Numerical Simulations of Particle Motions at Continuous Rotational Speed Changes in Horizontal Rotating Drums

Abstract

1. Introduction

- (1)

- An integrated view of the motion properties of binary particles in the rotating drums is made. Key characteristics of flow regimes and normal forces are analyzed and compared with two circular rotating drums and one elliptical drum, in order to provide further insight into the constant stream of changing rotational speeds;

- (2)

- Three independent particle motion characteristics: transient state, steady state, and the sudden change in states are investigated when the rotational speed is changed continuously.

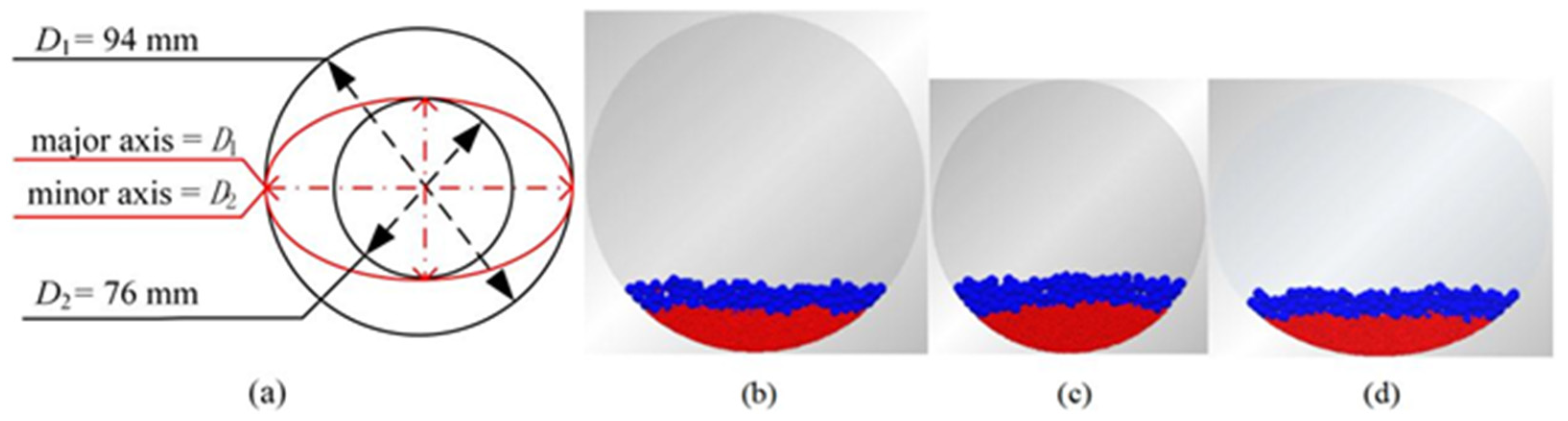

2. Materials and Methods

3. Results and Discussion

