Abstract

Sewage-water treatment comprehends primary, secondary, and tertiary steps to produce reusable water after removing sewage contaminants. However, a sewage-water treatment plant is typically a power and energy consumer and produces high volumes of sewage sludge mainly generated in the primary and secondary steps. The use of more efficient anaerobic digestion of sewage water with sewage sludge can produce reasonable flowrates of biogas, which is shown to be a consolidated strategy towards the energy self-sufficiency and economic feasibility of sewage-water treatment plants. Anaerobic digestion can also reduce the carbon footprint of energy sources since the biogas produced can replace fossil fuels for electricity generation. In summary, since the socio-economic importance of sewage treatment is high, this review examined works that contemplate: (i) improvements of sewage-water treatment plant bioenergy production and economic performances; (ii) the exploitation of technology alternatives for the energy self-sufficiency of sewage-water treatment plants; (iii) the implementation of new techniques for sewage-sludge management aiming at bioenergy production; and (iv) the implementation of sewage-water treatment with bioenergy production and carbon capture and storage.

1. Introduction

Sewage-water treatment plants (SWTPs) comprehend sewage-water management and the waste produced by the treatment process. The treatment steps within a SWTP are usually categorized as the primary, secondary, and tertiary levels of treatment. At the primary level, physical barriers remove coarse solid material, and the remaining solids are removed in sedimentation units. The secondary level removes soluble organics and suspended organics, while the tertiary level removes the remaining inorganics and other diluted organics as a finishing step [1]. However, sewage sludge is generated in large volumes during sewage-water treatment, and its disposal represents up to 50% of the current operating costs of a SWTP [2].

Aerobic and anaerobic digestion are typical strategies to reduce the sewage-sludge volume. However, the latter is preferable due to its concomitant biogas production [3]. Anaerobic digestion (AD) converts the organic matter—expressed as chemical oxygen demand COD (kgCOD/m3) or as biochemical oxygen demand BOD (kgBOD/m3)—of sewage sludge into biogas with 40–65% mol CH4 [4], reducing the sludge disposal volume [5]. Thus, with the biogas from AD, modern SWTPs are not limited to reusable water production but can also become self-sufficient in energy and export the surplus of produced power to the grid if a biogas-fired power plant operates jointly [6]. Given the current climate change concerns, it must be noted that there is a stringent recommendation that the biogas from AD be collected and burnt to avoid much more harmful greenhouse gas (GHG) CH4 emissions. Hence, it is natural that designers now plan SWTPs to be fully integrated with biogas-fired power plants [7,8,9].

Through the review of recent works published in the literature, the present work aims to consolidate the point that the use of biogas for power production in the context of modern SWTPs is mandatory, not only from the perspective of energy production, but also from the perspective of waste management and GHG emission control. In this regard, this review intends to cover the recognizable literature gap on SWTPs with bioenergy production and carbon capture and also encompasses sewage-water treatment basics and emerging approaches for the better utilization of biogas.

1.1. Sewage-Water Characteristics

Raw sewage water contains a complex mixture of organic matter that is usually reported in terms of COD, BOD, dissolved organic carbon (DOC), or trace organic contaminants. However, for a complete understanding of sewage-water treatment and to meet recent modeling advances, such as the AD Model No. 1 (ADM-1) [10], a deeper characterization of organic matter is required. The well-known study of Raunkjær et al. (1994) [11] reports the sewage-water characterization of a SWTP serving 97,000 person-equivalents and a load of 40,000 m³/day COD, ranging from 0.33 kgCOD/m3 to 0.8 kgCOD/m3, with 77% of species identified. They reported an average composition of 28%, 18%, and 31% of total COD corresponding to proteins, carbohydrates, and lipids, respectively. Similar results were shown by Gorini et al. (2011) [12] after analyzing domestic sewage-water samples with varying organic content from 0.24 kgCOD/m3 to 0.93 kgCOD/m3, with 74% of the total COD in terms of proteins, sugars, and lipids. Lipids presented the highest share with 38%, while sugar accounted for 15% and protein for 20%. After treatment, the treated water presented a fluctuating composition, from 0.028 kgCOD/m3 to 0.27 kgCOD/m3, with 52% of the total COD comprising proteins (30%), sugars (8%), and lipids (12%). Other works were dedicated to the characterization of sewage sludge but diverged mainly about the lipid content in sewage-activated sludge (SAS). Girault et al. (2012) [13] reported a physical-chemical characterization of SAS containing 51% proteins, 31% carbohydrates, and 18% lipids (% total COD). However, Nielfa et al. (2015) [14] reported 58% protein, 38% carbohydrates, and 4% lipids (% total COD) for SAS and 23% protein, 41% carbohydrates, and 36% lipids for the primary sludge, proving the difficulty of reaching a consensual average sludge composition due to the variable composition of raw sewage and the variable performance of settlers in the primary and secondary treatments. For a better comparison, Table 1 condenses the above information about the different characterizations (% of total COD) of sewage water and other streams of a typical SWTP.

Table 1.

Characterization of SWTP streams in terms of composition of COD.

1.2. Primary Sewage-Water Treatment

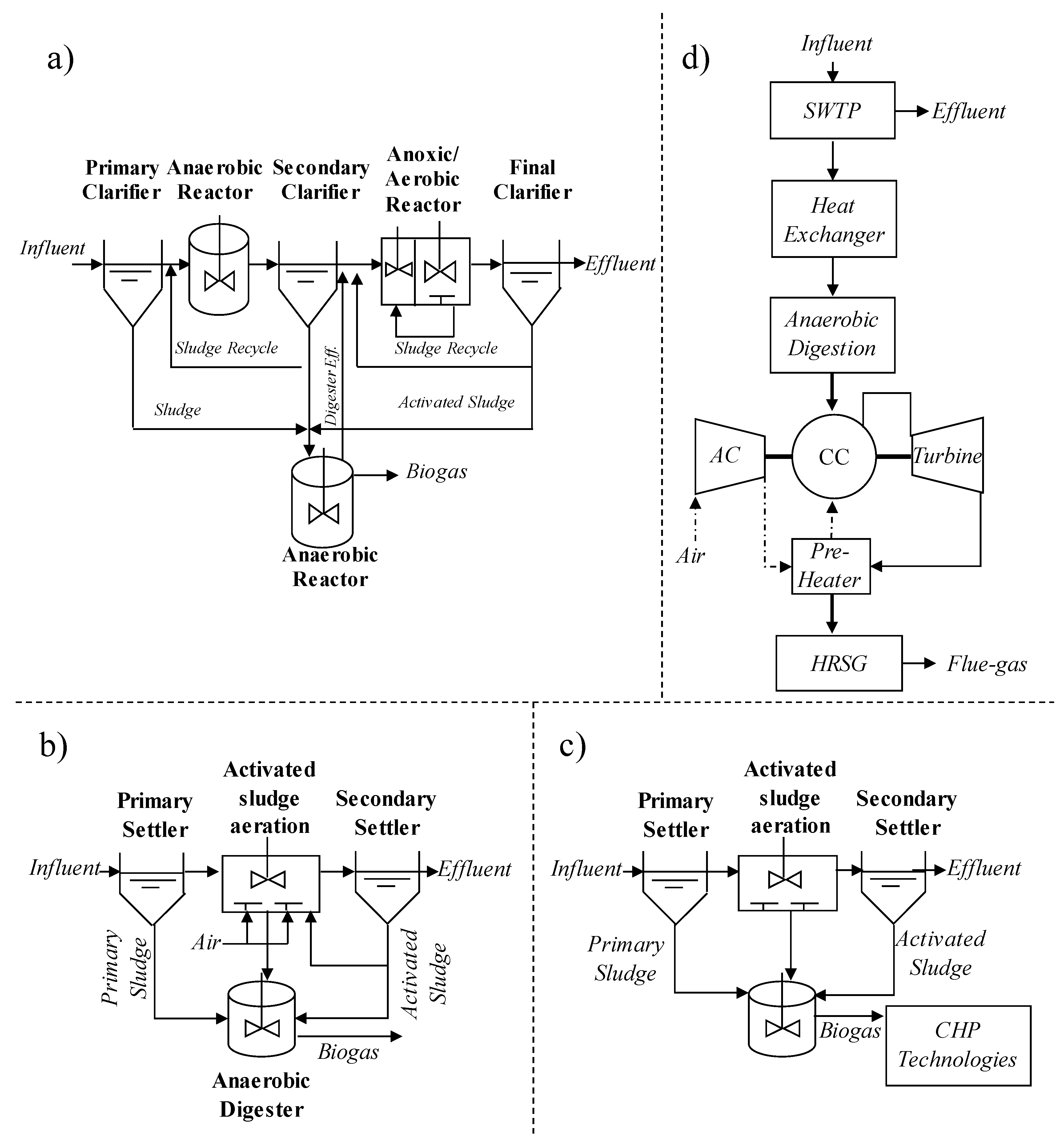

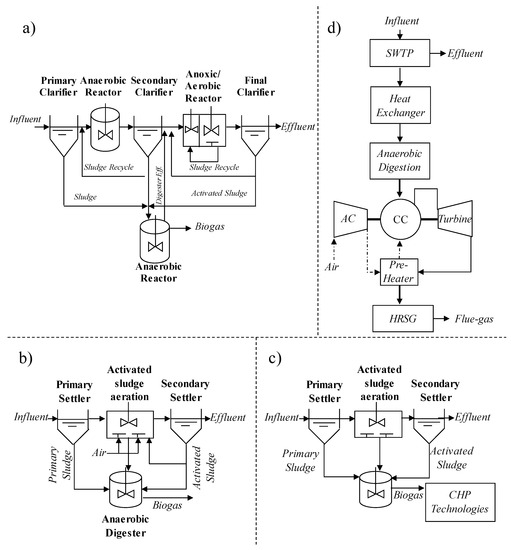

Primary treatment (Table 2) is the first step in a SWTP. It involves physical processes to catch gross material, such as grit, sand, garbage, solids, and suspended colloidal fats [15]. Raw sewage crosses through a metal grating that removes large solids and through screens to remove smaller items. A brief residence in the grit tank allows sand and gravel to settle out to protect the downstream equipment, such as pumps [1]. The sewage then goes to the primary settler (i.e., sedimentation tank or clarifier), where suspended organic solids settle (primary sludge) to equalize the quality and flow for more stable performance of the downstream units [16]. A typical arrangement of a SWTP with primary and secondary treatments comprising AD and microbial aerobic digestion (MAD) reactors was described by Bani Shahabadi et al. (2010) [17] and is shown in Figure 1a.

Table 2.

Typical Sewage-Water Treatment Processes.

Figure 1.

(a) SWTP with sewage-sludge AD [17]; (b) primary and secondary treatments with sludge AD for biogas and power production [18]; (c) SWTP with sewage-sludge AD and biogas applications in CHP technologies [19]; (d) SWTP with AD and GT burning biogas [20] (AC: air compressor; CC: combustion chamber; CHP: combined heat and power; HRSG: Heat Recovery Steam Generator).

