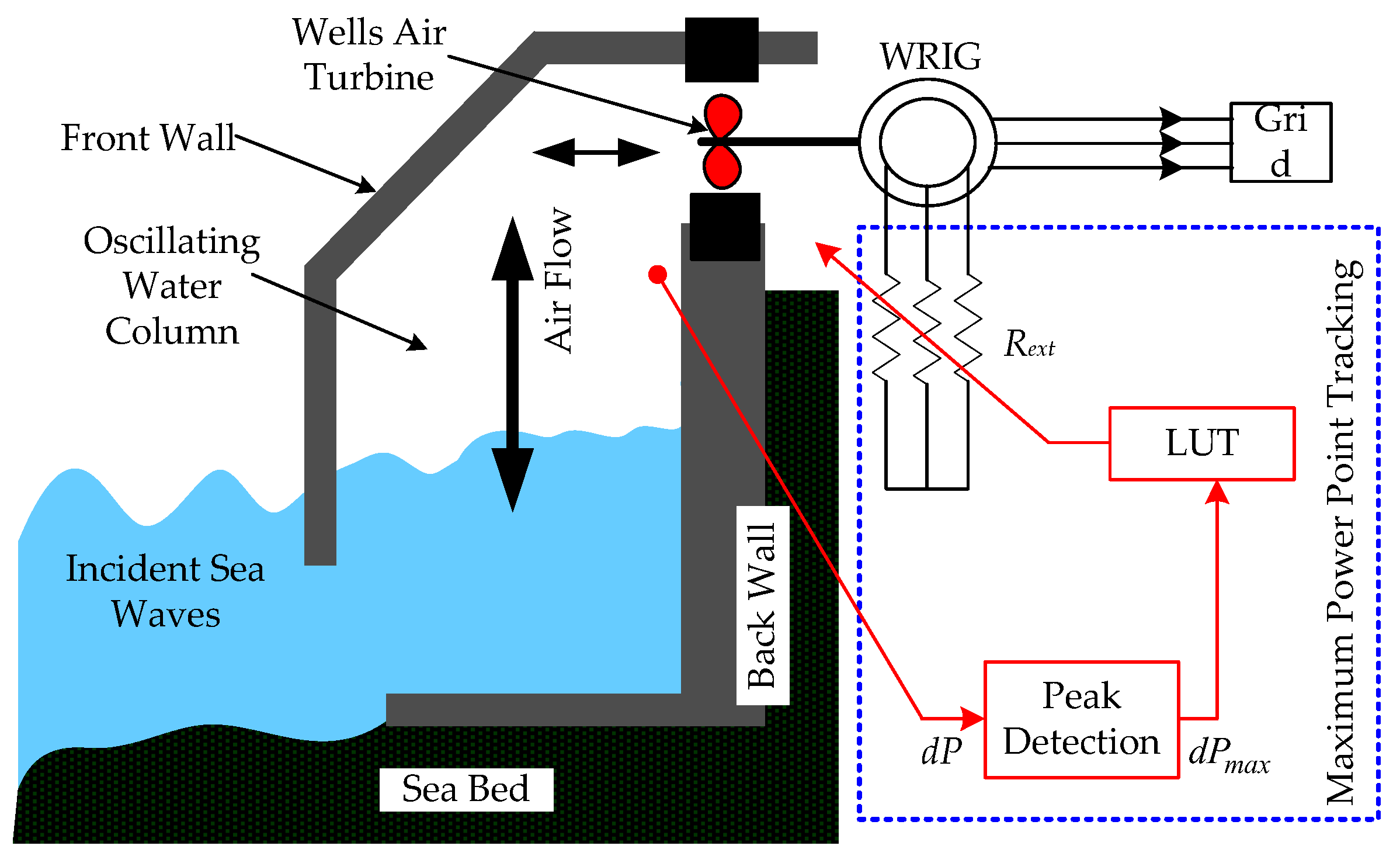

Maximizing Output Power in Oscillating Water Column Wave Power Plants: An Optimization Based MPPT Algorithm