3.1. Moving Particles at Different Rotational Speeds

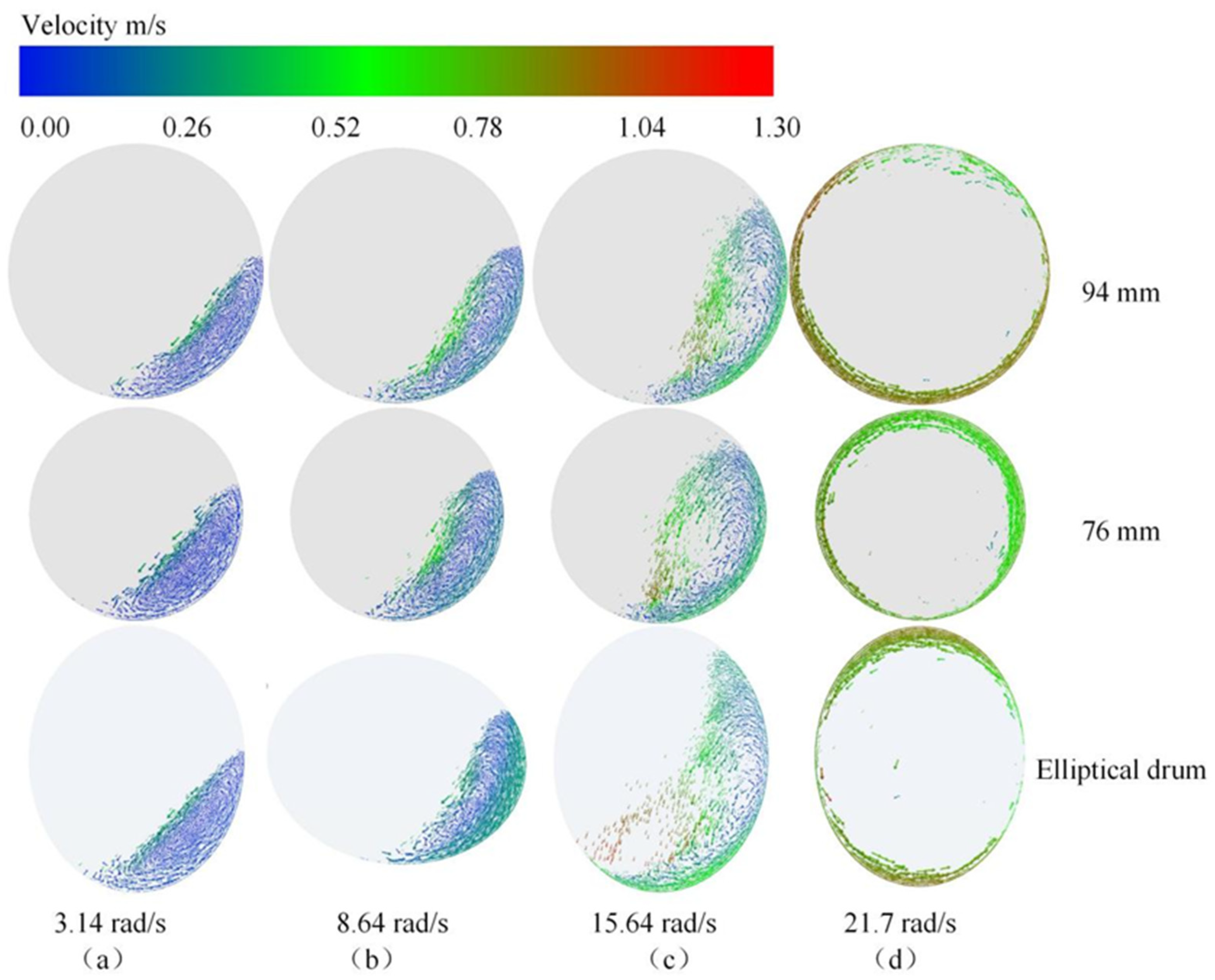

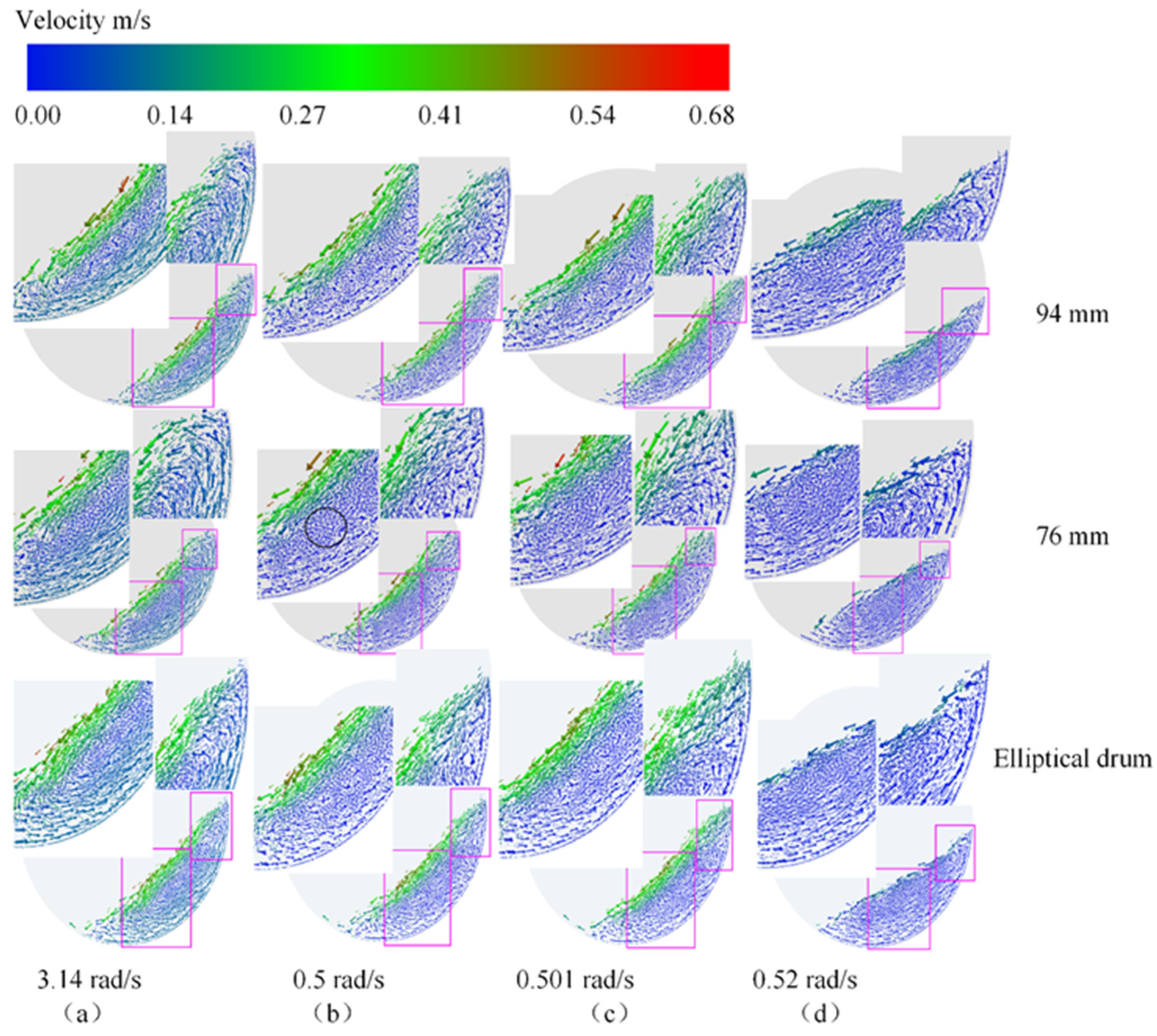

3.1.1. Flow Regimes

3.1.2. Normal Force

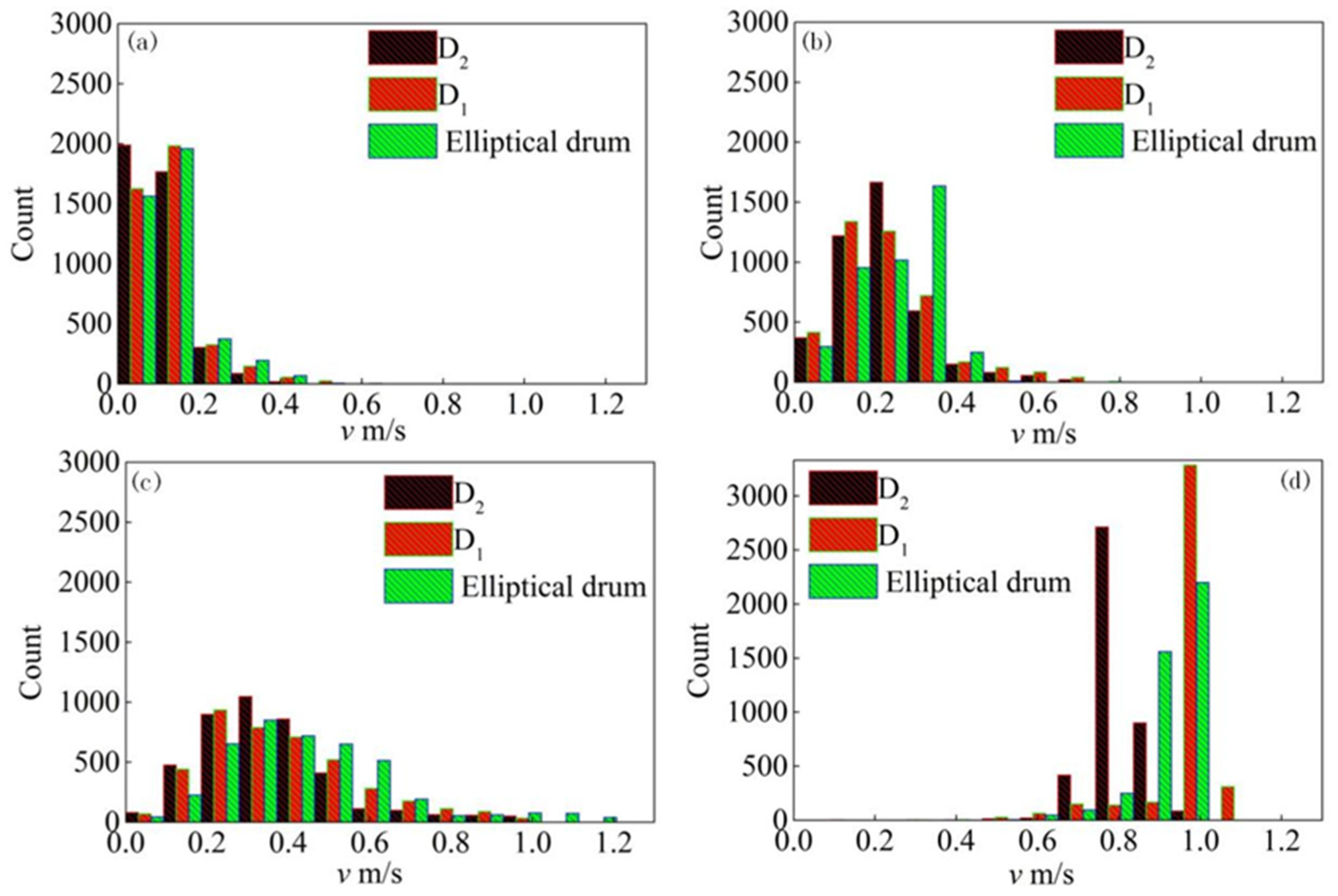

3.1.3. Particle Velocities at Different Rotational Speeds

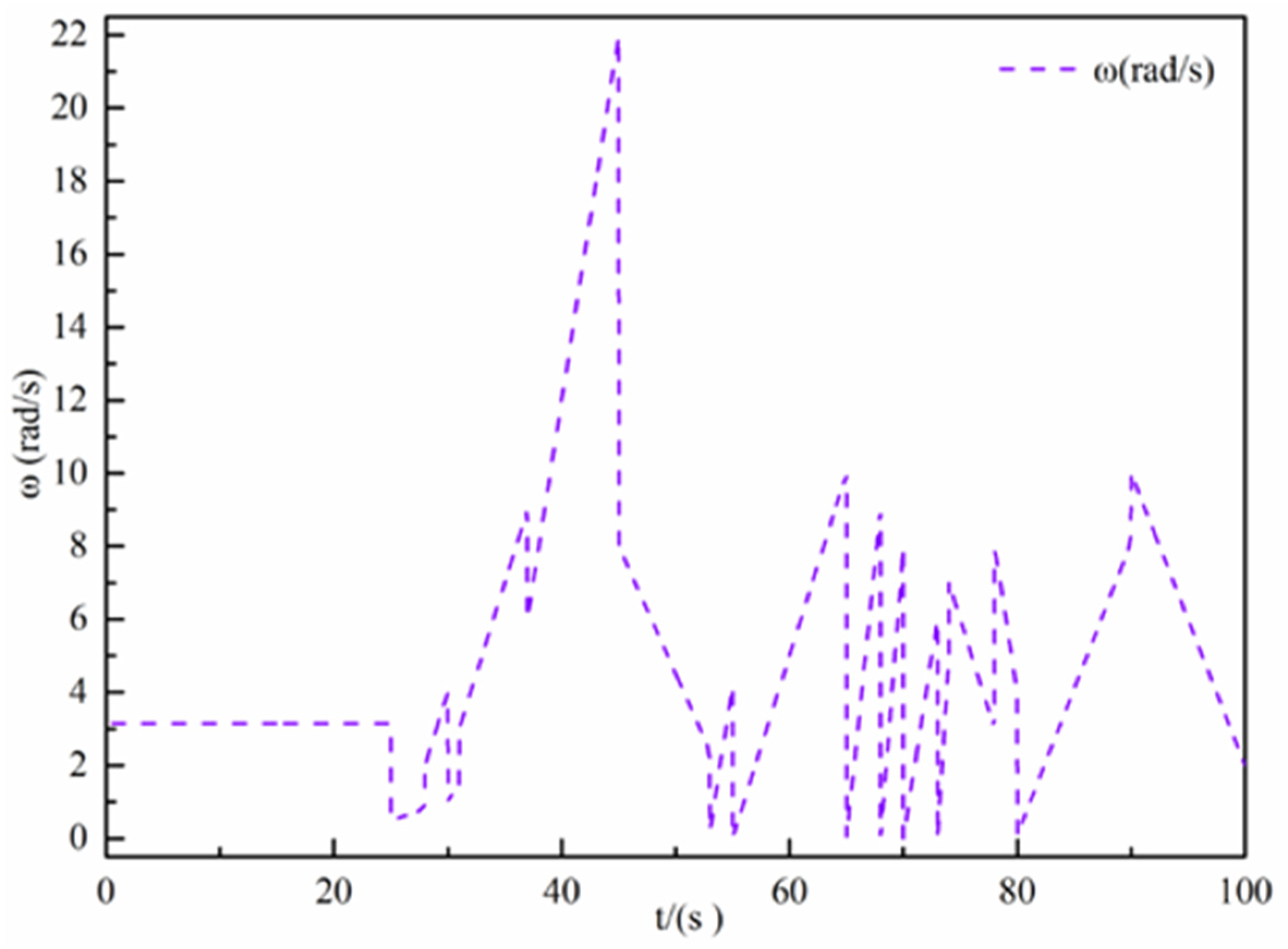

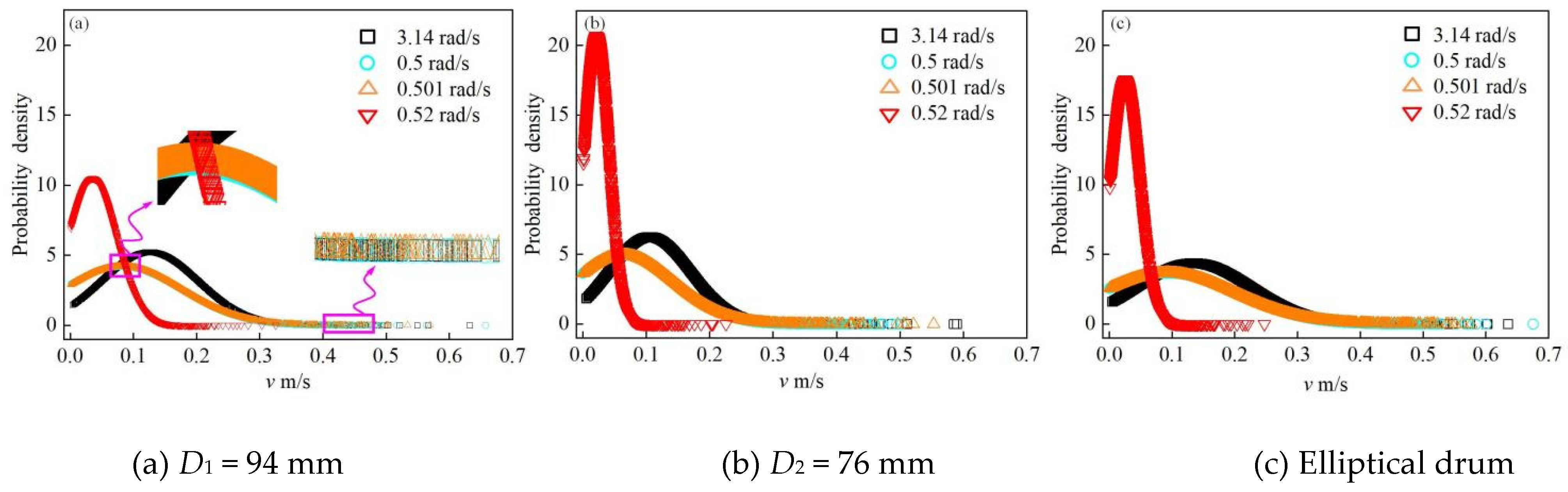

3.2. Transient Analysis of the Drums