Dissolved Air Flotation

Dissolved air flotation (DAF) has been used to improve primary treatment. DAF clarification is achieved by injecting pressurized air (3–9 bar) into an atmospheric sewage-water flotation tank [21]. Such rapid air expansion produces microbubbles that attach to suspended solids, floating them to the surface [21]. Coagulants are commonly added to DAF tanks, producing flocs and floc–bubble aggregates that rise to the surface in order to be removed by skimmers [22]. Edzwald (2010) [23] presented DAF models and DAF operating parameters. The main advantage of DAF is its short flocculation time, which allows the SWTP hydraulic loading to be increased. DAF implementation is more efficient than conventional sedimentation tanks because it not only acts on removing turbidity and particles, but also provides efficient microorganism removal, such as Giardia cysts and Cryptosporidium oocysts. The average DAF residence time is 10–20 min, with air flow adjusted to 6–10 g/tSW and a 10% recycle ratio. The main disadvantages of DAF over simple clarifiers are its greater mechanical complexity and power costs due to the compressed air. Johnson et al. (2014) [24] reported the first large-scale DAF for primary clarification in the Agua Nueva Water Reclamation Facility. However, they reported a slight enhancement of performance over conventional primary clarification, removing 50–75% of suspended material and 30–50% of COD.

1.3. Secondary Sewage-Water Treatment

In the secondary treatment (Table 2), a biological approach is conducted to remove organic matter measured as BOD or COD and to reduce the number of pathogens [1]. This step contemplates anaerobic and/or aerobic technologies for COD reduction. Aerobic treatments comprehend MAD, trickling filters, and aerated activated sludge (AAS), which also remove nitrogen and phosphorus. On the other hand, anaerobic treatment (AD) produces biogas as a by-product, while microorganisms break down the organic matter. Although AD and MAD are also classified as secondary treatments, these subjects are exclusively addressed in Section 2 due to their importance.

1.3.1. Aerated Activated Sludge

In the aerated activated sludge (AAS), the effluent from the primary treatment with high COD is treated to produce a low-COD liquid and slurry [1]. The AAS comprehends an aerated bioreactor tank, a settler separating the AAS solids and the treated sewage water, and a recycling of the activated sludge from the settler to the aerated bioreactor [18]. Figure 1b presents typical primary and secondary treatments, including AD for sewage-sludge processing. Compressed air is injected into the AAS bioreactor, fed with primary effluent and recycled activated sludge. After hydraulic retention times of HRT~1–10 days, the AAS effluent goes to the secondary settler (Figure 1b), where 80–90% COD is removed from the liquid effluent. Part of the settled activated sludge returns to the aerated bioreactor to re-seed the AAS process. The majority of the activated sludge follows through a series of treatment processes, such as AD, MAD, dewatering, incineration, or reuse as biofertilizer [25].

1.3.2. Trickling Filter

In modern SWTPs, sewage water flows through a trickling filter bed made of stones or corrugated plastic sheets. A biofilm is formed on the filter surfaces, the so-called zoogleal film, wherein microorganisms intercept the organic matter and aerobically decompose it. BOD removal in trickling filters is approximately 85% for low-rate filters [1]. Despite being a relatively well-known technology with promising results, the literature still concentrates on bench and pilot scales. Liang et al. (2020) [26] proposed a bench-scale bio-electrochemical trickling filter that uses semi-immersed electrodes in sewage water for two months, obtaining 97% COD removal at an organic load ratio of OLR = 1.0 kgCOD/m3/d. Forbis-Stokes et al. (2020) [27] reported three-staged filters that combine a crushed-charcoal trickling filter, a bamboo woodchip filter, and a scrap iron filter, showing that the filters removed 73–82% turbidity, 67–75% COD, and 31–50% phosphorus. Rehman et al. (2020) [28] studied the effects of the hydraulic retention time (HRT) in a pilot-scale trickling filter for domestic sewage-water treatment, which removed 70.9% of COD and 82.5% of the bacterial count for HRT = 2 d.

1.4. Tertiary Sewage-Water Treatment

Tertiary treatment (Table 2) corresponds to polishing methods after biological sewage-water treatments [1]. In this stage, the water quality is enhanced by physicochemical processes centered on removing microorganisms and pathogens for adequate utilization of the effluent as irrigation, street washing, or disposal to hydric bodies [15]. Tertiary treatment comprehends several techniques, and many works have focused on: (i) ozonization and advanced oxidation processes [29]; (ii) adsorption technologies [30], such as powdered/granulated activated carbon [31]; and (iii) physical technologies, such as reverse osmosis [32], filtration, and UV irradiation [33]. Ozonation and activated carbon adsorption are discussed in more detail due to their better insertion in the SWTP context.

1.4.1. Ozonization

Ozonization employs ozone gas (O3) for disinfection, decoloration, and sterilization [34]. Chys et al. (2017) [35] compared ozonization with three filtration techniques for the removal of 18 trace organic contaminants. Ozonization presented better removal than a slow sand filter or trickling filter, removing 90% of trace organics, but not as good as granular activated carbon. Mathon et al. (2017) [36] studied the ozone oxidation of 12 pesticides and pharmaceutical compounds usually present in SWTP effluents. The most effective ozone dose was 0.2–0.4 kgO3/kgDOC with 70% removal of contaminants. Ozonization has traditionally been adopted for water disinfection, but it is also reported as a pre-treatment for AD. Haak et al. (2016) [37] investigated the AD of DAF sludge after using ozonization as a pre-treatment. The biodegradability of sewage activated sludge (SAS) increased two times, and the biogas yield from ozonizated SAS was 160 LBiogas/kgCOD, while untreated SAS yielded only 80 LBiogas/kgCOD. Na (2018) [38] investigated ultrasonic ozonization pre-treatment for the AD of sludge with a dosage of 0.10 kgO3/kgCOD, and the biogas production was four to eight times the untreated sludge counterpart.

1.4.2. Activated Carbon

Physical adsorption using activated carbon is an established process for organic micro-pollutant removal. Activated carbon can be powder or granular [39]. In the case of granular activated carbon, adsorption beds are commonly installed with downstream filters for turbidity removal and should be periodically reactivated. On the other hand, powder activated carbon is dosed directly into clarifiers and gravity filters, being more efficient than granular due to the smaller particles and higher specific adsorption area [30].

Compared to ozonization oxidation, a broader range of organic micro-pollutants can be removed using activated carbon. Margot et al. (2013) [31] evaluated the removal of organic micro-pollutants by ozonization and powder activated carbon in a SWTP context, pointing out that specific substances were removed more efficiently by ozone, while powder activated carbon effectively removed a wider range of pollutants. Both treatments abated 80% or more of the majority of micro-pollutants in effluents and are feasible for SWTPs at ~5.65 gO3/m3 or 13 g/m3 of powder activated carbon. Ozonization removes coliphages to 5 UFP/mL (>95% removal) and reduces ~97% of fecal bacteria. On the other hand, powder activated carbon removes 54 ± 10% of DOC, >90% of phosphorus, 85 ± 20% of NH4+, and 72 ± 18% of BOD besides intestinal bacteria and coliphages (<5 UFP/mL) and the complete removal of total suspended solids (TSS). Hu et al. (2016) [40] obtained higher organic micro-pollutant removal for secondary effluent at 12 gDOC/m3 using powder activated carbon at 10–20 g/m3 in the tertiary filter (10 h filtration period) of a SWTP. Sher et al. (2021) [41] applied powder activated carbon at 10–20 g/m3 with 15–30 min contact time, removing 84.4–91.3% of suspended solid micro-pollutants, raising the removal efficiency to 88.9–93.6% by adding an FeCl3 coagulant.

1.5. Eco-Friendly Sewage-Water Treatment

Eco-friendly sewage-water treatment systems were studied by Vítězová et al. (2019) [42] for removing phenolic compounds, turbidity, and COD from sewage water. These authors demonstrated that spent coffee grounds are a very promising waste material that can be used to stimulate microorganism respiration activity and remove polyphenols from effluents due to its inclusion in microbiological metabolism. Kaushal and Mahajan (2021) [43] designed a hydroponic bench-scale system as a tertiary treatment, where evergreen ornamental plants were selected to reduce turbidity and COD. Lata and Siddharth (2021) [44] proposed a biological technique to control water quality by eliminating toxins using plant species that can be harvested and further utilized as biofuel briquette, replacing woods and other fuel. However, the main disadvantage of installing such innovative eco-friendly technologies is the high investment and maintenance costs at high scales, since these processes were proved at bench-scale only.

2. Sludge Processing

The major by-product of SWTPs corresponds to sludge from the primary and secondary treatments. Treatments such as MAD, autothermal thermophilic aerobic digestion (ATAD), and AD can stabilize sludge, reduce its solid content, and inactivate pathogenic microbes. Particularly, AD can manage sludge while producing biogas as a by-product, with a reasonable heating value due to its 50–70% mol CH4 content, which can be burnt to support heat consumption and/or for electricity generation [15].

2.1. Microbial Aerobic Digestion

MAD is a well-known process in SWTPs that biologically reduces COD, producing odorless water without bacteriological hazards. Typically, MAD occurs in continuously unheated and open tanks or aerated lagoons, wherein air/oxygen is injected via diffusers to biochemically oxidize the organic matter [47]. The most critical MAD parameter is the dissolved oxygen, which typically ranges 0.5–2 g/m3. Inadequate dissolved oxygen levels result in incomplete digestion and odors [48]. MAD is represented in Equation (1) for a hypothetic activated sludge with the minimal formula C5H7O2N. During MAD operation, the pH gradually drops by nitrification acid formation [47].

Compared to AD, MAD requires relatively lower investment; it is easy to operate, reduces volatile solids, and produces water with low BOD [48]. The MAD disadvantages comprise the power costs for compressed air supply and the lack of valuable by-products, such as biogas [49]. In MAD, SAS feeds an aerated bioreactor for some time—the so-called solid retention time (SRT)—wherein TSS and suspended volatile solids are destroyed. The MAD bioreactor operates with continuous SAS feeding and periodic withdrawals of the supernatant and digested SAS [50].

MAD performance is measured by solids and pathogen reductions. However, the destruction of DOC results in the liberation of NH3, causing the growth of nitrifying bacteria in MAD bioreactors, even if they are absent in the feed. As nitrification builds up, the sequential conversion of ammonia to nitrite and, ultimately, nitrate occurs [51]. The high concentration of nitrate and nitrite in the final effluent causes nutrient pollution in the receiving water bodies and encourages the excessive growth of aquatic plants, leading to a condition known as eutrophication. Hence, to avoid the eutrophication process, there is a need for an anoxic treatment of the wastewater to reduce nitrogen concentrations in the effluent to acceptable levels [52]. Under anoxic conditions, microorganisms catalyze the stepwise reduction of nitrate to N2. Abbott and Eskicioglu (2020) [53] considered an ammonia limit of 400 mg/L in the digester effluent and compared the results of sludge AD versus sequential AD plus aerobic/anoxic treatments for COD and nitrogen removal. The effluent of the single AD treatment exceeded the ammonia limits and achieved 52% COD removal, while the sequential AD+aerobic/anoxic process improved COD destruction up to 68.2% ± 2.1%, while the nitrogen concentration was kept within the limits. This confirms that aerobic/anoxic digestion can manage the high ammonia levels generated in the effluent.

