In modern enterprises, all processes that are understood as structured activities intended for production, i.e., transforming material, financial and information inputs into the final product, should take into account the principles of sustainable development and synergy. Enterprises in the 21st century face the problem of effective asset management. This applies to strategy building, planning, and organizing, as well as paying attention to the possibility of reusing materials and resources throughout the entire production process. Enterprises should adapt their activities to the new requirements arising from their environment. Enterprises should also pay more attention to designing processes that take into account new, innovative technologies that will not have a negative impact on the environment. An example of implementing new solutions may be the use of an innovative brush plate construction solution in electrolytic cells, which allows us to reduce energy consumption.

The energy consumption of an electrolytic cell depends on its construction and the method of its operation. Therefore, it is worth carrying out research to find out the impact of the above-mentioned parameters on energy consumption. The implementation of an innovative solution of the grooved brush plate allows us to reduce energy consumption. The design of the brush plate groove has an effect on energy consumption. Large surfaces of the groove positively indicate energy consumption. The optimized brush plate used in the electrolytic cell will not have a negative impact on the environment and will reduce energy consumption [1].

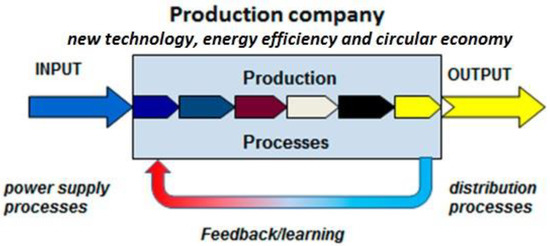

Changes taking place in the world force enterprises to undertake innovative activities that should be ecological and effective, i.e., eco-innovative and eco-efficient. To achieve such effects, companies should also manage processes, i.e., design and implement processes that take the circular economy into account. The schematic idea of processes in such companies is shown in Figure 1.

Figure 1.

The schematic idea of processes in the company [2].

In manufacturing enterprises, it is important to reduce energy consumption. High energy efficiency is a challenge for businesses and industry and can be achieved through the circular economy. In addition, the development of the energy sector in terms of renewable energy sources and the implementation of solutions aimed at reducing CO2 emissions is related to innovations in the energy sector. New, more efficient technologies and the implementation of an increasing number of scattered energy production sources based on renewable energy sources will allow us to reduce emissions or even achieve complete decarbonization. In addition, thanks to new digital solutions in the energy sector, a wide group of prosumers (energy producer and consumer) are activated, and an increasing number of enterprises are involved in the circular economy. Currently, more attention is being paid to the depletion of natural resources, environmental protection and sustainable development; as a result, the industry will move towards a circular economy [2]. The coal-based energy sector is responsible for harmful emissions, so solutions that will decarbonize the environment should be sought. Developing countries face the problem of decarbonizing and decentralizing the energy sector, as do the overwhelming majority of other countries. The uncertain economic situation of these countries is becoming a barrier to efficiently achieving zero emissions. One possible solutions is the use of hybrid grid-independent optimal systems based on renewable energy sources, used for the combined production of electricity and heat. Technical–economic–environmental results and reliability suggest that a potential option is the use of an autonomous fuel cell based on solar, wind, electrolyser and hydrogen energy, integrated with a modern solution such as a hydrogen boiler. Undoubtedly, it can be assumed that these carbon neutral remote power generation systems will ultimately be recognized in the market for their differentiated and distinctive energy quality if severe energy market constraints are imposed on coal production [3].

In recent years, a great number of environmental problems have inspired the scientific community in many academic centers and research institutes to search for new, innovative and economic solutions to meet energy demands. It is, therefore, important to connect remote villages and communities to the power grid in the right way, as connecting them will result in significant costs and harmful environmental effects. Therefore, communities that use natural and renewable energy resources have attracted the attention of researchers as their energy needs could be met by a standalone renewable power plant located within this local community.

Regarding applied solutions based on renewable energy sources, it is important to have a technical and economic assessment of a hybrid power plant independent of the network to jointly supply a distant micro-community with electricity and hydrogen. When using a RES-based power plant, a feasibility study should also be carried out on off-grid integrated solutions that combine several energy sources, i.e., water energy, wind energy and solar energy, which will generate and provide energy for the micro-community [4].

Innovative management of energy and production companies in the era of Industry 4.0 is a key element of the circular economy. The implementation of innovative processes allows us to make a transformation towards an intelligent (digital) enterprise, using virtual reality, supported by effective control of independent characters (NPC). The implementation of Industry 4.0 solutions, as well as the design of new machines in accordance with the latest achievements of the principles of mechanical engineering, will allow enterprises to implement new innovative product solutions, and will contribute to achieving better economic results and increasing operational efficiency [2]. The concept of Industry 4.0 combines many solutions from the IT world and is associated with elements such as the Internet of Things (IoT), machine learning and communication between machines. This allows for constant interaction between individual elements of the system and between humans, machines, and products [5].

