Ground Effect Influence on UAV Propeller Thrust: Experimental and CFD Validation

Abstract

1. Introduction

2. Materials and Methods

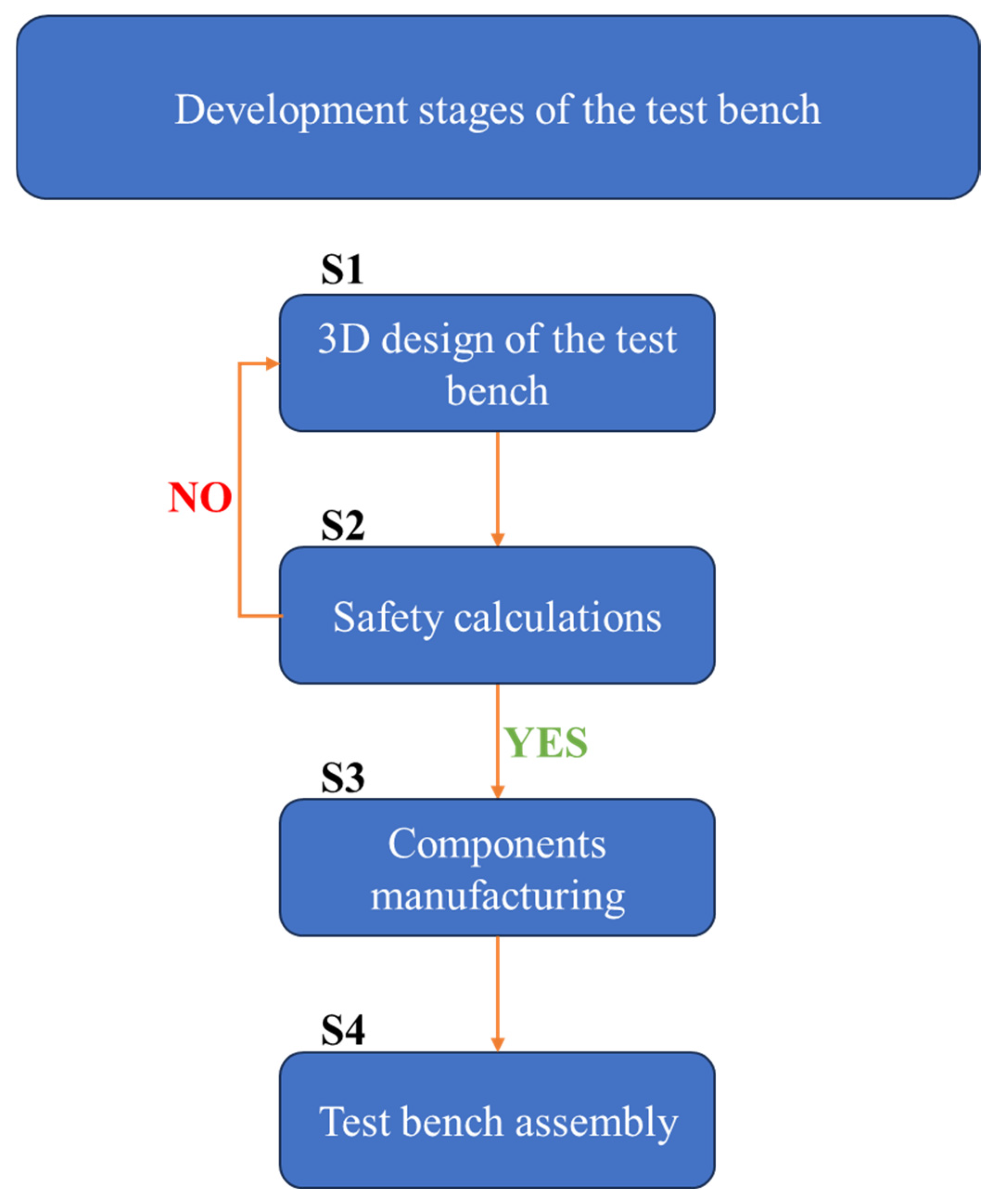

