New Approach for Failure Prognosis Using a Bond Graph, Gaussian Mixture Model and Similarity Techniques

Abstract

:1. Introduction

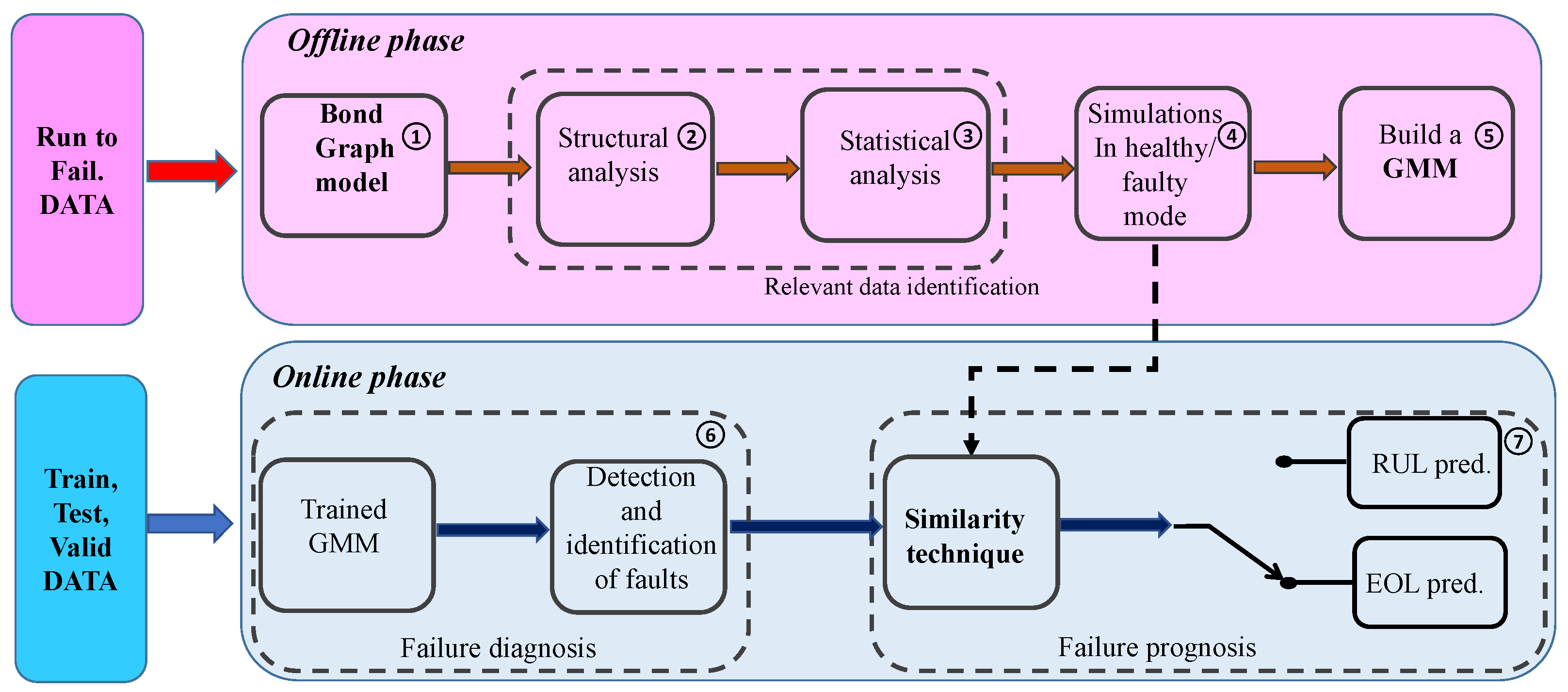

2. Proposed Approach

2.1. Offline Phase

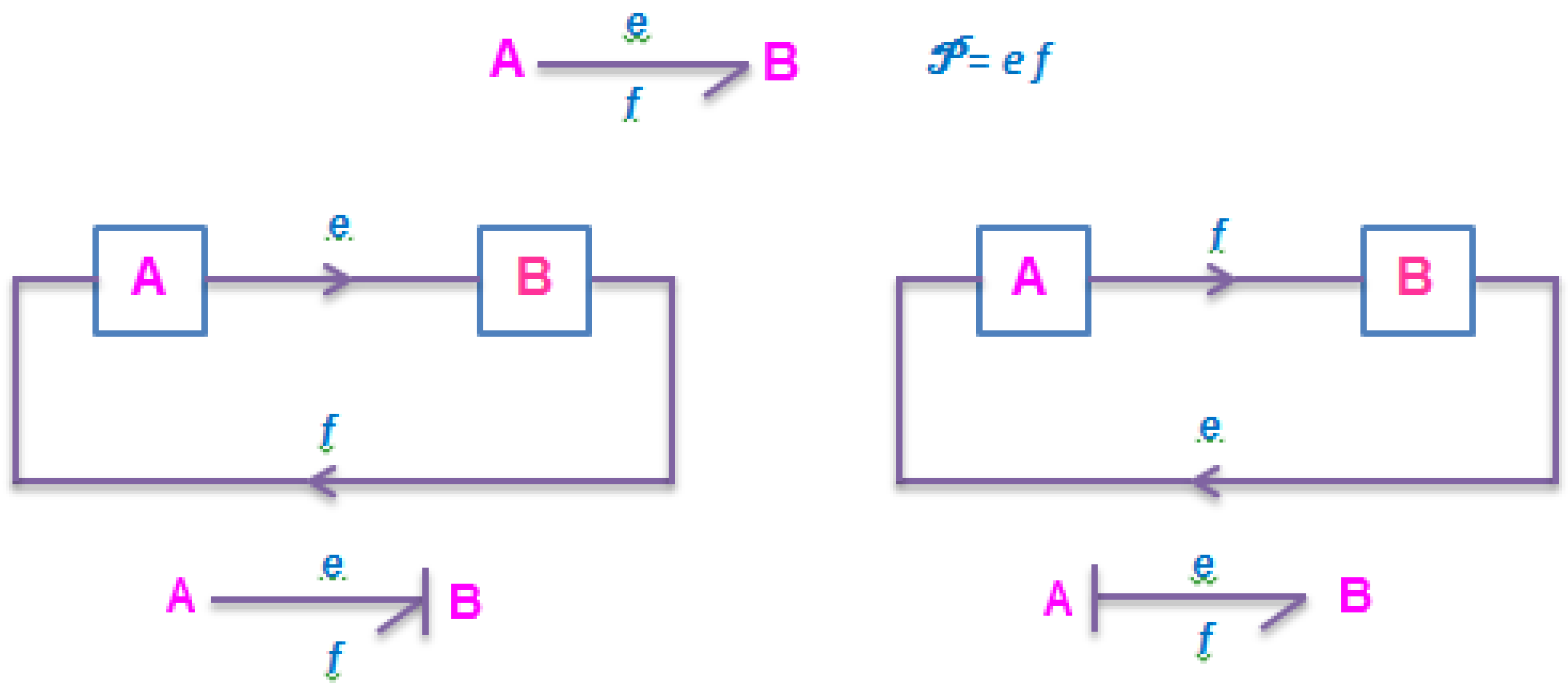

2.1.1. Structural Analysis by Bond Graph

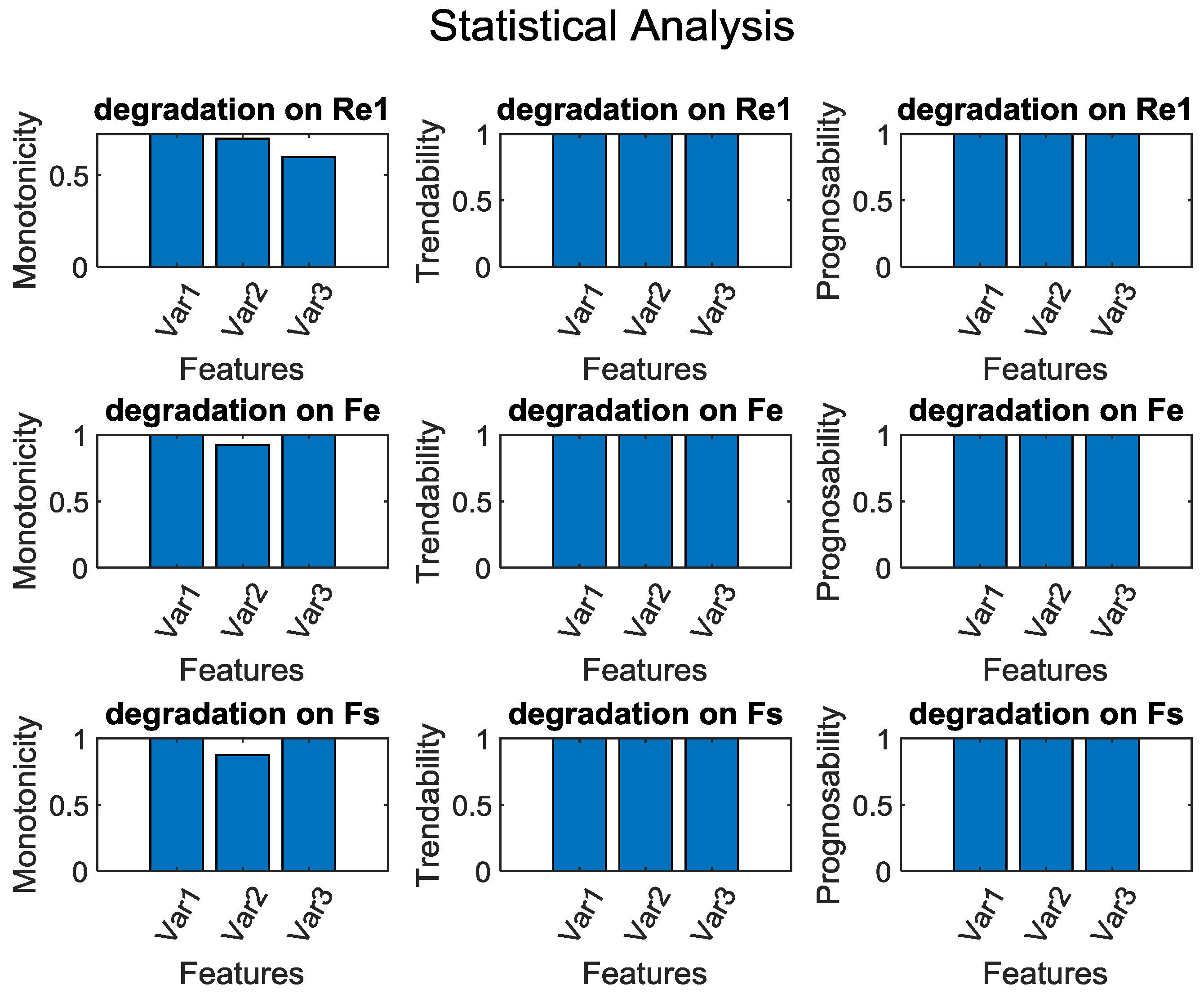

2.1.2. Statistical Analysis

2.1.3. Simulations in Normal/Faulty Mode

2.1.4. Gaussian Mixture Model

2.2. Online Phase

2.2.1. Diagnostic Step

2.2.2. Prognosis Step

3. Application and Experimental Results

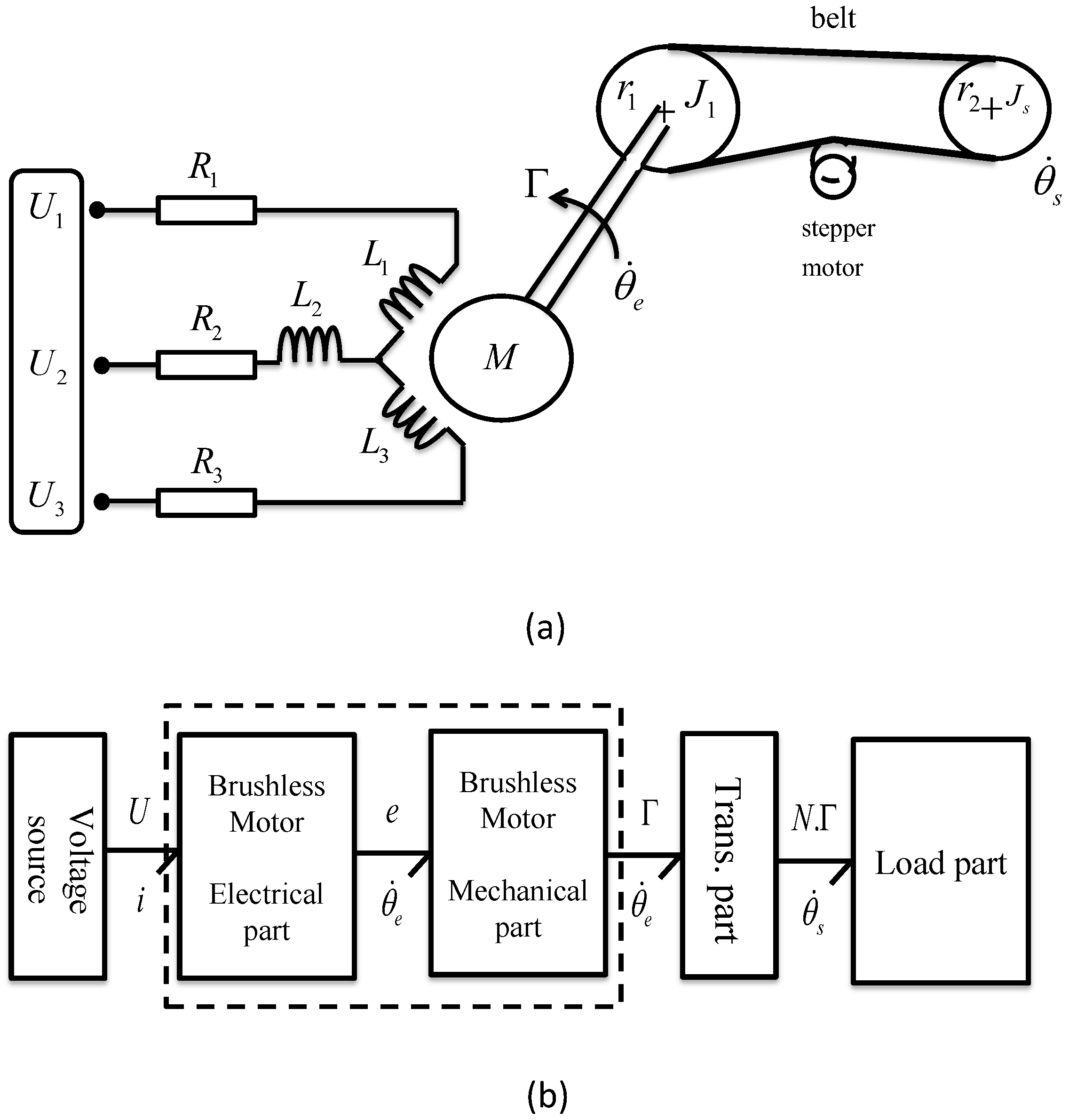

3.1. System Description

- The brushless motor part is a three phase motor. The electrical part corresponds to three RL circuits. It is composed of an input voltage source with , an electrical resistance , an inductance and a back electromotive force (EMF) with a constant , which is linear to the angular velocity of the rotor. The mechanical part is characterised by the rotor inertia , and a viscous friction parameter ;

- The transmission part concerns the belt which links the mechanical part to the load part. It is characterised by the belt stiffness K and by the transmission reduction constant ;

- The load part of the mechatronic system is a pulley that is characterised by its inertia and a viscous friction parameter . The instrumentation architecture of this system is composed of the angular position of the rotor and the angular position of the pulley . Since the position is not a flux variable neither an effort one, the velocities and are represented using a element on the BG model. They are obtained by differentiating the position information.

3.2. Structural and Statistical Analysis

- -

- A causal path is found between the element and the current sensor :

- -

- A causal path is found between the element and the angular speed of the rotor sensor :

- -

- A causal path is found between the element and the angular speed of the pulley sensor :