Abstract

:1. Introduction

2. Modelling of OWC Wave Power Plant

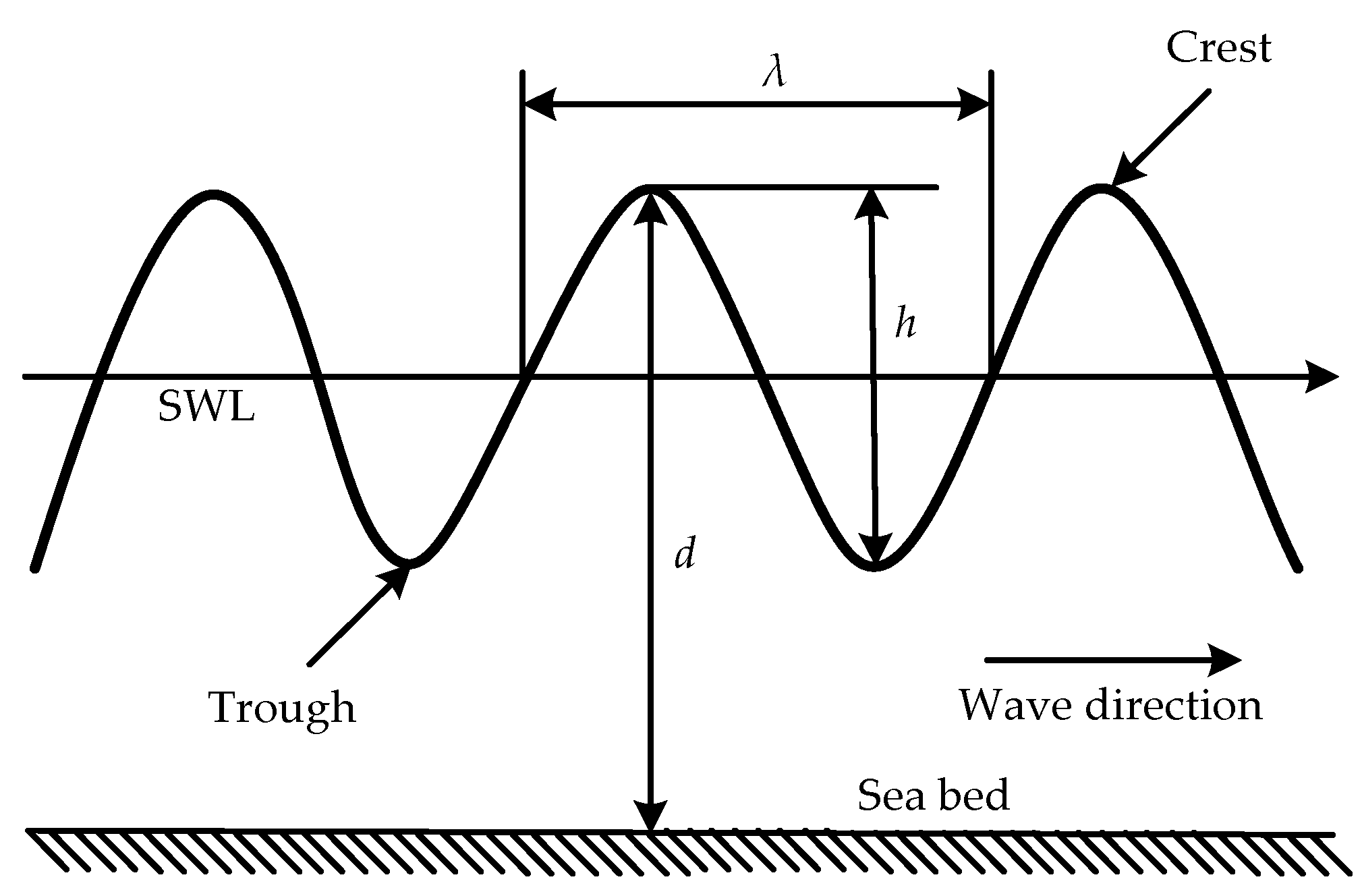

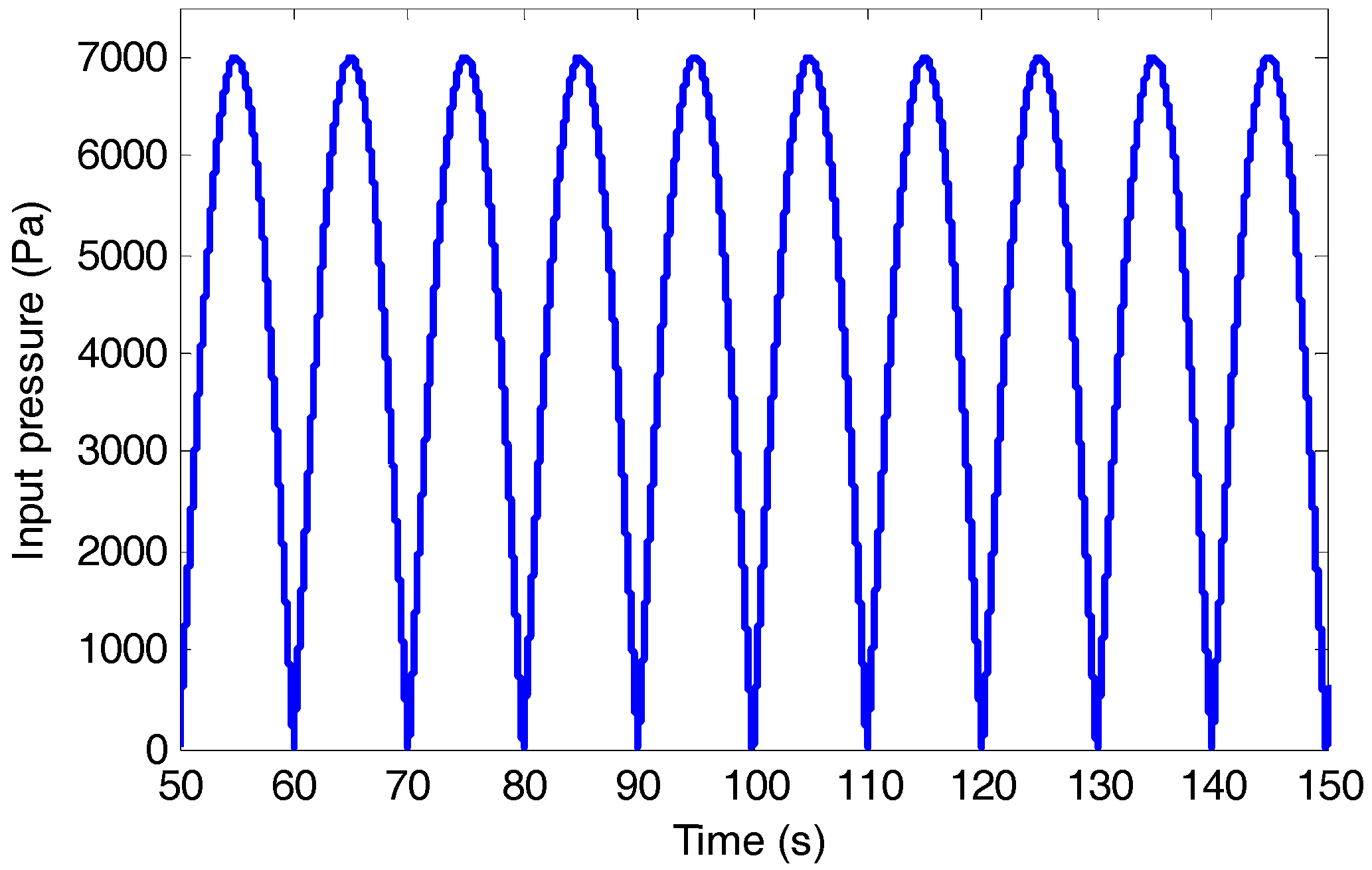

2.1. Mathematical Background of Ocean Waves

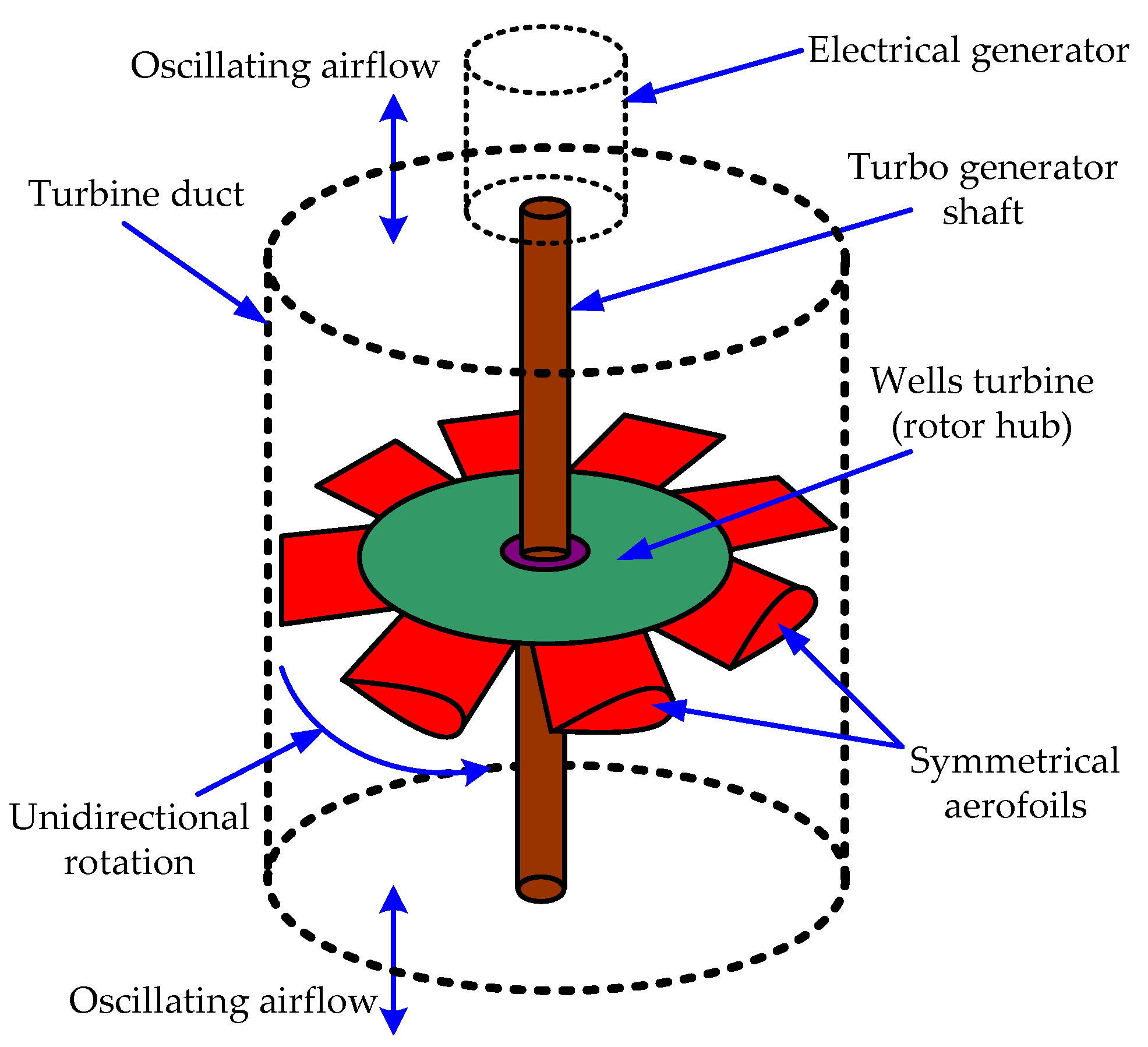

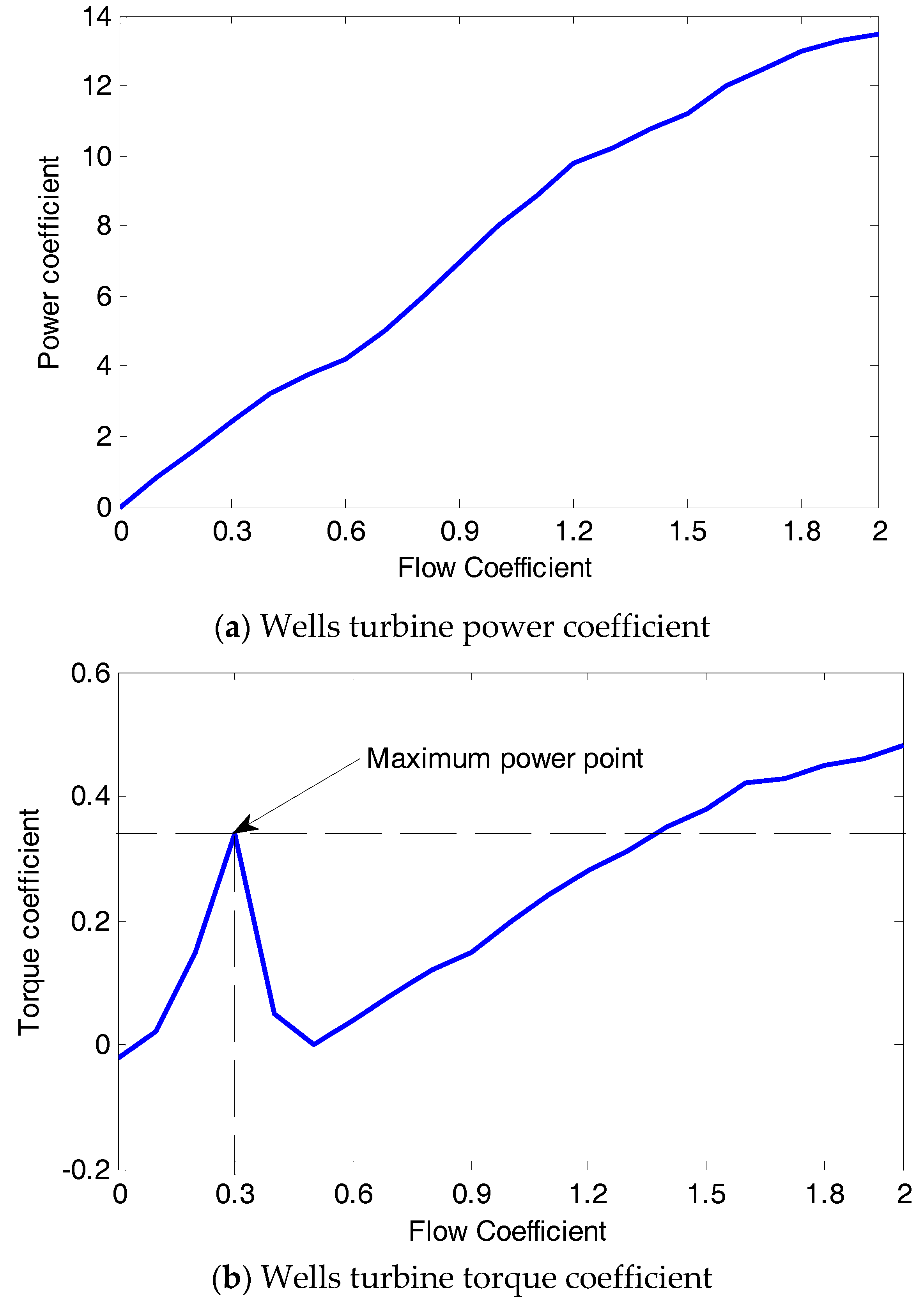

2.2. Wells Turbine

2.3. Wound Rotor Induction Generator Equations

3. Problem Formulation

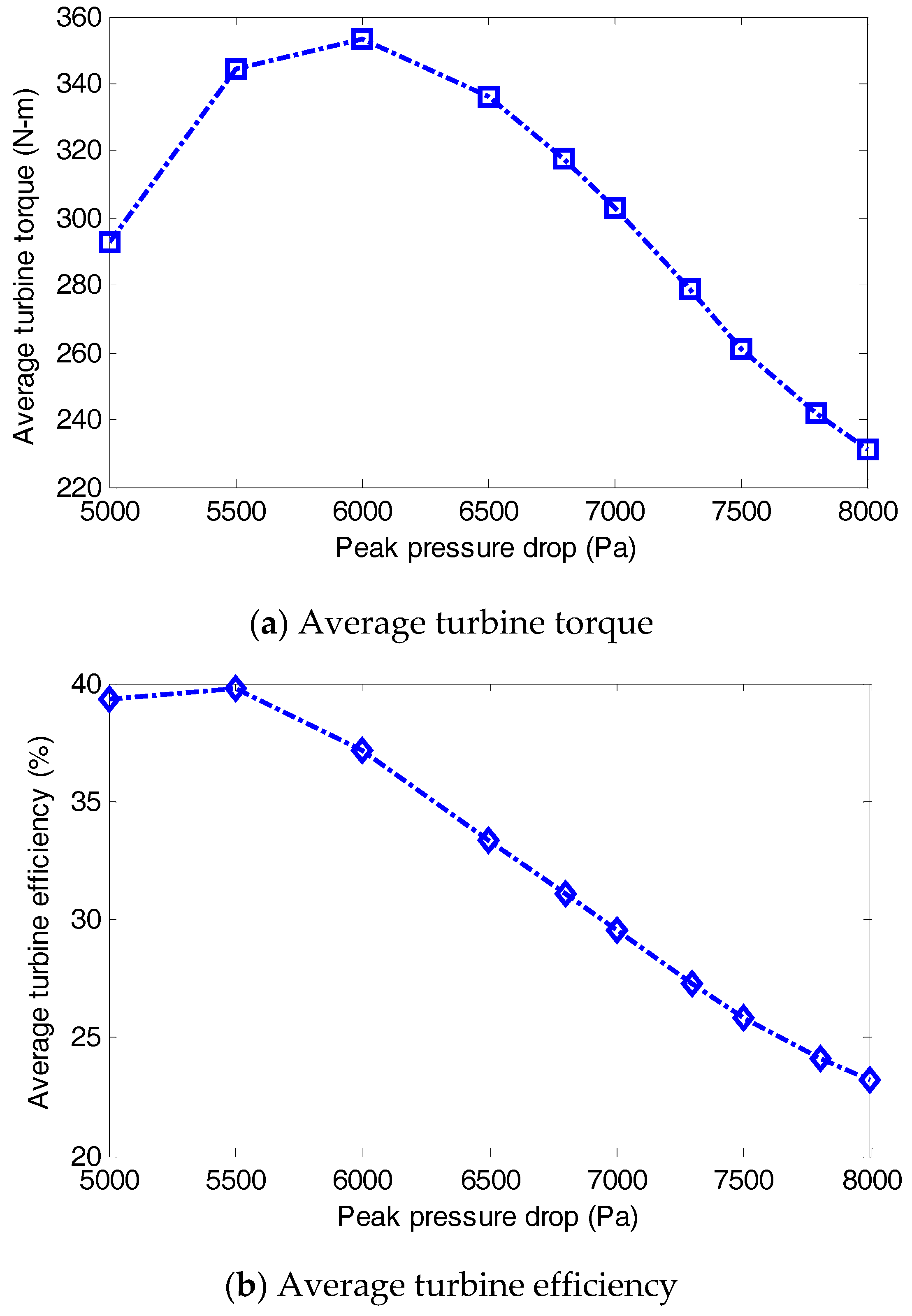

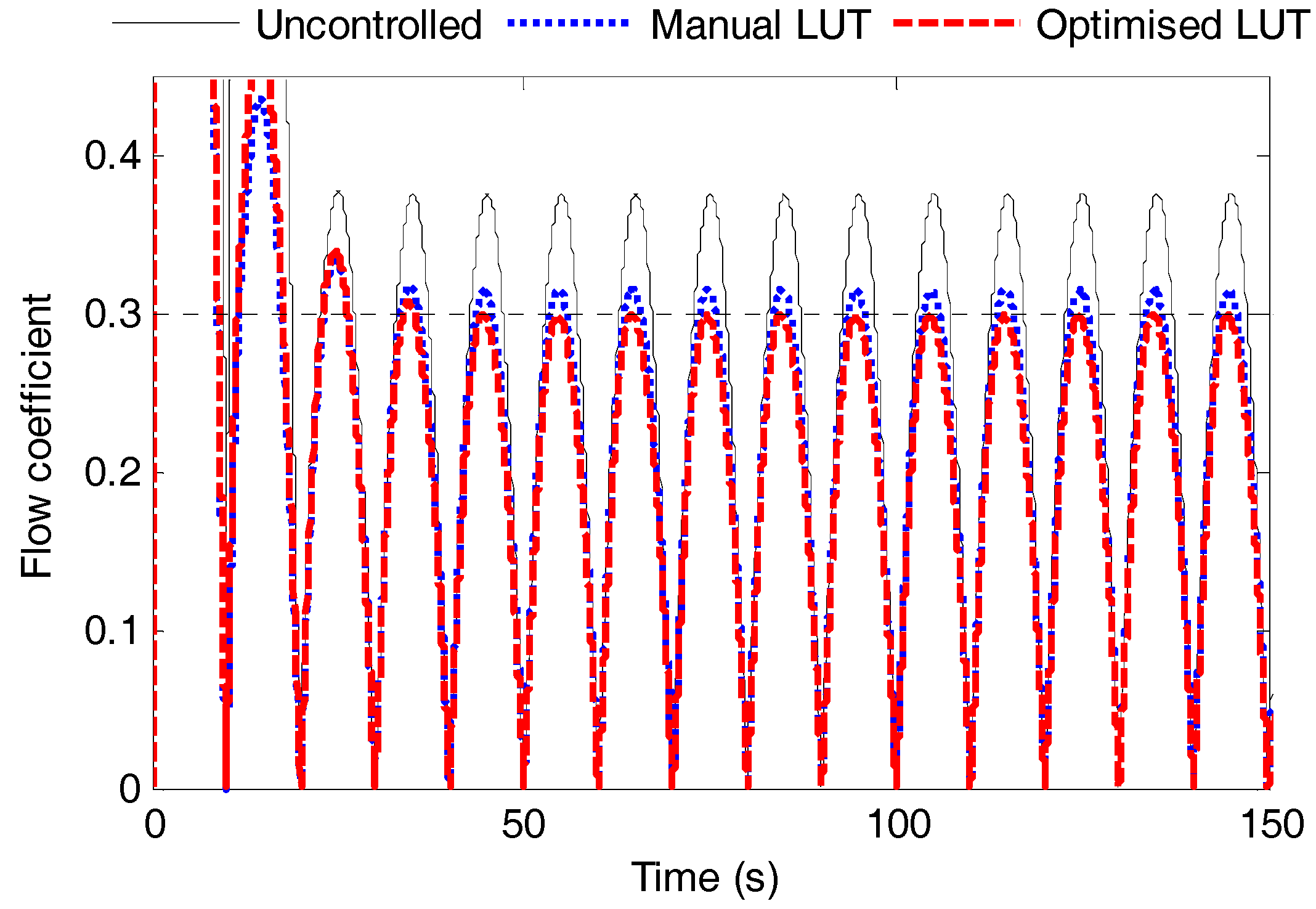

3.1. Turbine Performance without Control

3.2. Why Appropriate Rotor Resistance?

4. Maximization of Average Output Power

4.1. Performance Index

4.2. Particle Swarm Optimization

5. Simulation Results and Discussion

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Rodrigues, L. Wave power conversion systems for electrical energy production. In Proceedings of the International Conference on Renew Energies and Power Quality (ICREPQ’08), Salamanca, Spain, 21–23 May 2008. [Google Scholar]

- Drew, B.; Plummer, A.R.; Sahinkaya, M.N. A review of wave energy converter technology. Proc. Inst. Mech. E Part A J. Power Energy 2009, 223, 887–902. [Google Scholar] [CrossRef]

