Application of a Full-Scale Horizontal Anaerobic Digester for the Co-Digestion of Pig Manure, Food Waste, Excretion, and Thickened Sewage Sludge

Abstract

1. Introduction

1.1. Current Status of Bio-Gasification in Republic of Korea

1.2. Anaerobic Co-Digestion

1.3. Design of a Full Scale Anaerobic Co-Digester

2. Materials and Methods

2.1. Substrate Characteristics

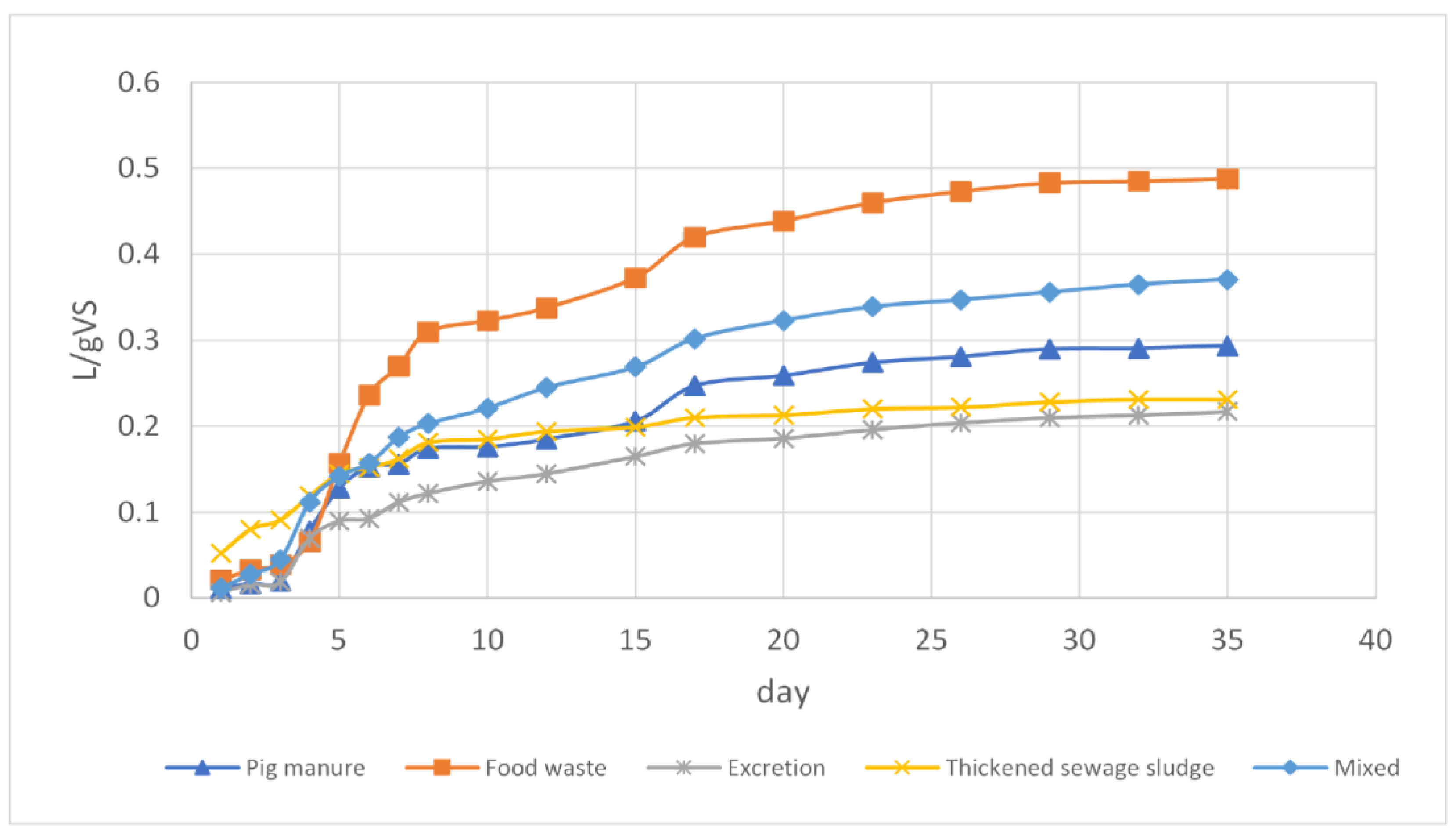

