Graphene Nanogap Interdigitated Asymmetric Electrodes for Photodetection

Abstract

1. Introduction

2. Materials and Methods

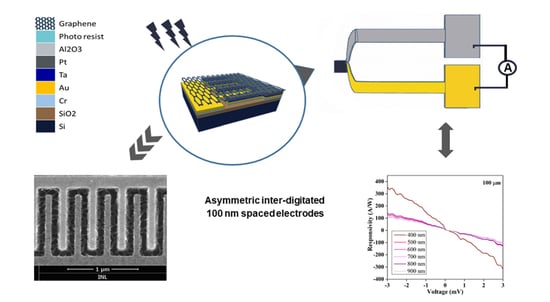

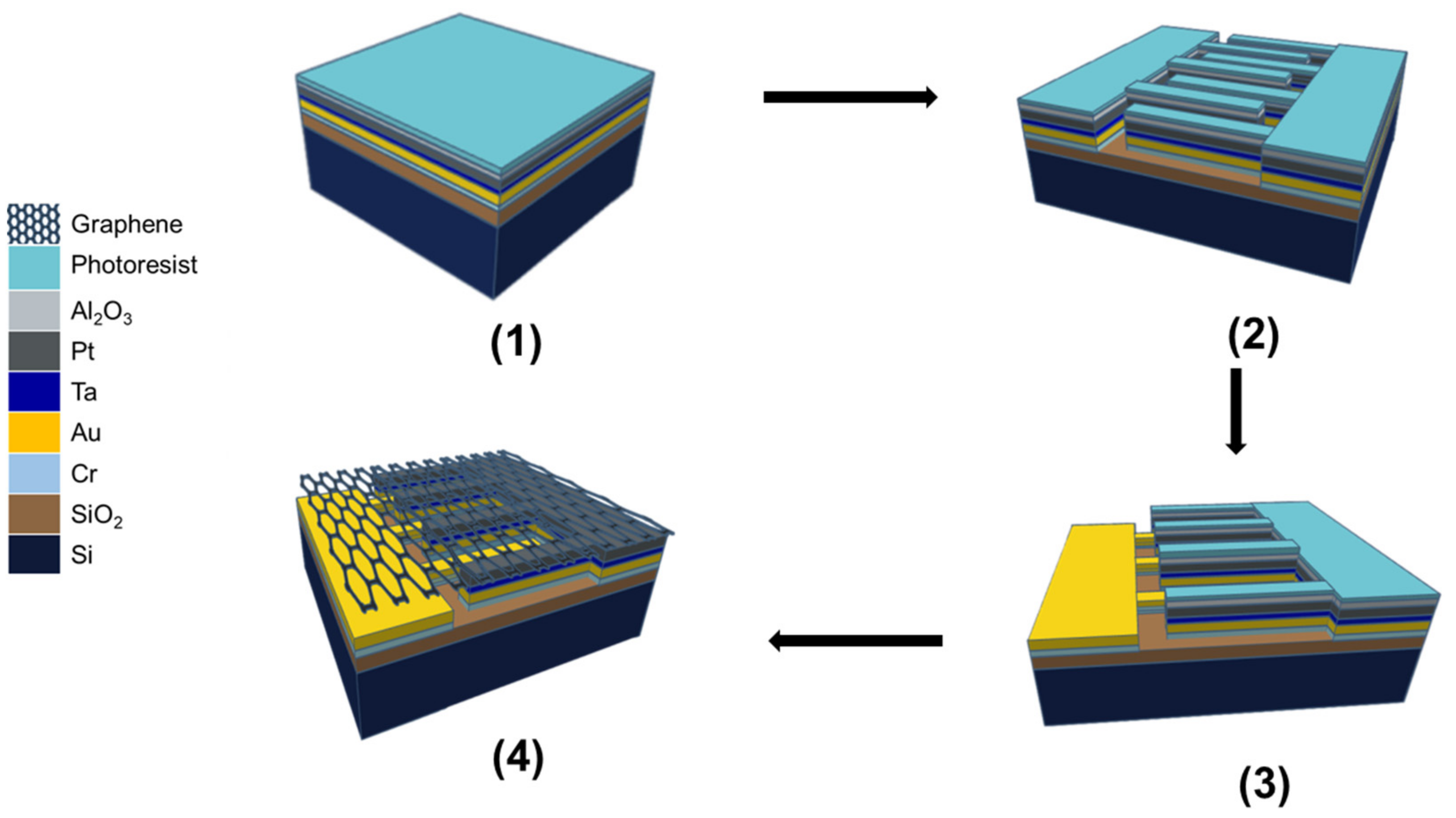

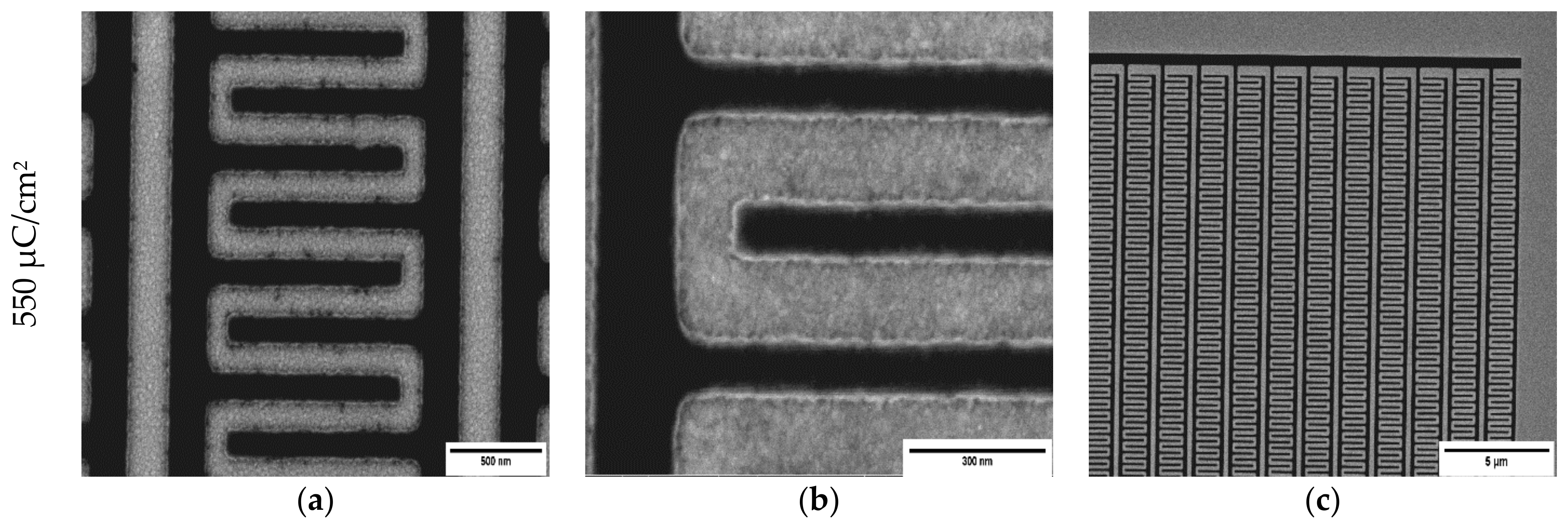

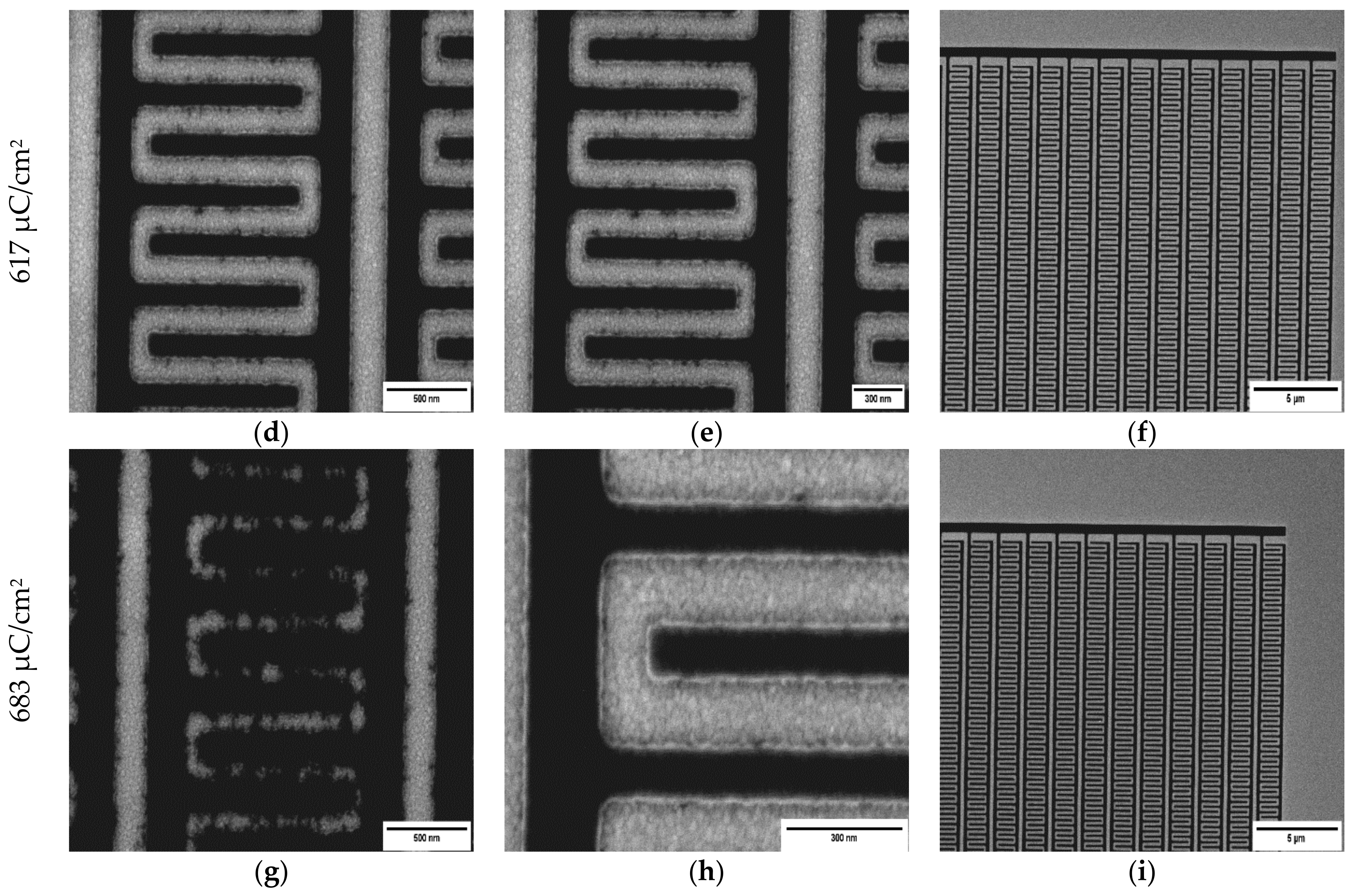

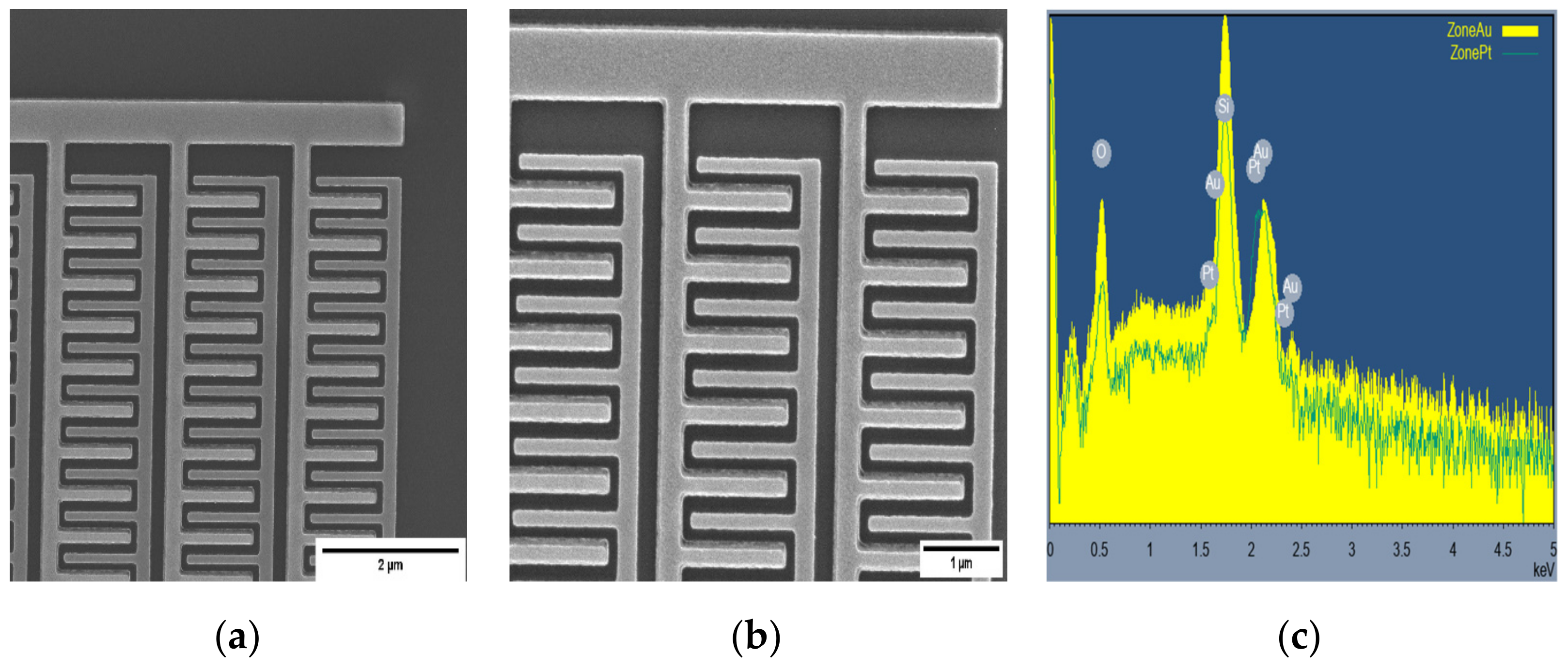

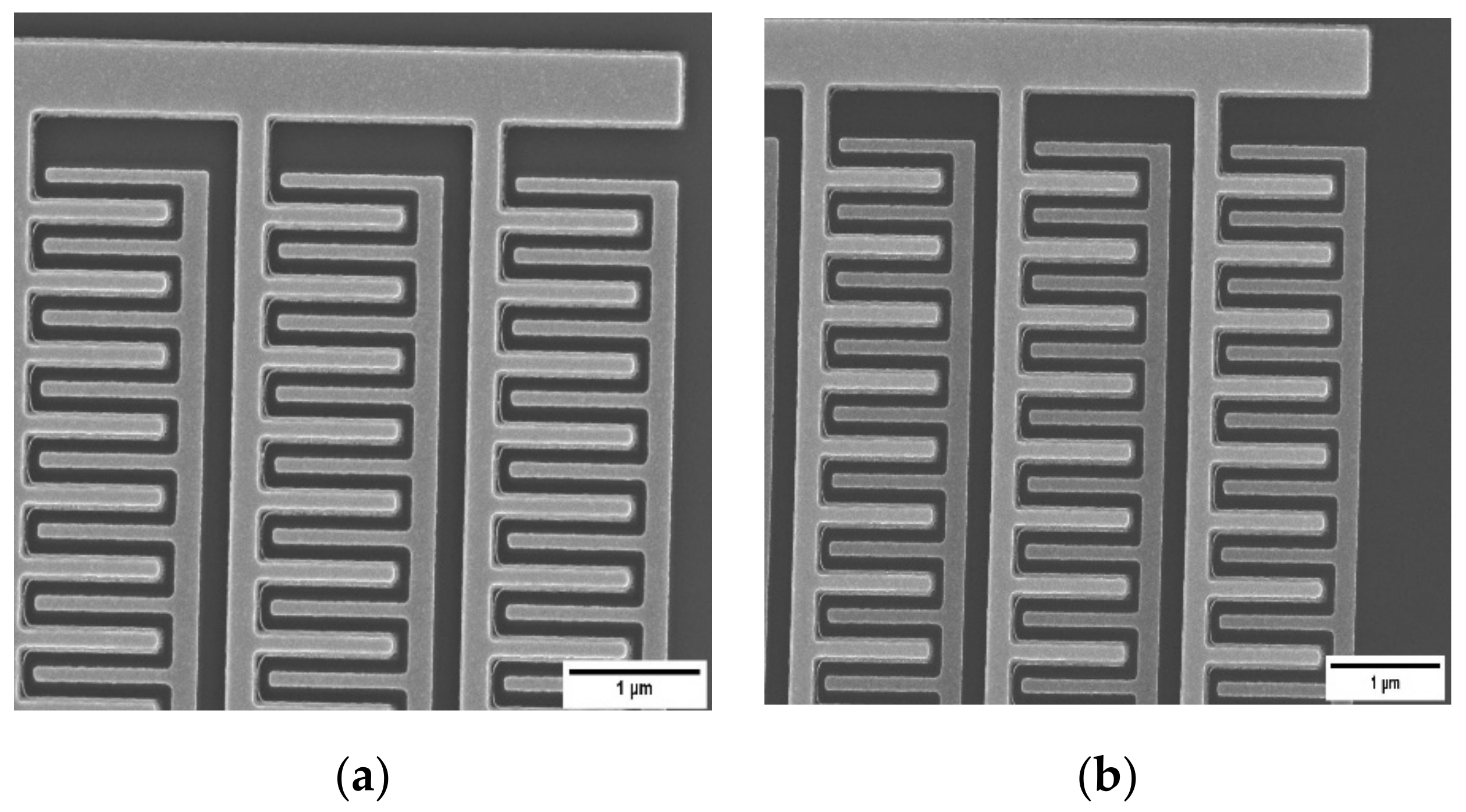

2.1. Fabrication of the Interdigitated Nanogap Electrodes

2.2. CVD Growth and Transfer of Graphene

2.3. Characterization

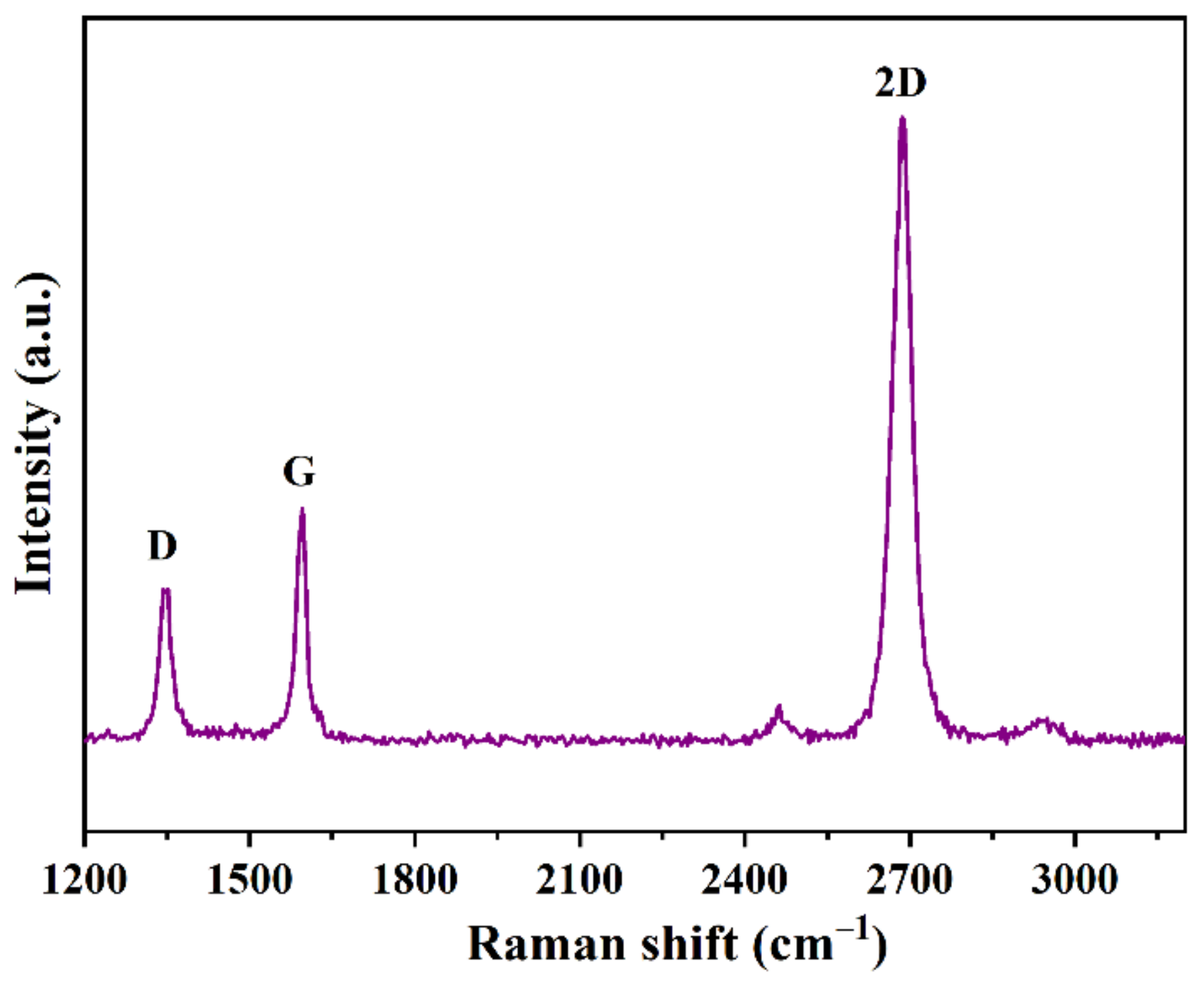

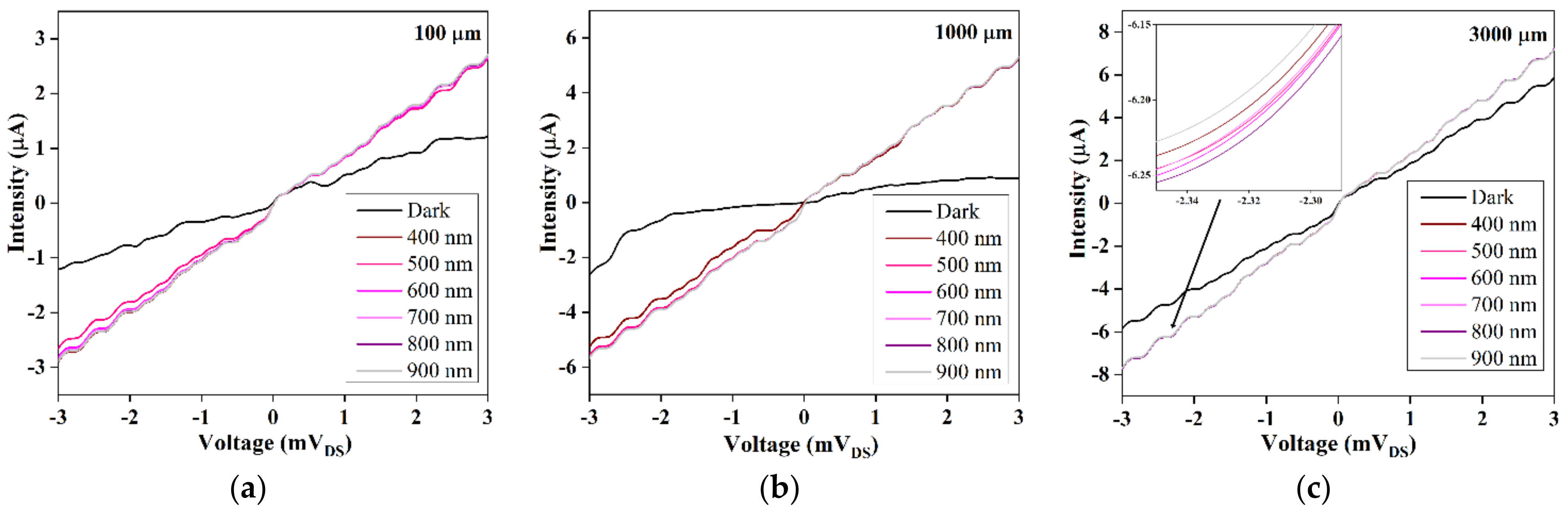