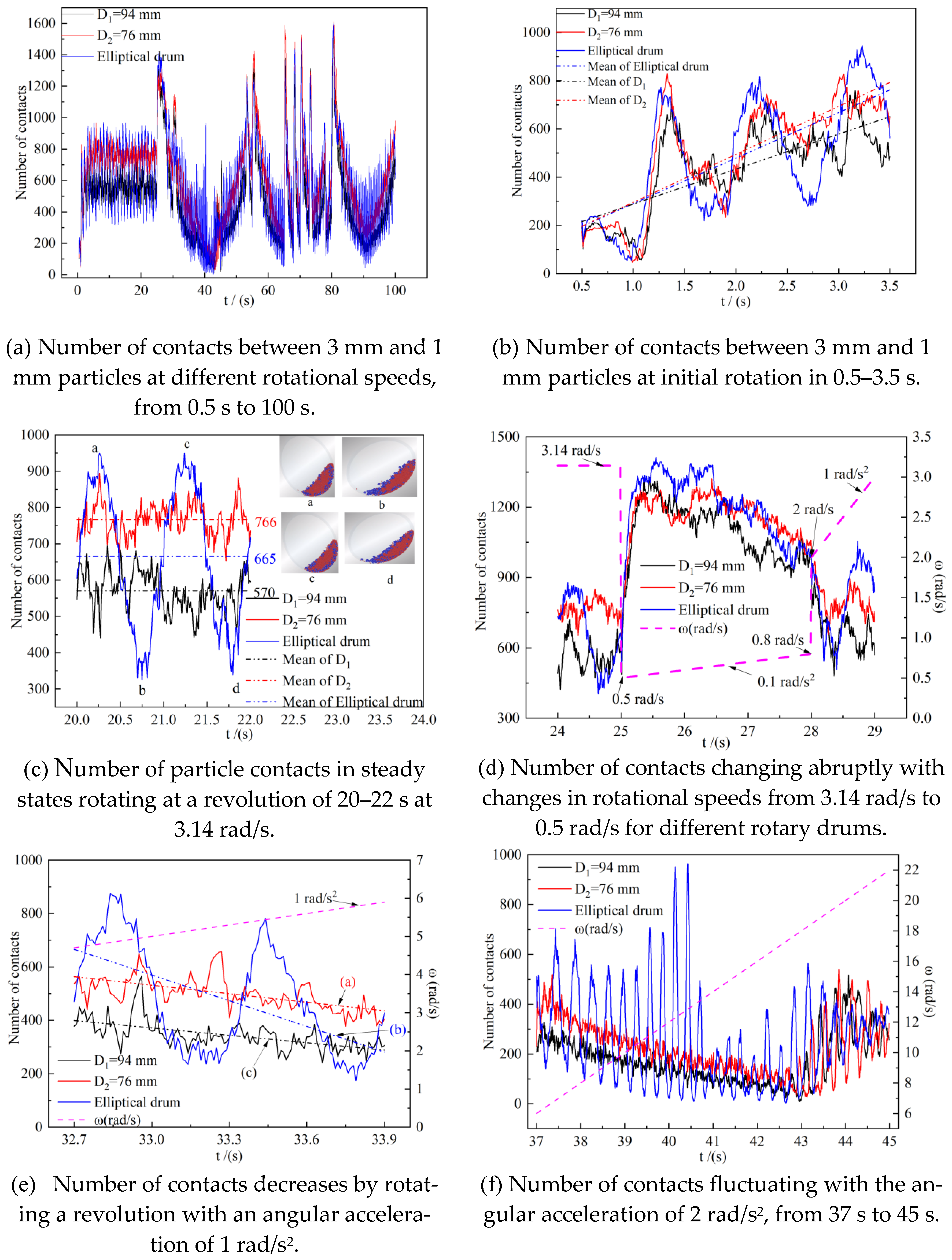

3.3. Number of Contacts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Güereca, L.P.; Torres, N.; Juárez-López, C.R. The co-processing of municipal waste in a cement kiln in Mexico. A life-cycle assessment approach. J. Clean. Prod. 2015, 107, 741–748. [Google Scholar] [CrossRef]

- Basinskas, G.; Sakai, M. Numerical study of the mixing efficiency of a ribbon mixer using the discrete element method. Powder Technol. 2016, 287, 380–394. [Google Scholar] [CrossRef]

- Gao, W.; Liu, L.; Liao, Z.; Chen, S.; Zang, M.; Tan, Y. Discrete element analysis of the particle mixing performance in a ribbon mixer with a double U-shaped vessel. Granul. Matter 2019, 21, 1–16. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Zhang, H.; Xu, X.; Yang, Z.; Xu, W. A Review of the Potential of District Heating System in Northern China. Appl. Therm. Eng. 2021, 188, 116605. [Google Scholar] [CrossRef]

- Tong, G.Q.; Li, Y.; Tagawa, K.; Feng, F. Effects of blade airfoil chord length and rotor diameter on aerodynamic performance of straight-bladed vertical axis wind turbines by numerical simulation. Energy 2022, 265, 126325. [Google Scholar] [CrossRef]

