Investigation of Low Cycle Fatigue Behaviors of Inertia-Friction-Welded Joints of the TC21 Titanium Alloy

Abstract

1. Introduction

2. Materials and Methods

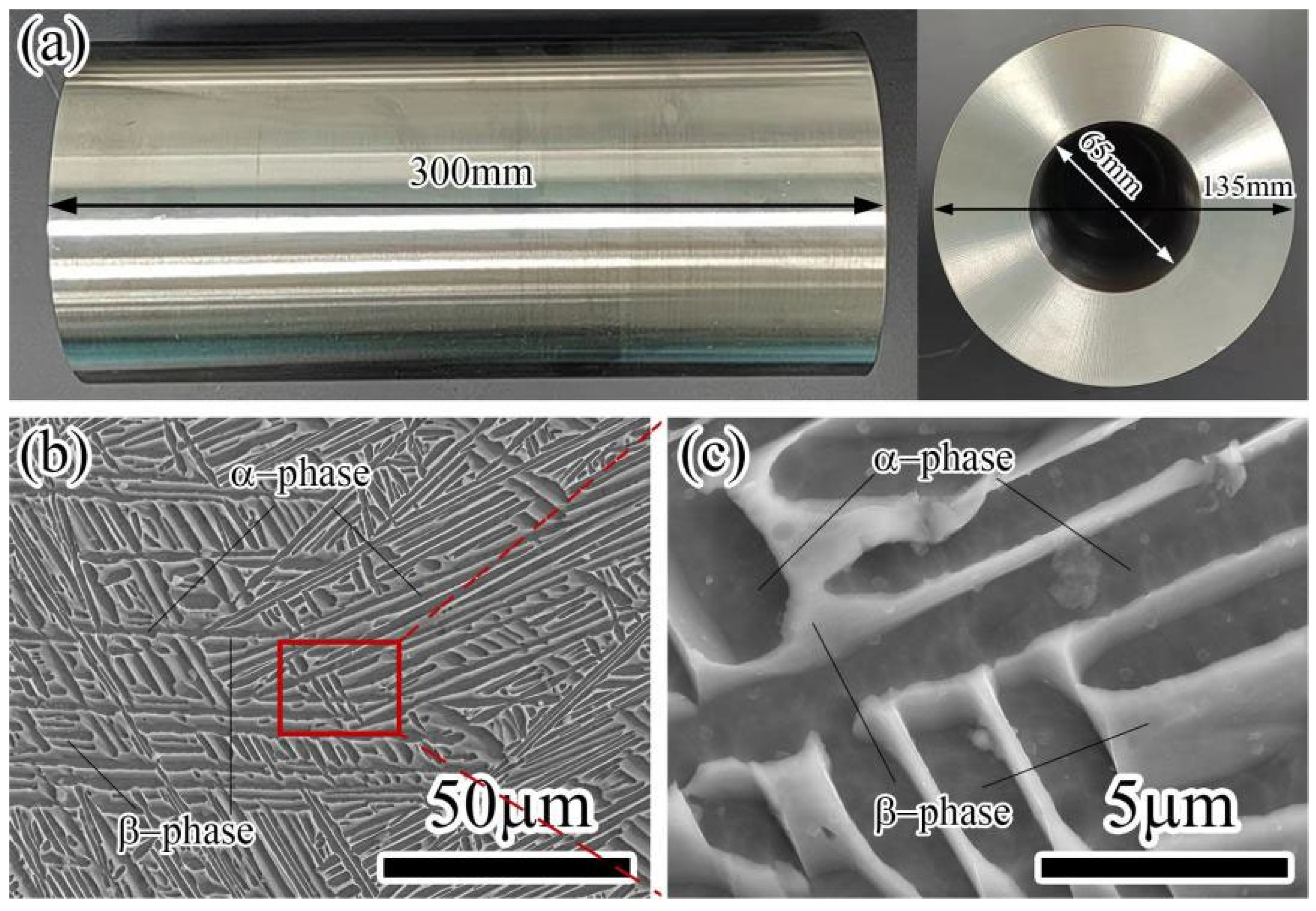

2.1. Material and Sample Preparation

2.2. Test Methods

3. Results and Discussion

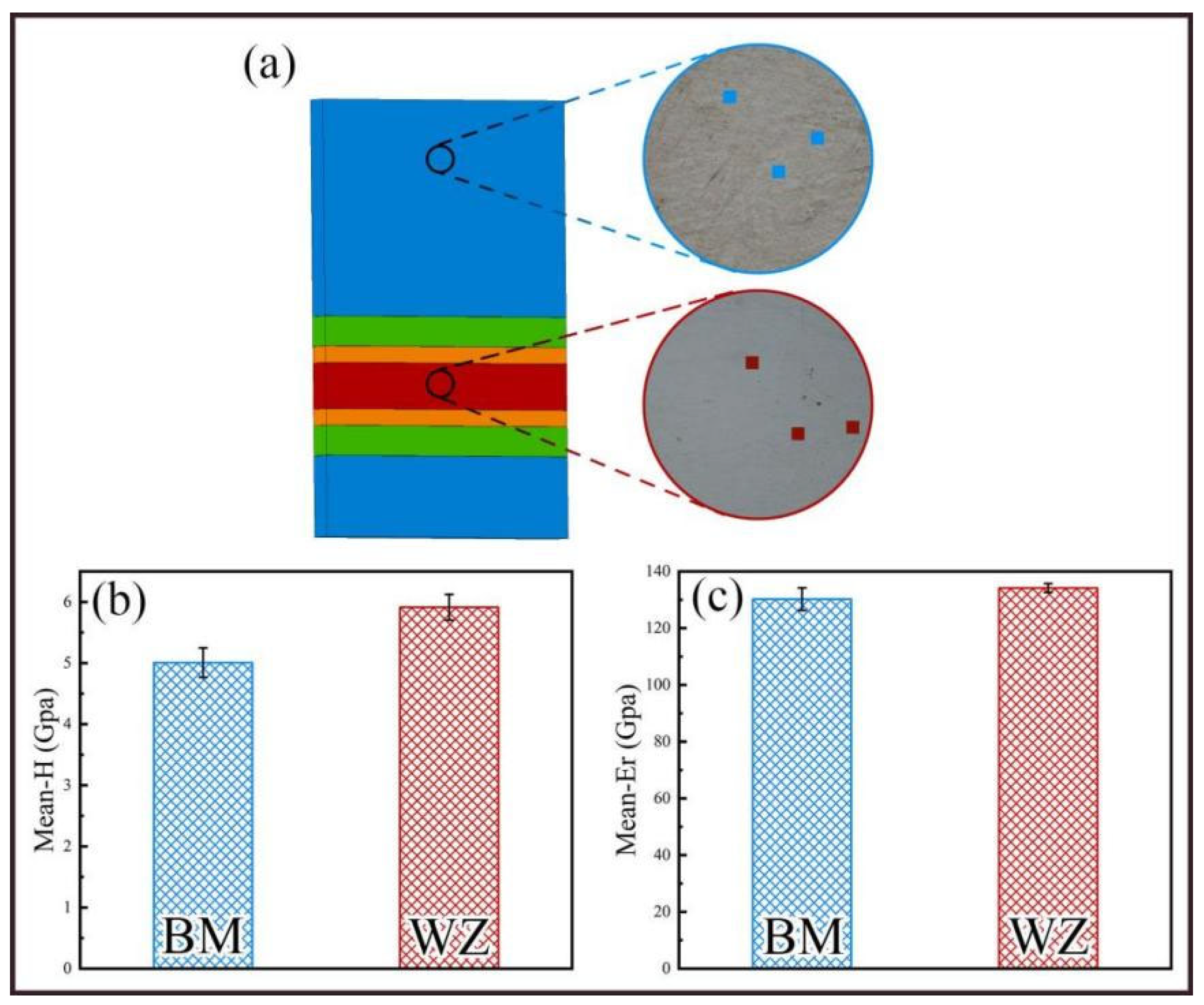

3.1. Microhardness

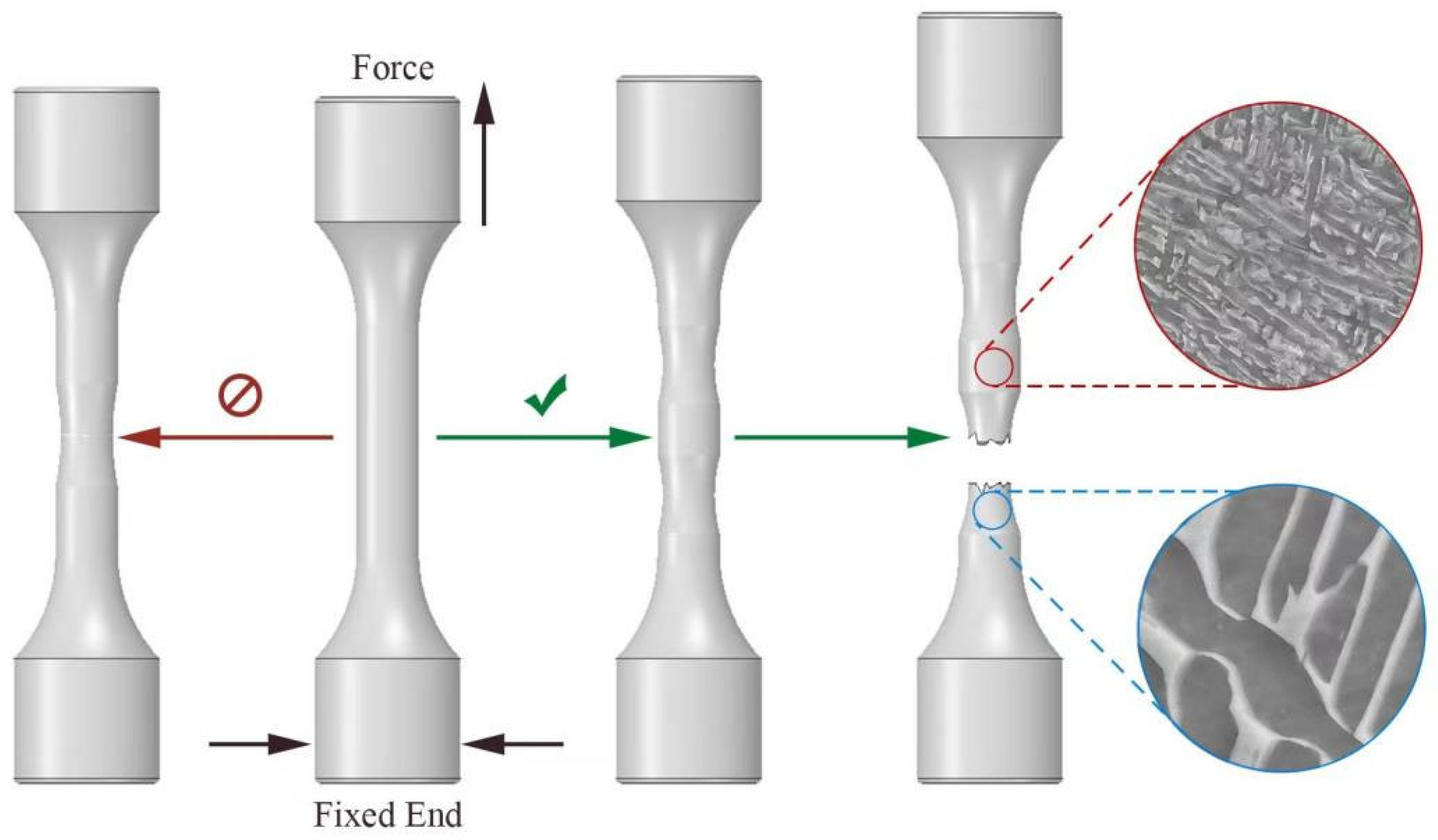

3.2. Results of Tensile Tests

