Influence of Transparent Envelope Parameters on Office Building Energy Use Intensity in the Different Thermal Climate Regions of China

Abstract

:1. Introduction

2. Methodology

2.1. Mathematical Descriptions

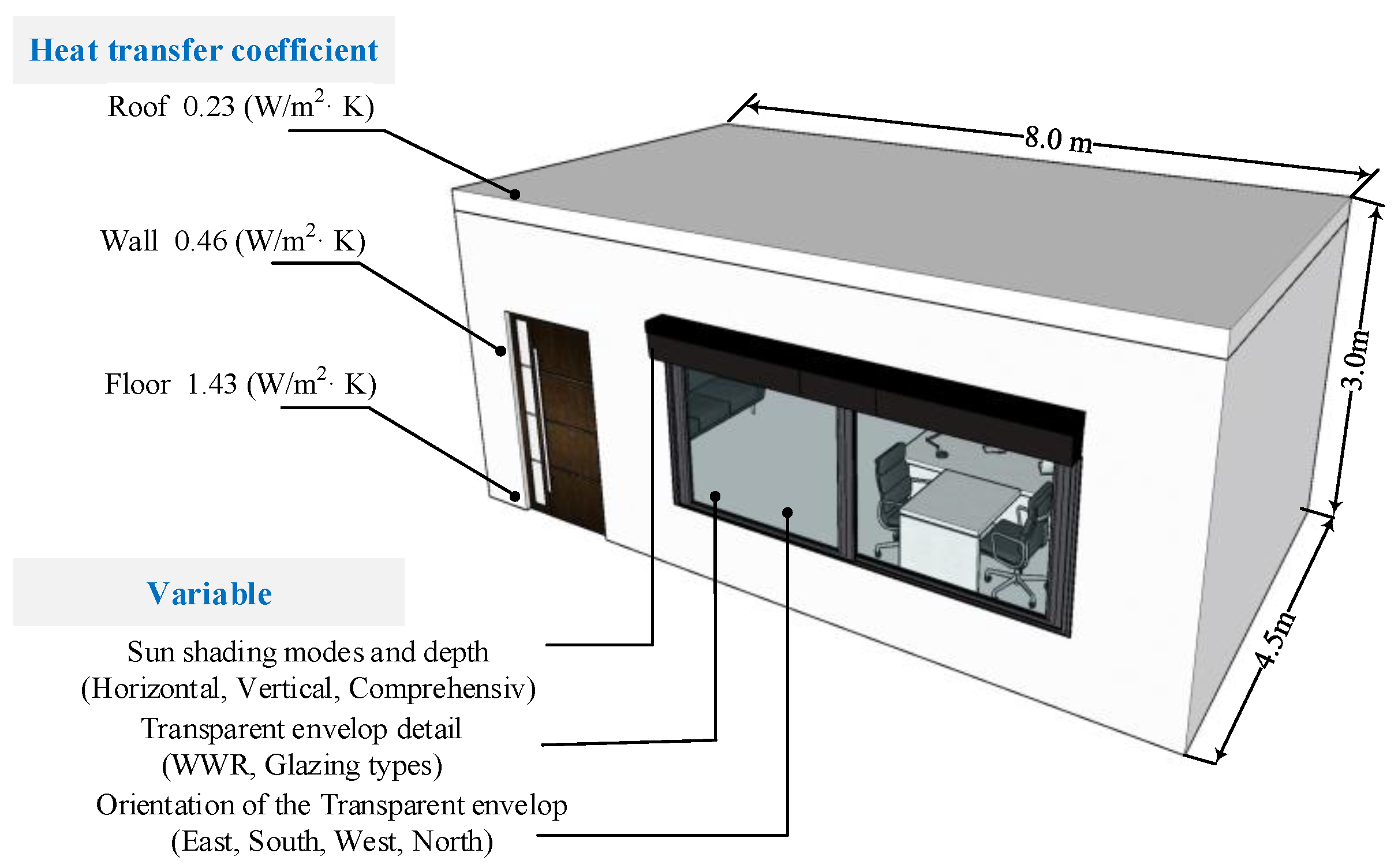

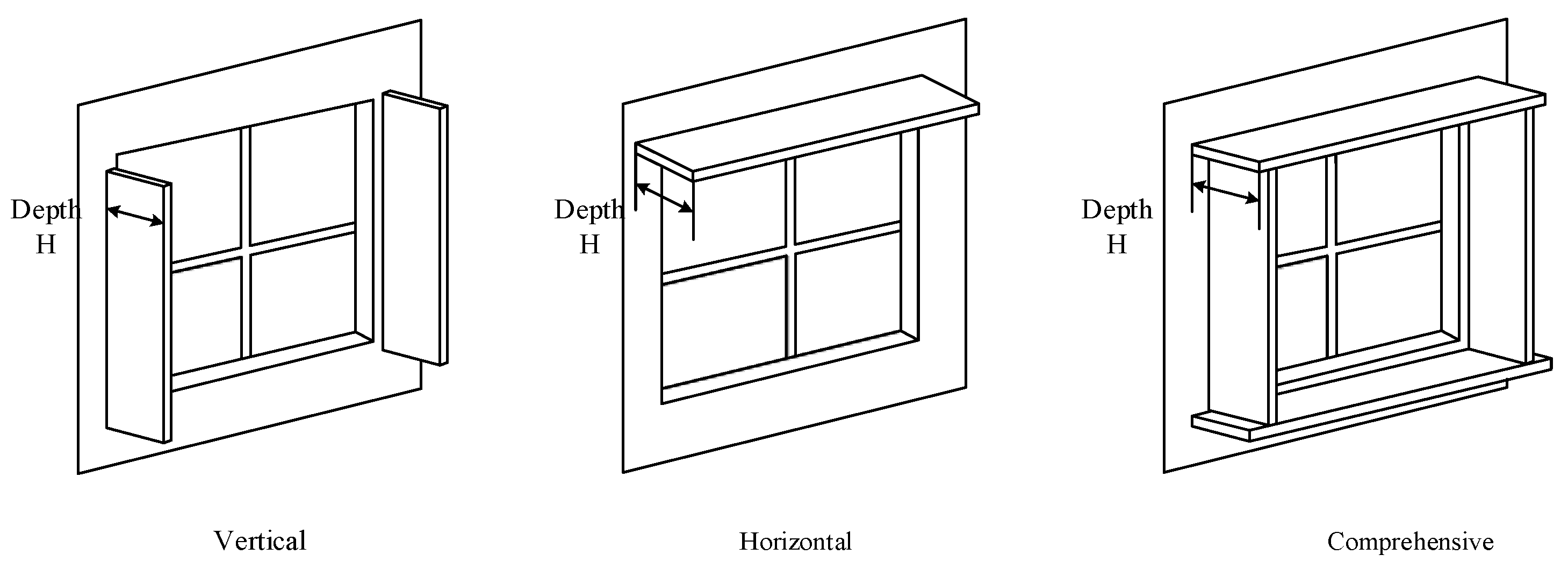

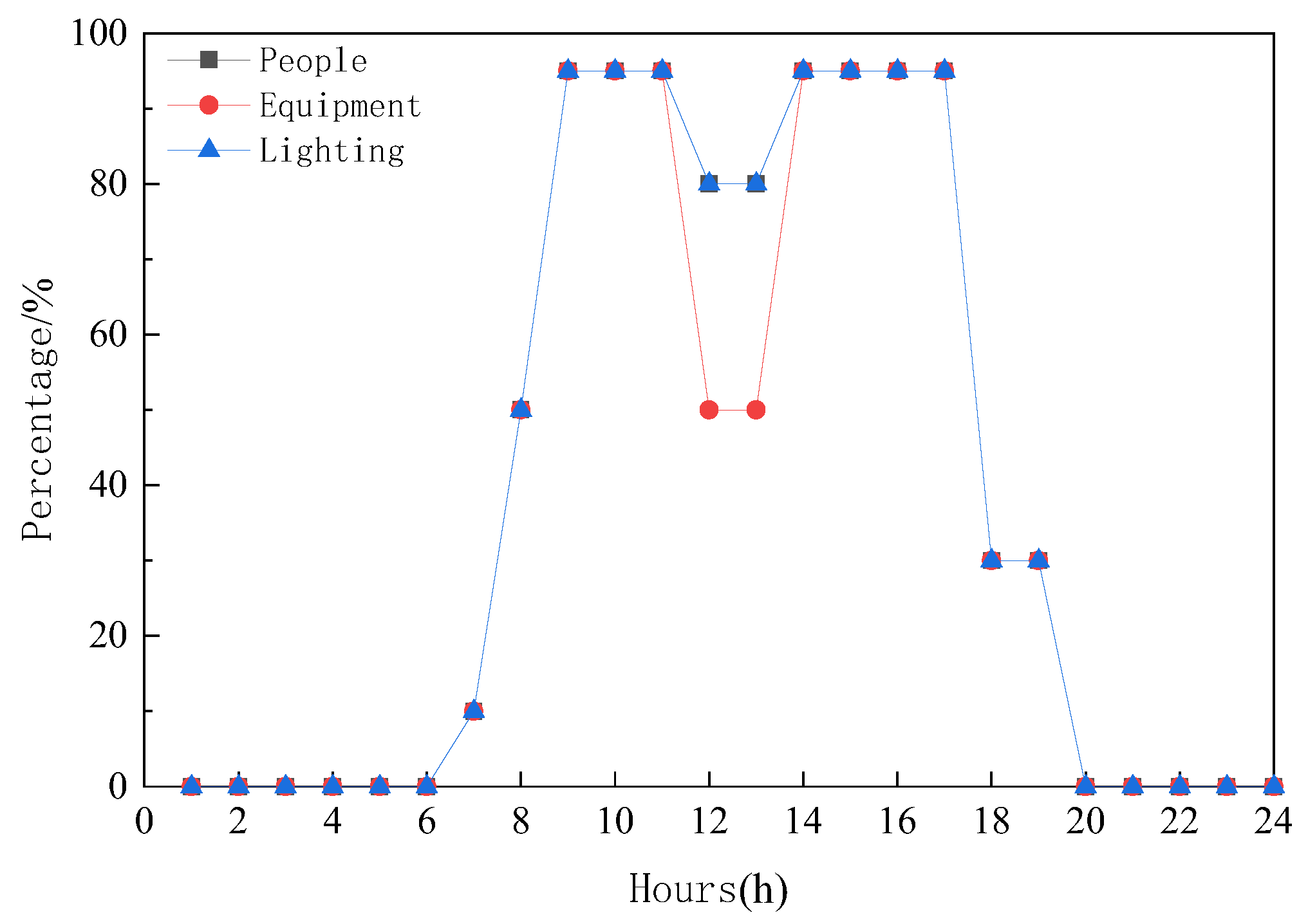

2.2. Parameters Information

3. Results

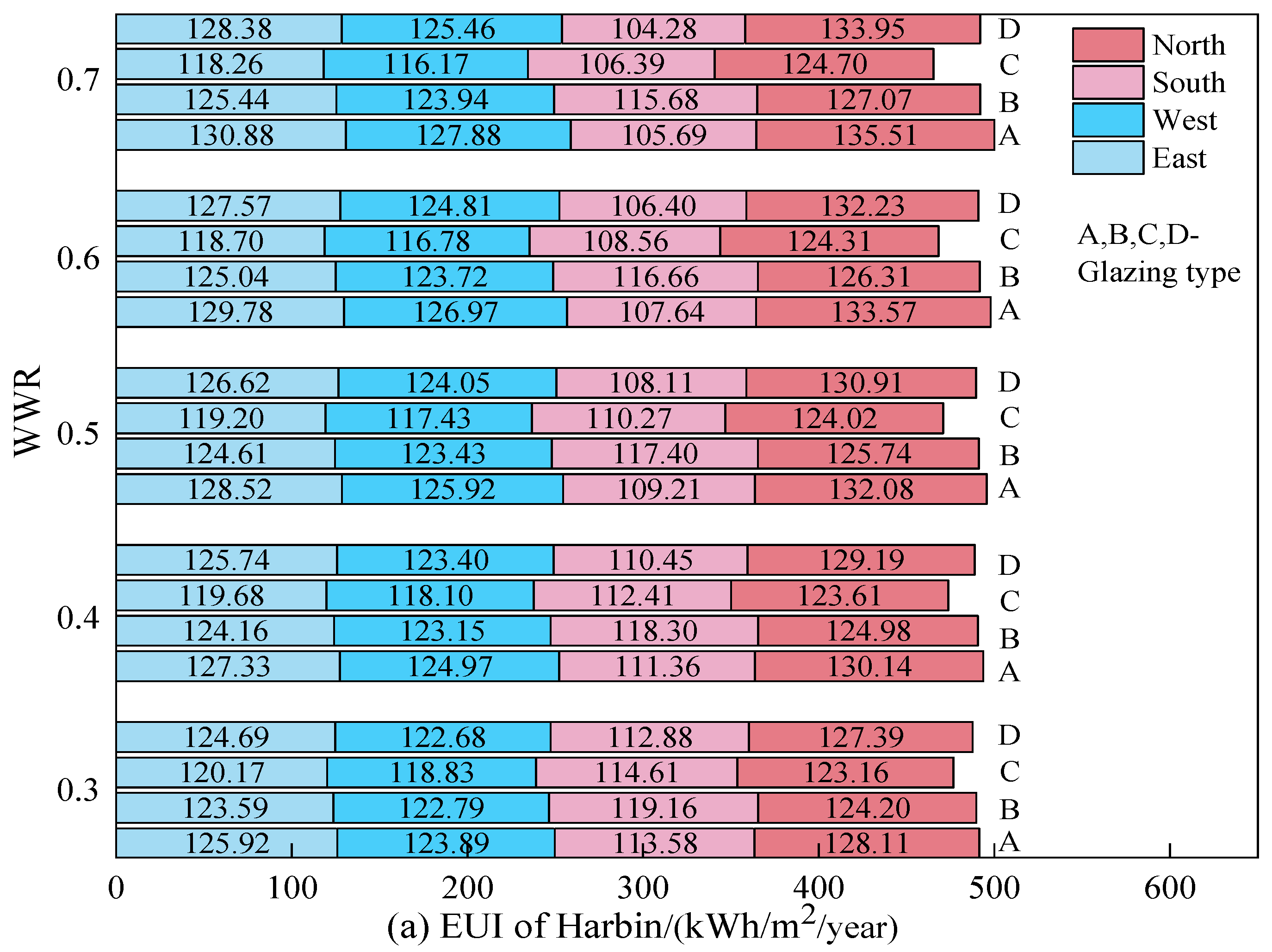

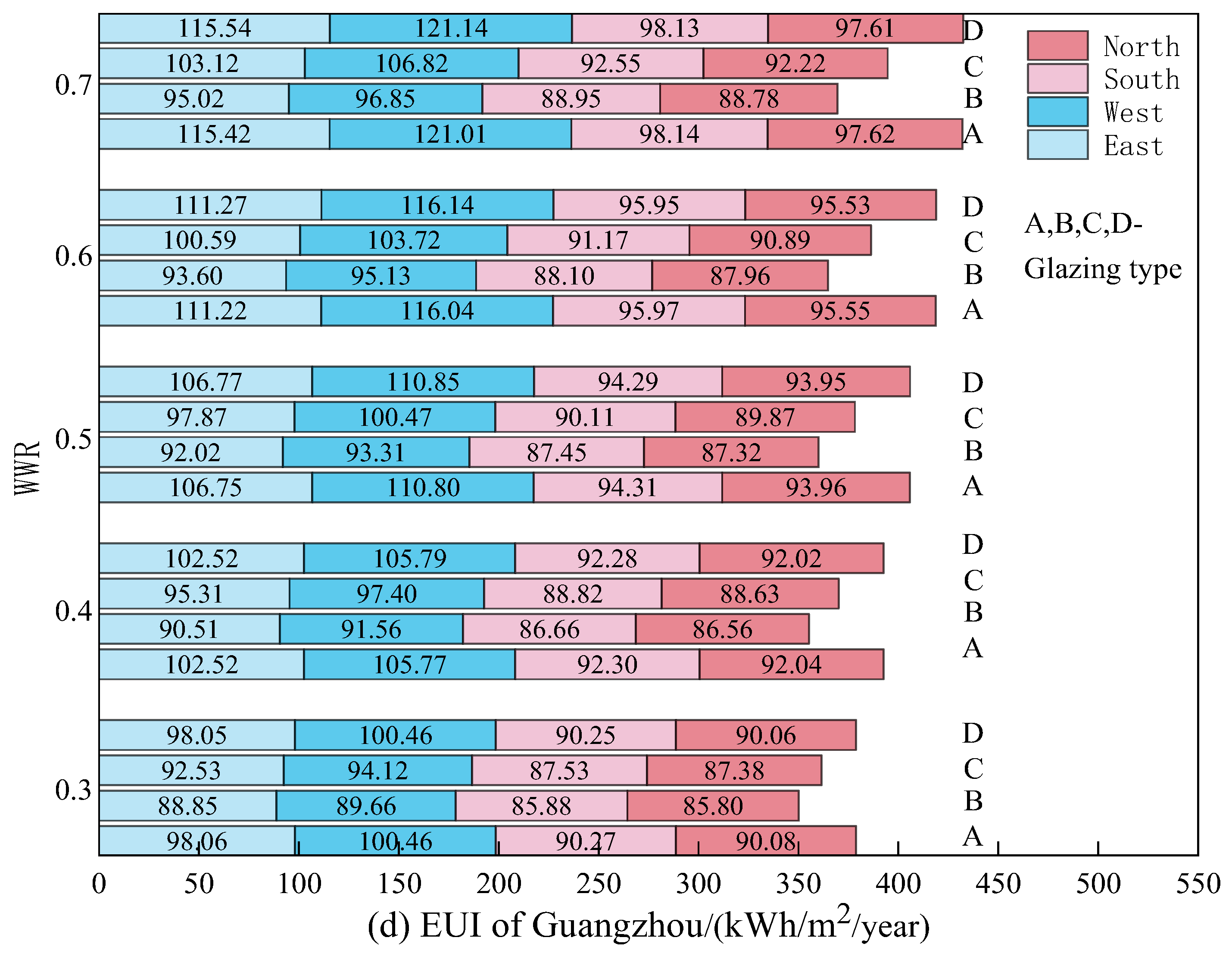

3.1. Impact of WWR, Orientation and Glazing Type on EUI

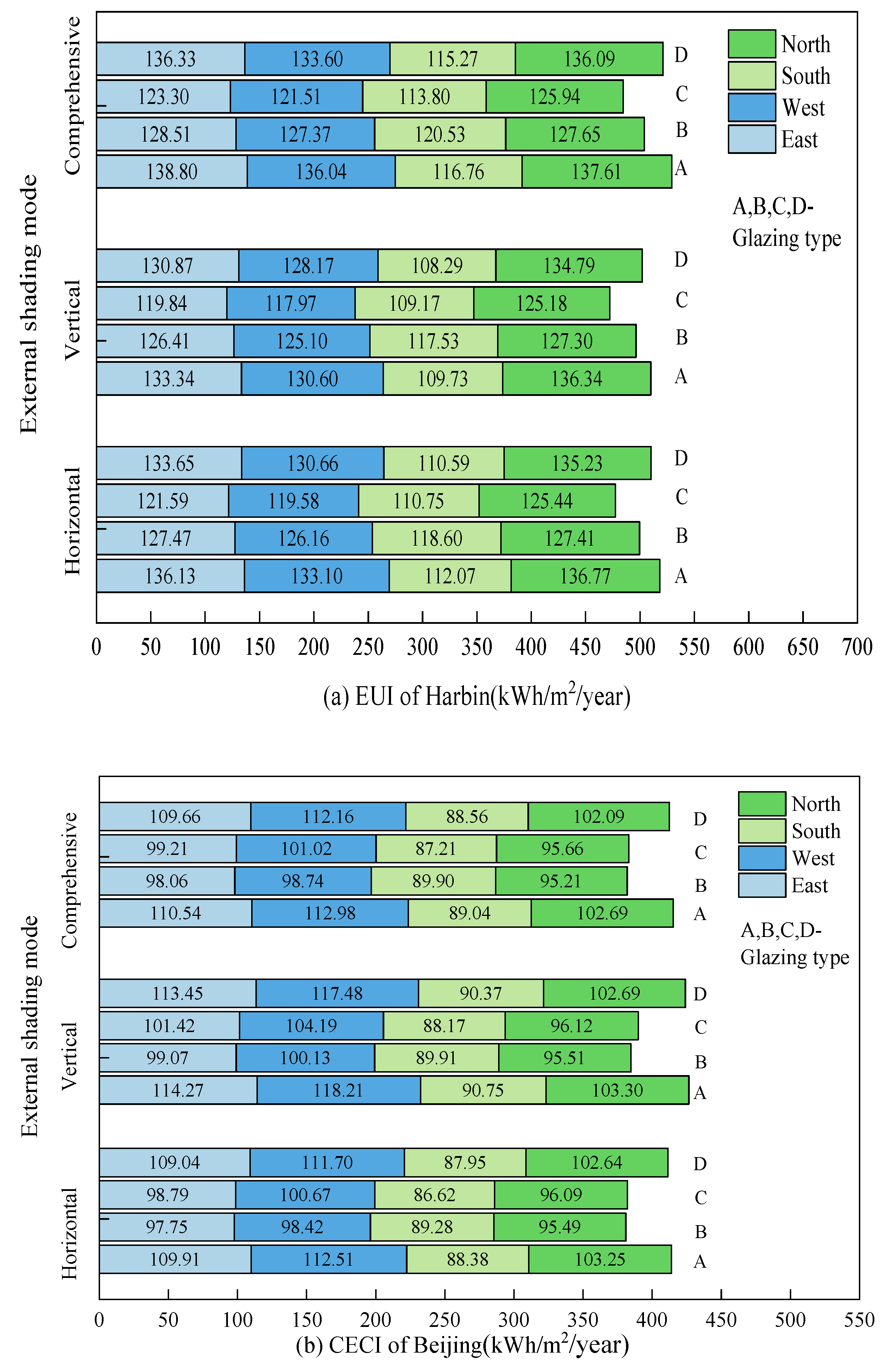

3.2. Impact of External Shading Mode, Orientation and Glazing Type on EUI

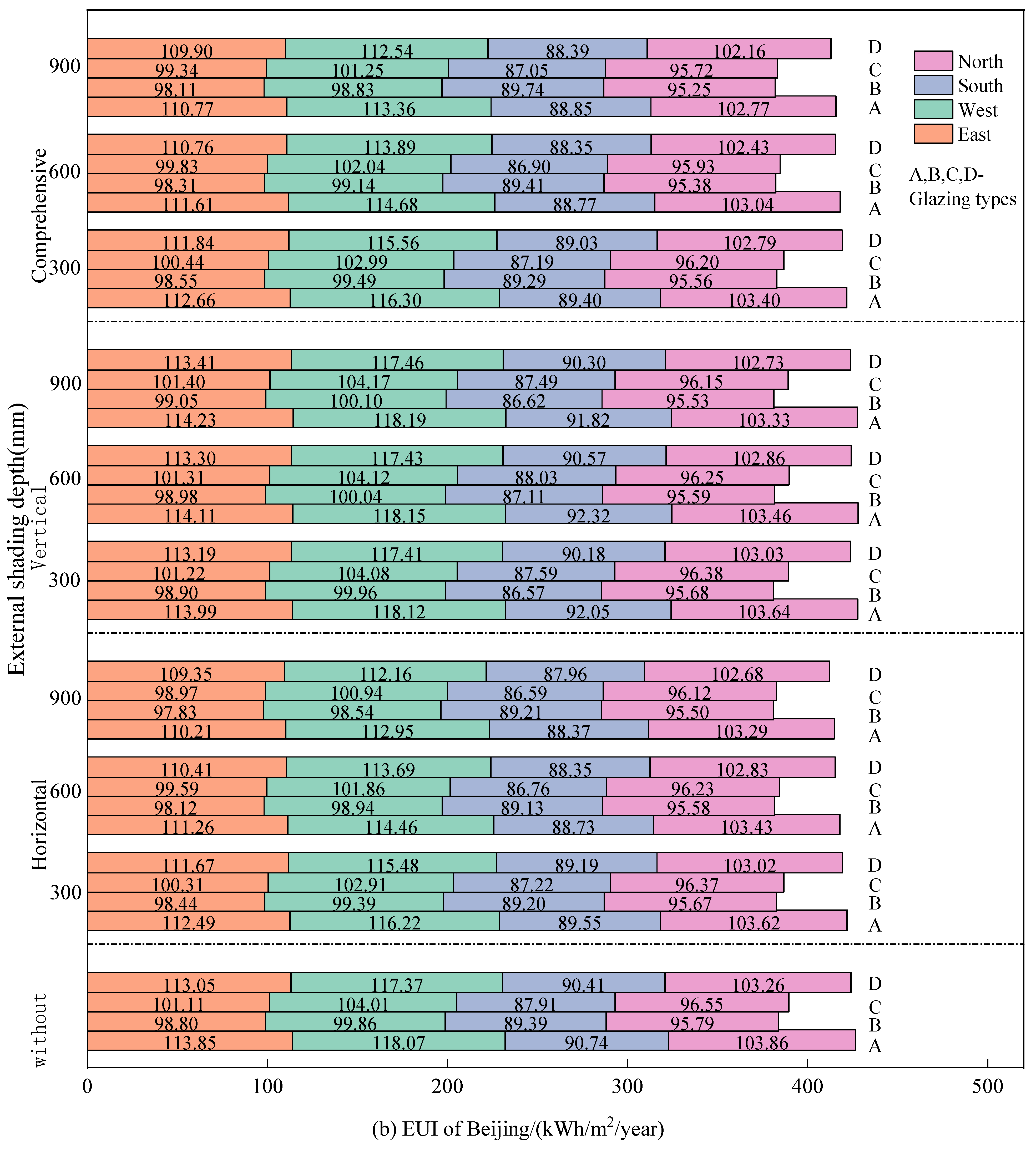

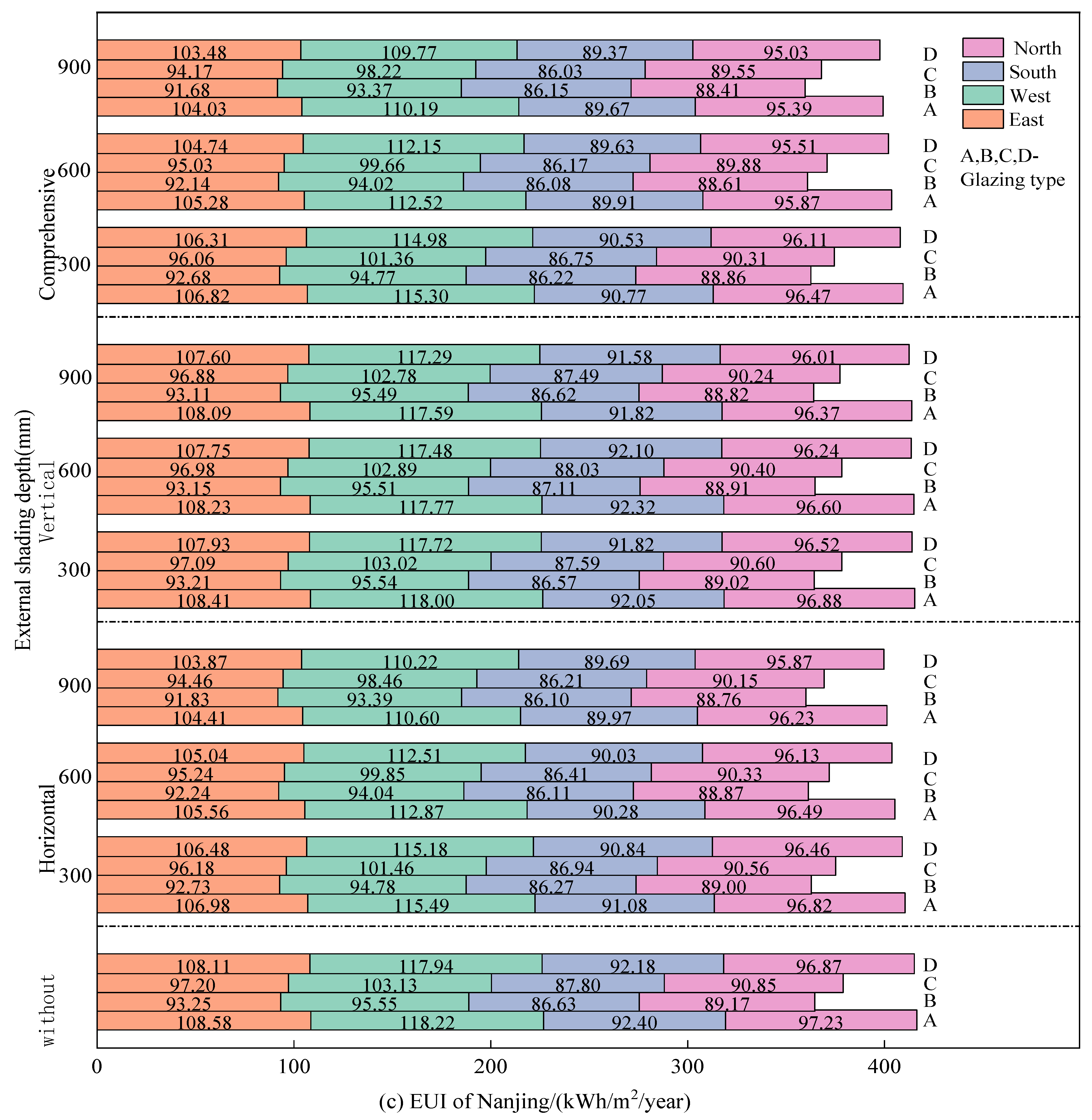

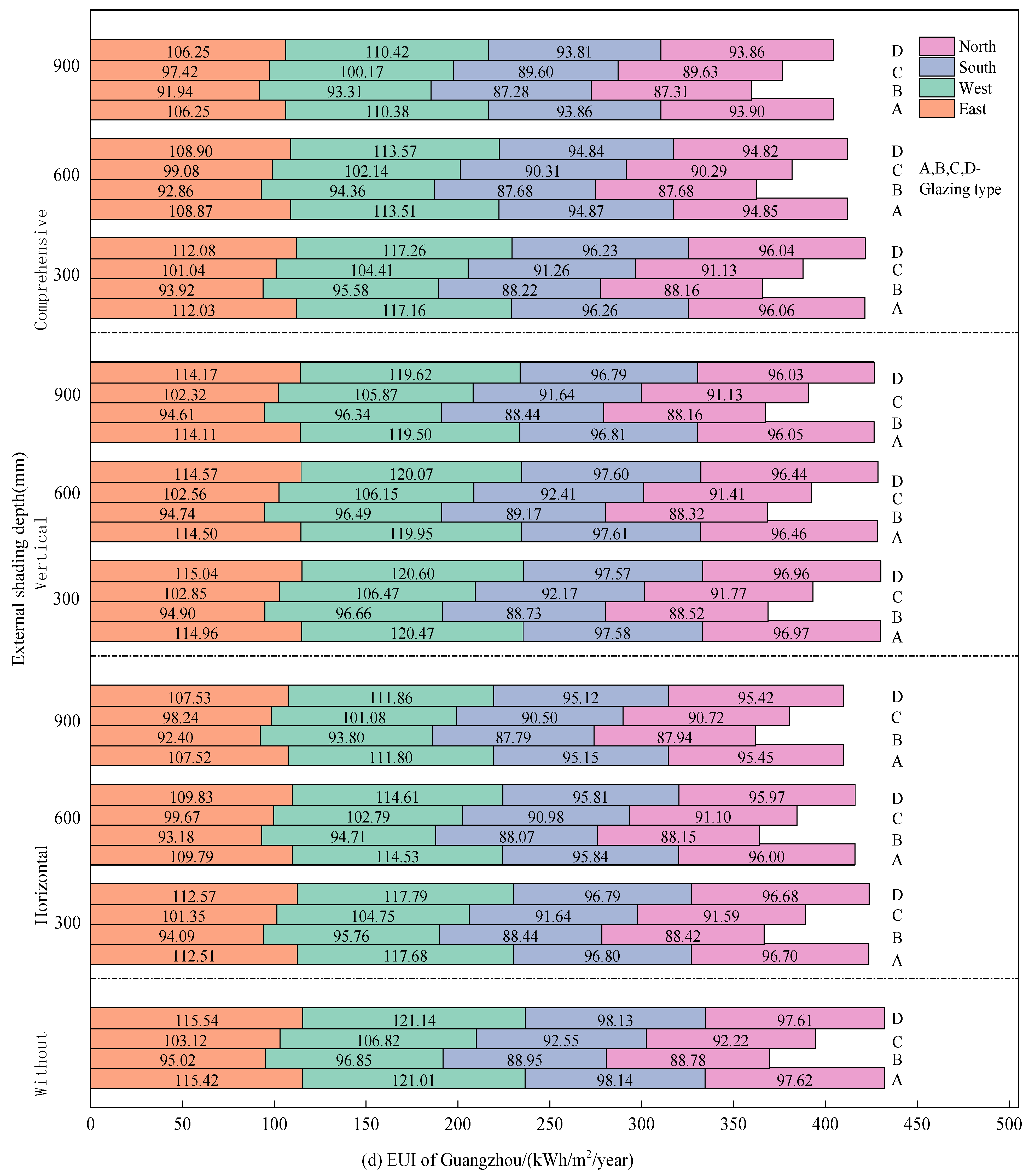

3.3. Impact of External Shading Depth, Orientation and Glazing Type on EUI

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Transparent envelope | TE |

| Energy use intensity | EUI |

