An Impacting Factors Analysis of Unsafe Acts in Coal Mine Gas Explosion Accidents Based on HFACS-ISM-BN

Abstract

1. Introduction

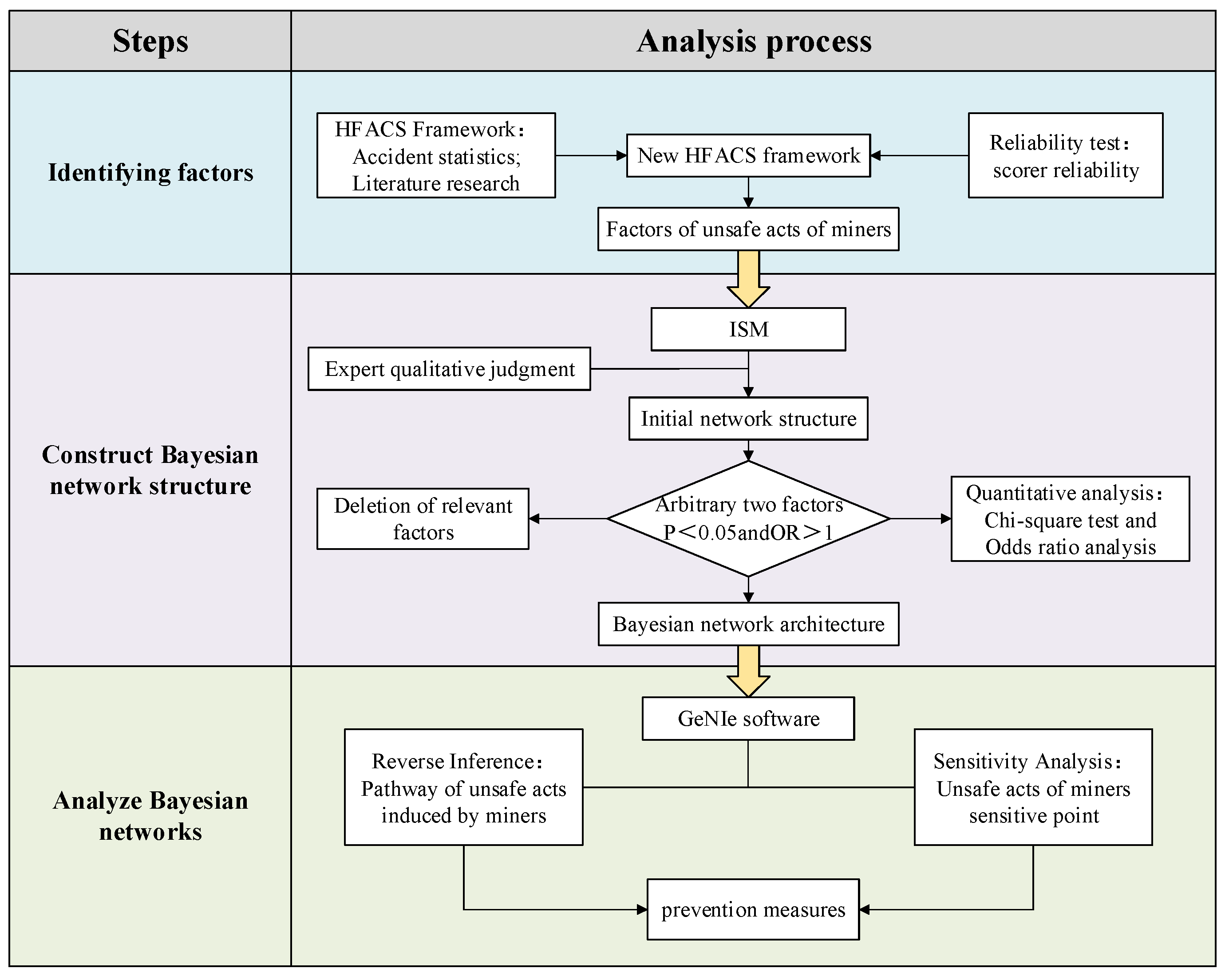

2. Materials and Methods

2.1. Establishment of the Impacting Factors System

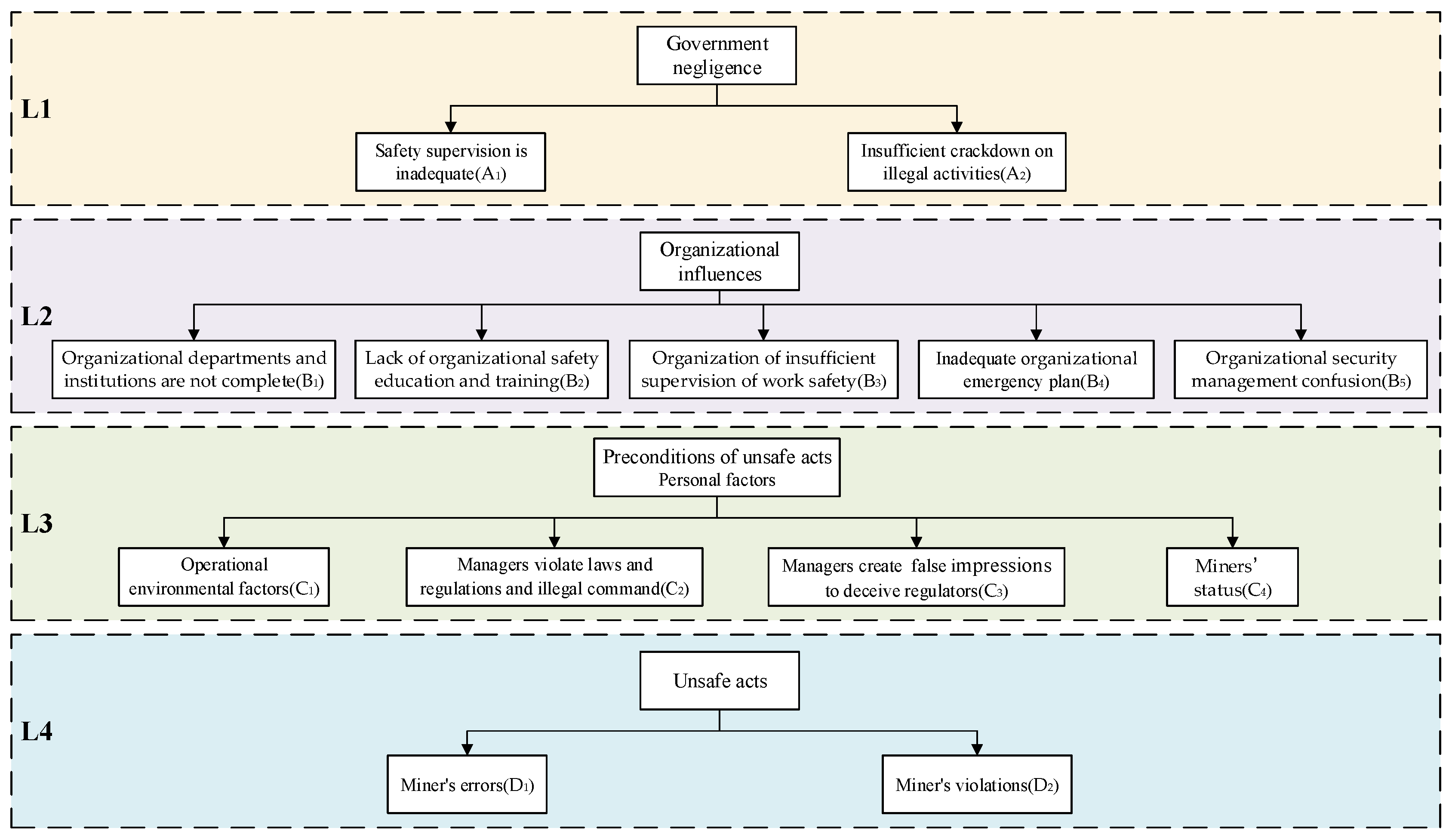

2.1.1. Improved HFACS Framework

- In the coal industry, government regulators need to be considered. The coal mine gas explosion accident can be effectively controlled by the supervision department to strengthen the supervision of coal mine production [20].

- In coal mining enterprises, the manifestations of management errors are more diverse [21]. For example, inadequate safety training will lead to secondary disasters, and imperfect safety management system will make the production process chaotic.

- In specific coal mines, the factors of enterprise managers need to be considered. For example, managers participate in production by giving production orders, and their errors may cause huge accidents.

- Increase the level of government dereliction of duty, which includes two factors: safety supervision is inadequate and insufficient crackdown on illegal activities.

- Remove the level of unsafe supervision, but retain the factors in unsafe supervision, and integrate these factors into other levels.

- Increase the number of factors affecting this level from 3 to 5.

- The level of unsafe acts no longer classifies miners’ errors and violations in detail, given that further subdivision of miner errors and violations based on accident cases could distort the data.