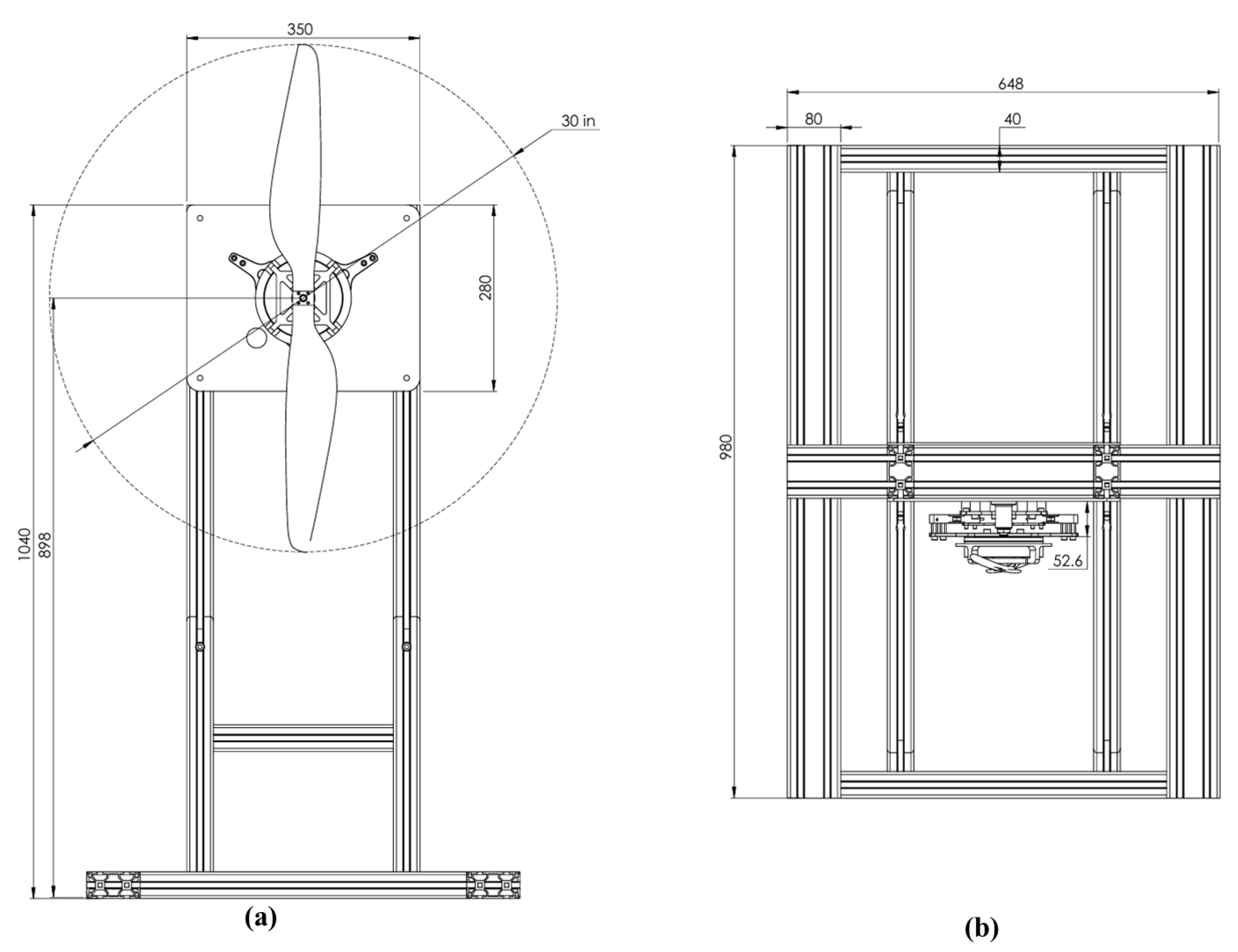

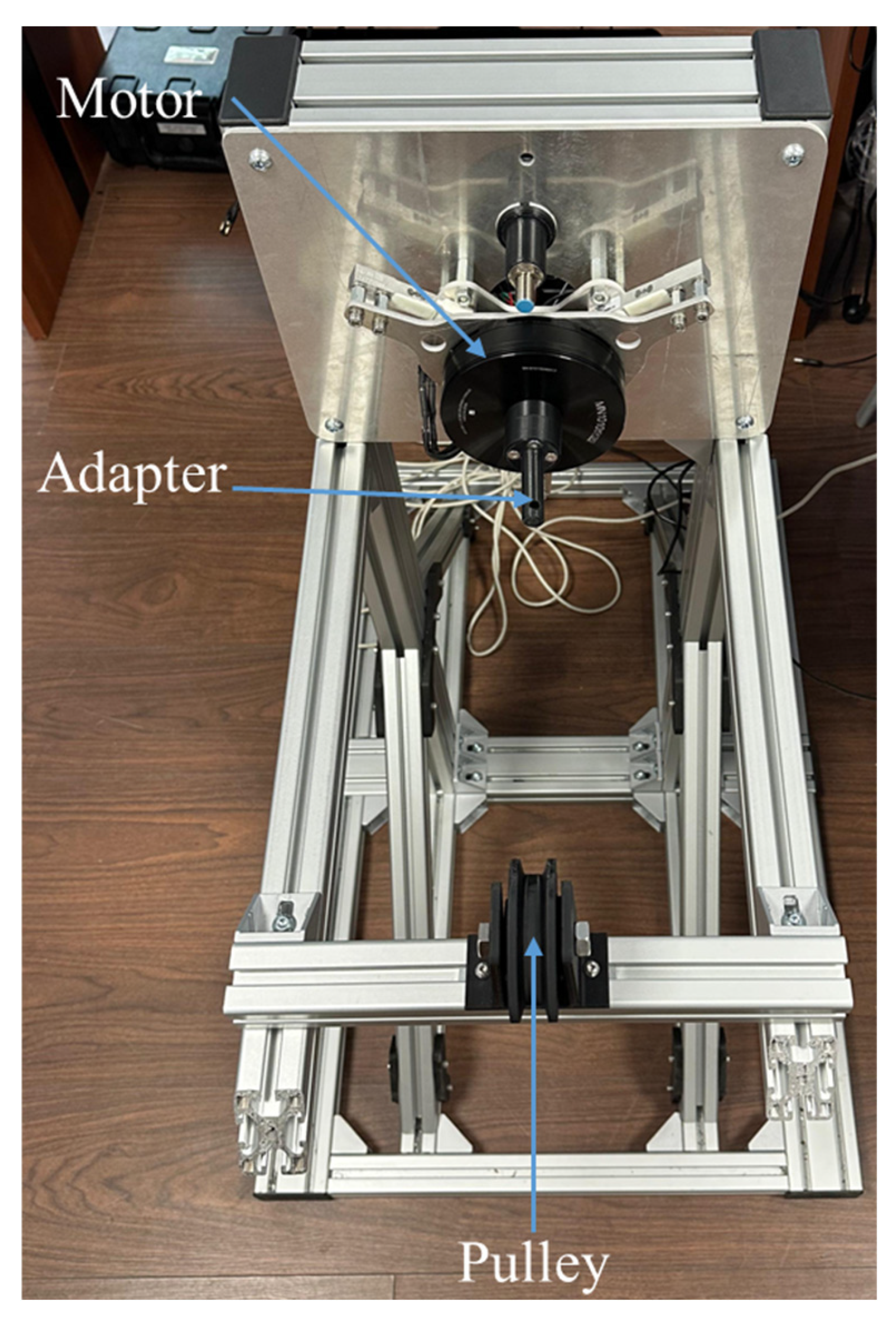

2.1. Design and Assembly of the Experimental Test Bench

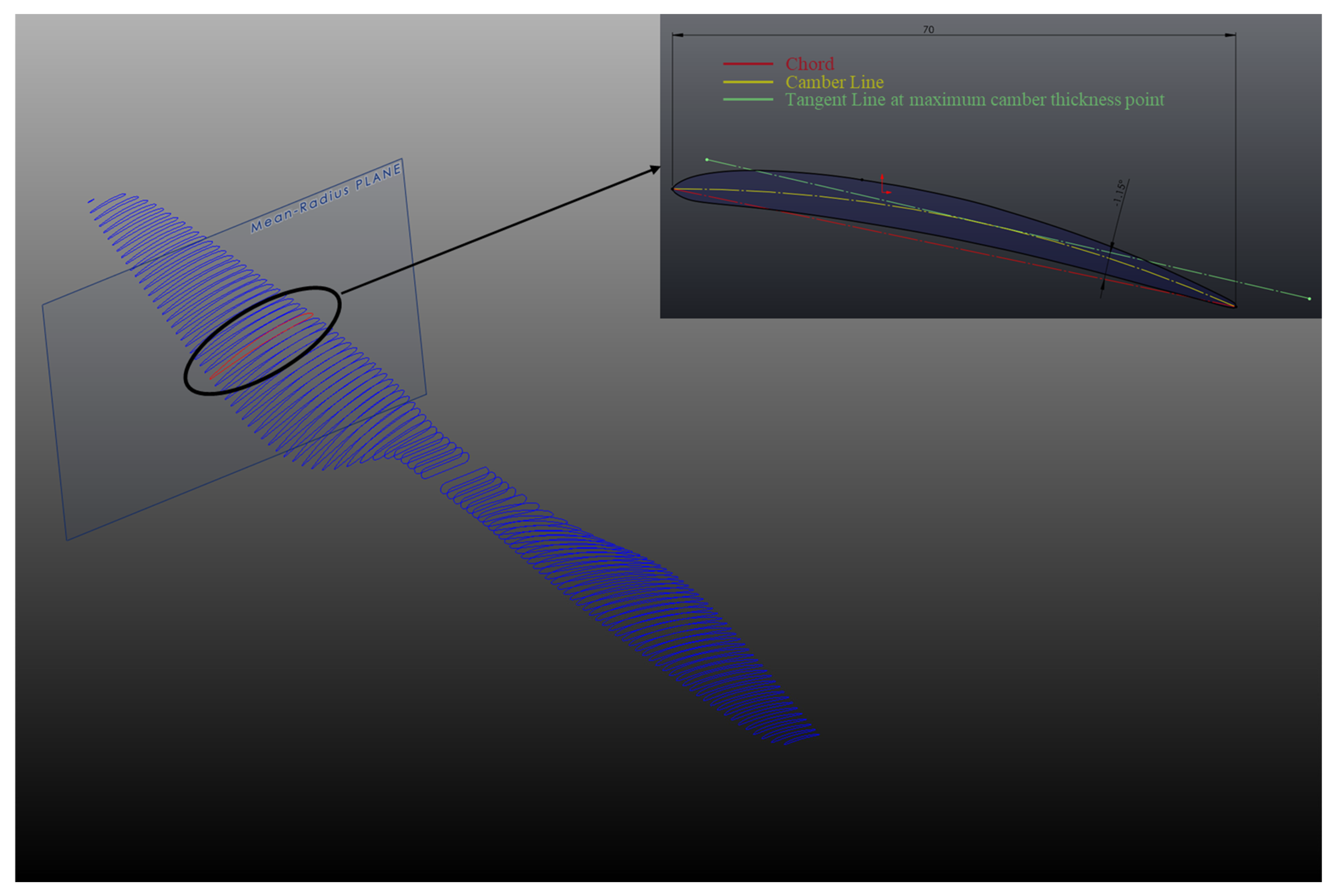

