Manufacturing Cell Integrated Layout Method Based on RNS-FOA Algorithm in Smart Factory

Abstract

:1. Introduction

- (1)

- Manufacturing cell integrated layout method for smart factory is proposed.

- (2)

- Based on the characteristics of smart factories, a multi-objective mathematical model of MCIL is constructed.

- (3)

- An adaptive RNS-FOA algorithm is designed, which is helpful for solving the combinatorial optimization problems of high-dimensional and large-scale.

- (4)

- High-quality cases can provide a reference for the cell layout of enterprise.

2. Literature Review

3. Proposition

3.1. Problem Hypothesis

- (1)

- Shape of the equipment is a cuboid, and the manufacturing cell is a rectangular block.

- (2)

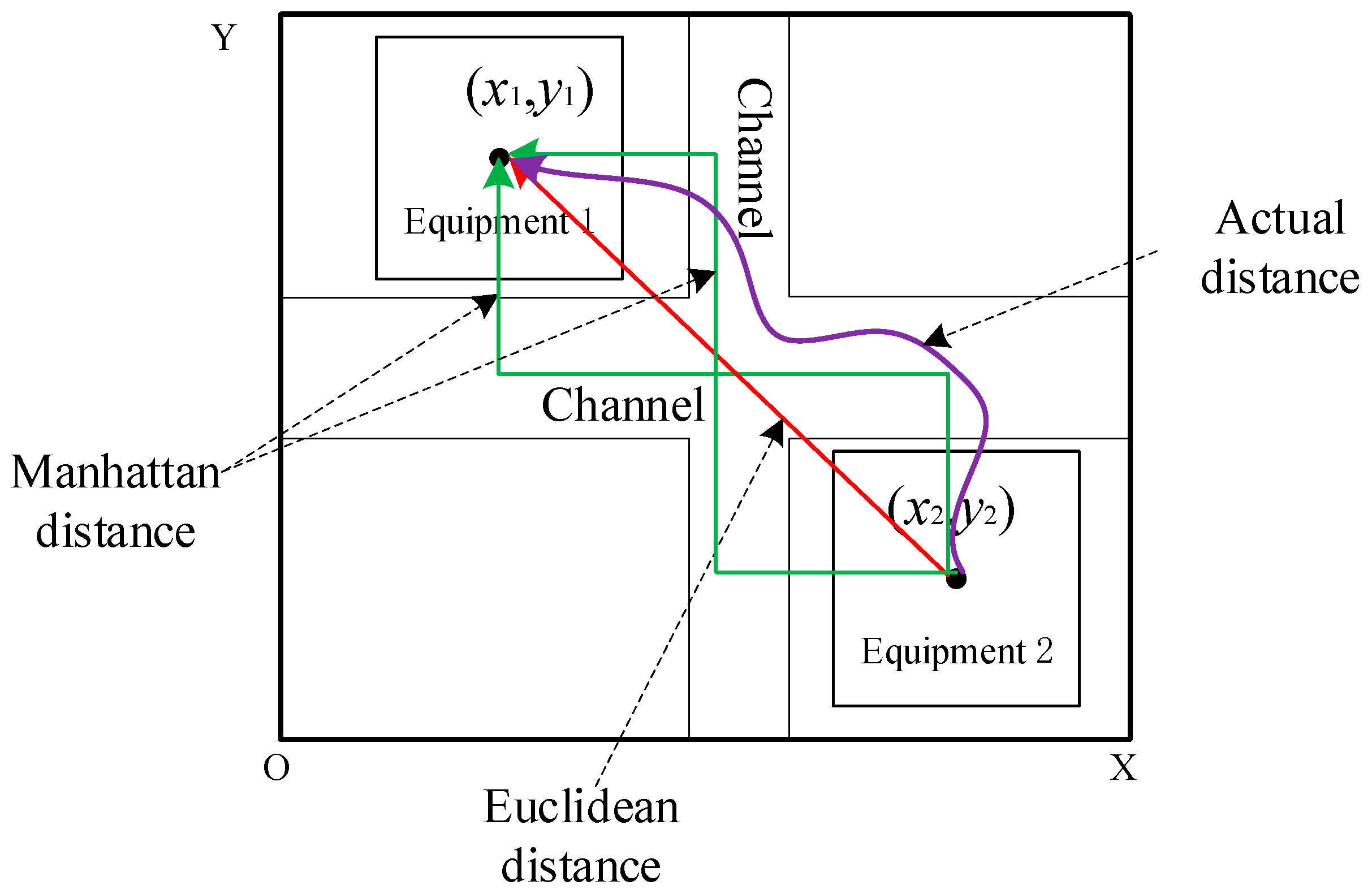

- Handling distance is the Manhattan distance.

- (3)

- The same layer is transported on the same horizontal line, and the product is transported through the center point of the equipment.

