Intelligent Automated Monitoring and Curing System for Cracks in Concrete Elements Using Integrated Sensors and Embedded Controllers

Abstract

1. Introduction

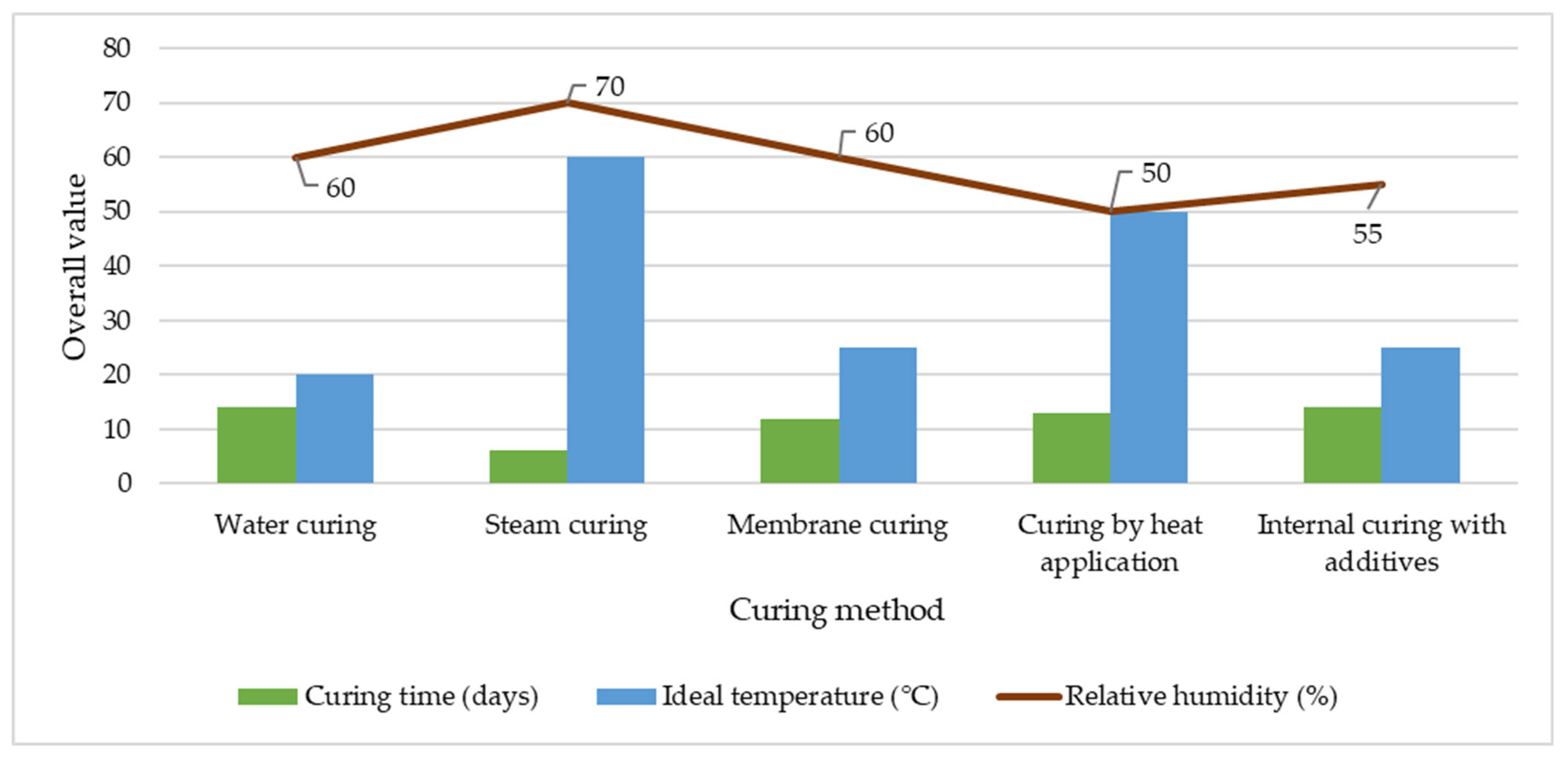

1.1. State of the Art

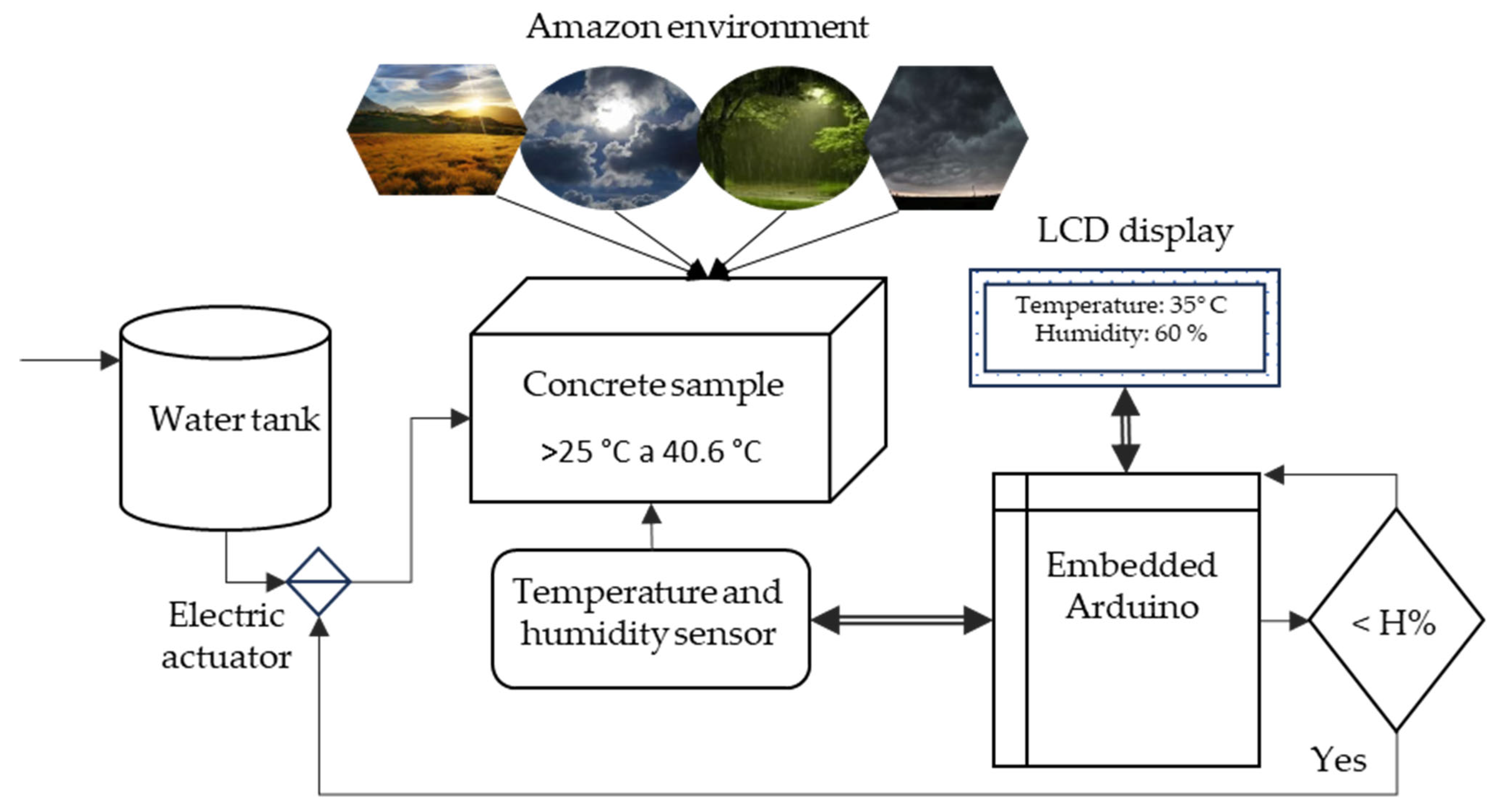

1.2. Intelligent Monitoring and Automated Curing System

1.3. Formation and Rehabilitation of Cracks in Concrete Elements

