Study on the Variation Characteristics of the Average Velocity of Special-Shaped Flake Particle Systems Moving in Elliptical Drums

Abstract

:1. Introduction

2. Numerical Methods

2.1. Establishment of DEM Model for Device and Irregular Particles

2.2. Calculation Method of Average Velocity of Special-Shaped Particle System

2.3. Comparison and Verification of Working Conditions

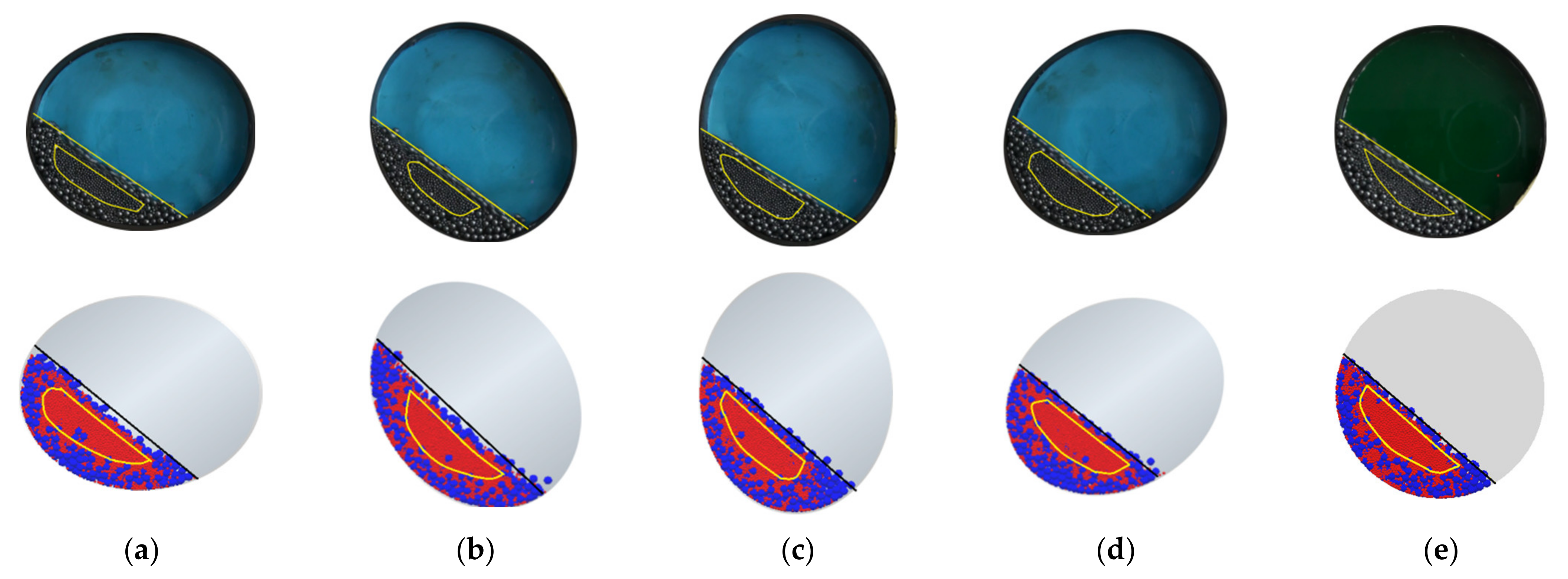

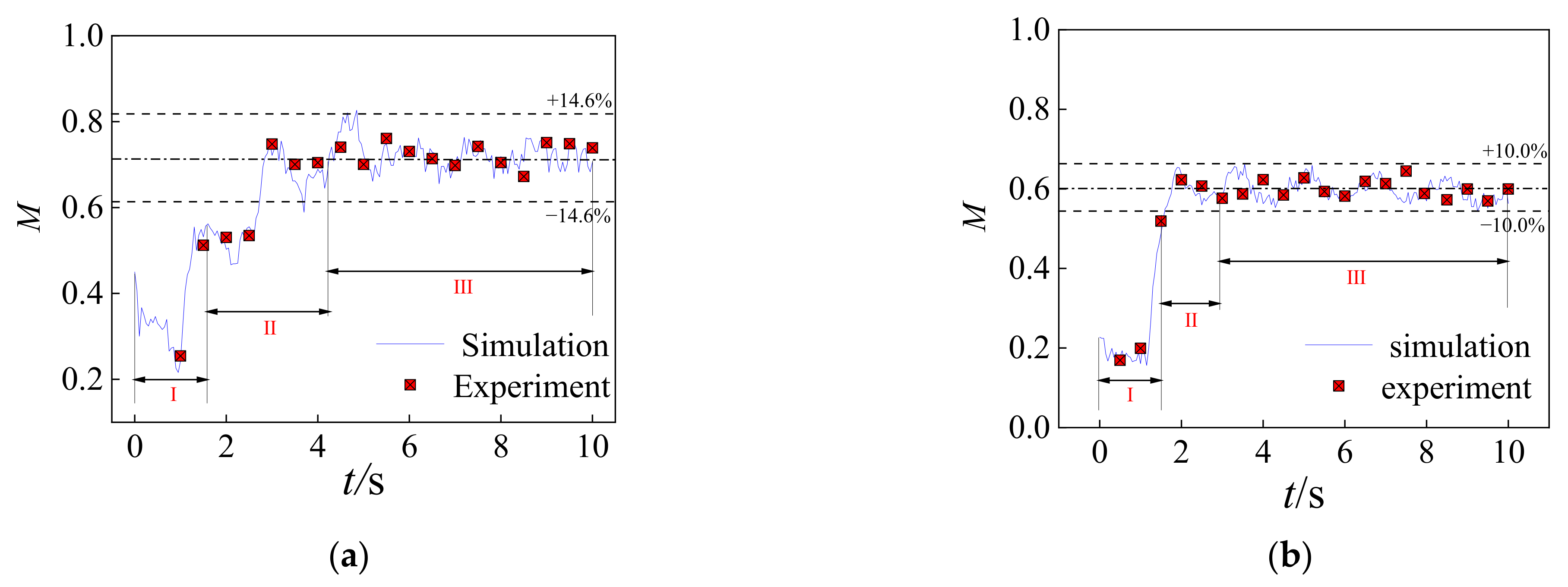

2.4. Lacey Mixing Index Validation

3. Results and Discussions