- Brekken, T.; Batten, B.; Amon, E. From blue to green. IEEE Control Syst. Mag. 2011, 31, 18–24. [Google Scholar] [CrossRef]

- Polinder, H.; Mecrow, B.C.; Jack, A.G.; Dickinson, P.G.; Mueller, M.A. Conventional and TFPM linear generators for direct-drive wave energy conversion. IEEE Trans. Energy Convers. 2005, 20, 260–267. [Google Scholar] [CrossRef]

- Das, B.; Pal, B.C. Voltage control performance of AWS connected for grid operation. IEEE Trans. Energy Convers. 2006, 21, 353–361. [Google Scholar] [CrossRef]

- Ceballos, S.; Rea, J.; Robles, E.; Lopez, I.; Pou, J. O’Sullivan, D. Control strategies for combining local energy storage with Wells turbine oscillating water column devices. Renew. Energy 2015, 83, 1097–1109. [Google Scholar] [CrossRef]

- O’Sullivan, D.L.; Lewis, A.W. Generator selection and comparative performance in offshore oscillating water column ocean wave energy converters. IEEE Trans. Energy Convers. 2011, 26, 603–614. [Google Scholar] [CrossRef]

- Hong, Y.; Waters, R.; Boström, C.; Eriksson, M.; Engström, J.; Leijon, M. Review on electrical control strategies for wave energy converting systems. Renew. Sustain. Energy Rev. 2014, 31, 329–342. [Google Scholar] [CrossRef]