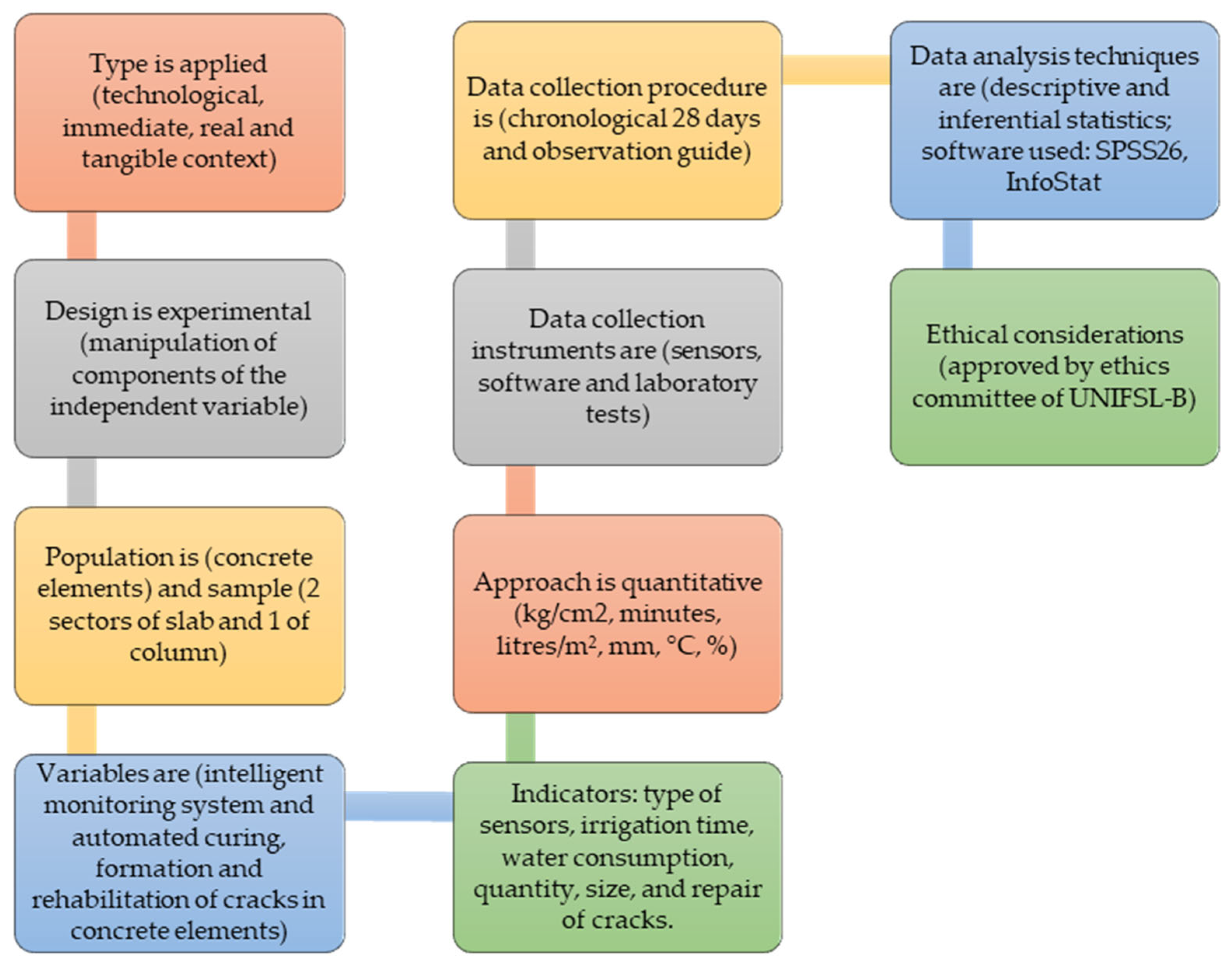

2. Methods

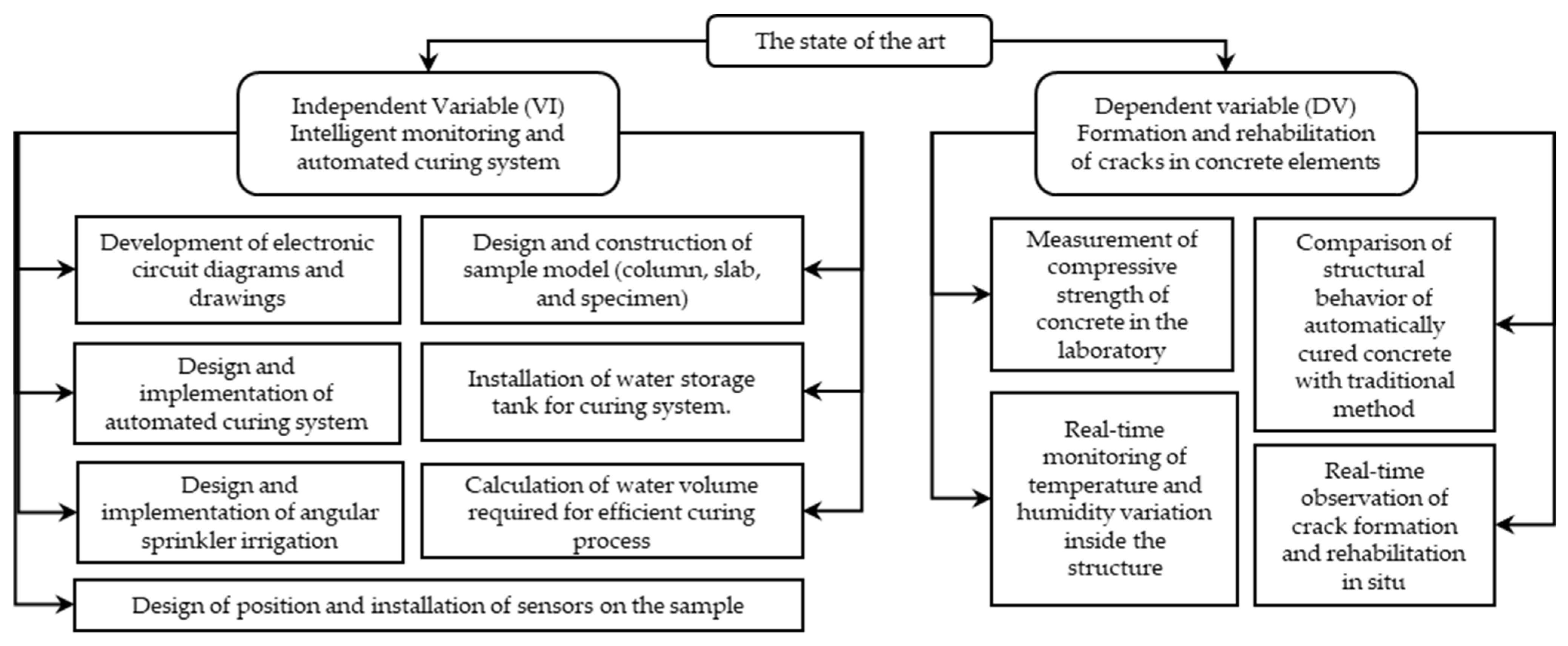

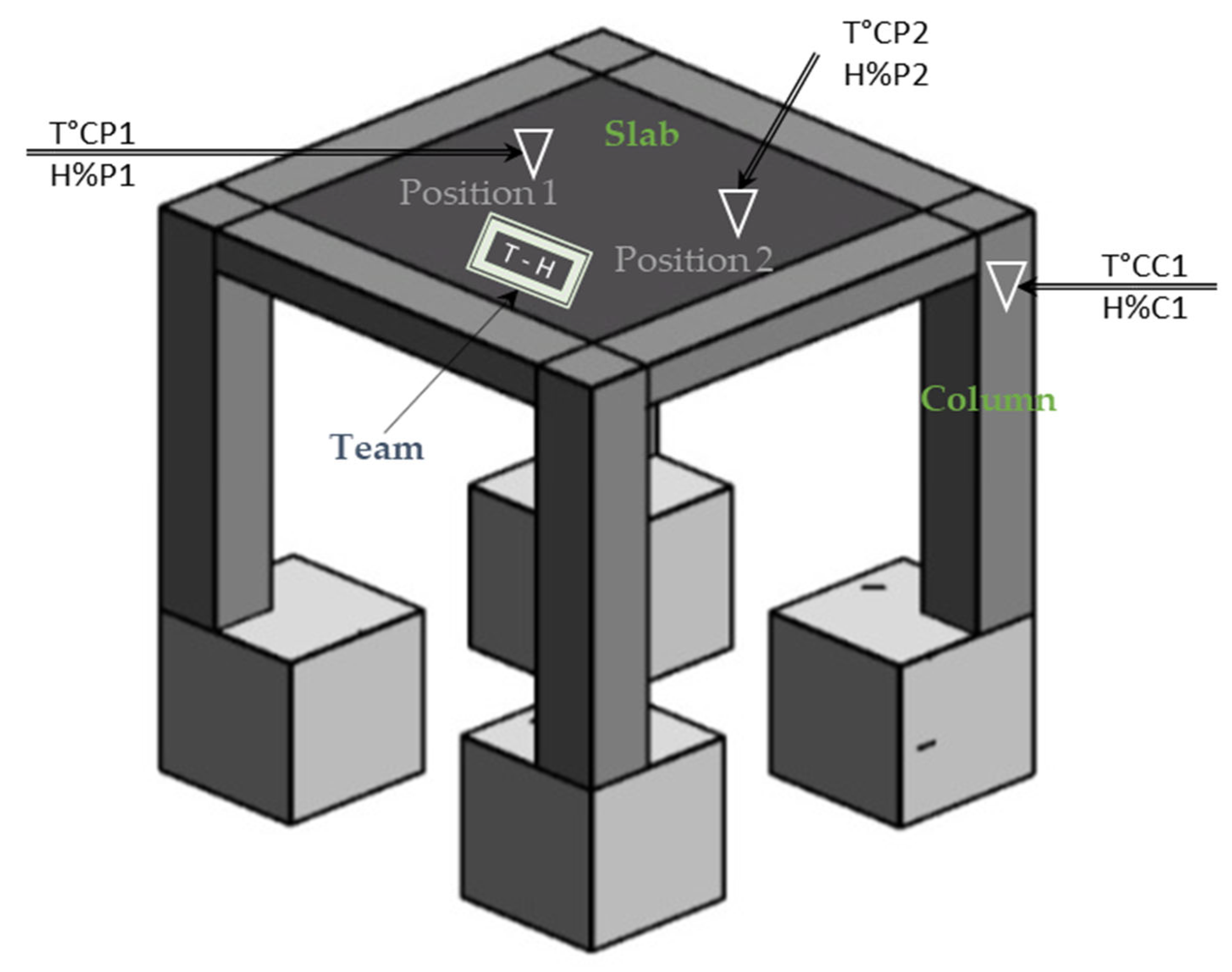

2.1. Variables and Indicators

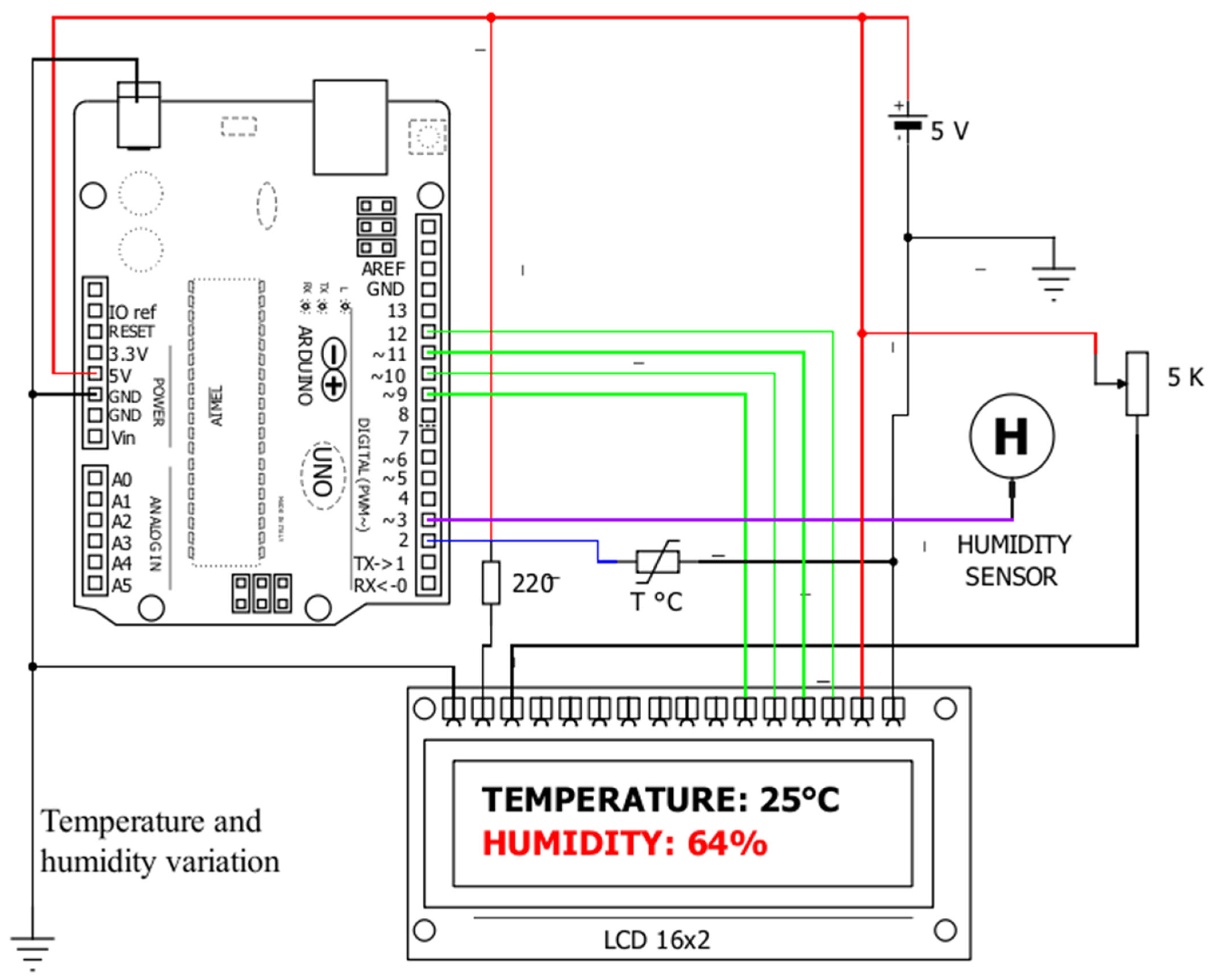

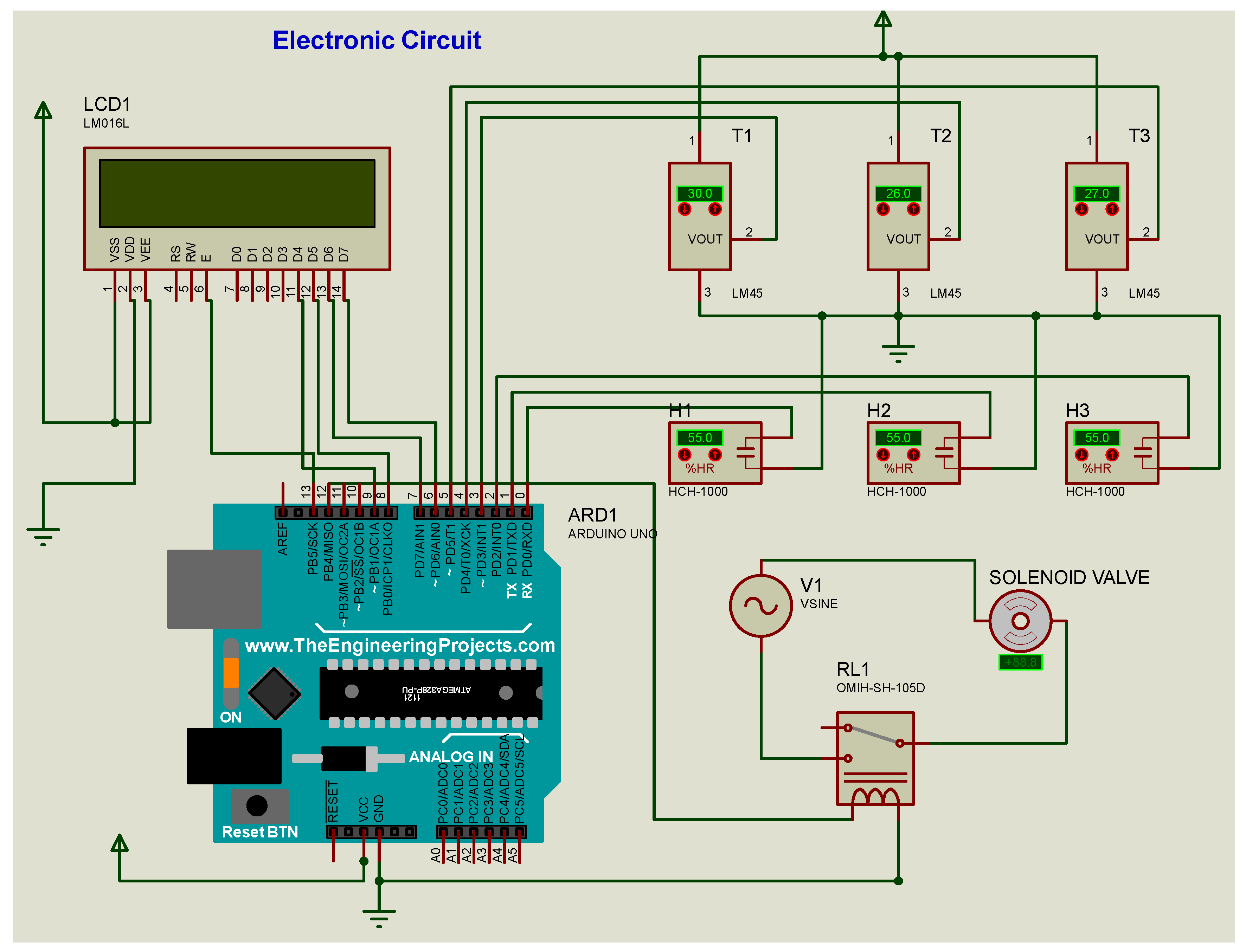

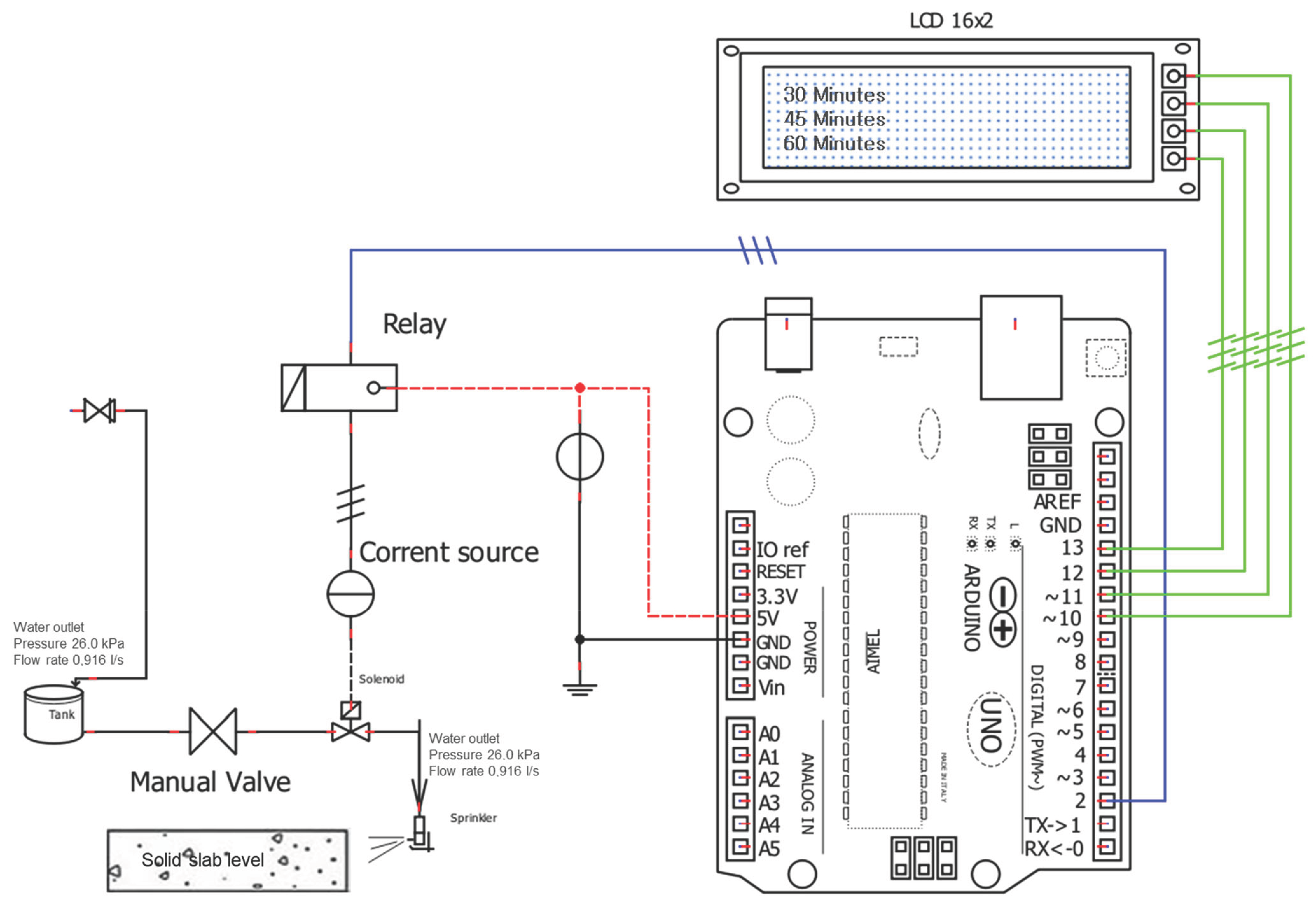

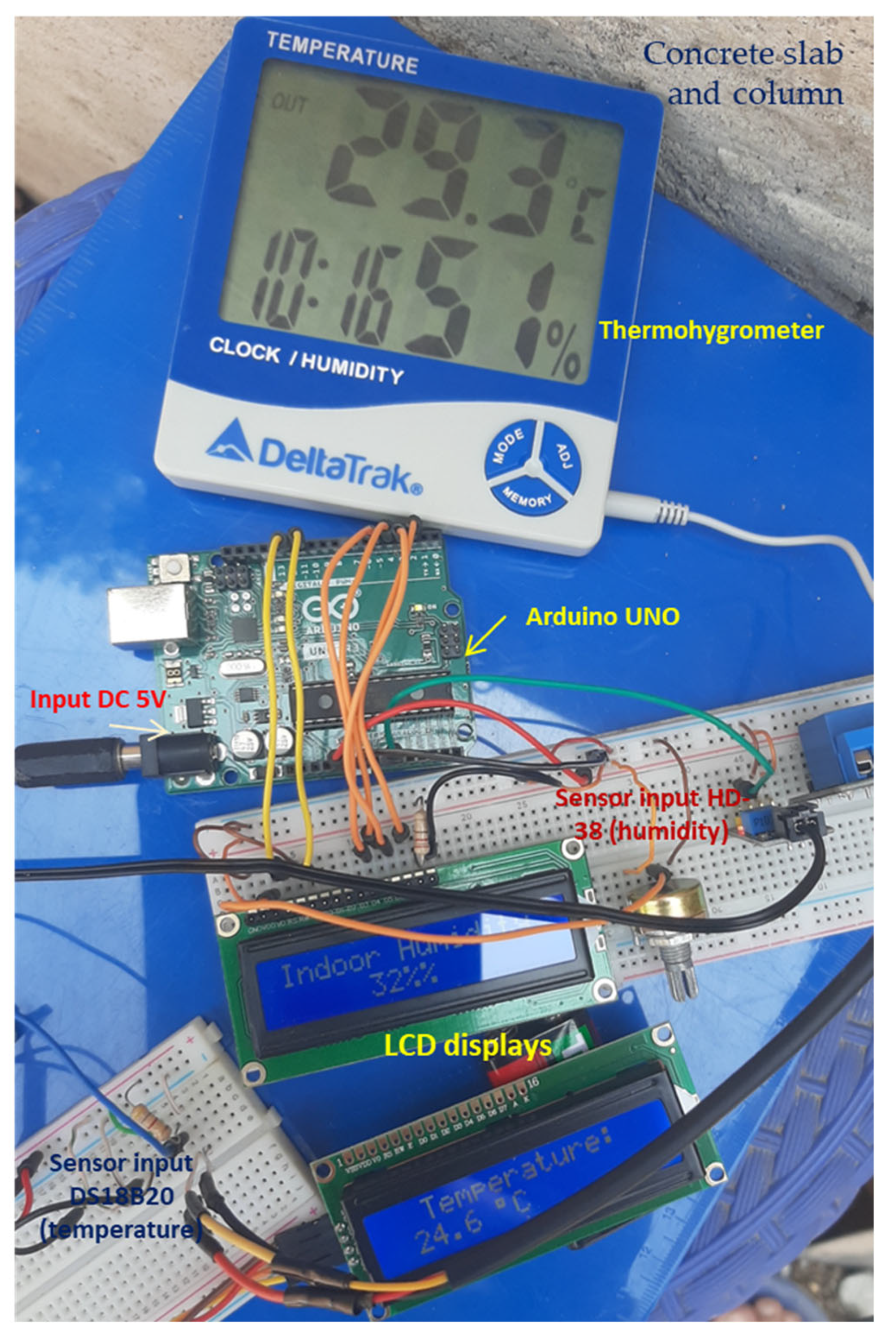

2.2. Instruments and Materials

2.3. Procedure