2.2. Analytical Modeling of Propeller Performance

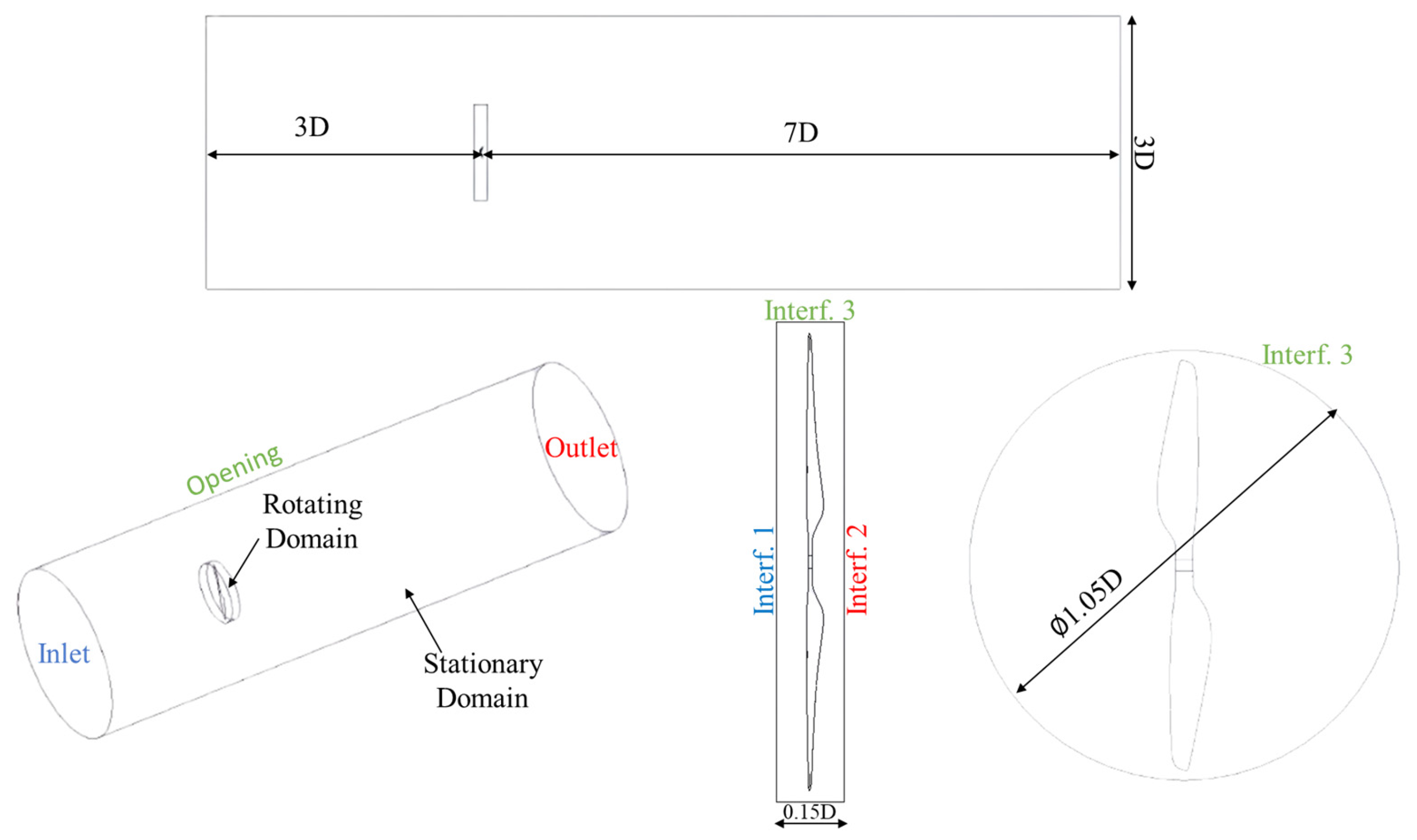

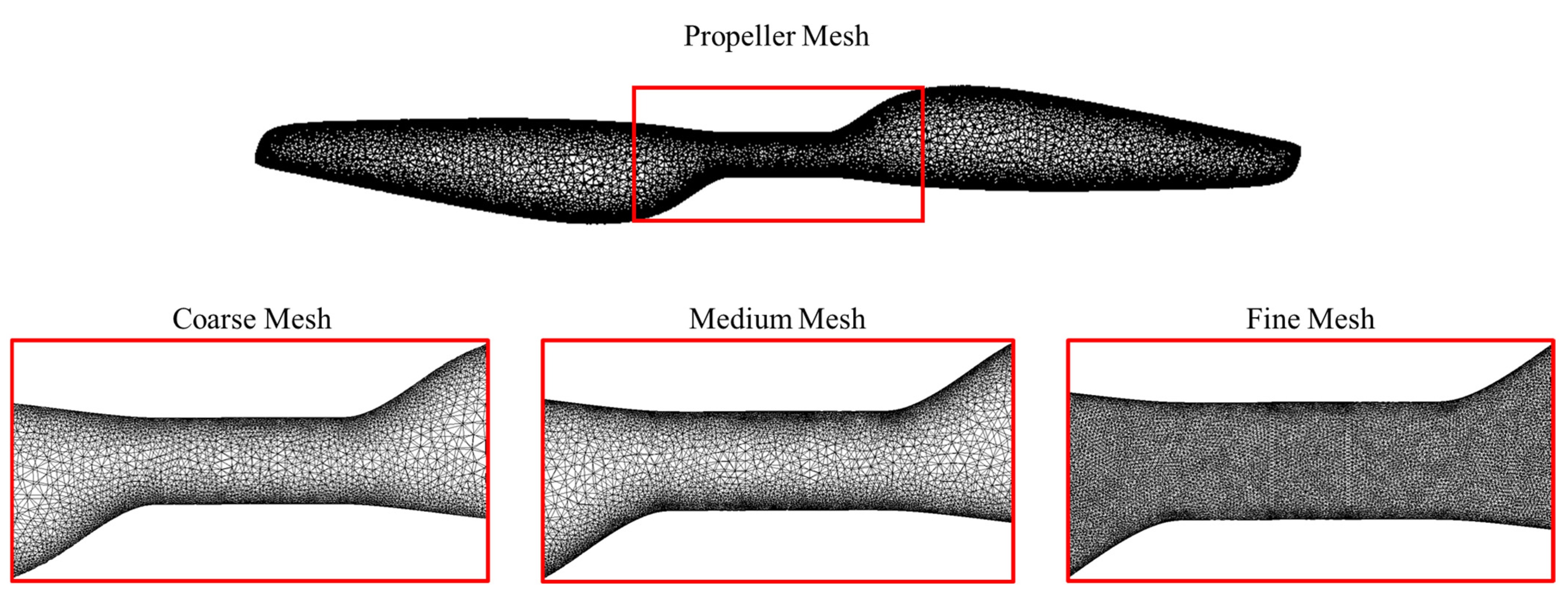

