Study of Patterns of Movement of Groups of Seed Potatoes in Conical Seed Box Based on the Dem-Model of the Process

Abstract

:1. Introduction

2. Theoretical Analyses

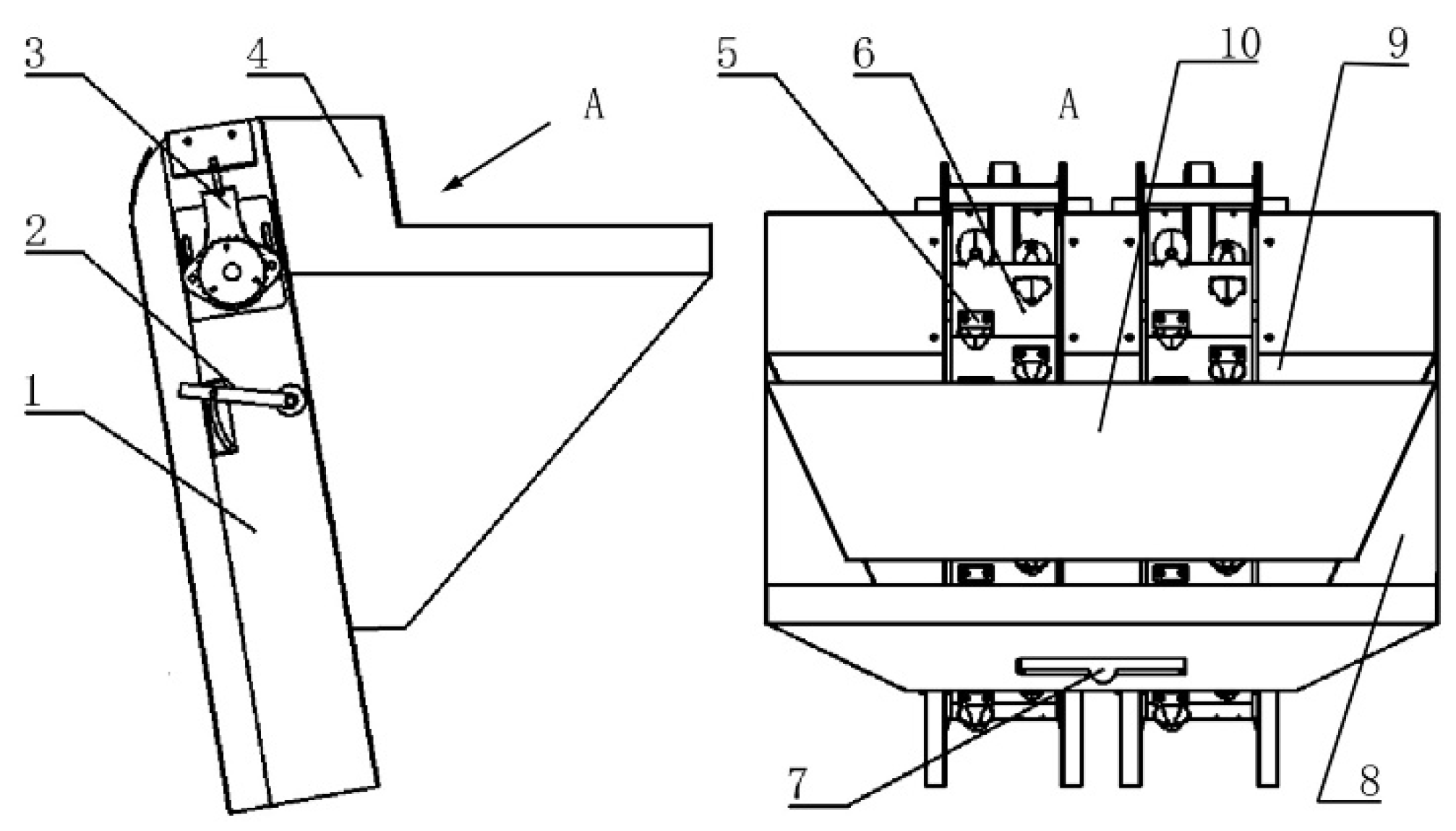

2.1. Cross-Angle Seed-Box Seed-Metering Device

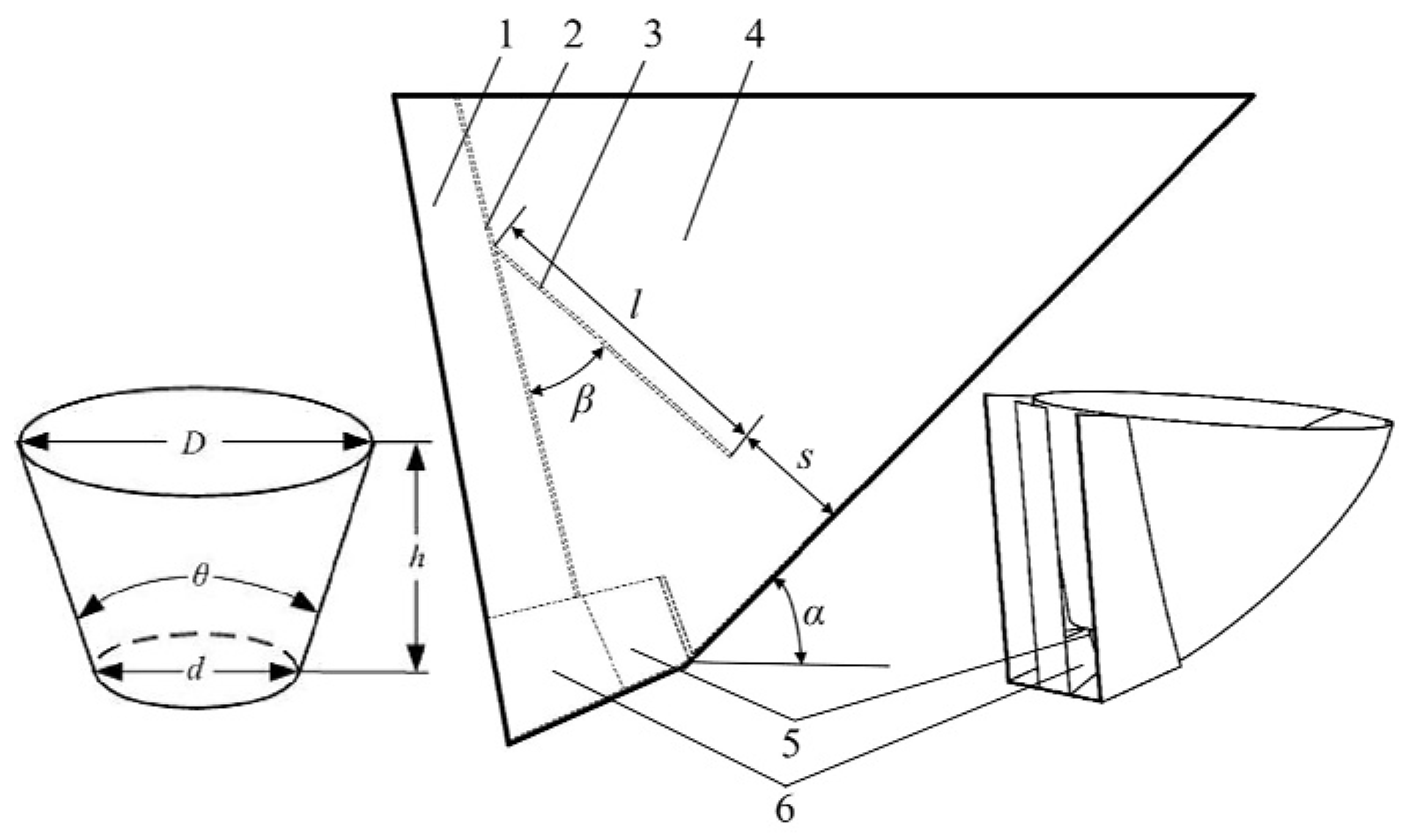

2.2. Kinetic Analysis of Seed Potato in the Seed Box

2.3. Establishment of Test Factors

2.3.1. Overall Structure of Conical Seed Box

2.3.2. Parameter (Angle) α Establishment of Parameter Range

2.3.3. Parameter (Angle) θ Establishment of Parameter Range

2.3.4. Establishment of the Length Parameter Range of the Drainage Plate in the Seed Box (l)

3. Tests and Methods

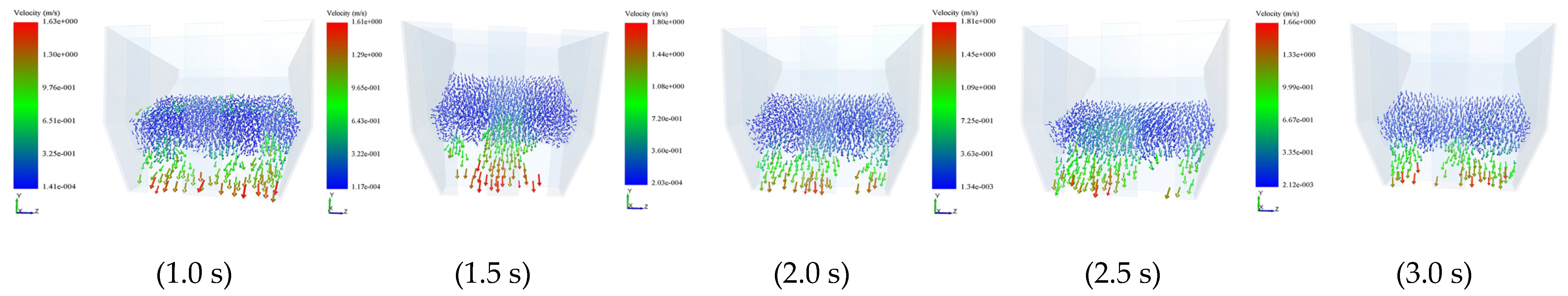

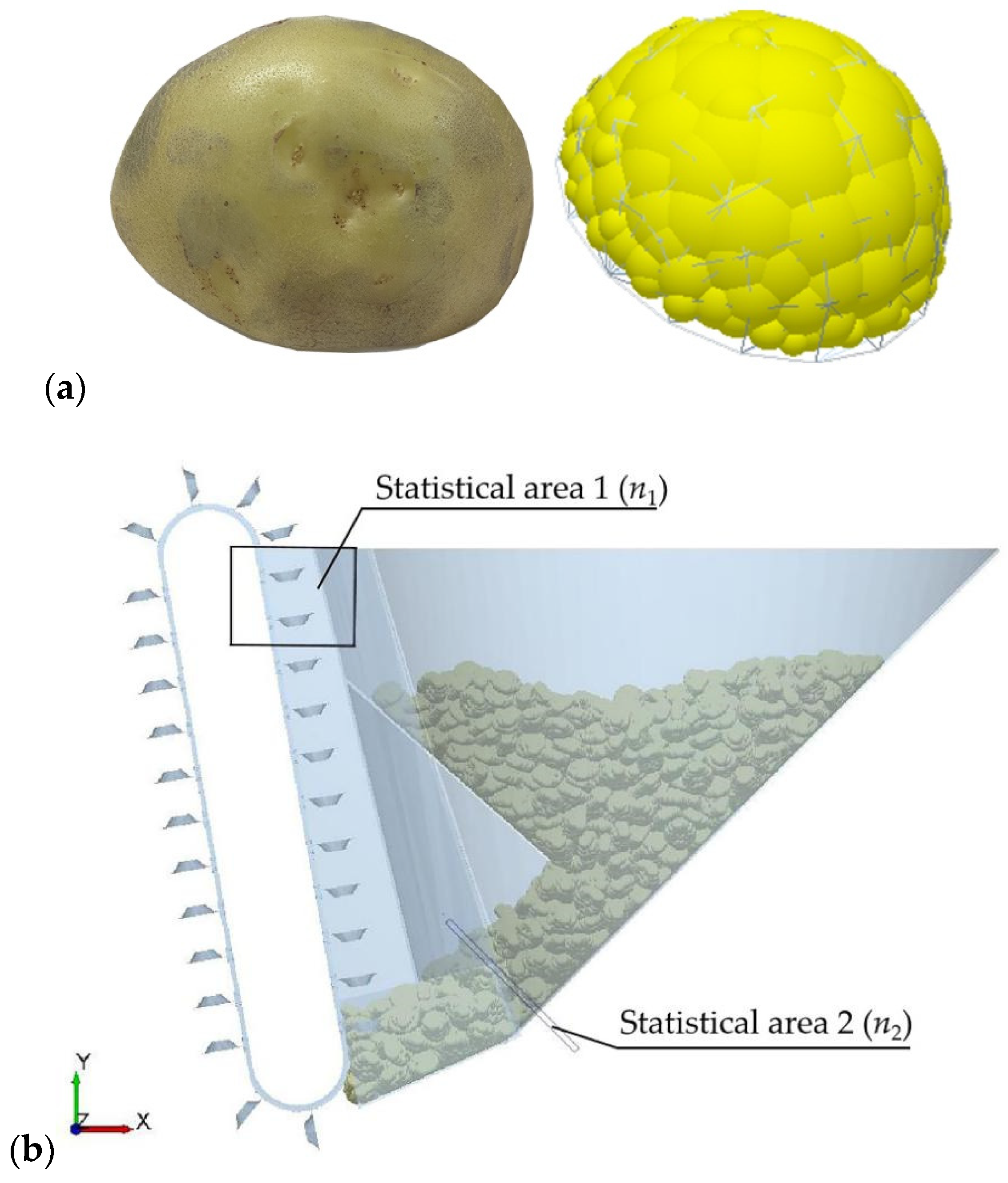

3.1. Model Establishment and Parameter Setting

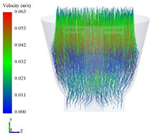

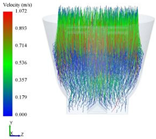