- Sample preparation: Design and manufacture of standardized molds; mixing and pouring of concrete with homogeneity.

- 2.

- Sensor installation: Strategic placement of sensors to capture surface and internal thermal and humidity variables.

- 3.

- Design and Monitoring: Use of Arduino for automated data recording (internal environmental conditions), which is displayed on LCD screens.

- 4.

- Curing activation: Embedded algorithm analyzed data and activated sprinklers and solenoid valves when deviations from defined thresholds (min) occurred, ensuring optimal conditions during curing.

- 5.

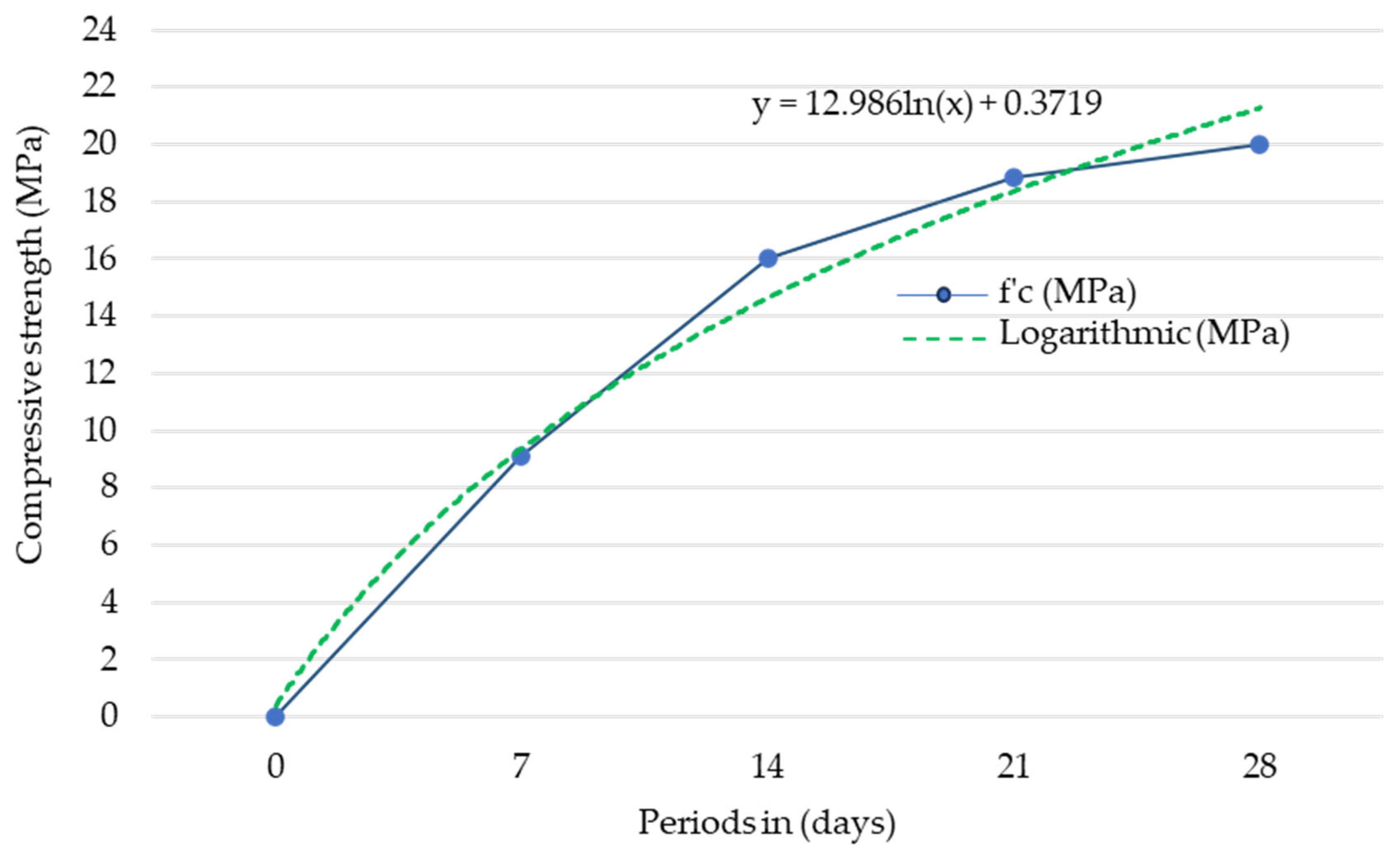

- Strength measurement: At 7, 14, and 21 days, compressive strength tests were performed in accordance with national and international technical standards: the National Building Code (RNE), ASTM C39, and ISO 1920-10. [75].