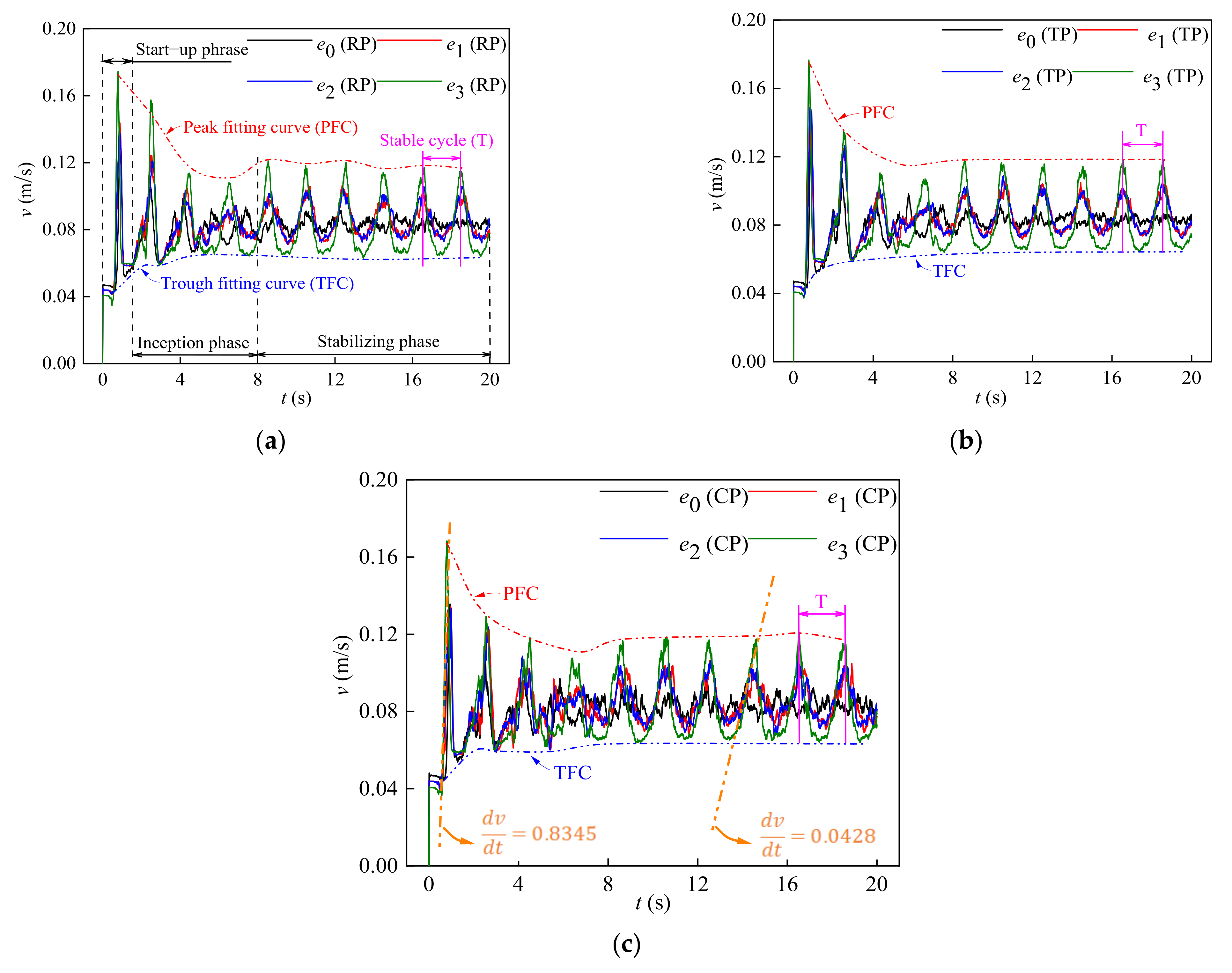

3.1. Influence of Rollers with Different Eccentricities on Average Speed

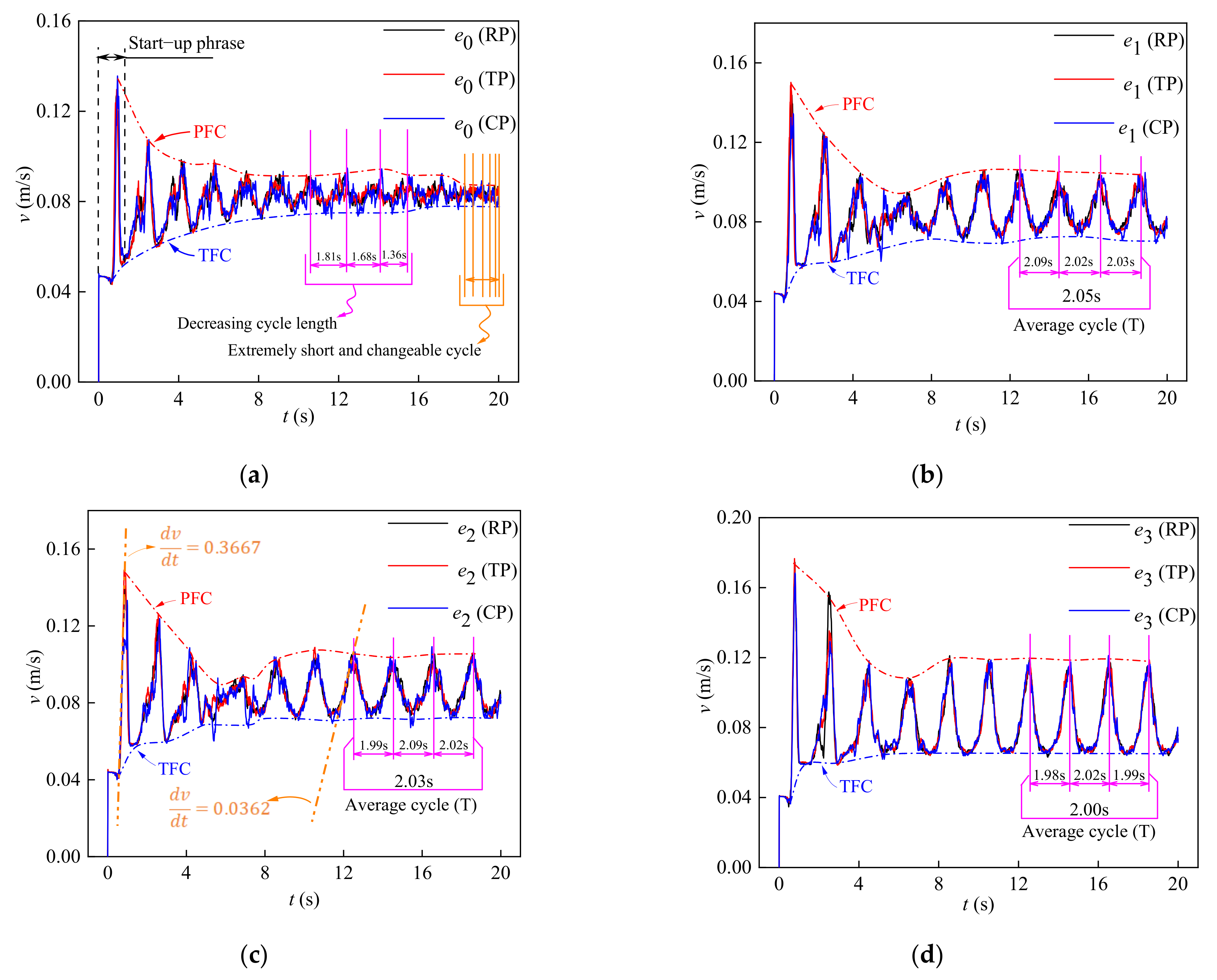

3.2. Comparison of Average Velocity of Particles with Different Shapes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