2.1.2. Reliability Test of the System of the Impacting Factors

2.2. Determination of Hierarchies and Dependencies

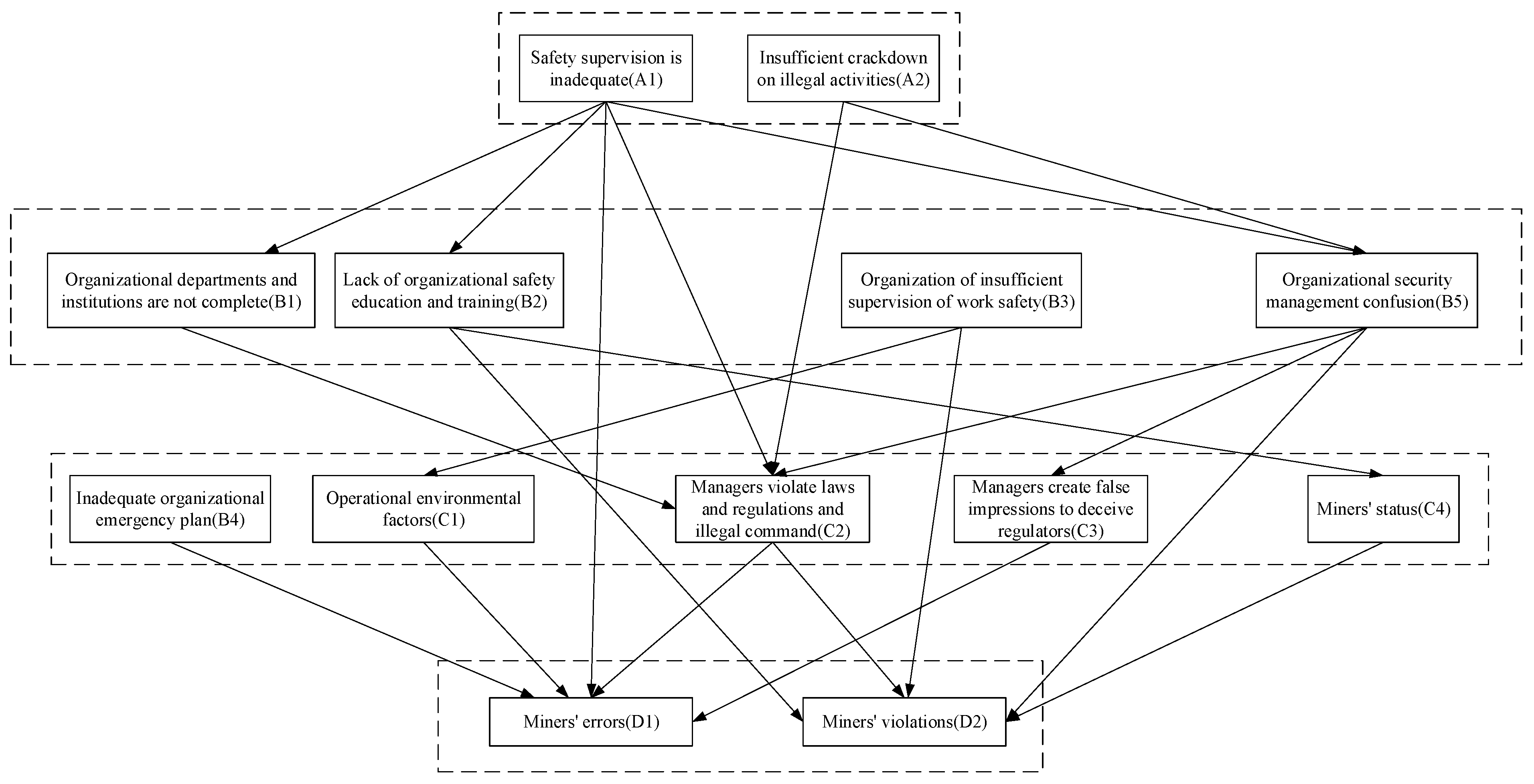

2.2.1. Construction of Hierarchy Structure Based on ISM

2.2.2. Test for Correlation of the Impacting Factors

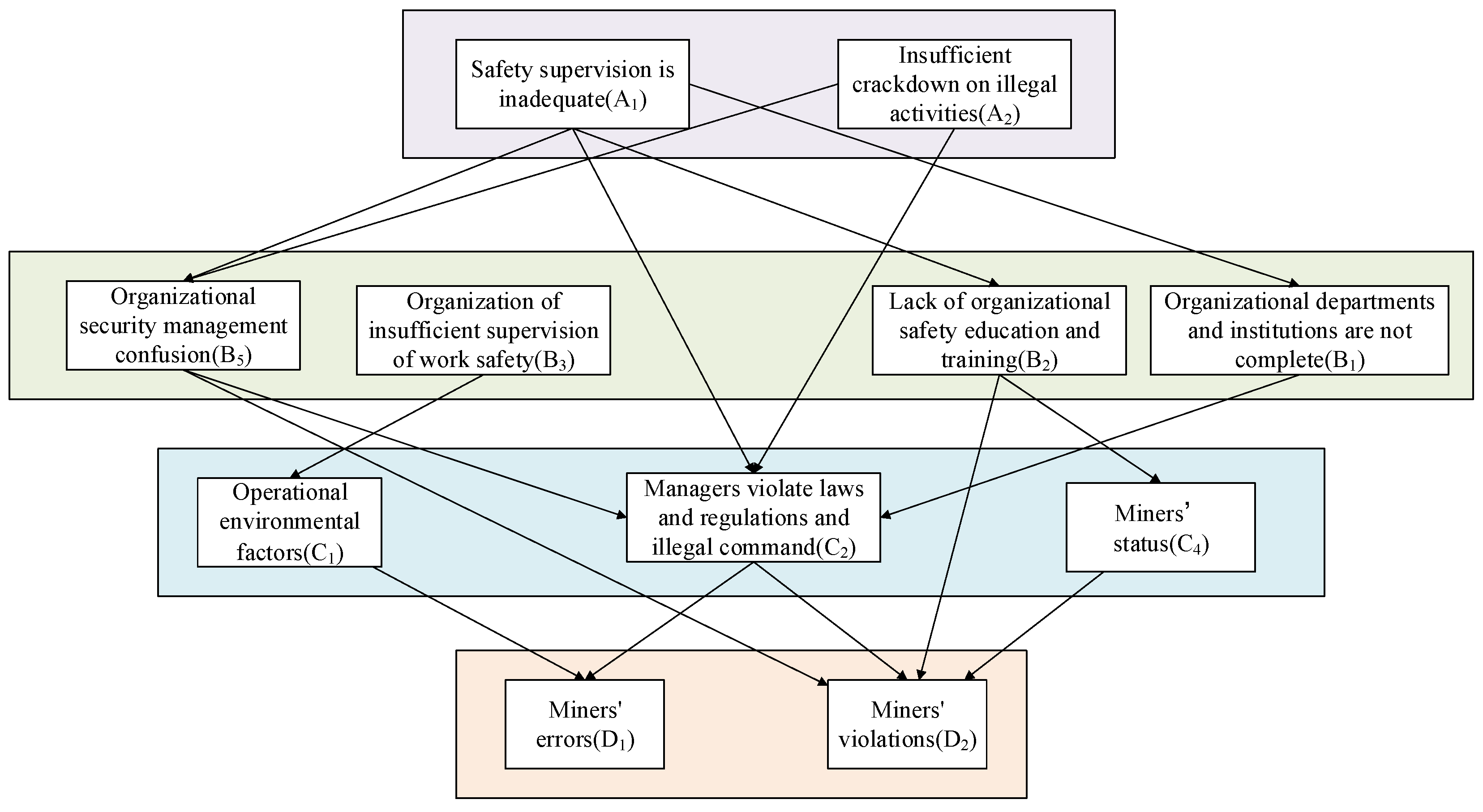

2.3. Construct Bayesian Networks

2.3.1. Determination of BN Parameters

2.3.2. Using GeNIe Software to Construct BN

3. Results

3.1. Induced Path Analysis

3.2. Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ge, X.; Su, S.; Yu, H.; Chen, G.; Lu, X. Smart mine construction based on knowledge engineering and internet of things. Int. J. Perform. Eng. 2018, 14, 1060. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, S.; Gunda, Y.R. Estimation of human error rate in underground coal mines through retrospective analysis of mining accident reports and some error reduction strategies. Saf. Sci. 2020, 123, 104555. [Google Scholar] [CrossRef]

- Huang, Y.; Zha, H.; Gao, J.; Linghu, J.; Xuan, J.; Zhou, J.; Dong, R.; Huo, J.; Zhang, H. Predicting the distribution of coalbed methane by ambient noise tomography with a dense seismic array. Chin. J. Geophys. 2021, 64, 3997–4011. [Google Scholar]