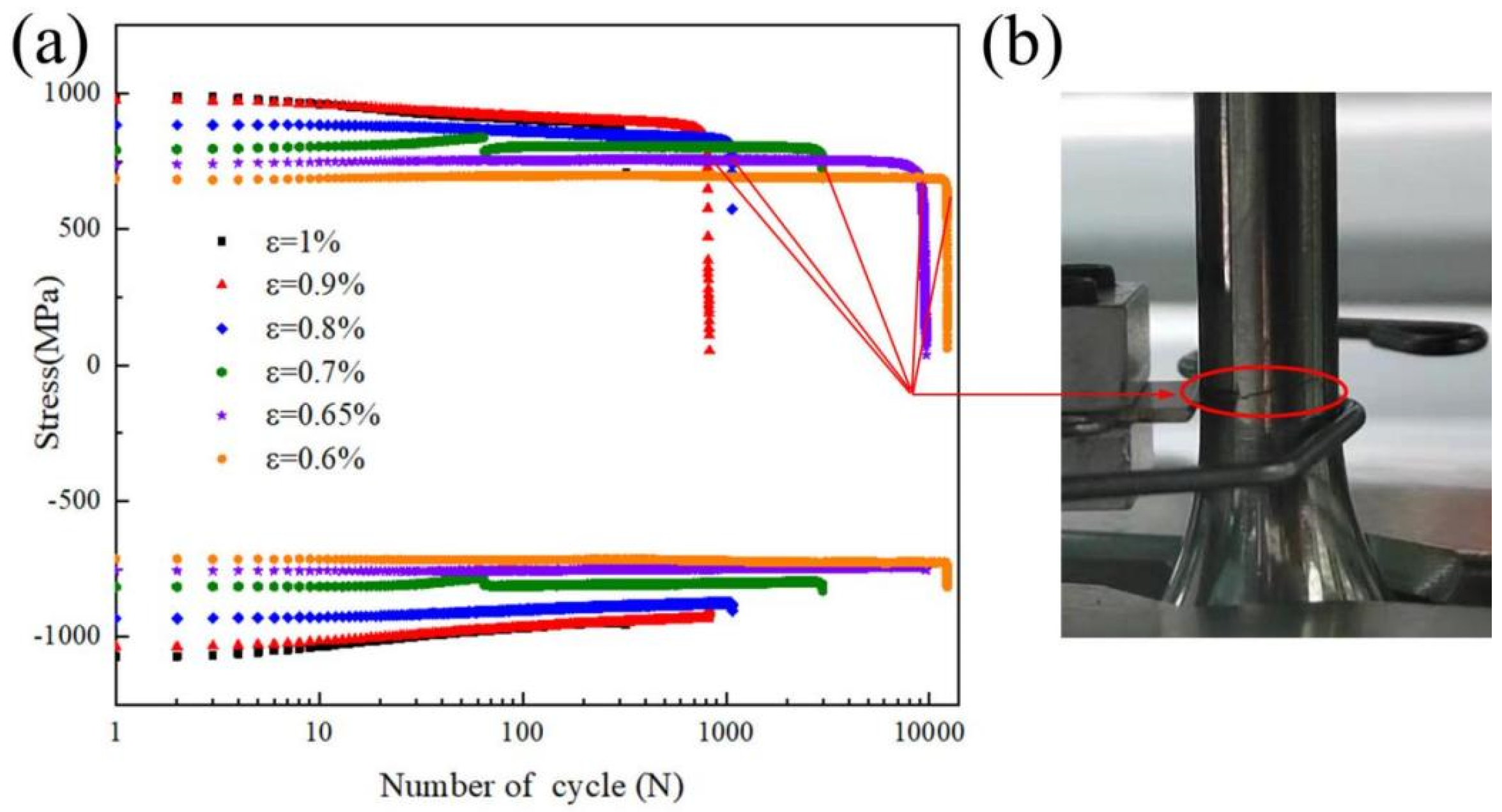

3.3. Test Results of Low Cycle Fatigue (LCF)

4. Conclusions

- (1)

- Inertial friction welding (IFW) of TC21 titanium alloy was successfully carried out. Relatively narrow IFW joints (about 5.1 mm) were achieved under suitable process parameters.

- (2)

- The approximation of nanohardness of the IFW weld zone is 5.913 GPa, which is 18% higher than that of BM (5.008 GPa). The approximation of equivalent Young’s modulus of the weld zone is 134.15 GPa, which is only 3% higher than that of BM (130.24 GPa).

- (3)

- The tensile tests show that the offset yield strength of IFW joints is about 941.6 MPa, peak stress is about 1025.1 MPa, elastic modulus is about 114.80 GPa, hardening index is about 0.074 and strength coefficient is about 1596.81.