2.3. Computational Fluid Dynamics (CFD) Analysis

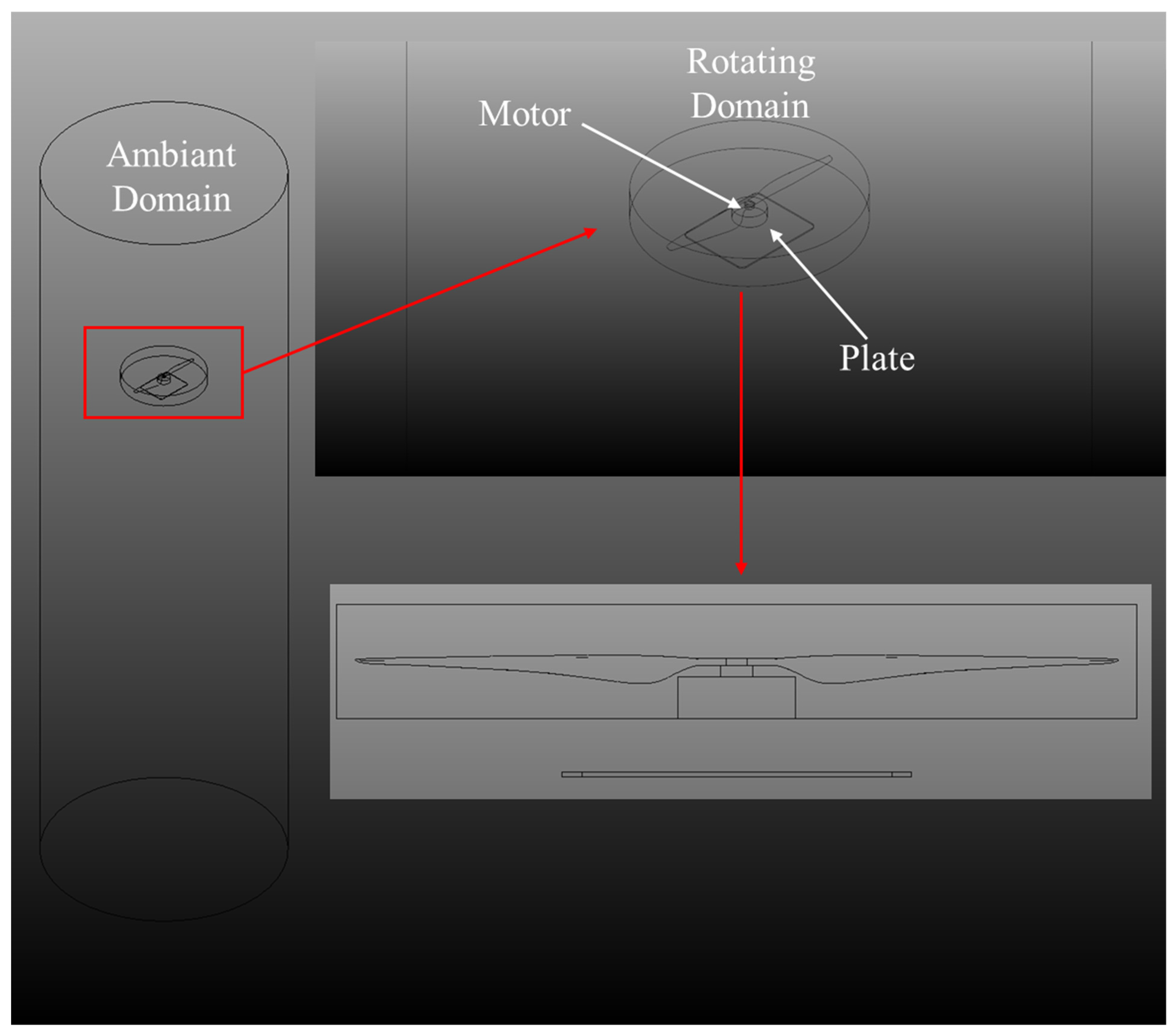

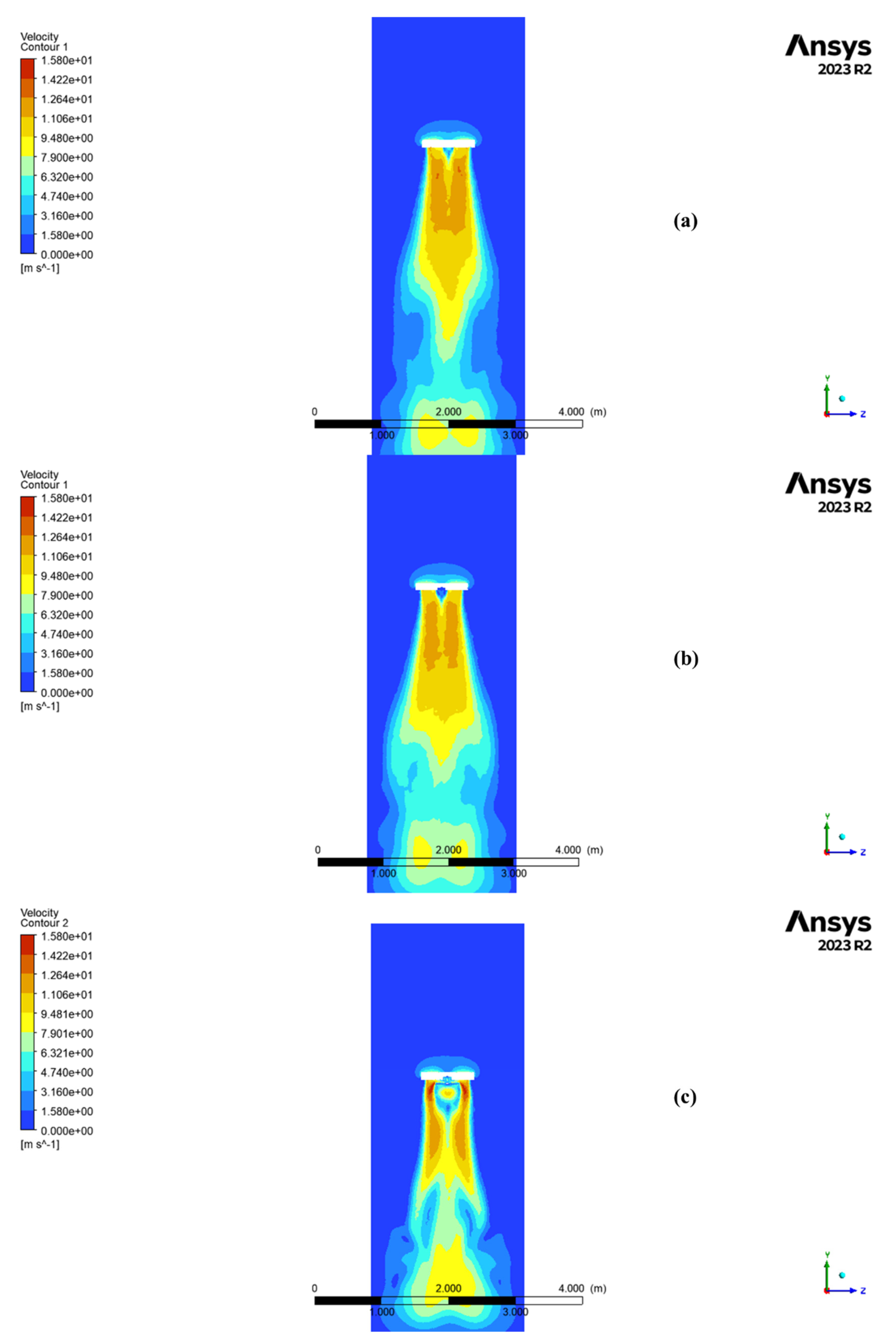

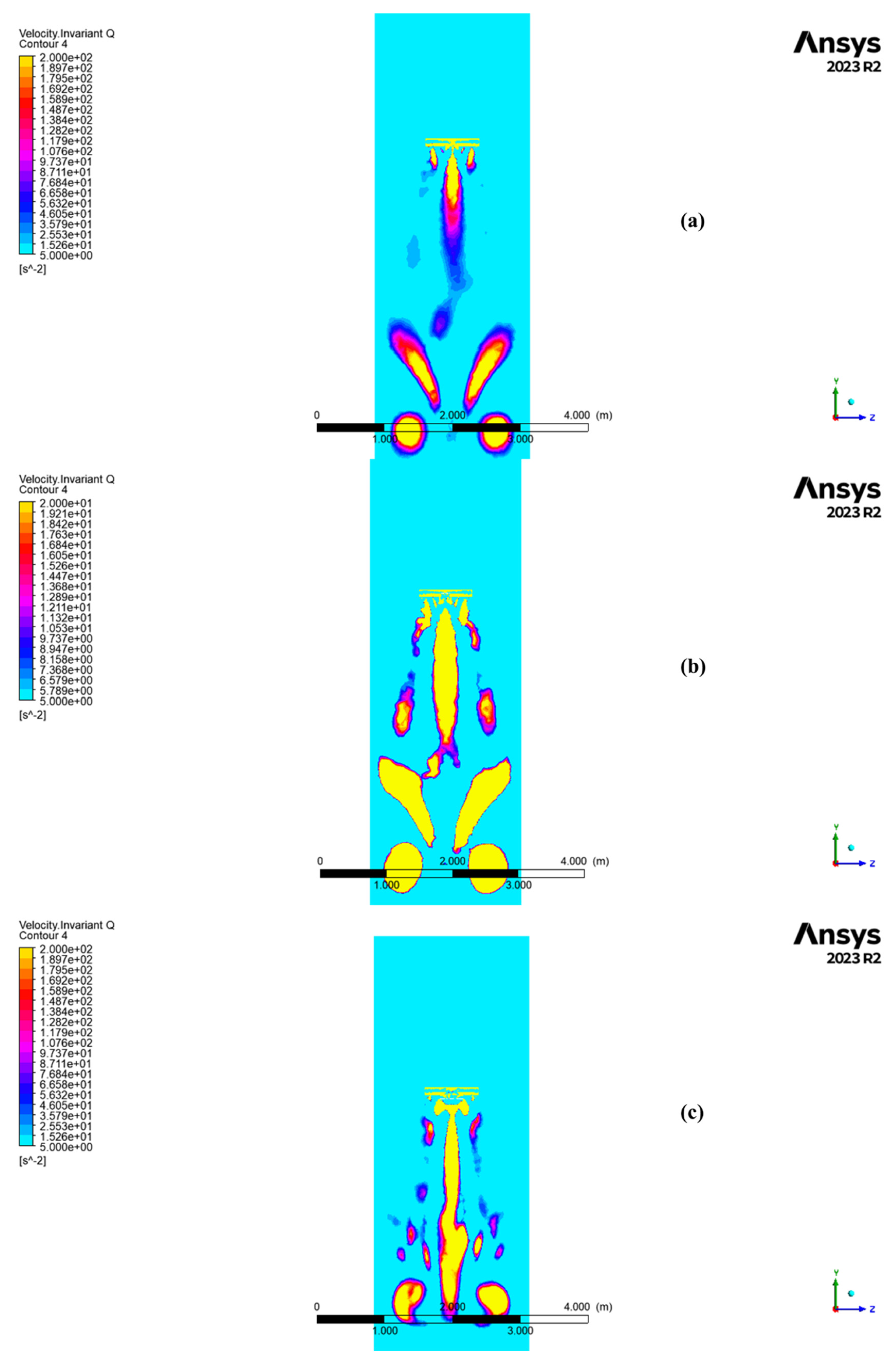