- 6.

2.4. Methodological Quality

3. Results

3.1. Evaluation of Mechanical Behavior Through Compression Tests

3.2. Verification of the Efficiency and Performance of the Electronic System

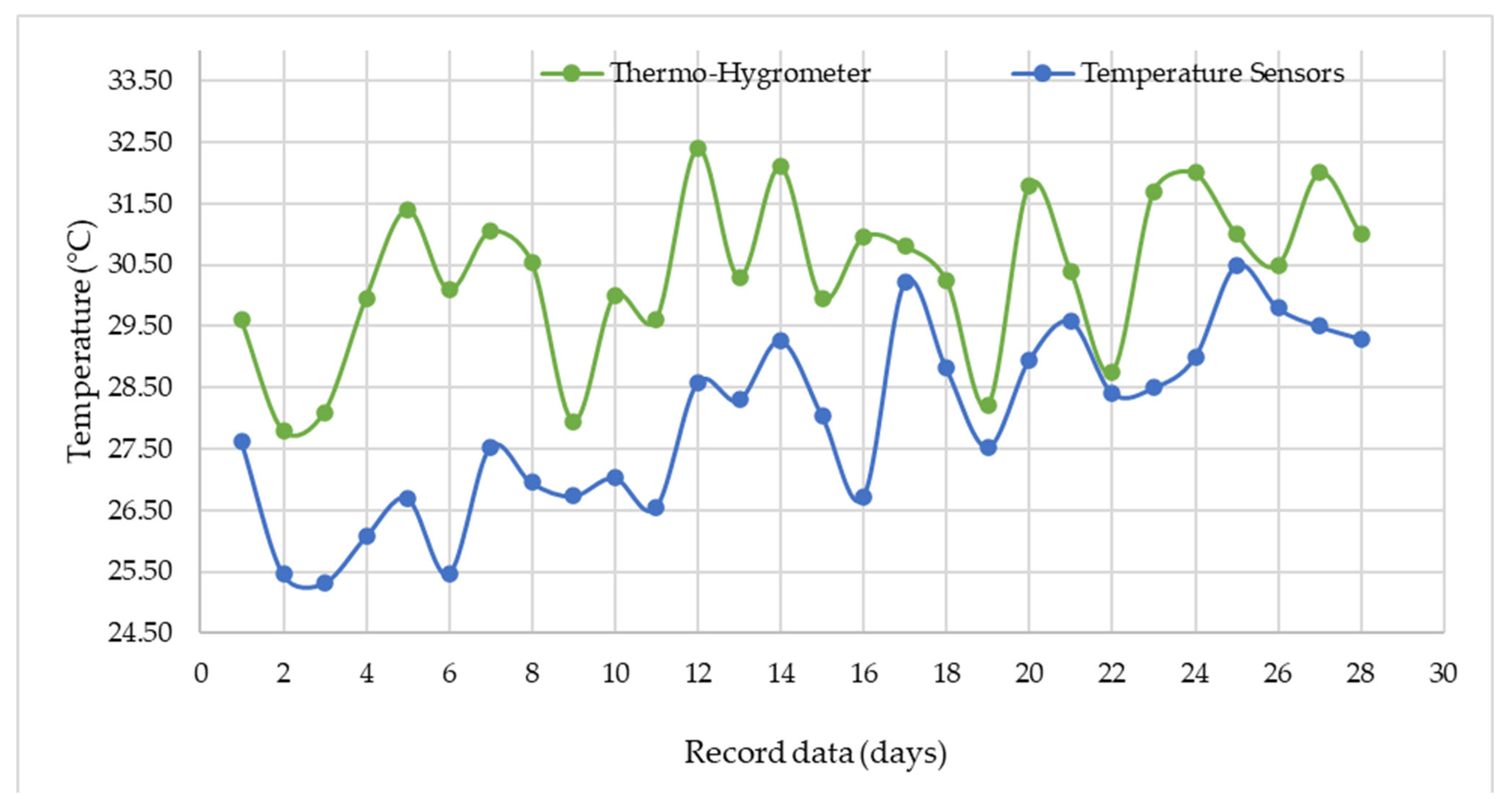

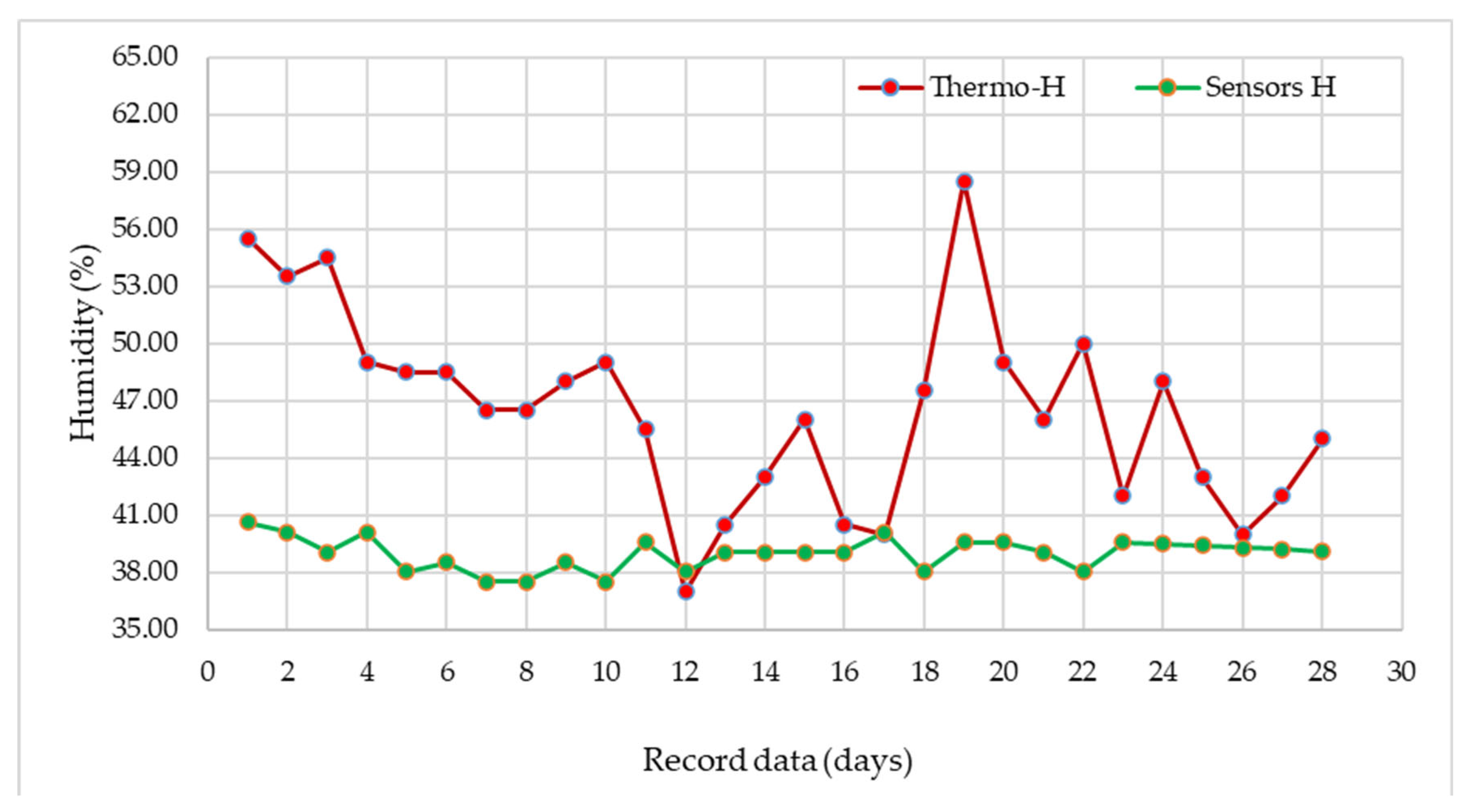

3.3. Accuracy, Sensitivity, and Response Time of Embedded Sensors

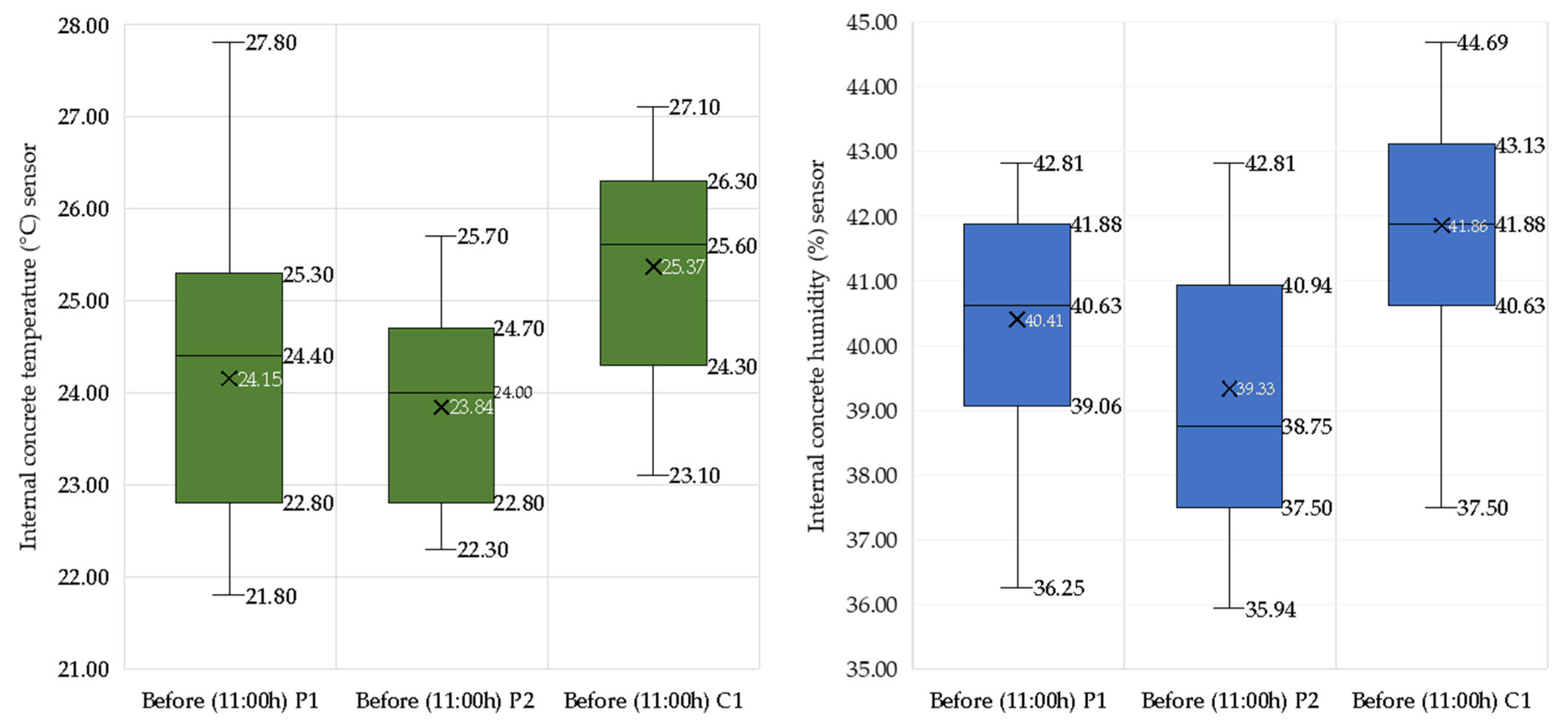

3.4. Internal Thermal and Hygrometric Analysis of Concrete

3.5. Crack Formation and Detection Using Embedded Monitoring

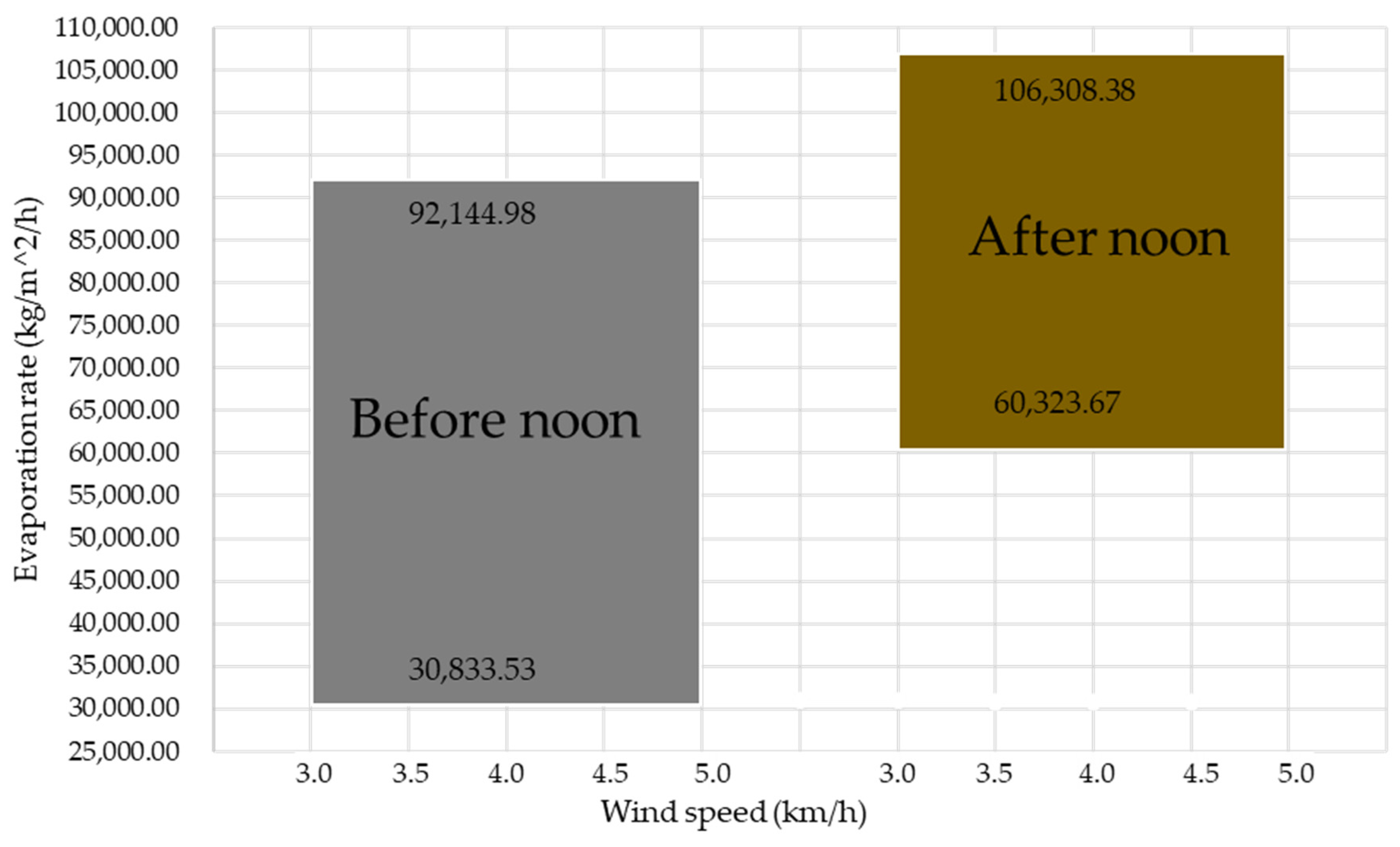

3.6. Efficiency of the Automated Irrigation System in Curing

3.7. Validation of the Elevated Tank as Part of the Automatic Curing System

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burlacu, A.; Sosoi, G.; Abid, C.; Barbuta, M.; Verdes, M.; Vizitiu, R.S.; Branoaea, M. Innovative Passive and Environmentally Friendly System for Improving the Energy Performance of Buildings. Materials 2022, 15, 7224. [Google Scholar] [CrossRef] [PubMed]

- Común, E.; Sanabria, A.; Mosquera, L.; Torre, A. Application of self-curing concrete method using polyethylene glycol. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, Virtual, 27–31 July 2020. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Al Mughairi, M.; Beach, T.; Rezgui, Y. Post-occupancy evaluation for enhancing building performance and automation deployment. J. Build. Eng. 2023, 77, 107388. [Google Scholar] [CrossRef]

- Younis, Z.A.; Nazari, M. Optimizing Sustainability of Concrete Structures Using Tire-Derived Aggregates: A Performance Improvement Study. CivilEng 2024, 5, 30–40. [Google Scholar] [CrossRef]

- Lou, B.; Ma, F. Evolution on fracture properties of concrete during steam curing. Case Stud. Constr. Mater. 2022, 16, e01105. [Google Scholar] [CrossRef]