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geim, A.; Novoselov, K. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Neto, A.C.; Guinea, F.; Peres, N.; Novoselov, K.; Geim, A. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Novoselov, K.; Geim, A.; Morozov, S.; Jiang, D.-E.; Zhang, Y.; Dubonos, S.; Grigorieva, I.; Firsov, A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Gao, K.; Ran, S.; Han, Q.; Yang, Q.; Jiang, H.; Fu, J.; Leng, C.; Feng, S.; Zhou, D.; Li, Z.; et al. High zero-bias responsivity induced by photogating effect in asymmetric device structure. Opt. Mater. 2022, 124, 112013. [Google Scholar] [CrossRef]

- Brida, D.; Tomadin, A.; Manzoni, C.; Kim, Y.; Lombardo, A.; Milana, S.; Nair, R.; Novoselov, K.; Ferrari, A.; Cerullo, G. Ultrafast collinear scattering and carrier multiplication in graphene. Nat. Commun. 2013, 4, 1987. [Google Scholar] [CrossRef] [PubMed]

- Dawlaty, J.; Shivaraman, S.; Chandrashekhar, M.; Rana, F.; Spencer, M. Measurement of ultrafast carrier dynamics in epitaxial graphene. Appl. Phys. Lett. 2008, 92, 042116. [Google Scholar] [CrossRef]

- Novoselov, K.; Geim, A.; Morozov, S.; Jiang, D.; Katsnelson, M.; Grigorieva, I.; Dubonos, S.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Nair, R.; Blake, P.; Grigorenko, A.; Novoselov, K.; Booth, T.; Stauber, T.; Peres, N.; Geim, A. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed]

- Kuzmenko, A.; Van Heumen, E.; Carbone, F.; Van Der Marel, D. Universal optical conductance of graphite. Phys. Rev. Lett. 2008, 100, 117401. [Google Scholar] [CrossRef]

- Akinwande, D.; Petrone, N.; Hone, J. Two-dimensional flexible nanoelectronics. Nat. Commun. 2014, 5, 5678. [Google Scholar] [CrossRef]

