Selection of Agricultural Machinery Based on Improved CRITIC-Entropy Weight and GRA-TOPSIS Method

Abstract

:1. Introduction

2. Literature Review

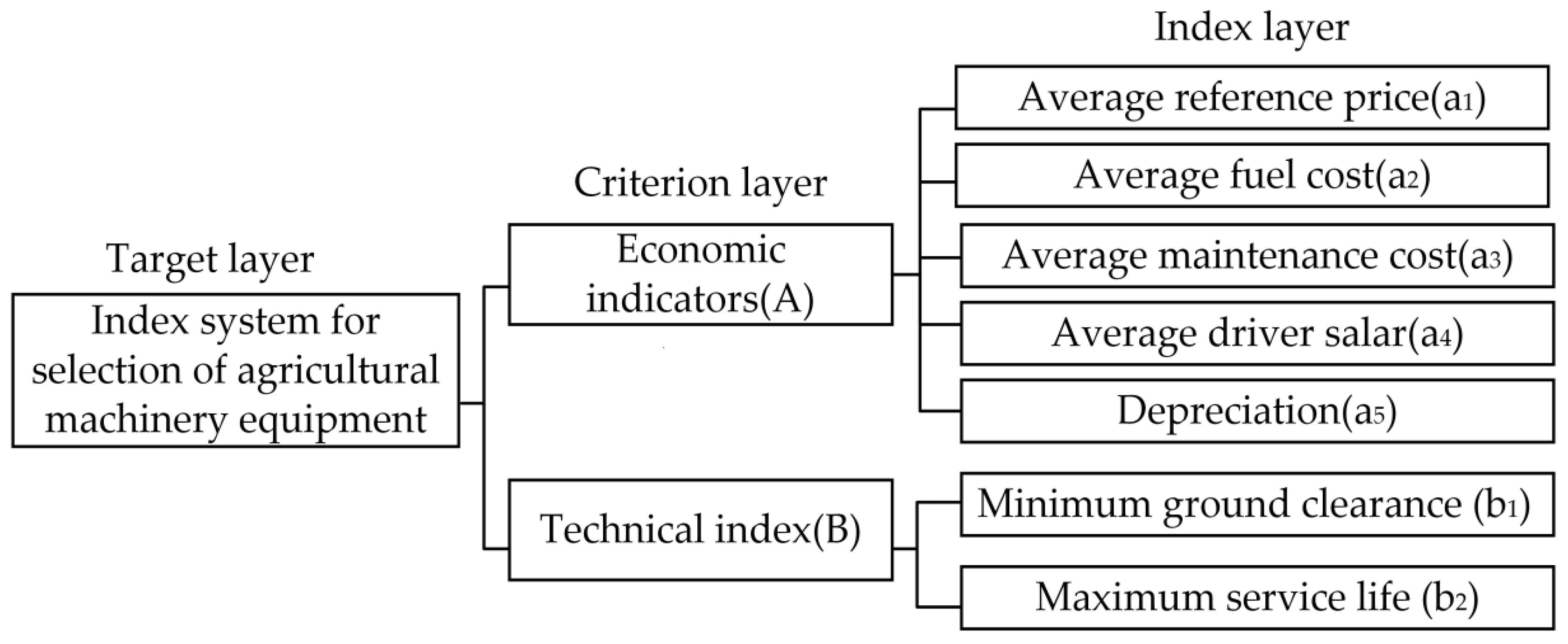

3. Construct an Innovative Evaluation Index Framework

4. Methodology

4.1. Research Framework

4.2. Standardization of Evaluation Indicators

4.3. Entropy Weight Method

4.4. CRITIC Method

4.5. CRITIC-Entropy Weight Method

4.6. GRA-TOPSIS Method

5. Case Study

5.1. Overview of the Study Area

5.2. Data Sources

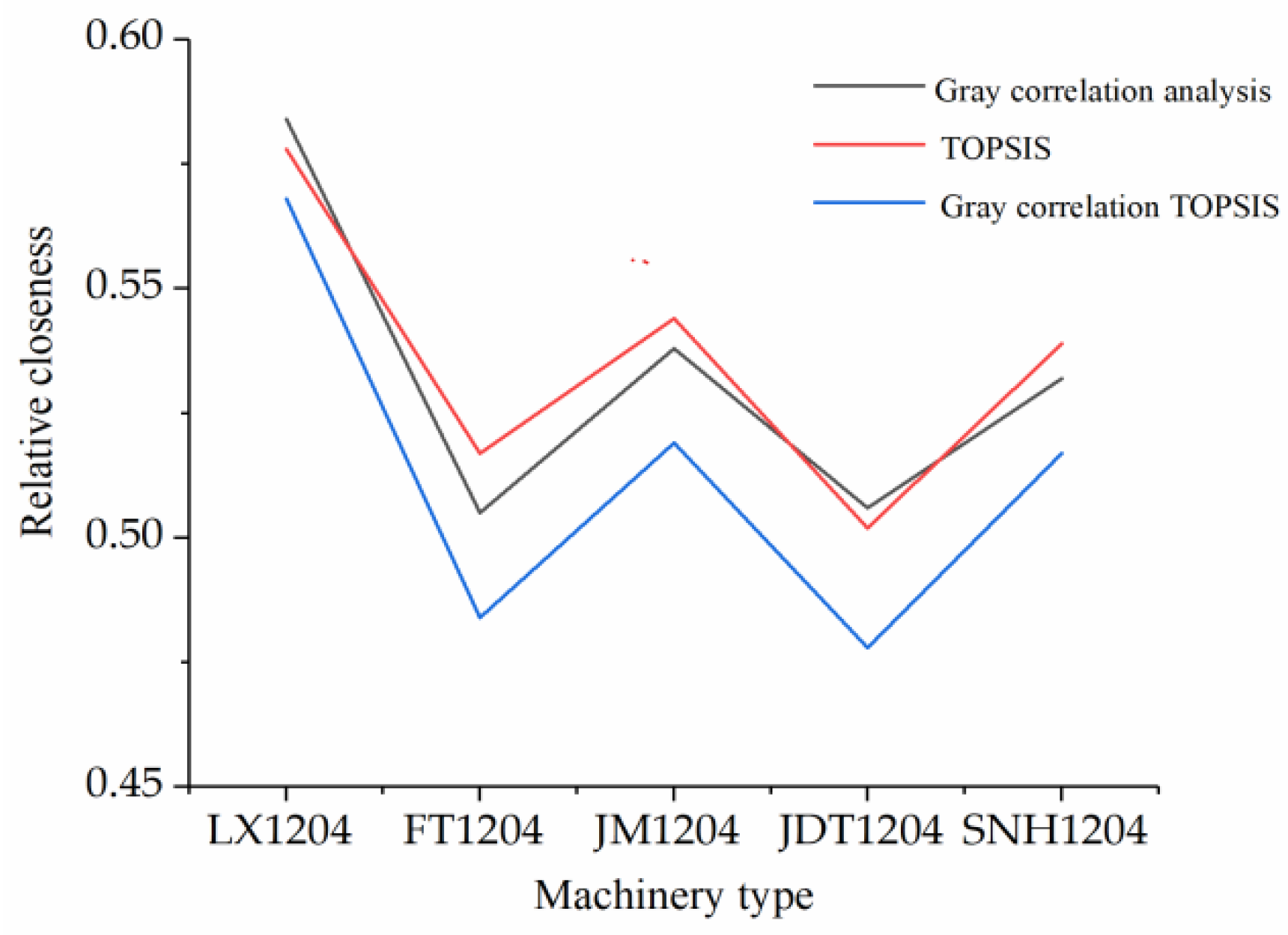