3.2. Single-Factor Simulation Test and Discussion

3.2.1. Test Evaluation Index

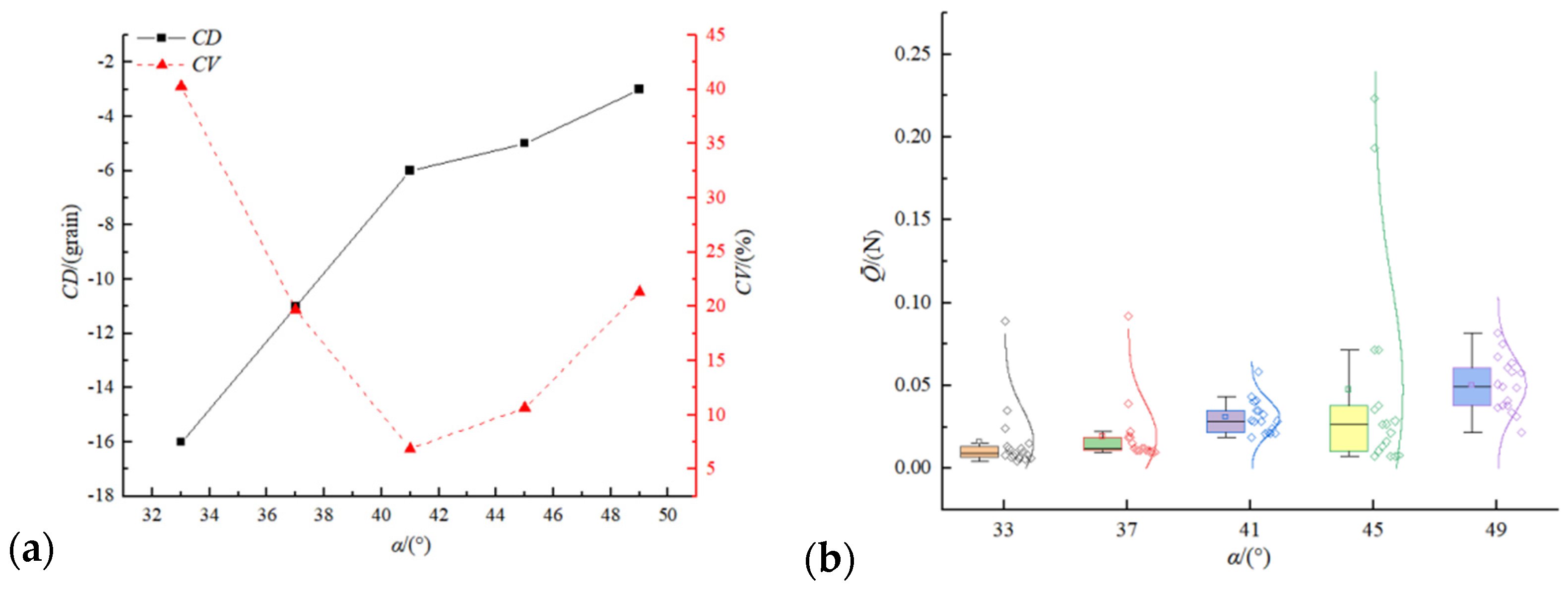

3.2.2. Parameter (Angle) α Single-Factor Simulation Tests and Analysis

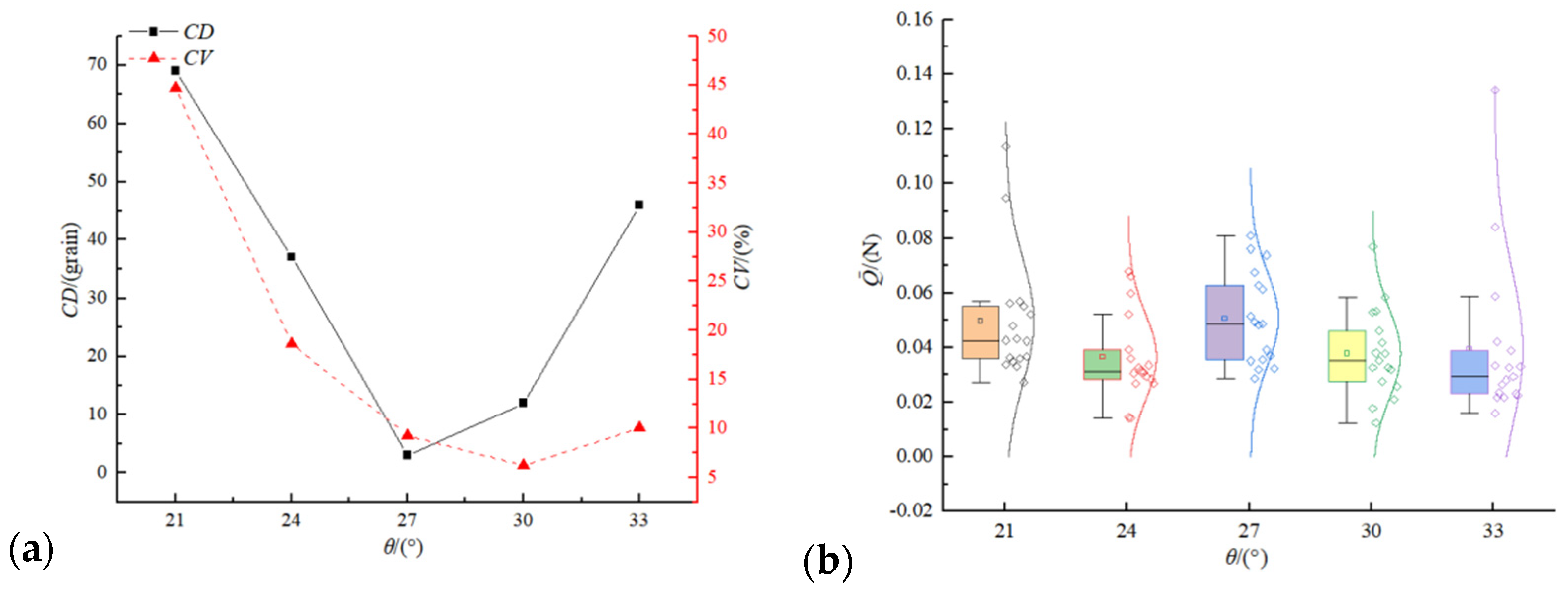

3.2.3. Parameter (Angle) θ Single-Factor Simulation Tests and Analysis

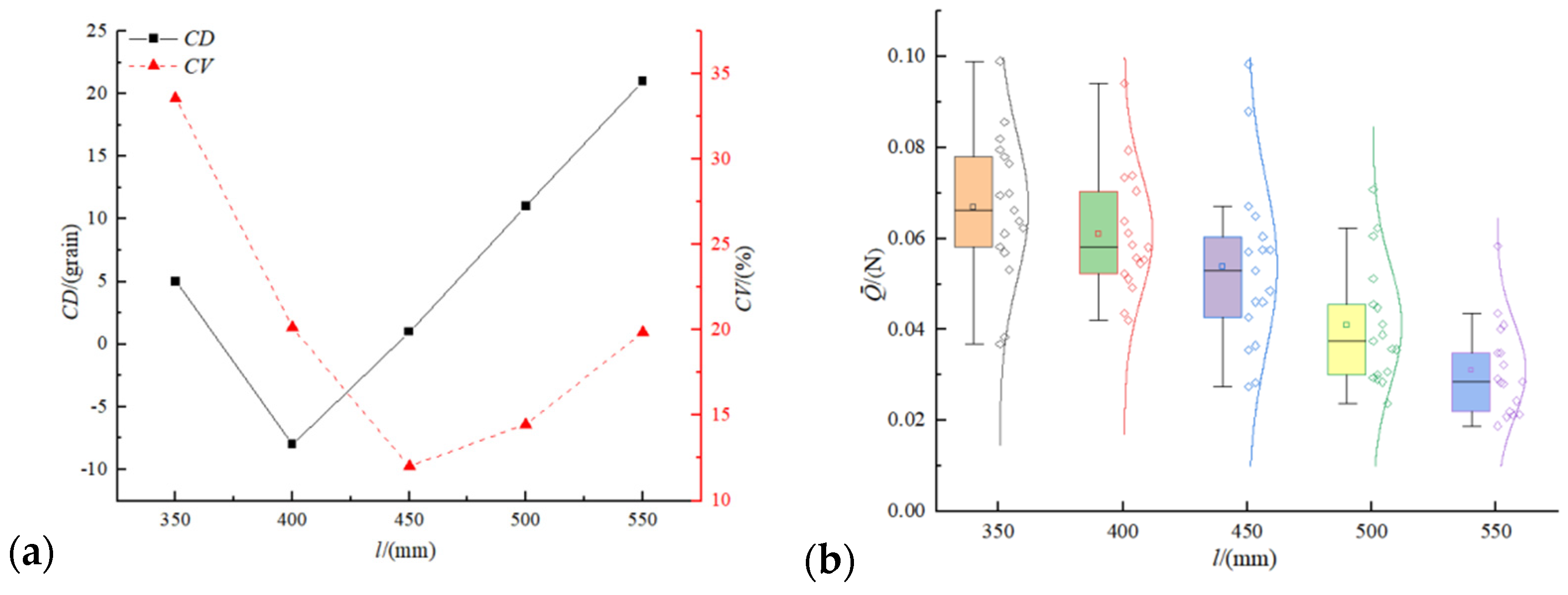

3.2.4. Parameter (Length) l Single-Factor Simulation Tests and Analysis

3.3. Orthogonal Simulation Test and Discussion

3.3.1. Experimental Design

3.3.2. Test Results and Discussion

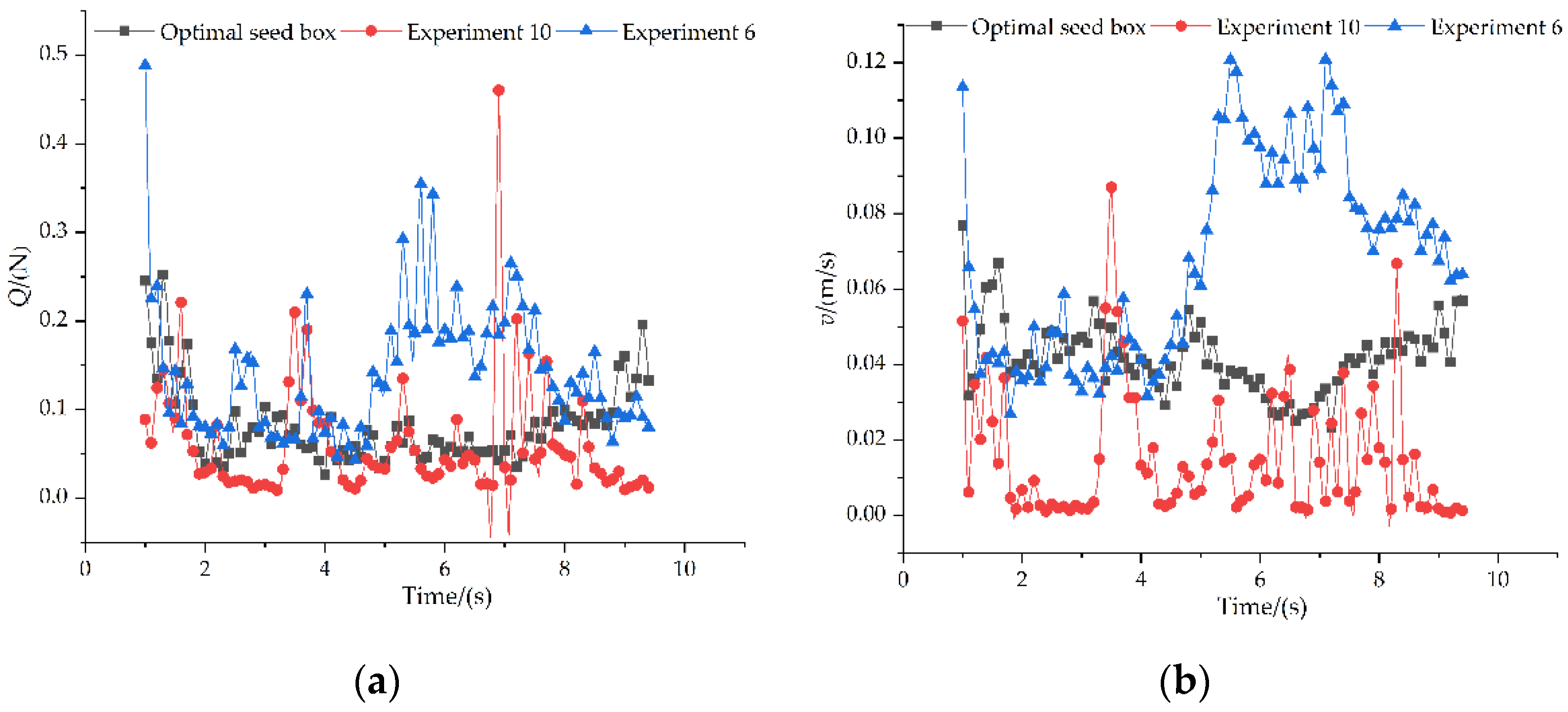

4. Bench-Verification Test and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.Y. Design of the fertilizing and seeding module of the small multifunctional agricultural machinery. Mod. Mach. 2016, 3, 5–11. [Google Scholar]

- Song, Y.P. Key Components Design of Potato Micro Seed Planter. Trans. Chin. Soc. Agric. Eng. 2018, 8, 3–14. [Google Scholar]