- Qiu, Q.; Huang, Z. Photodetectors of 2D Materials from Ultraviolet to Terahertz Waves. Adv. Mater. 2021, 33, 2008126. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Henriksen, E.; Jiang, Z.; Hao, Z.; Martin, M.; Kim, P.; Stormer, H.; Basov, D. Dirac charge dynamics in graphene by infrared spectroscopy. Nat. Phys. 2008, 4, 532–535. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611–622. [Google Scholar] [CrossRef]

- Larki, F.; Abdi, Y.; Kameli, P.; Salamati, H. An Effort Towards Full Graphene Photodetectors. Photonic Sens. 2022, 12, 31–67. [Google Scholar] [CrossRef]

- Koppens, F.; Mueller, T.; Avouris, P.; Ferrari, A.; Vitiello, M.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef]

- Yan, Z.; Yang, H.; Yang, Z.; Ji, C.; Zhang, G.; Tu, Y.; Du, G.; Cai, S.; Lin, S. Emerging Two-Dimensional Tellurene and Tellurides for Broadband Photodetectors. Small 2022, 18, 2200016. [Google Scholar] [CrossRef]

- Yu, W.; Gong, K.; Li, Y.; Ding, B.; Li, L.; Xu, Y.; Wang, R.; Li, L.; Zhang, G.; Lin, S. Flexible 2D materials beyond graphene: Synthesis, properties, and applications. Small 2022, 18, 2105383. [Google Scholar] [CrossRef]

- Mu, H.; Yu, W.; Yuan, J.; Lin, S.; Zhang, G. Interface and surface engineering of black phosphorus: A review for optoelectronic and photonic applications. Mater. Futures 2022, 1, 012301. [Google Scholar] [CrossRef]

- Urich, A.; Unterrainer, K.; Mueller, T. Intrinsic Response Time of Graphene Photodetectors. Nano Lett. 2011, 11, 2804–2808. [Google Scholar] [CrossRef]

- George, P.; Strait, J.; Dawlaty, J.; Shivaraman, S.; Chandrashekhar, M.; Rana, F.; Spencer, M. Ultrafast optical-pump terahertz-probe spectroscopy of the carrier relaxation and recombination dynamics in epitaxial graphene. Nano Lett. 2008, 8, 4248–4251. [Google Scholar] [CrossRef]

- Rana, F.; George, P.; Strait, J.; Dawlaty, J.; Shivaraman, S.; Chandrashekhar, M.; Spencer, M. Carrier recombination and generation rates for intravalley and intervalley phonon scattering in graphene. Phys. Rev. B 2009, 79, 115447. [Google Scholar] [CrossRef]

- Park, J.; Ahn, Y.; Ruiz-Vargas, C. Imaging of photocurrent generation and collection in single-layer graphene. Nano Lett. 2009, 9, 1742–1746. [Google Scholar] [CrossRef] [PubMed]

- Freitag, M.; Low, T.; Xia, F.; Avouris, P. Photoconductivity of biased graphene. Nat. Photonics 2013, 7, 53–59. [Google Scholar] [CrossRef]

- Pelella, A.; Grillo, A.; Faella, E.; Luongo, G.; Askari, M.; Di Bartolomeo, A. Graphene–Silicon Device for Visible and Infrared Photodetection. ACS Appl. Mater. Interfaces 2021, 13, 47895–47903. [Google Scholar] [CrossRef]

- Bartolomeo, A.; Luongo, G.; Iemmo, L.; Urban, F.; Giubileo, F. Graphene–Silicon Schottky Diodes for Photodetection. IEEE Trans. Nanotechnol. 2018, 17, 1133–1137. [Google Scholar] [CrossRef]

- Fang, H.; Hu, W. Photogating in low dimensional photodetectors. Adv. Sci. 2017, 4, 1700323. [Google Scholar] [CrossRef]

- Hu, A.-Q.; Liu, Q.-L.; Guo, X. Carrier localization enhanced high responsivity in graphene/semiconductor photodetectors. Chip 2022, 1, 100006. [Google Scholar] [CrossRef]

- Wu, H.; Ding, J.; Yang, D.; Li, J.; Shi, Y.; Zhou, Y. Graphene quantum dots doped ZnO superstructure (ZnO superstructure/GQDs) for weak UV intensity photodetector application. Ceram. Int. 2020, 46, 17800–17808. [Google Scholar] [CrossRef]

- Dawlaty, J.; Shivaraman, S.; Strait, J.; George, P.; Chandrashekhar, M.; Rana, F.; Spencer, M.; Veksler, D.; Chen, Y. Measurement of the optical absorption spectra of epitaxial graphene from terahertz to visible. Appl. Phys. Lett. 2008, 93, 131905. [Google Scholar] [CrossRef]

- Wang, F.; Dukovic, G.; Brus, L.; Heinz, T. Time-Resolved Fluorescence of Carbon Nanotubes and Its Implication for Radiative Lifetimes. Phys. Rev. Lett. 2004, 92, 177401. [Google Scholar] [CrossRef] [PubMed]

- Mueller, T.; Xia, F.; Avouris, P. Graphene photodetectors for high-speed optical communications. Nat. Photonics 2010, 4, 297–301. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, S.; Zheng, H.; Zhan, Y.; Li, D.; Cen, G.; Tang, J.; Lu, H.; Zhang, J.; Zhao, Z.; et al. Gold Enhanced Graphene-Based Photodetector on Optical Fiber with Ultrasensitivity over Near-Infrared Bands. Nanomaterials 2022, 12, 124. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Tang, M. Asymmetric interdigitated electrodes for amperometric detection of soluble products. J. Electrochem. Soc. 2021, 168, 057519. [Google Scholar] [CrossRef]

- Yoo, T.; Kim, Y.; Lee, S.; Kang, C.; Chang, K.; Hwang, H.; Revannath, N.; Lee, B. Zero-Bias Operation of CVD Graphene Photodetector with Asymmetric Metal Contacts. ACS Photonics 2018, 5, 365–370. [Google Scholar] [CrossRef]

- Guo, R.; Liu, W.; Zhang, Y.; Hou, Z.; He, C.; Li, J. Multi-channels electrode parallel structure graphene photodetector with high performance. Mater. Lett. 2020, 260, 126948. [Google Scholar] [CrossRef]

- Singh, R.S.; Nalla, V.; Chen, W.; Ji, W.; Wee, A. Photoresponse in epitaxial graphene with asymmetric metal contacts. Appl. Phys. Lett. 2012, 100, 093116. [Google Scholar] [CrossRef]

- Shimomura, K.; Imai, K.; Nakagawa, K.; Kawai, A.; Hashimoto, K.; Ideguchi, T.; Maki, H. Graphene photodetectors with asymmetric device structures on silicon chips. Carbon Trends 2021, 5, 100100. [Google Scholar] [CrossRef]

- Qiao, H.; Huang, Z.; Ren, X.; Liu, S.; Zhang, Y.; Qi, X.; Zhang, H. Self-powered photodetectors based on 2D materials. Adv. Opt. Mater. 2020, 8, 1900765. [Google Scholar] [CrossRef]