| Heat transfer coefficient | HTC |

| Solar heat gain coefficient | SHGC |

| Window-to-wall ratio | WWR |

| Climate regions | CR |

| Sun shading coefficient | SSC |

| Visible light transmittance | VLT |

References

- International Energy Agency. World Energy Statistics. 2021. Available online: https://www.iea.org/reports/tracking-buildings-2021 (accessed on 1 March 2022).

- Enerdata. World Energy & Climate Statistics Yearbook 2021. Available online: https://yearbook.enerdata.net/ (accessed on 1 March 2022).

- Tsinghua University Building Energy Efficiency Research Center. Research Report on Annual Development of Building Energy Conservation in China; Chapter 1 of Building Energy consumption and greenhouse gas emission in China; China Construction Industry Press: Beijing, China, 2020. (In Chinese) [Google Scholar]

- Khaled, K.; Berardi, U. Current and future coating technologies for architectural glazing applications. Energy Build. 2021, 244, 111022. [Google Scholar]

- Amaral, A.R.; Rodrigues, E.; Gaspar, A.R.; Gomes, Á. A thermal performance parametric study of window type, orientation, size and shadowing effect. Sustain. Cities Soc. 2016, 26, 456–465. [Google Scholar] [CrossRef]

- Yong, S.G.; Kim, J.H.; Gim, Y.; Kim, J.; Cho, J.; Hong, H.; Baik, Y.-J.; Koo, J. Impacts of building envelope design factors upon energy loads and their optimization in US standard climate zones using experimental design. Energy Build. 2017, 141, 1–15. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, J.; Yu, B.; Liao, L.; Li, J. Identification of passive solar design determinants in office building envelopes in hot and humid climates using data mining techniques. Build. Environ. 2021, 196, 107566. [Google Scholar] [CrossRef]

- Badeche, M.; Bouchahm, Y. Design optimization criteria for windows providing low energy demand in office buildings in Algeria. Environ. Sustain. Indic. 2020, 6, 100024. [Google Scholar] [CrossRef]

