Exploring the Failures of Deep Groove Ball Bearings Under Alternating Electric Current in the Presence of Commercial Lithium Grease

Abstract

1. Introduction

2. Materials and Methods

2.1. Greases Used

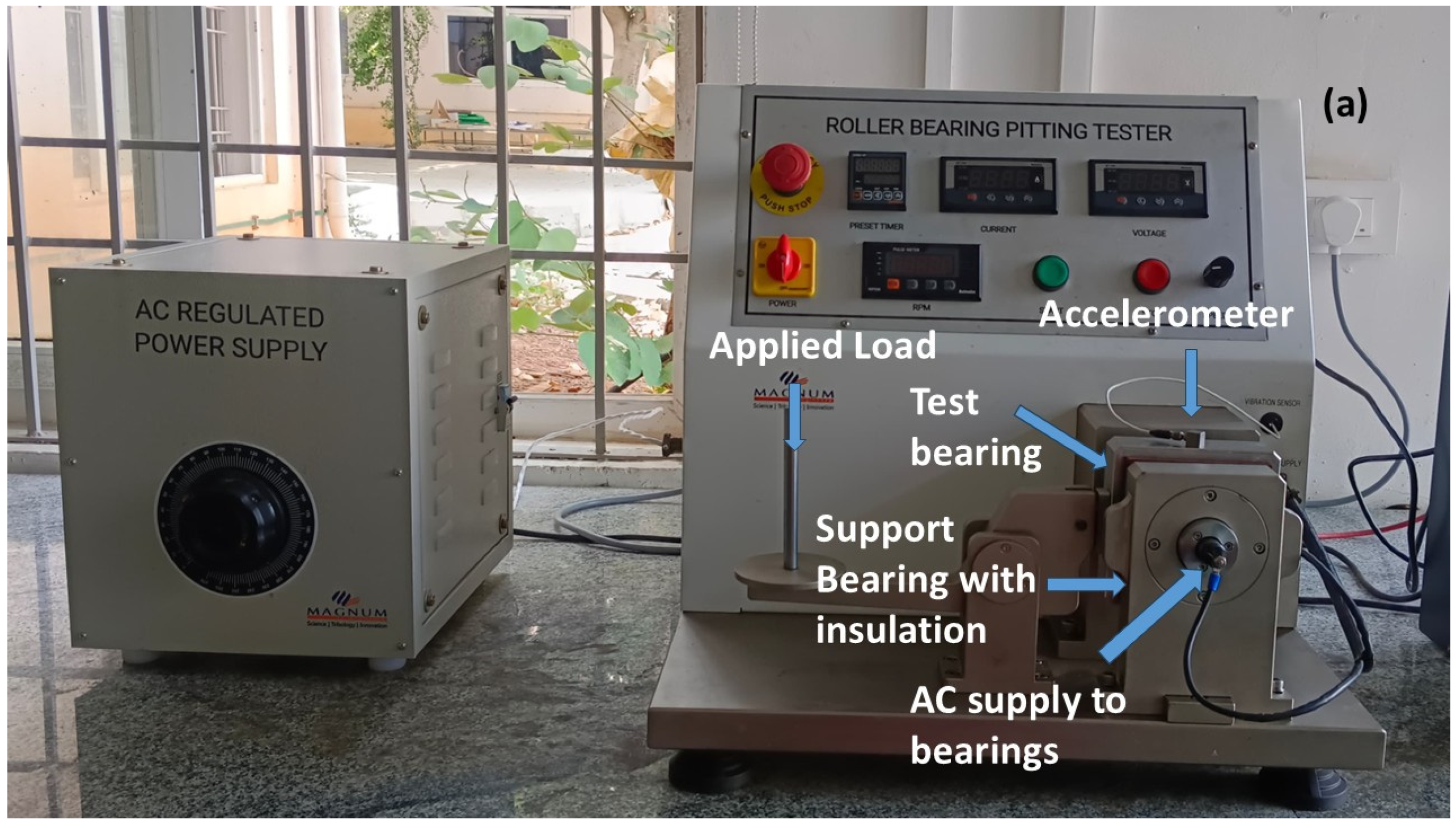

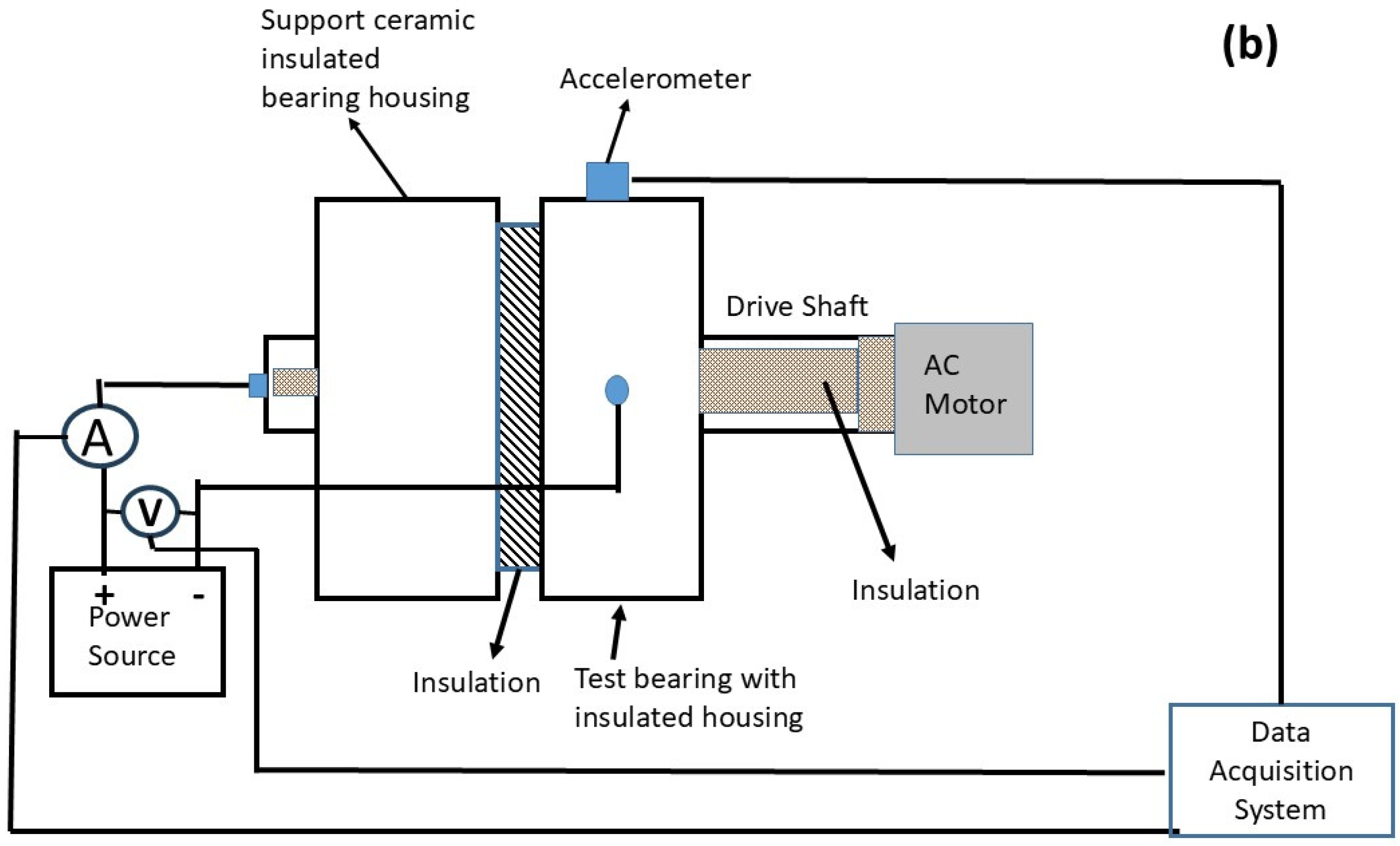

2.2. Full-Bearing Novel Tribo-Meter Used in This Work

2.3. Surface Characterisation of the Bearing Raceways to Determine the Wear Patterns

2.4. Analysis of Greases to Determine Their Degradation

3. Results and Discussions

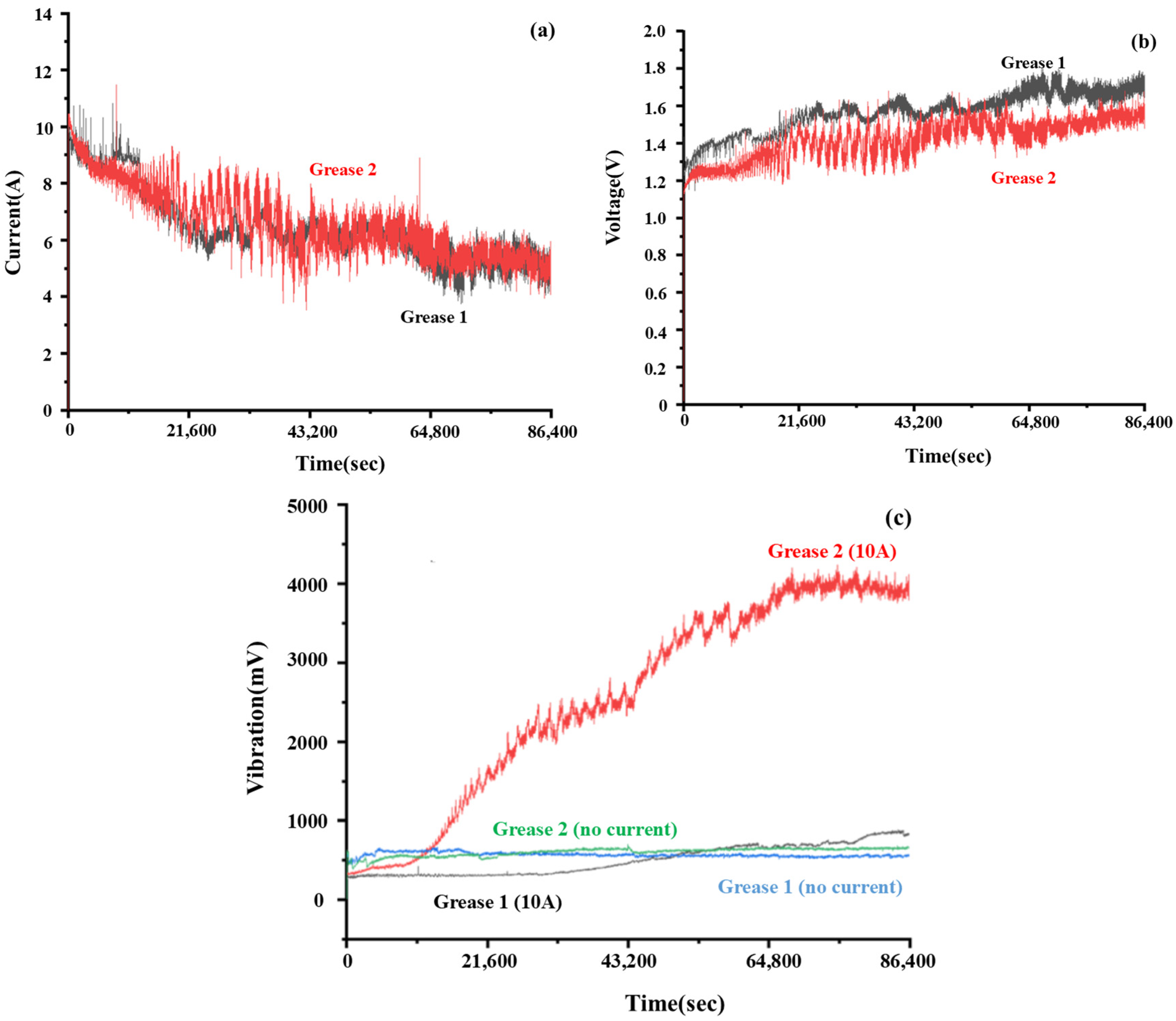

3.1. Performance of the Greases Under Electric Current

3.2. Statistical Analysis of Data (t-Test)

