, delamination, porosity, poor cure, adherend defects, non-uniform bondline thickness, and changes in other factors in the application can change the process [48].

It has been understood that in addition to the standard laboratory tests for the product, the tests performed on the prototype are also necessary to understand the material behavior. Of course, some prototypes and implementations are quite expensive. In such cases, it is possible to take advantage of the speed and flexibility of 3D printers in the production of complex parts. Although it is not cost-effective to use the 3D printing method where mass manufacturing is required, it plays an auxiliary role in new product development or product improvement.

4. Conclusions

When similar materials are bonded together, the process conditions and outcomes are more predictable. However, when dissimilar materials are bonded, the situation is a bit more complicated due to different material properties, and interpreting the results is a bit more difficult. Joint designs for adhesive bonding dissimilar materials such as metal and plastic require a thorough understanding of their behavior under load and in the event of damage. This study includes a case study on a product prototype as well as standard laboratory tests. Based on the test results, the following conclusions have been drawn:

- The greatest % elongation value was obtained in TPU/TPU (100%) joints, while the lowest elongation value was observed in Galvanized Steel/Tough PLA joints. The high elongation ability of TPU material contributed positively to the amount of elongation regardless of the material it was bonded to. The elongation values of Tough PLA and Galvanized steel were low due to their hardness, and the elongation value of the joints formed with these two materials was also low.

- Although the tensile strength of the TPU material increased with the increase in the fill rate, the tensile strength of the Tough PLA material was higher.

- The strength values of the joints made with similar materials were lower than those made with dissimilar materials. This result supports the main reason for joining different materials, which is to obtain systems with better properties.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Grujicic, M.; Sellappan, V.; Omar, M.A.; Seyr, N.; Obieglo, A.; Erdmann, M.; Holzleitner, J. An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J. Mater. Process. Technol. 2008, 197, 363–373. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Stambke, M. Potential of laser-manufactured polymer-metal hybrid joints. Phys. Procedia 2012, 39, 84–91. [Google Scholar] [CrossRef]

- Ozlati, A.; Movahedi, M.; Tamizi, M.; Tartifzadeh, Z.; Alipour, S. An alternative additive manufacturing-based joining method to make Metal/Polymer hybrid structures. J. Manuf. Process. 2019, 45, 217–226. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Dos Santos, J.F. Joining of polymers and polymer-metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- Boumerzoug, Z. Joining of dissimilar materials by friction stir welding. MATEC Web Conf. 2018, 224, 01118. [Google Scholar] [CrossRef]

- Glaser, M.; Matthes, S.; Hildebrand, J.; Bergmann, J.P.; Schaaf, P. Hybrid Thermoplastic-Metal joining based on Al/Ni multilayer foils—Analysis of the joining zone. Mater. Des. 2023, 226, 111561. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, Q.; Yang, H.; Yang, C.; Liu, Y.; Wang, C. Effect of surface treatments on the laser welding performance of dissimilar materials. J. Manuf. Process. 2022, 74, 465–473. [Google Scholar] [CrossRef]

- Dorn, L.; Liu, W. The stress state and failure properties of adhesive-bonded plastic/metal joints. Int. J. Adhes. Adhes. 1993, 13, 21–31. [Google Scholar] [CrossRef]

- Budzik, M.K.; Wolfahrt, M.; Reis, P.; Kozłowski, M.; Sena-Cruz, J.; Papadakis, L.; Nasr Saleh, M.; Machalicka, K.V.; de Teixeira de Freitas, S.; Vassilopoulos, A.P. Testing mechanical performance of adhesively bonded composite joints in engineering applications: An overview. J. Adhes. 2021, 98, 1–77. [Google Scholar] [CrossRef]

- Mariam, M.; Afendi, M.; Majid, M.A.; Ridzuan, M.; Azmi, A.; Sultan, M. Influence of hydrothermal ageing on the mechanical properties of an adhesively bonded joint with different adherends. Compos. Part B Eng. 2019, 165, 572–585. [Google Scholar] [CrossRef]

- Fernandes, R.L.; de Freitas, S.T.; Budzik, M.K.; Poulis, J.A.; Benedictus, R. Role of adherend material on the fracture of bi-material composite bonded joints. Compos. Struct. 2020, 252, 112643. [Google Scholar] [CrossRef]