2.2. Autothermal Thermophilic Aerobic Digestion

ATAD is sludge stabilization in which the system gradually rises to a thermophilic range (45–65 °C) thanks to the metabolic heat released by microorganisms during digestion [54]. Some works report high temperatures, such as Pembroke and Ryan (2019) [55], which evaluated ATAD for sewage-sludge stabilization and achieved temperature elevations to 70–75 °C. Liu et al. (2012) [56] investigated the effects of ATAD temperatures on the stabilization of sludge properties at thermophilic conditions of 45 °C and 55 °C. Martín et al. (2018) [57] presented a technical and economic analysis of ATAD for treating sewage sludge on small and medium scales considering temperature conditions similar to Liu et al (2012) [56]. Martín et al. (2018) [57] results showed a stabilized sludge that was economically feasible for agriculture applications with an optimal HRT = 7 d. However, they achieved 34% COD removal, while Liu et al (2012) [56] achieved 42.9% and 45% removal of volatile solids.

2.3. Combined Anaerobic and Aerobic Digestions of Sludge

Recently, a novel system has been considered to improve the digestion of sewage sludge, consisting of AD followed by MAD. Part of the biogas generated in the AD is used to supply the energy needed for the MAD aeration mixers and air compressors. The MAD step has been used to also remove nitrobenzene [58] and other aromatic hydrocarbons, such as biphenyl [59], from sewage water. Typically, MAD is applied as an AD complement, as presented by Ahmad et al. (2016) [60]. They investigated the sewage-sludge treatment in a real SWTP using sequential AD + MAD treatments and compared the removal of volatile solids and ammonia to single-stage AD. The AD + MAD system operated at SRT = 22.5 d with a 57.4 kgCOD/m³ in the feed. The combined AD + MAD achieved a COD removal 11% higher than the single-stage AD. In addition, the AD + MAD total ammonia generation was 72% lower than the single-stage AD. Evaluating the same technology combination, Ghanimeh et al. (2019) [61] studied AD + MAD for SWTPs, removing 84% of the initial COD in the AD step and an additional 8% of the initial COD in the MAD step, resulting in a total of 92% COD removal. In another work, Ghanimeh et al. (2018) [62] presented similar results for sequential AD + MAD for treating food waste and wastewater and achieved the removal of 94% COD (90% via AD and 4% via MAD), demonstrating that the MAD step after AD is a viable solution and improves the removal of volatile solids (VS) and COD. Novak et al. (2011) [63] evaluated sewage-sludge digestion in a triple-combined AD + MAD + AD system, consisting of AD followed by MAD and recycling MAD sludge back to AD. They compared volatile solid reduction and nitrogen removal for the following processes: three-step AD + MAD + AD, two-step AD + MAD, and single-step AD. The reported reduction in volatile solids in the single-stage AD (T = 35 °C, SRT = 20 d) was 50%, while in the two-step AD + MAD at identical conditions, volatile solid reduction increased to 62%; with AD + MAD + AD (T = 35 °C, SRT = 20 d), volatile solid reduction increased to 70%. The total nitrogen removal for AD+MAD and AD+MAD+AD was 64.5% and 70%, respectively. The results reported by Novak et al. (2011) [63] regarding COD and nitrogen removal are lower than those reported by Ghanimeh et al. (2018) [62] and Ghanimeh et al. (2019) [61]. However, this difference can be attributed to the difference in the organic composition and biodegradability of the feed.

2.4. Anaerobic Digestion

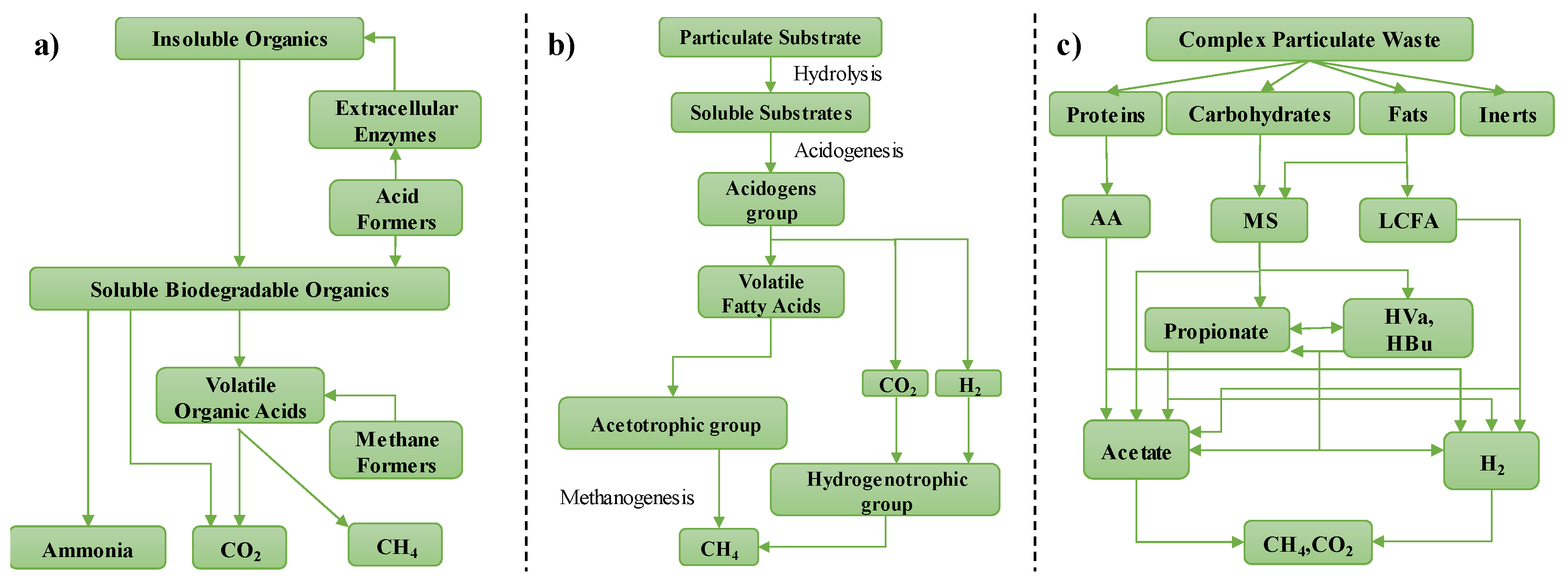

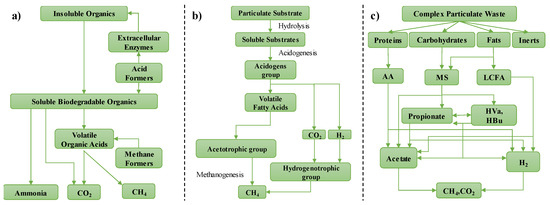

AD is a biological process that converts the organic matter present in various types of wastes (e.g., sewage sludge) into: (i) biogas, basically CH4 + CO2; (ii) biosolids, mostly microorganisms; and (iii) liquor, nutrients, and dissolved organic matter [64]. The AD phenomenology comprises four main steps [65]. In the first, hydrolysis, organic matter is degraded by extracellular enzymes into soluble compounds that can be used as an energy source by anaerobic microorganisms, i.e., no matter the feedstock complexity, its organic matter is firstly converted into carbohydrates, lipids, and proteins [66]. In the second step, acidogenesis, the carbohydrates and proteins degrade into volatile organic acids, releasing NH3, H2S and CO2 by-products. In the third step, acetogenesis, the volatile and long-chain fatty acids ferment into acetate and hydrogen with CO2 by-product [67]. In the last step, methanogenesis, the acetate, hydrogen, and part of the CO2 are converted by methanogenic organisms into more CO2 and CH4. In this step, two types of methanogenic microorganisms coexist: the acetotrophic, which splits acetate into CH4 and CO2, and the hydrogenotrophic, which uses CO2 and H2 to produce CH4 [68].

Pre-treatments in AD that aim to improve the biodegradability of sewage sludge and, consequently, increase biogas production are most frequently studied for SWTPs [69]. However, a positive impact on biogas production does not always translate into a positive energy balance for the SWTP. Khanh-Nguyen et al. (2021) [70] reviewed physical, chemical, thermal, and biological pre-treatment techniques and advertised that very few pre-treatment techniques are suitable for full-scale implementation in SWTPs. Moreover, the pre-treatment efficiency depends on the sewage-sludge composition, characteristics, and the overall AD system applied. Physical pre-treatments, such as ultrasonic treatment, high-pressure homogenization, microwave irradiation, and ball-mill, can increase biogas production at the expense of high energy requirements. On the other hand, chemical pre-treatments employ acids, alkalis, and oxidants to hydrolyze the sludge to improve its biodegradability. However, the costly chemicals and the neutralization step reduce the interest in chemical pre-treatments. Thermal pre-treatment increases organic solubilization and destroys pathogens via disintegration of the cell membranes. Biological pre-treatment is the most eco-friendly pre-treatment method and employs enzymatic, aerobic/anaerobic steps to predigest the sludge before AD, but this is a slow and costly process [71]. Taboada-Santos et al. (2019) [72] presented energy and economic assessments of sludge thermal hydrolysis as a pre-treatment before AD. They found that it is only justified to apply the pre-treatment when the total concentration of sludge solids in the feed is higher than 1–2%; otherwise, the impact of thermal hydrolysis on methane production is expected to be unprofitable. Considering a different pre-treatment technology, Heng et al. (2017) [73] proposed pre-treating activated sludge with H2O2 under UV light to enhance digestibility. Results comprise 81.5% COD removal and a 2.4 times greater biogas rate, compared to 54.7% COD removal for untreated sludge.

Anaerobic co-digestion of sewage sludge with the mixing of different types of waste has been reported in the literature to increase biodegradability and biogas production. Maragkaki et al. (2018) [74] improved biogas production and methane content by adding small amounts of other wastes to the sewage sludge without affecting the operation of digesters. However, the results showed small gains, demonstrating that more significant portions are necessary to considerably impact biogas production. On the other hand, Park et al. (2016) [75] and Maes et al. (2013) [76] obtained more significant results concerning increased biogas production. Park et al. (2016) [75] evaluated the AD of sewage sludge with food waste. They reported a yield of 522.9 LCH4/kgVolatile-Solids and a 72% increase in CH4 production due to the extra organic matter (food waste) fed to AD. Maes et al. (2013) [76] also tried to increase biogas production through the AD of glycerol and sewage sludge at mesophilic conditions. They added 1 kg of crude glycerol per m³ reactor per day without significant foaming problems and obtained a surplus CH4 production of 489 Nm³ per ton of crude glycerol added, a similar increase in productivity as obtained in Park et al. (2016) [75]. Hance et al. (2020) [77] evaluated the AD of sewage sludge with sugarcane molasses to improve biogas production with an optimum C/N ratio. They reported problems with unstable pH and COD increase in the product, but achieved a biogas production 6.7 times higher at the optimum C/N ratio of 23:1 than at C/N ratio of 10:1. Differently, Cardona et al. (2019) [78] did not achieve the same productivity increases for the AD of sewage sludge with fish waste and grass, showing that the CH4 production increased 1.9 times with fish waste and 1.7 times with grass. Kumari et al. (2018) [79] increased biogas production by executing the AD of sewage sludge with cow manure, dairy wastewater, kitchen waste, yard waste, and floral waste and achieved a COD removal in the range 76–86% after 20 days. Agreeing with the results of Cardona et al. (2019) [78], Kumari et al. (2018) [79] achieved a maximum increase of 1.5 times in terms of processing capacity.