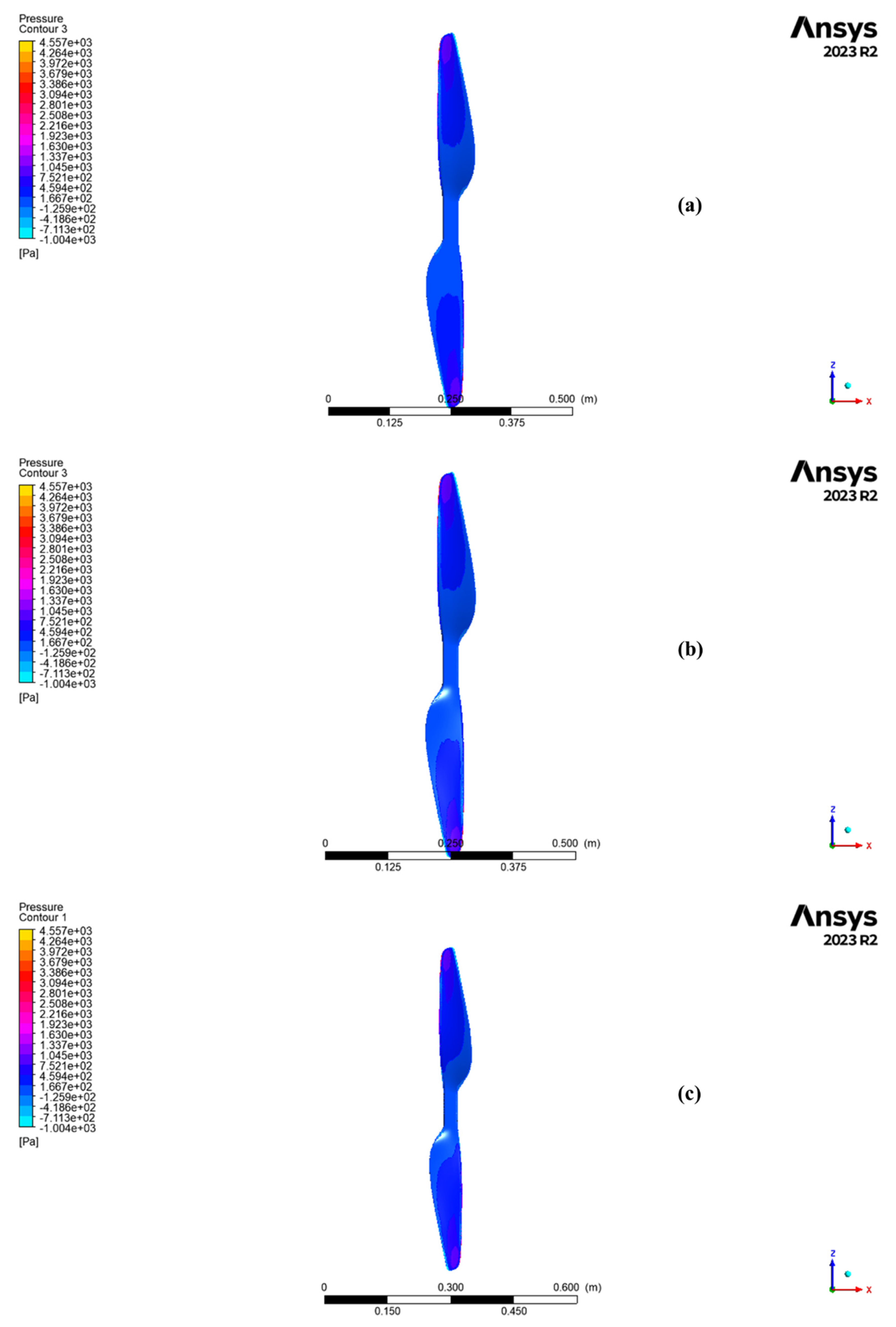

- the isolated propeller, considered in free-stream conditions

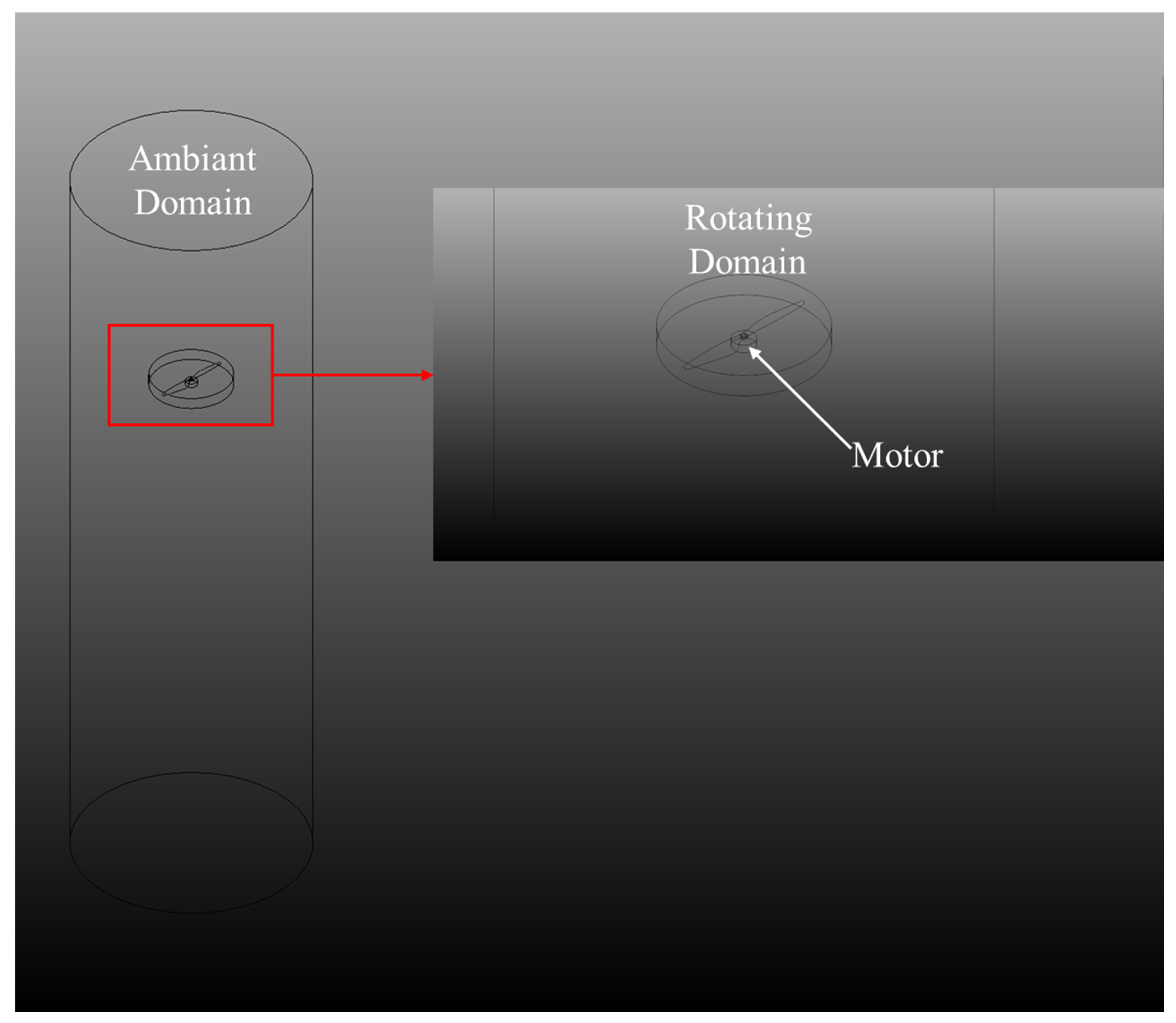

- the propeller coupled with the downstream-mounted motor

- the complete assembly consisting of propeller, motor, and mounting plate, corresponding to the actual configuration of the experimental stand