- Hu, J.P.; Guo, K.Z.; Chun, J.; Hou, C. Simulation and Experiment of Supplying Seeds in Box of Magnetic Precision Cylinder-seeder. Trans. Chin. Soc. Agric. Mech. 2014, 45, 61–65. [Google Scholar] [CrossRef]

- Niu, K.; Yuan, Y.; Luo, M.; Liu, Y.C.; Lv, C.X.; Fang, X.F. Design and experiment of potato metering device with double-deck seed tank. Trans. Chin. Soc. Agric. Mech. 2016, 32, 8–19. [Google Scholar] [CrossRef]

- Li, X.M.; Zhang, Z.L.; Wang, J.L. Roller Pneumatic Tray Seeding Machine Box Structure Design and Experimental Study. J. Agric. Mech. Res. 2012, 9, 5–9. [Google Scholar] [CrossRef]

- Chen, H.B. Rational Design of Solid Silo. Chem. Eq. Technol. 1995, 16, 4–7. [Google Scholar]

- Wang, L.W. Summary of arch-building mechanism and arch-breaking ways of materials in hopper. Foundry Equip. Technol. 1982, 4, 70–79. [Google Scholar]

- Jenike, A.W. Quantitative design of mass-flow bins. Powder Technol. 1967, 1, 237–244. [Google Scholar] [CrossRef]

