Wavelength-Stable Metal Grating Distributed Feedback Quantum Cascade Laser Emitting at λ ~ 7.2 μm

Abstract

:1. Introduction

2. Material Growth and Device Fabrication

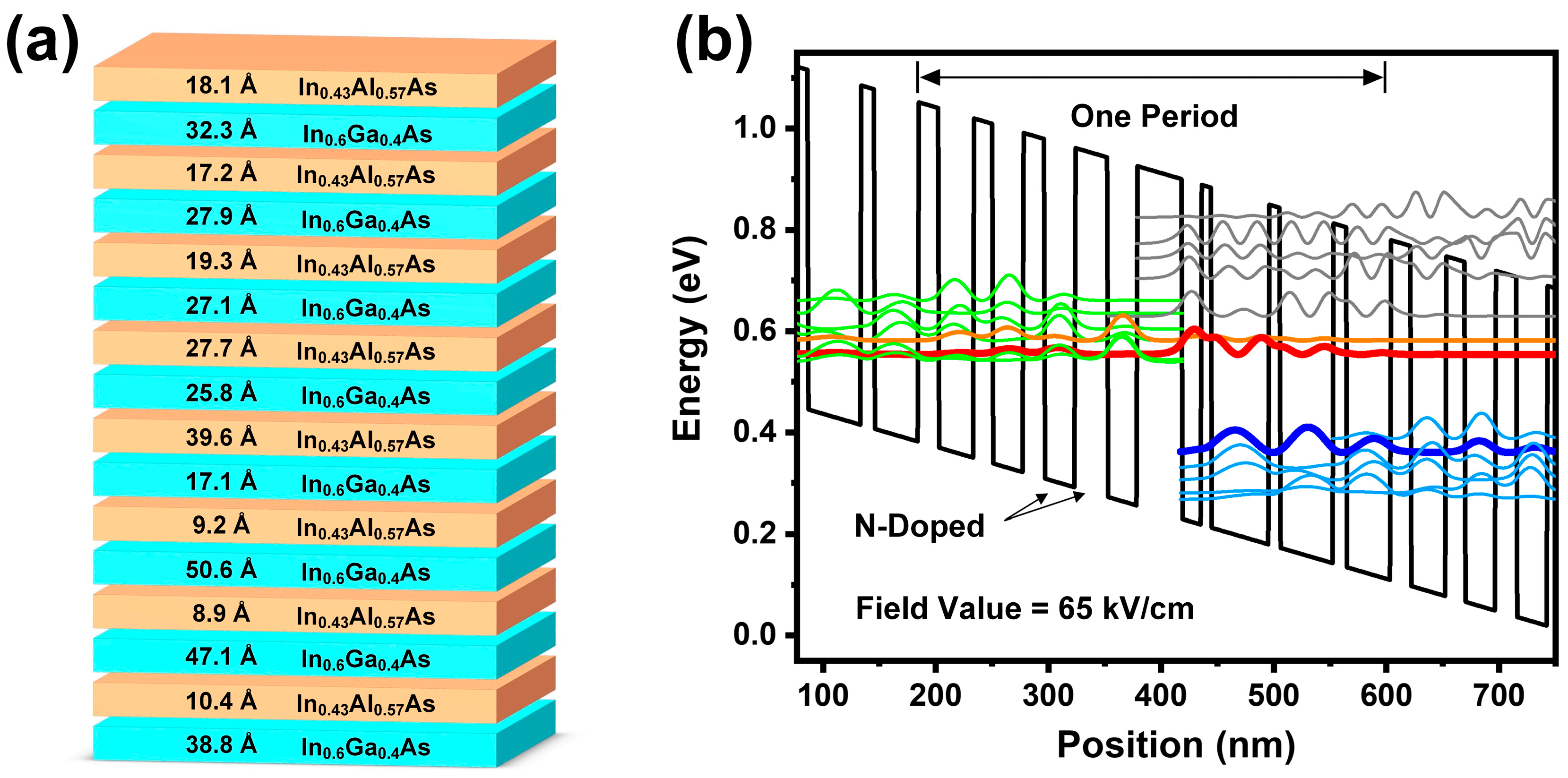

2.1. Material Epitaxy of QCL

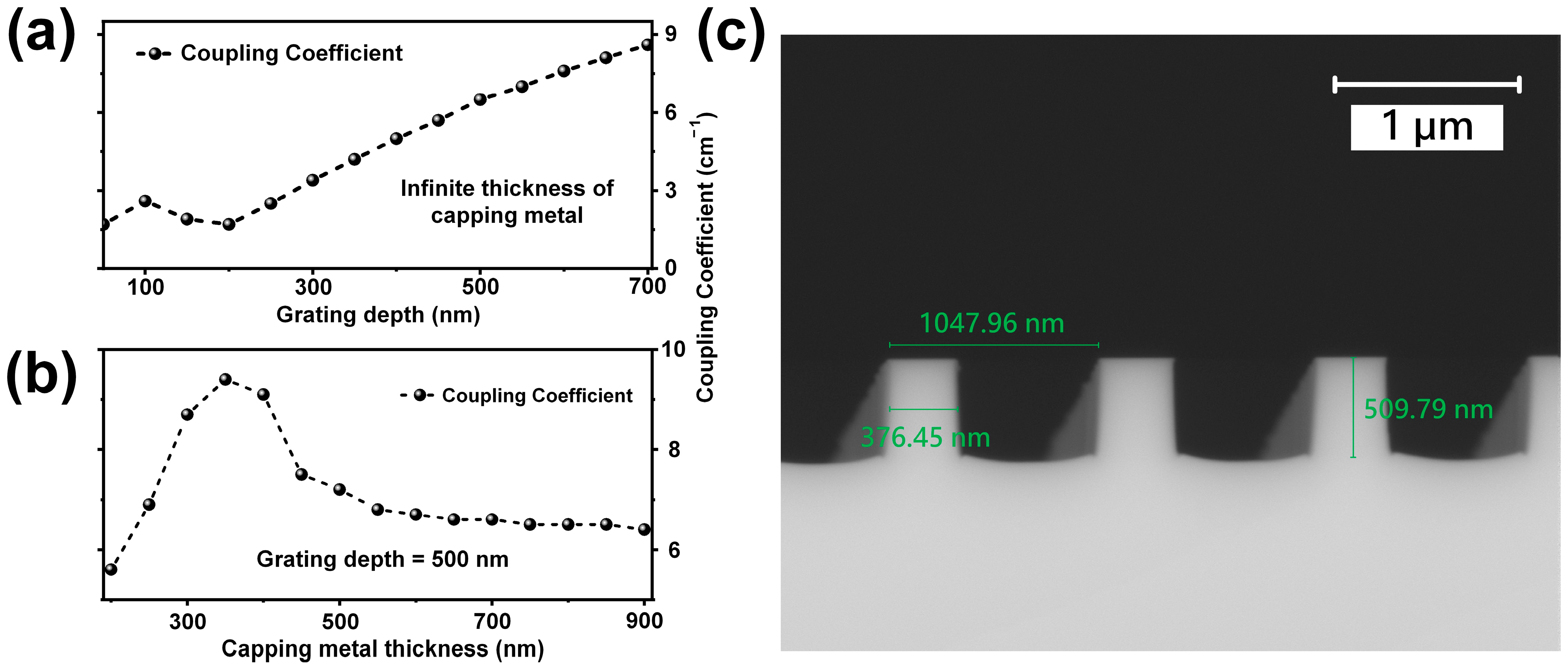

2.2. Design and Fabrication of Surface Metal Grating

2.3. Fabrication of QCL Devices

3. Results and Discussion

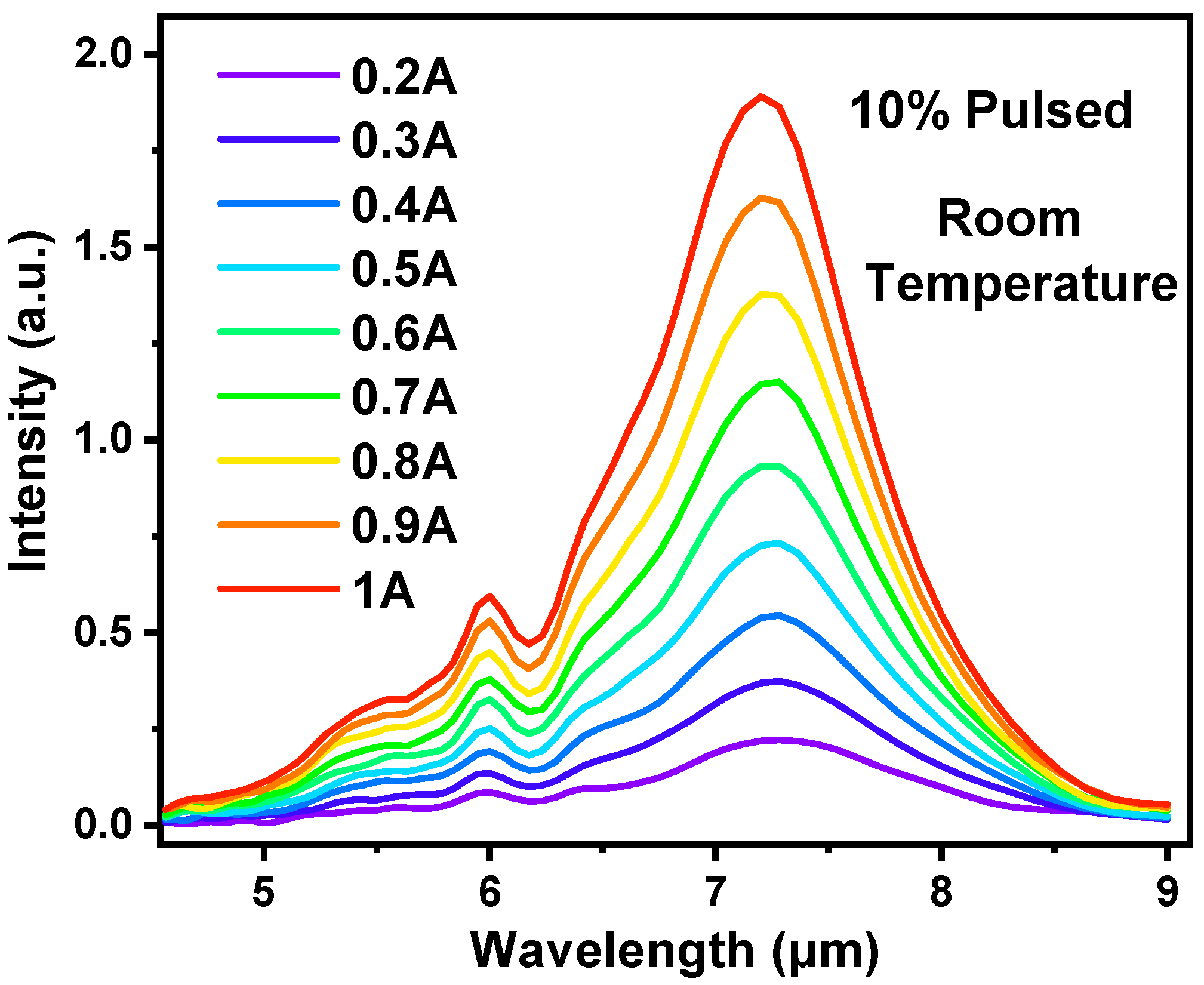

3.1. Electroluminescence Spectra of QCL