2.2. BMP Test

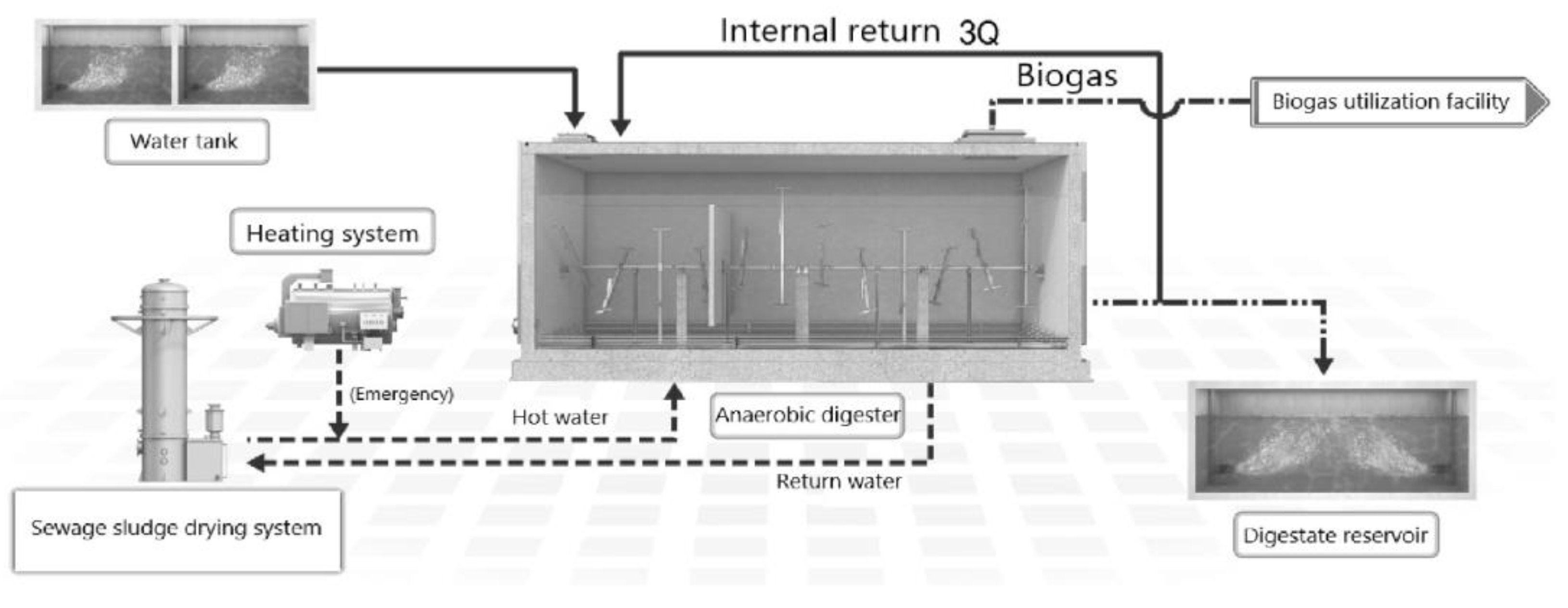

2.3. Full-Scale Anaerobic Co-Digestion Plant Design

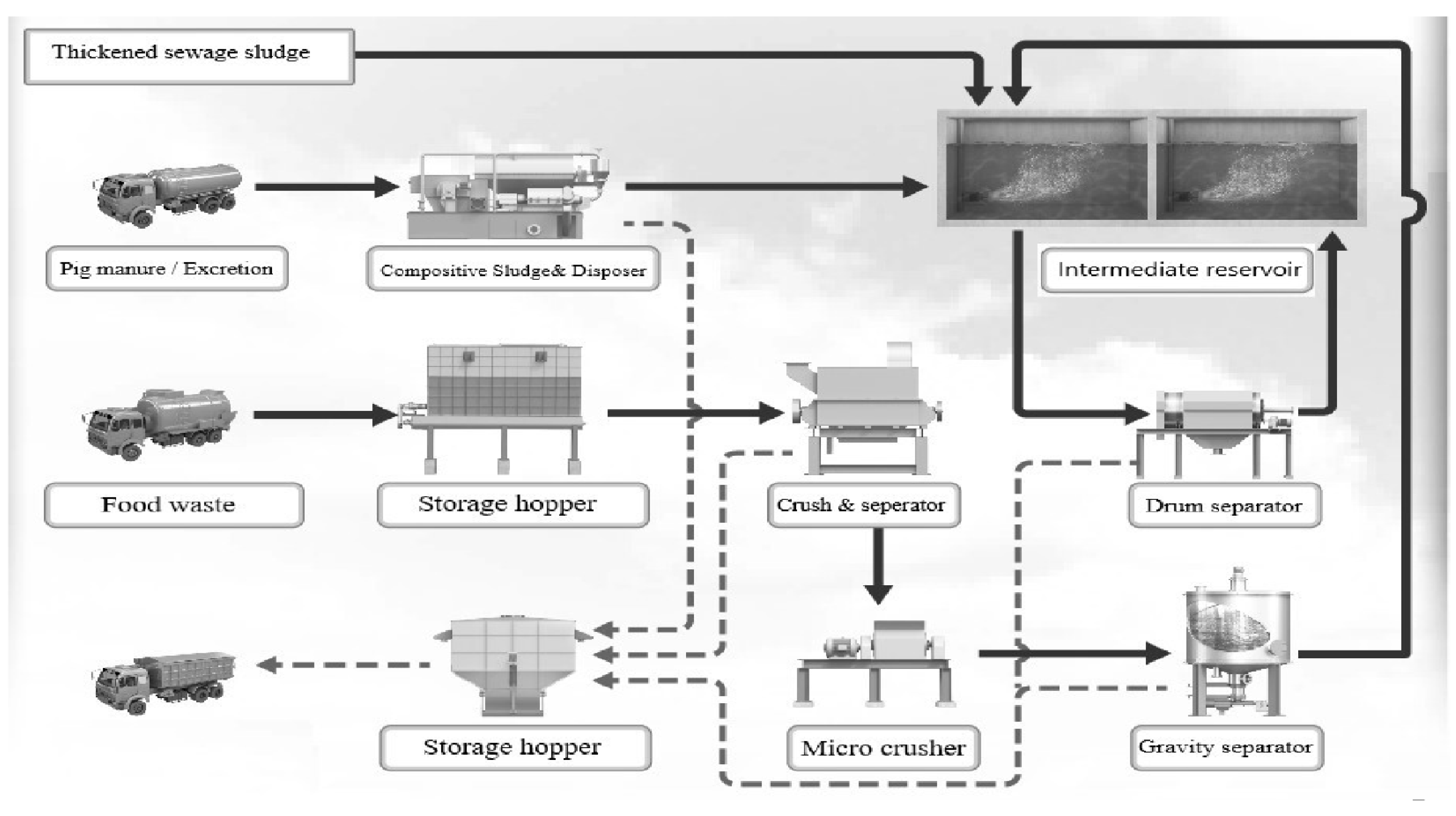

2.3.1. Design of the Pretreatment Facility

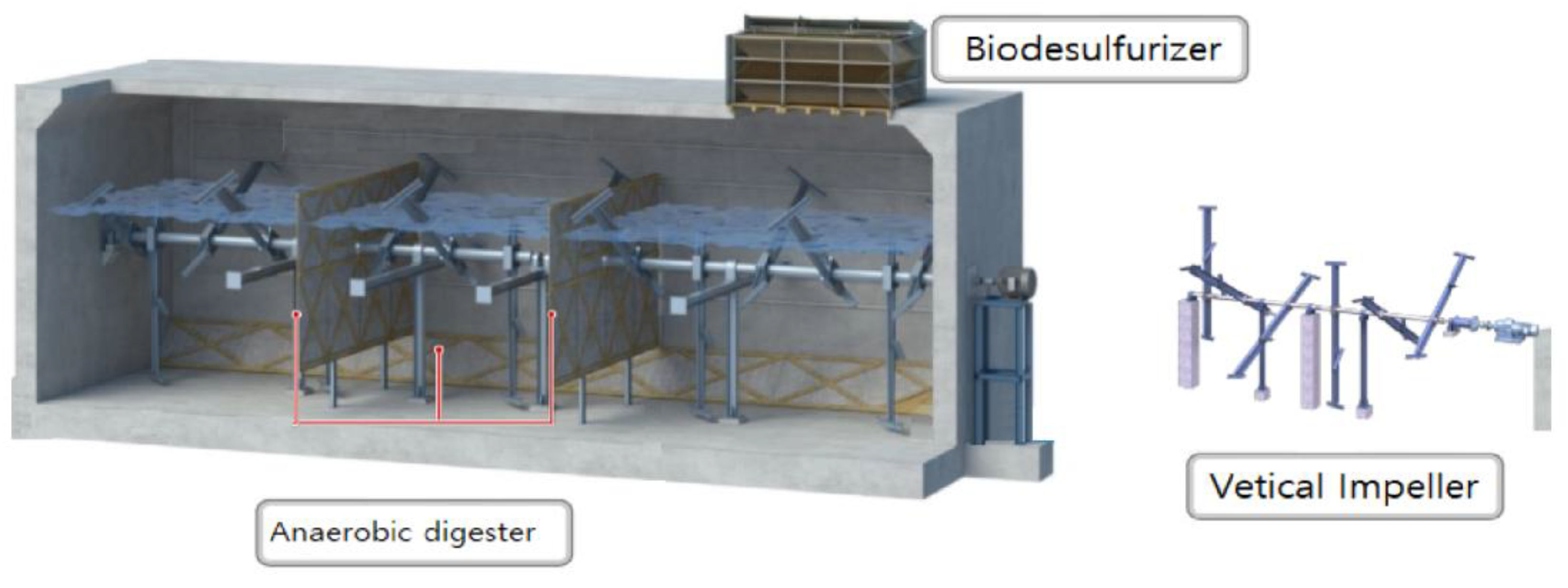

2.3.2. Design of the Anaerobic Digester

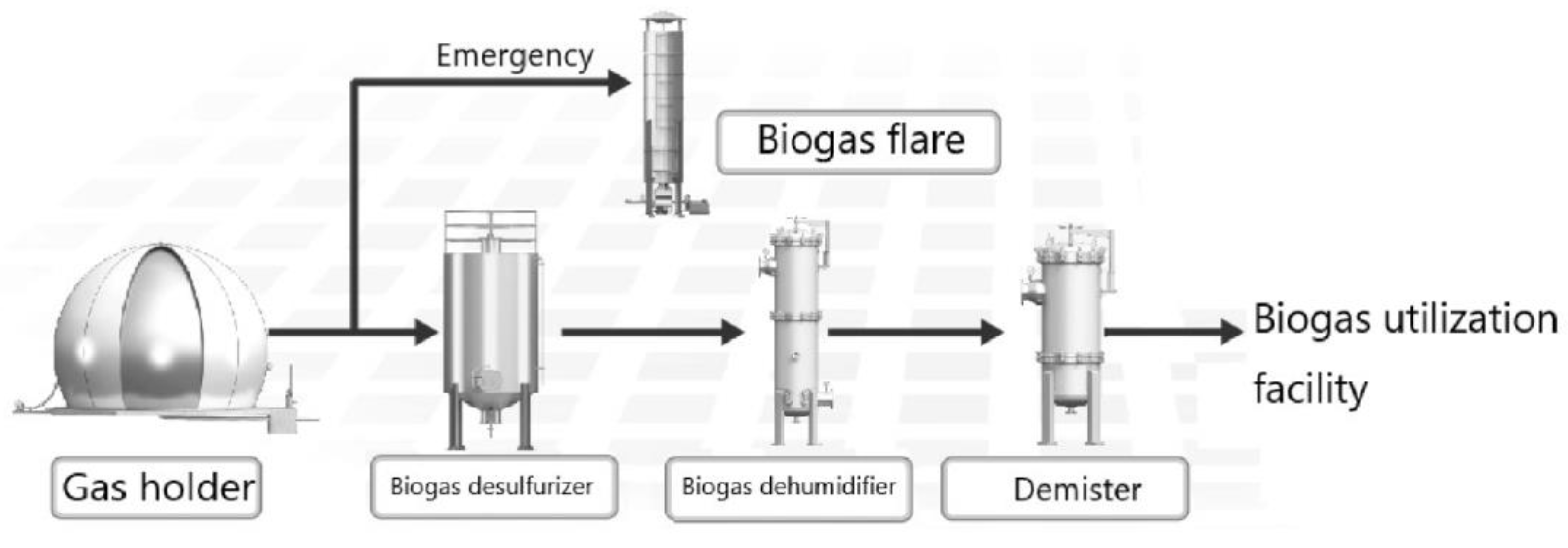

2.3.3. Design of the Biogas Treatment Facility