- Seong, M.-S.; Kim, T.-H.; Nguyen, K.-H.; Kweon, J.-H.; Choi, J.-H. A parametric study on the failure of bonded single-lap joints of carbon composite and aluminum. Compos. Struct. 2008, 86, 135–145. [Google Scholar] [CrossRef]

- Brockmann, W.; Geiß, P.L.; Klingen, J.; Schröder, B. Adhesive Bonding: Materials, Applications and Technology; John Wiley & Sons: Weinheim, Germany, 2008. [Google Scholar]

- Kah, P.; Suoranta, R.; Martikainen, J.; Magnus, C. Technıques for Joınıng Dıssımılar Materıals: Metals and Polymers. Rev. Adv. Mater. Sci. 2014, 36, 152–164. [Google Scholar]

- Meschut, G.; Hahn, O.; Janzen, V.; Olfermann, T. Innovative joining technologies for multi-material structures. Weld. World 2013, 58, 65–75. [Google Scholar] [CrossRef]

- Jun, G.; Lee, J.-W.; Shin, Y.; Kim, K.; Hwang, W. Solvent-aided direct adhesion of a metal/polymer joint using micro/nano hierarchical structures. J. Mater. Process. Technol. 2020, 285, 116744. [Google Scholar] [CrossRef]

- Aliakbari, M.; Jazani, O.M.; Sohrabian, M. Epoxy adhesives toughened with waste tire powder, nanoclay, and phenolic resin for metal-polymer lap-joint applications. Prog. Org. Coat. 2019, 136, 105291. [Google Scholar] [CrossRef]

- Dantas, M.; Carbas, R.; Marques, E.; Kushner, D.; da Silva, L. Flexible tubular metal-polymer adhesive joints under torsion loading. Int. J. Adhes. Adhes. 2020, 105, 102787. [Google Scholar] [CrossRef]

- Liu, Y.; Carnegie, C.; Ascroft, H.; Li, W.; Han, X.; Guo, H.; Hughes, D.J. Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle. Materials 2021, 14, 6991. [Google Scholar] [CrossRef]

- Elkins, D.S. Metal-Polymer Adhesive Bond Characterization in an Additive Manufacturing Environment. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2018. [Google Scholar]

- Hohimer, C.; Christ, J.; Aliheidari, N.; Mo, C.; Ameli, A. 3D printed thermoplastic polyurethane with isotropic material properties. In Behavior and Mechanics of Multifunctional Materials and Composites 2017; SPIE: Bellingham, WA, USA, 2017. [Google Scholar]

- BCN3D. How Flexible is TPU? Available online: https://www.bcn3d.com/everything-you-should-know-about-tpu/ (accessed on 3 October 2021).

- Incorporated. P.S. 3 Types of Plastic Used in 3D Printing. Available online: https://www.polymersolutions.com/blog/plastic-in-3d-printing/ (accessed on 12 February 2023).

- Kyutoku, H.; Maeda, N.; Sakamoto, H.; Nishimura, H.; Yamada, K. Effect of surface treatment of cellulose fiber (CF) on durability of PLA/CF bio-composites. Carbohydr. Polym. 2019, 203, 95–102. [Google Scholar] [CrossRef]

- TWI. What is PLA. Available online: https://www.twi-global.com/technical-knowledge/faqs/what-is-pla (accessed on 9 February 2022).

- Ultimaker. Ultimaker Tough PLA TDS. Available online: https://support.makerbot.com/s/article/1667411002379 (accessed on 17 February 2023).

- Ultimaker. Tough PLA. Available online: https://ultimaker.com/materials/tough-pla (accessed on 10 December 2022).

- Petrović, Z.S.; Ferguson, J. Polyurethane elastomers. Prog. Polym. Sci. 1991, 16, 695–836. [Google Scholar] [CrossRef]

- Abdullahi, T.; Ahmad, N.; Wahit, M.U.; Harun, Z. Adhesive Bonding of Thermoplastic Polyurethane with Metallic Wire. Adv. Sci. Lett. 2018, 24, 4045–4049. [Google Scholar] [CrossRef]

- Evlen, H. Investigation of the Effect of Infill Rate on Mechanical Properties of TPU and TPE Specimens Produced in 3D Printer. Dokuz Eylül Univ. Fac. Eng. J. Sci. Eng. 2019, 21, 793–804. [Google Scholar]

- Filament, S. TPU 92A. Available online: https://savafilament.com/standart-92a (accessed on 11 April 2022).