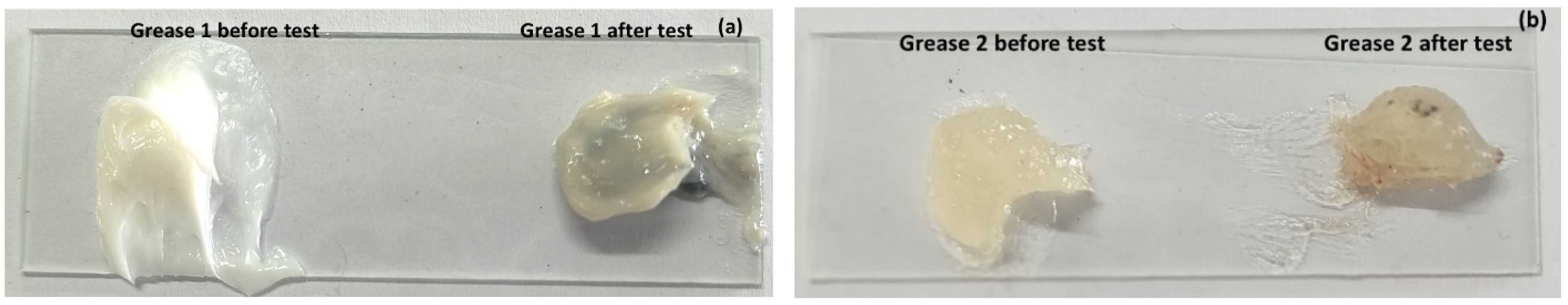

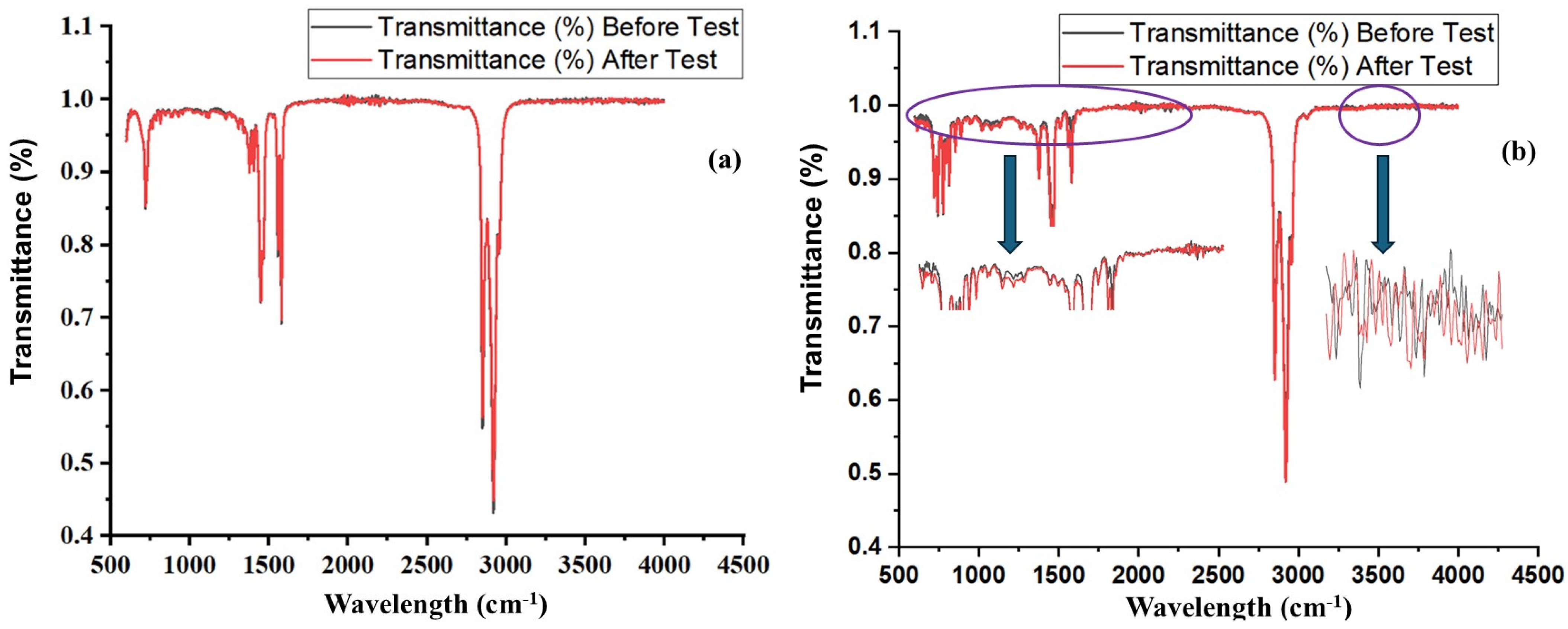

3.3. Investigating the Grease Degradation During the Tribo Test

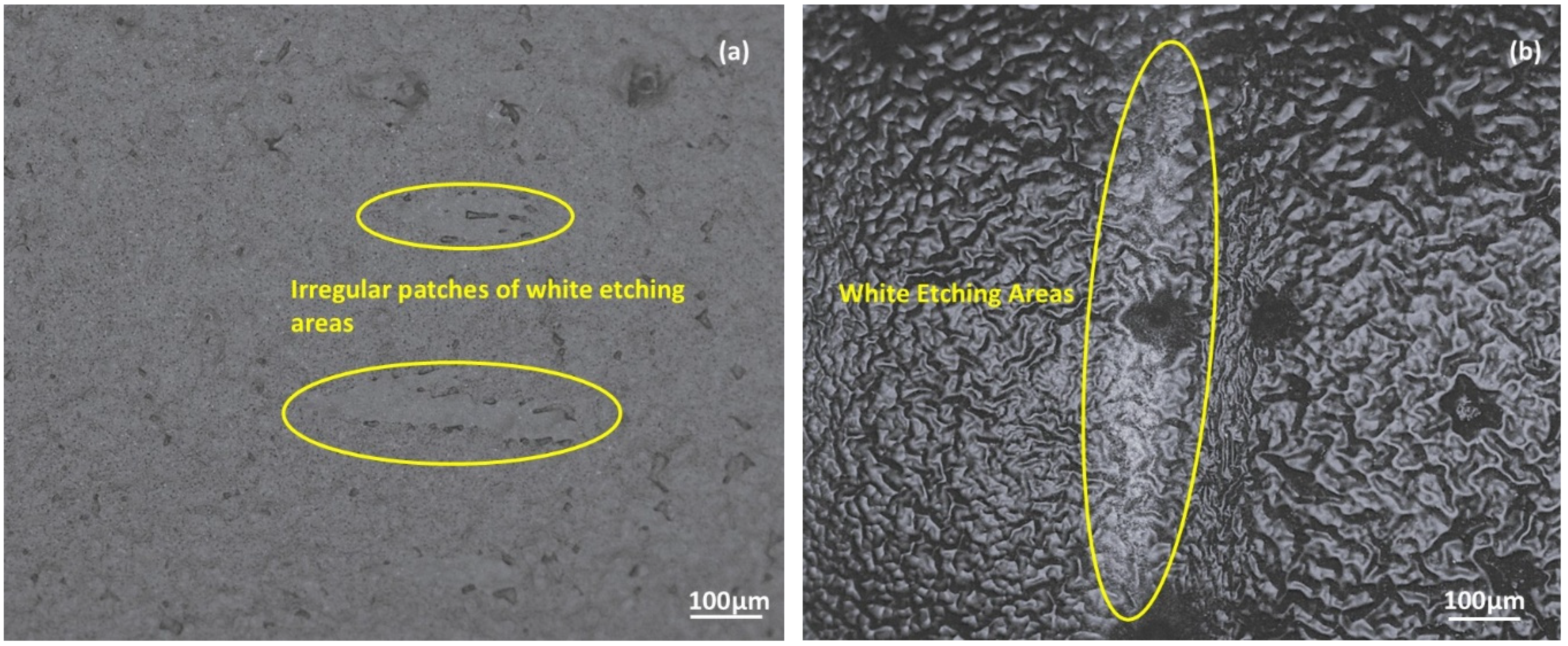

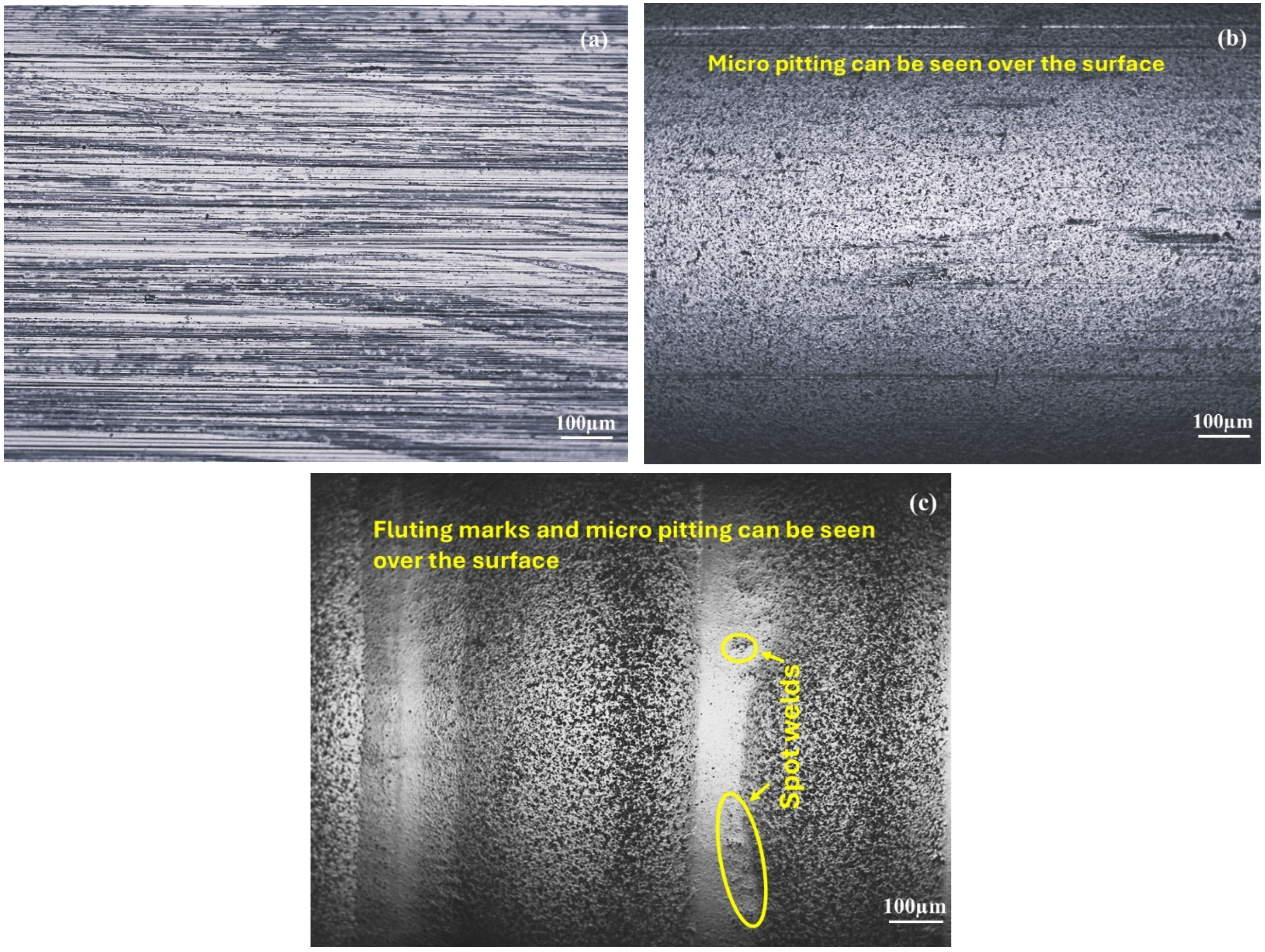

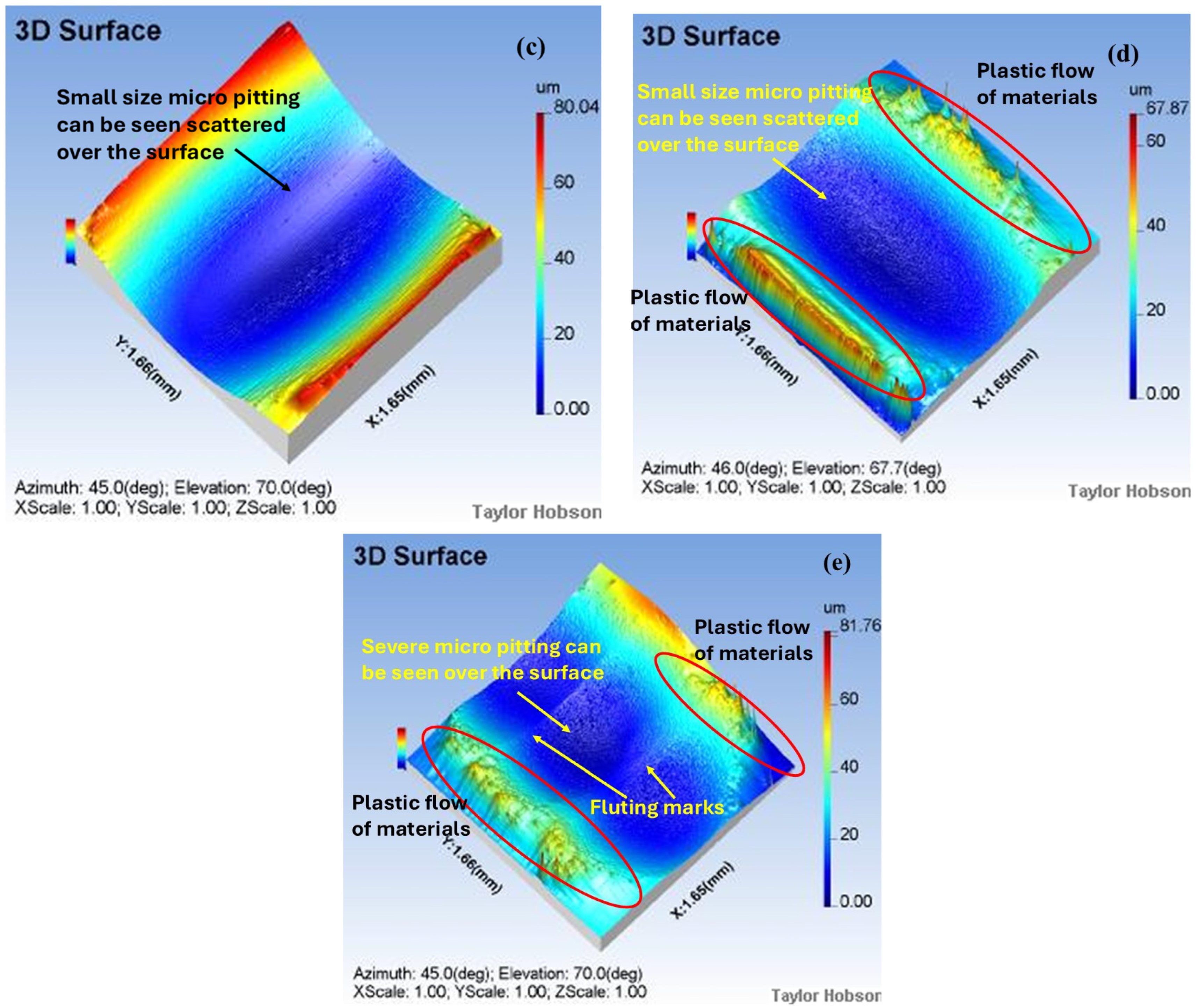

3.4. Exploring the Microstructural and Surface Damages of the Bearings During Tribo Test

3.5. Role of Oil, Surface Asperities, Oil Viscosity, and Wear Debris During the Tribo Test

4. Conclusions

- Choice of lubricant is important to protect the bearings from failure due to the passage of electric current. In this work, the lithium 12-hydroxy stearate grease containing ester and PAO performed