- Falcáo, A.F.O.; Justino, P.A.P. OWC wave energy devices with air flow control. Ocean Eng. 1999, 26, 1275–1295. [Google Scholar] [CrossRef]

- Falcáo, A.F.O.; Vieira, L.C.; Justino, P.A.P.; Andre, J.M.C.S. By-pass air-valve control of an OWC wave power plant. J. Offshore Mech. Arct. Eng. 2003, 125, 205–210. [Google Scholar] [CrossRef]

- Justino, P.A.P.; Falcão, A.F.O. Rotational speed control of an OWC wave power plant. J. Offshore Mech. Arct. Eng. 1999, 121, 65–70. [Google Scholar] [CrossRef]

- Falcão, A.F.O. Control of an oscillating-water-column wave power plant for maximum energy production. Appl. Ocean Res. 2002, 24, 73–82. [Google Scholar] [CrossRef]

- Jayashankar, V.; Karthikeyan, B.; Manivannan, K.; Venkatraman, N.; Rangaprasad, S. Maximizing power output from a wave energy plant. In Proceedings of the 2000 IEEE Power Engineering Society Winter Meeting, Singapore, 23–27 January 2000; pp. 1796–1801. [Google Scholar]

- Ravindran, M.; Koola, P.M. Energy from sea waves-the Indian wave energy program. Curr. Sci. 1991, 60, 676–680. [Google Scholar]