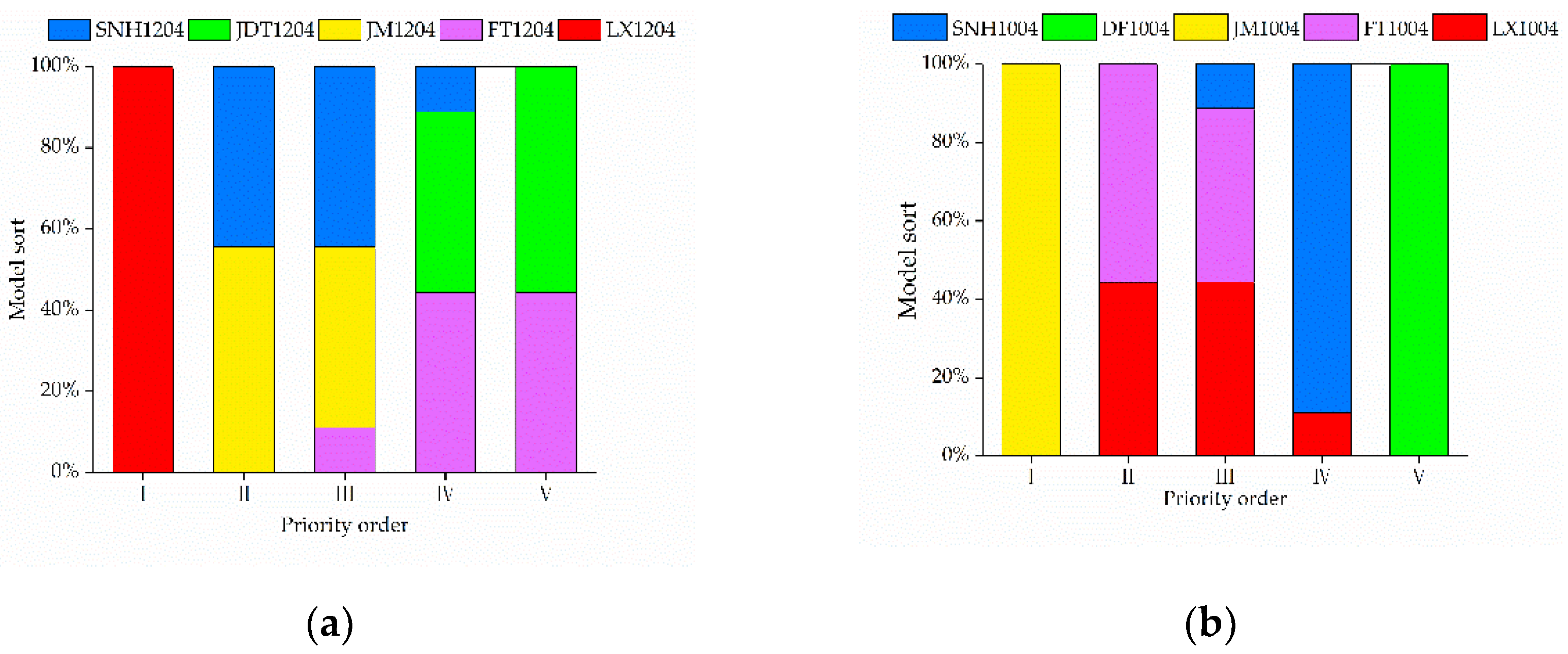

5.3. Results and Analysis

- (1)

- In the 88.2 kW power machinery, the comparison of LX1204 and JDT1204 exhibit that the two are of the same maximum service life and minimum ground gap. Although the average salary and average fuel cost of LX1204 are higher than those of JDT1204, LX1204 performs significantly better than JDT1204 after considering the average reference price, depreciation cost, and average maintenance cost indicators. Similarly, the comparison of the JM1204 and the FT1204 shows that the former is selected.

- (2)

- In the 73.5 kW power machinery, the comparison of LX1004 and DF1004 shows that when the maximum service life is the same, although the average salary and average fuel cost of DF1004 are lower than those of LX1004, LX1004 performs better than DF1004 after considering the average reference price, minimum ground gap, average maintenance cost, and depreciation cost indicators. Similarly, the comparison of the JM1004 and the FT1004 reveals that the former is selected.