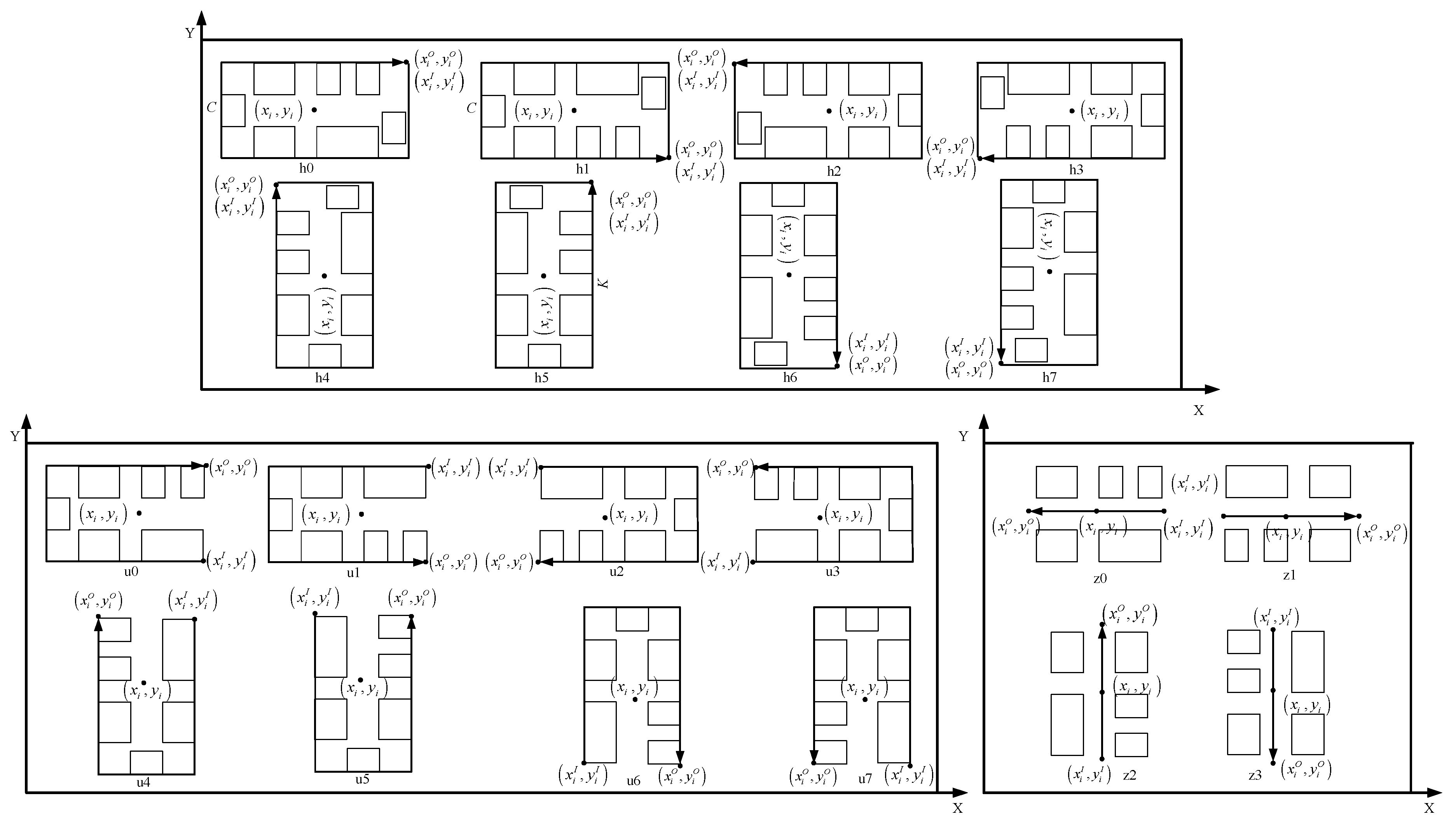

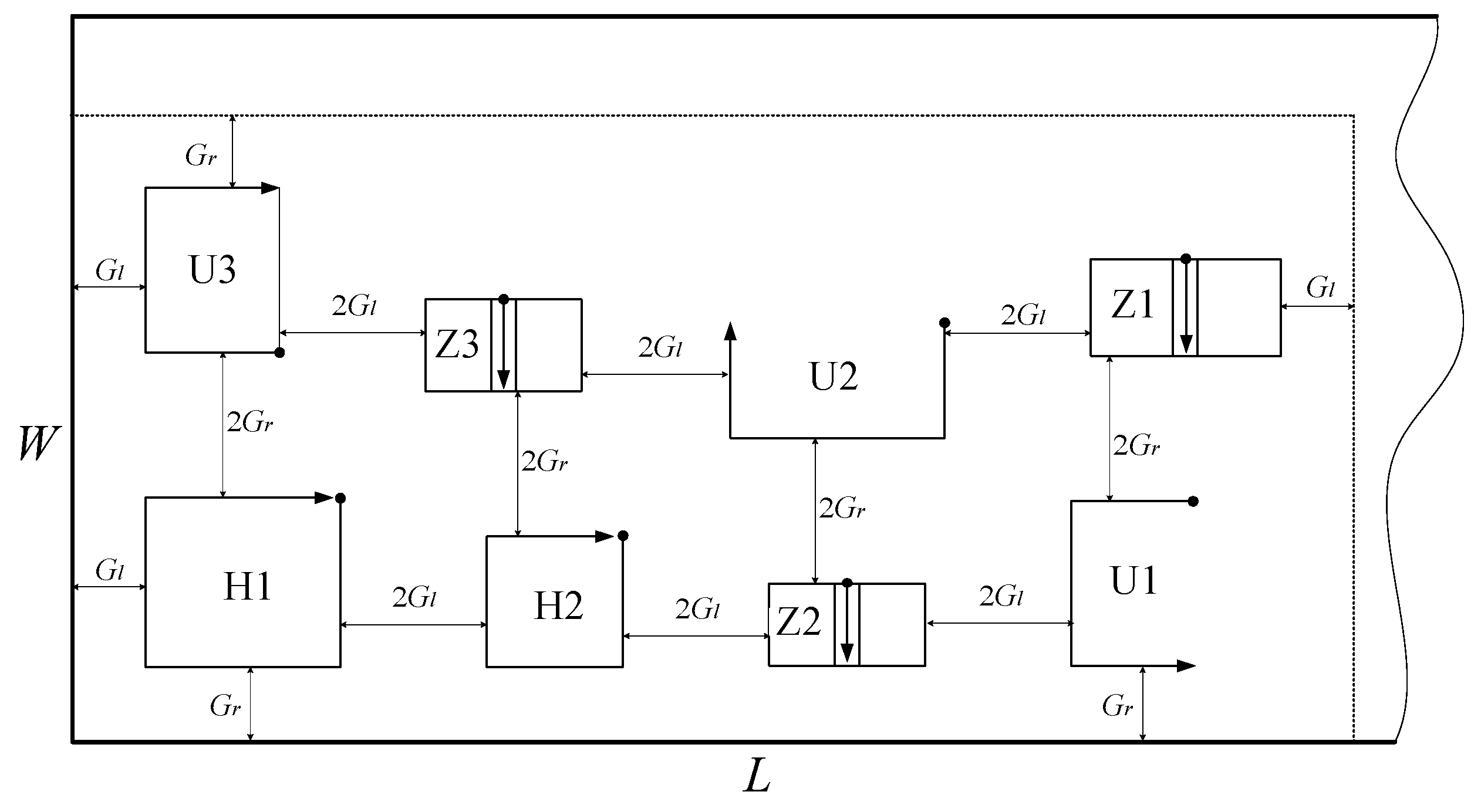

3.2. Problem Description

3.3. Mathematical Modeling

- (1)