- Anaç, N.; Doğan, Z. The Effect of Organic Fillers on the Mechanical Strength of the Joint in the Adhesive Bonding. Processes 2023, 11, 406. [Google Scholar] [CrossRef]

- ISO, B. Plastics-determination of tensile properties. Br. Stand. Ger. 1997. Available online: https://scholar.google.com.hk/scholar?q=Plastics-determination+of+tensile+properties&hl=zh-TW&as_sdt=0&as_vis=1&oi=scholart (accessed on 11 April 2022).

- Şentürk, B.; Çetin, K.; Nur Ürküt, S.; Anaç, N.; Koçar, O. Jig design and manufacturing for adhesive thickness control in adhesive joints. J. Mater. Manuf. 2022, 1, 17–23. [Google Scholar]

- Norelem. Rubber Buffers Steel or Stainless Steel, Type A. Available online: https://norelem.se/en/Product-overview/Systems-and-components-for-machine-and-plant-construction/26000/Rubber-buffers/Rubber-buffers-steel-or-stainless-steel-type-A/p/agid.5072 (accessed on 13 December 2022).

- Bol.com. Rubberen Metalen Element Buffer Type A. Available online: https://www.bol.com/nl/nl/p/rubberen-metalen-element-buffer-type-a-m8x20-schroefmaat-en-30x20-mm-trillingsdempers-geschikt-voor-airco-motoren-pompen/9300000011475438/?bltgh=uR--zLsy5T4N0nejnddMzA.2_49.51.ProductImage (accessed on 15 December 2020).

- Wampfler, C. Rubber to Metal Bumpers. Available online: https://www.conductix.com.tr/en/products/buffers-bumpers (accessed on 8 May 2021).

- Zhou, R.; Gao, W.; Xia, L.; Wu, H.; Guo, S. The study of damping property and mechanism of thermoplastic polyurethane/phenolic resin through a combined experiment and molecular dynamics simulation. J. Mater. Sci. 2018, 53, 9350–9362. [Google Scholar] [CrossRef]

- He, X.; Qu, M.; Shi, X. Damping Properties of Ethylene-Vinyl Acetate Rubber/Polylactic Acid Blends. J. Mater. Sci. Chem. Eng. 2016, 04, 15–22. [Google Scholar] [CrossRef]

- Ketabchi, M.R.; Ratnam, C.T.; Khalid, M.; Walvekar, R. Mechanical properties of polylactic acid/synthetic rubber blend reinforced with cellulose nanoparticles isolated from kenaf fibres. Polym. Bull. 2017, 75, 809–827. [Google Scholar] [CrossRef]

- Chang, J.; Tian, B.; Li, L.; Zheng, Y. Microstructure and Damping Property of Polyurethane Composites Hybridized with Ultraviolet Absorbents. Adv. Mater. Sci. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Qi, H.; Boyce, M. Stress–strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Helfenstein-Didier, C.; Taïnoff, D.; Viville, J.; Adrien, J.; Maire, É.; Badel, P. Tensile rupture of medial arterial tissue studied by X-ray micro-tomography on stained samples. J. Mech. Behav. Biomed. Mater. 2018, 78, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Nergizhan, A.; Koçar, O.; Hazer, B. Evaluation of Joint Strength in the Adhesive Bonding of Parts Produced by Additive Manufacturing. Int. J. 3D Print. Technol. Digit. Ind. 2002, 6, 449–458. [Google Scholar]

- Jasmee, S.; Omer, G.; Nordin, M.; Masripan, N.; Kamarolzaman, A. Hydrophobicity performance of thermoplastic polyurethane coated with TiO2 under thermal aging effect. In 1st Colloquium Paper: ADVANCED MATERIALS AND MECHANICAL ENGINEERING RESEARCH (CAMMER’18); Penerbit Universiti, Universiti Teknikal Malaysia Melaka: Durian Tunggal, Malaysia, 2018. [Google Scholar]

- Gooch, J.W. Encyclopedic Dictionary of Polymers; Springer Science & Business Media: Berlin, Germany, 2010; Volume 1. [Google Scholar]

- Ren, H.; Chen, X.; Chen, Y. Reliability Based Aircraft Maintenance Optimization and Applications; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Omairey, S.; Jayasree, N.; Kazilas, M. Defects and uncertainties of adhesively bonded composite joints. SN Appl. Sci. 2021, 3, 769. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).