The implementation of new innovative forms and solutions in production allows for the involvement of people and technical devices, but one should remember the factors both facilitating and limiting the implementing of innovative technical and technological solutions in processes related to dairy production. In the development of various branches of industry, it is important to simultaneously implement many solutions that will contribute to the improvement of the functioning of enterprises. The article presents an example of milking cows with a milking robot. In the dairy sector, it is important to systematically implement innovative solutions related to the breeding of cows and their milking. The modernization of the equipment increases efficiency and enables better use of existing potential. The use of modern milking robots affects not only the increase in milk yield of cows, but also the increase in biological progress. Therefore, it is important to develop further research related to dairy production as well as activities in the agricultural sector [6]. An improvement in the milking process can be developed using a model. Modeling the milking process in the milking robot allows for simulation tests of the cow milking machine-analysis of design parameters. It is important to theoretically develop a mathematical model of negative pressure drops in a form that allows us to study the influence of the construction parameters of the milking apparatus on the values of negative pressure drops in the jaw. The simulation tests of the milking apparatus were carried out with the use of a simplified model of negative pressure drops in the form of a fourth degree polynomial. Sensitivity analysis and simulation of the model with a simplified vacuum droplet structure in the holder was performed. Thanks to this, it was possible to analyze the influence of the design parameters of the milking machine on the milking process. The applied research methodology enables a broader analysis of the technical and technological solutions in milking machines and in the milking process. In order for the milking process to be efficient in terms of economy and energy use, the working time should be as short as possible and the volume of milk as high as possible [7]. Another production-related element is designing the perfect dairy farm. These are not only assessments of the economic efficiency of milk production, but also opinions expressed by various social groups in various terms, e.g., packaging, appearance, innovation, or taste [8]. Issues related to the processes of dairy production and running dairy farms are the subject of many studies and are subject to systematic assessments. These assessments relate to many aspects, starting with economic, environmental and ending with technical and technological issues. The assessment made by a wide range of respondents also constitutes a significant contribution in terms of improving a farm’s milk production.

As a result of such opinions, a vision of the ideal dairy farm may arise, although by creating the vision of the ideal dairy farm, respondents showed how different ideas about understanding the ideal dairy farm, e.g., the vision of farmers or consumers [9].

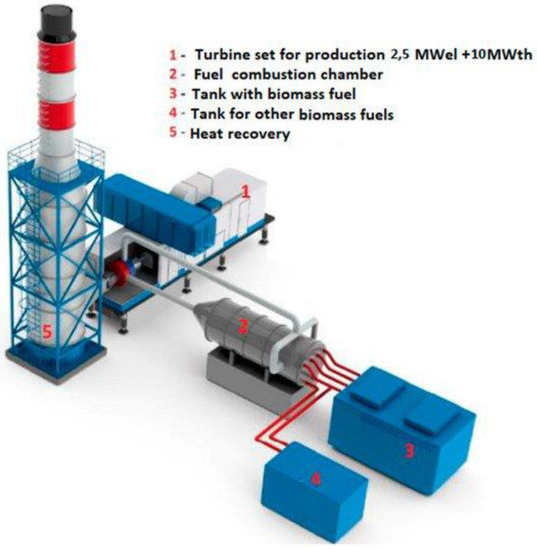

When talking about the processes related to energy production, it is worth looking at the aspects of energy production from renewable sources. The growing environmental requirements for reducing greenhouse gas emissions by various industries indicate lignocellulosic biomass (wood, straw, cereal grains, etc.) as an ideal raw material for energy production. In addition, the use of lignocellulosic biomass for energy production allows the use of small-scale cogeneration installations for energy production, reducing costs related to the transport of the raw material and increasing the resistance of the energy system to failures. An example is the production of electricity and heat from biomass waste using a converted AI-20 aviation turbine. By analyzing various energy materials, it is worth investigating the impact of biomass micronization on energy production with the rebuilt AI-20 aviation turbine. The turbine could generate energy from various sources. The input for production could be both solid biomass, represented by agricultural residues (sunflower husks, straw, hay) and wood biomass represented by forest residues or energy plantations (bark, energy trees, bamboo) and conventional fuels [10]. The conducted research shows that the most energy was obtained from absolutely dry sunflower husk (17.27 MJ/kg), and the least energy was produced from poplars (7.82 MJ/kg). The remaining types of biomass, i.e., wheat straw, hay and miscanthus, were characterized by high energy production values and were at the level of (about 17 MJ/kg). The means of connecting individual machine modules in the field of generating electricity and heat creates a certain concept of fuel flow between the segments during the production cycle. The organization of production and the type of individual phases of the production process have a huge impact on the form of flow. The line visualization of biomass power plant production is shown in Figure 2.

Figure 2.

Scheme of a biomass-fired power plant [10].

The type of material burned has an influence on production in terms of increasing or decreasing efficiency, especially when the machines operate in cogeneration. This type of device, depending on the raw material used, allows for reducing greenhouse gas emissions to the atmosphere and does not require any emission costs [11].