3. Anaerobic Digestion Modeling

In the past three decades, mathematical modeling of AD has been developed for different biomasses and process conditions [80]. Due to the various biochemical steps of the AD process, several possible substrates, and a wide range of operating conditions, inhibition, and interfacial mass transfer, AD models are typically complex, containing dozens of equations and parameters. Buswell and Mueller (1952) [81] were pioneers in modeling CH4 AD production. The Buswell equation is a generic stoichiometric relationship, Equation (2), expressing the conversion of organic matter into CH4 and CO2. Equation (2) is only indicated for well-defined feedstocks composed of sugars (e.g., glucose, sucrose, and lactose). The Buswell equation was applied by Mwandila et al. (2021) [82] to yield the biogas composition using a mixed feedstock of equal proportions made up of food leftovers, sewage sludge, and fecal matter. They modeled a feasible SWTP with energy production consisting of a 1400 m³ biodigester, with biogas output of 8.6 ML/day generating about 57 kW of electricity.

Another remarkable work was presented by Husain (1998) [83], in which an AD dynamic model was based on Hill (1983) [84]. Both models were structured around four state variables: (i) biodegradable volatile solids concentration; (ii) volatile fatty acids (VFA) concentration; (iii) concentration of acidogenic microbes; and (iv) concentration of methanogenic microbes. Husain et al. included more details in the chemical reactions, changed the parameter values, and considered the death rates of acidogenic and methanogenic microbes as Monod functions instead of assuming constant values as Hill (1983) [84] did. However, the Hill and Husain models did not include the hydrolysis step. Zaher et al. (2009) [85] presented a simple AD model that includes enzymatic hydrolysis and the acidogenic and methanogenic phases by acetotrophic and hydrogenotrophic microbes. The model contains 15 state variables validated at mesophilic conditions for real batch data. The model predicts the total biogas flow, without explicit gas composition.

The best-known AD model is the AD Model No.1, or ADM-1, which includes multiple steps describing the biochemical and physicochemical processes. The ADM-1 was proposed by Batstone et al. (2002) [10] for the International Water Association (IWA) task group for AD modeling. ADM-1 contains 35 state variables and 100 parameters of inputs, reaction kinetics, and outputs embodied as a dynamic non-distributed AD tank reactor. The biochemical kinetics are structured around disintegration, hydrolysis, acidogenesis, acetogenesis, and methanogenesis. The physicochemical processes comprehend liquid–gas transfers. Equation (3) presents the liquid phase mass balance of species i expressed in terms of equivalent COD, where the sum comprehends the kinetic rates ρj of processes j (among hydrolysis, acidogenesis, acetogenesis, and CH4/CO2 production) times the rate coefficient νi,j of component i in process j expressed in kgCOD/m³d. Sin,i and Sliq,i, respectively, represent the inlet and reactor liquid phase concentration of component i (kgCOD/m³); qin and qout represent the inlet and outlet flowrates (m³/d); and Vliq is the reactor liquid volume (m³). Figure 2 shows block diagrams of the AD models by Husain (1998) [83], Zaher et al. (2009) [85], and Batstone et al. (2002) [10].

Figure 2.

AD models: (a) Husain (1998) [83]; (b) Zaher et al. (2009) [85]; (c) Batstone et al. (2002) [10] (AA: amino acids; MS: monosaccharides; LCFA: long-chain fatty acids; HVa: valeric acid; HBu: butyric acid).

Ozgun (2019) [86] developed a full-scale sludge AD model with ADM-1 and demonstrated that ADM-1 is usable as a simulation tool for the AD of SWTP sludge under mesophilic conditions. Ersahin (2018) [87] conducted the ADM-1 calibration for a full-scale sludge AD, presenting optimized CH4 production at different conditions. Otuzalti and Perendeci (2018) [88], using ADM-1, modeled a real-scale AD reactor and accomplished parameter estimations for four kinds of rate constants: disintegration, carbohydrate hydrolysis, protein hydrolysis, and lipid hydrolysis, obtaining good agreement with real AD data. Derbal et al. (2009) [89] applied ADM-1 to simulate the AD of organic wastes with SAS at mesophilic conditions, obtaining a biogas rate of 0.296 m³/m³d for VolumeReactor = 2000 m³, HRT = 26.9 d, and OLR = 1.01 kgTSS/m³d.

4. Power Generation in Sewage-Water Treatment Plants

A challenge in SWTPs is to feasibly reconcile sludge management and energy production. Combined heat and power (CHP) technologies that use biogas from AD are approaches devised to produce power to achieve energy self-sufficiency while reducing sludge disposal. Silvestre et al. (2015) [90] analyzed SWTPs from an energy point of view and concluded that 67% of the initial energy content in the raw sewage water is transferred to sewage sludge. Then, at least 34% of sewage-water energy content can be recovered into biogas after AD. Udaeta et al. (2019) [91] evaluated the electricity generation potential from a SWTP in São Paulo (Brazil) to supply domestic demand and export biogas or electricity surpluses. In their results, the methane produced by this SWTP represented 4% of São Paulo gas demand and could generate 762.8 GWh/y, or 5% of São Paulo electricity demand. Mensah et al. (2021) [92] evaluated a SWTP with biogas production and electricity generation in Benin, West Africa. Agreeing with the conclusion of Udaeta et al. (2019) [91], the unexplored potential of biogas can supply 2% of the electricity imported by Benin. In addition, the avoided cost of public health was estimated at USD 40 million over a 15-year period.

An evaluation of an energy self-sufficient SWTP was carried out by Schaubroeck et al. (2015) [93], showing that the AD of sewage sludge enriched with kitchen waste and fats increased the methane content in the biogas and provided an additional 0.200 kWh/m3 of usable power. Two examples of the energy self-sufficiency of municipal SWTPs with CHP units were presented by Nowak et al. (2011) [94], wherein the biogas produced was used in CHP units reaching 40% thermodynamic yield, accompanied by 96% COD removal with 80% nitrogen removal. However, the CHP system used by Nowak et al. (2011) [94] presented only 7% of electricity surplus, because the major fraction of electricity was consumed for air compression, aeration, and stirring of the MAD tanks. Chen et al. (2016) [95] evaluated four possible cases to enhance the CHP scheme with an absorption chiller in a system with 1409 kW of power output. The thermodynamic yield significantly improved from 20.8% to 38.3% in the best case, with 2–3 years of payback time. Similarly, Sadhukhan (2014) [19] presented a feasible application of sewage-sludge AD, wherein the biogas was utilized in six different CHP technologies up to 500 kW (Figure 1c): (i) biogas engine; (ii) ignition biogas engine; (iii) micro-gas turbines (Micro-GT); (iv) proton exchange membrane fuel cell; (v) solid oxide fuel cell (SOFC); and (vi) SOFC gas turbine (SOFC-GT). The Micro-GT presented the most cost-effective results, accompanied by a reduction in GHG emissions of 0.0982 kgCO2eq/MJElectricity.

4.1. Biogas Gas Turbine Cycles and Biogas Combined Cycles

GTs and Micro-GTs comprehend an air compressor, combustion chamber, turbine expander, and electric generator. GTs are viable in a SWTP with a high biogas supply. A GT feature is the production of exhaust gases at a high volumetric flowrate and temperature. Moreover, a Micro-GT is essentially the same equipment, but with a small size for a smaller gas flowrate. Micro-GTs have typical power below 1000 kW, while GTs are sized above 1 MW [96].

A recent and viable solution for electricity generation in SWTPs is applying a GT as a single Biogas GT Cycle or as a Biogas GT Cycle combined with a steam Rankine cycle (Biogas Combined Cycle). In this context, Basrawi et al. (2012) [97] evaluated the isothermal AD of sewage sludge in which the produced biogas feeds the Micro-GT. The 30 kW, 65 kW, and 200 kW power units produced electricity at 40% of thermodynamic yield. In another work, Basrawi et al. (2017) [98] analyzed the optimum size of Micro-GT cogeneration for a SWTP in terms of its economic performance. They showed that the best net present value (NPV) is obtained when different sizes of Micro-GTs are combined to meet the available feed flowrate, approximately equal to the biogas production. Chang et al. (2019) [99] also presented a case study using a 30 kW Micro-GT fed with biogas from the AD of sewage sludge. The biogas production of 4424 m³/d in Chang et al. (2019) [99] is very similar to the 4321 m³/d reported by Basrawi et al. (2012) [97], with a slight difference in biogas composition (CH4/CO2): 60/40 in Chang et al. (2019) and 56/25 in Basrawi et al. (2012) [97]. In addition, Chang et al. (2019) reported that the SWTP consumed 25.82% of the biogas for heating, and the remaining was used for electricity generation at 172,003 kWh/y with a thermodynamic yield of 0.234 kWhElectric/kWh and electricity generation efficiency of 1.09 kWhElectric/m³Biogas.