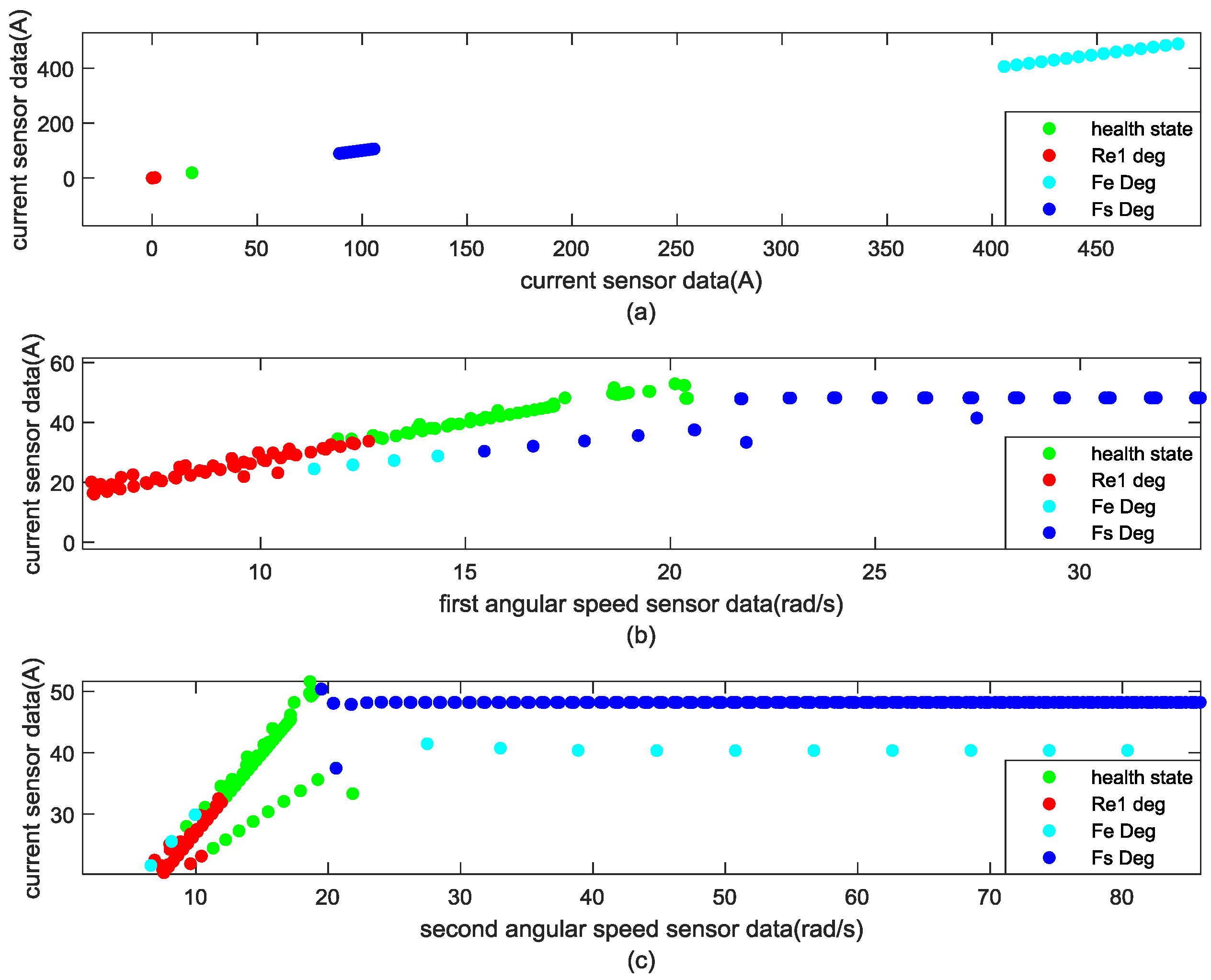

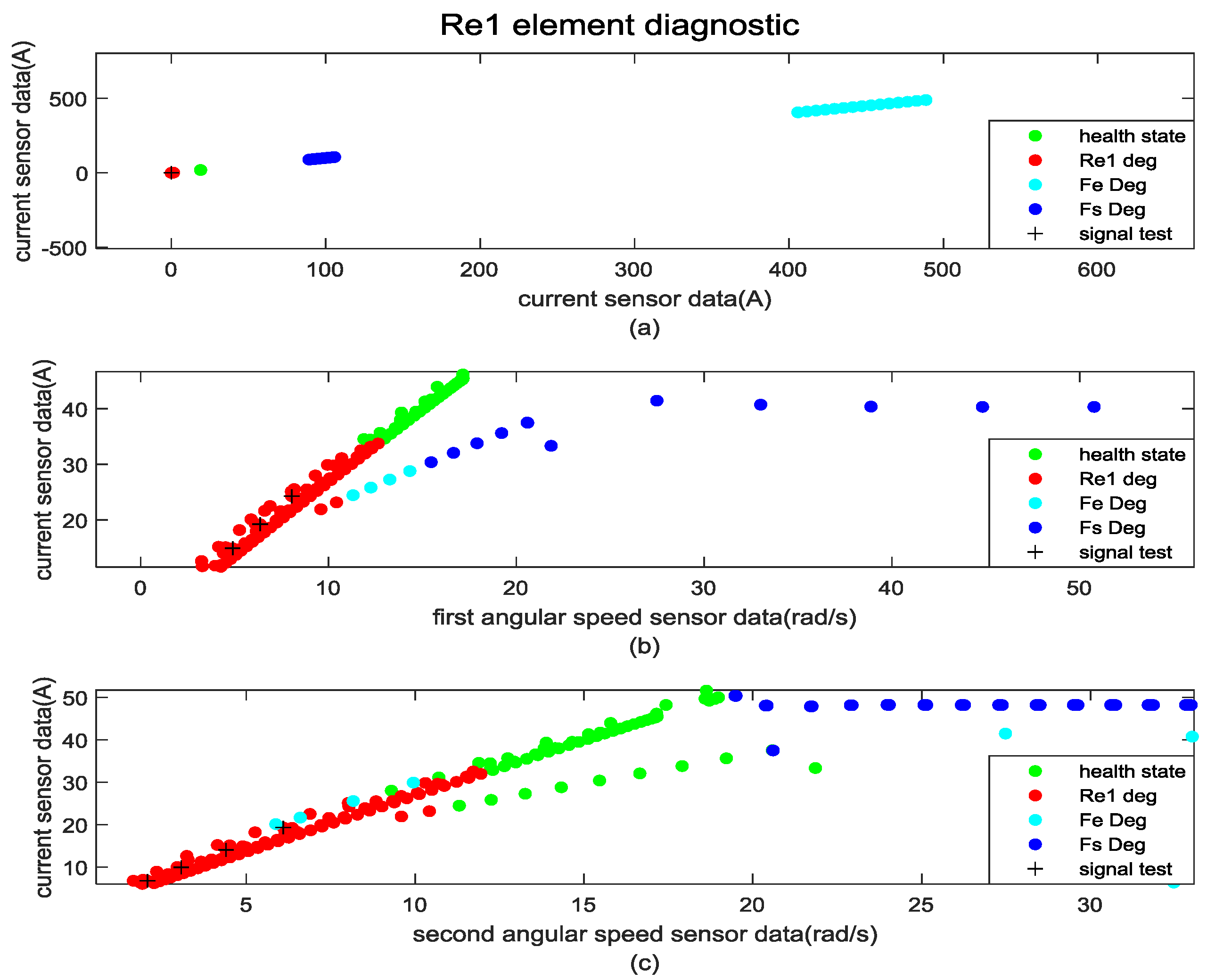

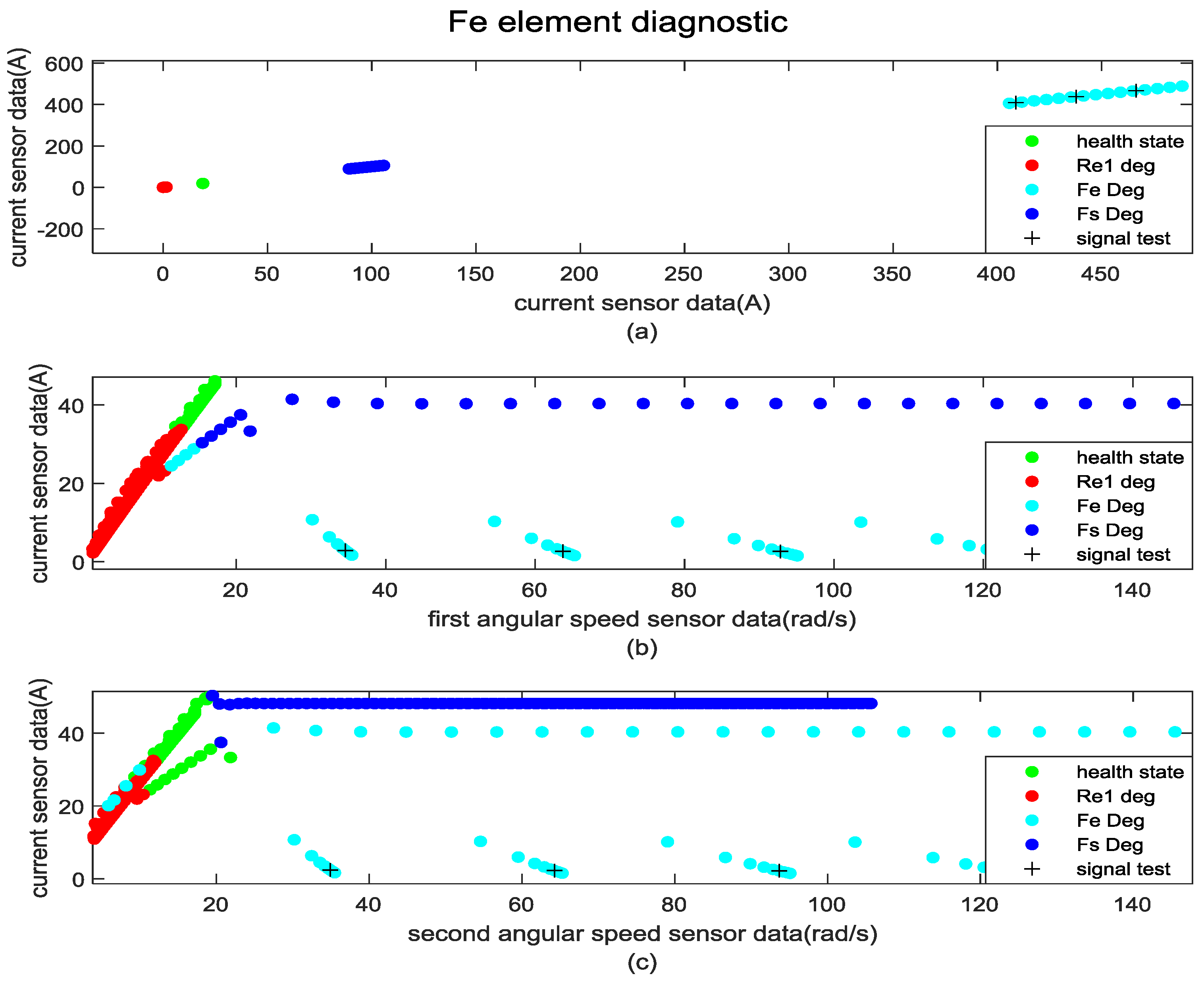

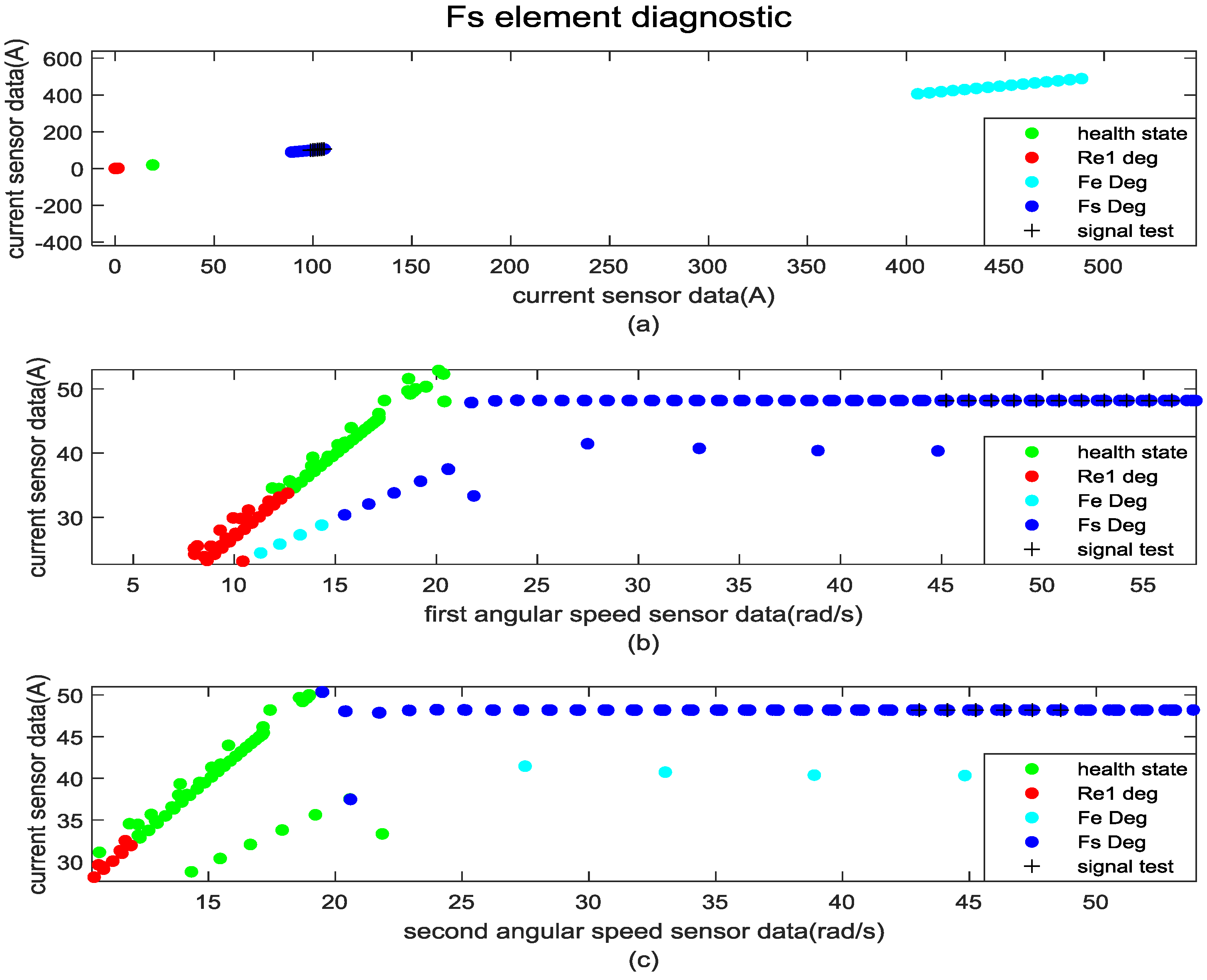

3.3. Clustering and Diagnostic by GMM

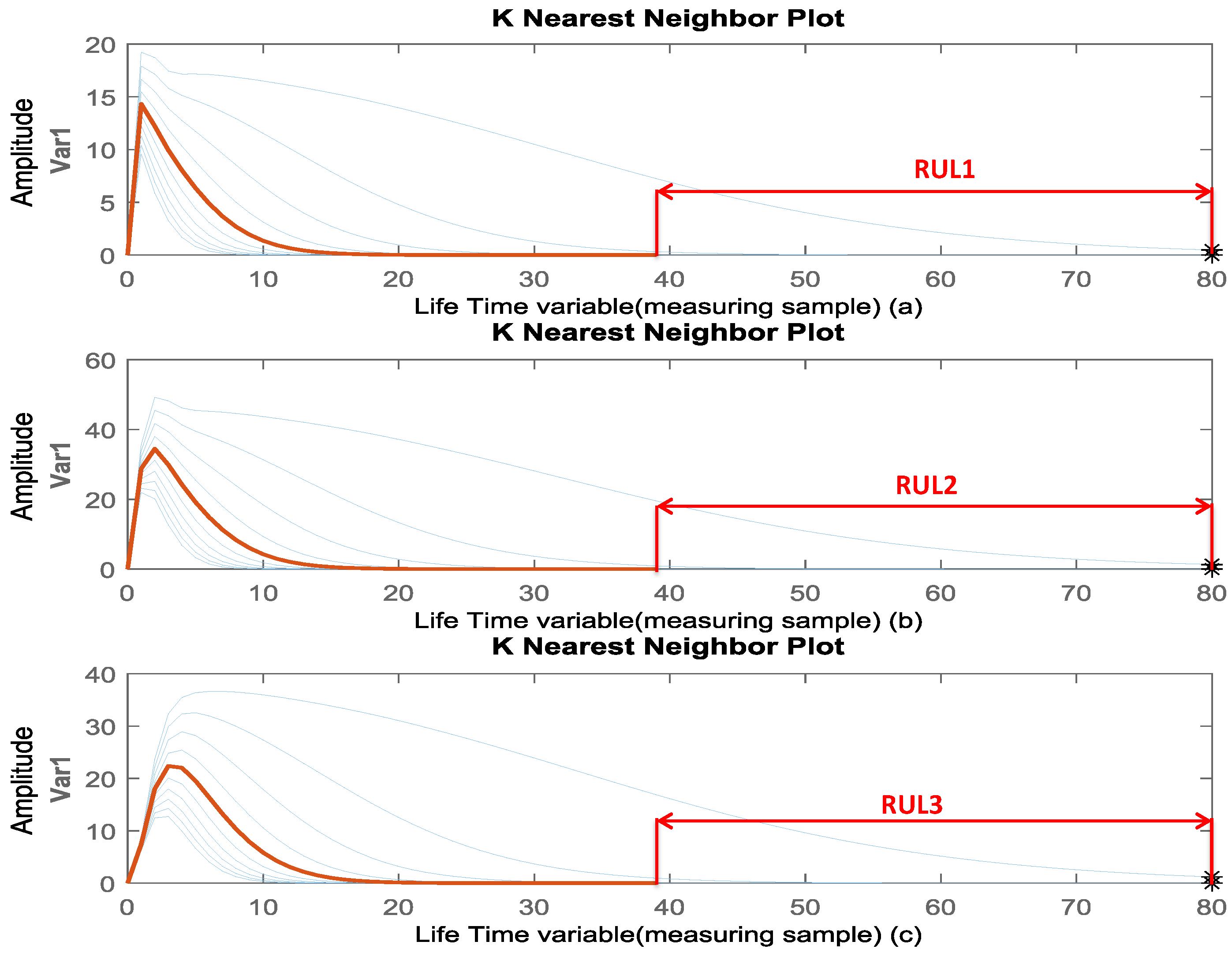

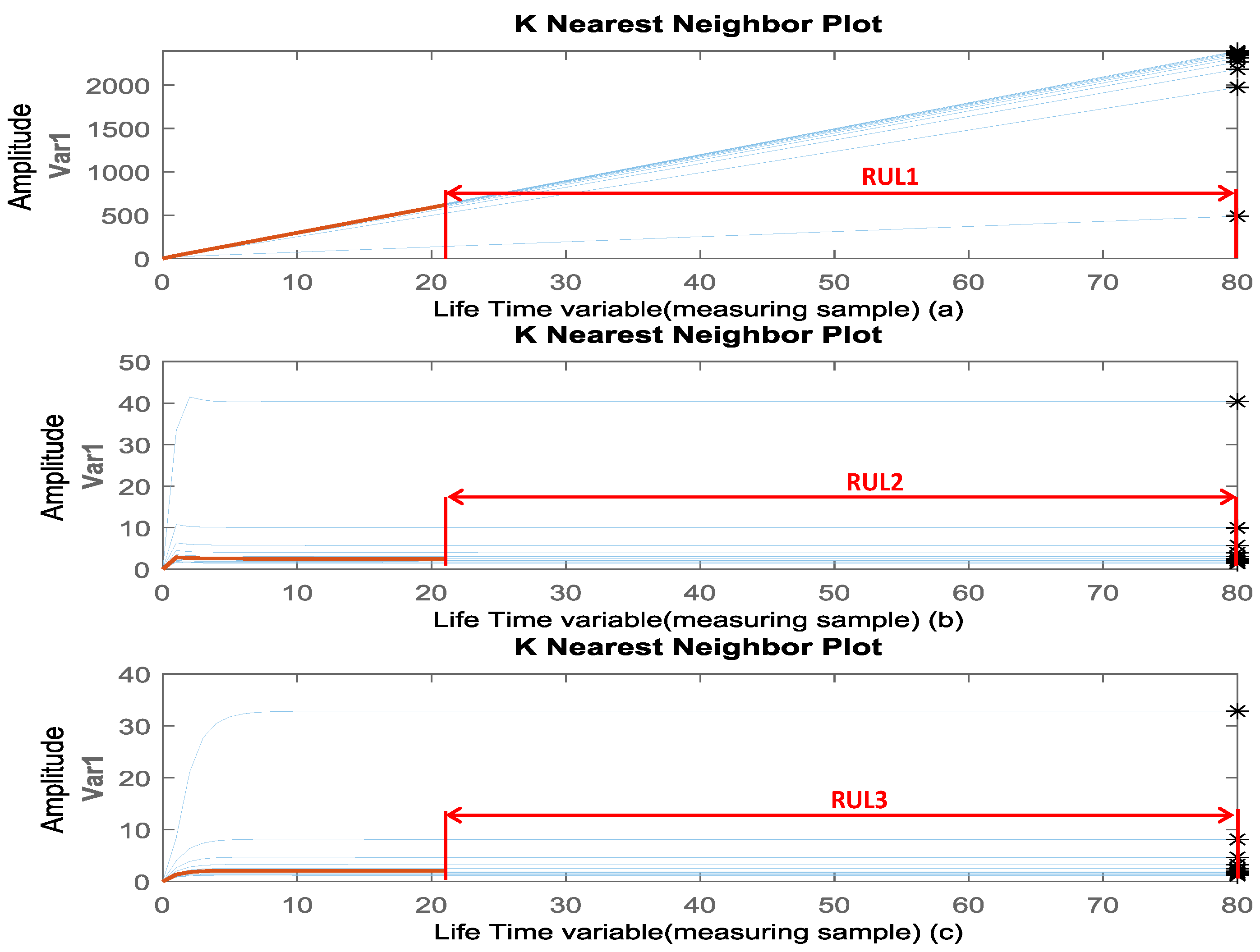

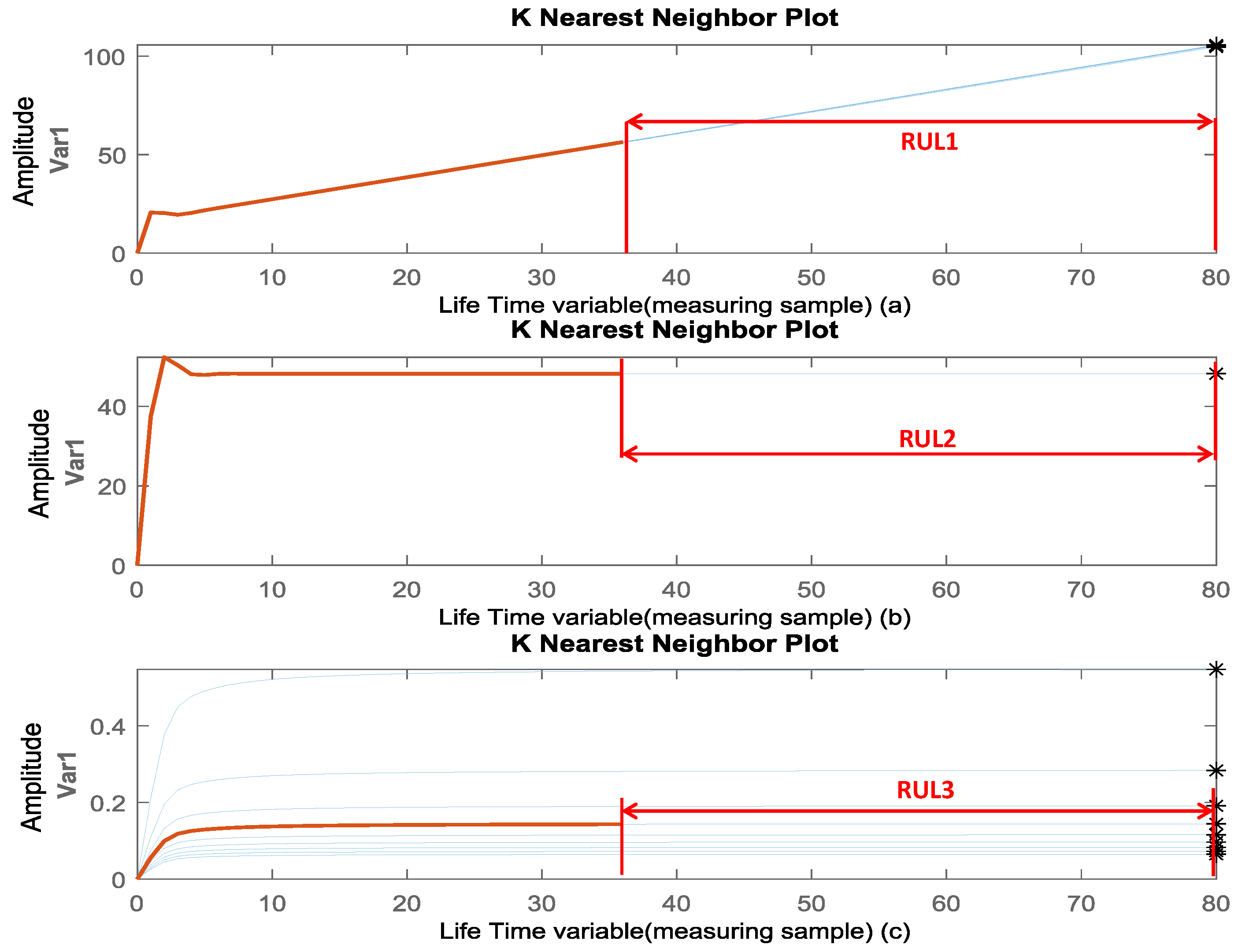

3.4. RUL Prediction

4. Discussion

- Indeed, the combination of a physical approach (the BG) for the structural analysis, with a probabilistic tool (GMM) for the diagnosis and a geometrical tool for the prognosis made it possible on the one hand to complete the real measured data by data generated in simulation using the BG model, to take advantage of the power of GMMs in the Gaussian combination for the separation of classes of operation. The geometric aspect of the similarity method, similar to the principle of geolocation, made it possible to predict the RUL without prior knowledge of the degradation profiles.

- In addition, the relevant variables, identified by structural analysis using BG; are affirmed by statistical evaluation metrics.