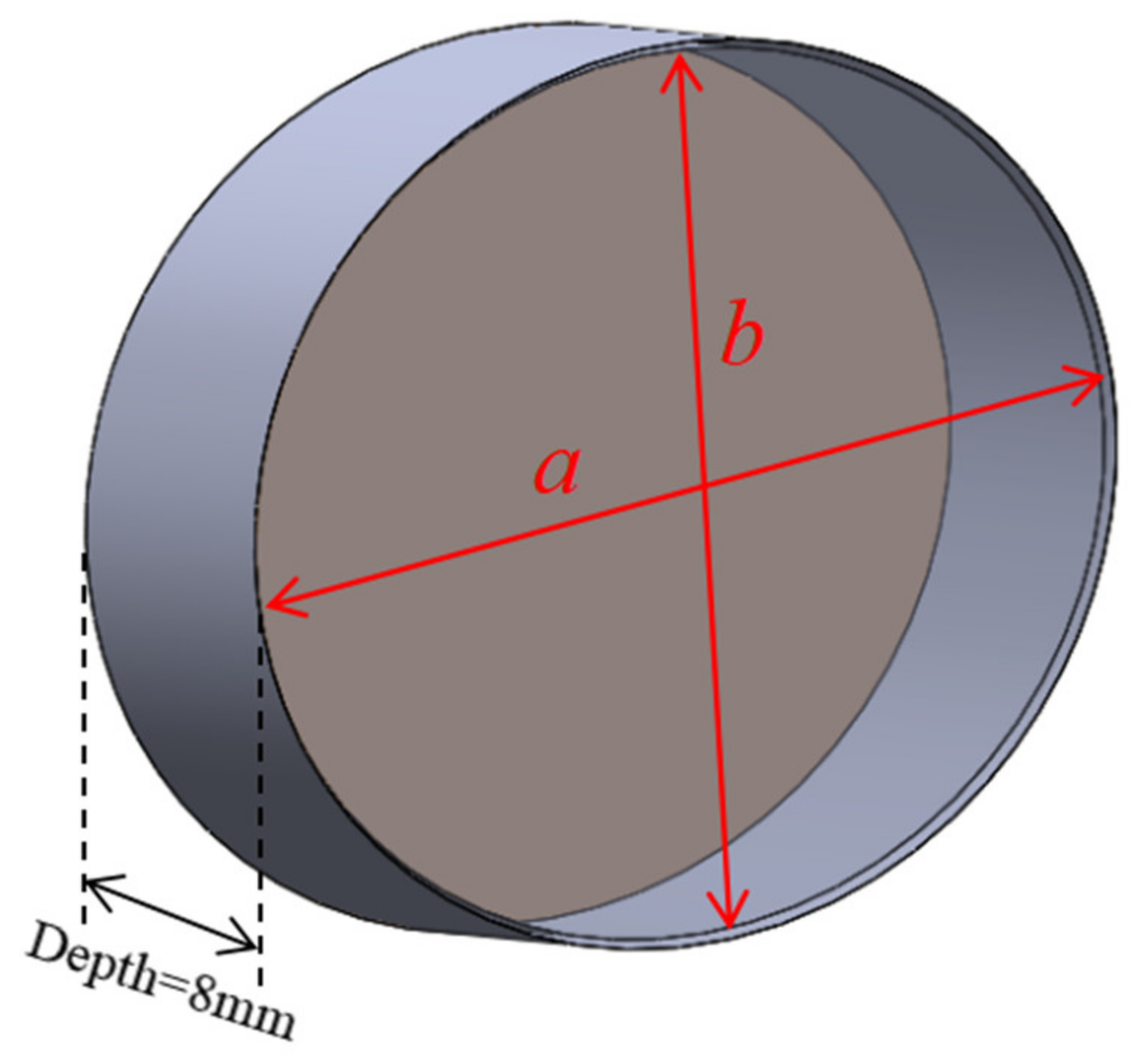

| a | Major axis of the elliptical drum, (mm) |

| b | Minor axis of the elliptical drum, (mm) |

| ej | Eccentricity of the elliptical drum, j = 1, 2, 3, 4, (-) |

| v | The average speed of particles, (m·s−1) |

| ui | Velocity of the particle in the rotating device, (m·s−1) |

| n | Quantity of all particles in the middle of the drum, (pcs) |

| t | Time, (s) |

| M | Lacey mixing index, (-) |

| T | Stable cycle length or average cycle length, (s) |

| A | Amplitude value of fluctuation, (m) |

| SRP | Surface area of rectangular flake particles, (mm2) |

| STP | Surface area of triangular flake particles, (mm2) |

| SCP | Surface area of circular flake particles, (mm2) |

Abbreviations

| PFC | Peak fitting curve of average particle velocity |

| TFC | Trough fitting cure of average particle velocity |

| RP | Rectangular flake particles (model or actual) |

| TP | Triangular flake particles (model or actual) |

| CP | Circular flake particles (model or actual) |

References

- Wu, W.N.; Liu, X.Y.; Zhang, R.; Hu, Z. DEM Investigation of The Power Draw For Material Movement in Rotary Drums with Axis Offset. Chem. Eng. Res. Des. 2019, 144, 310–317. [Google Scholar] [CrossRef]

- Rittisak, S.; Charoen, R.; Savedboworn, W. Broken Riceberry (BR) Powder Production Using a Double Drum Dryer and Its Utilization in the Development of Instant Beverages. Processes 2022, 10, 341. [Google Scholar] [CrossRef]