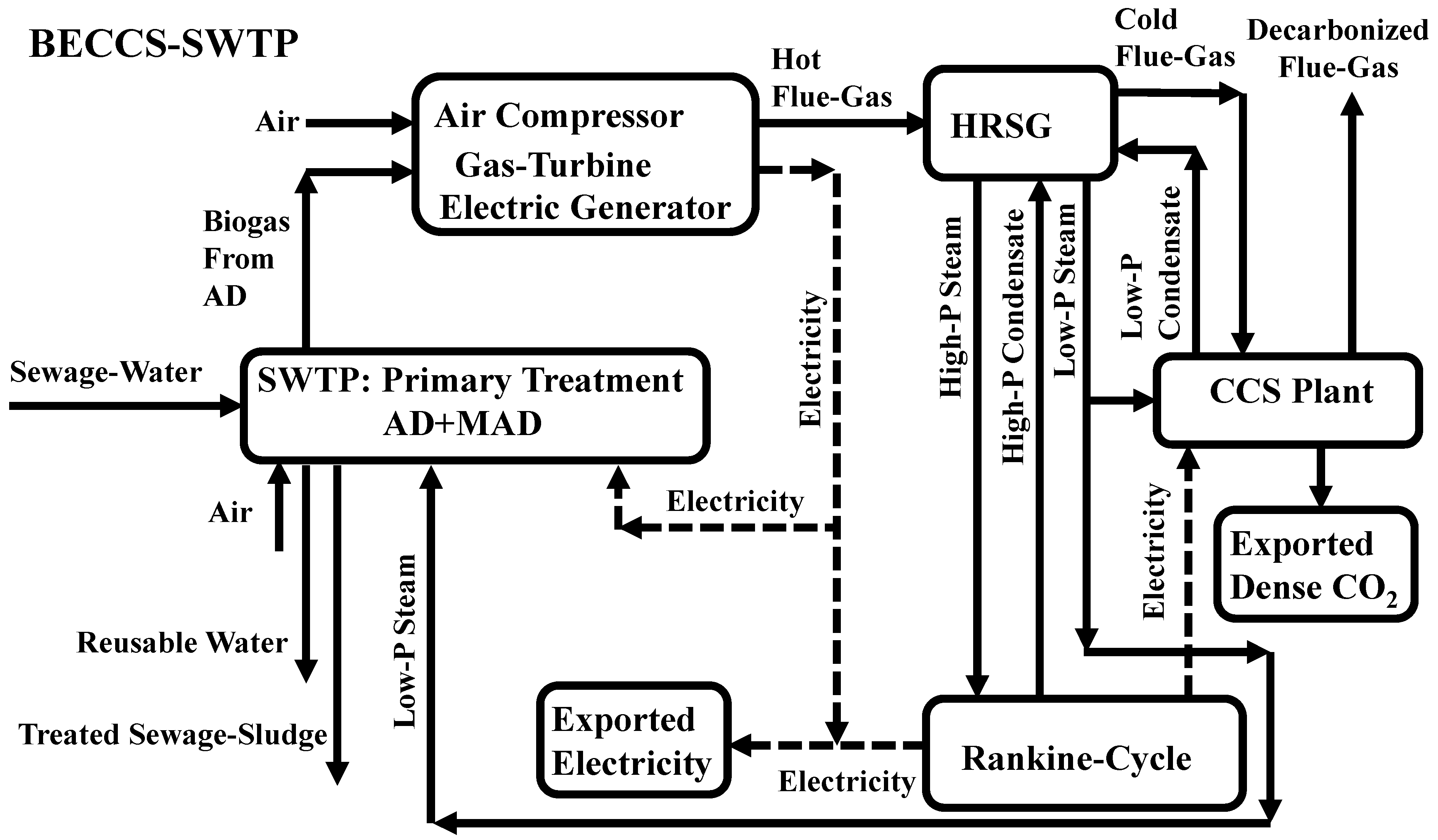

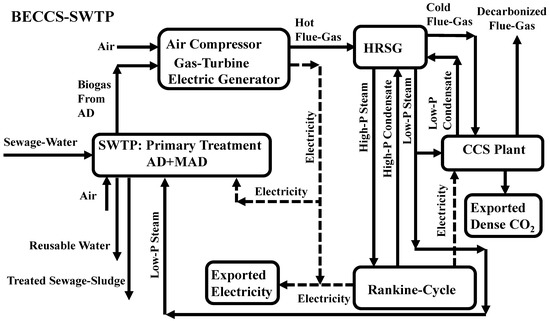

Another recent research trend in the context of SWTP power production is to integrate AD modeling with simulated Biogas GT Cycles or AD modeling with simulated Biogas Combined Cycles—i.e., GT Cycles integrated with steam Rankine cycles via Heat Recovery Steam Generators (HRSG)—for power production, with or without carbon capture and storage (CCS). Lee et al. (2017) [20] presented a SWTP-CHP-AD system (Figure 1d) where the mesophilic AD was simulated via Benchmark Simulation Model No. 2 (BSM2). Although Lee et al. (2017) [20] did not present the AD inlet composition (VReactor = 3400 m³, SRT = 19 d), a production of 2463.2 kgbiogas/d was fed to a Micro-GT, which was optimized to manipulate the temperature differences in the heat exchangers and the GT compression ratio. The power generated in the optimized system supplied 47% of the SWTP’s power demand and 100% of its heat demand. Differently from Lee et al. (2017) [20], Poblete et al. (2022) [100] designed and simulated a large-scale—GHG negative emission—SWTP in Figure 3, with optimized bioenergy production via Biogas Combined Cycle, integrating GT Cycles via HRSG to Rankine cycle running steam turbines, wherein the GTs were fed with the biogas production modeled via ADM-1 simulation. In this study, two GTs fired 205,600 m³/d of biogas, providing 14044 kW of power and an additional 8227 kW from the Rankine cycle, assuming no CCS in the flue gas. In the negative-emission case, Poblete et al. (2022) [100] showed that the Rankine cycle produced only 1928 kW due to the energy penalty of post-combustion CCS treating flue gas, but the captured CO2 can generate auxiliary revenues if exported as a dense enhanced oil recovery agent (Figure 3). Despite the impressive reduction in power brought by CCS, this study demonstrated that a SWTP operating as a Bioenergy with CCS (BECCS) system still has the potential to reach economic feasibility while promoting negative emissions, which is helpful in the climate-change scenario. Movahed and Avami (2020) [101] also employed ADM-1 to calculate the biogas produced from the primary and secondary sewage-sludge processing. However, differently from Poblete et al. (2022) [100], this study did not consider treating the flue gas for CCS and also did not consider the more efficient Combined Cycles, i.e., the biogas was fired in eight Micro-GTs with 100 kW power output instead of using large GTs coupled with HRSG and Rankine cycle.

Figure 3.

Conceptual BECCS SWTP from Poblete et al. (2022) [100] (Lines: Solid = material streams, Dashed = electricity).

4.2. Internal Combustion Engines

Internal combustion engines firing biogas are a long-established and reliable technology for co-generation systems (Mustafi et al., 2006) [102]. Henham and Makkar (1998) [103] experimentally evaluated the application of biogas in electricity generation systems with dual-fuel internal combustion engines. The experiments used a wide range of CH4/CO2 ratios to emulate biogas from different sources, including SWTPs. The authors concluded that after modifications in the ignition system, it is possible to use up to 60% biogas as fuel with low efficiency losses. Gómez et al. (2010) [104] estimated the cost of electricity generation from sewage-sludge AD using internal combustion engines in Spain. The sewage-sludge potential was estimated at 142 MWhElectric/y with a minimum electricity cost from sewage sludge at 0.11 €/kWh, which can be reduced exploiting an AD economy of scale.

4.3. Integrated CHP Systems

SWTPs can use CHP systems to enhance the energy recovery from sewage sludge through biogas utilization. In this regard, integrated CHP systems have been developed to increase energy recovery. Di Fraia et al. (2018) [105] proposed an integrated system for drying sewage sludge, with electricity production powered by the biogas from sewage-sludge AD coupled with solar energy collectors. The electricity produced by CHP was used to supply the SWTP’s demand. The thermal energy from the CHP unit, combined with solar energy, was employed to run the AD and thermal drying of the residual sludge. The solar collector has a thermal efficiency of 56%, and the CHP unit has 44% efficiency. However, they achieved a small percentage (~14%) of the energy recovery obtained by González-Arias et al. (2020) [106] via the integration of AD with pyrolysis, which can double electricity generation. González-Arias et al. (2020) [106] evaluated an integrated AD process with the pyrolysis of sewage sludge from AD, in which the sewage sludge was blended with fats and was submitted to mesophilic AD (T = 35 °C, HRT = 40 d). Results demonstrated that adding 3% w/v of fat to the sludge feed promoted a 25% increase in the generated electricity from biogas in the CHP unit. Moreover, increasing the fat ratio to 15% w/v allowed an increase of 2.4 times the electricity generation while fulfilling all heat needs for sludge drying. Confirming the approach of González-Arias et al. (2020) [106] as one of the most sustainable options, Mills et al. (2014) [107] showed the life-cycle assessment results for several configurations with CHP. The best economic and environmental performances were achieved for thermal hydrolysis AD coupled with CHP, followed by drying the digested sludge for solid fuel production and pyrolysis.

4.3.1. Solid Oxide Fuel Cell

The utilization of biogas in SOFCs is a promising way to achieve an energy self-sufficient SWTP and has been experimentally investigated at lab-scale. Giarola et al. (2018) [108] compared the performance of a SOFC system integrated with a SWTP with conventional alternatives and concluded that SOFCs may become cost-competitive in thermally optimized SWTPs. Mehr et al. (2018) [15] modeled a large-scale SOFC-CHP-SWTP, in which the biogas from sewage-sludge AD was reformed to H2 and CO. The authors concluded that a 27% savings of energy cost could be achieved. Wang et al. (2021) [109] analyzed the performance and operation parameters of biogas-fed SOFC-CHP-SWTP systems. The results showed that increasing the CH4 fraction in biogas leads to greater electrical efficiency, showing that SOFCs for biogas applications are competitive with other co-generation technologies.

4.3.2. Photovoltaic Systems

Gretzschel et al. (2020) [29] conducted a SWTP feasibility study that implemented water electrolysis for H2 and O2 productions driven by photovoltaic sources and CHP-SWTP units to provide the required electricity. The obtained H2 fed the local gas grid, and the O2 was used for micro-pollutant removal via ozonization of the sewage water. The photovoltaic power generation was 227 MWh/y, while the CHP unit produced 6173 MWhElectric/y at 38.5% thermodynamic yield. In an attempt to upgrade the biogas heating value, Su et al. (2017) [110] considered solar energy to reform biogas and improve the energy performance of CHP. The obtained synthesis gas was efficiently converted in the CHP to electric power and heat for the digester, saving 142.757 Nm³/y of biogas. In contrast to Gretzschel et al. (2020) [29] and Su et al. (2017) [110], Jacob et al. (2020) [111] did not use photovoltaic electricity to produce or modify biogas composition. They proposed photovoltaic technologies to supply the electrical and thermal demand of a SWTP, enabling them to sell the produced biogas as biomethane. The results showed significant economic and environmental gains over the conventional CHP, entailing internal return rates of 5–12.7%.

5. Power Generation in Sewage-Water Treatment with Carbon Capture and Storage

The growing climate change concerns motivate the minimization of GHG emissions and fossil energy consumption by SWTPs. However, the enormous volume of generated solid waste underlines the necessity of a sustainable way to handle it (Wei et al., 2020) [112]. Fighir et al. (2019) [113] remark that the massive GHG emissions of large-scale SWTPs come from firing biogas for heat production and CH4 emissions from AD, which has a global warming potential (GWP) 21 times greater than CO2. Bani Shahabadi et al. (2010) [17] studied a typical SWTP integrated with a Biogas Combined Cycle (BGCC) power plant fed with 1000 m³/d (~2.0 kgBOD/m3) of sewage water. They estimated a carbon credit of 34 kgCO2eq/d due to methane elimination in the BGCC instead of using conventional natural gas.

Life-cycle assessments of power-producing SWTPs are used to analyze the GWP and GHG emission of sewage-sludge treatment technologies. Buonocore et al. (2018) [114] results showed that AD was essential to achieve energy self-sufficient SWTPs, and the use of treated sewage water for irrigation as a final disposal reduces eutrophication of water bodies by 60%. Borzooei et al. (2020) [115] analyzed the carbon footprint and reported a 40% reduction in GHG emissions, considering the upgrading of biogas to biomethane, which is sent to the natural gas distribution grid. Keller and Hartley (2003) [116] concluded that GHG emissions from SWTPs are mainly driven by the selection of aerobic or anaerobic treatment for sludge management. In their study, the GHG emission of a SWTP combining AD+MAD resulted in a reduction of 1.4 kgCO2/kgCODRemoved compared to a fully MAD treatment. Niu et al. (2013) [117] approached sludge management and demonstrated that biogas utilization is crucial to reduce up to 24% of the total carbon footprint of SWTPs. Moreover, AD is responsible for contributing about 90% of GHG emissions when heat provided by the CHP units is insufficient to keep the temperature at 38 °C. In accordance with Buonocore et al. (2018) [114], Niu et al. (2013) [117], and Keller and Hartley (2003) [116], Münster and Lund (2009) [118] presented an energy analysis of different SWTP technologies that utilized organic waste for heat power production. They concluded that the best solution for minimizing GHG emissions is using organic waste to produce biogas and, consequently, CHP power production.