- Material handling

- (2)

- Workshop space occupation

- (3)

- Lost time

- (4)

- Cell stability

- (5)

- Non-logistics relationship

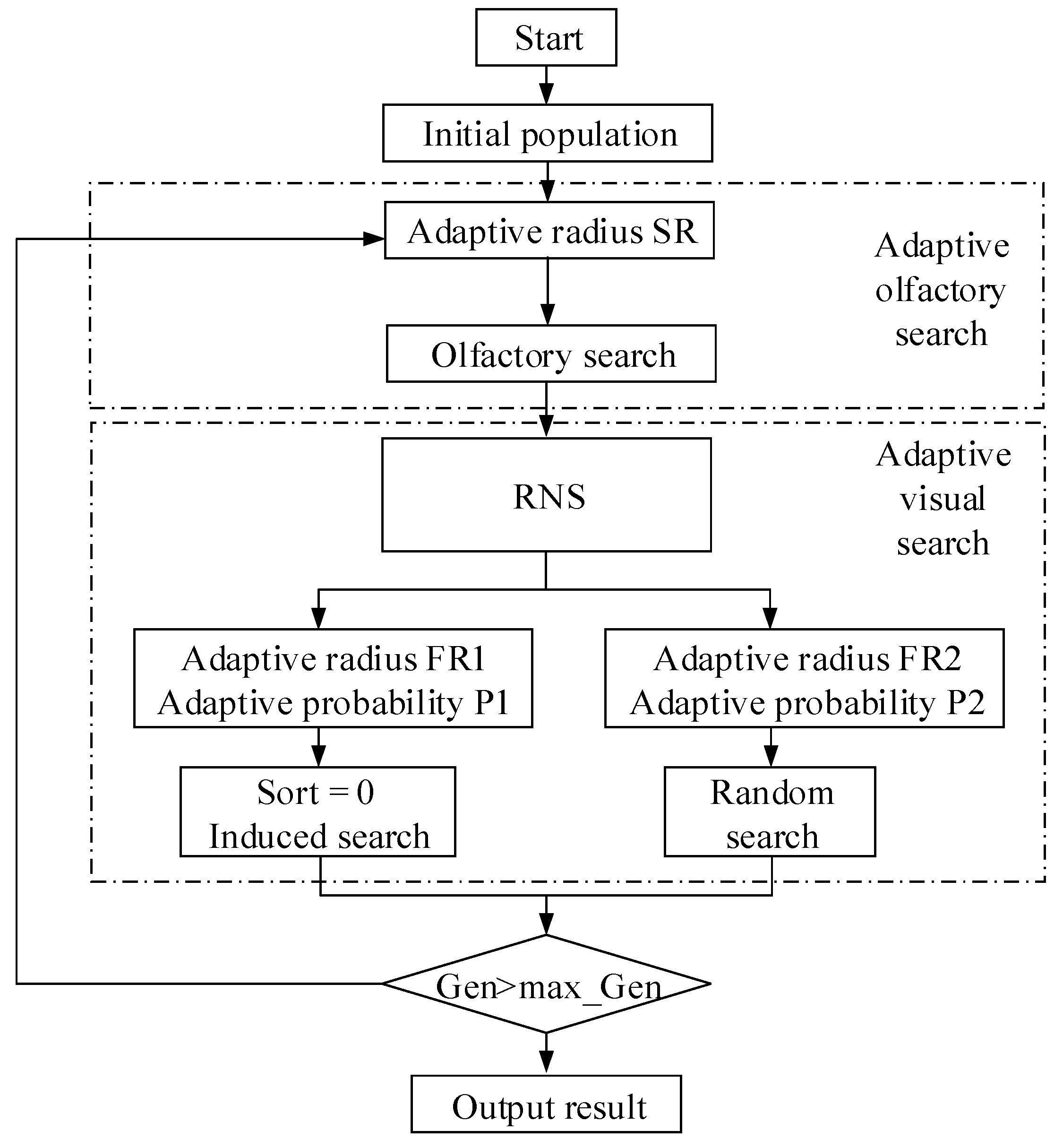

4. RNS-FOA Algorithm Design

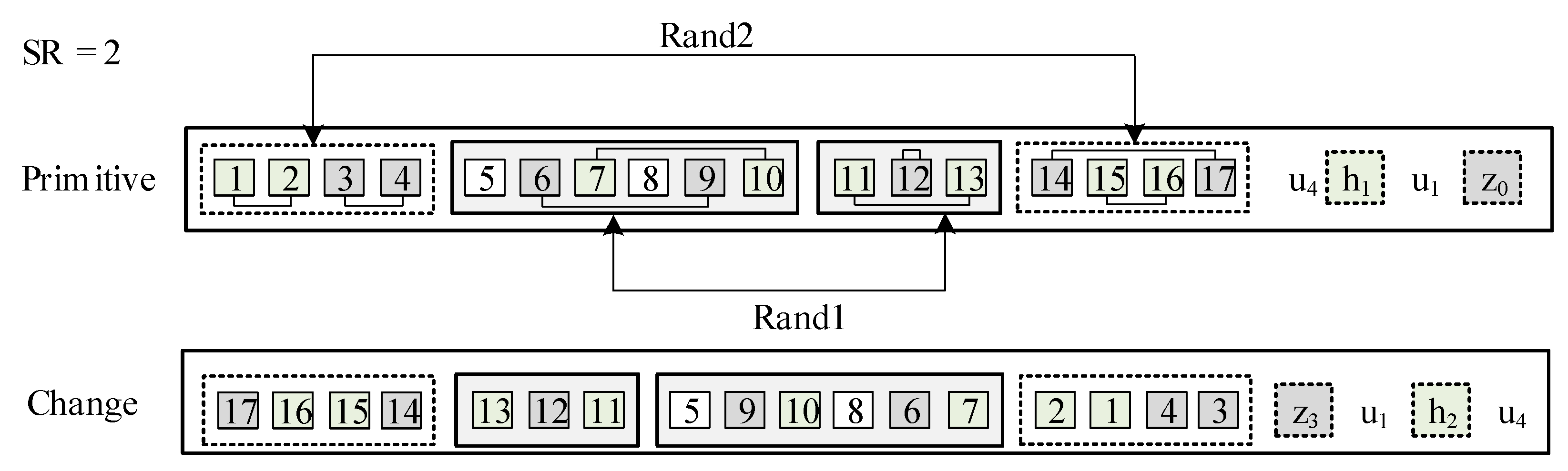

4.1. Coding and Initial Population

4.2. Adaptive Olfactory Search