2.4. Anaerobic Digester Inoculation, Operating Conditions, and Introduction of Organic Waste

2.5. Statistical Analysis

3. Results and Discussion

3.1. Organic Waste Analysis Result

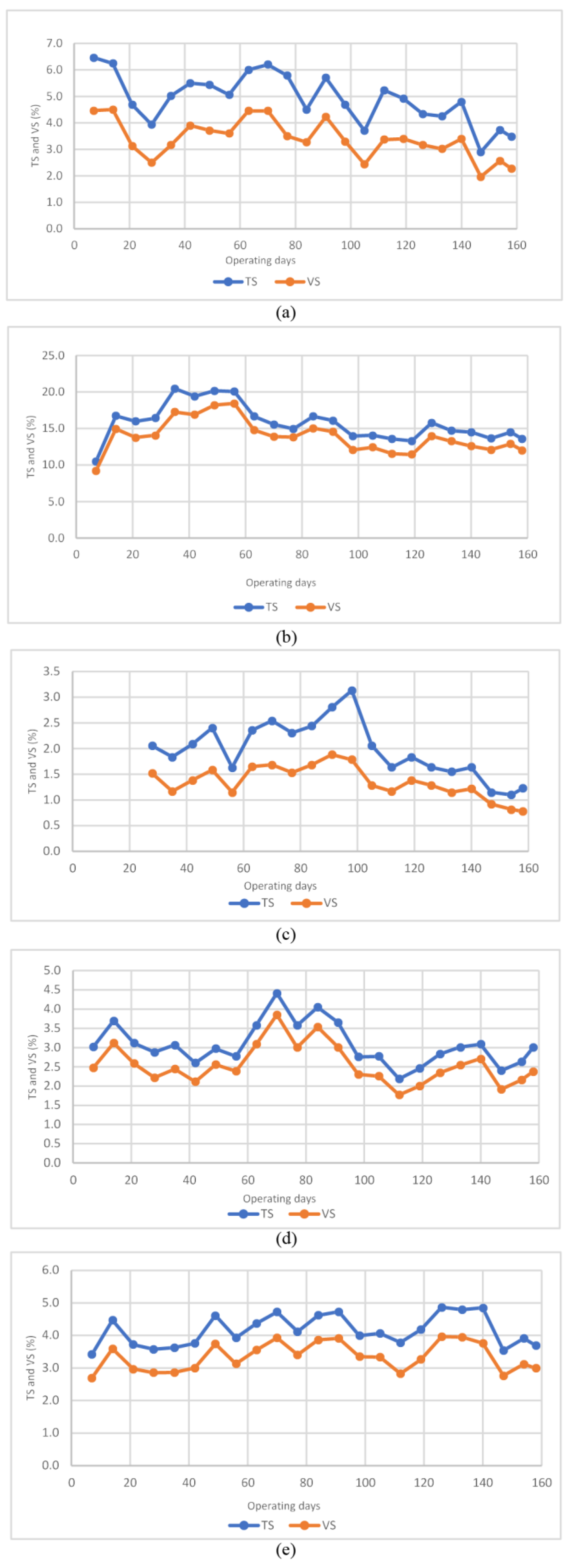

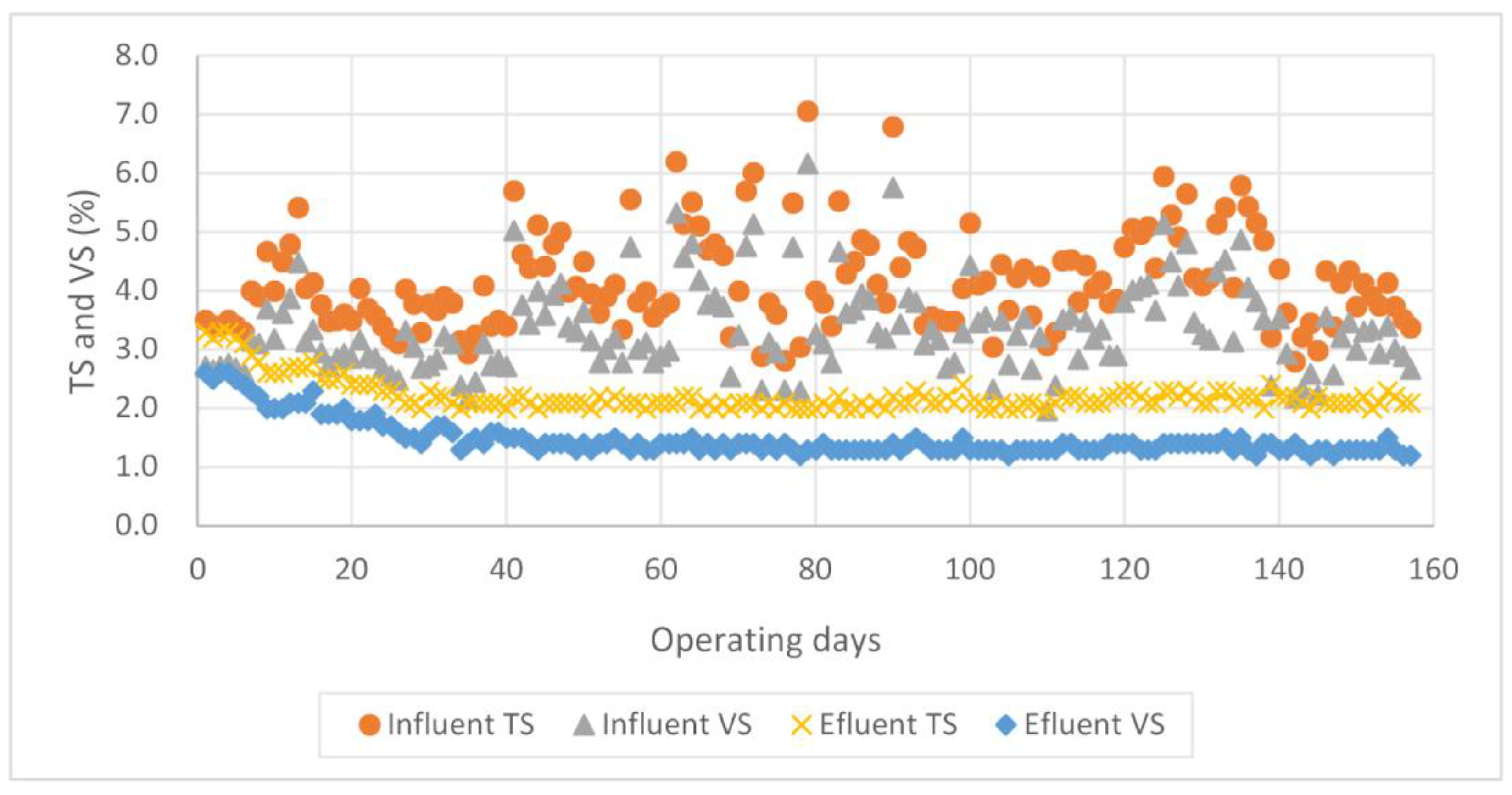

3.2. Solid Content of Organic Waste

3.3. Full-Scale Horizontal Anaerobic Co-Digestion Facility Operation

3.3.1. Full-Scale Horizontal Anaerobic Digester