- Mala, K.; Badrinath, S.N.; Chidanand, S.; Kailash, G.; Jayashankar, V. Analysis of power modules in the Indian wave energy plant. In Proceedings of the 2009 Annual IEEE India Conference, Gujarat, India, 18–20 December 2009; pp. 95–98. [Google Scholar]

- Rao, S.S.; Murthy, B.K. Control of induction generator in a Wells Turbine based wave energy system. In Proceedings of the 2005 International Conference on Power Electronics and Drives Systems, Kuala Lumpur, Malaysia, 28 November–1 December 2005; pp. 1590–1594. [Google Scholar]

- Muthukumar, S.; Desai, R.; Jayashankar, V.; Santhakumar, S.; Setoguchi, T. Design of a stand-alone wave energy plant. In Proceedings of the Fifteenth International Offshore and Polar Engineering Conference, Seoul, Korea, 19–24 June 2005; pp. 497–502. [Google Scholar]

- Murthy, B.K.; Rao, S.S. Rotor side control of Wells turbine driven variable speed constant frequency induction generator. Electr. Power Compon. Syst. 2005, 33, 587–596. [Google Scholar] [CrossRef]

- Torre-Enciso, Y.; Ortubia, I.; Aguileta, L.I.L.; Marques, J. Mutriku wave power plant: From the thinking out to the reality. In Proceedings of the 8th European Wave and Tidal Energy Conference, Uppsala, Sweden, 7–10 September 2009; pp. 319–329. [Google Scholar]