better than the other lithium grease containing ester, PAO, and aromatic oils. However, the physicochemical properties of the lubricant also play an important role, as seen in the next point.

- In non-electrified conditions, the tribological performance of both the greases was found to be similar. The bearing surface damages and the vibrations produced in both greases were almost similar in the non-electrified condition.

- Results indicated that during the tribo test, the average current maintained using Grease 1 (5.8 ± 0.81 A) was less than Grease 2 (6.3 ± 0.42 A), while the average voltage in Grease 1 (1.5 ± 0.02) was more than Grease 2 (1.4 ± 0.04 V). The vibrations of the bearing with Grease 1 (464 ± 58.39 mV) were 80% less than the vibrations recorded during the test with Grease 2 (2369 ± 238 mV), indicating a stable lubricating film of Grease 1 during the test.

- The viscosity of the lubricant is an important parameter as it is related to the film thickness formation between the mating pair, even in dynamic conditions. In the present work, the performance of the lubricant with higher viscosity (46–54 cSt) was found to be better with low vibrations and lesser surface damage as compared to the lubricant with 32–35 cSt viscosity.

- FTIR indicated that Grease 1 did not degrade like Grease 2, and hence Grease 1 worked effectively in preventing failures of the bearings under both electric and non-electrified conditions. Additionally, the discoloration of Grease 2 indicated that Grease 2 degraded with the passage of electric current.

- WEAs, micro-pitting, weld spots, plastic deformations, and flutings were failure mechanisms as observed from the microscopic images.

- Though the iron particles generated in non-electrified conditions were almost similar in both the greases, but in electrified conditions, higher iron particles as wear debris were observed in Grease 2, which exhibited high vibration during the test and major surface damage as compared to Grease 1.