- (3)

- For the same type of power machinery, the maximum service life of machinery with 88.2 kW is generally higher than that with 73.5 kW, whereas the price of machinery with 73.5 kW is lower than that with 88.2 kW. In the operation process of the regiment, for the operation projects of rice cutting, wheat farming, wheat soil preparation, and rice winter turning, the power machinery combination with 88.2 and 73.5 kW is used to complete the related agricultural operation projects due to the limitation of operation time. According to the ranking results, LX1204 in 88.2 kW and JM1004 in 73.5 kW are the optimal operating machinery sets.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, L.; Dan, J. The Application of Improved Gray Relational Model in Agricultural Equipment Selection. J. Agric. Mech. Res. 2014, 36, 40–42. [Google Scholar]

- Cao, L.; Cao, G.Q. Agricultural Machinery Selection Method Research When the Land Scare is Limited. J. Jiangxi Agric. Univ. 2013, 12, 300–304. [Google Scholar]

- Yan, X.H. Comprehensive Evaluation Model of Farm Machinery Selection Base on Closeness Degree. J. Lang Fang Teach. Coll. 2011, 11, 75–77. [Google Scholar]

- Meng, X.; Meng, J.; Ge, J. Application of Accumulation Factor in Analytic Hierarchy Process in Farm Machinery Selection. J. Agric. Mech. Res. 2009, 31, 93–95. [Google Scholar]

- Huang, D.M.; Zhou, Q.; Nie, J.M. Optimized Method Based on Value Engineering for Agricultural Machinery Lectotype and Mating Scheme. J. Agric. Mech. Res. 2004, 5, 90–91. [Google Scholar]

- Zhang, F.; Chen, T.; Teng, S.; Wang, J.; Xu, R.; Guo, Z. Model construction for field operation machinery selection and configuration in wheat-maize double cropping system. Int. J. Agric. Biol. Eng. 2021, 14, 8. [Google Scholar] [CrossRef]

- Yan, X.; Li, M.U. Appliance on Evaluation of Type Selection for Agricultural Machinery Based on Grey Relational Analysis Method. Appl. Mech. Mater. 2011, 55, 988–991. [Google Scholar]

- Wu, C.; Shang, J. Research on model of agricultural machinery selection based on principal component projection. In Proceedings of the International Conference on Electronic & Mechanical Engineering & Information Technology, Harbin, China, 12–14 August 2011. [Google Scholar]

- Yousif, L.A. Crop-machinery management system for field operations and farm machinery selection. J. Agric. Biotechnol. Sustain. Dev. 2013, 5, 84–90. [Google Scholar] [CrossRef] [Green Version]

- Søgaard, H.T.; SøRensen, C.G. A Model for Optimal Selection of Machinery Sizes within the Farm Machinery System. Biosyst. Eng. 2004, 89, 13–28. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, Y.; Liu, M. Study on Selection of Agricultural Machinery Based on Fuzzy DEA Method. J. Agric. Mech. Res. 2018, 40, 14–18. [Google Scholar]

- Ning, B.; Shan, Z.; Mathematics, D.O.; University, L.N. Optimal Selection for Agricultural Machinery Equipments of Combinated Weight Based on AHP Method and Improved G1 Method. J. Agric. Mech. Res. 2016, 38, 33–37. [Google Scholar]

- Yan, X.H. Evaluation Model of Farm Machinery Selection Based on Similarity Coefficient and Distance. J. Anhui Agric. Sci. 2011, 39, 11888–11891. [Google Scholar]

- Zhou, Q. Research on optimal selection of agricultural machinery based on fuzzy neural network and support vector machine. Stat. Decis. 2010, 23, 46–48. [Google Scholar]

- Zhao, H.; Li, C.; Li, L.; Liu, G.; He, Z.; Zhao, G. Study on model selection evaluation of castor combine harvester based on entropy-weight TOPSIS method. J. Chin. Agric. Mech. 2019, 40, 174–178. [Google Scholar]

- Almalki, S.; Zhang, Z.; Siyal, Z.A.; Shaikh, G.M.; Almalki, O. An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability. Processes 2020, 8, 418. [Google Scholar] [CrossRef] [Green Version]