- Pan, L.; Dai, F.; Pei, S.; Huang, J.; Liu, S. Influence of particle size and temperature on the yield and composition of products from the pyrolysis of Jimsar (China) oil shale. J. Anal. Appl. Pyrolysis 2021, 157, 105211. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Zhang, H.; Xu, X.; Yang, Z.; Xu, W. A Review of the Potential of District Heating System in Northern China. Appl. Therm. Eng. 2021, 188, 116605. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, B. Mixing and Heat Transfer of Binary Mixtures of Monodispersed Spherical Particles with Different Densities and Thermal Diffusivities. Particuology 2021, 58, 118–130. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Z.; Weigler, F.; Herz, F.; Mellmann, J.; Tsotsas, E. PTV Measurement and DEM Simulation of the Particle Motion in a Flighted Rotating Drum. Powder Technol. 2020, 363, 23–37. [Google Scholar] [CrossRef]

- Li, D.; Xu, X.; Chen, J.; Yang, K.; Liu, X.; Yang, L. Numerical Study on the Effect of Drum on the Flow Behavior of Binary-Size Particles in Rotating Drums. Powder Technol. 2021, 386, 108–119. [Google Scholar] [CrossRef]

- Lo, W.L.; Yang, F.L.; Chen, C.S.; Hsieh, S.H. Studying the Weak Effect of Particle Friction on the Velocity Profile of steady Dry Granular Flows in a Rotating Drum. Granul. Matter 2015, 17, 717–726. [Google Scholar] [CrossRef]

- Han, R.; Xin, Y.Y.; Wang, Z.; Li, R.; Yang, H.; Chen, Q. Numerical Simulation of Particle Velocity and Coordination Number Under the Slumping Regime in a Rotating Drum. Powder Technol. 2021, 394, 775–781. [Google Scholar] [CrossRef]

- Arntz, M.M.H.D.; Beeftink, H.H.; den Otter, W.K.; Briels, W.J.; Boom, R.M. Segregation of Granular Particles by Mass, Radius, and Density in a Horizontal Rotating Drum. AIChE J. 2013, 60, 50–59. [Google Scholar] [CrossRef]