- For the validation of the proposed method, the similarity technique is used to predict the RUL in three cases: a single sensor, two sensors and three sensors, the results show that the prediction of the RUL is almost the same, so, for the case study, fault diagnosis and failure prognosis can be performed using only one sensor data.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ISO 13381-1; Condition Monitoring and Diagnostics of Machines—Prognostics—Part 1: General Guidelines. ISO: Geneva, Switzerland, 2015.

- Djeziri, M.A.; Benmoussa, S.; Zio, E. Review on Health Indices Extraction and Trend Modeling for Remaining Useful Life Estimation. In Artificial Intelligence Techniques for a Scalable Energy Transition; Springer: Berlin/Heidelberg, Germany, 2020; pp. 183–223. [Google Scholar]

- Park, Y.J.; Fan, S.K.S.; Hsu, C.Y. A review on fault detection and process diagnostics in industrial processes. Processes 2020, 8, 1123. [Google Scholar] [CrossRef]

- Kordestani, M.; Saif, M.; Orchard, M.E.; Razavi-Far, R.; Khorasani, K. Failure prognosis and applications—A survey of recent literature. IEEE Trans. Reliab. 2019, 70, 728–748. [Google Scholar] [CrossRef]

- Djeziri, M.; Djedidi, O.; Benmoussa, S.; Bendahan, M.; Seguin, J.L. Failure Prognosis Based on Relevant Measurements Identification and Data-Driven Trend-Modeling: Application to a Fuel Cell System. Processes 2021, 9, 328. [Google Scholar] [CrossRef]

- Li, N.; Lei, Y.; Yan, T.; Li, N.; Han, T. A Wiener-process-model-based method for remaining useful life prediction considering unit-to-unit variability. IEEE Trans. Ind. Electron. 2018, 66, 2092–2101. [Google Scholar] [CrossRef]

- Cui, L.; Wang, X.; Wang, H.; Ma, J. Research on remaining useful life prediction of rolling element bearings based on time-varying Kalman filter. IEEE Trans. Instrum. Meas. 2019, 69, 2858–2867. [Google Scholar] [CrossRef]

- Moulahi, M.H.; Ben Hmida, F. Using extended Kalman filter for failure detection and prognostic of degradation process in feedback control system. Proc. Inst. Mech. Eng. Part I: J. Syst. Control. Eng. 2022, 236, 182–199. [Google Scholar] [CrossRef]