- Solangi, Y.A.; Tan, Q.; Mirjat, N.H.; Das Valasai, G.; Khan, M.W.A.; Ikram, M. An Integrated Delphi-AHP and Fuzzy TOPSIS Approach toward Ranking and Selection of Renewable Energy Resources in Pakistan. Processes 2019, 7, 118. [Google Scholar] [CrossRef] [Green Version]

- Abo-Sinna, M.A.; Amer, A.H.; Ibrahim, A.S. Extensions of TOPSIS for large scale multi-objective non-linear programming problems with block angular structure. Appl. Math. Model. 2008, 32, 292–302. [Google Scholar] [CrossRef]

- Beg, I.; Rashid, T. TOPSIS for hesitant fuzzy linguistic terms sets. Int. J. Intell. Syst. 2013, 28, 1162–1171. [Google Scholar] [CrossRef]

- Joshi, D.; Kumar, S. Intuitionistic fuzzy entropy and distance measure based TOPSIS method for multi-criteria decision making. Egypt. Inform. J. 2014, 15, 97–104. [Google Scholar] [CrossRef]

- Li, M.; Jin, L.; Wang, J. A new MCDM method combining QFD with TOPSIS for knowledge management system selection from the user’s perspective in intuitionistic fuzzy environment. Appl. Soft Comput. J. 2014, 21, 28–37. [Google Scholar] [CrossRef]

- Liu, Q. An extended TOPSIS method for multiple attribute decision making problems with unknown weight based on 2-dimension uncertain linguistic variables. J. Intell. Fuzzy Syst. 2014, 27, 2221–2230. [Google Scholar] [CrossRef]

- Wei, C.; Yan, F.; Rodríguez, R.M. Entropy measures for hesitant fuzzy sets and their application in multi-criteria decision-making. J. Intell. Fuzzy Syst. 2016, 31, 673–685. [Google Scholar] [CrossRef]

- Xu, Z.; Xia, M. Hesitant fuzzy entropy and cross-entropy and their use in multi-attribute decision-making. In Proceedings of the IEEE Globecom. IEEE Glob. Telecommun. Conf. 2007, 27, 799–822. [Google Scholar]

- Xu, Z.; Zhang, X. Hesitant fuzzy multi-attribute decision making based on TOPSIS with incomplete weight information. Knowl.-Based Syst. 2013, 52, 53–64. [Google Scholar] [CrossRef]

- Roszkowska, E.; Kusterka-Jefmańska, M.; Jefmański, B. Intuitionistic Fuzzy TOPSIS as a Method for Assessing Socioeconomic Phenomena on the Basis of Survey Data. Entropy 2021, 23, 563. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.N.; Huang, Y.F.; Cheng, I.F.; Nguyen, V. A Multi-Criteria Decision-Making (MCDM) Approach Using Hybrid SCOR Metrics, AHP, and TOPSIS for Supplier Evaluation and Selection in the Gas and Oil Industry. Processes 2018, 66, 252. [Google Scholar] [CrossRef] [Green Version]

- Sahu, R.K.; Raheman, H. A decision support system on matching and field performance prediction of tractor-implement system. Comput. Electron. Agric. 2008, 60, 76–86. [Google Scholar] [CrossRef]

- Bakhtiari, A.A.; Navid, H.; Hoseinzad, J. A Integer Linear Programming Agricultural Machinery Fleet Selection Model for Multi-cropping Systems. J. Agric. Sci. Sustain. Prod. 2011, 21, 40–43. [Google Scholar]

- Camarena, E.; Gracia, C.; Sixto, J. A Mixed Integer Linear Programming Machinery Selection Model for Multi-farm Systems. Biosyst. Eng. 2004, 87, 145–154. [Google Scholar] [CrossRef]

- Sakthivel, G.; Ilangkumaran, M.; Nagarajan, G.; Priyadharshini, G.V.; Kumar, S.D.; Kumar, S.S.; Suresh, K.S.; Selvan, G.T.; Thilakavel, T. Multi-criteria decision modelling approach for biodiesel blend selection based on GRA–TOPSIS analysis. Int. J. Ambient Energy 2014, 35, 139–154. [Google Scholar] [CrossRef]