- Statistical analysis indicates no significant variant in non-electrified conditions while significant variance can be observed in electrified conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morales Udaeta, M.E.; Chaud, C.A.; Gimenes, A.L.V.; Galvao, L.C.R. Electric Vehicles Analysis inside Electric Mobility Looking for Energy Efficient and Sustainable Metropolis. Open J. Energy Eff. 2015, 4, 1–14. [Google Scholar] [CrossRef][Green Version]

- Mei, J.; Zuo, Y.; Lee, C.H.T.; Kirtley, J. Modeling and Optimizing Method for Axial Flux Induction Motor of Electric Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 5. [Google Scholar] [CrossRef]

- Lu, J.D.; Hu, Y.H.; Chen, G.P.; Wang, Z.; Liu, J.L. Mutual Calibration of Multiple Current Sensors with Accuracy Uncertainties in IPMSM Drives for Electric Vehicles. IEEE Trans. Ind. Electron. 2020, 67, 69–79. [Google Scholar] [CrossRef]

- Patel, N.R.; Shah, V.A.; Lokhande, M.M. A Novel Approach to the Design and Development of 12/15 Radial Field C-Core Switched Reluctance Motor for Implementation in Electric Vehicle Application. IEEE Trans. Veh. Technol. 2018, 67, 8031–8040. [Google Scholar] [CrossRef]

- Yildirim, M.; Ayaz, M. A Survey on Comparison of Electric Motor Types and Drives Used for Electric Vehicles. Int. J. Adv. Sci. Technol. 2015, 84, 23–32. [Google Scholar] [CrossRef]

- Wang, X.; Lu, S.; Chen, K.; Wang, Q.; Zhang, S. Bearing Fault Diagnosis of Switched Reluctance Motor in Electric Vehicle Powertrain via Multisensor Data Fusion. IEEE Trans. Ind. Inform. 2022, 18, 2452–2464. [Google Scholar] [CrossRef]

- Hamachi, T.; Tohei, T.; Hayashi, Y.; Imanishi, M.; Usami, S.; Mori, Y.; Sakai, A. Comprehensive Analysis of Current Leakage at Individual Screw and Mixed Threading Dislocations in Freestanding GaN Substrates. Sci. Rep. 2023, 13, 2436. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical Bearing Failures in Electric Vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Liu, W. The Prevalent Motor Bearing Premature Failures Due to the High Frequency Electric Current Passage. Eng. Fail. Anal. 2014, 45, 118–127. [Google Scholar] [CrossRef]

- Morris, N.; Bleger, A.; Leighton, M. Automotive E-Motor Bearing Electrical Discharge Phenomena: An Experimental and Numerical Investigation. Tribol. Int. 2023, 188, 108524. [Google Scholar] [CrossRef]

- Lee, H.Y.; Ahn, S.H.; Im, H.T. A Research on Stray-Current Corrosion Mechanism of High Voltage Cable Connector on Electrification Vehicles. Corros. Sci. Technol. 2019, 18, 117–120. [Google Scholar] [CrossRef]

- Lou, Z.; Song, C.; Ren, Y.; Pang, X.; Lu, H.; Du, S.; Zhang, Y. Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages. Materials 2024, 17, 859. [Google Scholar] [CrossRef]

- Chiou, Y.C.; Lee, R.T.; Lin, C.M. Formation Criterion and Mechanism of Electrical Pitting on the Lubricated Surface under AC Electric Field. Wear 1999, 236, 62–72. [Google Scholar] [CrossRef]

- Janik, J.R.; Saha, S.; Evans, R.L. Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts. Lubricants 2024, 12, 268. [Google Scholar] [CrossRef]

- De Gaetano, D.; Zhu, W.; Sun, X.; Chen, X.; Griffo, A.; Jewell, G.W. Experimental Ball Bearing Impedance Analysis Under Different Speed and Electrical Conditions. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1312–1321. [Google Scholar] [CrossRef]

- Lin, C.-L.; Meehan, P.A. Morphological and Elemental Analysis of Wear Debris Naturally Formed in Grease Lubricated Railway Axle Bearings. Wear 2021, 484–485, 203994. [Google Scholar] [CrossRef]

- Desnica, E.; Ašonja, A.; Radovanović, L.; Palinkaš, I.; Kiss, I. Selection, Dimensioning and Maintenance of Roller Bearings. In 31st International Conference on Organization and Technology of Maintenance (OTO 2022). OTO 2022; Blažević, D., Ademović, N., Barić, T., Cumin, J., Desnica, E., Eds.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 592. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Güleç, M.; Sergeant, P. Bearing Current and Shaft Voltage in Electrical Machines: A Comprehensive Research Review. Machines 2023, 11, 550. [Google Scholar] [CrossRef]

- Graf, S.; Capan, R.; Koch, O.; Sauer, B. Electrically Induced Damage of Rolling Bearings Due to Parasitic Converter Currents in Electrical Drive Trains. In Commercial Vehicle Technology 2022; Berns, K., Dressler, K., Kalmar, R., Stephan, N., Teutsch, R., Thul, M., Eds.; Springer Vieweg: Wiesbaden, Germany, 2023; pp. 199–209. [Google Scholar] [CrossRef]

- Mehnert, M.; Faber, J.; Hossain, M.; Chester, S.A.; Steinmann, P. Experimental and Numerical Investigations of the Electro-Mechanical Response of Particle Filled Elastomers—Part II: Continuum Modeling Approach. Eur. J. Mech. A-Solids 2022, 96, 104661. [Google Scholar] [CrossRef]

- Xie, Z.; Xu, X. Experimental Study on Electro-Mechanical Response Characteristics of PZT5H Piezoelectric Ceramics Under Impact Loading. J. Asian Ceram. Soc. 2021, 9, 158–164. [Google Scholar] [CrossRef]

- Li, J.; Gao, B.; Wang, X.; Li, F.; Jing, G.; Bai, P.; Tian, Y. Influence and Mechanism of Ablation Pits on the Electrical Contact Stability of Conductive Slip Rings. J. Tsinghua Univ. Sci. Technol. 2025, 60, 41. [Google Scholar] [CrossRef]