- Cong, X.; Zhang, C.; Jiang, J.; Zhang, W.; Jiang, Y.; Jia, X. An improved unscented particle filter method for remaining useful life prognostic of Lithium-ion batteries with Li(NiMnCo)O2 cathode with capacity diving. IEEE Access 2020, 8, 58717–58729. [Google Scholar] [CrossRef]

- Kukurowski, N.; Pazera, M.; Witczak, M. Takagi–Sugeno Observer Design for Remaining Useful Life Estimation of Li-Ion Battery System under Faults. Electronics 2020, 9, 1537. [Google Scholar] [CrossRef]

- Ekanayake, T.; Dewasurendra, D.; Abeyratne, S.; Ma, L.; Yarlagadda, P. Model-based fault diagnosis and prognosis of dynamic systems: A review. Procedia Manuf. 2019, 30, 435–442. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, S.A.; Islam, M.M.; Kim, J.M. A reliable technique for remaining useful life estimation of rolling element bearings using dynamic regression models. Reliab. Eng. Syst. Saf. 2019, 184, 67–76. [Google Scholar] [CrossRef]

- Zhong, K.; Han, M.; Han, B. Data-driven based fault prognosis for industrial systems: A concise overview. IEEE/CAA J. Autom. Sin. 2019, 7, 330–345. [Google Scholar] [CrossRef]

- Benmoussa, S.; Djeziri, M.A.; Sanchez, R. Support Vector Machine Classification of Current Data for Fault Diagnosis and Similarity-Based Approach for Failure Prognosis in Wind Turbine Systems. In Artificial Intelligence Techniques for a Scalable Energy Transition; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–182. [Google Scholar]

- Motahari-Nezhad, M.; Jafari, S.M. ANFIS system for prognosis of dynamometer high-speed ball bearing based on frequency domain acoustic emission signals. Measurement 2020, 166, 108154. [Google Scholar] [CrossRef]

- Arunthavanathan, R.; Khan, F.; Ahmed, S.; Imtiaz, S. A deep learning model for process fault prognosis. Process Saf. Environ. Prot. 2021, 154, 467–479. [Google Scholar] [CrossRef]

- Dong, L.J.; Tang, Z.; Li, X.B.; Chen, Y.C.; Xue, J.C. Discrimination of mining microseismic events and blasts using convolutional neural networks and original waveform. J. Cent. South Univ. 2020, 27, 3078–3089. [Google Scholar] [CrossRef]