- Qiao, X. Optimization of Model Selection of Agricultural Machines and Allocation. J. South China Univ. Trop. Agric. 2007, 13, 78–81. [Google Scholar]

- Chang, Y.; Hou, K.; Wu, Y.; Li, X.; Zhang, J. A conceptual framework for establishing the index system of ecological environment evaluation-A case study of the upper Hanjiang River, China. Ecol. Indic. 2019, 107, 105568. [Google Scholar] [CrossRef]

- Wu, Z.; Guan, J.; He, J. An Empirical Study on The Calculation of Minimum Wage Standard—Dynamic Combination Calculation Based on Objective Weight of CRITIC-Entropy Weight method. Mod. Econ. Sci. 2019, 41, 103–117. [Google Scholar]

- Tao, C.J.; Chen, W.H.; Lin, L.H. Empirical Analysis on the Evolution Synergy of China’s Industrial Organizations—Taking China’s IT industry under the background of enterprise integration as an example. Manag. World 2007, 12, 67–72. [Google Scholar]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining objective weights in multiple criteria problems: The critic method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Quan, H.; Li, S.; Wei, H.; Hu, J. Personalized Product Evaluation Based on GRA-TOPSIS and Kan sei Engineering. Symmetry 2019, 11, 867. [Google Scholar] [CrossRef] [Green Version]

- Xing, Y.; Wang, J.; Ma, W.; Zhu, Z.; Statistics, S.O. China’s “Wu hua” Coordinated Development Measure Based on Improved CRITIC-G1 Weighting Method. Stat. Decis. 2019, 35, 42–46. [Google Scholar]

- Chen, P. Effects of normalization on the entropy based TOPSIS method. Expert Syst. Appl. 2019, 136, 33–41. [Google Scholar] [CrossRef]

- Chen, C.H. A Novel Multi-Criteria Decision-Making Model for Building Material Supplier Selection Based on Entropy-AHP Weighted TOPSIS. Entropy 2020, 22, 259. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Mo, R. A Comprehensive Decision-Making Approach Based on Hierarchical Attribute Model for Information Fusion Algorithms’ Performance Evaluation. Math. Probl. Eng. Theory Methods Appl. 2014, 22, 124156.1–124156.13. [Google Scholar] [CrossRef]

- Tu, S.W.; Zheng, K.M.; Zhang, Y.; Deng, M.X. Research on Overall Risk Assessment Model Construction Safety of Freeway High Cutting Slope Engineering Based on Improved CRITIC Method and Cloud Model. Saf. Environ. Eng. 2019, 26, 127–132. [Google Scholar]

- Wang, S.; Wei, M.L.; Song, X.P.; Liu, W.; Song, L. Stability analysis of high stage backfill based on improved CRITIC-G1 method combined with weighted cloud model. J. Chongqing Univ. 2022, 1, 1–12. [Google Scholar]

- Zafar, S.; Alamgir, Z.; Rehman, M.H. An effective blockchain evaluation system based on entropy-CRITIC weight method and MCDM techniques. Peer-to-Peer Netw. Appl. 2021, 14, 3110–3123. [Google Scholar] [CrossRef]

- Kirubakaran, B.; Ilangkumaran, M. Selection of optimum maintenance strategy based on FAHP integrated with GRA–TOPSIS. Ann. Oper. Res. 2016, 245, 285–313. [Google Scholar] [CrossRef]

- Guru, S.; Mahalik, D.K. A comparative study on performance measurement of Indian public sector banks using AHP-TOPSIS and AHP-grey relational analysis. Opsearch 2019, 56, 1213–1239. [Google Scholar] [CrossRef]