- Baek, S.H.; Lee, K.I.; Kim, S.M. Development of Real-Time Monitoring System Based on IoT Technology for Curing Compound Application Process during Cement Concrete Pavement Construction. Sensors 2023, 23, 8187. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Ramezanianpour, A.A. Effect of controlled environmental conditions on mechanical, microstructural and durability properties of cement mortar. Constr. Build Mater. 2018, 164, 134–149. [Google Scholar] [CrossRef]

- Alyousef, R.; Abbass, W.; Aslam, F.; Gillani, S.A.A. Characterization of high-performance concrete using limestone powder and supplementary fillers in binary and ternary blends under different curing regimes. Case Stud. Constr. Mater. 2023, 18, e02058. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; Zhou, F.; Shen, S.; Guo, A.; Xie, Y. Effect of steam curing regimes on temperature and humidity gradient, permeability and microstructure of concrete. Constr. Build Mater. 2021, 281, 122562. [Google Scholar] [CrossRef]

- Souza, E.; Pinheiro, P.; Coutinho, F.; Dias, J.; Pilar, R.; Pontes, M.J.; Leal-Junior, A. Smart Concrete Using Optical Sensors Based on Bragg Gratings Embedded in a Cementitious Mixture: Cure Monitoring and Beam Test. Sensors 2024, 24, 7998. [Google Scholar] [CrossRef]

- Ikumi, T.; Cairó, I.; Groeneveld, J.; Aguado, A.; de la Fuente, A. Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring. Sensors 2024, 24, 1756. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Fan, J.; Kong, B.; Cai, C.; Chen, K. Theory and application of new automated concrete curing system. J. Build. Eng. 2018, 17, 125–134. [Google Scholar] [CrossRef]

- Martinelli, E.; Pepe, M.; Lima, C.; Iacono, S.D.; Ferro, M.; Paciello, V.; Sommella, P. Pseudo-Adiabatic Concrete Curing Monitoring IoT-Enabled System. In Proceedings of the 2023 IEEE International Workshop on Metrology for Industry 4.0 and IoT, MetroInd4.0 and IoT 2023, Brescia, Italy, 6–8 June 2023. [Google Scholar] [CrossRef]

- RNE, Reglamento Nacional de Edificaciones RNE, Norma E.060. Peru. 2024. Available online: https://www.gob.pe/institucion/vivienda/informes-publicaciones/2309793-reglamento-nacional-de-edificaciones-rne (accessed on 22 June 2025).

