Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy

Abstract

:1. Introduction

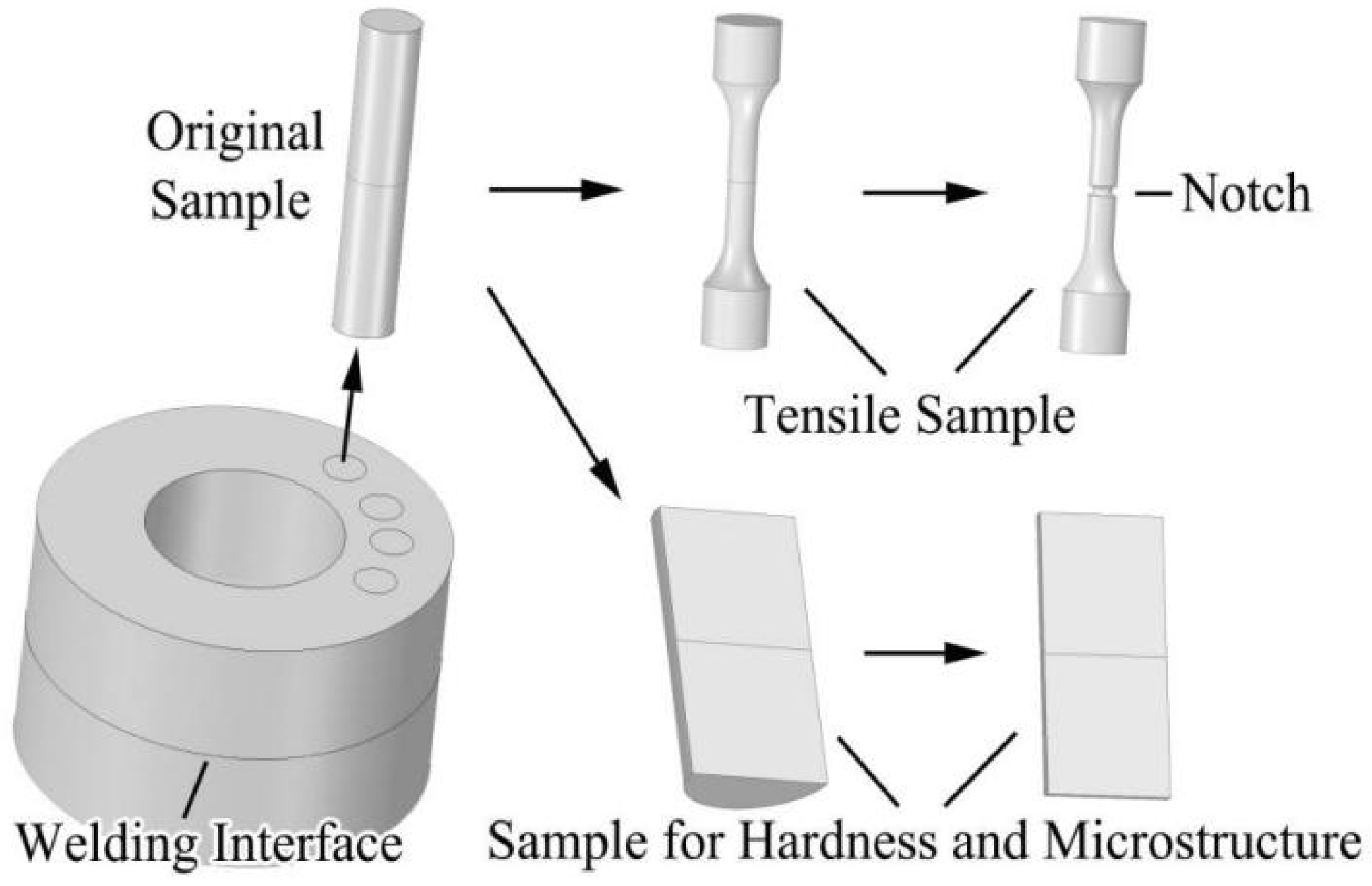

2. Materials and Methods

2.1. Material and Sample Preparation

2.2. Test Methods

3. Results and Discussion

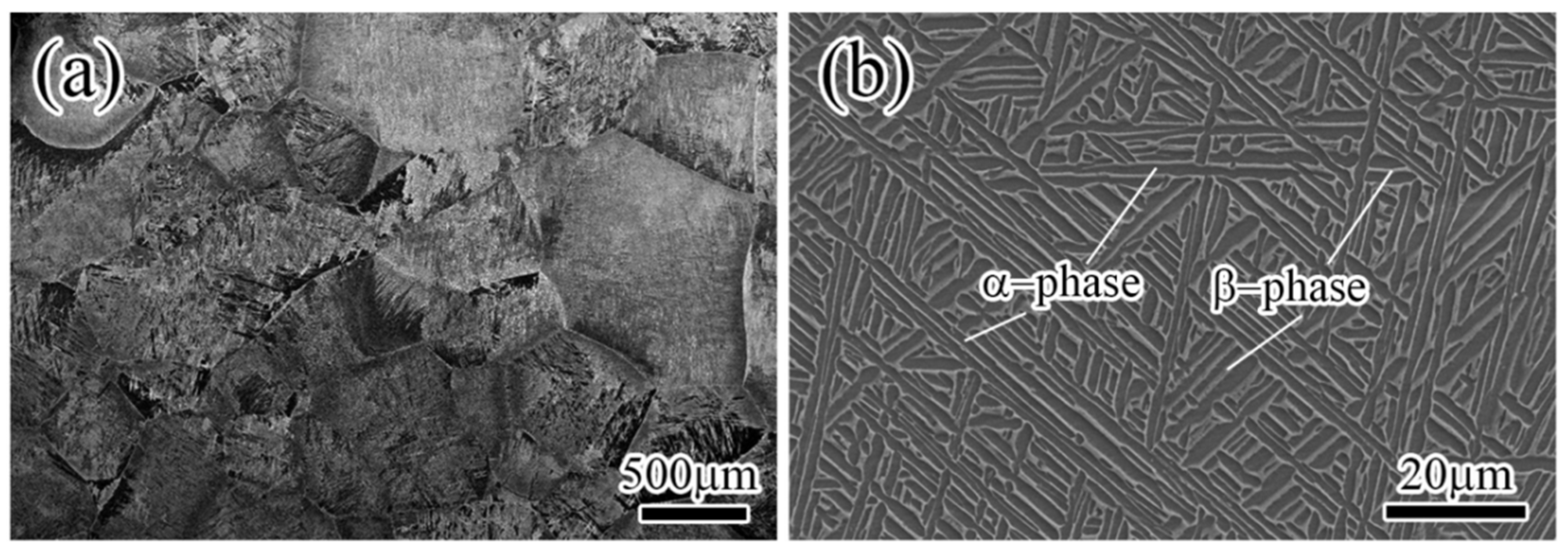