- Liao, W.; Wen, C.; Luo, Y.; Peng, J.; Li, N. Influence of different building transparent envelopes on energy consumption and thermal environment of radiant ceiling heating and cooling systems. Energy Build. 2022, 255, 111702. [Google Scholar] [CrossRef]

- Cuce, E. Accurate and reliable U-value assessment of argon-filled double glazed windows: A numerical and experimental investigation. Energy Build. 2018, 171, 100–106. [Google Scholar] [CrossRef]

- Aydin, O. Conjugate heat transfer analysis of double pane windows. Build. Environ. 2006, 41, 109–116. [Google Scholar] [CrossRef]

- Larsson, U.; Moshfegh, B.; Sandberg, M. Thermal analysis of super insulated windows (numerical and experimental investigations). Energy Build. 1999, 29, 121–128. [Google Scholar] [CrossRef]

- Müslüm, A.; Miraç, K. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar]

- Jiang, L. Energy saving design of passive super low energy consumption timber structure external enelosure structure. Sci. Technol. Eng. 2019, 19, 205–209. [Google Scholar]

- Ding, Y.; Liu, X.; Ding, Z.; Li, B. Influence of different glass on the indoor solar heat gain in hot summer areas. Acta Energiae Solaris Sin. 2014, 35, 177–182. [Google Scholar]

- Mohamed, E.; Carlo, C. Envelope Retrofit in Hot Arid Climates. Procedia Environ. Sci. 2017, 38, 264–273. [Google Scholar]

- Huang, Y.; Niu, J.; Chung, T. Comprehensive analysis on thermal and daylighting performance of glazing and shading designs on office building envelope in cooling-dominant climates. Appl. Energy 2014, 134, 215–228. [Google Scholar] [CrossRef]

- Arindam, D.; Akash, S. Reducing cooling load of buildings in the tropical climate through window glazing: A model to model comparison. J. Build. Eng. 2018, 15, 318–327. [Google Scholar]

- Somasundaram, S.; Chong, A.; Wei, Z.; Thangavelu, S.R. Energy saving potential of low-e coating based retrofit double glazing for tropical climate. Energy Build. 2020, 206, 109570. [Google Scholar] [CrossRef]

- Moghaddam, S.A.; Mattsson, M.; Ameen, A.; Akander, J.; Gameiro Da Silva, M.; Simões, N. Low-Emissivity Window Films as an Energy Retrofit Option for a Historical Stone Building in Cold Climate. Energies 2021, 14, 7584. [Google Scholar] [CrossRef]

- Alghoul, S.K.; Rijabo, H.G.; Mashena, M.E. Energy consumption in buildings: A correlation for the influence of window to wall ratio and window orientation in Tripoli, Libya. J. Build. Eng. 2017, 11, 82–86. [Google Scholar] [CrossRef]

- Zang, Z.; Ren, Z.; Deng, Q.; Zhang, Q. Impact of building shape coefficient and window-wall ratio on office building. Build. Energy Environ. 2017, 36, 23–26. [Google Scholar]

- Goia, F.; Haase, M.; Perino, M. Optimizing the configuration of a façade module for office buildings by means of integrated thermal and lighting simulations in a total energy perspective. Appl. Energy 2013, 108, 515–527. [Google Scholar] [CrossRef]