- Sunkara, K.R.; Herz, F.; Specht, E.; Mellmann, J. Transverse flow at the flight surface in flighted rotary drum. Powder Technol. 2015, 275, 161–171. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, H.; Hua, J. Granular flow characteristics and heat generation mechanisms in an agitating drum with sphere particles: Numerical modeling and experiments. Powder Technol. 2018, 339, 149–166. [Google Scholar] [CrossRef]

- Taswald, L.M.; Indresan, G. Experimental validation of DEM in rotating drums using Positron Emission Particle Tracking. Mech. Res. Commun. 2022, 121, 103861. [Google Scholar]

- Rasouli, M.; Dubé, O.; Bertrand, F.; Chaouki, J. Investigating the dynamics of cylindrical particles in a rotating drum using multiple radioactive particle tracking. AIChE J. 2016, 62, 2622–2634. [Google Scholar] [CrossRef]

- Parker, D.J.; Dijkstra, A.E.; Martin, T.W.; Seville, J.P.K. Positron emission particle tracking studies of spherical particle motion in rotating drums. Chem. Eng. Sci. 1997, 52, 2011–2022. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, X. A novel Markov chain method for predicting granular mixing process in rotary drums under different rotation speeds. Powder Technol. 2021, 386, 40–50. [Google Scholar] [CrossRef]

- Rahman, R.; Zhu, H.; Yu, A. Numerical analysis of effects of specularity coefficient and restitution coefficient on the hydrodynamics of particles in a rotating drum. Processes 2022, 10, 167. [Google Scholar] [CrossRef]

- Gao, K.; Du, C.; Dong, J.; Zeng, Q. Influence of the drum position parameters and the ranging arm thickness on the coal loading performance. Minerals 2015, 5, 723–736. [Google Scholar] [CrossRef]

- Li, D.; Liu, G.; Lu, H.; Zhang, Q.; Wang, Q.; Yu, H. Numerical simulation of different flow regimes in a horizontal rotating ellipsoidal drum. Powder Technol. 2016, 291, 86–96. [Google Scholar] [CrossRef]

- Li, D.; Wang, L.; Wang, Q.; Liu, G.; Lu, H.; Zhang, Q.; Hassan, M. Simulations of dynamic properties of particles in horizontal rotating ellipsoidal drums. Appl. Math. Model. 2016, 40, 7708–7723. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, J.; Wang, Z.; Qin, H.; Bai, J.; Wang, Q. Effect of moving baffle on average velocity and mixing of binary particles in rotating drums. J. Cent. South Univ. 2020, 27, 478–489. [Google Scholar] [CrossRef]

- Widhate, P.; Zhu, H.P.; Zeng, Q.H.; Dong, K.J. Particle velocity profile in an inclined rotating drum. EPJ Web Conf. 2021, 249, 14001. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, J.; Zhou, J.; Li, S.; Feng, J. Enhancing mixing of cohesive particles by baffles in a rotary drum. Particuology 2016, 25, 104–110. [Google Scholar] [CrossRef]

- Scherer, V.; Mönnigmann, M.; Berner, M.O.; Sudbrock, F. Coupled DEM–CFD simulation of drying wood chips in a rotary drum—Baffle design and model reduction. Fuel 2016, 184, 896–904. [Google Scholar] [CrossRef]

- Belyakov, I.I.; Breus, V.I.; Litvinova, L.A.; Poloskov, V.A. Causes of damage to baffle pipes in high-pressure drum boilers at the Ust’-Ilimsk heat and electric power plant. Power Technol. Eng. 2008, 42, 344–348. [Google Scholar] [CrossRef]

- Li, R.; Xiu, W.; Liu, B.; Zheng, G.; Yang, H. Velocity distribution of rice particles in a rotating drum. Powder Technol. 2021, 386, 394–398. [Google Scholar] [CrossRef]

- Lin, S.H.; Yang, H.; Li, R.; Zheng, G.; Zivkovic, V. Velocities of irregular particles in a continuously avalanching surface flow within a rotating drum. Powder Technol. 2018, 338, 376–382. [Google Scholar] [CrossRef]

- Wang, S.Q. Radial segregation of a gaussian-dispersed mixture of superquadric particles in a horizontal rotating drum. Powder Technol. 2021, 394, 813–824. [Google Scholar] [CrossRef]

- Salinas, V.; Quiñinao, C.; González, S.; Castillo, G. Triggering avalanches by transverse perturbations in a rotating drum. Sci. Rep. 2021, 11, 13936. [Google Scholar] [CrossRef]