- Tong, R.; Yang, Y.; Ma, X.; Zhang, Y.; Li, S.; Yang, H. Risk assessment of Miners’ unsafe behaviors: A case study of gas explosion accidents in coal mine, china. Int. J. Environ. Res. Public Health 2019, 16, 1765. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, D.; Wang, Q. Characteristics analysis of large and above coal mine accidents in China from 2005 to 2016. J. Saf. Environ. 2019, 19, 1847–1852. [Google Scholar]

- Chen, H.; Qi, H.; Tan, H. Study on fatal accidents in China’s coal mines based on feature sources and environment characteristics. China Saf. Sci. J. 2005, 15, 33–38. [Google Scholar]

- Li, Y.; Zhao, Z.; Tian, S. Review of research on unsafe behavior of miners. J. Saf. Sci. Techol. 2016, 12, 47–54. [Google Scholar]

- Dekker, S.W. Reconstructing human contributions to accidents: The new view on error and performance. J. Saf. Res. 2002, 33, 371–385. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Y.; Niu, Y. Routes to failure: Analysis of chemical accidents using the HFACS. J. Loss Prev. Process Ind. 2022, 75, 104695. [Google Scholar] [CrossRef]

- Ma, L.; Ma, X.; Lan, H.; Liu, Y.; Deng, W. A data-driven method for modeling human factors in maritime accidents by integrating DEMATEL and FCM based on HFACS: A case of ship collisions. Ocean Eng. 2022, 266, 112699. [Google Scholar] [CrossRef]

- Wan, Y.; Xia, H. Application of HFACS Model in Marine Traffic Accident Field. Int. Core J. Eng. 2021, 7, 135–140. [Google Scholar]

- Ye, G.; Duan, S.; Wang, H. Investigation on factors influencing contractor’s decision on safety investment. China Saf. Sci. J. 2014, 24, 23–29. [Google Scholar]