4.3. Adaptive Visual Search

4.3.1. Calculation of Food Concentration Value (Adaptation Value)

4.3.2. Flight Strategy

4.4. General Process of RNS-FOA Algorithm

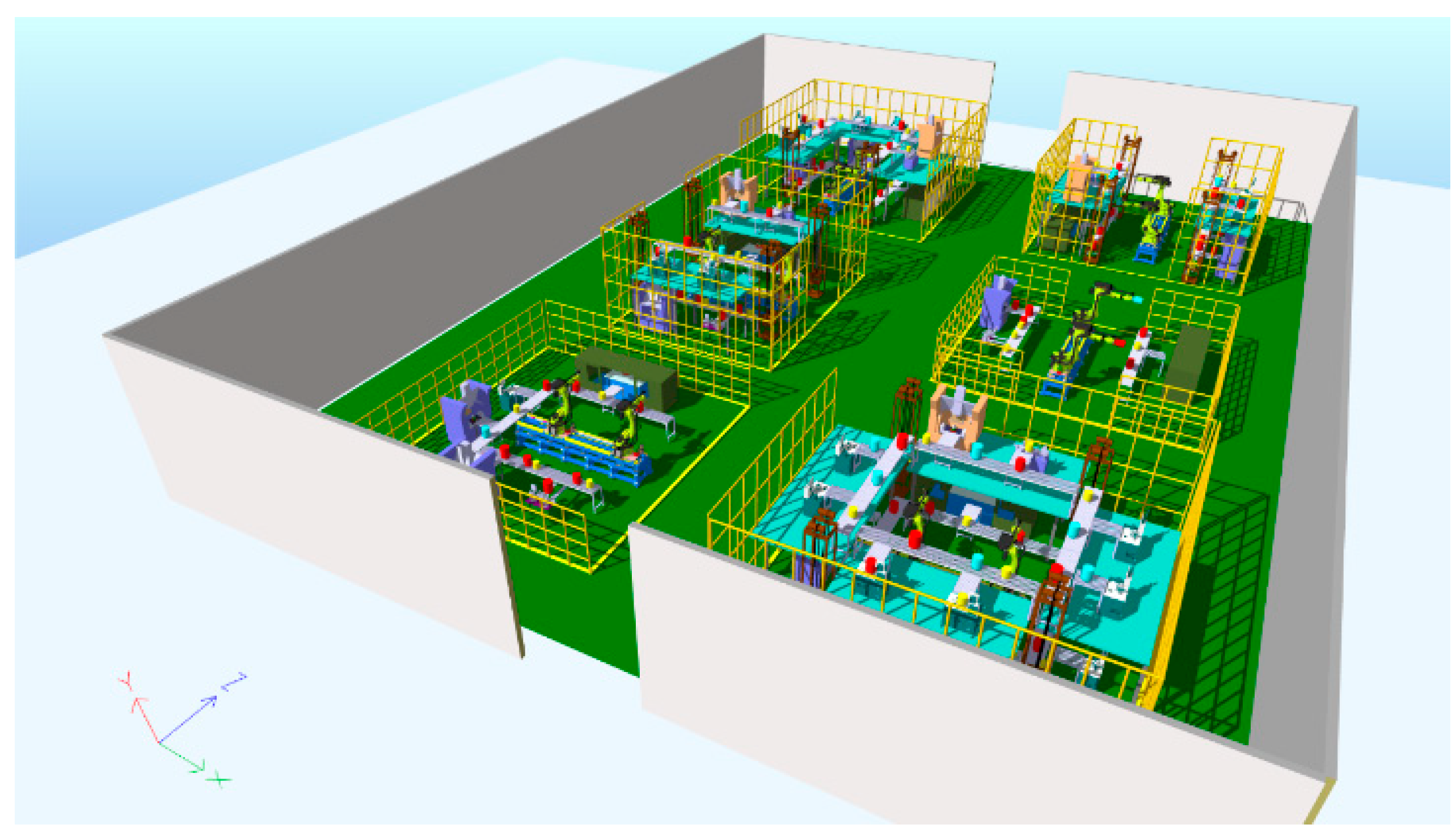

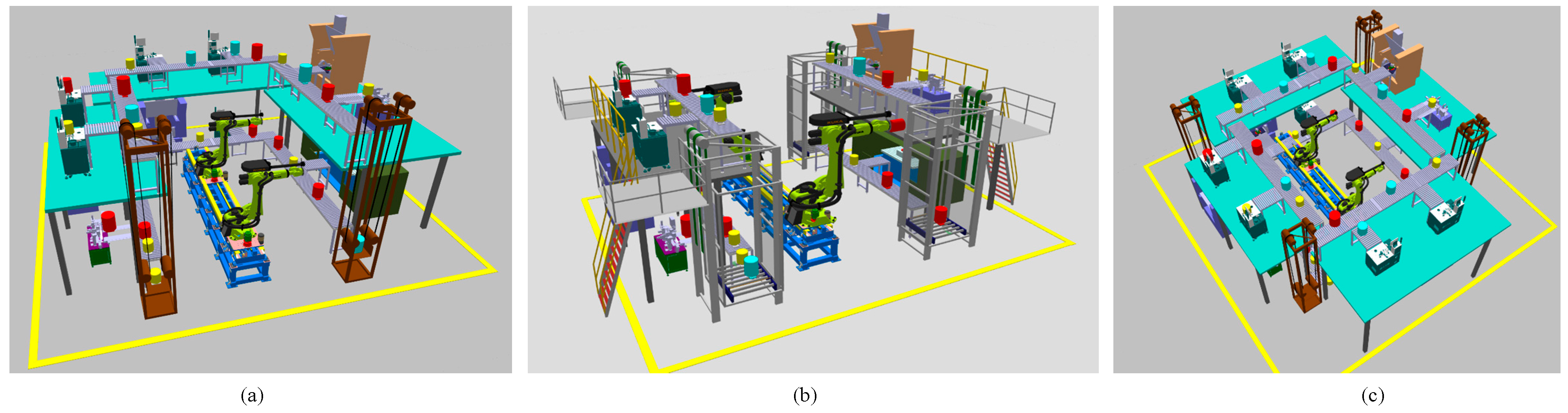

5. Case

5.1. Case Data

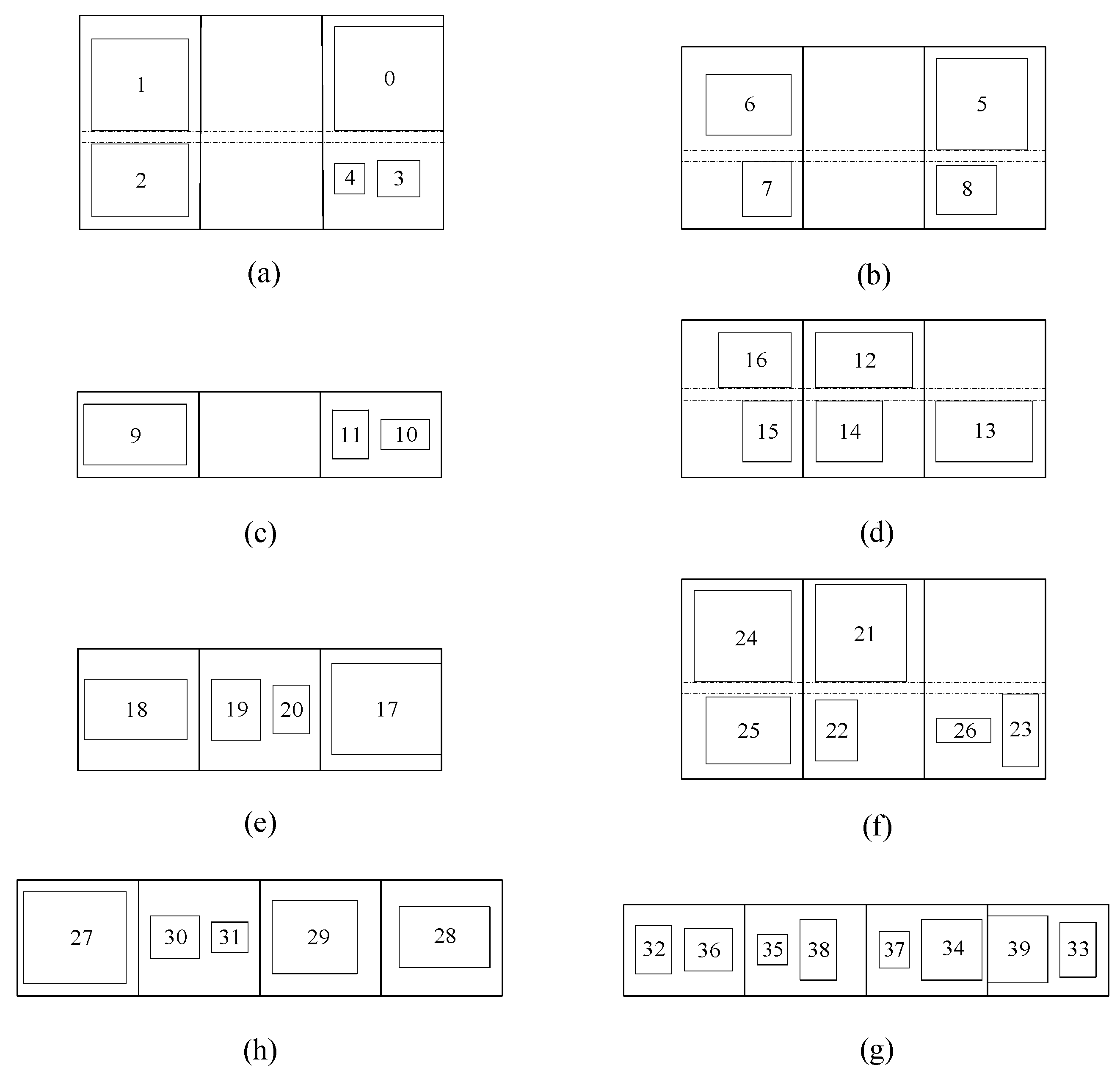

5.2. Case Solving Analysis

5.2.1. Parameters and Operating Environment

5.2.2. Analysis of Running Results

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xin, Y.; Guijiang, D. The Real-Time Prediction of Product Quality Based on the Equipment Parameters in a Smart Factory. Processes 2022, 10, 967. [Google Scholar] [CrossRef]