- Su, X.; Zhang, X. Environmental performance optimization of window–wall ratio for different window type in hot summer and cold winter zone in China based on life cycle assessment. Energy Build. 2010, 42, 198–202. [Google Scholar] [CrossRef]

- De Gastines, M.M.; Pattini, A.E. Window energy efficiency in Argentina-Determining factors and energy savings strategies. J. Clean. Prod. 2020, 247, 119104. [Google Scholar] [CrossRef]

- Kaasalainen, T.; Mäkinen, A.; Lehtinen, T.; Moisio, M.; Vinha, J. Architectural window design and energy efficiency: Impacts on heating, cooling and lighting needs in Finnish climates. J. Build. Eng. 2020, 27, 100996. [Google Scholar] [CrossRef]

- Parnian, B.; Esmatullah, N. Optimization of the design of the primary school classrooms in terms of energy and daylight performance considering occupants’ thermal and visual comfort. Energy Rep. 2020, 6, 1590–1607. [Google Scholar]

- Ashrafian, T.; Moazzen, N. The impact of glazing ratio and window configuration on occupants’ comfort and energy demand: The case study of a school building in Eskisehir, Turkey. Sustain. Cities Soc. 2019, 47, 101483. [Google Scholar] [CrossRef]

- Phillips, R.; Troup, L.; Fannon, D.; Eckelman, M.J. Triple bottom line sustainability assessment of window-to-wall ratio in US office buildings. Build. Environ. 2020, 182, 107057. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, B.; Sun, Y. Multi-objective optimization for energy consumption, daylighting and thermal comfort performance of rural tourism buildings in north China. Build. Environ. 2020, 176, 106841. [Google Scholar] [CrossRef]

- Englezou, M.; Michael, A. Assessment of daylight performance and the impact of shading devices for typical in-patient rooms in healthcare facilities in Cyprus. Procedia Manuf. 2020, 44, 277–285. [Google Scholar] [CrossRef]

- Asfour, O.S. A comparison between the daylighting and energy performance of courtyard and atrium buildings considering the hot climate of Saudi Arabia. J. Build. Eng. 2020, 30, 101299. [Google Scholar] [CrossRef]

- Delgarm, N.; Sajadi, B.; Azarbad, K.; Delgarm, S. Sensitivity analysis of building energy performance: A simulation-based approach using OFAT and variance-based sensitivity analysis methods. J. Build. Eng. 2018, 15, 181–193. [Google Scholar] [CrossRef]

- Xue, P.; Li, Q.; Xie, J.; Zhao, M.; Liu, J. Optimization of window-to-wall ratio with sunshades in China low latitude region considering daylighting and energy saving requirements. Appl. Energy 2019, 233, 62–70. [Google Scholar] [CrossRef]

- Rubio-Bellido, C.; Pérez-Fargallo, A.; Pulido-Arcas, J.A. Optimization of annual energy demand in office buildings under the influence of climate change in Chile. Energy 2016, 114, 569–585. [Google Scholar] [CrossRef]

- Xu, S.; Jiang, H.; Wang, J. Parameters Study on the Inflrence of Window-Wall Ration on Building Energy Consumption in Five Climatic Zones of China. Build. Sci. 2019, 35, 91–95. [Google Scholar]

- Marino, C.; Nucara, A.; Pietrafesa, M. Does window-to-wall ratio have a significant effect on the energy consumption of buildings? A parametric analysis in Italian climate conditions. J. Build. Eng. 2017, 13, 169–183. [Google Scholar] [CrossRef]

- Reza, F.; Asadi, S.; Soha, K. On the optimization of energy efficient fenestration for small commercial buildings in the United States. J. Clean. Prod. 2021, 283, 124604. [Google Scholar]

- Goia, F. Search for the optimal window-to-wall ratio in office buildings in different European climates and the implications on total energy saving potential. Sol. Energy 2016, 132, 467–492. [Google Scholar] [CrossRef]

- Wen, L.; Hiyama, K.; Koganei, M. A method for creating maps of recommended window-to-wall ratios to assign appropriate default values in design performance modeling: A case study of a typical office building in Japan. Energy Build. 2017, 145, 304–317. [Google Scholar] [CrossRef]

- Xie, X.; Chen, X.N.; Xu, B.; Pei, G. Investigation of occupied/unoccupied period on thermal comfort in Guangzhou: Challenges and opportunities of public buildings with high window-wall ratio. Energy 2022, 244, 123186. [Google Scholar] [CrossRef]

- Hoffmann, S.; Lee, E.S.; McNeil, A.; Fernandes, L.; Vidanovic, D.; Thanachareonkit, A. Balancing daylight, glare, and energy-efficiency goals: An evaluation of exterior coplanar shading systems using complex fenestration modeling tools. Energy Build. 2016, 112, 279–298. [Google Scholar] [CrossRef]

- Lin, Y.H.; Tsai, K.T.; Lin, M.D.; Yang, M.D. Design optimization of office building envelope configurations for energy conservation. Appl. Energy 2016, 171, 336–346. [Google Scholar] [CrossRef]

- Lau, A.K.K.; Salleh, E.; Lim, C.H.; Sulaiman, M.Y. Potential of shading devices and glazing configurations on cooling energy savings for high-rise office buildings in hot-humid climates: The case of Malaysia. Int. J. Sustain. Built Environ. 2016, 5, 387–399. [Google Scholar] [CrossRef]

- Imessad, K.; Derradji, L.; Messaoudene, N.A.; Mokhtari, F.; Chenak, A.; Kharchi, R. Impact of passive cooling techniques on energy demand for residential buildings in a Mediterranean climate. Renew. Energy 2014, 71, 589–597. [Google Scholar] [CrossRef]

- Idchabani, R.; El Ganaoui, M.; Sick, F. Analysis of exterior shading by overhangs and fins in hot climate. Energy Procedia 2017, 139, 379–384. [Google Scholar] [CrossRef]

- Zune, M.; Tubelo, R.; Rodrigues, L.; Gillott, M. Improving building thermal performance through an integration of Passivhaus envelope and shading in a tropical climate. Energy Build. 2021, 253, 111521. [Google Scholar] [CrossRef]

- Khoroshiltseva, M.; Slanzi, D.; Poli, I. A Pareto-based multi-objective optimization algorithm to design energy-efficient shading devices. Appl. Energy 2016, 184, 1400–1410. [Google Scholar] [CrossRef]

- Krstić-Furundžić, A.; Vujošević, M.; Petrovski, A. Energy and environmental performance of the office building facade scenarios. Energy 2019, 183, 437–447. [Google Scholar] [CrossRef]