- Patterson, J.M.; Shappell, S.A. Operator error and system deficiencies: Analysis of 508 mining incidents and accidents from Queensland, Australia using HFACS. Accid. Anal. Prev. 2010, 42, 1379–1385. [Google Scholar] [CrossRef] [PubMed]

- Lenné, M.G.; Salmon, P.M.; Liu, C.C.; Trotter, M. A systems approach to accident causation in mining: An application of the HFACS method. Accid. Anal. Prev. 2012, 48, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Zarei, E.; Yazdi, M.; Abbassi, R.; Khan, F. A hybrid model for human factor analysis in process accidents: FBN-HFACS. J. Loss Prev. Process Ind. 2019, 57, 142–155. [Google Scholar] [CrossRef]

- Ghasemi, F.; Gholamizadeh, K.; Farjadnia, A.; Sedighizadeh, A.; Kalatpour, O. Human and organizational failures analysis in process industries using FBN-HFACS model: Learning from a toxic gas leakage accident. J. Loss Prev. Process Ind. 2022, 78, 104823. [Google Scholar] [CrossRef]

- Ma, L.; Ma, X.; Xing, P.; Yu, F. A hybrid approach based on the HFACS-FBN for identifying and analysing human factors for fire and explosion accidents in the laboratory. J. Loss Prev. Process Ind. 2022, 75, 104675. [Google Scholar] [CrossRef]

- Cheng, L.; Guo, A.; Guo, H.; Cao, D. Research on coupling evolution path of gas explosion risks in coal mines. China Saf. Sci. J. 2022, 32, 59–64. [Google Scholar]

- Attri, R.; Dev, N.; Sharma, V. Interpretive structural modelling (ISM) approach: An overview. Res. J. Mgmt. Sci. 2013, 2319, 1171. [Google Scholar]

- Siu, N. Risk assessment for dynamic systems: An overview. Reliab. Eng. Syst. Saf. 1994, 43, 43–73. [Google Scholar] [CrossRef]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q.; Jiang, A.; Lv, T. An impacting factors analysis of miners’ unsafe acts based on HFACS-CM and SEM. Process Saf. Environ. Prot. 2019, 122, 221–231. [Google Scholar] [CrossRef]

- Niu, G.; Yan, S. Grey correlation analysis of coal mine accident triggering factors based on improved HFACS. Coal Eng. 2016, 48, 142–145. [Google Scholar]

- Wang, L.; Mo, X.; Cao, Q. A new method of HFACS-MM. China Saf. Sci. J. 2014, 24, 73–78. [Google Scholar]

- Ergai, A.; Cohen, T.; Sharp, J.; Wiegmann, D.; Gramopadhye, A.; Shappell, S. Assessment of the Human Factors Analysis and Classification System (HFACS): Intra-rater and inter-rater reliability. Saf. Sci. 2016, 82, 393–398. [Google Scholar] [CrossRef]

- Olsen, N.S. Coding ATC incident data using HFACS: Inter-coder consensus. Saf. Sci. 2011, 49, 1365–1370. [Google Scholar] [CrossRef]

- Olsen, N.S.; Shorrock, S.T. Evaluation of the HFACS-ADF safety classification system: Inter-coder consensus and intra-coder consistency. Accid. Anal. Prev. 2010, 42, 437–444. [Google Scholar] [CrossRef]

- Bañuls, V.A.; Turoff, M.; Hiltz, S.R. Collaborative scenario modeling in emergency management through cross-impact. Technol. Forecast. Soc. 2013, 80, 1756–1774. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Meng, Q.; Xie, H. Ship accident consequences and contributing factors analyses using ship accident investigation reports. Proc. Inst. Mech. Eng. Part O J. Ris. Reliab. Eng. Syst. Saf. 2019, 233, 35–47. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, L.; Yang, Y.; Hu, X.; Ou, C.; Zeng, R. An ISM-BN based research on navigation risk factors of inland waterway vessels. China Saf. Sci. J. 2022, 32, 37–44. [Google Scholar]

- Tallarida, R.J.; Murray, R.B.; Tallarida, R.J.; Murray, R.B. Chi-Square Test. In Manual of Pharmacologic Calculations: With Computer Programs; Tallarida, R.J., Murray, R.B., Tallarida, R.J., Murray, R.B., Eds.; Springer: Cham, Switzerland, 1987; pp. 140–142. [Google Scholar]

- Li, Z.; Wang, X.; Gong, S.; Sun, N.; Tong, R. Risk assessment of unsafe behavior in university laboratories using the HFACS-UL and a fuzzy Bayesian network. J. Saf. Res. 2022, 82, 13–27. [Google Scholar] [CrossRef]