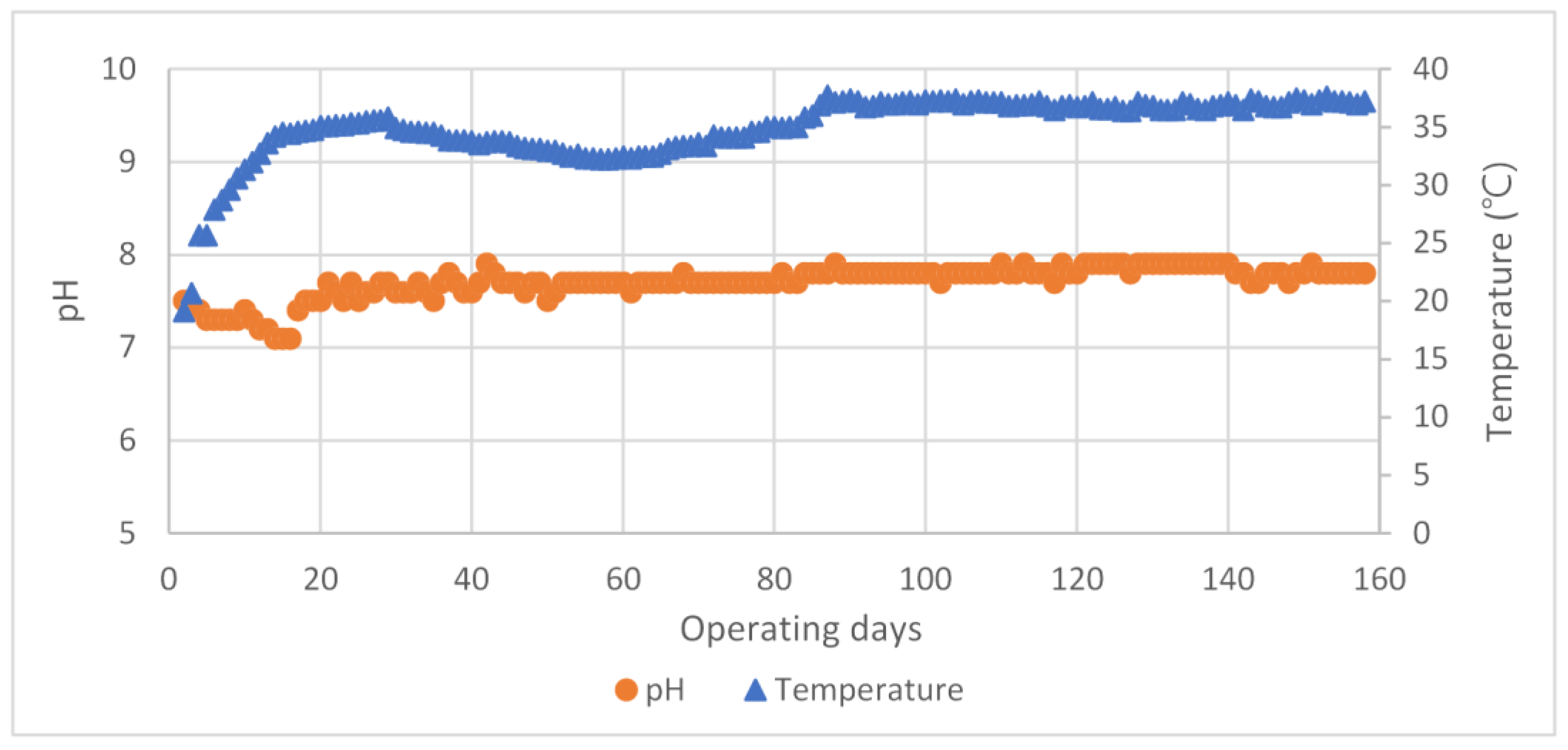

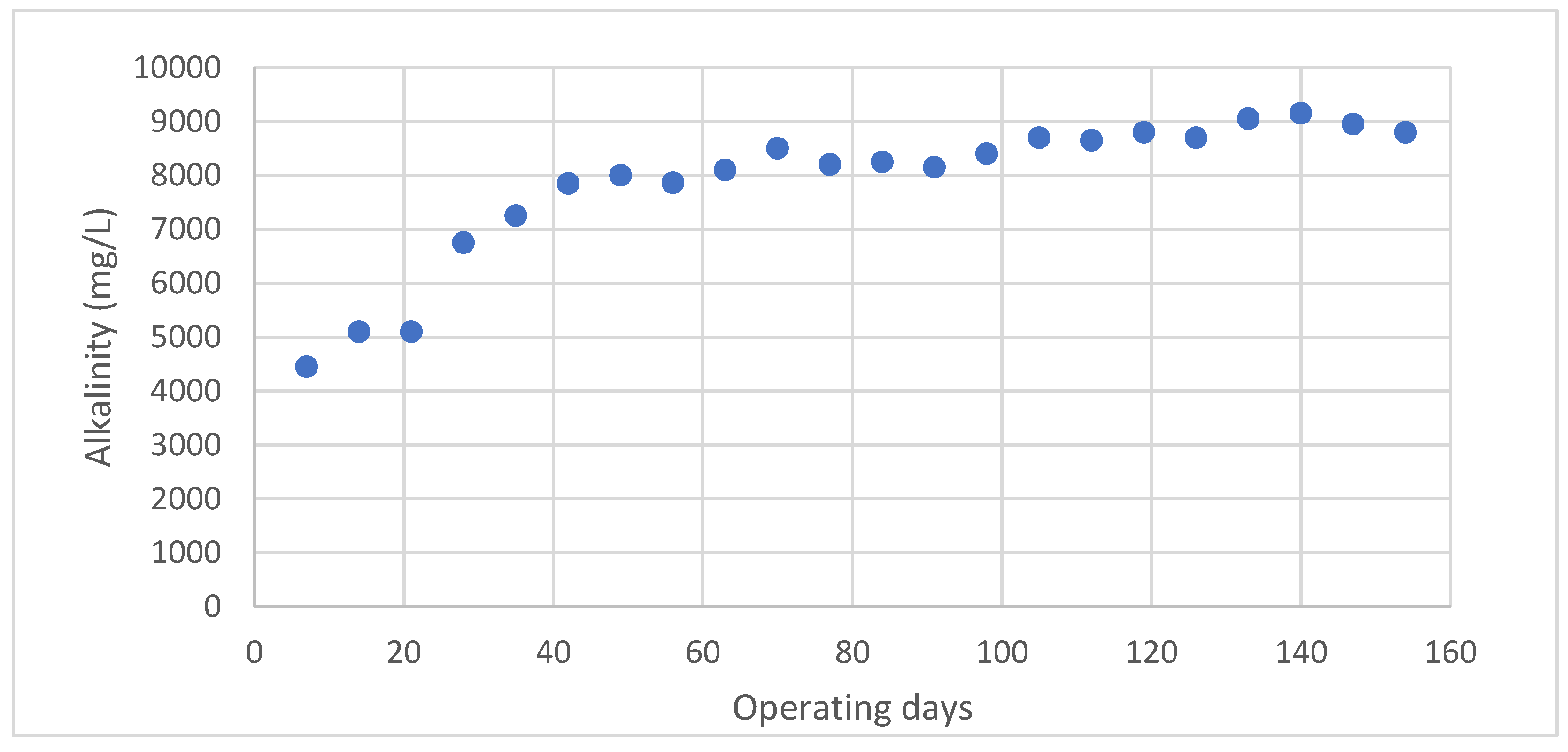

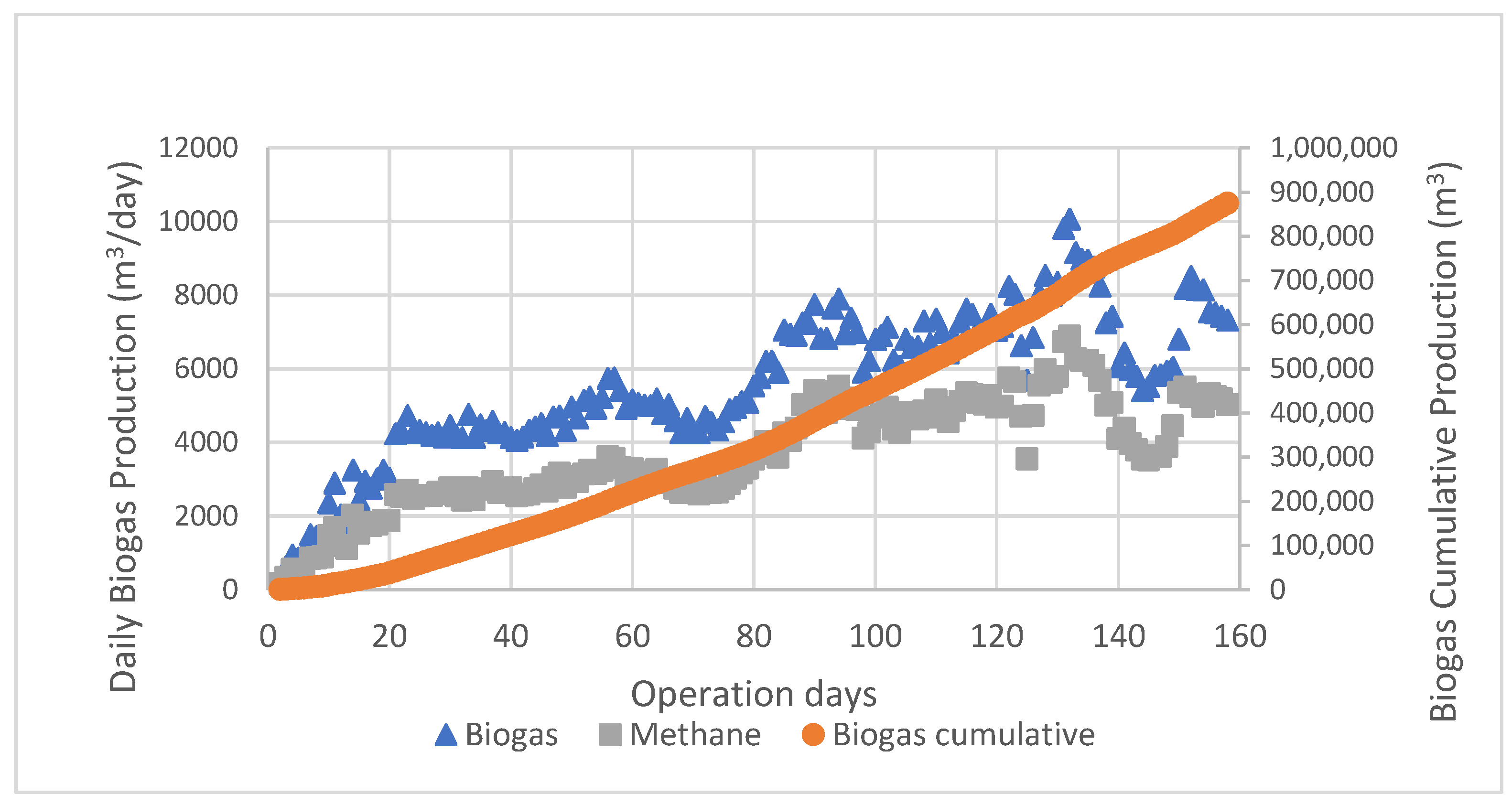

3.3.2. Results of the Full-Scale Horizontal Anaerobic Digester Operation

3.3.3. Effect of Parameters on Biogas Production and Methane Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

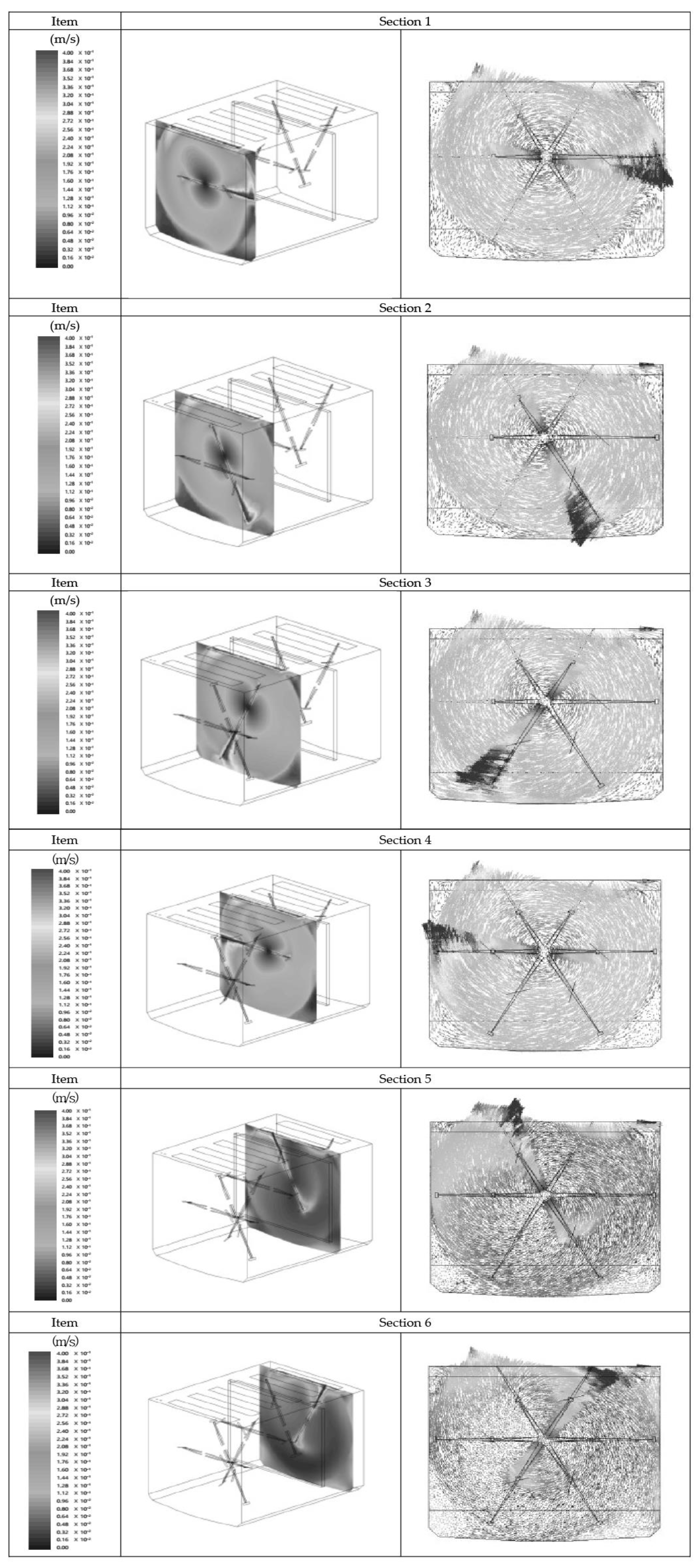

Appendix A. Modeling Purpose

Appendix B. Type of Modeling, Boundary Conditions, and Others

- Program: Fluent v6.3.26

- Numerical methods: Finite-volume method

- Grid: Unstructured mesh

| Item | Content | |

|---|---|---|

| Model | Turbulent Model | K-ε turbulence model Steady State Analysis |

| Multiphase | Phase: 2 (Water, Sludge) It is assumed that 6.3% TS sludge is always flowing in, and there is no chemical reaction between phases | |