- Celik, E.; Erdogan, M.; Gumus, A.T. An extended fuzzy TOPSIS–GRA method based on different separation measures for green logistics service provider selection. Int. J. Environ. Sci. Technol. 2016, 13, 1377–1392. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Sun, H.; Liu, N.; Zhou, D.; Taghizadeh-Hesary, F. Measuring Carbon Market Transaction Efficiency in the Power Industry: An Entropy-Weighted TOPSIS Approach. Entropy 2020, 22, 973. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Garg, H. Algorithm for Multiple Attribute Decision-Making with Interactive Archimedean Norm Operations Under Pythagorean Fuzzy Uncertainty. Int. J. Comput. Intell. Syst. 2021, 14, 503–527. [Google Scholar] [CrossRef]

| First-Level Indicator | Second-Level Indicator and Code | Meaning of Indicator | Property |

|---|---|---|---|

| Average reference price (a1) | Average purchase price of multiple agricultural machinery | − | |

| Average fuel cost (a2) | Average fuel cost per unit area of multiple agricultural machinery | − | |

| Economic indicator (A) | Average maintenance (a3) | Average repair cost per unit area of multiple agricultural machinery | − |

| Average salary (a4) | Average salary of drivers per unit of work area | − | |

| Depreciation fee (a5) | Value of agricultural machinery lost over time and application | − | |

| Minimum ground gap (b1) | Measure of the technical performance suitable for agricultural operations | − | |

| Maximum service life (b2) | Longest service life of agricultural machinery | + | |

| Average operating efficiency (b3) | Average operating time per unit area of multiple agricultural machinery | + | |

| Average workload (b4) | Average daily working area of multiple agricultural machinery | + | |

| Working period (b5) | Annual working days | + | |

| Failure rate (b6) | Failure probability of agricultural machinery in unit time | − | |

| Technical indicator (B) | Technological advancement (b7) | Application of high technology in agricultural machinery | + |

| Operation convenience (b8) | Easy to operate and manipulate | + | |

| Machine safety and comfort (b9) | Guarantee safe operation and environmental protection performances | + | |

| Part interchangeability (b10) | The generalization and standardization degrees of parts and the availability of parts | + | |

| Machine adaptability (b11) | Satisfaction of local terrain characteristics, production scale, etc. | + | |

| Agricultural machinery repair and maintenance spots (c1) | Agricultural machinery repair and maintenance spots and aftersales service level | + | |

| Growth rate of trained agricultural machinery operators (c2) | Increase in the number of agricultural machinery operators this year compared with that last year | + | |

| Social indicator (C) | Farmer responsiveness (c3) | Active response and extensive participation of farmers | + |

| Farmer satisfaction (c4) | Farmers’ satisfaction with the application of agricultural machinery | + | |

| Related agricultural policies (c5) | Subsidies for the purchase of different types of agricultural machinery | + |

| 88.2 kW Power Machinery | 73.5 kW Power Machinery |

|---|---|

| LX1204 | LX1004 |

| FT1204 | FT1004 |

| JM1204 | JM1004 |

| JDT1204 | DF1004 |

| SNH1204 | SNH1004 |

| Machinery Type | a1 | a2 | a3 | a4 | a5 | b1 | b2 |

|---|---|---|---|---|---|---|---|

| LX1204 | 1.000 | 0.000 | 0.760 | 0.861 | 1.000 | 0.300 | 1.000 |

| FT1204 | 0.900 | 0.634 | 1.000 | 0.000 | 0.900 | 0.000 | 0.667 |

| JM1204 | 0.978 | 0.207 | 0.345 | 0.222 | 0.978 | 0.744 | 0.667 |

| JDT1204 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 0.300 | 1.000 |

| SNH1204 | 0.489 | 0.883 | 0.261 | 0.556 | 0.489 | 1.000 | 0.000 |

| Index | a1 | a2 | a3 | a4 | a5 | b1 | b2 |

|---|---|---|---|---|---|---|---|

| Weight | 0.108 | 0.151 | 0.148 | 0.163 | 0.108 | 0.188 | 0.133 |

| Machinery Type | Euclidean Distance of Ideal Solution | Grey Relational Degree of Ideal Solution | ||