- Oniśko, A.; Druzdzel, M.J.; Wasyluk, H. Learning Bayesian network parameters from small data sets: Application of Noisy-OR gates. Int. J. Approx. Reason. 2001, 27, 165–182. [Google Scholar] [CrossRef]

| Level | Factors | Description of Risk Category |

|---|---|---|

| Government negligence | Safety supervision is inadequate (A1) | The daily supervision of coal mining enterprises by coal-related departments at all levels of government is inadequate, leading to the difficulty in implementing coal mine production rules and regulations, and the inadequate investigation of coal mine safety risks. |

| Insufficient crackdown on illegal activities (A2) | Coal-related departments at all levels of government have not cracked down enough on the illegal production and business activities of coal mining enterprises. | |

| Organizational influences | Organizational departments and institutions are not complete (B1) | The internal organization of coal mining enterprises is incomplete, resulting in incomplete departments in charge of coal mine safety, or personnel in charge of safety management are unprofessional or incompetent. |

| Lack of organizational safety education and training (B2) | Coal mine enterprises do not carry out safety training for managers and employees on time, including special meetings, emergency drills and job training, or the training carried out by coal mine enterprises is just a formality. | |

| Organization of insufficient supervision of work safety (B3) | Coal mining enterprises, including the various organizations within the enterprises and the managers responsible for safety work, did not check the safety risks in coal mines on time, or the checks were not meticulous. | |

| Inadequate organizational emergency plan (B4) | Coal mining enterprises have not formulated emergency measures to deal with emergencies, or the formulated emergency measures have insufficient timeliness and adaptability. | |

| Organizational security management confusion (B5) | The responsibility of the institutions and departments in coal mine enterprises is not clear, which leads to the duplication and absence of the management of each system in coal mine. | |

| Preconditions for unsafe acts | Operational environmental factors (C1) | Poor physical environment: Poor working place for employees, including but not limited to noise, dust, and temperature discomfort. |

| Poor technical environment: including but not limited to staff without professional and technical guidance and equipment performance deficiencies. | ||

| Managers violate laws and regulations and illegal command (C2) | Managers of coal mining enterprises violate laws and rules and regulations of the coal industry to organize employees to carry out production operations. | |

| Managers create false impressions to deceive regulators (C3) | Managers of coal mining enterprises falsified accounts, drawings, and data to deceive government departments. | |

| Miners’ status (C4) | Poor physiological condition: The employee has, including but not limited to, fatigue, sleepiness, and other conditions at work. | |

| Poor mental state: employees in the work, including but not limited to the existence of fluke psychology, paralysis, bravura psychology, etc. | ||

| Unsafe acts | Miners’ errors (D1) | Skill-based errors: An employee’s failure at work due to improper execution of procedures or inadequate operational skills. |

| Decision errors: An error of judgment by an employee due to insufficient information, knowledge, or experience. | ||

| Perceptual errors: When an employee’s perception and awareness of something deviates from the actual situation. | ||

| Miners’ violations (D2) | Habitual violations: When employees are working, they often choose to violate rules even though they clearly know the violation. | |

| Accidental violations: The violation caused by various accidental factors at work, and the violation is not intended by the employee. |

| Level | Factors | Index Consistency (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| All | 1 & 2 | 1 & 3 | 1 & 4 | 2 & 3 | 2 & 4 | 3 & 4 | ||

| Government negligence | Safety supervision is inadequate (A1) | 80.17 | 90 | 97 | 68 | 70 | 87 | 69 |

| Insufficient crackdown on illegal activities (A2) | 85.17 | 93 | 97 | 77 | 79 | 87 | 78 | |

| Organizational influences | Organizational departments and institutions are not complete (B1) | 80.83 | 91 | 97 | 69 | 68 | 88 | 72 |

| Lack of organizational safety education and training (B2) | 87.17 | 94 | 96 | 81 | 77 | 90 | 85 | |

| Organization of insufficient supervision of work safety (B3) | 80.17 | 87 | 94 | 72 | 69 | 81 | 78 | |

| Inadequate organizational emergency plan (B4) | 79 | 93 | 88 | 67 | 68 | 86 | 72 | |

| Organizational security management confusion (B5) | 90.17 | 91 | 94 | 92 | 93 | 87 | 84 | |

| Preconditions for unsafe acts | Operational environmental factors (C1) | 71.17 | 87 | 94 | 52 | 53 | 85 | 56 |

| Managers violate laws and regulations and illegal command (C2) | 86.67 | 88 | 97 | 81 | 77 | 85 | 92 | |

| Managers create false impressions to deceive regulators (C3) | 87.5 | 94 | 86 | 89 | 85 | 90 | 81 | |