- Tian, W.; Wang, Y.; Chen, L.; Li, L. Self-Powered Nanoscale Photodetectors. Small 2017, 13, 1701848. [Google Scholar] [CrossRef]

- Cha, J.; Son, J.; Hong, J. A Bottom-Electrode Contact: The Most Suitable Structure for Graphene Electronics. Adv. Mater. Interfaces 2020, 9, 2102207. [Google Scholar] [CrossRef]

- Bharadwaj, B.K.; Nath, D.; Pratap, R.; Raghavan, S. Making consistent contacts to graphene: Effect of architecture and growth induced defects. Nanotechnology 2016, 27, 205705. [Google Scholar] [CrossRef] [PubMed]

- Zarei, M.; Sharifi, M. Graphene nanoribbon photodetectors based on an asymmetric potential barrier: A new concept and a new structure. J. Comput. Electron. 2018, 17, 531–539. [Google Scholar] [CrossRef]

- Mueller, T.; Xia, F.; Freitag, M.; Tsang, J.; Avouris, P. Role of contacts in graphene transistors: A scanning photocurrent study. Phys. Rev. B 2009, 79, 245430. [Google Scholar] [CrossRef]

- Yao, Y.; Kats, M.; Genevet, P.; Yu, N.; Song, Y.; Kong, J.; Capasso, F. Broad electrical tuning of graphene-loaded plasmonic antennas. Nano Lett. 2013, 13, 1257–1264. [Google Scholar] [CrossRef]

- Chakraborty, C.; Beams, R.; Goodfellow, K.; Wicks, G.; Novotny, L.; Vamivakas, A. Optical antenna enhanced graphene photodetector. Appl. Phys. Lett. 2014, 105, 241114. [Google Scholar] [CrossRef]

- Cusati, T.; Fiori, G.; Gahoi, A.; Passi, V.; Lemme, M.; Fortunelli, A.; Iannaccone, G. Electrical properties of graphene-metal contacts. Sci. Rep. 2017, 7, 5109. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.; Potts, J.; Ruoff, R. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, X.; Gai, J. Progress and challenges in transfer of large-area graphene films. Adv. Sci. 2016, 3, 1500343. [Google Scholar] [CrossRef]

- Kobayashi, T.; Bando, M.; Kimura, N.; Shimizu, K.; Kadono, K.; Umezu, N.; Miyahara, K.; Hayazaki, S.; Nagai, S.; Mizuguchi, Y. Production of a 100-m-long high-quality graphene transparent conductive film by roll-to-roll chemical vapor deposition and transfer process. Appl. Phys. Lett. 2013, 102, 023112. [Google Scholar] [CrossRef]

- Ahn, Y.; Kim, H.; Kim, Y.-H.; Yi, Y.; Kim, S.-I. Procedure of removing polymer residues and its influences on electronic and structural characteristics of graphene. Appl. Phys. Lett. 2013, 102, 091602. [Google Scholar] [CrossRef]

- Suk, J.; Lee, W.; Lee, J.; Chou, H.; Piner, R.; Hao, Y.; Akinwande, D.; Ruoff, R. Enhancement of the electrical properties of graphene grown by chemical vapor deposition via controlling the effects of polymer residue. Nano Lett. 2013, 13, 1462–1467. [Google Scholar] [CrossRef] [PubMed]

- Ullah, S.; Yang, X.; Ta, H.; Hasan, M.; Bachmatiuk, A.; Tokarska, K.; Trzebicka, B.; Fu, L.; Rummeli, M. Graphene transfer methods: A review. Nano Res. 2021, 14, 3756–3772. [Google Scholar] [CrossRef]

- Liao, C.-D.; Capasso, A.; Queirós, T.; Domingues, T.; Cerqueira, F.; Nicoara, N.; Borme, J.; Freitas, P.; Alpuim, P. Optimizing PMMA solutions to suppress contamination in the transfer of CVD graphene for batch production. Beilstein J. Nanotechnol. 2022, 13, 796–806. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Gao, Y.; Cadusch, J.; Balendhran, S.; Crozier, K. Mid-Wave Infrared Polarization-Independent Graphene Photoconductor with Integrated Plasmonic Nanoantennas Operating at Room Temperature. Adv. Opt. Mater. 2021, 9, 2001854. [Google Scholar] [CrossRef]

- Gangnaik, A.; Georgiev, Y.; Holmes, J. New Generation Electron Beam Resists: A Review. Chem. Mater. 2017, 29, 1898–1917. [Google Scholar] [CrossRef]

- Hasan, R.; Luo, X. Promising Lithography Techniques for Next-Generation Logic Devices. Nanomanufact. Metrol. 2018, 1, 67–81. [Google Scholar] [CrossRef]

- Ferrari, A.; Meyer, J.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.; Roth, S. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Malard, L.; Pimenta, M.; Dresselhaus, G.; Dresselhaus, M. Raman spectroscopy in graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Wu, J.-B.; Lin, M.-L.; Cong, X.; Liu, H.-N.; Tan, P.-H. Raman spectroscopy of graphene-based materials and its applications in related devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef]

- Ferrari, A.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Thomsen, C.; Reich, S. Double Resonant Raman Scattering in Graphite. Phys. Rev. Lett. 2000, 85, 5214–5217. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Wang, Y.; Wang, L.; Ni, Z.; Wang, Z.; Wang, R.; Koo, C.; Shen, Z.; Thong, J. Probing layer number and stacking order of few-layer graphene by Raman Spectroscopy. Small 2010, 6, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Chakraborty, B.; Sood, A. Raman spectroscopy of graphene on different substrates and influence of defects. Bull. Mater. Sci. 2008, 31, 579–584. [Google Scholar] [CrossRef]

- Casiraghi, C.; Pisana, S.; Novoselov, K.; Geim, A.; Ferrari, A. Raman fingerprint of charged impurities in graphene. Appl. Phys. Lett. 2007, 91, 233108. [Google Scholar] [CrossRef]

- Casiraghi, C. Probing disorder and charged impurities in graphene by Raman spectroscopy. Phys. Status Solidi (RRL) Rapid Res. Lett. 2009, 3, 175–177. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Z.; Kumar, M.; Abhilash, T.; Liu, G.-J.; Hakonen, P. Defects in h-BN tunnel barrier for local electrostatic probing of two dimensional materials. APL Mater. 2018, 6, 091102. [Google Scholar] [CrossRef]

- Hanna, A.; Tinkham, M. Variation of the Coulomb staircase in a two-junction system by fractional electron charge. Phys. Rev. B 1991, 44, 5919–5922. [Google Scholar] [CrossRef]