Chernicharo et al. (2017) [119] evaluated the management of GHG emissions from UASB-based SWTPs, considering the carbon footprint as the main deciding factor. The CHP unit was feasible and avoided 201.3 tCO2eq/y, with exhaust gases used for the dehydration of thermal sludge reducing sludge volume and transportation fuel consumption. Maktabifard et al. (2019) [120] achieved a reduction of ~30% carbon footprint by applying energy recovery from CHP, a reduction slightly higher than that presented by Niu et al. (2013) [117]. Maktabifard et al. (2019) [120] also found that 8% of the carbon footprint could be reduced by substituting synthetic fertilizers with AD digestate. Campello et al. (2020) [121] evaluated the energy potential and the economic viability of SWTPs in Brazil. Their results indicated that biogas recovery systems are feasible in most cities, reaching a payback time of 8 years. Their findings also included an estimated potential electricity generation of 47,140 MWh/y and a potential reduction in GHG emissions close to 325,800 tCO2eq/y.

The use of negative-emission energy-producing technologies—or BECCS systems—is a recently proposed strategy to reduce the carbon footprint of large-scale power-producing processes. BECCS processes are large-scale bioenergy production systems coupled with permanent CO2 drainage from the carbon cycle, mitigating (or reverting) climate changes through systematic long-term negative emissions [122]. Pour et al. (2018) [123] presented the BECCS potential of municipal solid waste management via the integration of incineration and landfill processing with CCS. Ziółkowski et al. (2021) [124] modeled a BECCS power plant based on the gasification of sewage sludge. However, there are still few works in the literature that address BECCS configurations of full SWTPs handling water recovery, waste management, energy production, and carbon abatement simultaneously [125]. Poblete et al. (2022) [100] pioneered a BECCS large-scale SWTP case study (Figure 3) that treated 10 kgCOD/m³ sewage water in AD + MAD reactors, producing 60% mol CH4 biogas, which was used to produce bioenergy to supply electricity to the CCS plant and export the surplus to the grid. The main conclusion from Poblete et al. (2022) [100] was to demonstrate the techno-economic feasibility of a BECCS-SWTP accompanied by 9.95 tCO2/h of negative CO2 emissions, i.e., the large-scale BECCS-SWTP in Figure 3 can accomplish six simultaneous beneficial targets: (i) it recovers a great flowrate of reusable water from sewage water; (ii) it is self-sufficient for heating (via low-pressure steam) and electricity and even exports some; (iii) it is economically feasible and self-sustainable; (iv) it does not emit carbon to the atmosphere, thanks to its implementation of CCS treatment of flue gas; (v) it generates extra revenues by exporting the captured dense CO2 for enhanced oil recovery (i.e., CO2 is traded for oil); and (vi) it even combats climate change by draining CO2 from the atmosphere, as sewage solids partially come from vegetable sources.

Expanding the application of the BECCS concept, Poblete et al. (2020) [126] assessed the performance of a BECCS configuration of a small-scale rural AD plant that processed animal wastes with biogas production. In this case, biogas fed a Biogas Combined Cycle (BGCC) power plant with CCS. Energy storage is implemented via dynamic Compressed Air Storage (CAS) in order to store power production during nighttime periods of low power consumption. The study claimed the feasibility of BECCS-BGCC-CCS-CAS in a carbon taxation scenario with 1.03 tCO2/h negative emission. Unlike Poblete et al. (2022) [100] and Poblete et al. (2020) [126], in which biogas production and waste management gave rise to a BECCS process, in the works of Pandey et al. (2016) [127], Huang et al. (2016) [128], and Lu et al. (2015) [129], CCS is performed via microbial electrolytic carbon capture (MECC). Wastewater was used as an electrolyte for microbial electrolytic carbon sequestration and hydrogen production. Unlike AD, MECC can operate at low temperatures (~4 °C), presenting low sludge production and offering potential treatment for a wide range of organic contaminants of wastewater. However, this type of technology is still immature, and the MECC costs are still barriers that limit its applications. Similar to MECC, microbial electro-synthesis (MES) differs in the cathode reactions and the production of bio-commodities from sewage water [130]. In Batlle-Vilanova et al. (2019) [131], the biogas produced in the AD of sewage sludge was upgraded by using MES, increasing the content of methane in the biogas and producing chlorine for the disinfection of treated sewage water.

6. Conclusions

Modern SWTPs comprise several engineering challenges to meet the objectives of restoring water quality and minimizing sewage-sludge production, while being self-sufficient in energy and reducing carbon emissions when flue gas post-combustion CCS is implemented. The literature review demonstrates that the AD of sewage sludge and sewage water—and the consequent biogas production—has consolidated itself as a resort to balance SWTP energy deficits, while simultaneously resolving sewage-sludge disposal and reducing GHG emissions, because biogas is a direct substitute for fossil fuels. Moreover, electricity generation and exportation of surplus to the grid are feasible in the SWTP context. Finally, the literature review reveals that it is possible to integrate large-scale sewage-water treatment with biogas production, power generation and flue-gas treatment via CCS to create a truly BECCS-SWTP process that exports dense CO2 as extra revenue and drains carbon from the atmosphere while producing large flowrates of reusable water. The mapping of publications on the present theme shows a broad interest in integrating the treatment of sewage water and wastewater with energy production, carbon abatement, and waste management, in which the growth of new technologies, such as SOFC, photovoltaic power generation, and biogas CHP alternatives, also play important roles to increase SWTP and BECCS-SWTP energy efficiency. Further interesting specific analyses on the vast topic of BECCS-SWTP, such as the application of a meta-analysis on the conflicting information on COD composition of SWTP streams in Section 1.1, a thermodynamic analysis of BECCS-SWTP, an exergy analysis of BECCS-SWTP, and/or an energy analysis of BECCS-SWTP, are left here as suggestions for future works.

Author Contributions

Conceptualization J.L.d.M.; Methodology J.L.d.M. and O.d.Q.F.A.; Software I.B.S.P.; Validation I.B.S.P. and J.L.d.M.; Formal Analysis J.L.d.M. and O.d.Q.F.A.; Investigation I.B.S.P. and J.L.d.M.; Resources J.L.d.M. and O.d.Q.F.A.; Data Curation I.B.S.P.; Writing – Original Draft I.B.S.P. and J.L.d.M.; Visualization I.B.S.P. and J.L.d.M.; Writing – Review and Editing J.L.d.M. and O.d.Q.F.A.; Supervision J.L.d.M. and O.d.Q.F.A.; Project Administration J.L.d.M. and O.d.Q.F.A.; Funding Acquisition J.L.d.M. and O.d.Q.F.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge financial support from Petrobras S/A (grant 5850.0107386.18.9). J.L.d.M. and O.d.Q.F.A. also acknowledge support from CNPq-Brazil (311076/2017-3).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

AAS: Aerated Activated Sludge; AD: Anaerobic Digestion; ADM-1: Anaerobic Digestion Model No. 1; ATAD: Autothermal Thermophilic Aerobic Digestion; BGCC: Biogas Combined Cycle; BECCS: Bioenergy with CCS; CCS: Carbon Capture and Storage; CHP: Combined Heat and Power; DAF: Dissolved Air Floatation; DOC: Dissolved Organic Carbon; GHG: Greenhous Gas; GT: Gas Turbine; GWP: Global Warming Potential; HRSG: Heat Recovery Steam Generator; MAD: Microbial Aerobic Digestion; MECC: Microbial Electrolytic Carbon Capture. MES: Microbial Electro-Synthesis; SAS: Sewage Activated Sludge; SCG: Spent Coffee Ground; SOFC: Solid Oxide Fuel Cell; SWTP: Sewage-Water Treatment Plant; TSS: Total Suspended Solids; UFP: Ultrafine Particles; VFA: Volatile Fatty Acids.

Nomenclature

| BOD | Biochemical oxygen demand (kgBOD/m3) |

| COD | Chemical oxygen demand (kgCOD/m3) |

| HRT | Hydraulic retention time (d) |

| NPV | Net present value (USD) |

| OLR | Organic load rate (kgCOD/m3d) |

| SRT | Solid retention time (day) |

| T | Temperature (K) |

| Greek symbols | |

| η | Adiabatic efficiency |

| ρliq | Liquid density (kg/m3) |

References

- Gerba, C.P.; Pepper, I.L. Chapter 22—Municipal Wastewater Treatment. In Environmental and Pollution Science; Brusseau, M.L., Pepper, I.L., Gerba, C.P., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 393–418. [Google Scholar] [CrossRef]

- Appels, L.; Lauwers, J.; Degrève, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sustain. Energy Rev. 2011, 15, 4295–4301. [Google Scholar] [CrossRef]

- Aziz, A.; Basheer, F.; Sengar, A.; Irfanullah; Khan, S.U.; Farooqi, I.H. Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci. Total Environ. 2019, 686, 681–708. [Google Scholar] [CrossRef] [PubMed]

- Schwarzenbeck, N.; Pfeiffer, W.; Bomball, E. Can a wastewater treatment plant be a powerplant? A case study. Water Sci. Technol. 2008, 57, 1555–1561. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.D.; Upadhyay, A.; Shrivastava, S.; Vivekanand, V. Life-cycle assessment of sewage sludge-based large-scale biogas plant. Bioresour. Technol. 2020, 309, 123373. [Google Scholar] [CrossRef] [PubMed]

- Kamali, M.; Costa, M.E.; Aminabhavi, T.M.; Capela, I. Sustainability of treatment technologies for industrial biowastes effluents. Chem. Eng. J. 2019, 370, 1511–1521. [Google Scholar] [CrossRef]

- Iglesias, R.; Muñoz, R.; Polanco, M.; Díaz, I.; Susmozas, A.; Moreno, A.; Guirado, M.; Carreras, N.; Ballesteros, M. Biogas from Anaerobic Digestion as an Energy Vector: Current Upgrading Development. Energies 2021, 14, 2742. [Google Scholar] [CrossRef]

- Odirile, P.T.; Marumoloa, P.M.; Manali, A.; Gikas, P. Anaerobic Digestion for Biogas Production from Municipal Sewage Sludge: A Comparative Study between Fine Mesh Sieved Primary Sludge and Sedimented Primary Sludge. Water 2021, 13, 3532. [Google Scholar] [CrossRef]

- Kiselev, A.; Magaril, E.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards Circular Economy: Evaluation of Sewage Sludge Biogas Solutions. Resources 2019, 8, 91. [Google Scholar] [CrossRef] [Green Version]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.A.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Raunkjær, K.; Hvitved-Jacobsen, T.; Nielsen, P.H. Measurement of pools of protein, carbohydrate and lipid in domestic wastewater. Water Res. 1994, 28, 251–262. [Google Scholar] [CrossRef]

- Gorini, D.; Choubert, J.-M.; Le Pimpec, P.; Heduit, A. Concentrations and fate of sugars, proteins and lipids during domestic and agro-industrial aerobic treatment. Water Sci. Technol. 2011, 63, 1669–1677. [Google Scholar] [CrossRef] [PubMed]

- Girault, R.; Bridoux, G.; Nauleau, F.; Poullain, C.; Buffet, J.; Steyer, J.-P.; Sadowski, A.G.; Béline, F. A waste characterisation procedure for ADM1 implementation based on degradation kinetics. Water Res. 2012, 46, 4099–4110. [Google Scholar] [CrossRef] [PubMed]

- Nielfa, A.; Cano, R.; Pérez, A.; Fdez-Polanco, M. Co-digestion of municipal sewage sludge and solid waste: Modelling of carbohydrate, lipid and protein content influence. Waste Manag. Res. 2015, 33, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Mehr, A.S.; MosayebNezhad, M.; Lanzini, A.; Yari, M.; Mahmoudi, S.M.S.; Santarelli, M. Thermodynamic assessment of a novel SOFC based CCHP system in a wastewater treatment plant. Energy 2018, 150, 299–309. [Google Scholar] [CrossRef]

- Voutchkov, N. Introduction to Wastewater Clarifier Design. 2017. Available online: https://s3.amazonaws.com/suncam/docs/278.pdf/ (accessed on 25 January 2022).