- Fátima, L.; Adriana, E.; Simon, C. Smart Pharmaceutical Manufacturing: Ensuring End-to-End Traceability and Data Integrity in Medicine Production. Big Data Res. 2021, 24, 100172. [Google Scholar] [CrossRef]

- Gyusun, H.; Jeongcheol, L.; Jinwoo, P. Developing Performance Measurement System for Internet of Things and smart Factory Environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Glenn, T. Sustainable Product Lifecycle Management, Industrial Big Data and Internet of Things Sensing Networks in Cyber-Physical System-based Smart Factories. J. Self-Gov. Manag. Economics. 2021, 9, 9–19. [Google Scholar]

- Navid, S.; Thomas, L.; Lars, L. Integration of digital factory with smart factory based on Internet of Things. Procedia CIRP 2016, 50, 512–517. [Google Scholar] [CrossRef]

- Seyed, M.S.S.; Yoo, H.S.; Sang, D.N. A Conceptual Definition and Future Directions of Urban Smart Factory for Sustainable Manufacturing. Sustainability 2022, 14, 1221. [Google Scholar] [CrossRef]

- Rao, B.C. Frugal Manufacturing in Smart Factories for Widespread Sustainable Development. R. Soc. Open Sci. 2021, 8, 210375. [Google Scholar] [CrossRef]

- Vikrant, S.; Gidwani, B.D. Cellular Manufacturing System Practices in Manufacturing Industries: A Pilot Study. Int. J. Indian Cult. Bus. Manag. 2022, 25, 550–569. [Google Scholar]

- Long, H.; Yiming, M.; Gaoxiang, W. IRobot-factory: An Intelligent Robot Factory Based on Cognitive Manufacturing and Edge Computing. Future Gener. Comput. Syst. 2019, 90, 569–577. [Google Scholar] [CrossRef]

- Yanlin, Z.; Jiansha, L.; Wenchao, Y. A New Cellular Manufacturing Layout: Multi-Floor Linear Cellular Manufacturing Layout. Int. J. Adv. Robot. Syst. 2020, 17, 1–14. [Google Scholar] [CrossRef]

- Yanlin, Z.; Jiansha, L.; Qing, Y. 3D-U Intelligent Manufacturing Cell Facilities Layout Based on Self-Adapting Multi-Objective Fruit Fly Optimization Algorithm. Comput. Integr. Manuf. Syst. 2020, 26, 2743–2752. [Google Scholar] [CrossRef]

- Mariem, B.; Marc, Z.; Roberta, C. 3D Facility Layout Problem. J. Intell. Manuf. 2021, 32, 1065–1090. [Google Scholar] [CrossRef]

- Shine-Der, L. Configuring Layout for a Cellular Manufacturing System. Int. J. Syst. Sci. 1998, 29, 557–564. [Google Scholar] [CrossRef]

- Chen, S.L.; Lee, K.M.; Li, I.C. Using MQTT IIot Gateway to Implement Bi-Direction Communication. J. Chin. Soc. Mech. 2020, 41, 585–594. [Google Scholar]

- Yan, W.; Siyu, X.; Huang, Z. Coupling Layout Optimization of Key Plant and Industrial Area. Processes 2020, 8, 185. [Google Scholar] [CrossRef]

- Yu, W.Y.; Fang, J.J. Integrated Cellular and Facility Layout Design with Linear Shaped Production Cell. Ind. Eng. Manag. 2016, 21, 102–108. [Google Scholar]

- Liu, J.; Liang, C.Y. Simulation Research and Implementation of Design-Oriented Hybrid Manufacturing Systems. Comput. Integr. Manuf. Syst. 2016, 22, 1264–1271. [Google Scholar] [CrossRef]

- Hamdia, M.; Islam, H.A.; Sayed, M.T. Heuristic-based Approach to Solve Layout Design and Workers’ Assignment Problem in the Cellular Manufacturing System. Int. J. Manag. Sci. Eng. Manag. 2022, 17, 49–65. [Google Scholar] [CrossRef]

- He, X.C.; Wu, X.; Ding, Y.K. Research of Manufacturing Cell Formation Based On U-Shaped Layout. J. Zhejiang Univ. Technol. 2017, 45, 88–93. [Google Scholar]

- Qi, B.S.; Qi, E.S. A Lean Design Method for U-Shaped Manufacturing Cell Facility Layout Based on Improved Genetic Algorithm. Ind. Eng. Manag. 2017, 22, 7–14. [Google Scholar]

- Frittandi, F.; Rainisa, M.H.; David, T.L. The Application of U-shaped Line Balancing at Furniture Manufacturing. Int. Conf. Ind. Syst. Eng. Technol. Innov. Manag. 2022, 2, 155–165. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Dai, D.M. Layout Design for Cellular Manufacturing Systems Based on Unidirectional Loop Flow Path. Comput. Integr. Manuf. Syst. 2013, 19, 1224–1231. [Google Scholar]

- Deb, K.; Jain, H. An Evolutionary Many-Objective Optimization Algorithm Using Reference-Point-Based Non-dominated Sorting Approach, Part I: Solving Problems with Box Constraints. IEEE Trans. Evol. Comput. 2014, 18, 577–601. [Google Scholar] [CrossRef]

- Reza, P.M.; Sadigh, R. Muiltiobjective Optimization Using Non-Dominated Sorting in Genetic Algorithms. J. Ind. Inf. Integr. 2017, 8, 49–58. [Google Scholar] [CrossRef]

- Nidamarthi, S.; Deb, K. An Integrated Simulation-Based Optimization Technique for Multi-Objective Dynamic Facility Layout Problem. Evol. Comput. 1994, 2, 221–248. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Ahrari, A.; Blank, J.; Deb, K. A Proximity-Based Surrogate-Assisted Method for Simulation-Based Design Optimization of a Cylinder Head Water Jacket. Eng. Optim. 2020, 1, 1–19. [Google Scholar] [CrossRef]