- NTP 334.090; Norma Técnica Peruana. INDECOPI: Lima, Peru, 2011.

- Astm C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2001.

- Cataldo, A.; Schiavoni, R.; Masciullo, A.; Cannazza, G.; Micelli, F.; De Benedetto, E. Combined punctual and diffused monitoring of concrete structures based on dielectric measurements. Sensors 2021, 21, 4872. [Google Scholar] [CrossRef] [PubMed]

- Tareen, N.; Kim, J.; Kim, W.K.; Park, S. Fuzzy logic-based and nondestructive concrete strength evaluation using modified carbon nanotubes as a hybrid pzt–cnt sensor. Materials 2021, 14, 2953. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Nigussie, E. Automated concrete curing and assessment of strength and durability using IoT system. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Donadello, I.; Di Francescomarino, C.; Maggi, F.M.; Ricci, F.; Shikhizada, A. Outcome-Oriented Prescriptive Process Monitoring based on Temporal Logic Patterns. Eng. Appl. Artif. Intell. 2023, 126, 106899. [Google Scholar] [CrossRef]

- Liu, W.; He, S.; Mou, J.; Xue, T.; Chen, H.; Xiong, W. Digital twins-based process monitoring for wastewater treatment processes. Reliab. Eng. Syst. Saf. 2023, 238, 109416. [Google Scholar] [CrossRef]

- Huang, L.; Tang, L.; Löfgren, I.; Olsson, N.; Babaahmadi, A.; Esping, O.; Li, Y.; Yang, Z. Non-destructive test system to monitor hydration and strength development of low CO2 concrete. Constr. Build. Mater. 2023, 408, 133774. [Google Scholar] [CrossRef]

- Babu, J.C.; Kumar, M.S.; Jayagopal, P.; Sathishkumar, V.E.; Rajendran, S.; Kumar, S.; Karthick, A.; Mahseena, A.M.; Ahmed, A. IoT-Based Intelligent System for Internal Crack Detection in Building Blocks. J. Nanomater. 2022, 2022, 3947760. [Google Scholar] [CrossRef]

- Korda, E.; Tsangouri, E.; Snoeck, D.; De Schutter, G.; Aggelis, D.G. The sensitivity of Acoustic Emission (AE) for monitoring the effect of SAPs in fresh concrete. MATEC Web Conf. 2023, 378, 04006. [Google Scholar] [CrossRef]

- Reddy, V.M.; Hamsalekha, S.; Reddy, V.S. An IoT enabled real-time monitoring system for automatic curing and early age strength monitoring of concrete. AIP Conf. Proc. 2021, 2358, 080018. [Google Scholar] [CrossRef]

- Kim, S.; Jung, D.; Kim, J.Y.; Mun, J.H. Study on Early Age Concrete’s Compressive Strengths in Unmanaged Curing Condition Using IoT-Based Maturity Monitoring. Buildings 2024, 14, 798. [Google Scholar] [CrossRef]

- Bhavsar, D.; Limbasia, B.; Mori, Y.; Aglodiya, M.I.; Shah, M. A comprehensive and systematic study in smart drip and sprinkler irrigation systems. Smart Agric. Technol. 2023, 5, 100303. [Google Scholar] [CrossRef]

- Qian, J.; Zhang, P.; Wu, Y.; Jia, R.; Yang, J. Study on Corrosion Monitoring of Reinforced Concrete Based on Longitudinal Guided Ultrasonic Waves. Appl. Sci. 2024, 14, 1201. [Google Scholar] [CrossRef]

- Ziaja, D.; Jurek, M.; Wiater, A. Elastic Wave Application for Damage Detection in Concrete Slab with GFRP Reinforcement. Materials 2022, 15, 8523. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Huang, Z.; Zhao, H. Doping dependence of Meissner effect in cuprate superconductors. Phys. C Supercond. Appl. 2010, 470, 1968–1976. [Google Scholar] [CrossRef]

- Wang, R.; Wu, H.; Zhao, M.; Liu, Y.; Chen, C. The Classification and Mechanism of Microcrack Homogenization Research in Cement Concrete Based on X-ray CT. Buildings 2022, 12, 1011. [Google Scholar] [CrossRef]

- Tang, Z.S.; Lim, Y.Y.; Smith, S.T.; Mostafa, A.; Lam, A.C.; Soh, C.K. Monitoring the curing process of in-situ concrete with piezoelectric-based techniques—A practical application. Struct. Health Monit. 2023, 22, 518–539. [Google Scholar] [CrossRef]

- Al Agha, W.; Pal, S.; Dev, N. Challenges for structural health monitoring of concrete curing using piezoelectric sensor and electromechanical impedance (EMI) technique: A critical review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Guo, L.; Wang, W.; Zhong, L.; Guo, L.; Zhang, F.; Guo, Y. Texture analysis of the microstructure of internal curing concrete based on image recognition technology. Case Stud. Constr. Mater. 2022, 17, e01360. [Google Scholar] [CrossRef]

- Lo, K.-C.; Kwok, H.-W.T.; Siu, M.-F.F.; Shen, Q.G.; Lau, C.-K.; Liu, H. Internet of Things-Based Concrete Curing Invention for Construction Quality Control. Adv. Civ. Eng. 2021, 2021, 9933615. [Google Scholar] [CrossRef]

- Prakash, A.; Munipally, S.K.; Fernando, P.E. Fernando. Prediction of Concrete Constituents’ Behavior Using Internet of Things (IoT). Key Eng. Mater. 2023, 959, 161–170. [Google Scholar] [CrossRef]

- AMohamed, K.; Bouibes, A.; Bauchy, M.; Casar, Z. Molecular modelling of cementitious materials: Current progress and benefits. RILEM Tech. Lett. 2022, 7, 209–219. [Google Scholar] [CrossRef]

- Honrubia, M.M.; Domingo, J.M.; Herraiz-Martínez, F.J.; Giannetti, R. Low-Cost Electronics for Automatic Classification and Permittivity Estimation of Glycerin Solutions Using a Dielectric Resonator Sensor and Machine Learning Techniques. Sensors 2023, 23, 3940. [Google Scholar] [CrossRef]

- Komary, M.; Komarizadehasl, S.; Tošić, N.; Segura, I.; Lozano-Galant, J.A.; Turmo, J. Low-Cost Technologies Used in Corrosion Monitoring. Sensors 2023, 23, 1309. [Google Scholar] [CrossRef]

- Ptacek, L.; Strauss, A.; Hinterstoisser, B.; Zitek, A. Curing assessment of concrete with hyperspectral imaging. Materials 2021, 14, 3848. [Google Scholar] [CrossRef]

- Mohe, N.S.; Shewalul, Y.W.; Agon, E.C. Experimental investigation on mechanical properties of concrete using different sources of water for mixing and curing concrete. Case Stud. Constr. Mater. 2022, 16, e00959. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Adesina, A.; de Azevedo, A.R.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S. Review on effect of steam curing on behavior of concrete. Clean. Mater. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Wang, H.; Guo, B.; Guo, Y.; Jiang, R.; Zhao, F.; Wang, B. Effects of Curing Methods on the Permeability and Mechanism of Cover Concrete. J. Build. Mater. Sci. 2023, 5, 20–31. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Johari, M.A.M.; Alharbi, Y.R.; Abadel, A.A.; Amran, Y.M.; Tayeh, B.A.; Abutaleb, A. Influence of steam curing regimes on the properties of ultrafine POFA-based high-strength green concrete. J. Build. Eng. 2021, 38, 102204. [Google Scholar] [CrossRef]

- Wang, X.; Wang, G.; Gong, F.; Qin, L.; Gao, Z.; Cheng, X. Evaluation and Analysis of Asphalt Concrete Density Based on Core Samples. J. Mater. Civ. Eng. 2024, 36, 04023523. [Google Scholar] [CrossRef]

- Kumar, A.; Saxena, S.; Rawat, V.S. Effect of Various Methods of Curing on Concrete Using Crusher Dust as Replacement to Natural Sand. Macromol. Symp. 2024, 413, 2200211. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, G.; Zhang, G. Effect of Curing Time on the Surface Permeability of Concrete with a Large Amount of Mineral Admixtures. Adv. Civ. Eng. 2022, 2022, 1034388. [Google Scholar] [CrossRef]