- Ban, H.; Roh, S.; Park, W.J. Performance Evaluation of Buried Concrete Pipe Considering Soil Pressure and Crack Propagation Using 3D Finite Element Analysis. Appl. Sci. 2021, 11, 3292. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, M.; Zhou, P.; Zhao, Z.; Li, X.; Xu, X.; Song, X. Analysis of Earth Pressure Variation for Partial Displacement of Retaining Wall. Appl. Sci. 2021, 11, 4152. [Google Scholar] [CrossRef]

- Ma, Z.R.; Gao, L.; Zhong, Y.L.; Ma, S.; An, B.L. Arching Detection Method of Slab Track in High-Speed Railway Based on Track Geometry Data. Appl. Sci. 2020, 10, 6799. [Google Scholar] [CrossRef]

- Nikiitenko, A.V. Mathematical simulation of the arch formation process of the loose protecting filtering material in the load box of the drainage machine bunker. Prirodoobustroistvo 2010, 1, 89–93. [Google Scholar]

- CEN. Design of Steel Structures: Part 1–6. General Rules—Supplementary Rules for the Shell Structures; CEN: Brussels, Belgium, 2002; p. 83. [Google Scholar]

- Izmaylov, A.Y.; Kolchin, N.N.; Lobachevskiy, Y.P.; Kynev, N.G. Modern technologies and special equipment for potato production Following materials of the Potato Europe 2014 exhibition part 1. Сельскoхoзяйственные Машины И Технoлoгии 2015, 2. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Mousaviraad, M.; Rosentrater, K.A. Discrete Element Model Calibration Using Multi-Responses and Simulation of Corn Flow in a Commercial Grain Auger. Trans. ASABE 2018, 61, 1743–1755. [Google Scholar] [CrossRef]

- Zhou, M.; Hua, Z.; Wang, J.; Lei, W.; Yin, D. New type of transverse moving box mechanism for pot seedling transplanting machine. Int. J. Agric. Biol. Eng. 2018, 11, 70–75. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Li, H.; Wang, Q.; He, J.; Liu, P. Anti-blocking performance of ultrahigh-pressure waterjet assisted furrow opener for no-till seeder. Int. J. Agric. Biol. Eng. 2020, 13, 64–70. [Google Scholar] [CrossRef]

- Yang, P.; Li, L.; Aubertin, M. Theoretical and Numerical Analyses of Earth Pressure Coefficient along the Centerline of Vertical Openings with Granular Fills. Appl. Sci. 2018, 8, 1721. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.L. The development of wood particulate to bridge over openings abroad. Fores. Grass. Mach. 2014, 25, 56–57. [Google Scholar]

- Lv, J.Q.; Yang, X.H.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and Test of Seed Potato Cutting Device with Vertical and Horizontal Knife Group. Trans. Chin. Soc. Agric. Mech. 2020, 51, 89–97. [Google Scholar] [CrossRef]

- Liu, J.Y. Phenomenon analysis and elimination means of bulk material bridging in storage daybin. Chin. Rubb. Tech. Equip. 2016, 21, 4–11. [Google Scholar]