- Nazir, H.; Bajwa, I.S.; Samiullah, M. Robust Secure Color Image Watermarking Using 4d Hyperchaotic System, Dwt, Hbd, and Svd Based on Improved FOA Algorithm. Secur. Commun. Netw. 2021, 28, 256–271. [Google Scholar] [CrossRef]

- Salehi, M.; Farhadi, S.; Moieni, A. A Hybrid Model Based on General Regression Neural Network and Fruit Fly Optimization Algorithm For Forecasting and Optimizing Paclitaxel Biosynthesis in Corylus Avellana Cell Culture. Plant. Methods 2021, 17, 1–13. [Google Scholar] [CrossRef]

- Yuan, X.; Cao, G.H.; Zhao, J. On A Novel Multi-Swarmfruit Fly Optimization Algorithm and Its Application. Appl. Math. Comput. 2014, 233, 260–271. [Google Scholar] [CrossRef]

- Meng, T.; Pan, Q.K. An Improved Fruit Fly Optimization Algorithm for Solving the Multidimensional Knapsack Problem. Appl. Soft Comput. 2017, 50, 79–93. [Google Scholar] [CrossRef]

- Wang, L.; Lv, C.X.; Zeng, Y.R. Literature Survey of Fruit Fly Optimization Algorithm. Control. Decis. 2017, 32, 1153–1162. [Google Scholar]

- Rahimi, V.; Arkat, J.; Farughi, H.R. A Vibration Damping Optimization Algorithm for the Integrated Problem of Cell Formation, Cellular Scheduling, and Intercellular Layout. Comput. Ind. Eng. 2020, 143, 6439–6456. [Google Scholar] [CrossRef]

- Forghani, K.; Ghomi, S.M.T. Joint Cell Formation, Cell Scheduling, and Group Layout Problem in Virtual and Classical Cellular Manufacturing Systems. Appl. Soft Comput. 2020, 97, 867–890. [Google Scholar] [CrossRef]

- Besbes, M.; Zolghadri, M.; Affonso, R.C. A Methodology for Solving Facility Layout Problem Considering Barriers: Genetic Algorithm Coupled With A* Search. J. Intell. Manuf. 2020, 31, 615–640. [Google Scholar] [CrossRef]

- Xie, Y.; Zhou, S.H.; Xiao, Y.Y. A Beta-Accurate Linearization Method of Euclidean Distance for The Facility Layout Problem with Heterogeneous Distance Metrics. Eur. J. Oper. Res. 2018, 365, 26–38. [Google Scholar] [CrossRef]

- Zheng, X.L.; Wang, L. An Order-Based Fruit Fly Optimization Algorithm for Stochastic Resource-constrained Project Scheduling. Control. Theory Appl. 2015, 4, 540–545. [Google Scholar]