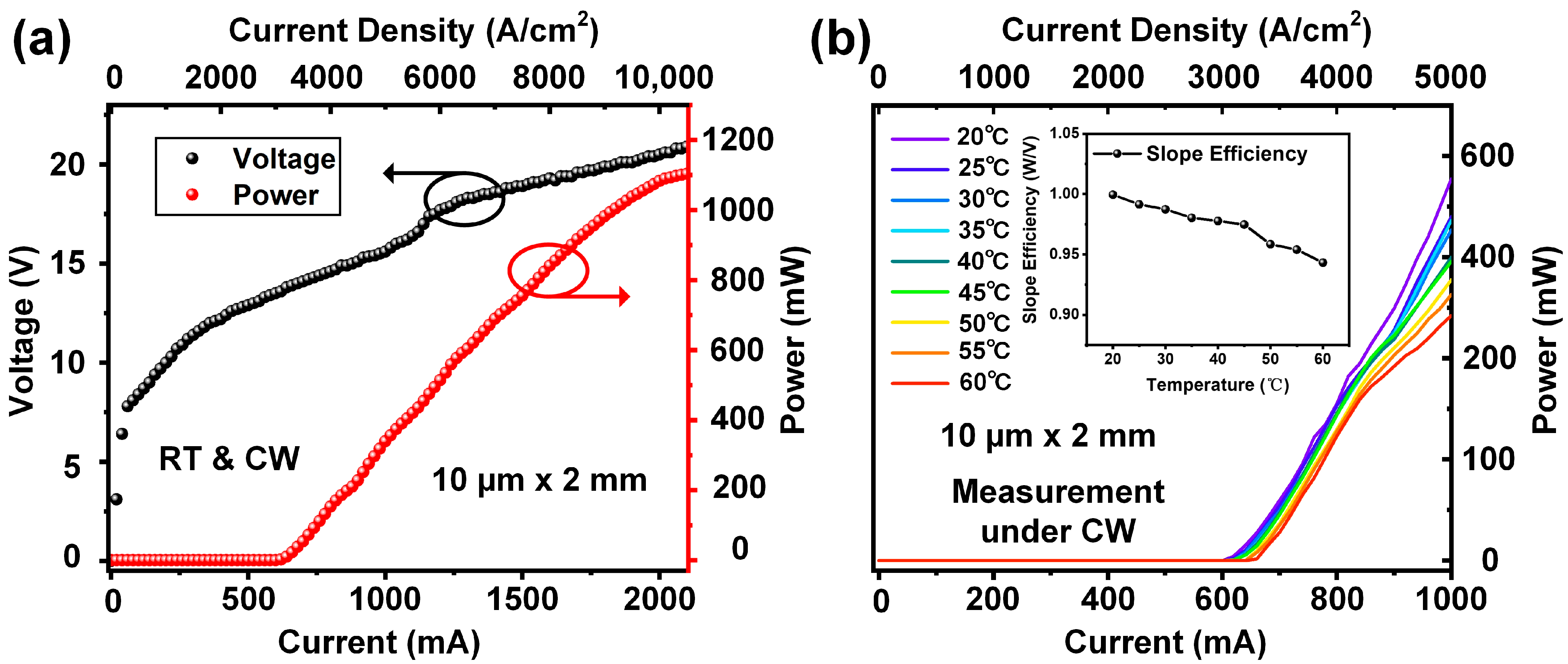

3.2. Lasing Performance of Metal Grating DFB QCL

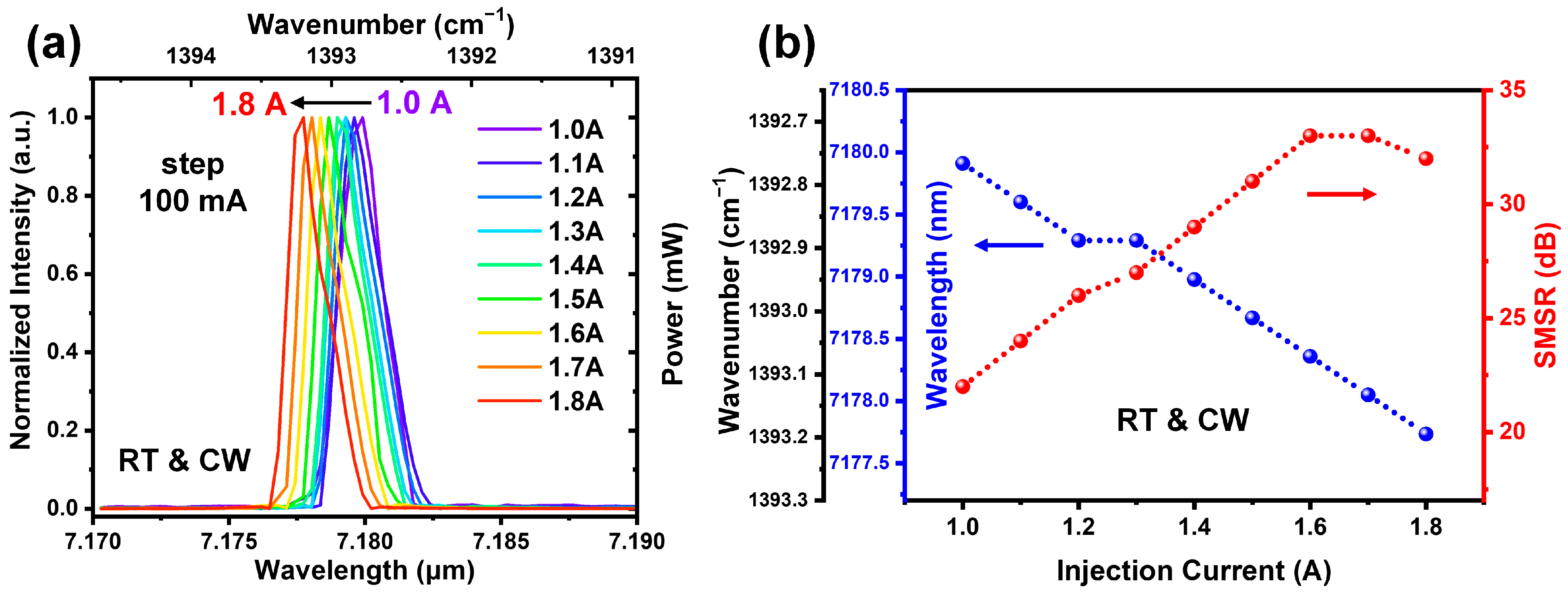

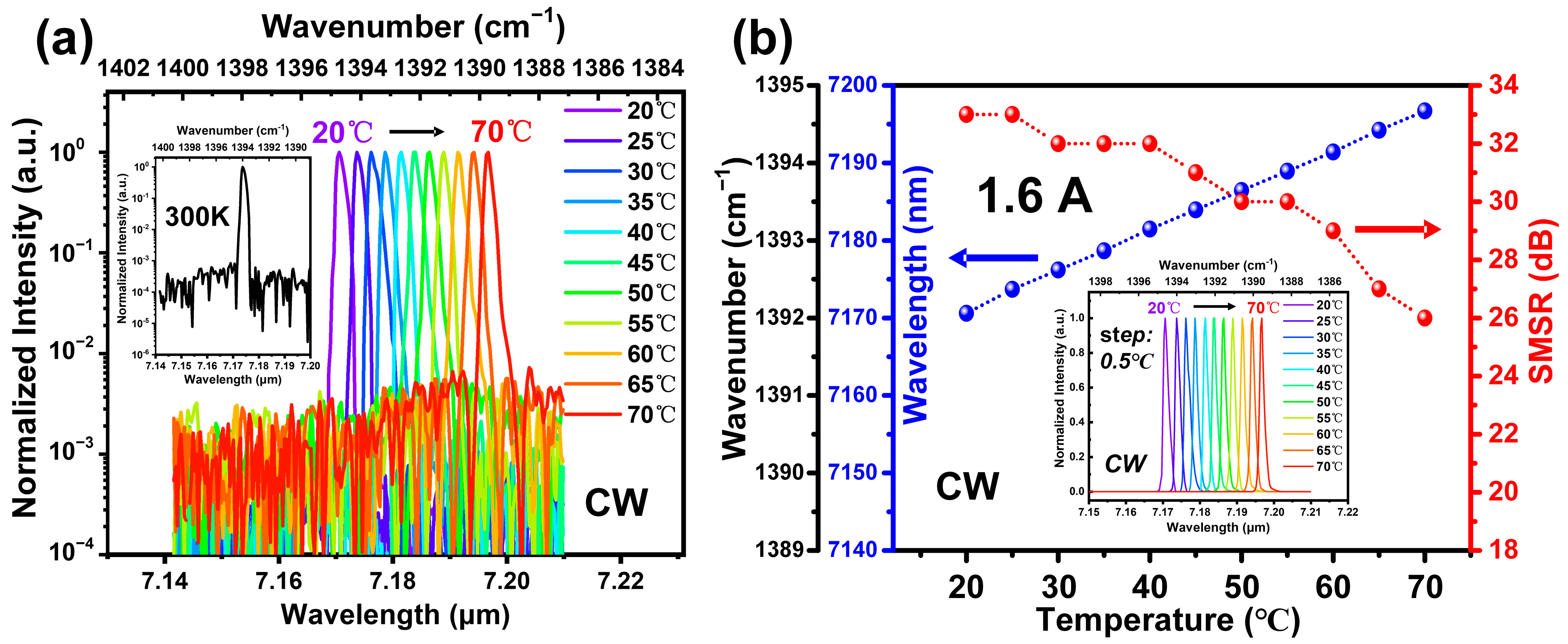

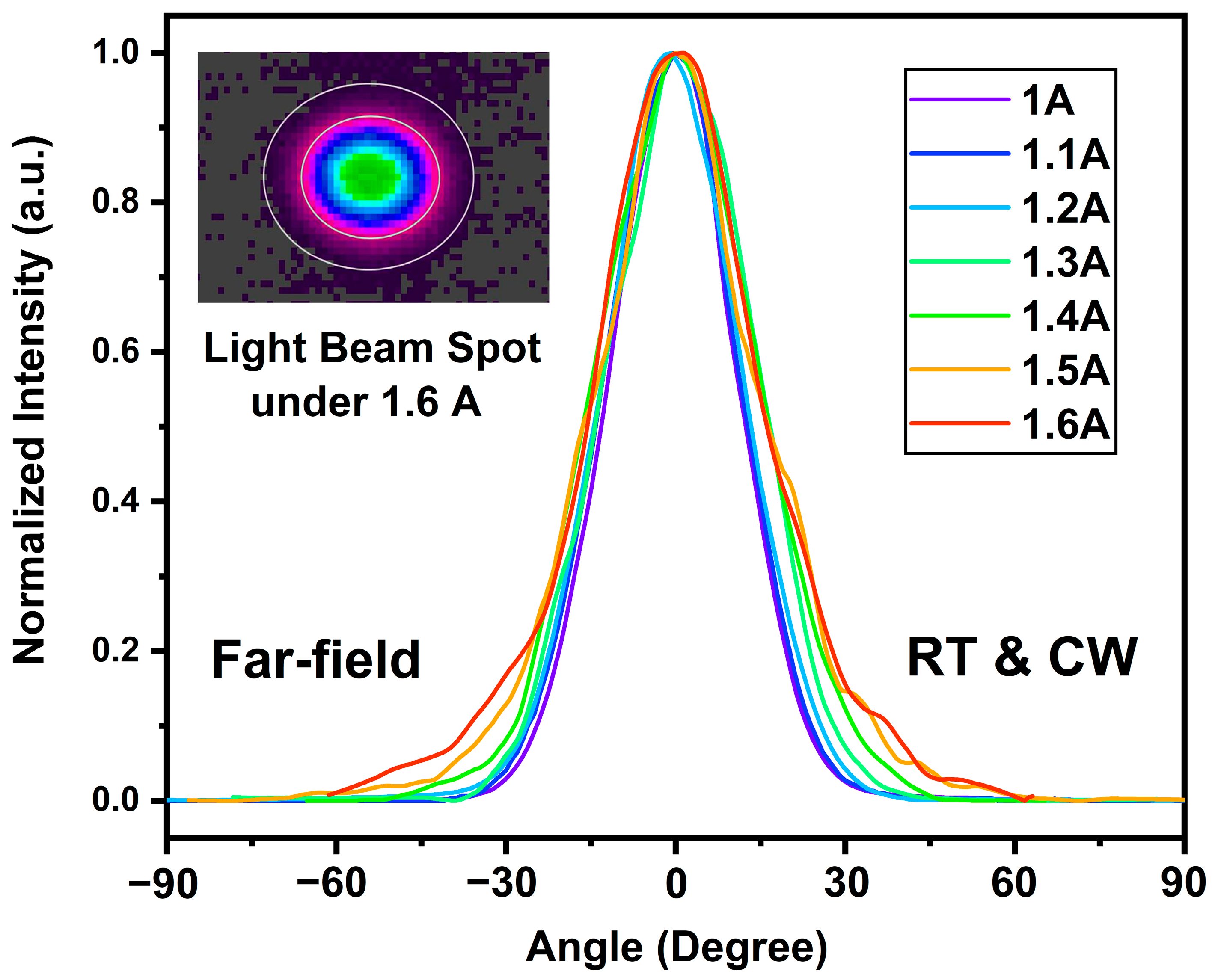

3.3. Wavelength-Stable Metal Grating DFB QCL

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hugi, A.; Villares, G.; Blaser, S.; Liu, H.C.; Faist, J. Mid-infrared frequency comb based on a quantum cascade laser. Nature 2012, 492, 229. [Google Scholar] [CrossRef] [PubMed]