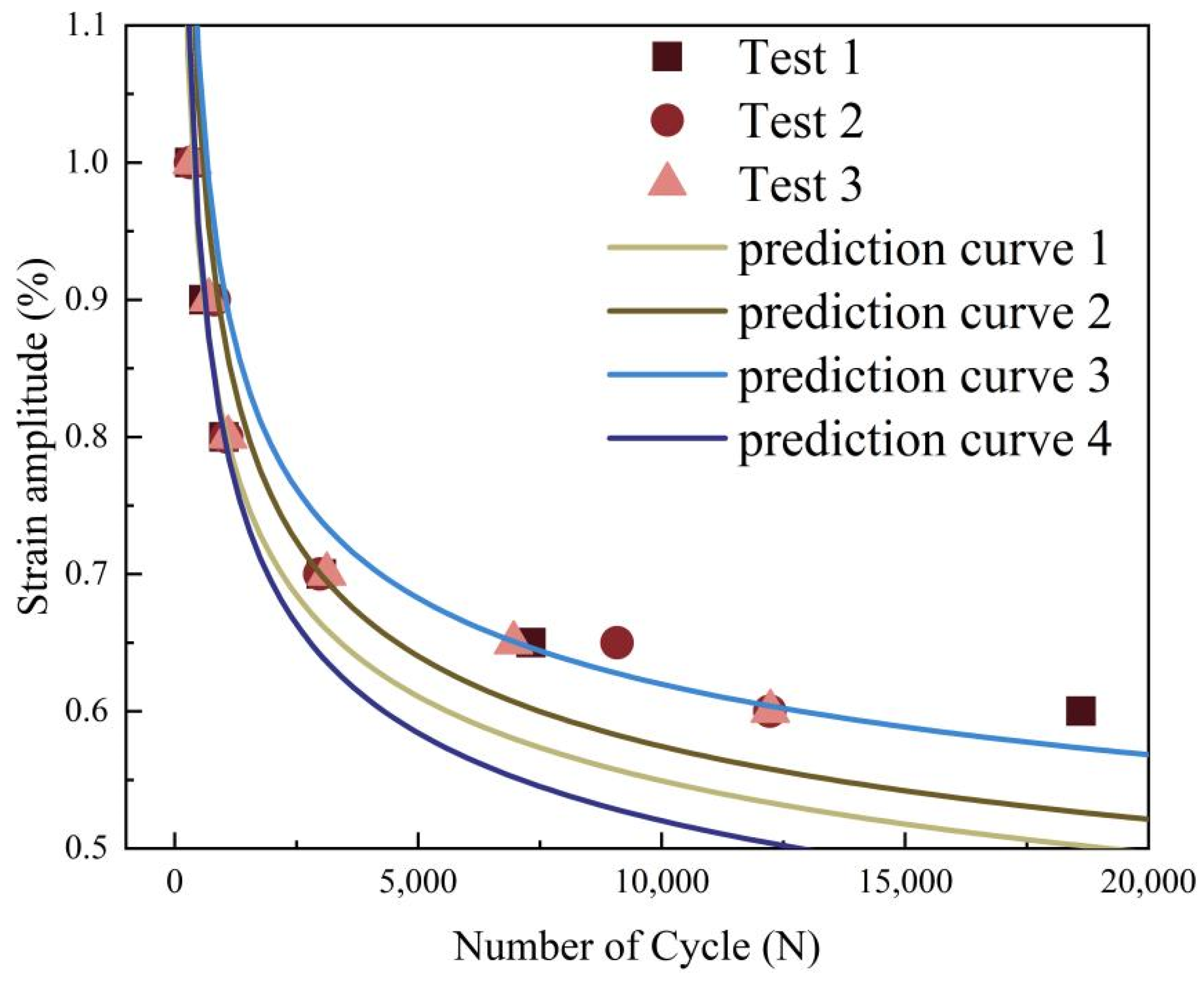

- (4)

- The results of the low cycle fatigue test show that there is no obvious cyclic hardening and cyclic softening of IFW joints of TC21 aluminum alloys. There is almost no hysteresis loop when the strain amplitude is lower than 0.7%, because there is almost no plastic deformation in IFW joints under low strain amplitude.

- (5)

- The results of LCF life prediction show that the Manson general slope method and Yao Weixing corrected parametric method are suitable for LCF life prediction of the IFW joints of TC21 titanium alloys.