- Amundarain, M.; Alberdi, M.; Garrido, A.; Garrido, I. Control of the stalling behaviour in wave power generation plants. In Proceedings of the 2009 Compatibility and Power Electronics, Badajoz, Spain, 20–22 May 2009; pp. 117–122. [Google Scholar]

- Alberdi, M.; Amundarain, M.; Maseda, F.J.; Barambones, O. Stalling behaviour improvement by appropriately choosing the rotor resistance value in wave power generation plants. In Proceedings of the 2009 International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009; pp. 64–67. [Google Scholar]

- Amundarain, M.; Alberdi, M.; Garrido, I.; Garrido, A. Wells turbine control in wave power generation plants. In Proceedings of the 2009 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 3–6 May 2009; pp. 177–182. [Google Scholar]

- Amundarain, M.; Alberdi, M.; Garrido, A.J.; Garrido, I. Neural control of the Wells turbine-generator module. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) Held Jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 7315–7320. [Google Scholar]

- Young, I.R. Wind Generated Ocean Waves; Elsevier: Oxford, UK, 1999. [Google Scholar]

- Brooke, J. Wave Energy Conversion; Elsevier: Oxford, UK, 2003. [Google Scholar]

- Mishra, S.K.; Purwar, S.; Kishor, N. An optimal and non-linear speed control of oscillating water column wave energy plant with wells turbine and DFIG. Int. J. Renew. Energy Res. 2016, 6, 995–1006. [Google Scholar]

- Amundarain, M.; Alberdi, M.; Garrido, A.J.; Garrido, I.; Maseda, J. Wave energy plants: Control strategies for avoiding the stalling behaviour in the Wells turbine. Renew. Energy 2010, 35, 2639–2648. [Google Scholar] [CrossRef]

- Amundarain, M.; Alberdi, M.; Garrido, A.J.; Garrido, I. Control strategies for OWC wave power plants. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010. [Google Scholar]

- Setoguchi, T.; Santhakumar, S.; Takao, M.; Kim, T.H.; Kaneko, K. A modified Wells turbine for wave energy conversion. Renew. Energy 2003, 28, 79–91. [Google Scholar] [CrossRef]

- Wilamowski, B.M.; Irwin, J.D. Power Electronics and Motor Drives; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Clerc, M. Particle Swarm Optimization; ISTE Ltd.: London, UK, 2006. [Google Scholar]

- Laudani, A.; Fulginei, F.R.; Lozito, G.M.; Salvini, A. Swarm/flock optimization algorithms as continuous dynamic systems. Appl. Math. Comput. 2014, 243, 670–683. [Google Scholar] [CrossRef]

- Shilaja, C.; Ravi, K. Optimal power flow considering intermittent wind power using particle swarm optimization. Int. J. Renew. Energy Res. 2016, 6, 504–509. [Google Scholar]

- Rao, R.V.; Patel, V. Design optimization of shell and tube heat exchangers using swarm optimization algorithms. Proc. Inst. Mech. E. Part A J. Power Energy 2011, 225, 619–634. [Google Scholar] [CrossRef]