- Sanchez, L.J.; Hager, C.H.; Evans, R.D. Rolling Element Bearing Damage in the Presence of Applied Electric Current. Tribol. Trans. 2024, 67, 602–613. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor Bearing Damage Induced by Bearing Current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of Electric Vehicles: A Review of Critical Components, Current State and Future Improvement Trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Lugt, P.M.; van Zoelen, M.T.; Vieillard, C.; Berens, F.; Gruell, R.; Preisinger, G.; Meaney, P. Grease Performance in Ball and Roller Bearings for All-Steel and Hybrid Bearings. Tribol. Trans. 2022, 65, 1–13. [Google Scholar] [CrossRef]

- Randall, R.B. Vibration Based Condition Monitoring: Industrial, Automotive and Aerospace Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Joe, S.B.; Gomathi, T.; Marshiana, D.; Krishnamoorthy, N.R. Effects of Joule Heating on the Temperature-Voltage Relationship in Copper. In Proceedings of the 2021 6th International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 20–22 January 2021; pp. 400–403. [Google Scholar] [CrossRef]

- Balakrishna, G.V.; Gnanamoorthy, R. Current–Voltage–Friction Characteristics of Grease in Electromechanically Loaded Sliding Contacts. J. Tribol. 2023, 145, 041701. [Google Scholar] [CrossRef]

- Xu, F.; Ding, N.; Li, N.; Liu, L.; Hou, N.; Xu, N.; Guo, W.; Tian, L.; Xu, H.; Wu, C.-M.L.; et al. A Review of Bearing Failure Modes, Mechanisms and Causes. Eng. Fail. Anal. 2023, 147, 107518. [Google Scholar] [CrossRef]

- Evenhuis, C.J. Joule Heating Effects and the Experimental Determination of Temperature during CE. Electrophoresis 2009, 30, 897–909. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Guo, F.; Jing, Z.; Li, B.; Zhang, L.; Wang, X. Study on Electric Erosion in Grease Lubrication Using Optical Interference Method. Tribol. Int. 2024, 195, 109596. [Google Scholar] [CrossRef]

- Li, Z.; Guo, F.; Jing, Z.; Li, B.; Zhang, L.; Wang, X. Study on Grease Lubrication and Electric Erosion Characteristics in AC Electric Fields. Lubricants 2024, 12, 79. [Google Scholar] [CrossRef]

- Turnbull, R.; Rahmani, R.; Paul, S.; Rahnejat, H. Electrotribodynamics of Ball Bearings in Electrical Machines. Tribol. Int. 2023, 188, 108817. [Google Scholar] [CrossRef]

- Joshi, A. Electrical Characterisations of Bearings. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2019; pp. 1–90. Available online: https://research.chalmers.se/en/publication/508930 (accessed on 10 May 2025).

- Janik, J.R.; Saha, S.; Jackson, R.L.; Mills, G. Rheological and Electro-Pitting Performance of Electric Vehicle Motor Greases with Various Nanoparticle Greases. J. Tribol. 2024, 147, 051110. [Google Scholar] [CrossRef]

- Kanazawa, Y.; Sayles, R.S.; Kadiric, A. Film Formation and Friction in Grease Lubricated Rolling-Sliding Non-Conformal Contacts. Tribol. Int. 2017, 109, 505–518. [Google Scholar] [CrossRef]

- Du, Z.; He, Q.; Wan, H.; Zhang, L.; Xu, Z.; Xu, Y.; Li, G. TiO2 and CeO2 Nanoparticles as Lithium Complex Grease Additives for Enhanced Lubricity. Ind. Lubr. Tribol. 2024, 76, 70–80. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Development of New Green Lubricating Grease Formulations Based on Cellulosic Derivatives and Castor Oil. Green Chem. 2009, 11, 931–939. [Google Scholar] [CrossRef]

- Abu Saad, S.; Elmahjubi, A. Nanotechnology: Concepts, Importance and the Current State of Scientific Research. In Proceedings of the Conference on Engineering Sciences and Technology (CEST) 2018, Garaboulli, Libya, 25–27 September 2018; Volume 4, pp. 555–561. [Google Scholar] [CrossRef]

- Chang, H.; Lan, C.W.; Chen, C.H.; Kao, M.J.; Guo, J.B. Anti-Wear and Friction Properties of Nanoparticles as Additives in the Lithium Grease. Int. J. Precis. Eng. Manuf. 2014, 15, 2059–2063. [Google Scholar] [CrossRef]

- Deepika. Nanotechnology Implications for High Performance Lubricants. SN Appl. Sci. 2020, 2, 1128. [Google Scholar] [CrossRef]

- Ono, A. Revision of the Standard Method (JIS G 1253) for Spark Discharge Atomic Emission Spectrometry of Iron and Steel. Tetsu-to-Hagané. 1995, 81, 869–875. [Google Scholar] [CrossRef][Green Version]

- JIS G 1253-13; Iron and Steel—Method for Spark Discharge Atomic Emission Spectrometric Analysis. Japanese Standard Association: Tokyo, Japan, 1995.

- Suzumura, J. Prevention of Electrical Pitting on Rolling Bearings by Electrically Conductive Grease. Q. Rep. RTRI 2016, 57, 42–47. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5185; Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES). ASTM: West Conshohocken, PA, USA, 2018.

- Calabokis, O.P.; Nuñez de la Rosa, Y.; Borges, P.C.; Cousseau, T. The Corrosive Effects of Aftermarket Oil Additives on High-Leaded Tin Bronze Alloy. Materials 2024, 17, 1326. [Google Scholar] [CrossRef]

- Bai, B.; Davis, L.; Ramkumar, P. Electrical current effects on white etching areas formation in bearing steel under dynamic loading. Wear 2025, 570, 205977. [Google Scholar] [CrossRef]

- Kim, T.K. T test as a parametric statistic. Korean J. Anesthesiol. 2015, 68, 540–546. [Google Scholar] [CrossRef] [PubMed]

- Shreffler, J.; Huecker, M.R. Hypothesis Testing, P Values, Confidence Intervals, and Significance. In StatPearls [Internet]; StatPearls Publishing: Treasure Island, FL, USA, 2025; [Updated 13 March 2023]. Available online: https://www.ncbi.nlm.nih.gov/books/NBK557421/ (accessed on 10 May 2025).