- Shahabadi, M.B.; Yerushalmi, L.; Haghighat, F. Estimation of greenhouse gas generation in wastewater treatment plants—Model development and application. Chemosphere 2010, 78, 1085–1092. [Google Scholar] [CrossRef]

- Orhon, D.; Germirli Babuna, F.; Karahan Özgün, Ö. Industrial Wastewater Treatment by Activated Sludge; IWA Publishing: London, UK, 2009. [Google Scholar] [CrossRef]

- Sadhukhan, J. Distributed and micro-generation from biogas and agricultural application of sewage sludge: Comparative environmental performance analysis using life cycle approaches. Appl. Energy 2014, 122, 196–206. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Esfahani, I.J.; Ifaei, P.; Moya, W.; Yoo, C. Thermo-environ-economic modeling and optimization of an integrated wastewater treatment plant with a combined heat and power generation system. Energy Convers. Manag. 2017, 142, 385–401. [Google Scholar] [CrossRef]

- Nemerow, N.L. Chapter 5—Removal of Suspended Solids, Industrial Waste Treatment; Butterworth-Heinemann: Oxford, UK, 2007; pp. 53–77. ISBN 9780123724939. [Google Scholar] [CrossRef]

- Moran, S. Chapter 7—Clean water unit operation design: Physical processes. In An Applied Guide to Water and Effluent Treatment Plant Design; Moran, S., Ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 69–100. [Google Scholar] [CrossRef]

- Edzwald, J.K. Dissolved air flotation and me. Water Res. 2010, 44, 2077–2106. [Google Scholar] [CrossRef]

- Johnson, B.R.; Phillips, J.; Bauer, T.; Smith, G.; Smith, G.; Sherlock, J. Startup and Performance of the World’s First Large Scale Primary Dissolved Air Floatation Clarifier; Evoqua Water Technologies LLC: Waukesha, WI, USA, 2014; pp. 712–721. [Google Scholar]

- Demirbas, A.; Edris, G.; Alalayah, W.M. Sludge production from municipal wastewater treatment in sewage treatment plant. Energy Sources, Part A Recover. Util. Environ. Eff. 2017, 39, 999–1006. [Google Scholar] [CrossRef]

- Liang, Q.; Yamashita, T.; Koike, K.; Matsuura, N.; Honda, R.; Hara-Yamamura, H.; Yokoyama, H.; Yamamoto-Ikemoto, R. A bioelectrochemical-system-based trickling filter reactor for wastewater treatment. Bioresour. Technol. 2020, 315, 123798. [Google Scholar] [CrossRef]

- Forbis-Stokes, A.A.; Miller, G.H.; Segretain, A.; Rabarison, F.; Andriambololona, T.; Deshusses, M.A. Nutrient removal from human fecal sludge digestate in full-scale biological filters. Chemosphere 2020, 257, 127219. [Google Scholar] [CrossRef] [PubMed]

- Rehman, A.; Ayub, N.; Naz, I.; Perveen, I.; Ahmed, S. Effects of Hydraulic Retention Time (HRT) on the Performance of a Pilot-Scale Trickling Filter System Treating Low-Strength Domestic Wastewater. Pol. J. Environ. Stud. 2019, 29, 249–259. [Google Scholar] [CrossRef]

- Gretzschel, O.; Schäfer, M.; Steinmetz, H.; Pick, E.; Kanitz, K.; Krieger, S. Advanced Wastewater Treatment to Eliminate Organic Micropollutants in Wastewater Treatment Plants in Combination with Energy-Efficient Electrolysis at WWTP Mainz. Energies 2020, 13, 3599. [Google Scholar] [CrossRef]

- Boehler, M.; Zwickenpflug, B.; Hollender, J.; Ternes, T.; Joss, A.; Siegrist, H. Removal of micropollutants in municipal wastewater treatment plants by powder-activated carbon. Water Sci. Technol. 2012, 66, 2115–2121. [Google Scholar] [CrossRef]

- Margot, J.; Kienle, C.; Magnet, A.; Weil, M.; Rossi, L.; de Alencastro, L.F.; Abegglen, C.; Thonney, D.; Chèvre, N.; Schärer, M.; et al. Treatment of micropollutants in municipal wastewater: Ozone or powdered activated carbon? Sci. Total Environ. 2013, 461–462, 480–498. [Google Scholar] [CrossRef]

- Burch, K.D.; Han, B.; Pichtel, J.; Zubkov, T. Removal efficiency of commonly prescribed antibiotics via tertiary wastewater treatment. Environ. Sci. Pollut. Res. 2019, 26, 6301–6310. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, F.; Hu, Y.; Feng, C.; Wu, H. Ozonation in water treatment: The generation, basic properties of ozone and its practical application. Rev. Chem. Eng. 2017, 33, 49–89. [Google Scholar] [CrossRef]

- Chys, M.; Demeestere, K.; Ingabire, A.S.; Dries, J.; Van Langenhove, H.; Van Hulle, S.W.H. Enhanced treatment of secondary municipal wastewater effluent: Comparing (biological) filtration and ozonation in view of micropollutant removal, unselective effluent toxicity, and the potential for real-time control. Water Sci. Technol. 2017, 76, 236–246. [Google Scholar] [CrossRef]

- Mathon, B.; Coquery, M.; Miege, C.; Penru, Y.; Choubert, J.-M. Removal efficiencies and kinetic rate constants of xenobiotics by ozonation in tertiary treatment. Water Sci. Technol. 2017, 75, 2737–2746. [Google Scholar] [CrossRef]

- Haak, L.; Roy, R.; Pagilla, K. Toxicity and biogas production potential of refinery waste sludge for anaerobic digestion. Chemosphere 2016, 144, 1170–1176. [Google Scholar] [CrossRef] [PubMed]

- Na, W. Impact of ultrasonication-ozonation pretreatment on anaerobic digestion of sewage sludge. Nat. Environ. Pollut. Technol. 2018, 17, 539–542. [Google Scholar]

- Marsh, H.; Rodríguez-Reinoso, F. Chapter 8—Applicability of Activated Carbon, Activated Carbon; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2006; pp. 383–453. ISBN 9780080444635. [Google Scholar] [CrossRef]

- Hu, J.; Aarts, A.; Shang, R.; Heijman, B.; Rietveld, L. Integrating powdered activated carbon into wastewater tertiary filter for micro-pollutant removal. J. Environ. Manag. 2016, 177, 45–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sher, F.; Hanif, K.; Rafey, A.; Khalid, U.; Zafar, A.; Ameen, M.; Lima, E.C. Removal of micropollutants from municipal wastewater using different types of activated carbons. J. Environ. Manag. 2020, 278, 111302. [Google Scholar] [CrossRef]

- Vítězová, M.; Jančiková, S.; Dordević, D.; Vítěz, T.; Elbl, J.; Hanišáková, N.; Jampílek, J.; Kushkevych, I. The Possibility of Using Spent Coffee Grounds to Improve Wastewater Treatment Due to Respiration Activity of Microorganisms. Appl. Sci. 2019, 9, 3155. [Google Scholar] [CrossRef] [Green Version]

- Kaushal, J.; Mahajan, P. Design and evaluation of hydroponic system for tertiary treatment of STP wastewater: An eco friendly approach. Mater. Today Proc. 2021, 45, 4914–4918. [Google Scholar] [CrossRef]

- Lata, S. Siddharth Sustainable and eco-friendly approach for controlling industrial wastewater quality imparting succour in water-energy nexus system. Energy Nexus 2021, 3, 100020. [Google Scholar] [CrossRef]

- Lüddeke, F.; Heß, S.; Gallert, C.; Winter, J.; Güde, H.; Löffler, H. Removal of total and antibiotic resistant bacteria in advanced wastewater treatment by ozonation in combination with different filtering techniques. Water Res. 2015, 69, 243–251. [Google Scholar] [CrossRef]

- Wang, H.; Mustafa, M.; Yu, G.; Östman, M.; Cheng, Y.; Wang, Y.; Tysklind, M. Oxidation of emerging biocides and antibiotics in wastewater by ozonation and the electro-peroxone process. Chemosphere 2019, 235, 575–585. [Google Scholar] [CrossRef]

- Water Environment. Operation of Municipal Wastewater Treatment Plants: MoP No. 11, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2008; Available online: https://www.accessengineeringlibrary.com/content/book/9780071543675 (accessed on 25 January 2022).