| Miners’ status (C4) | 85 | 96 | 95 | 77 | 75 | 91 | 76 | |

| Unsafe acts | Miners’ errors (D1) | 71.67 | 87 | 92 | 53 | 60 | 83 | 55 |

| Miners’ violations (D2) | 78.5 | 89 | 93 | 67 | 68 | 82 | 72 | |

| Total | 81.78 | 90.77 | 93.85 | 72.69 | 72.46 | 86.31 | 74.62 | |

| Factor Correlation | p | OR | |

|---|---|---|---|

| A1 & B1 | 10.083 | 0.001 | 1.361 |

| A1 & B2 | 11.068 | 0.001 | 1.485 |

| A1 & B5 | 16.549 | 0.0001 | 1.153 |

| A1 & C2 | 6.75 | 0.009 | 1.407 |

| A2 & B5 | 62.916 | 0.0001 | 1.082 |

| A2 & C2 | 44.541 | 0.0001 | 1.6596 |

| B1 & C2 | 32.013 | 0.0001 | 1.0303 |

| B2 & C4 | 19.946 | 0.0001 | 10.286 |

| B2 & D2 | 12 | 0.001 | 1.249 |

| B3 & C1 | 7.623 | 0.006 | 1.511 |

| B5 & C2 | 8.515 | 0.004 | 1.287 |

| B5 & D2 | 15.502 | 0.0001 | 1.643 |

| C1 & D1 | 8.791 | 0.003 | 2.026 |

| C2 & D1 | 42.925 | 0.0001 | 1.617 |

| C2 & D2 | 6.047 | 0.014 | 2.1465 |

| C4 & D2 | 54.656 | 0.0001 | 1.1633 |

| A1 | A2 | B3 | |

|---|---|---|---|

| State0 | 0.5 | 0.78 | 0.56 |

| State1 | 0.5 | 0.22 | 0.44 |

| B3 | State0 | State1 | B3 | State0 | State1 |

|---|---|---|---|---|---|

| State0 | 40 | 25 | State0 | 0.714 | 0.568 |

| State1 | 16 | 19 | State1 | 0.286 | 0.432 |

| Factor | Induced Path |

|---|---|

| Miners’ errors (D1) | (1) (A1) Safety supervision is inadequate (50%) → (B5) Organizational security management confusion (76%) → (C2) Managers violate laws and regulations and illegal command (67%) → (D1) Miners’ errors (100%) |

| (2) (A1) Safety supervision is inadequate (50%) → (C2) Managers violate laws and regulations and illegal command (67%) → (D1) Miners’ errors (100%) | |

| (3) (A1) Safety supervision is inadequate (50%) →(B1) Organizational departments and institutions are not complete (28%) → (D1) Miners’ errors (100%) | |

| (4) (A2) Insufficient crackdown on illegal activities (21%) → (B5) Organizational security management confusion (76%) → (C2) Managers violate laws and regulations and illegal command (67%) → (D1) Miners’ errors (100%) | |

| (5) (A2) Insufficient crackdown on illegal activities (21%) → (C2) Managers violate laws and regulations and illegal command (67%) → (D1) Miners’ errors (100%) | |

| (6) (B3) Organization of insufficient supervision of work safety (45%) → (C1) Operational environmental factors (39%) → (D1) Miners’ errors (100%) | |

| Miners’ violations (D2) | (1) (A1) Safety supervision is inadequate (54%) → (B5) Organizational security management confusion (86%) → (D2) Miners’ violations (100%) |

| (2) (A1) Safety supervision is inadequate (54%) → (B5) Organizational security management confusion (86%) → (C2) Managers violate laws and regulations and illegal command (82%) → (D2) Miners’ violations (100%) | |

| (3) (A1) Safety supervision is inadequate (54%) → (B1) Organizational departments and institutions are not complete (27%) → (C2) Managers violate laws and regulations and illegal command (82%) → (D2) Miners’ violations (100%) | |

| (4) (A1) Safety supervision is inadequate (54%) → (C2) Managers violate laws and regulations and illegal command (82%) → (D2) Miners’ violations (100%) | |

| (5) (A1) Safety supervision is inadequate (54%) → (B2) Lack of organizational safety education and training (33%) → (D2) Miners’ violations (100%) | |

| (6) (A1) Safety supervision is inadequate (54%) → (B2) Lack of organizational safety education and training (33%) → (C4) Miners’ status (8%) → (D2) Miners’ violations (100%) | |

| (7) (A2) Insufficient crackdown on illegal activities (26%) → (B5) Organizational security management confusion (86%) → (D2) Miners’ violations (100%) | |

| (8) (A2) Insufficient crackdown on illegal activities (26%) → (B5) Organizational security management confusion (86%) → (C2) Managers violate laws and regulations and illegal command (82%) → (D2) Miners’ violations (100%) | |

| (9) (A2) Insufficient crackdown on illegal activities (26%) → (C2) Managers violate laws and regulations and illegal command (86%) → (D2) Miners’ violations (100%) |