|---|---|---|---|---|

| Positive | Negative | Positive | Negative | |

| LX1204 | 0.790 | 1.000 | 1.000 | 0.733 |

| FT1204 | 1.000 | 0.869 | 0.866 | 0.847 |

| JM1204 | 0.809 | 0.846 | 0.842 | 0.756 |

| JDT1204 | 0.967 | 0.956 | 0.848 | 1.000 |

| SNH1204 | 0.785 | 0.945 | 0.780 | 0.830 |

| Machinery Type | GRA | TOPSIS | GRA-TOPSIS | |||

|---|---|---|---|---|---|---|

| Relative Closeness | Sort | Relative Closeness | Sort | Relative Closeness | Sort | |

| LX1204 | 0.584 | 1 | 0.578 | 1 | 0.568 | 1 |

| FT1204 | 0.505 | 5 | 0.517 | 4 | 0.484 | 4 |

| JM1204 | 0.538 | 2 | 0.544 | 2 | 0.519 | 2 |

| JDT1204 | 0.506 | 4 | 0.502 | 5 | 0.478 | 5 |

| SNH1204 | 0.532 | 3 | 0.539 | 3 | 0.517 | 3 |

| Machinery Type | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 |

|---|---|---|---|---|---|---|---|---|---|

| Relative Closeness | |||||||||

| LX1204 | 0.575 | 0.573 | 0.571 | 0.570 | 0.568 | 0.566 | 0.564 | 0.562 | 0.560 |

| FT1204 | 0.501 | 0.497 | 0.493 | 0.488 | 0.484 | 0.480 | 0.476 | 0.473 | 0.469 |

| JM1204 | 0.525 | 0.524 | 0.522 | 0.520 | 0.519 | 0.517 | 0.516 | 0.514 | 0.513 |

| JDT1204 | 0.463 | 0.467 | 0.471 | 0.475 | 0.478 | 0.482 | 0.486 | 0.490 | 0.494 |

| SNH1204 | 0.491 | 0.498 | 0.504 | 0.510 | 0.517 | 0.523 | 0.529 | 0.535 | 0.541 |

| Machinery Type | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 | = 0.1 = 0.9 |

|---|---|---|---|---|---|---|---|---|---|

| Relative Closeness | |||||||||

| LX1004 | 0.545 | 0.535 | 0.525 | 0.515 | 0.501 | 0.496 | 0.491 | 0.485 | 0.480 |

| FT1004 | 0.527 | 0.523 | 0.518 | 0.514 | 0.509 | 0.505 | 0.500 | 0.495 | 0.491 |

| JM1004 | 0.624 | 0.630 | 0.635 | 0.640 | 0.646 | 0.651 | 0.657 | 0.662 | 0.668 |

| DF1004 | 0.468 | 0.467 | 0.466 | 0.462 | 0.464 | 0.463 | 0.462 | 0.461 | 0.460 |

| SNH1004 | 0.522 | 0.516 | 0.511 | 0.506 | 0.505 | 0.495 | 0.485 | 0.476 | 0.466 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Zhao, Y.; Zhou, X.; Wei, Z. Selection of Agricultural Machinery Based on Improved CRITIC-Entropy Weight and GRA-TOPSIS Method. Processes 2022, 10, 266. https://doi.org/10.3390/pr10020266

Lu H, Zhao Y, Zhou X, Wei Z. Selection of Agricultural Machinery Based on Improved CRITIC-Entropy Weight and GRA-TOPSIS Method. Processes. 2022; 10(2):266. https://doi.org/10.3390/pr10020266

Chicago/Turabian StyleLu, Haonan, Yongman Zhao, Xue Zhou, and Zikai Wei. 2022. "Selection of Agricultural Machinery Based on Improved CRITIC-Entropy Weight and GRA-TOPSIS Method" Processes 10, no. 2: 266. https://doi.org/10.3390/pr10020266

APA StyleLu, H., Zhao, Y., Zhou, X., & Wei, Z. (2022). Selection of Agricultural Machinery Based on Improved CRITIC-Entropy Weight and GRA-TOPSIS Method. Processes, 10(2), 266. https://doi.org/10.3390/pr10020266