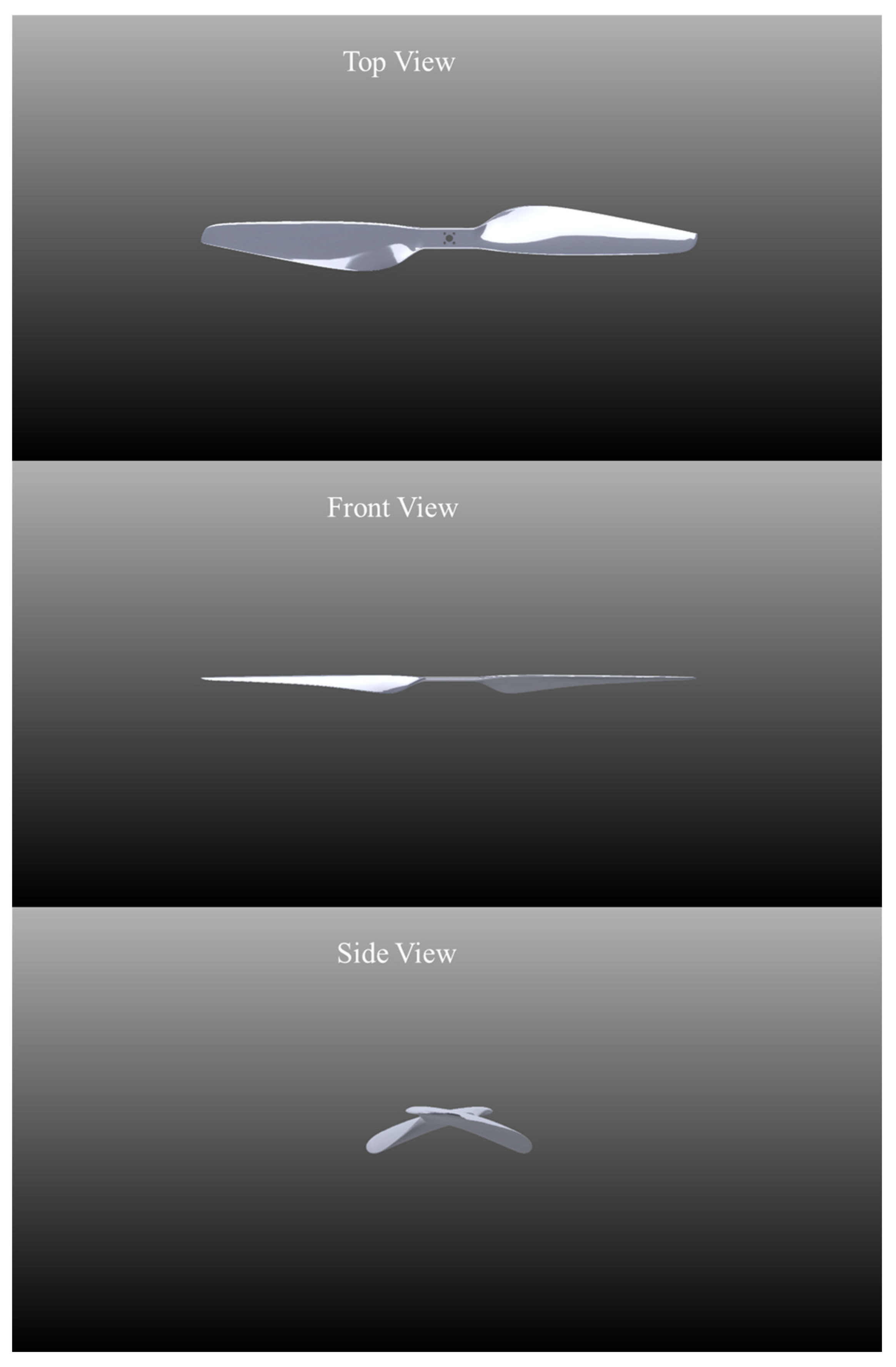

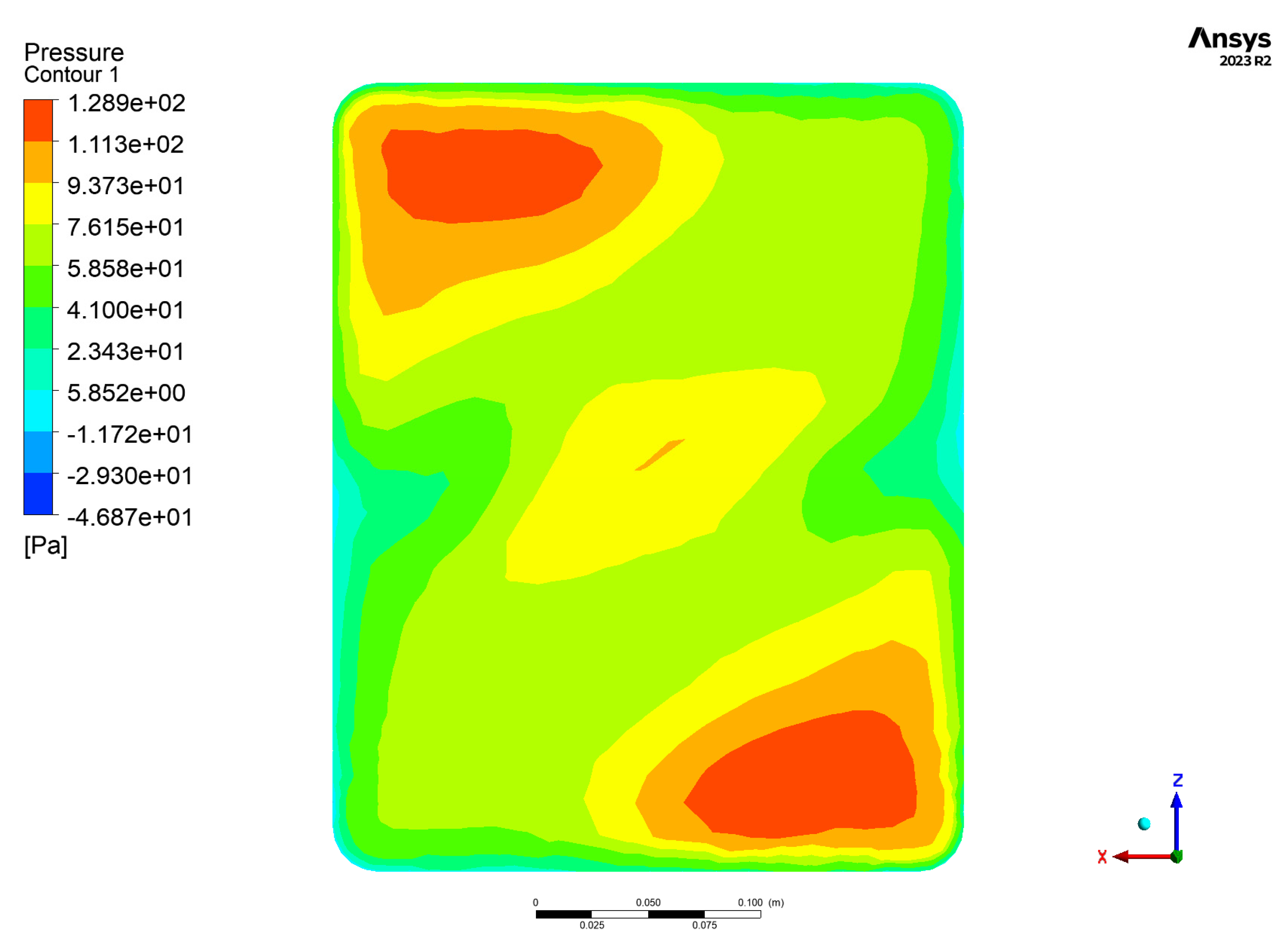

2.3.1. Isolated Propeller

2.3.2. Propeller + Motor