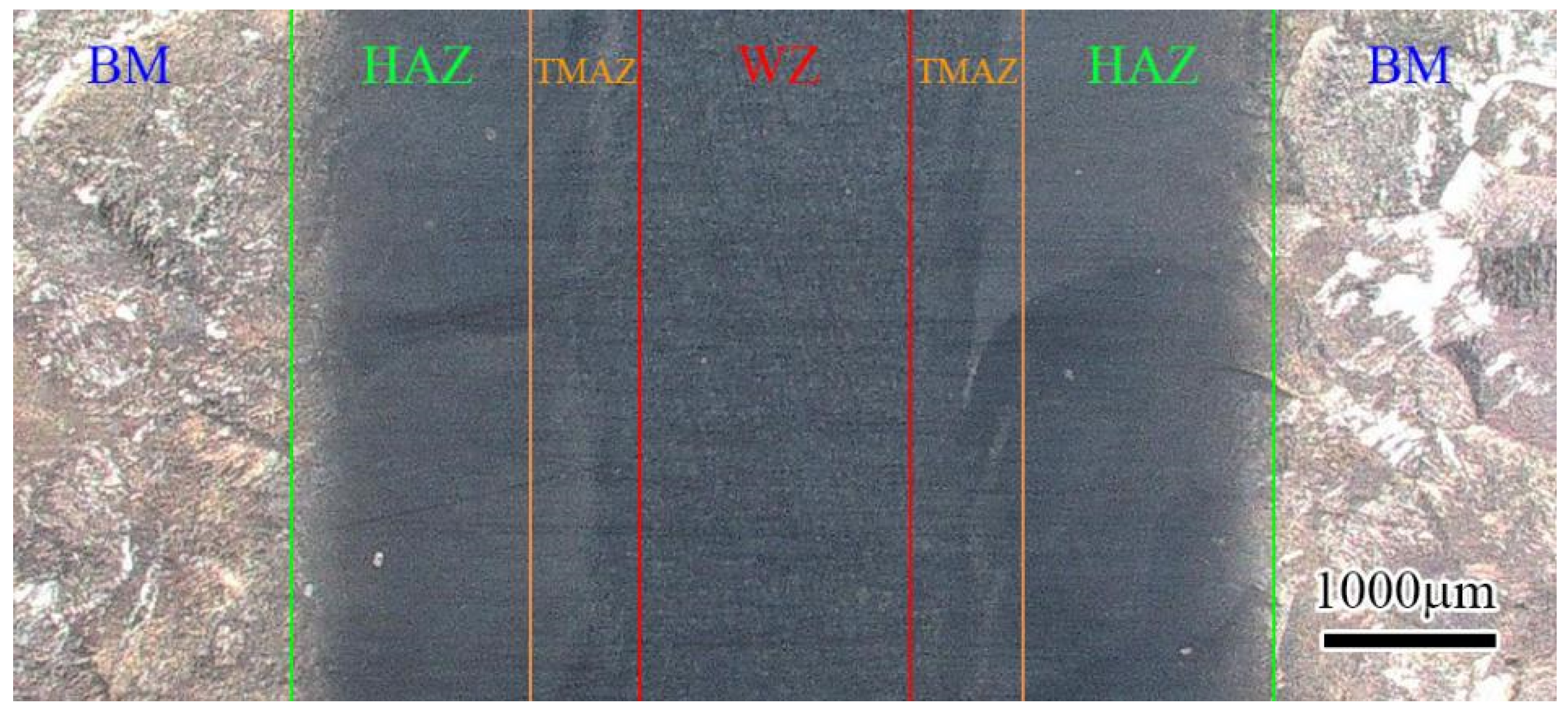

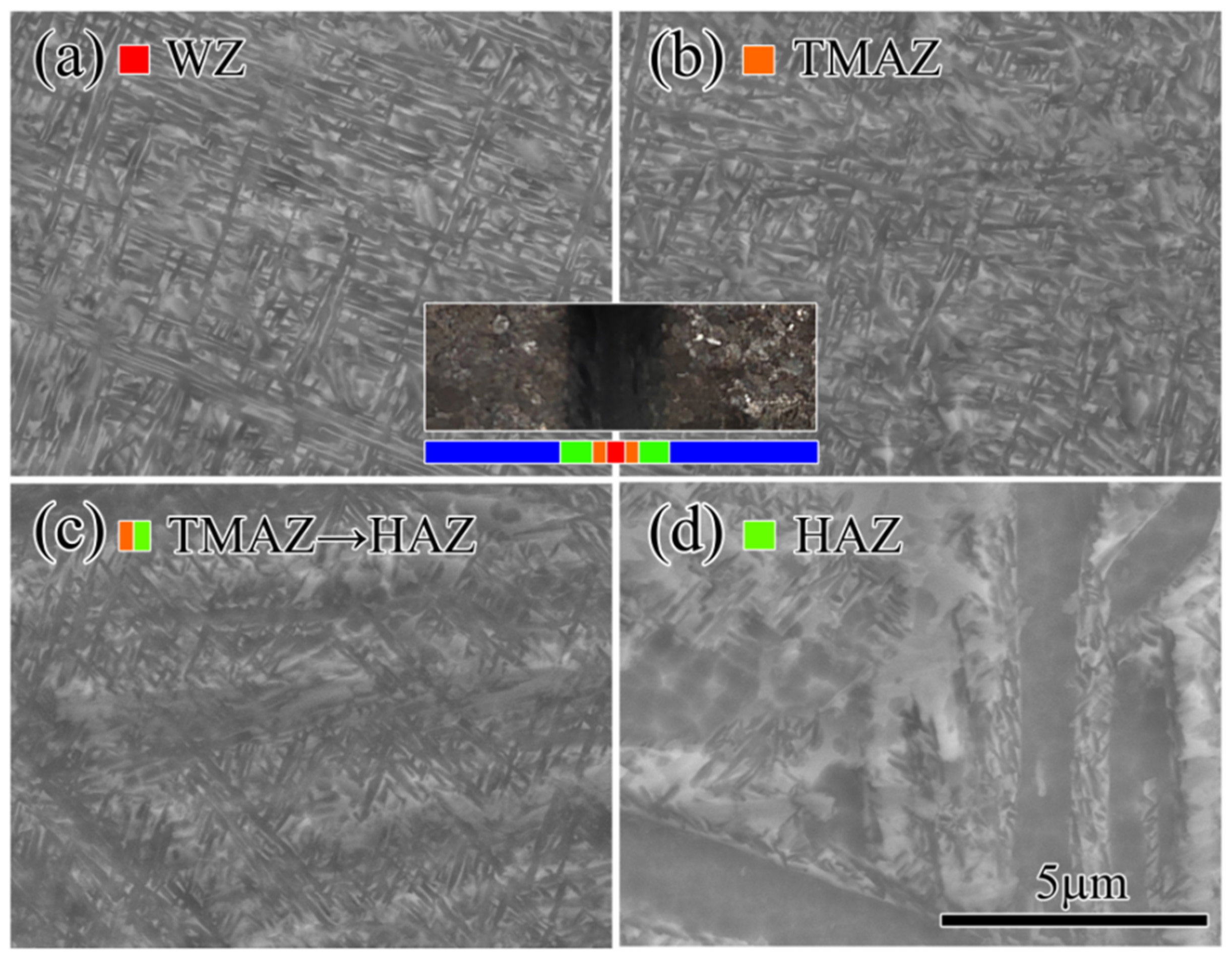

3.1. Microstructure

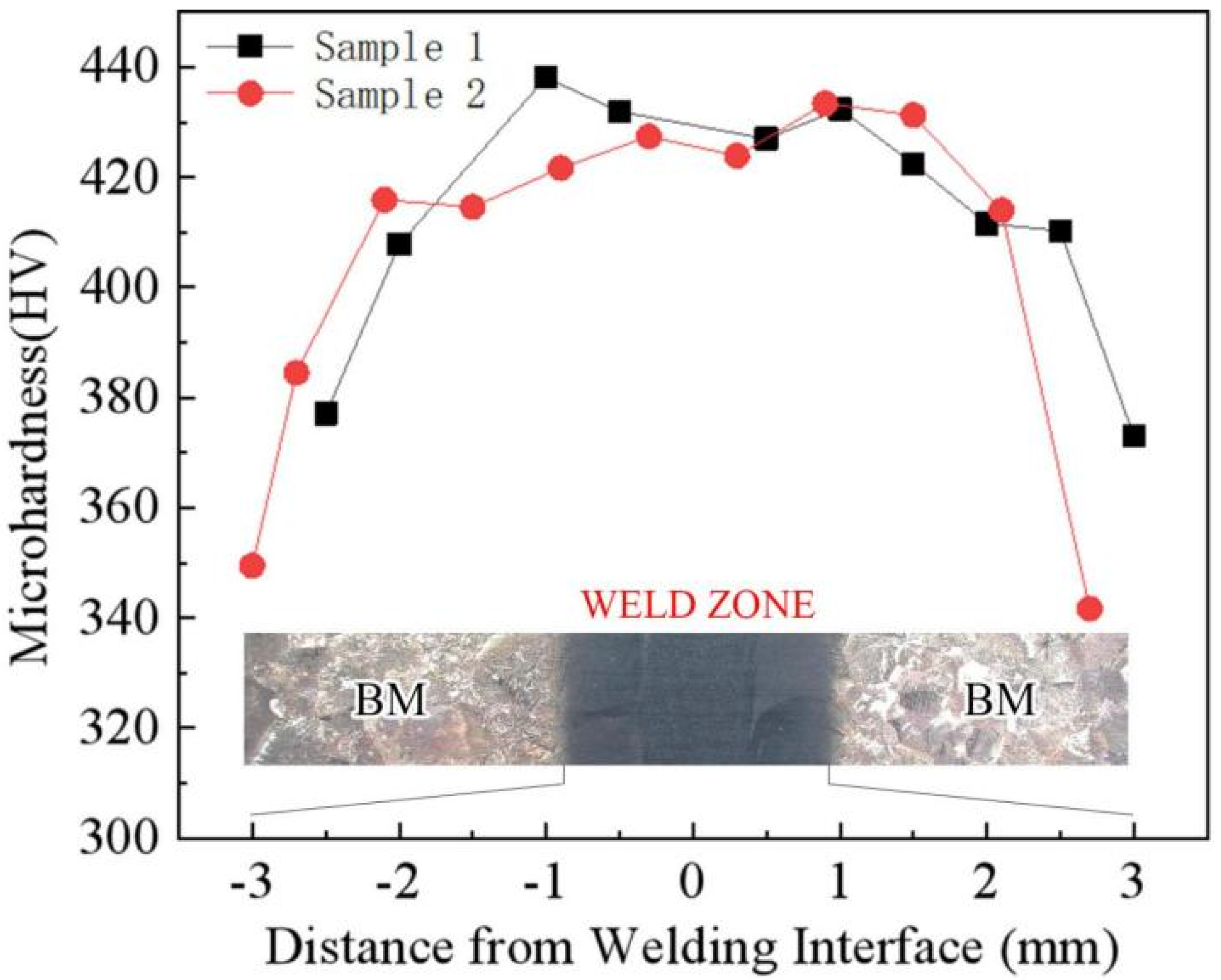

3.2. Microhardness

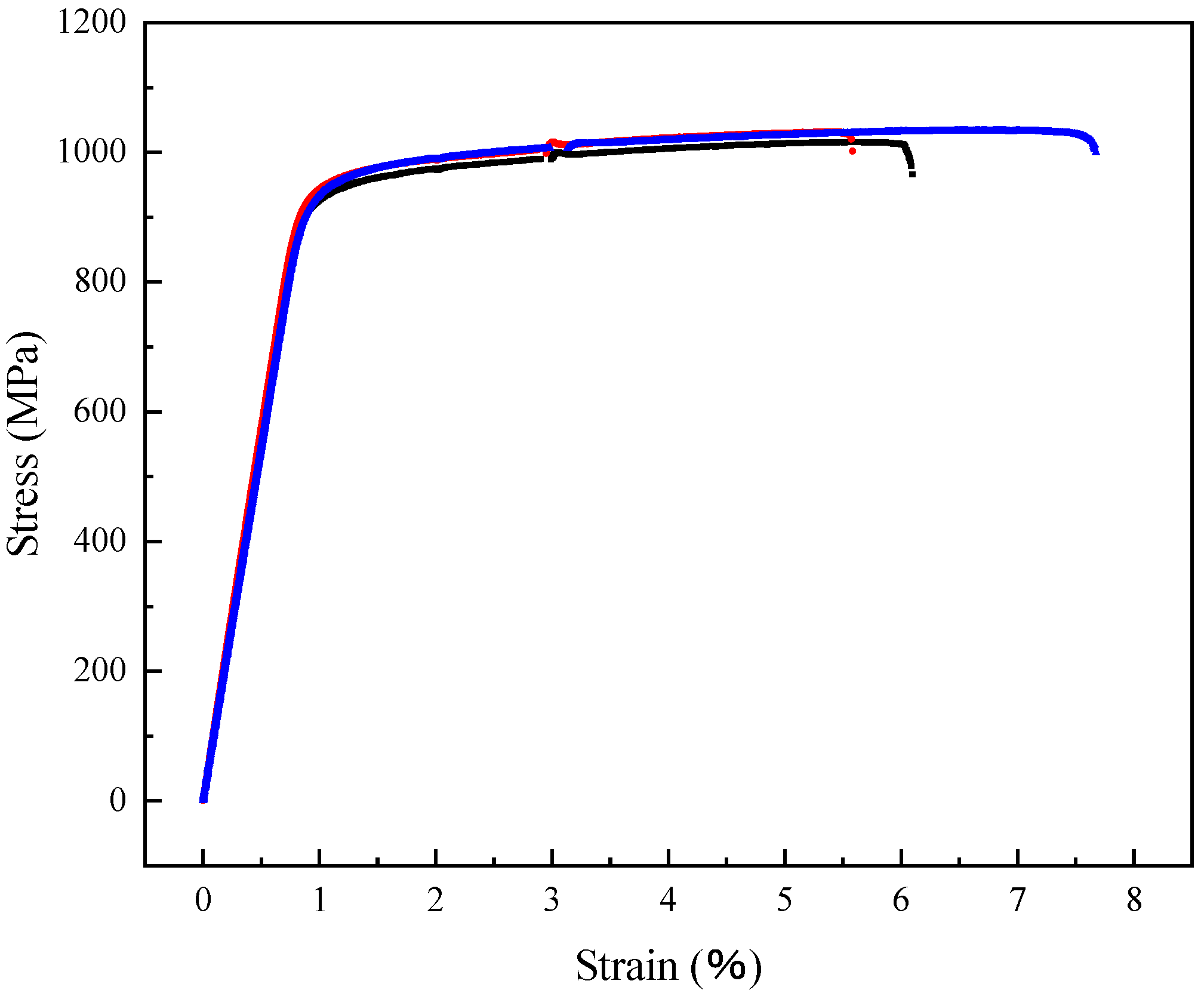

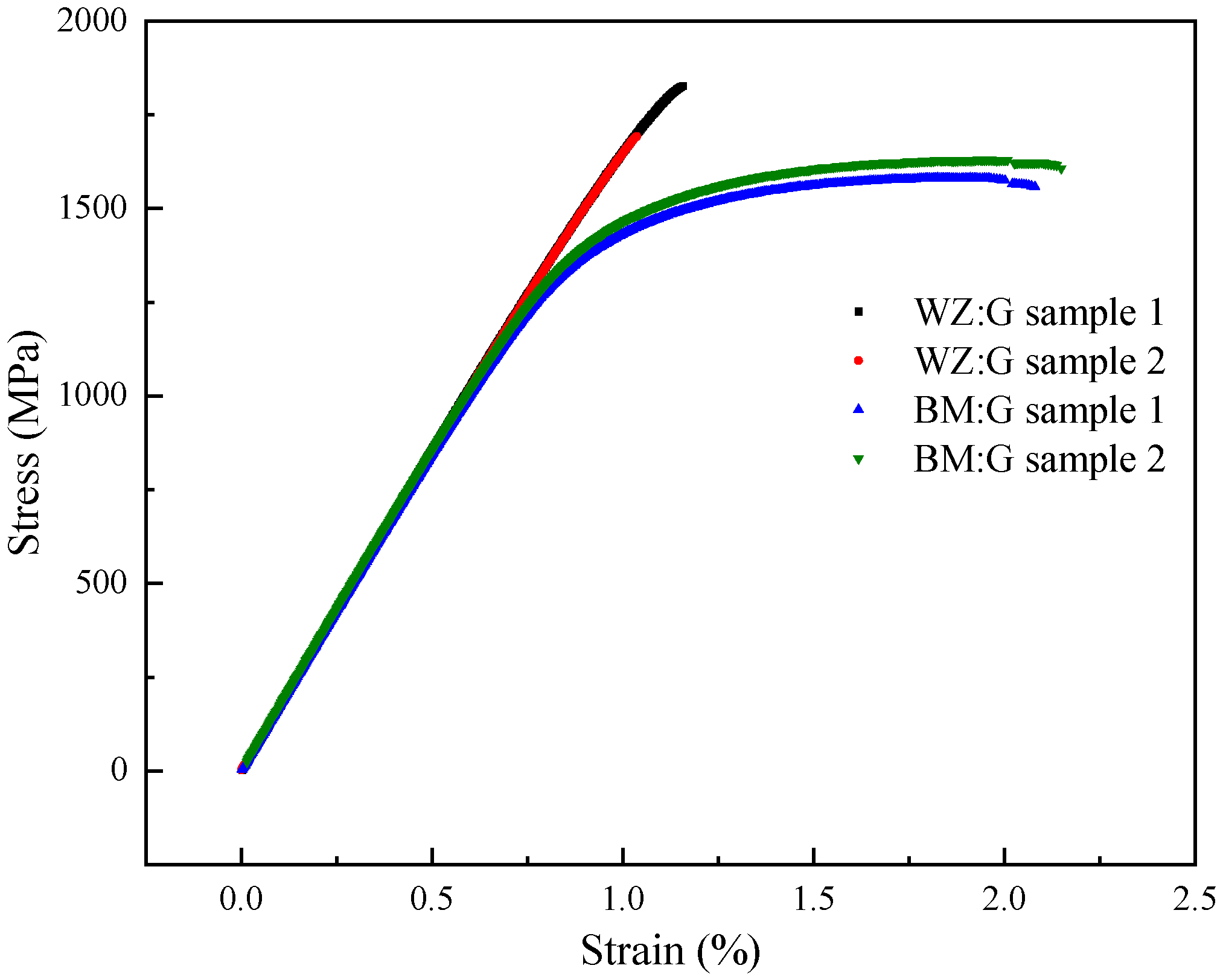

3.3. Tensile Properties

4. Conclusions

- (1)

- Inertia friction welding (IFW) of TC21 titanium alloy was successfully completed.IFW joints with a total width of about 5.1 mm, including WZ, TMAZ, and HAZ, were formed. The width of central WZ was about 1.5 mm, and the widths of TMAZ and HAZ were about 0.5 mm and 1.3 mm, respectively. The results show that a very narrow joint was formed using the IFW method.

- (2)

- The weld zone has a dynamic recrystallization microstructure, which is composed of a uniform fine-needle α phase. The microstructure of TMAZ consists of a β phase base and fine-needle α phase. HAZ almost maintains the basket-weave microstructure of the base metal, but there are many fine-needle α phases precipitated within β phases.

- (3)

- The microhardness of the IFW joint zone is higher than that of the base metal. Tensile tests using normal tensile samples without grooves indicate that the fracture positions in the base metal are all far away from the weld zone. A joint with excellent mechanical properties was formed using the IFW method under suitable parameters.