| Material Property | Sludge | Density: 1.1 kg/m3 Viscosity: 0.00152 kg/m·s Under TS, 6.3%; VS, 4.9%, the specific gravity is 1.008 kg/m3, Temperature: 38 °C |

| Basic condition | Operating Condition | Gravity: 9.81 m/s2 Standard atmospheric pressure |

| Boundary Conditions | Inlet (sludge) | Velocity—Inlet: 0.05 m/s (80 m3/day, 150 A pipe inflow rate) Second Phase VF: 0.063 (TS 6.3%) Temperature: 38 °C |

| Inlet (circulation) | Velocity—Inlet: 0.087 m/s Second Phase VF: 0.029 (TS 2.9%) | |

| Rotation Area | Motion Type: Moving Reference Frame Angular-Velocity: 1.0 RPM | |

| Wall | Exterior wall and floor of the digester Impeller: No Shear Condition Digester upper water surface layer: Free Slip Condition | |

| Outlet | Naturally discharged under atmospheric pressure | |

Appendix C. Analysis of Results

- The results indicated that the flow velocity distribution changed according to the position of the agitator impeller.

- The swirling flow was reduced because of the bulkhead, and the flow effect occurred in the corner.

- There was a low speed (≤0.1 m/s) area in the rotating shaft. However, the flow speed of the upper and lower parts was 0.2 m/s, which appeared to give a sufficient stirring effect.

- The strength of the swirling flow increased as it exited the agitator.

- The largest displacement vector was observed at the impeller location.

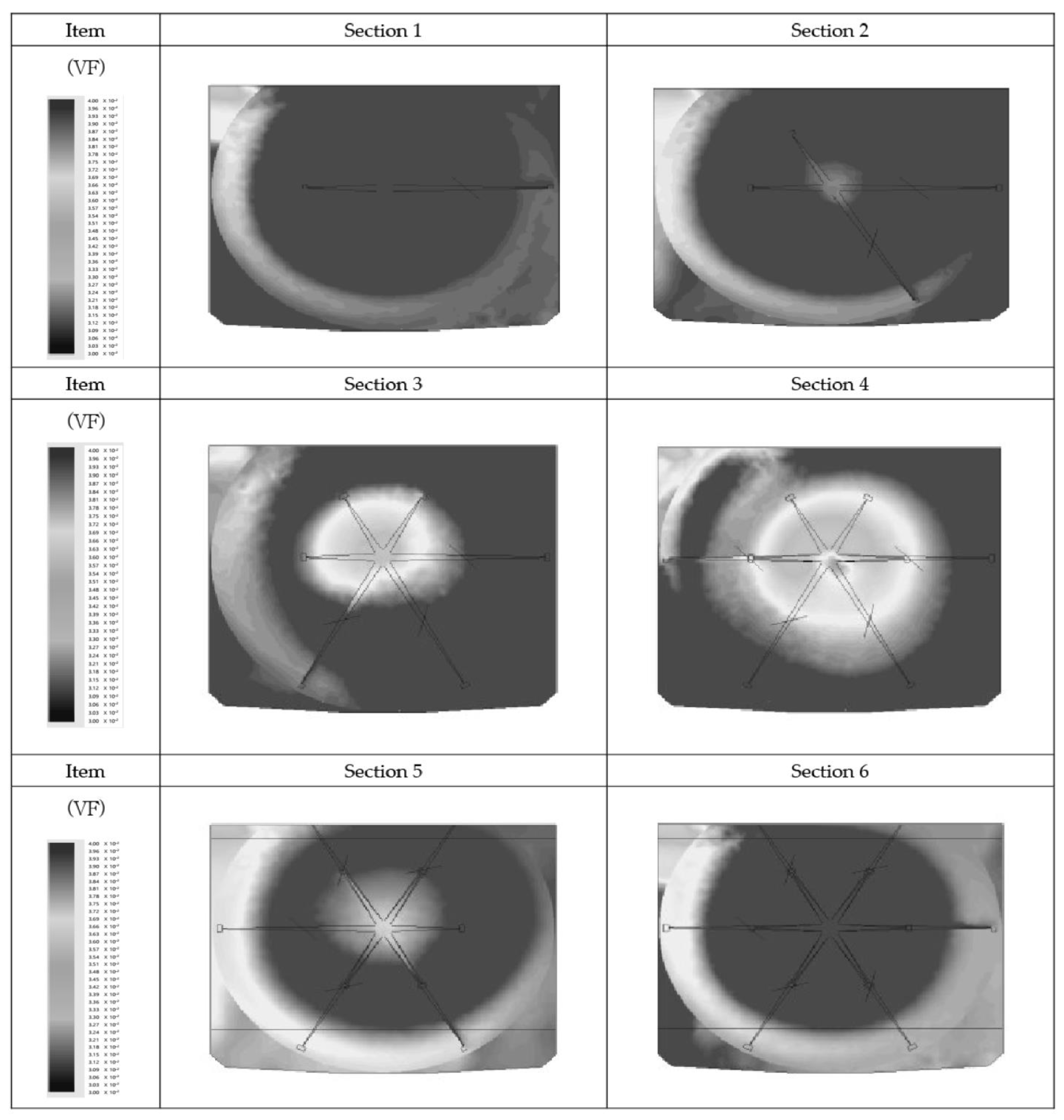

Appendix D. Analysis of Results (Concentration Distribution)

- A low-concentration area was observed in the center owing to the up- and downstream flow based on the bulkhead. However, the rotation of the agitator removed the low-concentration area through repetitive maxing.

- A relatively uniform concentration distribution with a concentration difference of <5% according to the position of the impeller was confirmed.

References

- Ministry of Environment, South Korea. Comprehensive Policy of Waste Resources and Biomass. 2008. Available online: https://www.keco.or.kr/kr/business/facility/communityid/199/view.do?idx=343 (accessed on 20 December 2022).

- Ministry of Environment, South Korea. The Policy Direction of Biogasification. 2022. Available online: https://me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%ED%8F%90%EC%9E%90%EC%9B%90&menuId=10259&orgCd=&condition.toInpYmd=null&condition.fromInpYmd=null&condition.deleteYn=N&condition.deptNm=null&seq=7923 (accessed on 20 December 2022).

- Ministry of Environment, South Korea. Status of Organic Waste Biogasification Facilities in 2021 in Korea. Available online: https://me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%EB%B0%94%EC%9D%B4%EC%98%A4%EA%B0%80%EC%8A%A4&menuId=10259&orgCd=&condition.toInpYmd=null&condition.fromInpYmd=null&condition.deleteYn=N&condition.deptNm=null&seq=7932 (accessed on 20 December 2022).