- Koç, S.G.; Kalfa, S.M. The effects of shading devices on office building energy performance in Mediterranean climate regions. J. Build. Eng. 2021, 44, 102653. [Google Scholar] [CrossRef]

- Costa, J.F.W.; Amorim, C.N.D.; Silva, J.C.R. Retrofit guidelines towards the achievement of net zero energy buildings for office buildings in Brasilia. J. Build. Eng. 2020, 32, 101680. [Google Scholar] [CrossRef]

- Du, T.; Jansen, S.; Turrin, M.; van den Dobbelsteen, A. Effect of space layouts on the energy performance of office buildings in three climates. J. Build. Eng. 2021, 39, 102198. [Google Scholar] [CrossRef]

- Alhuwayil, W.K.; Mujeebu, M.A.; Algarny, A.M.M. Impact of external shading strategy on energy performance of multi-story hotel building in hot-humid climate. Energy 2019, 169, 1166–1174. [Google Scholar] [CrossRef]

- De Luca, F.; Sepúlveda, A.; Varjas, T. Multi-performance optimization of static shading devices for glare, daylight, view and energy consideration. Build. Environ. 2022, 217, 109110. [Google Scholar] [CrossRef]

- Alwetaishi, M.; Al-Khatri, H.; Benjeddou, O.; Shamseldin, A.; Alsehli, M.; Alghamdi, S.; Shrahily, R. An investigation of shading devices in a hot region: A case study in a school building. Ain Shams Eng. J. 2021, 12, 3229–3239. [Google Scholar] [CrossRef]

- Cheng, C.L.; Liao, L.M.; Chou, C.P. A study of summarized correlation with shading performance for horizontal shading devices in Taiwan. Sol. Energy 2013, 90, 1–16. [Google Scholar] [CrossRef]

- Sghiouri, H.; Mezrhab, A.; Karkri, M.; Naji, H. Shading devices optimization to enhance thermal comfort and energy performance of a residential building in Morocco. J. Build. Eng. 2018, 18, 292–302. [Google Scholar] [CrossRef]

- Bellia, L.; De Falco, F.; Minichiello, F. Effects of solar shading devices on energy requirements of standalone office buildings for Italian climates. Appl. Therm. Eng. 2013, 54, 190–201. [Google Scholar] [CrossRef]

- Zhao, J.; Du, Y. Multi-objective optimization design for windows and shading configuration considering energy consumption and thermal comfort: A case study for office building in different climatic regions of China. Sol. Energy 2020, 206, 997–1017. [Google Scholar] [CrossRef]

- GB50189-2015; Design Standard for Energy Efficiency of Public Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2015.

- Chen, D.; Liu, Y.; Tang, K.; Lu, B. Research on Structure Optimization and Energy Saving of Hollow Glass. Constuction Technol. 2022, 51, 97–103. (In Chinese) [Google Scholar]

- Meteorological Data Room of National Meteorological Information Center, Department of Building Science of Tsinghua University. Special Meteorological Data Set for Building Thermal Environment Analysis in China; China Architecture & Building Press: Beijing, China, 2005. [Google Scholar]

- GB50176-2016; Gode for Thermal Design of Civil Building. China Building Industry Press: Beijing, China, 2005. (In Chinese)

- Liu, F. Study on Energy Saving Potential of the Double Shape-Stabilized Phase Change Material Wallboard Using in the Major Climate Zones of Our Country; Huazhong University of Science & Techology: Wuhan, China, 2016. (In Chinese) [Google Scholar]

| Type | Subtype | Parameter | Type | Subtype | Parameter | Type | Subtype | Parameter |

|---|---|---|---|---|---|---|---|---|

(Orientation) | East | (WWR) | 0.3 | (Sun shading mode) | without | |||

| West | 0.4 | Horizontal | ||||||

| South | 0.5 | Vertical | ||||||

| North | 0.6 | Comprehensive | ||||||

| 0.7 | ||||||||

(External shading depth) | 300 mm | (Glazing type) | A | (Typical city) | Harbin | |||

| 600 mm | B | Beijing | ||||||

| 900 mm | C | Nanjing | ||||||

| 1000 mm | D | Guangzhou |

| Types | Heat Transfer Coefficient/(W/(m2·K)) | Sun Shading Coefficient | Solar Heat Gain Coefficient | Visible Light Transmittance |

|---|---|---|---|---|

| A | 2.70 | 0.81 | 0.70 | 0.79 |

| B | 1.32 | 0.25 | 0.22 | 0.50 |

| C | 1.32 | 0.45 | 0.39 | 0.50 |

| D | 2.50 | 0.81 | 0.70 | 0.79 |

| CR for Building Thermal Design | Typical City | Latitude (°) | Longitude (°) | Altitude (m) | Heating Period | Cooling Period |

|---|---|---|---|---|---|---|

| Severe cold region | Harbin | 45.75° N | 126.77° E | 143 | 20 October~20 April of the next year | Nothing |

| Cold region | Beijing | 39.93° N | 116.28° E | 55 | 15 November~15 March of the next year | 15 June–30 September |

| Hot summer and cold winter region | Nanjing | 32.00° N | 118.80° E | 7.0 | 15 December~15 March of the next year | 1 June~30 September |

| Hot summer and warm winter region | Guangzhou | 23.17° N | 113.33° E | 41 | Nothing | 1 May~30 September |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; He, Z.; Liu, Y.; Tao, C.; Wang, H.; Lu, B.; Li, J.; Lu, Y. Influence of Transparent Envelope Parameters on Office Building Energy Use Intensity in the Different Thermal Climate Regions of China. Processes 2023, 11, 2908. https://doi.org/10.3390/pr11102908

Chen D, He Z, Liu Y, Tao C, Wang H, Lu B, Li J, Lu Y. Influence of Transparent Envelope Parameters on Office Building Energy Use Intensity in the Different Thermal Climate Regions of China. Processes. 2023; 11(10):2908. https://doi.org/10.3390/pr11102908

Chicago/Turabian StyleChen, Demin, Zihuai He, Yinghui Liu, Congxi Tao, Hao Wang, Biao Lu, Jiaqi Li, and Yuehong Lu. 2023. "Influence of Transparent Envelope Parameters on Office Building Energy Use Intensity in the Different Thermal Climate Regions of China" Processes 11, no. 10: 2908. https://doi.org/10.3390/pr11102908

APA StyleChen, D., He, Z., Liu, Y., Tao, C., Wang, H., Lu, B., Li, J., & Lu, Y. (2023). Influence of Transparent Envelope Parameters on Office Building Energy Use Intensity in the Different Thermal Climate Regions of China. Processes, 11(10), 2908. https://doi.org/10.3390/pr11102908