- Shammas, N.; Wang, L. Aerobic Digestion—Biological Treatment Processes. In Handbook of Environmental Engineering; Humana Press: Totowa, NJ, USA, 2009; Volume 8, pp. 635–667. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Kassaveti, A.; Ladas, D. 6—Food Waste Treatment Methodologies. In Waste Management for the Food Industries; Arvanitoyannis, I.S., Ed.; Academic Press: Amsterdam, The Netherlands, 2008; pp. 345–410. [Google Scholar] [CrossRef]

- Jaibiba, P.; Naga Vignesh, S.; Hariharan, S. Chapter 10—Working principle of typical bioreactors. In Bioreactors; Elsevier: Amsterdam, The Netherlands, 2020; pp. 145–173. ISBN 9780128212646. [Google Scholar] [CrossRef]

- Wong, C.H.; Barton, G.W.; Barford, J.P. Chapter 25—The nitrogen cycle and its application in wastewater treatment. In Handbook of Water and Wastewater Microbiology; Academic Press: Cambridge, MA, USA, 2003; pp. 427–439. ISBN 9780124701007. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, Y.; Li, B.; Guo, J.; Yang, Q.; Wang, S. Biological Removal of Nitrogen from Wastewater. In Reviews of Environmental Contamination and Toxicology; Whitacre, D.M., Ed.; Springer: New York, NY, USA, 2008; Volume 192. [Google Scholar] [CrossRef]

- Abbott, T.; Eskicioglu, C. Comparison of anaerobic, cycling aerobic/anoxic, and sequential anaerobic/aerobic/anoxic digestion to remove triclosan and triclosan metabolites from municipal biosolids. Sci. Total Environ. 2020, 745, 140953. [Google Scholar] [CrossRef]

- Layden, N.M.; Mavinic, D.S.; Kelly, H.G.; Moles, R.; Bartlett, J. Autothermal thermophilic aerobic digestion (ATAD)—Part I: Review of origins, design, and process operation. J. Environ. Eng. Sci. 2007, 6, 665–678. [Google Scholar] [CrossRef]

- Pembroke, J.T.; Ryan, M.P. Autothermal Thermophilic Aerobic Digestion (ATAD) for Heat, Gas, and Production of a Class A Biosolids with Fertilizer Potential. Microorganisms 2019, 7, 215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, S.; Zhu, N.; Ning, P.; Li, L.Y.; Gong, X. The one-stage autothermal thermophilic aerobic digestion for sewage sludge treatment: Effects of temperature on stabilization process and sludge properties. Chem. Eng. J. 2012, 197, 223–230. [Google Scholar] [CrossRef]

- Martín, M.A.; Gutiérrez, M.C.; Dios, M.; Siles, J.A.; Chica, A.F. Application of ATAD technology for digesting sewage sludge in small towns: Operation and costs. J. Environ. Manag. 2018, 215, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Aziz, M.A.; Ng, W.J.; Zhou, X.J. Acidogenic-aerobic treatment of a wastewater containing nitrobenzene. Bioresour. Technol. 1994, 48, 37–42. [Google Scholar] [CrossRef]

- Ng, W.J.; Hu, J.Y.; Ong, S.L.; Aziz, M.A. Effect of Acidogenic Stage on Aerobic Toxic Organic Removal. J. Environ. Eng. 1999, 125, 495–500. [Google Scholar] [CrossRef]

- Ahmad, M.; Denee, M.A.; Jiang, H.; Eskicioglu, C.; Kadota, P.; Gregonia, T. Sequential Anaerobic/Aerobic Digestion for Enhanced Carbon/Nitrogen Removal and Cake Odor Reduction. Water Environ. Res. 2016, 88, 2233–2244. [Google Scholar] [CrossRef]

- Ghanimeh, S.; Abou Khalil, C.; Mosca Angelucci, D.; Tomei, M.C. Anaerobic-aerobic sequential treatment: Temperature optimization and cost implications. J. Air Waste Manag. Assoc. 2019, 69, 1170–1181. [Google Scholar] [CrossRef]

- Ghanimeh, S.; Abou Khalil, C.; Mosleh, C.B.; Habchi, C. Optimized anaerobic-aerobic sequential system for the treatment of food waste and wastewater. Waste Manag. 2018, 71, 767–774. [Google Scholar] [CrossRef]

- Novak, J.T.; Banjade, S.; Murthy, S.N. Combined anaerobic and aerobic digestion for increased solids reduction and nitrogen removal. Water Res. 2011, 45, 618–624. [Google Scholar] [CrossRef]

- Stamatelatou, K.; Antonopoulou, G.; Lyberatos, G. 12—Production of biogas via anaerobic digestion. In Handbook of Biofuels Production; Luque, R., Campelo, J., Clark, J., Eds.; Woodhead Publishing: Sawston, UK, 2011; pp. 266–304. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Angelidaki, I.; Ellegaard, L.; Ahring, B.K. A comprehensive model of anaerobic bioconversion of complex substrates to biogas. Biotechnol. Bioeng. 1999, 63, 363–372. [Google Scholar] [CrossRef]

- Manchala, K.R.; Sun, Y.; Zhang, D.; Wang, Z.-W. Chapter Two-Anaerobic Digestion Modelling. In Advances in Bioenergy; Li, Y., Ge, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 69–141. [Google Scholar] [CrossRef]

- Carlsson, M.; Lagerkvist, A.; Morgan-Sagastume, F. The effects of substrate pre-treatment on anaerobic digestion systems: A review. Waste Manag. 2012, 32, 1634–1650. [Google Scholar] [CrossRef] [PubMed]

- Khanh Nguyen, V.; Kumar Chaudhary, D.; Hari Dahal, R.; Hoang Trinh, N.; Kim, J.; Chang, S.W.; Hong, Y.; Duc La, D.; Nguyen, X.C.; Hao Ngo, H.; et al. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 2020, 285, 119105. [Google Scholar] [CrossRef]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.-P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef]

- Taboada-Santos, A.; Lema, J.M.; Carballa, M. Energetic and economic assessment of sludge thermal hydrolysis in novel wastewater treatment plant configurations. Waste Manag. 2019, 92, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Heng, G.C.; Isa, M.H.; Lim, J.-W.; Ho, Y.-C.; Zinatizadeh, A.A.L. Enhancement of anaerobic digestibility of waste activated sludge using photo-Fenton pretreatment. Environ. Sci. Pollut. Res. 2017, 24, 27113–27124. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Kyriakou, A.; Lasaridi, K.; Manios, T. Boosting biogas production from sewage sludge by adding small amount of agro-industrial by-products and food waste residues. Waste Manag. 2018, 71, 605–611. [Google Scholar] [CrossRef]

- Park, K.Y.; Jang, H.M.; Park, M.-R.; Lee, K.; Kim, D.; Kim, Y.M. Combination of different substrates to improve anaerobic digestion of sewage sludge in a wastewater treatment plant. Int. Biodeterior. Biodegrad. 2016, 109, 73–77. [Google Scholar] [CrossRef]

- Maes, L.; Weemaes, M.; Hellinck, N.; De Gueldre, G.; Van De Steene, B. Co-digestion of glycerine and sewage sludge to optimise green electricity production. Water Sci. Technol. 2013, 67, 2863–2867. [Google Scholar] [CrossRef] [PubMed]

- Hance, V.; Kivevele, T.; Njau, K.N. Modification of municipal wastewater for improved biogas recovery. Water Pract. Technol. 2020, 15, 683–696. [Google Scholar] [CrossRef]

- Cardona, L.; Levrard, C.; Guenne, A.; Chapleur, O.; Mazéas, L. Co-digestion of wastewater sludge: Choosing the optimal blend. Waste Manag. 2019, 87, 772–781. [Google Scholar] [CrossRef] [PubMed]

- Kumari, K.; Suresh, S.; Arisutha, S.; Sudhakar, K. Anaerobic co-digestion of different wastes in a UASB reactor. Waste Manag. 2018, 77, 545–554. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Mailier, J.; Martin, C.; Rodríguez, J.; Aceves-Lara, C.A.; Wouwer, A.V. Model selection, identification and validation in anaerobic digestion: A review. Water Res. 2011, 45, 5347–5364. [Google Scholar] [CrossRef]

- Buswell, A.M.; Mueller, H.F. Mechanism of Methane Fermentation. Ind. Eng. Chem. Res. 1952, 44, 550–552. [Google Scholar] [CrossRef]

- Mwandila, G.; Mwanza, M.; Sikhwivhilu, K.; Siame, J.; Mutanga, S.S.; Simposya, A. Modeling energy requirements for a biogas-supported decentralized Water treatment systems for communities in chambishi (Zambia) and diepsloot (South Africa) townships. Renew. Energy Focus 2021, 37, 20–26. [Google Scholar] [CrossRef]

- Husain, A. Mathematical models of the kinetics of anaerobic digestion—a selected review. Biomass Bioenergy 1998, 14, 561–571. [Google Scholar] [CrossRef]

- Hill, D. Simplified monod kinetics of methane fermentation of animal wastes. Agric. Wastes 1983, 5, 1–16. [Google Scholar] [CrossRef]

- Zaher, U.; Pandey, P.; Chen, S. A simple elemental continuity based model application to study the anaerobic microbial activity for the treatment of dairy manure. Appl. Math. Model. 2009, 33, 3553–3564. [Google Scholar] [CrossRef]

- Ozgun, H. Anaerobic Digestion Model No. 1 (ADM1) for mathematical modeling of full-scale sludge digester performance in a municipal wastewater treatment plant. Biodegradation 2019, 30, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Ersahin, M.E. Modeling the dynamic performance of full-scale anaerobic primary sludge digester using Anaerobic Digestion Model No. 1 (ADM1). Bioprocess Biosyst. Eng. 2018, 41, 1539–1545. [Google Scholar] [CrossRef] [PubMed]

- Otuzalti, M.M.; Perendeci, N.A. Modeling of real scale waste activated sludge anaerobic digestion process by Anaerobic Digestion Model 1 (ADM1). Int. J. Green Energy 2018, 15, 454–464. [Google Scholar] [CrossRef]

- Derbal, K.; Bencheikh-Lehocine, M.; Cecchi, F.; Meniai, A.-H.; Pavan, P. Application of the IWA ADM1 model to simulate anaerobic co-digestion of organic waste with waste activated sludge in mesophilic condition. Bioresour. Technol. 2009, 100, 1539–1543. [Google Scholar] [CrossRef]

- Silvestre, G.; Fernández, B.; Bonmati, A. Significance of anaerobic digestion as a source of clean energy in wastewater treatment plants. Energy Convers. Manag. 2015, 101, 255–262. [Google Scholar] [CrossRef]

- Udaeta, M.E.M.; de S. Medeiros, G.A.; da Silva, V.O.; Galvão, L.C.R. Basic and procedural requirements for energy potential from biogas of sewage treatment plants. J. Environ. Manag. 2019, 236, 380–387. [Google Scholar] [CrossRef] [PubMed]

- Mensah, J.H.R.; Silva, A.T.Y.L.; dos Santos, I.F.S.; Ribeiro, N.D.S.; Gbedjinou, M.J.; Nago, V.G.; Tiago Filho, G.L.; Barros, R.M. Assessment of electricity generation from biogas in Benin from energy and economic viability perspectives. Renew. Energy 2020, 163, 613–624. [Google Scholar] [CrossRef]

- Schaubroeck, T.; De Clippeleir, H.; Weissenbacher, N.; Dewulf, J.; Boeckx, P.; Vlaeminck, S.E.; Wett, B. Environmental sustainability of an energy self-sufficient sewage treatment plant: Improvements through DEMON and co-digestion. Water Res. 2015, 74, 166–179. [Google Scholar] [CrossRef]

- Nowak, O.; Keil, S.; Fimml, C. Examples of energy self-sufficient municipal nutrient removal plants. Water Sci. Technol. 2011, 64, 1–6. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, T.; Yang, H.; Peng, J. Study on energy and economic benefits of converting a combined heating and power system to a tri-generation system for sewage treatment plants in subtropical area. Appl. Therm. Eng. 2016, 94, 24–39. [Google Scholar] [CrossRef]

- Siemens. Gas Turbine Portfolio—We Power the World with Innovative Gas Turbines. 2020. Available online: https://assets.new.siemens.com/siemens/assets/api/uuid:10f4860b140b2456f05d32629d8d758dc00bcc30/gas-turbines-siemens-interactive.pdf (accessed on 25 January 2022).