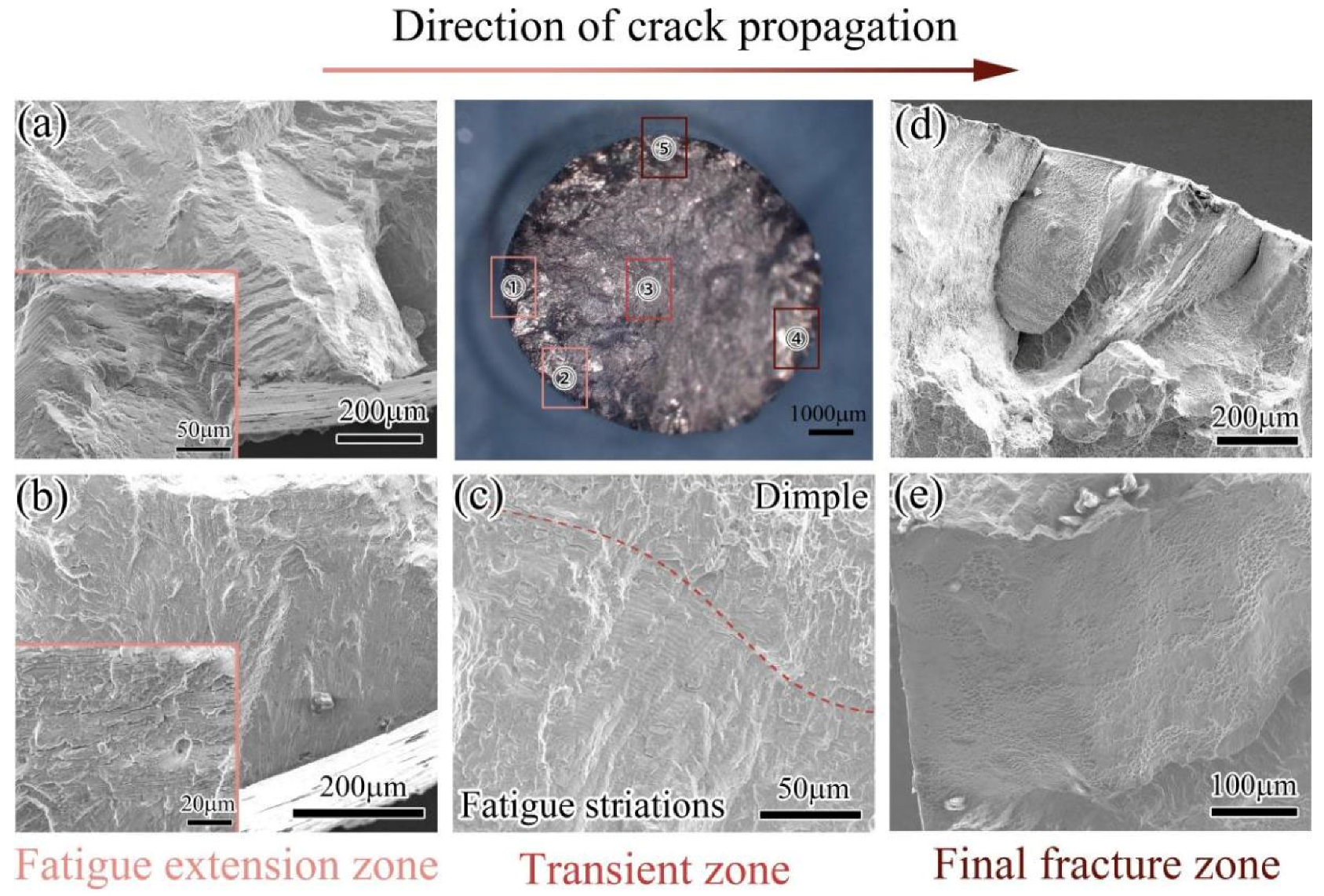