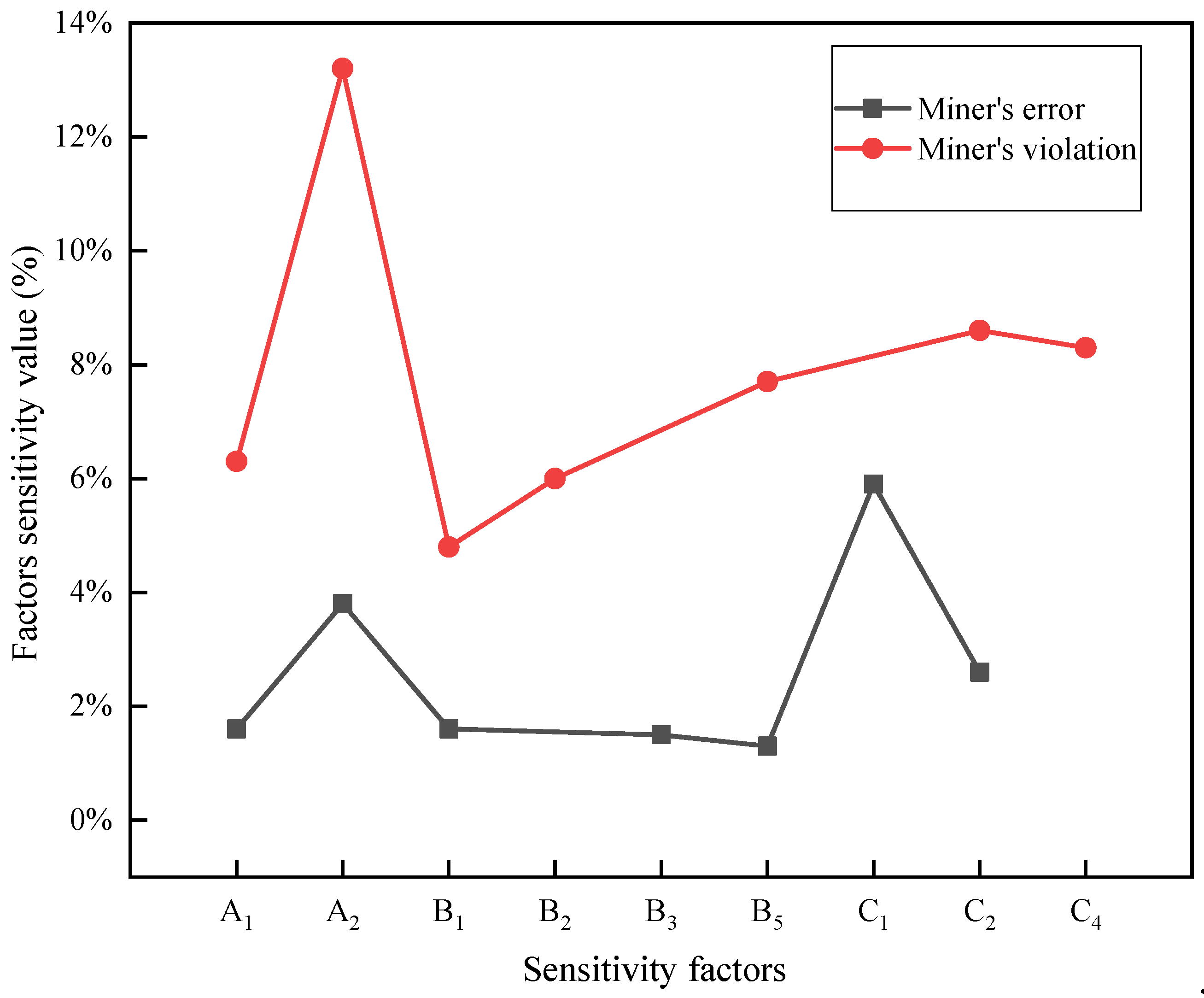

| Nodes | Sensitivity Coefficient | Rank | Nodes | Sensitivity Coefficient | Rank | ||

|---|---|---|---|---|---|---|---|

| D1 | C1 | 0.059 | 1 | D2 | A2 | 0.132 | 1 |

| A2 | 0.038 | 2 | C2 | 0.086 | 2 | ||

| C2 | 0.026 | 3 | C4 | 0.083 | 3 | ||

| A1 | 0.016 | 4 | B5 | 0.077 | 4 | ||

| B1 | 0.016 | 5 | A1 | 0.063 | 5 | ||

| B3 | 0.015 | 6 | B2 | 0.06 | 6 | ||

| B5 | 0.013 | 7 | B1 | 0.048 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, L.; Zhao, J.; Yang, J. An Impacting Factors Analysis of Unsafe Acts in Coal Mine Gas Explosion Accidents Based on HFACS-ISM-BN. Processes 2023, 11, 1055. https://doi.org/10.3390/pr11041055

Niu L, Zhao J, Yang J. An Impacting Factors Analysis of Unsafe Acts in Coal Mine Gas Explosion Accidents Based on HFACS-ISM-BN. Processes. 2023; 11(4):1055. https://doi.org/10.3390/pr11041055

Chicago/Turabian StyleNiu, Lixia, Jin Zhao, and Jinhui Yang. 2023. "An Impacting Factors Analysis of Unsafe Acts in Coal Mine Gas Explosion Accidents Based on HFACS-ISM-BN" Processes 11, no. 4: 1055. https://doi.org/10.3390/pr11041055

APA StyleNiu, L., Zhao, J., & Yang, J. (2023). An Impacting Factors Analysis of Unsafe Acts in Coal Mine Gas Explosion Accidents Based on HFACS-ISM-BN. Processes, 11(4), 1055. https://doi.org/10.3390/pr11041055