| Turbine | Generator | PSO |

|---|---|---|

| n = 8 | p = 4 | n = 10 |

| kt = 0.7079 | Rs = 0.0181 | m = 1 |

| r = 0.7285 | Lls = 0.13 | kmax = 10 |

| at = 1.1763 | Lm = 7.413 | c1 = 2 |

| b = 0.4 | Rr = 0.0334 | c2 = 2 |

| l = 0.38 | Llr = 0.16 | wmax = 0.9 |

| gb = 1:2 | f = 50 Hz | wmin = 0.1 |

| J = 50 | Vs = 390 V, Prated = 55 kW |

| dPmax (Pa) | φ | ||

|---|---|---|---|

| 5000 | 0–0.2789 | 39.39 | −22.87 |

| 5500 | 0–0.3006 | 39.98 | −27.27 |

| 6000 | 0–0.3254 | 37.56 | −28.29 |

| 6500 | 0–0.3511 | 33.77 | −26.82 |

| 6800 | 0–0.3665 | 31.40 | −25.29 |

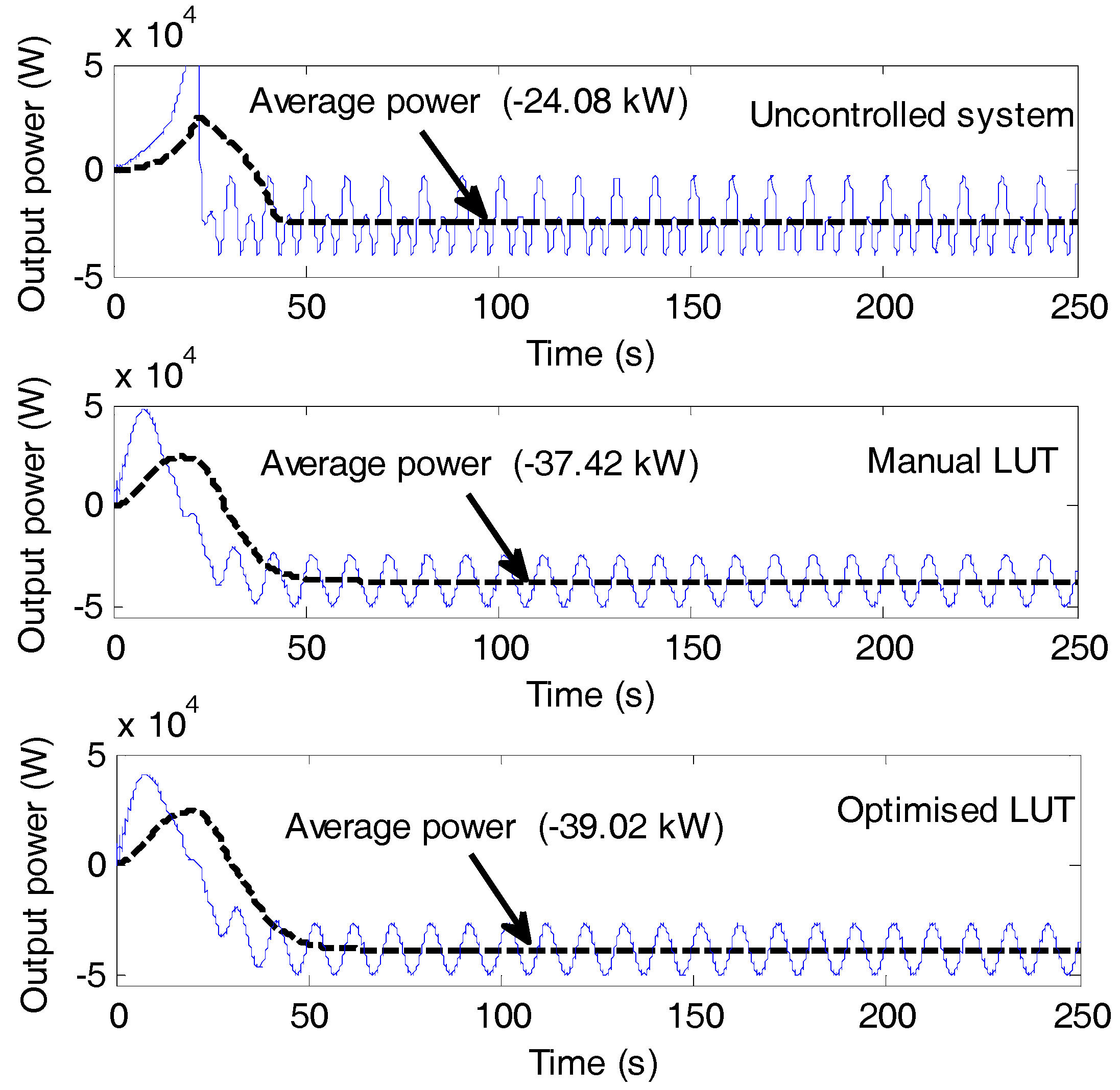

| 7000 | 0–0.3767 | 29.83 | −24.08 |

| 7300 | 0–0.3921 | 27.53 | −22.02 |

| 7500 | 0–0.4026 | 26.08 | −20.57 |

| 7800 | 0–0.4196 | 24.38 | −19.01 |

| 8000 | 0–0.4305 | 23.39 | −18.15 |

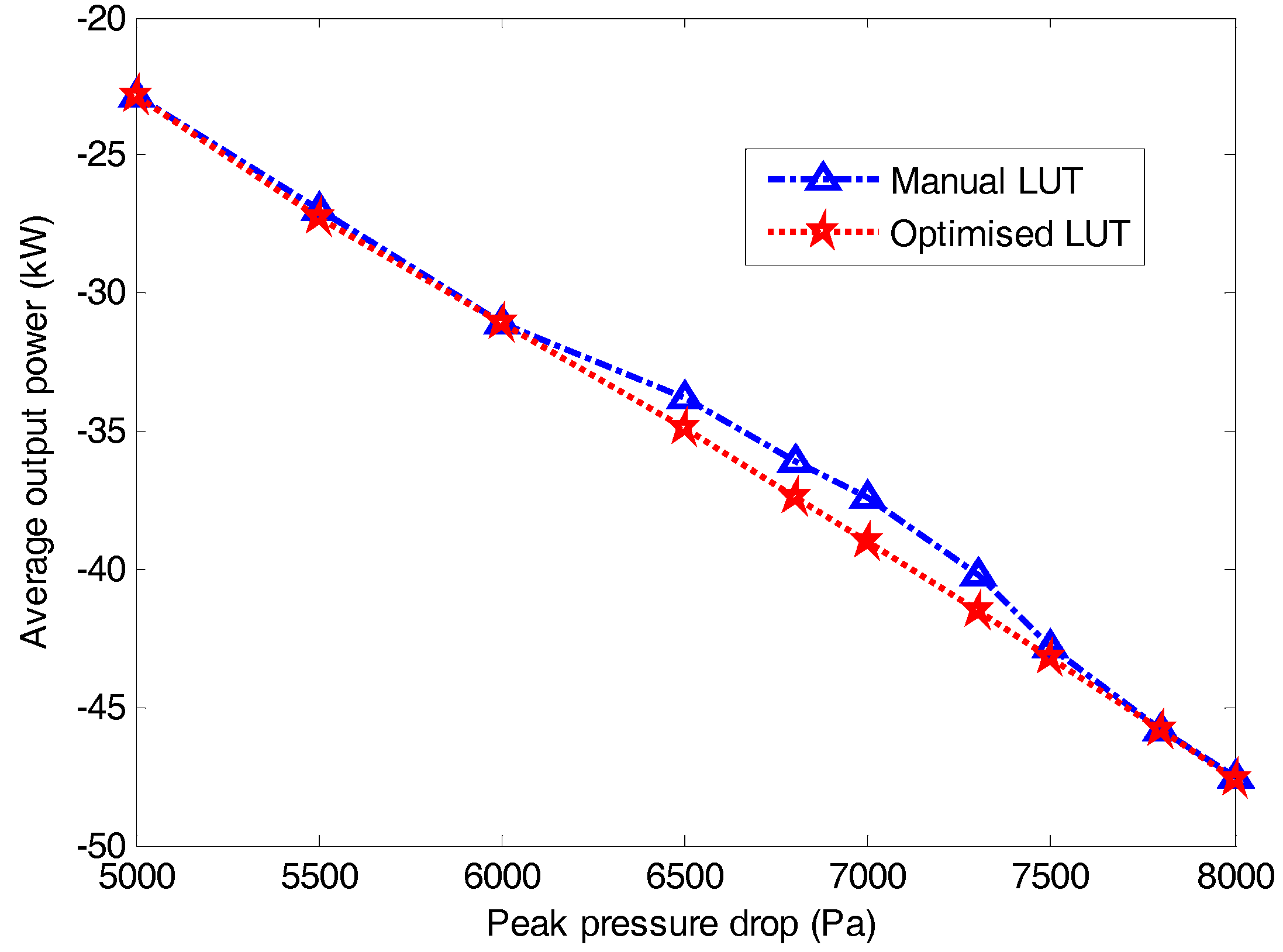

| dPmax (Pa) | Rext (Ω) | φ | ||

|---|---|---|---|---|

| 5000 | 0.00 | 0–0.2789 | 39.39 | −22.87 |

| 5500 | 0.10 | 0–0.2919 | 39.88 | −27.01 |

| 6000 | 0.20 | 0–0.3029 | 39.96 | −31.04 |

| 6500 | 0.30 | 0–0.3135 | 39.00 | −33.84 |

| 6800 | 0.40 | 0–0.3141 | 38.88 | −36.08 |

| 7000 | 0.45 | 0–0.3157 | 38.68 | −37.42 |

| 7300 | 0.55 | 0–0.3137 | 38.88 | −40.21 |

| 7500 | 0.65 | 0–0.3074 | 39.45 | −42.81 |

| 7800 | 0.75 | 0–0.3034 | 39.69 | −45.81 |

| 8000 | 0.85 | 0–0.2981 | 39.72 | −47.57 |

| dPmax (Pa) | Rext (Ω) | Φ | ||

|---|---|---|---|---|

| 5000 | 0.0 | 0–0.2789 | 39.39 | −22.87 |

| 5500 | 0.0186 | 0–0.2995 | 39.99 | −27.26 |

| 6000 | 0.2434 | 0–0.2995 | 39.99 | −31.06 |