- Nguyen-Van, H.; Baranov, A.N.; Loghmari, Z.; Cerutti, L.; Rodriguez, J.-B.; Tournet, J.; Narcy, G.; Boissier, G.; Patriarche, G.; Bahriz, M.; et al. Quantum cascade lasers grown on silicon. Sci. Rep. 2008, 8, 7206. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Li, J.; Tan, K.H.; Wicaksono, S.; Da Chua, Y.; Wang, C.; Dai, M.; Roth, V.; Fatt, Y.S.; Wang, Q. Beam combining of a broadly and continuously tunable quantum cascade laser. Opt. Express 2022, 30, 35999. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.J.; Pflügl, C.; Diehl, L.; Capasso, F.; Edamura, T.; Furuta, S.; Yamanishi, M.; Kan, H. High performance quantum cascade lasers based on three-phonon-resonance design. Appl. Phys. Lett. 2009, 94, 011103. [Google Scholar] [CrossRef]

- Yao, Y.; Hoffman, A.J.; Gmachl, C.F. Mid-infrared Quantum Cascade Lasers. Nat. Photonics 2012, 6, 432. [Google Scholar] [CrossRef]

- Faist, J.; Capasso, F.; Sivco, D.L.; Sirtori, C.; Hutchinson, A.L.; Cho, A.Y. Quantum Cascade Laser. Science 1994, 264, 553–556. [Google Scholar] [CrossRef]

- Tournié, E.; Baranov, A.N. Mid-Infrared Semiconductor Lasers: A Review. Adv. Semicond. Lasers 2012, 86, 183–226. [Google Scholar] [CrossRef]

- Wang, F.; Slivken, S.; Wu, D.H.; Razeghi, M. Room temperature quantum cascade lasers with 22% wall plug efficiency in continuous-wave operation. Opt. Express 2020, 28, 17532. [Google Scholar] [CrossRef]

- Lyakh, A.; Maulini, R.; Tsekoun, A.; Go, R.; Pflügl, C.; Diehl, L.; Wang, Q.J.; Capasso, F.; Patel, C.K.N. 3 W continuous-wave room temperature single-facet emission from quantum cascade lasers based on nonresonant extraction design approach. Appl. Phys. Lett. 2009, 95, 141113. [Google Scholar] [CrossRef]

- Vitiello, M.S.; Scalari, G.; Williams, B.; De Natale, P. Quantum cascade lasers: 20 years of challenges. Opt. Express 2015, 23, 5167. [Google Scholar] [CrossRef]