| No. | [li,wi,hi] | Weight | Time | Cell Shape |

|---|---|---|---|---|

| 0 | [1.8,1.5,1.7] | 200 | 30 | Z1 |

| 1 | [1.6,1.2,1.5] | 150 | 15 | |

| 2 | [1.6,1.4,1.2] | 160 | 18 | |

| 3 | [0.7,0.5,0.6] | 80 | 21 | |

| 4 | [0.5,0.5,0.5] | 50 | 20 | |

| 5 | [1.5,1.2,1.5] | 130 | 25 | Z2 |

| 6 | [1.4,1.0,1.0] | 120 | 18 | |

| 7 | [0.8,0.8,0.9] | 90 | 10 | |

| 8 | [1.0,0.5,0.8] | 100 | 16 | |

| 9 | [1.7,1.5,1.0] | 180 | 14 | Z3 |

| 10 | [0.8,0.7,0.5] | 90 | 13 | |

| 11 | [0.6,0.5,0.8] | 70 | 12 | |

| 12 | [1.5,1.6,0.9] | 180 | 11 | U1 |

| 13 | [1.6,1.5,1.0] | 190 | 18 | |

| 14 | [1.0,1.1,1.0] | 110 | 27 | |

| 15 | [0.8,0.9,1.0] | 100 | 28 | |

| 16 | [1.2,0.8,0.9] | 110 | 24 | |

| 17 | [1.8,1.6,1.5] | 210 | 25 | U2 |

| 18 | [1.7,1.8,1.0] | 180 | 42 | |

| 19 | [0.8,0.8,1.0] | 110 | 45 | |

| 20 | [0.5,0.6,0.8] | 70 | 31 | |

| 21 | [1.7,1.5,1.6] | 180 | 38 | U3 |

| 22 | [0.8,0.7,1.0] | 130 | 41 | |

| 23 | [0.6,0.8,1.2] | 80 | 36 | |

| 24 | [1.6,1.4,1.5] | 160 | 12 | |

| 25 | [1.4,1.2,1.1] | 140 | 42 | |

| 26 | [0.9,1.0,0.4] | 130 | 37 | |

| 27 | [1.7,1.4,1.5] | 180 | 22 | H1 |

| 28 | [1.6,1.5,1.0] | 160 | 42 | |

| 29 | [1.4,1.6,1.2] | 120 | 24 | |

| 30 | [0.9,0.8,0.7] | 100 | 39 | |

| 31 | [0.4,0.6,0.5] | 50 | 25 | |

| 32 | [0.6,0.5,0.8] | 60 | 28 | H2 |

| 33 | [0.7,0.6,0.9] | 70 | 26 | |

| 34 | [1.0,1.1,1.0] | 120 | 21 | |

| 35 | [0.5,0.5,0.5] | 60 | 16 | |

| 36 | [0.8,0.4,0.7] | 80 | 14 | |

| 37 | [0.5,0.5,0.6] | 70 | 19 | |

| 38 | [0.7,0.6,1.0] | 90 | 20 | |

| 39 | [0.9,1.0,1.1] | 110 | 25 |

| No. | Product Process Path | Processing Batch | Handling Batches |

|---|---|---|---|

| 1 | 16-12-15-14--7-8-6-5--21-25-22-26-24-23--32-36-37-34-33-39 | 6000 | 10 |

| 2 | 10-9-11--0-4-2-3-1--19-18-17-20 | 5000 | 10 |

| 3 | 20-19--3-2-1-0--9-11--26-22-25-23--33-32-34-38-36-35 | 8000 | 10 |

| 4 | 4-0-1--26-22-25-23--32-36-37-34-33-39 | 6000 | 20 |

| 5 | 28-31-30-27-29--24-23-25-26--15-13-16--1-4-0 | 3000 | 10 |

| 6 | 7-8--14-16--31-28-27--37-36-33-32--6-7-5 | 5000 | 20 |

| 7 | 14-16--1-4-0--10-9--18-17-20 | 4000 | 10 |

| 8 | 29-27-29-31--22-25-24-21--35-34-37-38-35 | 7000 | 10 |

| 9 | 6-5-8--39-35-36-33-38-37--16-12-15-14 | 5000 | 20 |

| 10 | 38-36-32--15-13-16--24-23-25-26 | 4000 | 10 |

| O-D | Grade | O-D | Grade | O-D | Grade | O-D | Grade |

|---|---|---|---|---|---|---|---|

| 0-1 | O | 14-16 | I | 27-31 | I | 36-39 | A |

| 0-2 | I | 17-18 | A | 28-29 | O | 38-39 | I |

| 0-4 | I | 17-19 | I | 28-30 | E | L1-L3 | O |

| 1-3 | A | 18-19 | I | 28-31 | A | L1-U2 | E |

| 3-4 | E | 18-20 | E | 30-31 | O | L1-U3 | O |

| 5-7 | E | 21-23 | A | 32-34 | O | L1-H2 | I |

| 6-7 | I | 21-24 | I | 32-36 | E | L2-U2 | I |

| 6-8 | A | 21-26 | I | 32-37 | O | L2-H1 | E |

| 9-10 | I | 22-24 | A | 32-39 | I | L2-U1 | I |

| 9-11 | E | 22-25 | E | 33-36 | I | L2-U2 | I |

| 10-11 | O | 23-25 | O | 33-38 | E | L2-H1 | A |

| 12-13 | E | 23-26 | E | 34-35 | I | U1-H1 | O |

| 12-14 | E | 24-25 | I | 34-36 | I | U2-H2 | A |

| 12-16 | O | 24-26 | O | 34-38 | A | H1-H2 | I |

| 13-15 | A | 27-29 | I | 35-38 | O |

| Algorithm | MCIY Layout Scheme | D, V, T, B, E |

|---|---|---|

| RNS-FOA | (27,30,31,29,28)(25,22,26,23,24,21)(36,32,35,38,37,34,33,39)(9,11,10)(7,8,6,5)(18,19,20,17)(15,14,13,16,12)(2,4,3,1,0)[h0,u0,h5,z3,z3,u4,u1,z3] | 187595.0,912.0,1588942.6,4642.6,30.4 |

| (25,22,23,26,24,21)(32,36,33,39,34,37,35,38)(14,13,15,16,12)(17,20,19,18)(6,8,5,7)(2,3,4,1,0)(27,28,31,30,29)(9,10,11)[u4,h1,u1,u0,z2,z3 h5,z1] | 189310.0,835.8,1577643.2,4674.1,31.2 | |

| (31,30,28,27,29)(8,7,5,6)(19,20,18,17)(11,10,9)(36,35,32,34,37,38,33,39)(13,14,15,12,16)(25,26,23,22,24,21)(4,3,2,0,1)[h0,z0,u3,z2,h5,u1,u4,z2] | 198000.0,855.2,1512590.8,4642.6,30.7 | |

| NSAG III | (33,39,35,37,38,36,32,34)(7,8,5,6)(19,20,17,18)(13,14,16,12,15)(22,25,24,26,21,23)(1,0,3,4,2)(9,11,10)(28,29,31,30,27)[h4,z3,u6,u5,u7,z2,z1,h0] | 210657.5,1020.3,1812176.8,5482.8,33.2 |

| (38,39,37,34,35,33,36,32)(28,30,31,27,29)(19,20,17,18)(16,14,13,15,12)(25,24,26,23,22,21)(3,2,1,0,4),(8,7,6,5)(11,10,9)[h5,h5,u4,u0,u4,z3,z1,z3] | 199355.0,1024.1,2043603.8,5107.80,33.2 | |

| (12,15,14,16,13)(5,8,6,7)(22,24,21,26,25,23)(11,10,9)(17,18,20,19)(36,32,33,39,34,35,37,38)(27,29,28,31,30)(1,4,3,0,2)[u7,z0,u6,z2,u4,h3,h3,z2] | 198525.0,986.4,2140589.5,5304.9,34.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y. Manufacturing Cell Integrated Layout Method Based on RNS-FOA Algorithm in Smart Factory. Processes 2022, 10, 1759. https://doi.org/10.3390/pr10091759

Zhao Y. Manufacturing Cell Integrated Layout Method Based on RNS-FOA Algorithm in Smart Factory. Processes. 2022; 10(9):1759. https://doi.org/10.3390/pr10091759

Chicago/Turabian StyleZhao, Yanlin. 2022. "Manufacturing Cell Integrated Layout Method Based on RNS-FOA Algorithm in Smart Factory" Processes 10, no. 9: 1759. https://doi.org/10.3390/pr10091759

APA StyleZhao, Y. (2022). Manufacturing Cell Integrated Layout Method Based on RNS-FOA Algorithm in Smart Factory. Processes, 10(9), 1759. https://doi.org/10.3390/pr10091759