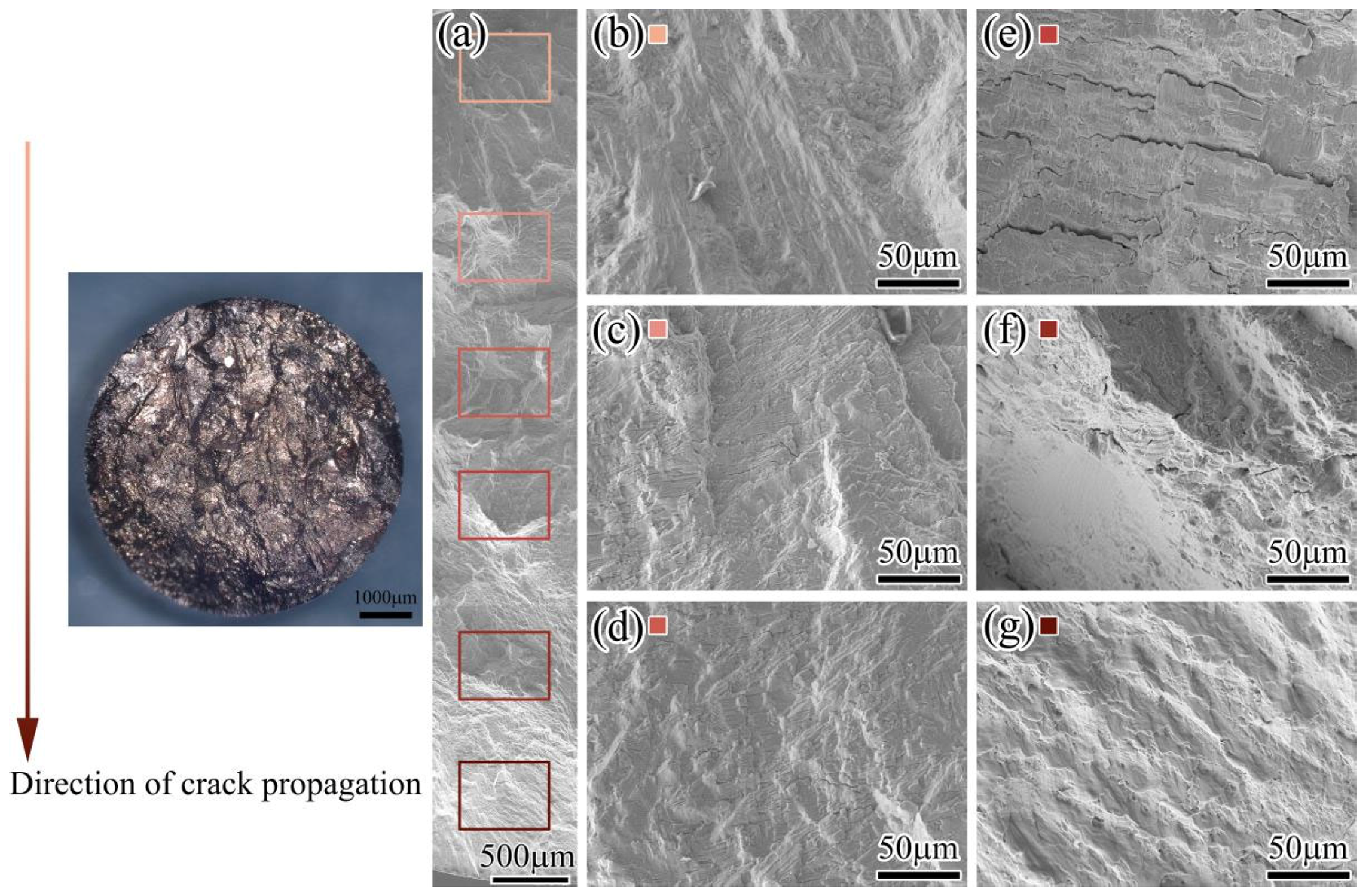

- (6)