- Mikami, H.; Kawamura, T. Influence of Electrical Current on Bearing Flaking Life; SAE Technical Paper 2007-01-0113; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Wu, N.; Zong, Z.M.; Fei, Y.W.; Ma, J. Studies on Thermal Oxidation Stability of Aviation Lubricating Oils. In Proceedings of the 2017 International Conference on Mechanical, Material and Aerospace Engineering (2MAE 2017), Beijing, China, 12–14 May 2017; p. 02002. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Li, J.; Tang, Z.; Wang, J. Thermal oxidation of aviation lubricating oil: Mechanism, influencing factors, evaluation methods, and antioxidants. Asia-Pac. J. Chem. Eng. 2024, 19, e3114. [Google Scholar] [CrossRef]

- Fei, Y.-W.; Ma, S.-J.R.J.; Guo, F. Study on Thermal Oxidation and Viscosity Degradation for Synthetic Aviation Lubricant Fluids. IOP Conf. Ser. Mater. Sci. Eng. 2020, 729, 012072. [Google Scholar] [CrossRef]

- Shekhawat, D.; Jain, A.; Vashishtha, N.; Singh, A.P.; Kumar, R. Tribological Performance Comparison of Lubricating Greases for Electric Vehicle Bearings. Lubricants 2025, 13, 108. [Google Scholar] [CrossRef]

- Sreeraj, K.; Ramkumar, P. Replication of white etching area evolution using novel modified dynamic load pin-on-disc tribometer on bearing steel. Tribol. Int. 2018, 126, 336–343. [Google Scholar] [CrossRef]

- Tajedini, M.; Bahrami, R.; Azhdari, R.; Sue, H.J.; Liang, H. Influence of electric current on tribological performance of grease lubricated steels. Trib. Int. 2024, 200, 110121. [Google Scholar] [CrossRef]

- Xie, G.X.; Luo, J.B.; Liu, S.H.; Guo, D.; Li, G.; Zhang, C.H. Effect of Liquid Properties on the Growth and Motion Characteristics of Micro-Bubbles Induced by Electric Fields in Confined Liquid Films. J. Phys. D Appl. Phys. 2009, 42, 115502. [Google Scholar] [CrossRef]

| Bearing Parts | Element (%) | |||||

|---|---|---|---|---|---|---|

| Carbon | Manganese | Silicon | Sulphur | Phosphorus | Chromium | |

| Raceway | 0.934 | 0.381 | 0.234 | 0.011 | 0.005 | 1.421 |

| Bearing balls | 0.916 | 0.350 | 0.240 | 0.017 | 0.022 | 1.370 |

| Cage | 0.064 | 0.233 | - | 0.014 | 0.017 | - |

| Properties | Grease 1 | Grease 2 |

|---|---|---|

| Thickener type | Lithium 12 hydroxy stearate | Lithium 12 hydroxy stearate |

| Thickener content (%) | 10–12 | 8–10 |

| Base oil type | Ester + PAO | Ester + PAO + Aromatic oil |

| Base oil viscosity at 40 °C | 46–54 | 32–35 |

| NLGI grade | 2 | 1 |

| Drop point °C | 180 | 180 |

| Elements | Unit | Grease 1 | Grease 2 |

|---|---|---|---|

| Lithium | ppm | 6906 | 1905 |

| Boron | ppm | 12 | 13 |

| Magnesium | ppm | 4 | 1 |

| Zinc | ppm | 1 | 7 |

| Phosphorus | ppm | 255 | 42 |

| Calcium | ppm | 52 | 32 |

| Sulphur | ppm | 2767 | 1816 |

| Comparison | p-Value | |

|---|---|---|

| Grease 1 vs. Grease 2 | No Current | 10 A |

| 0.9355 | 0.0447 | |

| 0 A vs. 10 A | Grease 1 | Grease 2 |

| 0.1403 | 0.0594 | |

| Passage of Current | Grease | Unit | Fe Content |

|---|---|---|---|

| No current | Grease 1 | ppm | 6 |

| Grease 2 | ppm | 8 | |

| 10 A current | Grease 1 | ppm | 56 |

| Grease 2 | ppm | 270 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhaumik, S.; Yunus, M.; Jothikumar, S.; Hareesh, G.; Paleu, V.; Sharma, A.K.; Mavani, S. Exploring the Failures of Deep Groove Ball Bearings Under Alternating Electric Current in the Presence of Commercial Lithium Grease. Technologies 2025, 13, 275. https://doi.org/10.3390/technologies13070275

Bhaumik S, Yunus M, Jothikumar S, Hareesh G, Paleu V, Sharma AK, Mavani S. Exploring the Failures of Deep Groove Ball Bearings Under Alternating Electric Current in the Presence of Commercial Lithium Grease. Technologies. 2025; 13(7):275. https://doi.org/10.3390/technologies13070275

Chicago/Turabian StyleBhaumik, Shubrajit, Mohamed Yunus, Sarveshpranav Jothikumar, Gurram Hareesh, Viorel Paleu, Ashok Kumar Sharma, and Shail Mavani. 2025. "Exploring the Failures of Deep Groove Ball Bearings Under Alternating Electric Current in the Presence of Commercial Lithium Grease" Technologies 13, no. 7: 275. https://doi.org/10.3390/technologies13070275

APA StyleBhaumik, S., Yunus, M., Jothikumar, S., Hareesh, G., Paleu, V., Sharma, A. K., & Mavani, S. (2025). Exploring the Failures of Deep Groove Ball Bearings Under Alternating Electric Current in the Presence of Commercial Lithium Grease. Technologies, 13(7), 275. https://doi.org/10.3390/technologies13070275