- (4)

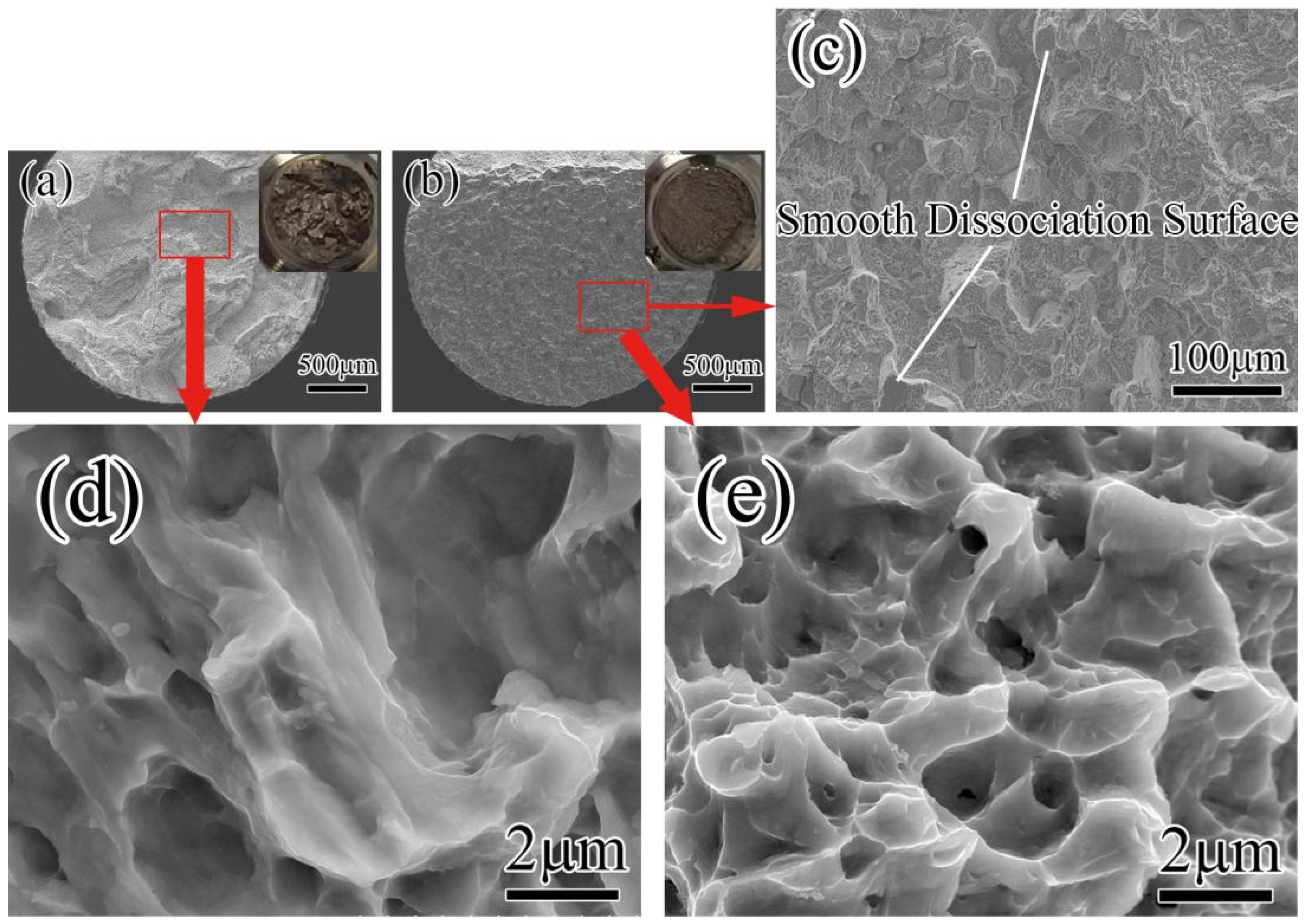

- Tensile tests using the samples with grooves were conducted, and the results show that the IFW joint has about a 20% higher tensile strength and lower plasticity than the base metal. Fracture morphology analysis indicates that the fracture of the base metal is a ductile–brittle mixed fracture, and the fracture of the IFW joint is closer to a brittle fracture.