- Jin, W.; Jiang, L.; Han, L.; Huang, H.; Zhi, F.; Yang, G.; Niu, Y.; Chen, L.; Wang, L.; Chen, Z. Influence of curing temperature on freeze-thaw resistance of limestone powder hydraulic concrete. Case Stud. Constr. Mater. 2022, 17, e01322. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.A.; Mohammed, A.A. Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 2022, 16, e01036. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, J.; Guo, Y.; Wang, C. Early shrinkage experiment of concrete and the development law of its temperature and humidity field in natural environment. J. Build. Eng. 2023, 63, 105528. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Ma, C.; Cai, C.; Wang, J. Effect of surface curing condition on the humidity field and moisture transfer in concrete. Constr. Build Mater. 2024, 411, 134701. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Chauhdary, J.N.; Li, H.; Jiang, Y.; Pan, X.; Hussain, Z.; Javaid, M.; Rizwan, M. Advances in Sprinkler Irrigation: A Review in the Context of Precision Irrigation for Crop Production. Agronomy 2024, 14, 47. [Google Scholar] [CrossRef]

- Vu, C.-C.; Ho, N.-K. A comparative study on the probability distribution model for the compressive strength of concrete with consideration of the size effect. J. Eng. Res. 2024, 13, 1403–1413. [Google Scholar] [CrossRef]

- Li, D.; Tang, Z.; Kang, Q.; Zhang, X.; Li, Y. Machine Learning-Based Method for Predicting Compressive Strength of Concrete. Processes 2023, 11, 390. [Google Scholar] [CrossRef]

- Paudel, S.; Pudasaini, A.; Shrestha, R.K.; Kharel, E. Compressive strength of concrete material using machine learning techniques. Clean. Eng. Technol. 2023, 15, 100661. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Kioumarsi, M.; Shekarchi, M. Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cem. Concr. Compos. 2022, 125, 104276. [Google Scholar] [CrossRef]

- Jung, S.; Lee, S.; Yu, J. Ontological approach for automatic inference of concrete crack cause. Appl. Sci. 2021, 11, 252. [Google Scholar] [CrossRef]

- M’hammed, T.; Hamid, K. An experimental study on the influence of arid climate on early-age cracking of concrete—A case study of the city of Adrar in Algeria. AIMS Mater. Sci. 2021, 8, 200–220. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 305R-2—Guide to Hot Weather Concreting; American Concrete Institute: Farmington Hills, MI, USA, 2010; Volume ACI 305R-2, p. 2020. [Google Scholar]

- Habibbulloh, M.; Anggaryani, M.; Satriawan, M.; Saputra, O.; Zakaria, A.; Septiawan, F. Suitability of Torricelli’s Theorem Formulation in Cases of Leaking Reservoirs with Video Analysis Tracker. J. Phys. Conf. Ser. 2023, 2623, 012021. [Google Scholar] [CrossRef]

- Franchini, M.; Lanza, L. Use of Torricelli’s equation for describing leakages in pipes of different elastic materials, diameters and orifice shape and dimensions. Procedia Eng. 2014, 89, 290–297. [Google Scholar] [CrossRef]

- Nakayama, Y.; Boucher, R.F. Introduction to Fluid Mechanics; Butterworth-Heinemann: Oxford, UK, 1999. [Google Scholar]

- Ravasini, S.; Vecchi, F.; Belletti, B.; Muttoni, A. Verification of deflections and cracking of RC flat slabs with numerical and analytical approaches. Eng. Struct. 2023, 284, 115926. [Google Scholar] [CrossRef]

- Thompson, J.E.; Paluch, A.S. Revisiting the Clausius/Clapeyron Equation and the Cause of Linearity. Thermo 2023, 3, 412–423. [Google Scholar] [CrossRef]

- Marhasova, V.; Garafonova, O.; Deril, Z.; Rudenko, O. Scientific Research Methodology as A General Approach and Perspective Of The Research Process. Her. Khmelnytskyi Natl. Univ. Econ. Sci. 2022, 312, 328–334. [Google Scholar] [CrossRef] [PubMed]

- Oval, R.; Nuh, M.; Costa, E.; Madyan, O.A.; Orr, J.; Shepherd, P. A prototype low-carbon segmented concrete shell building floor system. Structures 2023, 49, 124–138. [Google Scholar] [CrossRef]

- Germann, C. Methodology and Empirical Research. In Chairperson Succession; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Vladlenov, D. Scientific Foundations in Research in Engineering; International Science Group: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Silaban, R.S. Analisa Struktur Bangunan Rumah Susun MBR Type—36 (3 Lantai) Prototype Pada Wilayah Gempa Dan Non Gempa Study Kasus Rusun MBR Pemkab Kotim. Media Ilm. Tek. Sipil 2023, 11, 58–67. [Google Scholar] [CrossRef]

- Young, M.D.; Diem, S. Handbook of Critical Education Research: Qualitative, Quantitative, and Emerging Approaches; Routledge: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Li, Y. Research Methodology. In Educational Change Amongst English Language College Teachers in China; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- ISO 1920-10; Testing of Concrete: Determination of Static Modulus of Elasticity in Compression. ISO: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/51829.html (accessed on 22 June 2025).

- Yang, J. An empirical survey of statistical research methods in applied science. J. King Saud. Univ. Sci. 2022, 34, 102008. [Google Scholar] [CrossRef]

- Bustamante, S. Research Methodology and Procedure. In CSR, Sustainability, Ethics and Governance; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Moed, H.F.; Glänzel, W.; Schmoch, U. Handbook of Quantitative Science and Technology Research; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Khan, A.-M.; Kee, S.-H.; Pathan, A.-S.K.; Nahid, A.-A. Image Processing Techniques for Concrete Crack Detection: A Scientometrics Literature Review. Remote Sens. 2023, 15, 2400. [Google Scholar] [CrossRef]

- Levchenko, A.; Polikutin, A.; Barabash, D. Crack resistance of reinforced concreted and reinforced rubber concrete beams. Arch. Tech. Sci. 2020, 1, 21–26. [Google Scholar] [CrossRef]

- Filho, J.R.T.; Abbas, Y.; Oudenhoven, J.; Matthys, S. Application of Cost Effective and Real-Time Resistivity Sensor to Study Early Age Concrete. Sensors 2023, 23, 7525. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Q.; Zhou, S.; Li, S.; Li, Y.; Wu, C. Enhanced CO2 uptake of cement pastes incorporated with dimethylamine: Mechanisms and effects on microstructure and strength. Innov. Infrastruct. Solut. 2024, 10, 15. [Google Scholar] [CrossRef]

| Coding of Humidity Sensor HD-38, LCD, and ARDUINO | Coding of DS18B20 Temperature Sensor, LCD, and Arduino | Solenoid Valve Coding (Automation) and Arduino |

|---|---|---|

|

|

|

| Start and End of Pouring. | Start and End of Installation. | Cracks are Displayed (No). | Cracks are Displayed (Yes). | Spray Curing. | Cracks are Displayed (No). | T°C Variation. | H% Variation. |

|---|---|---|---|---|---|---|---|

| 17:00 a 18:20 | 18:35 a 19:00 | 19:41 | 20:40 | 20:40 a 20:44 | 20:45 a 20:50 | 28 a 29.9 | 53 a 54 |

| Curing Interval. | Days. | Irrigation Times (Per Day). | Water (L). | Total (L). |

|---|---|---|---|---|

| 7 | 48 | 2 | 672 | |

| 7 | 36 | 2 | 504 | |

| 7 | 24 | 2 | 336 | |

| 7 | 12 | 2 | 168 | |

| Amount of water used (L) | 1680 | |||

| Time It Takes to Repeat Watering (Minutes). | Time Taken to Water Each Repetition (Seconds). | Number of Watering Times (Per Day). | Watering Time Per Day (Seconds). | Total Watering Time in 7 Days. |

|---|---|---|---|---|

| 30 | 25 | 48 | 1200 | 140 |

| 45 | 25 | 36 | 900 | 105 |

| 60 | 25 | 24 | 600 | 70 |

| 75 | 25 | 12 | 300 | 35 |

| Working time of the solenoid valve (hours). | 5.83 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ascona García, P.P.; Ordoñez Carpio, G.E.; Zelada Zamora, W.M.; Aguirre Camacho, M.A.; Rojas Pintado, W.; Cuadros Rojas, E.J.; Mundaca Ramos, H.M.; Arce Fernández, N. Intelligent Automated Monitoring and Curing System for Cracks in Concrete Elements Using Integrated Sensors and Embedded Controllers. Technologies 2025, 13, 284. https://doi.org/10.3390/technologies13070284

Ascona García PP, Ordoñez Carpio GE, Zelada Zamora WM, Aguirre Camacho MA, Rojas Pintado W, Cuadros Rojas EJ, Mundaca Ramos HM, Arce Fernández N. Intelligent Automated Monitoring and Curing System for Cracks in Concrete Elements Using Integrated Sensors and Embedded Controllers. Technologies. 2025; 13(7):284. https://doi.org/10.3390/technologies13070284

Chicago/Turabian StyleAscona García, Papa Pio, Guido Elar Ordoñez Carpio, Wilmer Moisés Zelada Zamora, Marco Antonio Aguirre Camacho, Wilmer Rojas Pintado, Emerson Julio Cuadros Rojas, Hipatia Merlita Mundaca Ramos, and Nilthon Arce Fernández. 2025. "Intelligent Automated Monitoring and Curing System for Cracks in Concrete Elements Using Integrated Sensors and Embedded Controllers" Technologies 13, no. 7: 284. https://doi.org/10.3390/technologies13070284

APA StyleAscona García, P. P., Ordoñez Carpio, G. E., Zelada Zamora, W. M., Aguirre Camacho, M. A., Rojas Pintado, W., Cuadros Rojas, E. J., Mundaca Ramos, H. M., & Arce Fernández, N. (2025). Intelligent Automated Monitoring and Curing System for Cracks in Concrete Elements Using Integrated Sensors and Embedded Controllers. Technologies, 13(7), 284. https://doi.org/10.3390/technologies13070284