- Zhao, X.; Huang, Y.; Chen, S.; Li, J. Study and Test of Potato Planter with Filming and Piping Device. J. Agric. Mechan. Res. 2018, 40, 124–129. [Google Scholar]

- Ketterhagen, W.R.; Curtis, J.S.; Wassgren, C.R.; Hancock, B.C. Predicting the flow mode from hoppers using the discrete element method. Powder Technol. 2009, 195, 1–10. [Google Scholar] [CrossRef]

- Jenike, A.W. Gravity Flow of Bulk Solids; Bulletin No. 108; Utah State University: Salt Lake, UT, USA, 1961. [Google Scholar]

- Deng, W.J.; Li, Z.W.; Qiu, X.L.; Wang, W.; Wu, X.; Zheng, D.K. The Research of Rice Liquidity and Arching Based on Crossed Diversion Seed-box. J. Agric. Mechan. Res. 2013, 12, 145–149. [Google Scholar]

- Lv, J.Q.; Yu, J.Y.; Feng, X.; Li, Z.H.; Yang, X.H.; Xin, Y.W. Analysis of physical characteristics of potato seed potato. In Proceedings of the Potato Industry and Healthy Consumption, Enshi, China, 25–28 May 2019. [Google Scholar]

- Kawakami, T.; Oohori, H.; Tajima, K. Seed potato production system in Japan starting from foundation seed of potato. Breed. Sci. 2015, 65, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Akita, M.; Ohta, Y. A simple method for mass propagation of potato (Solanum tuberosum L.) using a bioreactor without forced aeration. Plant. Cell. Rep. 1998, 18, 284–287. [Google Scholar] [CrossRef]

- Shi, L.; Sun, W.; Zhao, W. Parameter determination and validation of discrete element model of seed potato mechanical seeding. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–42. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Shi, L. Determination of restitution coefficient of potato tubers collision in harvest and analysis of its influence factors. Chin. Soc. Agric. Eng. 2017, 13, 58–65. [Google Scholar] [CrossRef]

- Lobo-Guerrero, S.; Vallejo, L.E. Fibre-reinforcement of granular materials: DEM visualisation and analysis. Geomech. Geoengin. 2010, 5, 79–89. [Google Scholar] [CrossRef]

- Bourrier, F.; Kneib, F.; Chareyre, B.; Fourcaud, T. Discrete modeling of granular soils reinforcement by plant roots. Ecol. Eng. 2013, 61, 646–657. [Google Scholar] [CrossRef]

- Norman-Ham, H.A.; Hanna, M.H.; Richard, T.L. Solid Manure Distribution by Rear- and Side-Delivery Spreaders. Trans. ASABE 2008, 51, 831–843. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Zhou, M.C.; Li, H.R.; Jiang, Z.H. Experiment on Dynamic Droplet Distribution Uniformity for PWM Variable Spray System. Trans. Chin. Soc. Agric. Mach. 2015, 46. [Google Scholar] [CrossRef]

- Zhang, J.X.; Rui, Z.Y.; Cai, J.L.; Wang, Y.C.; Yeerbolati, T.; Gao, Z.M. Design and Test of Front Mounted Belt Clamping and Conveying Cotton-stalk Pulling Device. Trans. Chin. Soc. Agric. Mach. 2017, 13, 1–9. [Google Scholar]

- Solhi, L.; Sun, H.S.; Daswani, S.H.; Shojania, S.; Springate, C.M.; Brumer, H. Controlled sulfation of mixed-linkage glucan by Response Surface Methodology for the development of biologically applicable polysaccharides. Carbohydr. Polym. 2021, 269, 118275. [Google Scholar] [CrossRef]

- Zhao, X.X. Design and Seed Metering Performance of Potato Seed Metering Device; Shihezi University: Xinjiang, China, 2017. [Google Scholar]

| Material or Contact | Property | Value | Source |

|---|---|---|---|

| Seed | Dimensions (maximum diameter × thickness) (mm2) | φ55 × 27 | Measuring |

| Density (kg/m3) | 1048 | [29] | |

| Shear modulus (Pa) | 1.336 × 106 | [29] | |

| Poisson’s ratio | 0.57 | [29] | |

| Machine | Density (kg/m3) | 7800 | EDEM2018 software material library |

| Shear modulus (Pa) | 7 × 1010 | EDEM2018 software material library | |

| Poisson’s ratio | 0.30 | EDEM2018 software material library | |

| Seed-seed | Coefficient of restitution | 0.79 | [30] |

| Dynamic-friction coefficient | 0.452 | [29] | |

| Rolling-friction coefficient | 0.024 | [29] | |

| Seed-machine | Coefficient of restitution | 0.71 | [30] |

| Dynamic-friction coefficient | 0.445 | [29] | |

| Rolling-friction coefficient | 0.269 | [29] |

| Factors 1 | |||

|---|---|---|---|

| X1 | X2 | X3 | |

| Level | (α, °) | (θ, °) | (l, mm) |

| 1 | 41 | 24 | 400 |

| 0 | 45 | 27 | 450 |

| −1 | 49 | 30 | 500 |

| Evaluation Indicators | |||||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Y1 | Y2 | |