- Gui, N.; Yang, X.; Tu, J.; Jiang, S. Numerical study of the motion behaviour of three-dimensional cubic particle in a thin drum. Adv. Powder Technol. 2018, 29, 426–437. [Google Scholar] [CrossRef]

- Wu, W.N.; Liu, X.Y.; Zhang, R.; Hu, Z. DEM investigation of the power draw for material movement in rotary drums with axis offset. Chem. Eng. Res. Des. 2019, 144, 310–317. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, Y.; Liu, R.; Liu, S. Study on the variation characteristics of the average velocity of special-shaped flake particle systems moving in elliptical drums. Processes 2022, 10, 1704. [Google Scholar] [CrossRef]

- Mellmann, J. The transverse motion of solids in rotating cylinders-forms of motion and transition behavior. Powder Technol. 2001, 118, 69–78. [Google Scholar] [CrossRef]

- Huang, D.C.; Lu, M.; Sun, G.; Feng, Y.D.; Sun, M.; Wu, H.P.; Deng, K.M. Ringlike spin segregation of binary mixtures in a high-velocity rotating drum. Phys. Rev. E 2012, 85, 031305. [Google Scholar]

- Arntz, M.M.H.D.; Beeftink, H.H.; den Otter, W.K.; Briels, W.J.; Boom, R.M. Segregation of granular particles by mass, radius, and density in a horizontal rotating drum. AIChE J. 2014, 60, 50–59. [Google Scholar] [CrossRef]

- Ding, Y.L.; Forster, R.; Seville, J.P.K.; Parker, D.J. Segregation of granular flow in the transverse plane of a rolling mode rotating drum. Int. J. Multiph. Flow 2002, 28, 635–663. [Google Scholar] [CrossRef]

- Ding, Y.L.; Forster, R.; Seville, J.P.K.; Parker, D.J. Solids motion in rolling mode rotating drums operated at low to medium rotational speeds. Chem. Eng. Sci. 2001, 56, 561769–561780. [Google Scholar] [CrossRef]

- Ding, Y.L.; Forster, R.; Seville, J.P.K.; Parker, D.J. Granular motion in rotating drums: Bed turnover time and slumping–rolling transition. Powder Technol. 2002, 124, 12418–12427. [Google Scholar] [CrossRef]

- Santomaso, A.; Olivi, M.; Canu, P. Mechanisms of mixing of granular materials in drum mixers under rolling regime. Chem. Eng. Sci. 2004, 59, 3269–3280. [Google Scholar] [CrossRef]

- Santomaso, A.; Olivi, M.; Canu, P. Mixing kinetics of granular materials in drums operated in rolling and cataracting regime. Powder Technol. 2005, 152, 41–51. [Google Scholar] [CrossRef]

- Santos, D.A.; Dadalto, F.O.; Scatena, R.; Duarte, C.R.; Barrozo, M.A.S. A hydrodynamic analysis of a rotating drum operating in the rolling regime. Chem. Eng. Res. Des. 2015, 94, 204–212. [Google Scholar] [CrossRef]

- Li, D.; Liu, G.D.; Lu, H.L.; Zhang, Q.H.; Wang, Q.; Yu, H.B. Numerical simulation of different flow regimes in a horizontal rotating ellipsoidal drum. Powder Technol. 2016, 291, 86–96. [Google Scholar] [CrossRef]

- Li, D.; Wang, L.; Wang, Q.; Liu, G.D.; Lu, H.; Zhang, Q.H.; Hassan, M. Simulations of dynamic properties of particles in horizontal rotating ellipsoidal drums. Appl. Math. Model. 2016, 40, 7708–7723. [Google Scholar] [CrossRef]

- Ayeni, O.O.; Wu, C.L.; Joshi, J.B.; Nandakumar, K. A discrete element method study of granular segregation in non-circular rotating drums. Powder Technol. 2015, 283, 549–560. [Google Scholar] [CrossRef]

- Liao, C.C.; Hsiau, S.S.; Nien, H.C. Effect of adding a small amount of liquid on density-induced wet granular segregation in a rotating drum. Adv. Powder Technol. 2016, 27, 1265–1271. [Google Scholar] [CrossRef]

- Yamanoto, M.; Ishihara, S.; Kano, J. Evaluation of particle density effect for mixing behavior in a rotating drum mixer by DEM simulation. Adv. Powder Technol. 2016, 27, 864–870. [Google Scholar] [CrossRef]