- Hashimoto, J.; Yoshinaga, H.; Mori, H.; Tsuji, Y.; Murata, M.; Kato, T.; Ekawa, M.; Iguchi, Y.; Katsuyama, T. Low power-consumption mid-infrared distributed feedback quantum cascade laser for gas-sensing application. Electron. Lett. 2017, 53, 549–551. [Google Scholar] [CrossRef]

- Bismuto, A.; Blaser, S.; Terazzi, R.; Gresch, T.; Muller, A. High performance, low dissipation quantum cascade lasers across the mid-IR range. Opt. Express 2015, 23, 5477–5484. [Google Scholar] [CrossRef] [PubMed]

- Maulini, R.; Lyakh, A.; Tsekoun, A.; Patel, C.K.N. λ~7.1 μm quantum cascade lasers with 19% wall-plug efficiency at room temperature. Opt. Express 2011, 19, 17203. [Google Scholar] [CrossRef] [PubMed]

- Kapsalidis, F.; Shahmohammadi, M.; Süess, M.J.; Wolf, J.M.; Gini, E.; Beck, M.; Hundt, M.; Tuzson, B.; Emmenegger, L.; Faist, J. Dual-wavelength DFB quantum cascade lasers: Sources for multi-species trace gas spectroscopy. Appl. Phys. B 2018, 124, 107. [Google Scholar] [CrossRef]

- Darvish, S.R.; Zhang, W.; Evans, A.; Yu, J.S.; Slivken, S.; Razeghi, M. High-power, continuous-wave operation of distributed-feedback quantum-cascade lasers at λ∼7.8 µm. Appl. Phys. Lett. 2006, 89, 251119. [Google Scholar] [CrossRef]

- Hinkov, B.; Hugi, A.; Beck, M.; Faist, J. RF-modulation of mid-infrared distributed feedback quantum Cascade Lasers. Opt. Express 2016, 24, 3294. [Google Scholar] [CrossRef]

- Darvish, S.R.; Slivken, S.; Evans, A.; Yu, J.S.; Razeghi, M. Room-temperature, high-power, and continuous-wave operation of distributed-feedback quantum-cascade lasers at λ∼9.6 μm. Appl. Phys. Lett. 2006, 88, 201114. [Google Scholar] [CrossRef]

- Ma, Y.; Lewicki, R.; Razeghi, M.; Tittel, F.K. QEPAS based ppb-level detection of CO and N2O using a high power CW DFB-QCL. Opt. Express 2013, 21, 1008. [Google Scholar] [CrossRef]

- Jia, Z.-W.; Wang, L.-J.; Zhang, J.-C.; Liu, F.-Q.; Zhou, Y.-H.; Wang, D.-B.; Jia, X.-F.; Zhuo, N.; Liu, J.-Q.; Zhai, S.-Q.; et al. High efficiency, low power-consumption DFB quantum cascade lasers without lateral regrowth. Nanoscale Res. Lett. 2017, 12, 281. [Google Scholar] [CrossRef]

- Wang, D.-B.; Zhang, J.-C.; Cheng, F.-M.; Zhao, Y.; Zhuo, N.; Zhai, S.-Q.; Wang, L.-J.; Liu, J.-Q.; Liu, S.-M.; Liu, F.-Q.; et al. Stable single-mode operation of distributed feedback quantum cascade laser by optimized reflectivity facet coatings. Nanoscale Res. Lett. 2018, 13, 37. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, J.; Sun, Y.; Zhuo, N.; Zhai, S.; Liu, J.; Wang, L.; Liu, S.; Liu, F. High performance distributed feedback quantum cascade laser emitting at λ∼6.12 μm. Opt. Express 2022, 30, 5848. [Google Scholar] [CrossRef]

- Carras, M.; De Rossi, A. Photonic modes of metallodielectric periodic waveguides in the midinfrared spectral range. Phys. Rev. B 2006, 74, 235120. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Bai, Y.; Bandyopadhyay, N.; Slivken, S.; Razeghi, M. Room-temperature continuous wave operation of distributed feedback quantum cascade lasers with Watt-level power output. Appl. Phys. Lett. 2010, 97, 231119. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Bai, Y.; Bandyopadhyay, N.; Slivken, S.; Razeghi, M. 2.4 W room temperature continuous wave operation of distributed feedback quantum Cascade Lasers. Appl. Phys. Lett. 2011, 98, 181106. [Google Scholar] [CrossRef]

- Yao, D.-Y.; Liu, F.-Q.; Zhang, J.-C.; Wang, L.-J.; Liu, J.-Q.; Wang, Z.-G. High Power Surface Metal Grating Distributed Feedback Quantum Cascade Lasers Emitting at λ∼8.3μm. Chin. Phys. Lett. 2012, 29, 094205. [Google Scholar] [CrossRef]