Energy production also entails a whole range of biofuels produced on the basis of renewable energy sources. The issue of reducing emissions in transport is important, so it is also worth conducting research into selected sectors of biofuels for transport. In the scientific community, the directions of development of these sectors and the factors limiting the pace of their growth are analyzed on a large scale. Currently, the attention of researchers is increasingly focused on the development of the alternative fuels sector. In addition, issues related to waste used in the alternative fuels sector are now among the leading environmental engineering projects. The potential of the biofuel sector operating in Poland was examined, with particular emphasis on the guidelines resulting from EU law. The article discusses the sector of esters, liquid biofuels, the lignocellulose sector, the sector of liquid biocarbon, and additionally highlights the electromobility sector as a highly attractive sector with the prospect of further reducing emissions. Vehicles commonly referred to as electric (electromobility), such as hybrids, electric or hydrogen cells have a good future ahead of them. Therefore, it seems appropriate that the production of electric vehicles in Poland should be based on solutions already used by renowned and reputable car companies [12]. Another issue related to the use of renewable energy in transport is the example of bioethanol and methyl esters. In Poland, the situation related to biofuels and alternative fuels is highly variable; therefore, the research was intended to demonstrate the nature of this sector. Research conducted and observations made have allowed for a proper presentation of the production potential in Poland. In addition, the reasons for changes in the production structure of these fuels were analyzed and attention was paid to changes in the political and legal conditions [13].

This Special Issue on “Processes in Enterprises and Circular Economy Concerning Conventional Energy and Renewable Energy” offers an overview (through original full-length, review articles and case report) of the various processes used in different branches of industry and economy.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

I would like to thank all the contributors and the editorial staff of Processes for their enthusiastic support of this Special Issue.

Conflicts of Interest

The author declare no conflict of interest.

References

- Yi, S.; Yang, Z.; Zhou, L.; Zhang, G. The Effect of Brush Plate Structure and Operating Parameters on the Energy Consumption of Electrolytic Cells. Processes 2021, 9, 2186. [Google Scholar] [CrossRef]

- Borowski, P. Innovative Processes in Managing an Enterprise from the Energy and Food Sector in the Era of Industry 4.0. Processes 2021, 9, 381. [Google Scholar] [CrossRef]

- Rezaei, M.; Dampage, U.; Das, B.K.; Nasif, O.; Borowski, P.F.; Mohamed, M.A. Investigating the Impact of Economic Uncertainty on Optimal Sizing of Grid-Independent Hybrid Renewable Energy Systems. Processes 2021, 9, 1468. [Google Scholar] [CrossRef]

- Xia, T.; Rezaei, M.; Dampage, U.; Alharbi, S.; Nasif, O.; Borowski, P.; Mohamed, M. Techno-Economic Assessment of a Grid-Independent Hybrid Power Plant for Co-Supplying a Remote Micro-Community with Electricity and Hydrogen. Processes 2021, 9, 1375. [Google Scholar] [CrossRef]

- Borowski, P. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Gaworski, M. Implementation of Technical and Technological Progress in Dairy Production. Processes 2021, 9, 2103. [Google Scholar] [CrossRef]

- Golisz, E.; Kupczyk, A.; Majkowska, M.; Trajer, J. Simulation Tests of a Cow Milking Machine—Analysis of Design Parameters. Processes 2021, 9, 1358. [Google Scholar] [CrossRef]

- Gaworski, M.; Borowski, P.F.; Zajkowska, M. Attitudes of a group of young Polish consumers towards selected features of dairy products. Agron. Res. 2021, 19, 1023–1038. [Google Scholar] [CrossRef]

- Gaworski, M.; de Cacheleu, C.; Inghels, C.; Leurs, L.; Mazarguil, C.; Ringot, B.; Tzu-Chen, C. The Topic of the Ideal Dairy Farm Can Inspire How to Assess Knowledge about Dairy Production Processes: A Case Study with Students and Their Contributions. Processes 2021, 9, 1357. [Google Scholar] [CrossRef]

- Borowski, P.F.; Patuk, I.; Bandala, E.R. Innovative Industrial Use of Bamboo as Key “Green” Material. Sustainability 2022, 14, 1955. [Google Scholar] [CrossRef]

- Roman, K.; Barwicki, J.; Hryniewicz, M.; Szadkowska, D.; Szadkowski, J. Production of Electricity and Heat from Biomass Wastes Using a Converted Aircraft Turbine AI-20. Processes 2021, 9, 364. [Google Scholar] [CrossRef]

- Borowski, P.F.; Kupczyk, A.; Biernat, K.; Mączyńska-Sęczek, J.; Detka, T.; Golisz, E.; Gawłowska, A.; Di Nardo, M. Problems of Selected Sectors of Biofuels for Transport in Poland. Processes 2021, 9, 1573. [Google Scholar] [CrossRef]

- Kupczyk, A.; Mączyńska-Sęczek, J.; Golisz, E.; Borowski, P.F. Renewable Energy Sources in Transport on the Example of Methyl Esters and Bioethanol. Processes 2020, 8, 1610. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).