- Tang, S.J.; Yu, C.Q.; Feng, Y.B.; Xie, J.; Gao, Q.H.; Si, X.S. Remaining useful life estimation based on Wiener degradation processes with random failure threshold. J. Cent. South Univ. 2016, 23, 2230–2241. [Google Scholar] [CrossRef]

- Nor, A.K.M.; Pedapati, S.R.; Muhammad, M.; Leiva, V. Overview of Explainable Artificial Intelligence for Prognostic and Health Management of Industrial Assets Based on Preferred Reporting Items for Systematic Reviews and Meta-Analyses. Sensors 2021, 21, 8020. [Google Scholar] [CrossRef]

- Dauphin-Tanguy, G. Les bond graphs et leur application en mécatronique. Tech. L’ingénieur. Inform. Ind. 1999, 9 (Suppl. 7222), 1–24. [Google Scholar] [CrossRef]

- Borutzky, W. Bond Graph Methodology: Development and Analysis of Multidisciplinary Dynamic System Models; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Baraldi, P.; Bonfanti, G.; Zio, E. Differential evolution-based multi-objective optimization for the definition of a health indicator for fault diagnostics and prognostics. Mech. Syst. Signal Process. 2018, 102, 382–400. [Google Scholar] [CrossRef]

- Wang, Z.; Zarader, J.L.; Argentieri, S. A novel aircraft fault diagnosis and prognosis system based on Gaussian mixture models. In Proceedings of the 2012 12th International Conference on Control Automation Robotics & Vision (ICARCV), Guangzhou, China, 5–7 December 2012; IEEE: New Jersey, NJ, USA, 2012; pp. 1794–1799. [Google Scholar]

- Peng, Y.; Cheng, J.; Liu, Y.; Li, X.; Peng, Z. An adaptive data-driven method for accurate prediction of remaining useful life of rolling bearings. Front. Mech. Eng. 2018, 13, 301–310. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Zheng, Y.; Wang, K. Adaptive prognosis of centrifugal pump under variable operating conditions. Mech. Syst. Signal Process. 2019, 131, 576–591. [Google Scholar] [CrossRef]

- Ma, Y.F.; Jia, X.; Hu, Q.; Bai, H.; Guo, C.; Wang, S. A new state recognition and prognosis method based on a sparse representation feature and the hidden semi-markov model. IEEE Access 2020, 8, 119405–119420. [Google Scholar] [CrossRef]

- Wang, X.L.; Gu, H.; Xu, L.; Hu, C.; Guo, H. A SVR-based remaining life prediction for rolling element bearings. J. Fail. Anal. Prev. 2015, 15, 548–554. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. An integrated approach to bearing prognostics based on EEMD-multi feature extraction, Gaussian mixture models and Jensen-Rényi divergence. Appl. Soft Comput. 2018, 71, 36–50. [Google Scholar] [CrossRef]

- Sayah, M.; Guebli, D.; Noureddine, Z.; Al Masry, Z. Deep LSTM Enhancement for RUL Prediction Using Gaussian Mixture Models. Autom. Control Comput. Sci. 2021, 55, 15–25. [Google Scholar] [CrossRef]

- Yu, G.; Li, C.; Sun, J. Machine fault diagnosis based on Gaussian mixture model and its application. Int. J. Adv. Manuf. Technol. 2010, 48, 205–212. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S. Performance Degradation Prediction Based on a Gaussian Mixture Model and Optimized Support Vector Regression for an Aviation Piston Pump. Sensors 2020, 20, 3854. [Google Scholar] [CrossRef]

- Yu, J. Bearing performance degradation assessment using locality preserving projections and Gaussian mixture models. Mech. Syst. Signal Process. 2011, 25, 2573–2588. [Google Scholar] [CrossRef]

- Bektas, O.; Jones, J.A.; Sankararaman, S.; Roychoudhury, I.; Goebel, K. A neural network filtering approach for similarity-based remaining useful life estimation. Int. J. Adv. Manuf. Technol. 2019, 101, 87–103. [Google Scholar] [CrossRef] [Green Version]

- Yu, W.; Kim, I.Y.; Mechefske, C. An improved similarity-based prognostic algorithm for RUL estimation using an RNN autoencoder scheme. Reliab. Eng. Syst. Saf. 2020, 199, 106926. [Google Scholar] [CrossRef]

- Wang, T.; Yu, J.; Siegel, D.; Lee, J. A similarity-based prognostics approach for remaining useful life estimation of engineered systems. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1–6. [Google Scholar]

- Cai, H.; Jia, X.; Feng, J.; Li, W.; Pahren, L.; Lee, J. A similarity based methodology for machine prognostics by using kernel two sample test. ISA Trans. 2020, 103, 112–121. [Google Scholar] [CrossRef]

- Shu, J.; Xu, Y.; Jin, X.; Han, D.; Xia, T. A Novel Similarity-based Method for Remaining Useful Life Prediction under Multiple Fault Modes. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing), Nanjing, China, 15–17 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–7. [Google Scholar]

- Benmoussa, S.; Djeziri, M.A. Remaining useful life estimation without needing for prior knowledge of the degradation features. IET Sci. Meas. Technol. 2017, 11, 1071–1078. [Google Scholar] [CrossRef]

- Benmoussa, S.; Djeziri, M. Experimental Application on a Mechanical Transmission System of Integrated Fault Diagnosis and Fault Prognosis method. IFAC-PapersOnLine 2018, 51, 1016–1023. [Google Scholar] [CrossRef]

| Nominal Values | Unit | Uncertainties | |

|---|---|---|---|

| (N.m.s.rad) | |||

| (Kg.m) | |||

| K | (N.m.rad) | ||

| N | − | ||

| (N.m.s.rad) | |||

| (Kg.m) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mebarki, N.; Benmoussa, S.; Djeziri, M.; Mouss, L.-H. New Approach for Failure Prognosis Using a Bond Graph, Gaussian Mixture Model and Similarity Techniques. Processes 2022, 10, 435. https://doi.org/10.3390/pr10030435

Mebarki N, Benmoussa S, Djeziri M, Mouss L-H. New Approach for Failure Prognosis Using a Bond Graph, Gaussian Mixture Model and Similarity Techniques. Processes. 2022; 10(3):435. https://doi.org/10.3390/pr10030435

Chicago/Turabian StyleMebarki, Nassima, Samir Benmoussa, Mohand Djeziri, and Leïla-Hayet Mouss. 2022. "New Approach for Failure Prognosis Using a Bond Graph, Gaussian Mixture Model and Similarity Techniques" Processes 10, no. 3: 435. https://doi.org/10.3390/pr10030435

APA StyleMebarki, N., Benmoussa, S., Djeziri, M., & Mouss, L.-H. (2022). New Approach for Failure Prognosis Using a Bond Graph, Gaussian Mixture Model and Similarity Techniques. Processes, 10(3), 435. https://doi.org/10.3390/pr10030435