- Mullen, K.; Ben-Jacob, E.; Jaklevic, R.; Schuss, Z. I-Vcharacteristics of coupled ultrasmall-capacitance normal tunnel junctions. Phys. Rev. B 1988, 37, 98–105. [Google Scholar] [CrossRef]

- Geng, H.; Yuan, D.; Yang, Z.; Tang, Z.; Zhang, X.; Yang, K.; Su, Y. Graphene van der Waals heterostructures for high-performance photodetectors. J. Mater. Chem. C 2019, 7, 11056–11067. [Google Scholar] [CrossRef]

- Zhu, X.; Xie, Q.; Tian, H.; Zhang, M.; Gou, Z.; He, S.; Gu, P.; Wu, H.; Li, J.; Yang, D. High photoresponse sensitivity of lithium-doped ZnO (LZO) thin films for weak ultraviolet signal photodetector. J. Alloys Compd. 2019, 805, 309–317. [Google Scholar] [CrossRef]

- Ogawa, S.; Shimatani, M.; Fukushima, S.; Okuda, S.; Kanai, Y.; Ono, T.; Matsumoto, K. Broadband photoresponse of graphene photodetector from visible to long-wavelength infrared wavelengths. Opt. Eng. 2019, 58, 057106. [Google Scholar]

- Fukushima, S.; Shimatani, M.; Okuda, S.; Ogawa, S.; Kanai, Y.; Ono, T.; Inoue, K.; Matsumoto, K. High-Responsivity Graphene Infrared Photodetectors Using Photo-Gating Effect, Infrared Technology and Applications XLV; SPIE: Paris, France, 2019; pp. 450–455. [Google Scholar]

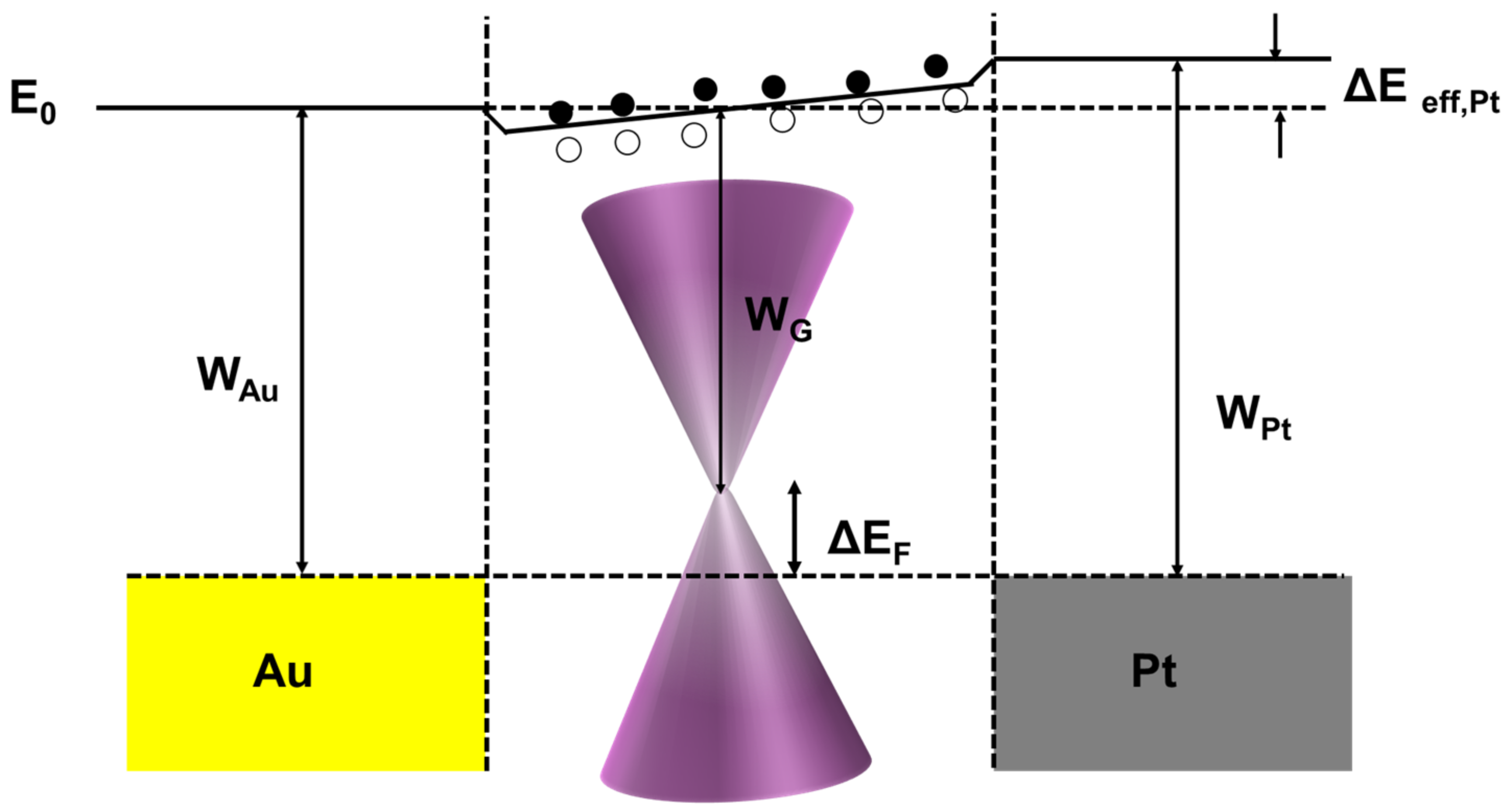

- Giovannetti, G.; Khomyakov, P.; Brocks, G.; Karpan, V.; van den Brink, J.; Kelly, P. Doping Graphene with Metal Contacts. Phys. Rev. Lett. 2008, 101, 026803. [Google Scholar] [CrossRef] [PubMed]

- Khomyakov, P.; Giovannetti, G.; Rusu, P.; Brocks, G.; van den Brink, J.; Kelly, P. First-principles study of the interaction and charge transfer between graphene and metals. Phys. Rev. B 2009, 79, 195425. [Google Scholar] [CrossRef]

- Ruffino, F.; Meli, G.; Grimaldi, M. Nanoscale electrical characteristics of metal (Au, Pd)–graphene–metal (Cu) contacts. Solid State Commun. 2016, 225, 1–6. [Google Scholar] [CrossRef]

- Lee, E.; Balasubramanian, K.; Weitz, R.; Burghard, M.; Kern, K. Contact and edge effects in graphene devices. Nat. Nanotechnol. 2008, 3, 486–490. [Google Scholar] [CrossRef] [PubMed]

- Gan, X.; Shiue, R.-J.; Gao, Y.; Meric, I.; Heinz, T.; Shepard, K.; Hone, J.; Assefa, S.; Englund, D. Chip-integrated ultrafast graphene photodetector with high responsivity. Nat. Photonics 2013, 7, 883–887. [Google Scholar] [CrossRef]