- Teng, Y.-Y.; Stern, E.A. Plasma radiation from metal grating surfaces. Phys. Rev. Lett. 1967, 19, 511–514. [Google Scholar] [CrossRef]

- Cao, Q.; Lalanne, P. Negative role of surface plasmons in the transmission of metallic gratings with very narrow slits. Phys. Rev. Lett. 2002, 88, 057403. [Google Scholar] [CrossRef]

- Han, Z.; Forsberg, E.; He, S. Surface Plasmon Bragg gratings formed in metal-insulator-metal waveguides. IEEE Photonics Technol. Lett. 2007, 19, 91–93. [Google Scholar] [CrossRef]

- Noll, R.; Macomber, S. Analysis of grating surface emitting lasers. IEEE J. Quantum Electron. 1990, 26, 456–466. [Google Scholar] [CrossRef]

- Shinada, S.; Hashizume, J.; Koyama, F. Surface plasmon resonance on microaperture vertical-cavity surface-emitting laser with metal grating. Appl. Phys. Lett. 2003, 83, 836–838. [Google Scholar] [CrossRef]

- Schröter, U.; Heitmann, D. Surface-plasmon-enhanced transmission through metallic gratings. Phys. Rev. B 1998, 58, 15419–15421. [Google Scholar] [CrossRef]

- Carras, M.; Garcia, M.; Marcadet, X.; Parillaud, O.; De Rossi, A.; Bansropun, S. Top grating index-coupled distributed feedback quantum Cascade Lasers. Appl. Phys. Lett. 2008, 93, 011109. [Google Scholar] [CrossRef]

- Carras, M.; Maisons, G.; Simozrag, B.; Garcia, M.; Parillaud, O.; Massies, J.; Marcadet, X. Room-temperature continuous-wave metal grating distributed feedback quantum Cascade Lasers. Appl. Phys. Lett. 2010, 96, 161105. [Google Scholar] [CrossRef]

- Kogelnik, H.; Shank, C.V. Coupled-wave theory of distributed feedback lasers. J. Appl. Phys. 1972, 43, 2327–2335. [Google Scholar] [CrossRef]

- Myers, T.L.; Williams, R.M.; Taubman, M.S.; Gmachl, C.; Capasso, F.; Sivco, D.L.; Baillargeon, J.N.; Cho, A.Y. Free-running frequency stability of mid-infrared quantum cascade lasers. Opt. Lett. 2002, 27, 170–172. [Google Scholar] [CrossRef]

- Finger, N.; Schrenk, W.; Gornik, E. Analysis of TM-polarized DFB laser structures with metal surface gratings. IEEE J. Quantum Electron. 2000, 36, 780–786. [Google Scholar] [CrossRef]

- Rabinovich, W.; Feldman, B. Spatial hole burning effects in distributed feedback lasers. IEEE J. Quantum Electron. 1989, 25, 20–30. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, K.; Liu, Z.; Cheng, F.; Yang, P.; Li, H.; Niu, S.; Ge, G.; Xu, H.; Zhuo, N.; Su, H.; et al. Wavelength-Stable Metal Grating Distributed Feedback Quantum Cascade Laser Emitting at λ ~ 7.2 μm. Chemosensors 2024, 12, 2. https://doi.org/10.3390/chemosensors12010002

Ma K, Liu Z, Cheng F, Yang P, Li H, Niu S, Ge G, Xu H, Zhuo N, Su H, et al. Wavelength-Stable Metal Grating Distributed Feedback Quantum Cascade Laser Emitting at λ ~ 7.2 μm. Chemosensors. 2024; 12(1):2. https://doi.org/10.3390/chemosensors12010002

Chicago/Turabian StyleMa, Kedi, Zizhuo Liu, Fengmin Cheng, Pengchang Yang, Hongxiao Li, Shan Niu, Gaohui Ge, Hao Xu, Ning Zhuo, Hui Su, and et al. 2024. "Wavelength-Stable Metal Grating Distributed Feedback Quantum Cascade Laser Emitting at λ ~ 7.2 μm" Chemosensors 12, no. 1: 2. https://doi.org/10.3390/chemosensors12010002

APA StyleMa, K., Liu, Z., Cheng, F., Yang, P., Li, H., Niu, S., Ge, G., Xu, H., Zhuo, N., Su, H., & Zhang, J. (2024). Wavelength-Stable Metal Grating Distributed Feedback Quantum Cascade Laser Emitting at λ ~ 7.2 μm. Chemosensors, 12(1), 2. https://doi.org/10.3390/chemosensors12010002