- (5)

- The microstructure of the uniform fine-needle α phase formed in the weld zone is believed to be responsible for increasing the microhardness and tensile strength of IFW joints. However, too many fine-needle α phases also result in the decreased plasticity of IFW joints compared with the base metal.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rashid, R.A.R.; Vafadar, A. Review on machining of additively manufactured nickel and titanium alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Emiralioğlu, A.; Ünal, R. Additive manufacturing of gamma titanium aluminide alloys: A review. J. Mater. Sci. 2022, 57, 4441–4466. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhang, C.B.; Zhou, J.; Liangm, W.; Li, Y.L. Analysis of the Microstructure and Mechanical Properties During Inertia Friction Welding of the near-Alpha Ta19 Titanium Alloy. Chin. J. Mech. Eng. 2020, 33, 88. [Google Scholar] [CrossRef]

- Hui, L.; Zhao, Y.S.; Zhou, S.; An, J.L.; Wang, L. Analysis of Corrosion Fatigue Properties of Notched Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2020, 49, 2706–2711. [Google Scholar]

- Tan, C.S.; Fan, Y.D.; Li, X.J.; Huang, C.W.; He, J.H.; Zhang, G.J. Effect of the Multiscale Lamellar on Mechanical Properties of Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2021, 50, 4410–4417. [Google Scholar]

- Song, J.W.; Tan, C.S.; Sun, Q.Y.; Xiao, L.; Zhao, Y.Q.; Sun, J. Effect of Step-Quenching on Microstructure and Mechanical Properties of Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2019, 48, 1260–1266. [Google Scholar]

- Wen, X.; Wan, M.; Huang, C.; Tan, Y.; Lei, M.; Liang, Y.; Cai, X. Effect of microstructure on tensile properties, impact toughness and fracture toughness of TC21 alloy. Mater. Des. 2019, 180, 107898. [Google Scholar] [CrossRef]

- Li, W.; Vairis, A.; Preuss, M.; Ma, T. Linear and rotary friction welding review. Int. Mater. Rev. 2016, 61, 71–100. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Peng, Y.; Ma, X. Microstructure and tensile strength of aluminum/stainless steel joint welded by inertia friction and continuous drive friction. Weld. World 2020, 64, 1799–1809. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Jin, F. Effect of welding parameters on high-temperature tensile and fatigue properties of FGH96 inertia friction welded joints. Weld. World 2019, 63, 1033–1053. [Google Scholar] [CrossRef]

- Wen, H.Y.; You, G.Q.; Ding, Y.H.; Li, P.Q.; Tong, X.; Guo, W. Effect of Friction Pressure on Zk60/Ti Joints Formed by Inertia Friction Welding. J. Mater. Eng. Perform. 2019, 28, 7702–7709. [Google Scholar] [CrossRef]

- Liu, H.-J.; Feng, X.-L. Microstructures and interfacial quality of diffusion bonded TC21 titanium alloy joints. Trans. Nonferrous Met. Soc. China 2011, 21, 58–64. [Google Scholar] [CrossRef]

- Wang, K.; Wu, M.; Yan, Z.; Li, D.; Xin, R.; Liu, Q. Dynamic restoration and deformation heterogeneity during hot deformation of a duplex-structure TC21 titanium alloy. Mater. Sci. Eng. A 2018, 712, 440–452. [Google Scholar] [CrossRef]

- Zhou, S.L.; Tao, J.; Gou, D.J. Studying on Appearance of Weld of Fine Grain TC21 Alloy in TIG. J. Mater. Eng. 2009, S1, 69–72. [Google Scholar]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F. Assessment of Microstructure and Tensile Behavior of Continuous Drive Friction Welded Titanium Tubes. Mater. Sci. Eng. A 2017, 687, 249–258. [Google Scholar] [CrossRef]

| Al | Mo | Nb | Sn | Zr | Cr | Fe | O | C | N | H | Si | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.35 | 2.75 | 2.09 | 2.03 | 2.06 | 1.48 | 0.098 | 0.099 | 0.020 | 0.017 | 0.002 | ≤0.13 | Bal. |

| Initial Rotating Speed (RPM) | Moment of Inertia (kg·m2) | Friction Pressure (MPa) | Upsetting Pressure (MPa) |

|---|---|---|---|

| 700 | 388 | 76 | 102 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhao, S.; Li, Z.; Wang, M.; Wu, F.; Wang, H.; Zhou, J. Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy. Processes 2022, 10, 752. https://doi.org/10.3390/pr10040752

Li Z, Zhao S, Li Z, Wang M, Wu F, Wang H, Zhou J. Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy. Processes. 2022; 10(4):752. https://doi.org/10.3390/pr10040752

Chicago/Turabian StyleLi, Zihao, Shengsheng Zhao, Zhijun Li, Meng Wang, Fayu Wu, Hongying Wang, and Jun Zhou. 2022. "Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy" Processes 10, no. 4: 752. https://doi.org/10.3390/pr10040752

APA StyleLi, Z., Zhao, S., Li, Z., Wang, M., Wu, F., Wang, H., & Zhou, J. (2022). Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy. Processes, 10(4), 752. https://doi.org/10.3390/pr10040752