- Liao, C.C.; Hsiau, S.S.; Nien, H.C. Density-driven spontaneous streak segregation patterns in a thin rotating drum. Phys. Rev. E 2014, 89, 062204. [Google Scholar] [CrossRef]

- Soni, R.K.; Mohanty, R.; Mohanty, S.; Mishra, B.K. Numerical analysis of mixing of particles in drum mixers using DEM. Adv. Powder Technol. 2016, 27, 531–540. [Google Scholar] [CrossRef]

- DEM solutions Limited. EDEM 2.7 User Guide; DEM solutions Limited: Edinburgh, UK, 2003. [Google Scholar]

- Geng, F.; Gang, L.; Wang, Y.C.; Yuan, Z.; Li, Y. Numerical investigation on particle mixing in a ball mill. Powder Technol. 2016, 292, 64–73. [Google Scholar] [CrossRef]

- Yang, R.Y.; Zou, R.P.; Yu, A.B. Microdynamic analysis of particle flow in a horizontal rotating drum. Powder Technol. 2003, 130, 138–146. [Google Scholar] [CrossRef]

- Emady, H.N.; Anderson, K.V.; Borghard, W.G.; Muzzio, F.J.; Glasser, B.J.; Cuitino, A. Prediction of conductive heating time scales of particles in a rotary drum. Chem. Eng. Sci. 2016, 152, 45–54. [Google Scholar] [CrossRef]

- Rezaeizadeh, M.; Fooladi, M.; Powell, M.S.; Mansouri, S.H.; Weerasekara, N.S. A new predictive model of lifter bar wear in mills. Miner. Eng. 2010, 23, 1174–1181. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Cogné, C.; Guessasma, M.; Bellenger, E.; Fortin, J. Discrete modeling of granular flow with thermal transfer: Application to the discharge of silos. Appl. Therm. Eng. 2009, 29, 1846–1853. [Google Scholar] [CrossRef]

- Möbius, M.E.; Lauderdale, B.E.; Nagel, S.R.; Jaeger, H.M. Brazil-nut effect: Size separation of granular particles. Nature 2001, 414, 270. [Google Scholar] [CrossRef]

- Shinbrot, T. Granular materials: The Brazil nut effect—In reverse. Nature 2004, 429, 352–353. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Particle size [mm] | 1, 3 |

| Drum density [kg/m3] | 7800 |

| Particle density [kg/m3] | 1800 |

| Number of particles | 4020, 150 |

| Gravity [m/s2] | 9.8 |

| Shear modulus of particle [Pa] | 1 × 108 |

| Shear modulus of drum [Pa] | 8 × 108 |

| Poisson ratio of particle | 0.25 |

| Poisson ratio of drum | 0.29 |

| Coefficient of restitution | 0.1 |

| Coefficient of static friction | 0.9 |

| Coefficient of rolling friction | 0.01 |

| Time step [s] | 1.45 × 10−6 |

| D1 = 94 mm | D2 = 76 mm | Elliptical Drum | |

|---|---|---|---|

| m | −106.29 | −92.23 | −320.13 |

| n | 4038.88 | 3415.14 | 11,133.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, L.; Song, C.; Li, W.; Qin, H.; Wang, Q. Numerical Simulations of Particle Motions at Continuous Rotational Speed Changes in Horizontal Rotating Drums. Processes 2023, 11, 47. https://doi.org/10.3390/pr11010047

Zhao Y, Zhang L, Song C, Li W, Qin H, Wang Q. Numerical Simulations of Particle Motions at Continuous Rotational Speed Changes in Horizontal Rotating Drums. Processes. 2023; 11(1):47. https://doi.org/10.3390/pr11010047

Chicago/Turabian StyleZhao, Yuze, Lidong Zhang, Changpeng Song, Weiwei Li, Hong Qin, and Qing Wang. 2023. "Numerical Simulations of Particle Motions at Continuous Rotational Speed Changes in Horizontal Rotating Drums" Processes 11, no. 1: 47. https://doi.org/10.3390/pr11010047

APA StyleZhao, Y., Zhang, L., Song, C., Li, W., Qin, H., & Wang, Q. (2023). Numerical Simulations of Particle Motions at Continuous Rotational Speed Changes in Horizontal Rotating Drums. Processes, 11(1), 47. https://doi.org/10.3390/pr11010047