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Luo, L.; Li, D.; Varjani, S.; Xu, Y.; Wong, J.W.C. Promoting Anaerobic Co-digestion of Sewage Sludge and Food Waste with Different Types of Conductive Materials: Performance, Stability, and Underlying Mechanism. Bioresour. Technol. 2021, 337, 125384. [Google Scholar] [CrossRef] [PubMed]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic Digestion of Organic Solid Wastes. An Overview of Research Achievements and Perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A Critical Review on Anaerobic Co-digestion Achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, J. Enhancement of Methane Production in Anaerobic Digestion Process: A review. Appl. Energy 2019, 240, 120–137. [Google Scholar] [CrossRef]

- Zhang, R.; El-Mashad, H.M.; Hartman, K.; Wang, F.; Liu, G.; Choate, C.; Gamble, P. Characterization of Food Waste as Feedstock for Anaerobic Digestion. Bioresour. Technol. 2007, 98, 929–935. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the Anaerobic Digestion of Food Waste for Biogas Production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic Co-digestion Process for Biogas Production: Progress, Challenges and Perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Rasapoora, M.; Young, B.; Brarb, R.; Sarmahc, A.; Zhuangc, W.-Q.; Baroutiana, S. Recognizing the Challenges of Anaerobic Digestion: Critical Steps Toward Improving Biogas Generation. Fuel 2020, 261, 116497. [Google Scholar] [CrossRef]

- Rincon-Perez, J.; Celis, L.B.; Morales, M.; Alatriste-Mondragon, F.; Tapia-Rodríguez, A.; Razo-Flores, E. Improvement of Methane Production at Alkaline and Neutral pH from Anaerobic Co-digestion of Microalgal Biomass and Cheese Whey. Biochem. Eng. J. 2021, 169, 107972. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Kwietniewska, E.; Tys, J. Process Characteristics, Inhibition Factors and Methane Yields of Anaerobic Digestion Process, with Particular Focus on Microalgal Biomass Fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Su, L.; Sun, X.; Liu, C.; Ji, R.; Zhen, G.; Chen, M.; Zhang, L. Thermophilic Solid-State Anaerobic Digestion of Corn Straw, Cattle Manure, and Vegetable Waste: Effect of Temperature, Total Solid Content, and C/N Ratio. Archaea 2020, 2020, 8841490. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yan, W.; Sheng, K.; Sanati, M. Comparison of High-Solids to Liquid Anaerobic Co-digestion of Food Waste and Green Waste. Bioresour. Technol. 2014, 154, 215–221. [Google Scholar] [CrossRef] [PubMed]

- Parkin, G.F.; Owen, W.F. Fundamentals of Anaerobic Digestion of Wastewater sludges. J. Environ. Eng.-ASCE 1986, 112, 600–604. [Google Scholar] [CrossRef]

- Li, Y.; Park, S.Y.; Zhu, J. Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energy Rev. 2011, 15, 821–836. [Google Scholar] [CrossRef]

- Riya, S.; Suzuki, K.; Terada, A.; Hosomi, M. Influence of C/N Ratio on Performance and Microbial Community Structure of Dry-Thermophilic Anaerobic Co-Digestion of Swine Manure and Rice Straw. Med. Bioeng. 2016, 5, 11–14. [Google Scholar] [CrossRef]

- Comino, E.; Rosso, M.; Riggio, V. Investigation of Increasing Organic Loading Rate in the Co-digestion of Energy Crops and Cow Manure Mix. Bioresour. Technol. 2010, 101, 3013–3019. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources; Wiley-VCH Verlag GmbH& Co. KGaA: Weinheim, Germany, 2008. [Google Scholar] [CrossRef]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Food waste treatment through Anaerobic Co-digestion: Effects of Mixing Intensity on the Thermohydraulic Performance and Methane Production of a Liquid Recirculation Digester. Process Saf. Environ. Prot. 2021, 147, 1171–1184. [Google Scholar] [CrossRef]

- Lindmark, J.; Thorin, E.; Fdhila, R.B.; Dahlquist, E. Effects of Mixing on the Result of Anaerobic Digestion: Review. Renew. Sustain. Energy Rev. 2014, 40, 1030–1047. [Google Scholar] [CrossRef]

- Choi, C.; Lee, C.-Y.; Song, C.-Y.; Yoon, Y. Plant (Dongdaemun Environment and Resources Center) Operation Case Study: Anaerobic Digestion of Food Waste. Korea Soc. Waste Manag. 2016, 33, 819–832. [Google Scholar] [CrossRef]

- Lee, Y.; Park, H.; Yu, Y.; Yoo, H.; Yoo, S. Pilot-scale Study of Horizontal Anaerobic Digester for Biogas Production using Food Waste. World Acad. Sci. Eng. Technol. 2011, 59, 2531–2534. [Google Scholar]

- Koch, K.; Hafner, S.D.; Weinrich, S.; Astals, S.; Holliger, C. Power and Limitations of Biochemical Methane Potential (BMP) Tests. Front. Energy Res. 2020, 8, 63. [Google Scholar] [CrossRef]

- Filer, J.; Ding, H.H.; Chang, S. Biochemical Methane Potential (BMP) Assay Method for Anaerobic Digestion Research. Water 2019, 11, 921. [Google Scholar] [CrossRef]

- Kumho Engineering and Construction. Technical Proposal for Resource Recycling Facility Installation Project in Seosan City; Kumho Engineering and Construction: Seoul, Republic of Korea, 2017. [Google Scholar]

- Mao, L.; Tsui, T.-H.; Zhang, J.; Dai, E.Y.; Tong, Y.W. Mixing effects on decentralized high-solid digester for horticultural waste: Startup, operation and sensitive microorganisms. Bioresour. Technol. 2021, 333, 125216. [Google Scholar] [CrossRef]

- Cui, M.-H.; Zheng, Z.-Y.; Yang, M.; Sangeetha, T.; Zhang, Y.; Liu, H.-B.; Fu, B.; Liu, H.; Chen, C.-J. Revealing hydrodynamics and energy efficiency of mixing for high-solid anaerobic digestion of waste activated sludge. Waste Manag. 2021, 121, 1–10. [Google Scholar] [CrossRef]

- Sol Lisboa, M.; Lansing, S. Characterizing food waste substrates for co-digestion through biochemical methane potential (BMP) experiments. Waste Manag. 2013, 33, 2664–2669. [Google Scholar] [CrossRef]

| Total (m3/d) | Food Waste (m3/d) | Pig Manure (m3/d) | Excretion (m3/d) | Thickened Sewage Sludge (m3/d) |

|---|---|---|---|---|

| 320 | 50 | 100 | 70 | 100 |

| Organic Waste | Number of Samples | Sampling Point | Analysis Items |

|---|---|---|---|

| Pig manure | 4 | Seosan City livestock farms |

|

| Food waste | 2 | Food waste treatment facility in Seosan STP | |

| Excretion | 1 | Excreta treatment facility in Seosan STP | |

| Thickened sewage sludge | 1 | Thickened sewage sludge transfer pipe in Seosan STP |

| Pig Manure | Food Waste | Excretion | Thickened Sewage Sludge |

|---|---|---|---|

| 0.27 | 0.47 | 0.20 | 0.22 |

| Contents | Pig Manure | Food Waste | Excretion | Thickened Sewage Sludge | Mixed |

|---|---|---|---|---|---|

| TS (%) | 4.5 | 21 | 3.2 | 3.7 | 6.5 |

| VS (%) | 3.0 | 17.8 | 2.3 | 2.8 | 5.1 |

| FS (%) | 4.5 | 3.2 | 0.8 | 0.9 | 1.4 |

| Moisture Content (%) | 95.5 | 79.0 | 96.8 | 96.3 | 93.5 |

| Content | Pig Manure (m3/day) | Food Waste (m3/day) | Excretion (m3/day) | Thickened Sewage Sludge (m3/day) | Mixed (m3/day) | |

|---|---|---|---|---|---|---|

| Design | 100 | 70 | 50 | 100 | 320 | |

| Inflow | 2020.02 | 16 | 1 | 0 | 37 | 54 |

| 2020.03 | 55 | 12 | 26 | 78 | 170 | |

| 2020.04 | 46 | 16 | 61 | 104 | 227 | |

| 2020.05 | 59 | 29 | 58 | 77 | 224 | |

| 2020.06 | 96 | 38 | 61 | 100 | 295 | |

| 2020.07 | 101 | 34 | 53 | 110 | 299 | |

| Average | 70 | 25 | 50 | 92 | 237 | |

| Items | Units | Farm 1 | Farm 2 | Farm 3 | Farm 4 | Food Waste 1 | Food Waste 2 | Excretion | Thickened Sewage Sludge | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Apparent density | kg/m3 | 0.98 | 1.02 | 1.02 | 1.02 | 1.06 | 1.08 | 0.96 | 1 | ||