- The results of fracture morphology show that the fatigue cracks initiate and propagate at multiple points in the LCF samples, and the transient fracture zone is larger under high strain amplitude. However, under low strain amplitude, a fatigue crack nucleates and propagates at a single point, and the crack propagation zone is larger.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.X.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S.L. Machinability of Additively Manufactured Titanium Alloys: A Comprehensive Review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Mi, G.B.; Huang, X.; Cao, J.X.; Cao, C.X.; Huang, X.S. Frictional Ignition of Ti40 Fireproof Titanium Alloys for Aero-Engine in Oxygen-Containing Media. Trans. Nonferrous Met. Soc. China 2013, 23, 2270–2275. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Cui, C.X.; Hu, B.M.; Zhao, L.C.; Liu, S.J. Titanium Alloy Production Technology, Market Prospects and Industry Development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Qian, X.H.; Duan, X.Y.; Zou, J.Y. Effects of Different Tool Microstructures on the Precision Turning of Titanium Alloy Tc21. Int. J. Adv. Manuf. Technol. 2020, 106, 5519–5526. [Google Scholar] [CrossRef]

- Hui, L.; Zhao, Y.S.; Zhou, S.; An, J.L.; Wang, L. Analysis of Corrosion Fatigue Properties of Notched Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2020, 49, 2706–2711. [Google Scholar]

- Song, J.W.; Tan, C.S.; Sun, Q.Y.; Xiao, L.; Zhao, Y.Q.; Sun, J. Effect of Step-Quenching on Microstructure and Mechanical Properties of Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2019, 48, 1260–1266. [Google Scholar]

- Muhrat, A.; Puga, H.; Barbosa, J. Low-Temperature Brazing of Titanium Using Al-Based Filler Alloys. Adv. Mater. Sci. Eng. 2018, 2018, 4570120. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A Review on Laser Beam Welding of Titanium Alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 1071–1098. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.S.; Kokawa, H. Friction-Stir Welding and Processing of Ti-6al-4v Titanium Alloy: A Review. J. Mater. Sci. Technol. 2018, 34, 58–72. [Google Scholar] [CrossRef]

- Mo, D.F.; Song, T.F.; Fang, Y.J.; Jiang, X.S.; Luo, C.Q.; Simpson, M.D.; Luo, Z.P. A Review on Diffusion Bonding between Titanium Alloys and Stainless Steels. Adv. Mater. Sci. Eng. 2018, 2018, 8701890. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Zhang, C.B.; Zhou, J.; Liang, W.; Li, Y.L. Analysis of the Microstructure and Mechanical Properties During Inertia Friction Welding of the near-Alpha Ta19 Titanium Alloy. Chin. J. Mech. Eng. 2020, 33, 88. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.Y.; Peng, Y.; Ma, X.F. Microstructure and Tensile Strength of Aluminum/Stainless Steel Joint Welded by Inertia Friction and Continuous Drive Friction. Weld. World 2020, 64, 1799–1809. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.L.; Jin, F. Effect of Welding Parameters on High-Temperature Tensile and Fatigue Properties of Fgh96 Inertia Friction Welded Joints. Weld. World 2019, 63, 1033–1053. [Google Scholar] [CrossRef]

- Nie, B.H.; Song, Y.; Huang, X.Y.; Qi, H.Y.; Zhao, Z.H.; Chen, D.C. Low Cycle Fatigue Behavior of Tc21 Titanium Alloy with Bi-Lamellar Basketweave Microstructure. Crystals 2022, 12, 796. [Google Scholar] [CrossRef]

- Kang, G.Z.; Luo, H.L. Review on Fatigue Life Prediction Models of Welded Joint. Acta Mech. Sin. 2020, 36, 701–726. [Google Scholar] [CrossRef]

- Singh, V. Effects of Prior Cold Working on Low Cycle Fatigue Behavior of Stainless Steels, Titanium Alloy Timetal 834 and Superalloy in 718: A Review. Trans. Indian Inst. Met. 2010, 63, 167–172. [Google Scholar] [CrossRef]

- Wang, H.Y.; Li, Z.H.; Zhao, S.S.; Li, Z.J.; Tang, W.J.; Wu, F.Y.; Zhou, J. Microstructure Evolution of Inertia Friction Welded Joints of Tc21 Titanium Alloy. Processes 2022, 10, 1086. [Google Scholar] [CrossRef]

- Li, Z.H.; Zhao, S.S.; Li, Z.J.; Wang, M.; Wu, F.Y.; Wang, H.Y.; Zhou, J. Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of Tc21 Titanium Alloy. Processes 2022, 10, 752. [Google Scholar] [CrossRef]

- Shi, Z.F.; Guo, H.Z.; Liu, R.; Wang, X.C.; Yao, Z.K. Microstructure and Mechanical Properties of Tc21 Titanium Alloy by near-Isothermal Forging. Trans. Nonferrous Met. Soc. China 2015, 25, 72–79. [Google Scholar] [CrossRef]

- Cai, W.Y.; Morovat, M.A.; Engelhardt, M.D. True Stress-Strain Curves for Astm A992 Steel for Fracture Simulation at Elevated Temperatures. J. Constr. Steel Res. 2017, 139, 272–279. [Google Scholar] [CrossRef]