- Gao, Y.; Tao, L.; Tsang, H.; Shu, C. Graphene-on-silicon nitride waveguide photodetector with interdigital contacts. Appl. Phys. Lett. 2018, 112, 211107. [Google Scholar] [CrossRef]

- Chen, Z.; Cheng, Z.; Wang, J.; Wan, X.; Shu, C.; Tsang, H.; Ho, H.; Xu, J. High responsivity, broadband, and fast graphene/silicon photodetector in photoconductor mode. Adv. Opt. Mater. 2015, 3, 1207–1214. [Google Scholar] [CrossRef]

- Ostovari, F.; Moravvej-Farshi, M. Photodetectors with zigzag and armchair graphene nanoribbon channels and asymmetric source and drain contacts: Detectors for visible and solar blind applications. J. Appl. Phys. 2016, 120, 144505. [Google Scholar] [CrossRef]

- Selamneni, V.; Mukherjee, A.; Raghavan, H.; Gomathi, P.; Kolli, C.; Pal, S.; Hazra, A.; Sahatiya, P. Plasmonic Au Nanoparticles Coated on ReS2 Nanosheets for Visible-Near-Infrared Photodetectors. ACS Appl. Nano Mater. 2020, 5, 11381–11390. [Google Scholar] [CrossRef]

- Li, J.; Nie, C.; Sun, F.; Tang, L.; Zhang, Z.; Zhang, J.; Zhao, Y.; Shen, J.; Feng, S.; Shi, H.; et al. Enhancement of the Photoresponse of Monolayer MoS2 Photodetectors Induced by a Nanoparticle Grating. ACS Appl. Mater. Interfaces 2020, 12, 8429–8436. [Google Scholar] [CrossRef] [PubMed]

| Photodetectors | Dark Current (µA) | Photoresponsivity (A/W) | Applied Voltage (V) | Wavelength (nm) | Gap (nm) | Source |

|---|---|---|---|---|---|---|

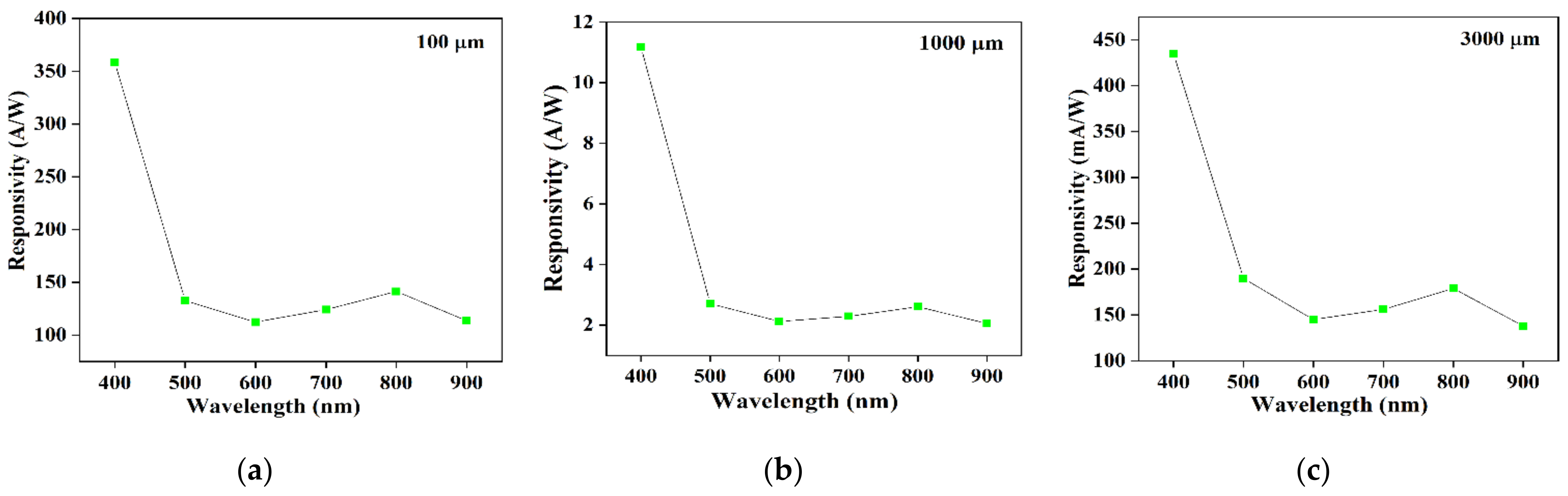

| Au/graphene/Pt | 10 | 358 2.028 | 3 × 10−3 0 | 400 | - | This work |

| Au/graphene/Ti | 70 × 10−3 | 52 × 10−3 | 0 | - | - | [34] |

| Au/graphene/Al | 2 | 4.9 × 10−3 | 0 | 632.8 | - | [36] |

| Graphene-silicon | - | 104 0.23 | 5 | 632 1550 | 105 | [79] |

| Graphene-silicon | 20 | 2.36 | 1 | 1550 | 200 | [78] |

| JC-antennas-graphene | - | 4.8 × 10−3 | 0.1 | - | 40 | [54] |

| Au/graphene/Ti * | - | 13.4 × 10−3 | 0 | 247 | 6 | [80] |

| Au-NPs/ReS2 | - | 2.1 | 0 | 554 | [81] | |

| Au-NPs/MoS2 | - | 38.57 | 0 | 532 | [82] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elkarous, R.; Bardaoui, A.; Borme, J.; Sghaier, N.; Alpuim, P.; Santos, D.M.F.; Chtourou, R. Graphene Nanogap Interdigitated Asymmetric Electrodes for Photodetection. Chemosensors 2023, 11, 181. https://doi.org/10.3390/chemosensors11030181

Elkarous R, Bardaoui A, Borme J, Sghaier N, Alpuim P, Santos DMF, Chtourou R. Graphene Nanogap Interdigitated Asymmetric Electrodes for Photodetection. Chemosensors. 2023; 11(3):181. https://doi.org/10.3390/chemosensors11030181

Chicago/Turabian StyleElkarous, Rabiaa, Afrah Bardaoui, Jérôme Borme, Nabil Sghaier, Pedro Alpuim, Diogo M. F. Santos, and Radhouane Chtourou. 2023. "Graphene Nanogap Interdigitated Asymmetric Electrodes for Photodetection" Chemosensors 11, no. 3: 181. https://doi.org/10.3390/chemosensors11030181

APA StyleElkarous, R., Bardaoui, A., Borme, J., Sghaier, N., Alpuim, P., Santos, D. M. F., & Chtourou, R. (2023). Graphene Nanogap Interdigitated Asymmetric Electrodes for Photodetection. Chemosensors, 11(3), 181. https://doi.org/10.3390/chemosensors11030181