- Gui, N.; Yang, X.T.; Tu, J.Y.; Jiang, S. Effect of roundness on the discharge flow of granular particles. Powder Technol. 2016, 314, 140–147. [Google Scholar] [CrossRef]

- Tang, X.; Yue, Y.; Wang, S.; Shen, Y. Modelling of gas-solid-liquid flow and particle mixing in a rotary drum. Powder Technol. 2022, 409, 117758. [Google Scholar] [CrossRef]

| Value | Eccentricity | |||

|---|---|---|---|---|

| e0 = 0 | e1 = 0.45 | e2 = 0.60 | e3 = 0.75 | |

| major axis a (mm) | 84 | 94 | 94 | 94 |

| minor axis b (mm) | 84 | 76 | 75.2 | 60.87 |

| Parameters Value | Parameters Value |

|---|---|

| Particles’ Poisson ratio (−) | 0.25 |

| Particles’ shear modulus () | 1 × 108 |

| Particle density (kg·m−3) | 1800 |

| Drum—Particles’ restitution coefficient | 0.1 |

| Particles—Particles’ restitution coefficient | 0.5 |

| Drum—Particles’ static friction coefficient | 0.9 |

| Particles—Particles’ static friction coefficient | 0.1 |

| Rolling friction coefficient | 0.05 |

| Particle Filling Method (Quantity/pcs) | Drum Speed (rpm) | Data Acquisition | Data Fitting |

|---|---|---|---|

| 1 mm (6050) + RP (948) | 15, 45 | Average velocity of particles | Peak fitting cure (PFC) |

| 1 mm (6050) + TP (1090) | Trough fitting cure (TFC) | ||

| 1 mm (6050) + CP (554) | Average velocity fitting cure |

| Eccentricity | Peak (PFC)/Trough (TFC) | Inception Phase | Stabilizing Phase | |||

|---|---|---|---|---|---|---|

| 0 s | 8 s | 8~20 s | Cycle Length (T/s) | |||

| Average velocity of particles (v/m·s−1) | e0 | Peak | 0.127 | 0.092 | 0.086~0.091 | 1.95 |

| Trough | 0.043 | 0.074 | 0.072~0.080 | |||

| e1 | Peak | 0.144 | 0.094 | 0.097~0.104 | 2.19 | |

| Trough | 0.043 | 0.071 | 0.072~0.075 | |||

| e2 | Peak | 0.140 | 0.097 | 0.101~0.106 | 1.97 | |

| Trough | 0.042 | 0.075 | 0.072~0.074 | |||

| e3 | Peak | 0.174 | 0.108 | 0.115~0.121 | 1.93 | |

| Trough | 0.035 | 0.065 | 0.064~0.066 | |||

| Eccentricity | Particle Shape | e0 | e1 | e2 | e3 |

|---|---|---|---|---|---|

| Average velocity (v/m·s−1) | RP | 0.080~0.087 | 0.069~0.106 | 0.068~0.109 | 0.063~0.121 |

| TP | 0.080~0.087 | ||||

| CP | 0.078~0.089 | ||||

| Average cycle (T/s) | -- | 2.05 | 2.03 | 2.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhao, Y.; Liu, R.; Liu, S. Study on the Variation Characteristics of the Average Velocity of Special-Shaped Flake Particle Systems Moving in Elliptical Drums. Processes 2022, 10, 1704. https://doi.org/10.3390/pr10091704

Zhang L, Zhao Y, Liu R, Liu S. Study on the Variation Characteristics of the Average Velocity of Special-Shaped Flake Particle Systems Moving in Elliptical Drums. Processes. 2022; 10(9):1704. https://doi.org/10.3390/pr10091704

Chicago/Turabian StyleZhang, Lidong, Yuze Zhao, Ruoyun Liu, and Shuning Liu. 2022. "Study on the Variation Characteristics of the Average Velocity of Special-Shaped Flake Particle Systems Moving in Elliptical Drums" Processes 10, no. 9: 1704. https://doi.org/10.3390/pr10091704

APA StyleZhang, L., Zhao, Y., Liu, R., & Liu, S. (2022). Study on the Variation Characteristics of the Average Velocity of Special-Shaped Flake Particle Systems Moving in Elliptical Drums. Processes, 10(9), 1704. https://doi.org/10.3390/pr10091704