- Lv, F.; Yang, F.; Duan, Q.Q.; Yang, Y.S.; Wu, S.D.; Li, S.X.; Zhang, Z.F. Fatigue Properties of Rolled Magnesium Alloy (Az31) Sheet: Influence of Specimen Orientation. Int. J. Fatigue 2011, 33, 672–682. [Google Scholar] [CrossRef]

- Manson, S.S. Fatigue: A complex subject: Some simple approximations. Exp. Mech. 1965, 5, 193–226. [Google Scholar] [CrossRef]

- Muralidharan, U.; Manson, S.S. Materials universal slopes equation for estimation of fatigue characteristics. J. Engeering Mater. Technol. 1988, 110, 55–58. [Google Scholar] [CrossRef]

- Bäumel Jr, A.; Seeger, T. Materials Data for Cycle Loading:Supplement I; Elsevier Science Publishers: Amsterdam, The Netherlands, 1990. [Google Scholar]

- Yao, W.X. Fatigue Life Estimation of Structures; National Defense Industry Press: Beijing, China, 2003. [Google Scholar]

| Al | Mo | Nb | Sn | Zr | Cr | Fe | O | C | N | H | Si | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.35 | 2.75 | 2.09 | 2.03 | 2.06 | 1.48 | 0.098 | 0.099 | 0.020 | 0.017 | 0.002 | ≤0.13 | Bal. |

| Test No. | Elastic Modulus (MPa) | Offset Yield Strength S0.2 (MPa) | Peak Stress SMAX (MPa) | Shrinkage on Cross-Section (%) (%) |

|---|---|---|---|---|

| Test 1 | 115499.4 | 946.0 | 1031.5 | 15.36 |

| Test 2 | 112646.3 | 911.8 | 992.8 | 13.51 |

| Test 3 | 116241.5 | 967.1 | 1051.0 | 15.97 |

| Average | 114795.7 | 941.6 | 1025.1 | 14.95 |

| Sample No. | Δstotal (MPa) | Δetotal | E (MPa) | ee | ep | Average ee | Average ep |

|---|---|---|---|---|---|---|---|

| 1%-1# | 1860 | 2% | 112,000 | 1.66% | 0.34% | 1.657% | 0.343% |

| 1%-2# | 1890 | 2% | 113,000 | 1.67% | 0.33% | ||

| 1%-3# | 1870 | 2% | 114,000 | 1.64% | 0.36% | ||

| 0.9%-1# | 1840 | 1.8% | 114,000 | 1.61% | 0.19% | 1.593% | 0.207% |

| 0.9%-2# | 1830 | 1.8% | 114,000 | 1.61% | 0.19% | ||

| 0.9%-3# | 1780 | 1.8% | 114,000 | 1.56% | 0.24% | ||

| 0.8%-1# | 1720 | 1.6% | 114,000 | 1.51% | 0.09% | 1.510% | 0.090% |

| 0.8%-2# | 1750 | 1.6% | 114,000 | 1.54% | 0.06% | ||

| 0.8%-3# | 1690 | 1.6% | 114,000 | 1.48% | 0.12% |

| Method No. | Prediction Method | ||||

|---|---|---|---|---|---|

| 1 | Manson general slope method (1965) | −0.12 | −0.6 | ||

| 2 | Muralidharan–Manson (1988) | −0.09 | −0.56 | ||

| 3 | Bäumel–Seeger (1990) | 0.35 | −0.095 | −0.69 | |

| 4 | Yao Weixing (2003) | −0.12 | −0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Li, Z.; Zhao, S.; Tang, W.; Li, Z.; Wu, F. Investigation of Low Cycle Fatigue Behaviors of Inertia-Friction-Welded Joints of the TC21 Titanium Alloy. Processes 2022, 10, 2548. https://doi.org/10.3390/pr10122548

Wang H, Li Z, Zhao S, Tang W, Li Z, Wu F. Investigation of Low Cycle Fatigue Behaviors of Inertia-Friction-Welded Joints of the TC21 Titanium Alloy. Processes. 2022; 10(12):2548. https://doi.org/10.3390/pr10122548

Chicago/Turabian StyleWang, Hongying, Zihao Li, Shengsheng Zhao, Weijie Tang, Zhijun Li, and Fayu Wu. 2022. "Investigation of Low Cycle Fatigue Behaviors of Inertia-Friction-Welded Joints of the TC21 Titanium Alloy" Processes 10, no. 12: 2548. https://doi.org/10.3390/pr10122548

APA StyleWang, H., Li, Z., Zhao, S., Tang, W., Li, Z., & Wu, F. (2022). Investigation of Low Cycle Fatigue Behaviors of Inertia-Friction-Welded Joints of the TC21 Titanium Alloy. Processes, 10(12), 2548. https://doi.org/10.3390/pr10122548