| 6500 | 0.4420 | 0–0.2995 | 39.87 | −34.94 |

| 6800 | 0.5464 | 0–0.2995 | 39.83 | −37.36 |

| 7000 | 0.6041 | 0–0.2995 | 39.81 | −39.02 |

| 7300 | 0.6833 | 0–0.2995 | 39.78 | −41.54 |

| 7500 | 0.7291 | 0–0.2995 | 39.77 | −43.26 |

| 7800 | 0.7970 | 0–0.2995 | 39.76 | −45.87 |

| 8000 | 0.8321 | 0–0.2995 | 39.75 | −47.65 |

| Rext (Ω) | |Pg| (kW) | |PL| (kW) | Overall Power Extraction = |Pg| − |PL| (kW) |

|---|---|---|---|

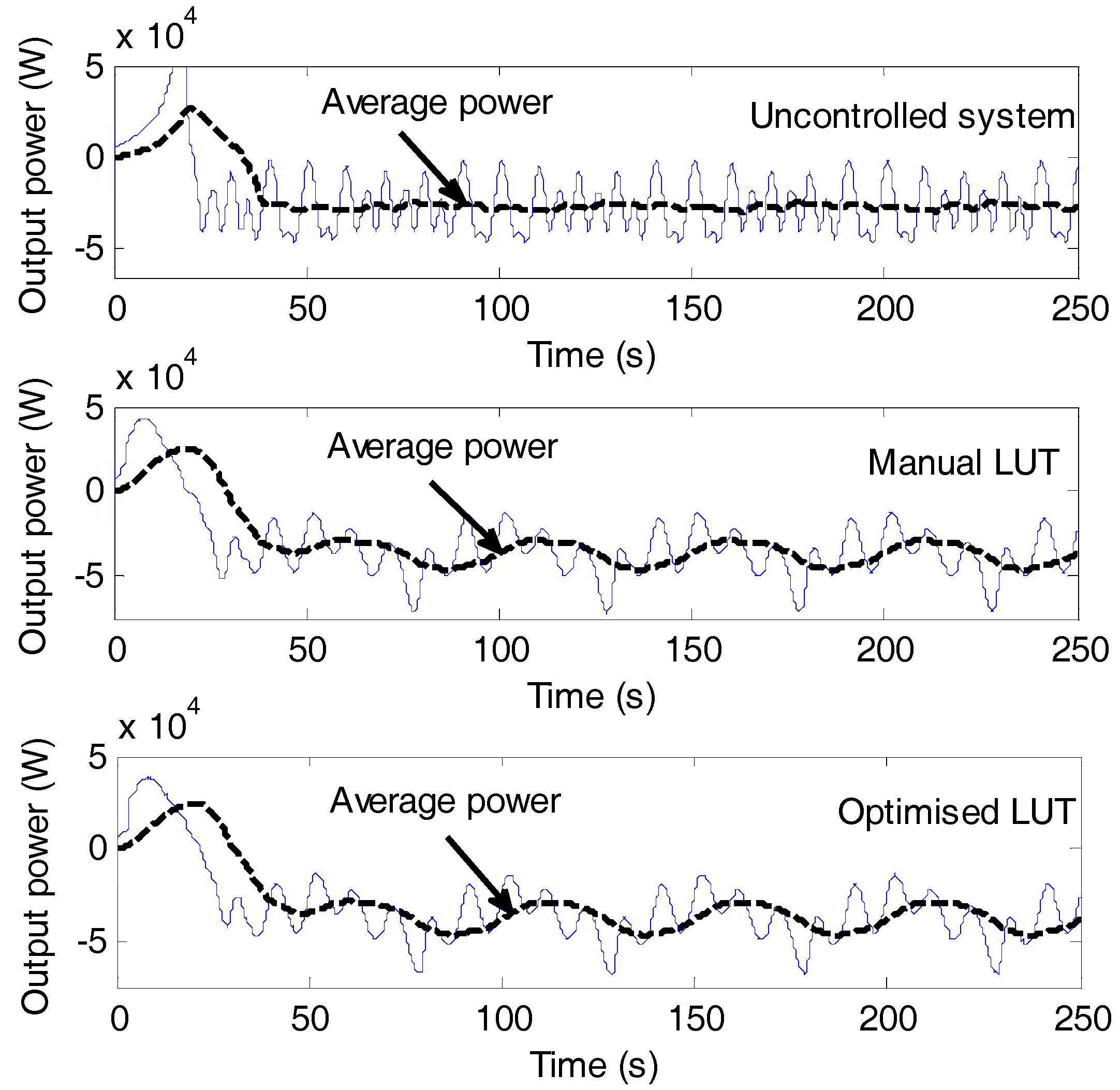

| 0.00 (uncontrolled) | 23.69 | 0.00 | 23.69 |

| 0.45 (manual) | 37.42 | 3.36 | 34.06 |

| 0.6041 (optimised) | 39.02 | 4.52 | 34.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishra, S.K.; Purwar, S.; Kishor, N. Maximizing Output Power in Oscillating Water Column Wave Power Plants: An Optimization Based MPPT Algorithm. Technologies 2018, 6, 15. https://doi.org/10.3390/technologies6010015

Mishra SK, Purwar S, Kishor N. Maximizing Output Power in Oscillating Water Column Wave Power Plants: An Optimization Based MPPT Algorithm. Technologies. 2018; 6(1):15. https://doi.org/10.3390/technologies6010015

Chicago/Turabian StyleMishra, Sunil Kumar, Shubhi Purwar, and Nand Kishor. 2018. "Maximizing Output Power in Oscillating Water Column Wave Power Plants: An Optimization Based MPPT Algorithm" Technologies 6, no. 1: 15. https://doi.org/10.3390/technologies6010015

APA StyleMishra, S. K., Purwar, S., & Kishor, N. (2018). Maximizing Output Power in Oscillating Water Column Wave Power Plants: An Optimization Based MPPT Algorithm. Technologies, 6(1), 15. https://doi.org/10.3390/technologies6010015