| Experiment | α | θ | l | CD (Grain) | CV (%) |

| 1 | −1 | −1 | 0 | 50 | 21.12 |

| 2 | 1 | −1 | 0 | 23 | 32.36 |

| 3 | −1 | 1 | 0 | 13 | 7.56 |

| 4 | 1 | 1 | 0 | 2 | 23.9 |

| 5 | −1 | 0 | −1 | −2 | 12.13 |

| 6 | 1 | 0 | −1 | −7 | 40.1 |

| 7 | −1 | 0 | 1 | 36 | 12.23 |

| 8 | 1 | 0 | 1 | −5 | 13.7 |

| 9 | 0 | −1 | −1 | 35 | 28.92 |

| 10 | 0 | 1 | −1 | 3 | 11.21 |

| 11 | 0 | −1 | 1 | 26 | 26.65 |

| 12 | 0 | 1 | 1 | 45 | 6.9 |

| 13 | 0 | 0 | 0 | 8 | 10.98 |

| 14 | 0 | 0 | 0 | −5 | 11.23 |

| 15 | 0 | 0 | 0 | −2 | 12.78 |

| 16 | 0 | 0 | 0 | 4 | 4.71 |

| 17 | 0 | 0 | 0 | 4 | 16.18 |

| Source of Variance | CD(Y1)/Grain | CV(Y2)/% | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | DF 1 | F | Significance level p 2 | Sum of Squares | DF 1 | F | Significance Level p 2 | |

| Model | 5202.07 | 9 | 10.76 | 0.0025 ** | 1441.31 | 9 | 7.56 | 0.0071 ** |

| X1 | 882.00 | 1 | 16.42 | 0.0049 ** | 406.41 | 1 | 19.18 | 0.0032 ** |

| X2 | 630.13 | 1 | 11.73 | 0.0111 * | 442.23 | 1 | 20.87 | 0.0026 ** |

| X3 | 666.13 | 1 | 12.40 | 0.0097 ** | 135.14 | 1 | 6.38 | 0.0395 * |

| X1X2 | 64.00 | 1 | 1.19 | 0.3112 | 6.50 | 1 | 0.31 | 0.5968 |

| X1X3 | 324.00 | 1 | 6.03 | 0.0437 * | 175.56 | 1 | 8.29 | 0.0237 * |

| X2X3 | 650.25 | 1 | 12.10 | 0.0103 * | 1.04 | 1 | 0.049 | 0.8310 |

| 2.53 | 1 | 0.047 | 0.8344 | 131.55 | 1 | 6.21 | 0.0415 * | |

| 1852.42 | 1 | 34.48 | 0.0006 ** | 84.11 | 1 | 3.97 | 0.0866 | |

| 84.32 | 1 | 1.57 | 0.2505 | 32.41 | 1 | 1.53 | 0.2560 | |

| Residual | 376.05 | 7 | 148.30 | 7 | ||||

| Lack of fit | 267.25 | 3 | 3.28 | 0.1409 | 78.84 | 3 | 1.51 | 0.3401 |

| Pure error | 108.80 | 4 | 69.46 | 4 | ||||

| Total | 5578.12 | 16 | 1589.61 | 16 | ||||

| Experiment | Simulation Time (s) | ||||

|---|---|---|---|---|---|

| 1 | 3 | 5 | 7 | 9 | |

| 6 |  |  |  |  |  |

| 10 |  |  |  |  |  |

| Optimal seed box |  |  |  |  |  |

| Test No. | Multiple Rate (%) | Missing Rate (%) | CVd 1 (%) |

|---|---|---|---|

| 1 | 5.42 | 2.34 | 9.74 |

| 2 | 6.11 | 2.71 | 10.48 |

| 3 | 5.09 | 2.91 | 11.61 |

| 4 | 4.74 | 1.93 | 9.27 |

| 5 | 5.37 | 2.51 | 11.05 |

| Average value | 5.346 | 2.48 | 10.43 |

| Test Index | Chinese National Standards | Intersection-Angle Seed Box | Conical Seed Box |

|---|---|---|---|

| Multiple Rate (%) | ≤20% | 10.11% | 5.35% |

| Missing Rate (%) | ≤13% | 6.48% | 2.48% |

| CVd 1(%) | ≤33% | 19.61% | 10.43% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, H.; Hu, B.; Chen, Y.; Luo, X.; Wang, J.; Mao, Z.; Yuan, C. Study of Patterns of Movement of Groups of Seed Potatoes in Conical Seed Box Based on the Dem-Model of the Process. Processes 2022, 10, 363. https://doi.org/10.3390/pr10020363

Cai H, Hu B, Chen Y, Luo X, Wang J, Mao Z, Yuan C. Study of Patterns of Movement of Groups of Seed Potatoes in Conical Seed Box Based on the Dem-Model of the Process. Processes. 2022; 10(2):363. https://doi.org/10.3390/pr10020363

Chicago/Turabian StyleCai, Hui, Bin Hu, Yong Chen, Xin Luo, Jian Wang, Zibin Mao, and Chenglin Yuan. 2022. "Study of Patterns of Movement of Groups of Seed Potatoes in Conical Seed Box Based on the Dem-Model of the Process" Processes 10, no. 2: 363. https://doi.org/10.3390/pr10020363

APA StyleCai, H., Hu, B., Chen, Y., Luo, X., Wang, J., Mao, Z., & Yuan, C. (2022). Study of Patterns of Movement of Groups of Seed Potatoes in Conical Seed Box Based on the Dem-Model of the Process. Processes, 10(2), 363. https://doi.org/10.3390/pr10020363