| pH | 8.3 | 8.1 | 8.9 | 8.4 | 4.3 | 4.1 | 7.3 | 6.6 | |||

| Three components | Moisture | % | 96.9 | 96.8 | 97.2 | 96.8 | 80 | 79.2 | 96.9 | 96.4 | |

| Ash | 0.8 | 0.9 | 0.7 | 1 | 2.2 | 2.7 | 0.7 | 1.2 | |||

| Combustible | 2.3 | 2.3 | 2.1 | 2.2 | 17.8 | 18.1 | 2.5 | 2.5 | |||

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||

| TS | % | 3.1 | 3.2 | 2.8 | 3.2 | 20 | 20.8 | 3.1 | 3.6 | ||

| VS | 2.3 | 2.3 | 2.1 | 2.2 | 17.8 | 18.1 | 2.5 | 2.5 | |||

| Chemical composition | C | 36.3 | 36.5 | 33.9 | 36.1 | 41.2 | 43.9 | 38.5 | 40.1 | ||

| H | 4.6 | 4.7 | 4.9 | 4.5 | 6.5 | 6.1 | 5.6 | 5.2 | |||

| O | 29.1 | 27.1 | 28.5 | 28.1 | 29.1 | 32.2 | 26.8 | 28.8 | |||

| N | 2.8 | 2.7 | 3 | 3.1 | 4.8 | 5.3 | 5.4 | 6.5 | |||

| S | 0.3 | 0.3 | 0.5 | 0.6 | 0 | 0 | 0.1 | 0.1 | |||

| Cl | 0 | 0.1 | 0.1 | 0 | 0.1 | 0.2 | 0 | 0.1 | |||

| Caloric value (Colorimeter) | 3275.00 | 3410.00 | 3213.00 | 3275.00 | 4310.90 | 4431.80 | 3884.80 | 3712.80 | |||

| Heavy metals | As | mg/kg | N.D | N.D | N.D | N.D | N.D | N.D | 0.1 | N.D | |

| Cd | N.D | N.D | N.D | N.D | N.D | N.D | N.D | N.D | |||

| Cr | 3.9 | 4.7 | 4.5 | N.D | N.D | N.D | 3.5 | 15.4 | |||

| Cu | 22.4 | 33.9 | 19.1 | 17.5 | 0.4 | 0.1 | 3.1 | 2.1 | |||

| Pb | N.D | N.D | N.D | N.D | N.D | N.D | N.D | N.D | |||

| Ni | 1.2 | 1.8 | 0.4 | 0.8 | 0.3 | 0.6 | 0.4 | 0.1 | |||

| Zn | 129 | 115 | 139 | 134 | 15 | 16.1 | 24.1 | 11.7 | |||

| Hg | N.D | N.D | N.D | N.D | N.D | N.D | N.D | 0.1 | |||

| Items | Units | Farm 1 | Farm 2 | Farm 3 | Farm 4 | Food Waste 1 | Food Waste 2 | Excretion | Thickened Sewage Sludge |

|---|---|---|---|---|---|---|---|---|---|

| BOD | mg/L | 27,541.8 | 27,631.5 | 29,841.5 | 30,806.4 | 160,074.8 | 155,245.3 | 9845.5 | 17,218.0 |

| CODMn | 22,318.1 | 22,763.5 | 21,874.1 | 23,645.3 | 109,031.6 | 127,659.1 | 8078.5 | 13,789.0 | |

| CODcr | 60,978.5 | 51,024.1 | 54,264.3 | 57,350.1 | 215,177.9 | 244,555.4 | 34,996.1 | 71,909.5 | |

| SS | 29,832.1 | 29,058.4 | 27,373.5 | 28,167.5 | 169,153.1 | 175,323.2 | 15,616.0 | 26,323.5 | |

| Nor | 148.1 | 167.3 | 194.5 | 124.7 | 613.5 | 794.6 | 93.4 | 139.8 | |

| T-N | 4402.0 | 5400.9 | 4156.8 | 3982.8 | 6151.3 | 6389.1 | 1383.3 | 2427.5 | |

| T-P | 880.1 | 817.7 | 842.3 | 847.5 | 770.6 | 801.0 | 221.1 | 794.8 | |

| Total coliforms | total coliforms/mL | 173,000 | 167,000 | 159,000 | 197,000 | 6200 | 4300 | 25,300 | 37,100 |

| NH3-N | mg/L | 1937.0 | 1810.0 | 2188.0 | 1753.0 | 379.1 | 435.8 | 987.1 | 174.1 |

| NO2-N | 210.1 | 276.6 | 344.5 | 244.5 | 19.8 | 24.6 | 161.5 | N.D | |

| PO4-P | 47.5 | 37.1 | 14.8 | 26.8 | 54.7 | 39.5 | 7.4 | 134.7 | |

| Alkalinity | 15,251.0 | 20,890.0 | 16,758.0 | 18,934.0 | 2100.0 | 1567.0 | 3051.0 | 643.0 |

| Gas Production Rate | Unit | Substrate | ||||

|---|---|---|---|---|---|---|

| Pig Manure | Food Waste | Excretion | Thickened Sewage Sludge | Mixed | ||

| BMP Test | Nm3CH4/kg VSin | 0.30 | 0.47 | 0.22 | 0.23 | 0.37 |

| Operation Data | 0.35 | 0.60 | 0.26 | 0.28 | 0.39 | |

| Dependent Variable | Independent Variable | Unstandardized Coefficient | Standardized Coefficient | t | p | VIF | |

|---|---|---|---|---|---|---|---|

| B | SE | ß | |||||

| Biogas Production | Temperature | 295.652 | 30.835 | 0.427 | 9.588 *** | 0.000 | 1.599 |

| pH | 6122.640 | 498.053 | 0.552 | 12.293 *** | 0.000 | 1.621 | |

| Influent VS | 217.331 | 100.381 | 0.078 | 2.165 * | 0.032 | 1.046 | |

| Durbin-Watson = 1.825, R2 = 0.810, Adj-R2 = 0.806, F = 217.220 *** (p < 0.001) | |||||||

| Methane Content | Temperature | 0.787 | 0.114 | 0.477 | 6.916 *** | 0.000 | 1.599 |

| pH | 8.276 | 1.838 | 0.313 | 4.503 *** | 0.000 | 1.621 | |

| Influent VS | 0.629 | 0.370 | 0.095 | 1.697 | 0.092 | 1.046 | |

| Durbin-Watson = 2.070, R2 = 0.544, Adj-R2 = 0.535, F = 60.898 *** (p < 0.001) | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, Y.; Khim, J.; Kim, J.D. Application of a Full-Scale Horizontal Anaerobic Digester for the Co-Digestion of Pig Manure, Food Waste, Excretion, and Thickened Sewage Sludge. Processes 2023, 11, 1294. https://doi.org/10.3390/pr11041294

Park Y, Khim J, Kim JD. Application of a Full-Scale Horizontal Anaerobic Digester for the Co-Digestion of Pig Manure, Food Waste, Excretion, and Thickened Sewage Sludge. Processes. 2023; 11(4):1294. https://doi.org/10.3390/pr11041294

Chicago/Turabian StylePark, Yongwoon, Jeehyeong Khim, and Jong Doo Kim. 2023. "Application of a Full-Scale Horizontal Anaerobic Digester for the Co-Digestion of Pig Manure, Food Waste, Excretion, and Thickened Sewage Sludge" Processes 11, no. 4: 1294. https://doi.org/10.3390/pr11041294

APA StylePark, Y., Khim, J., & Kim, J. D. (2023). Application of a Full-Scale Horizontal Anaerobic Digester for the Co-Digestion of Pig Manure, Food Waste, Excretion, and Thickened Sewage Sludge. Processes, 11(4), 1294. https://doi.org/10.3390/pr11041294