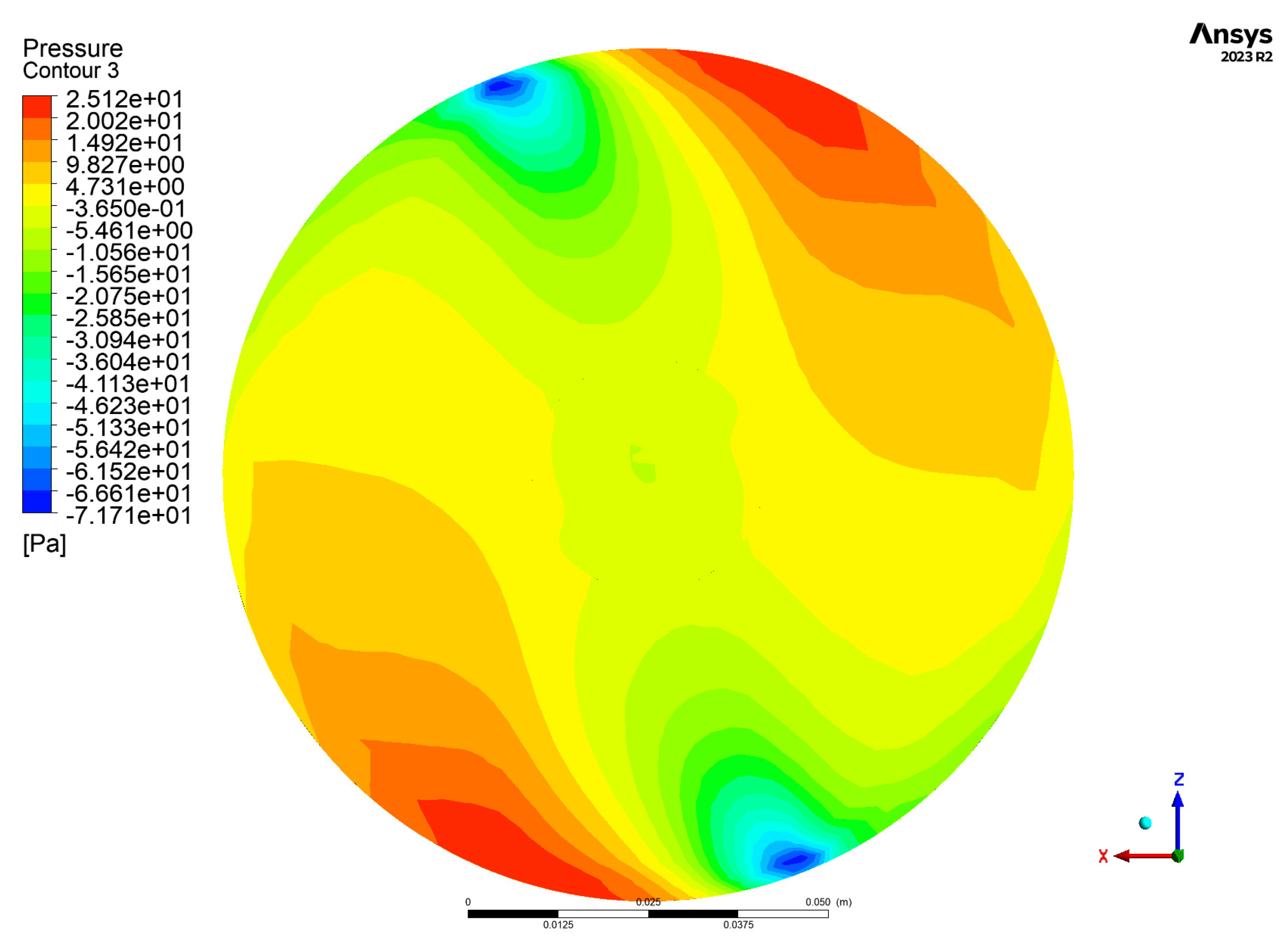

2.3.3. Propeller + Motor + Plate

2.3.4. CFD Results

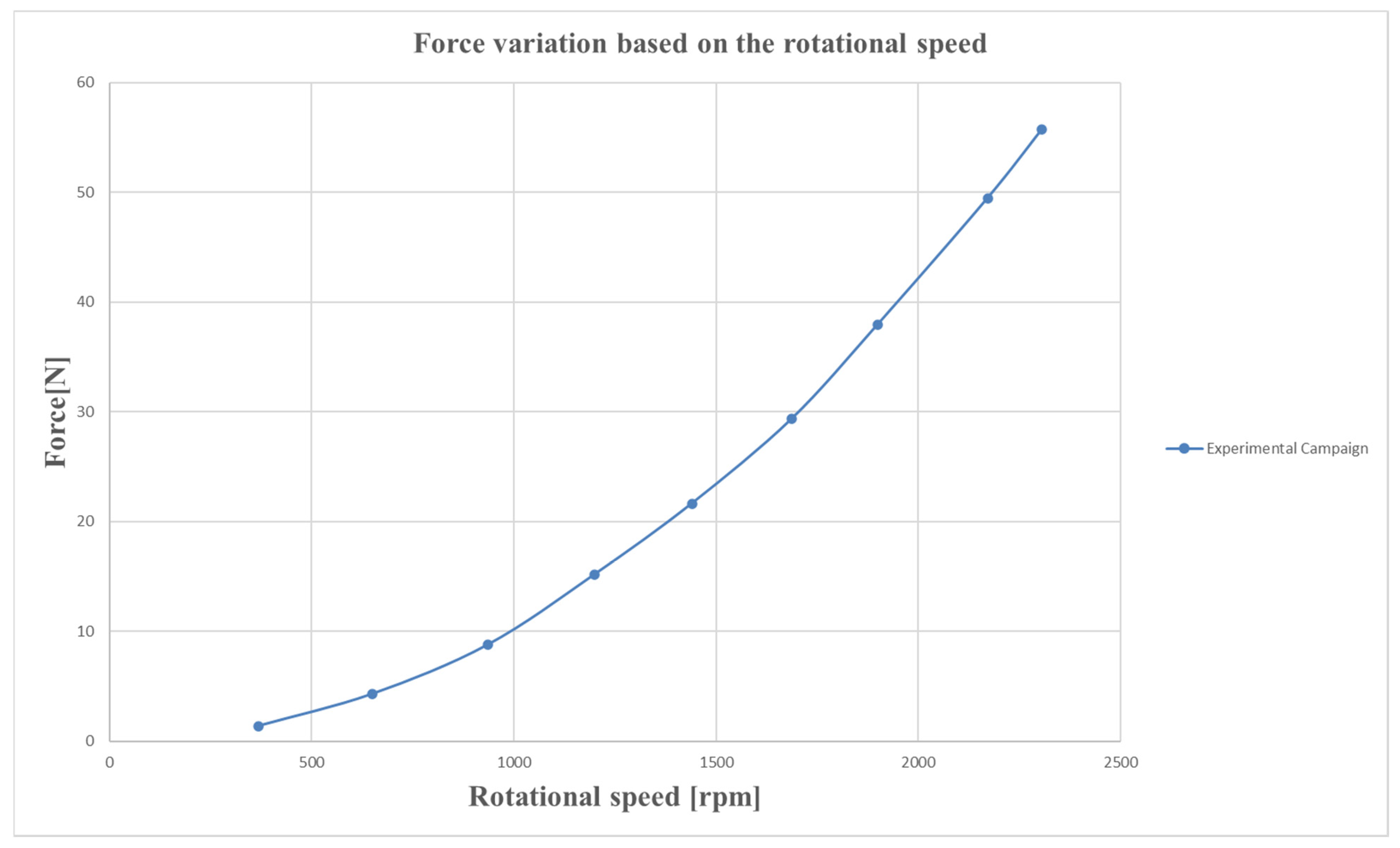

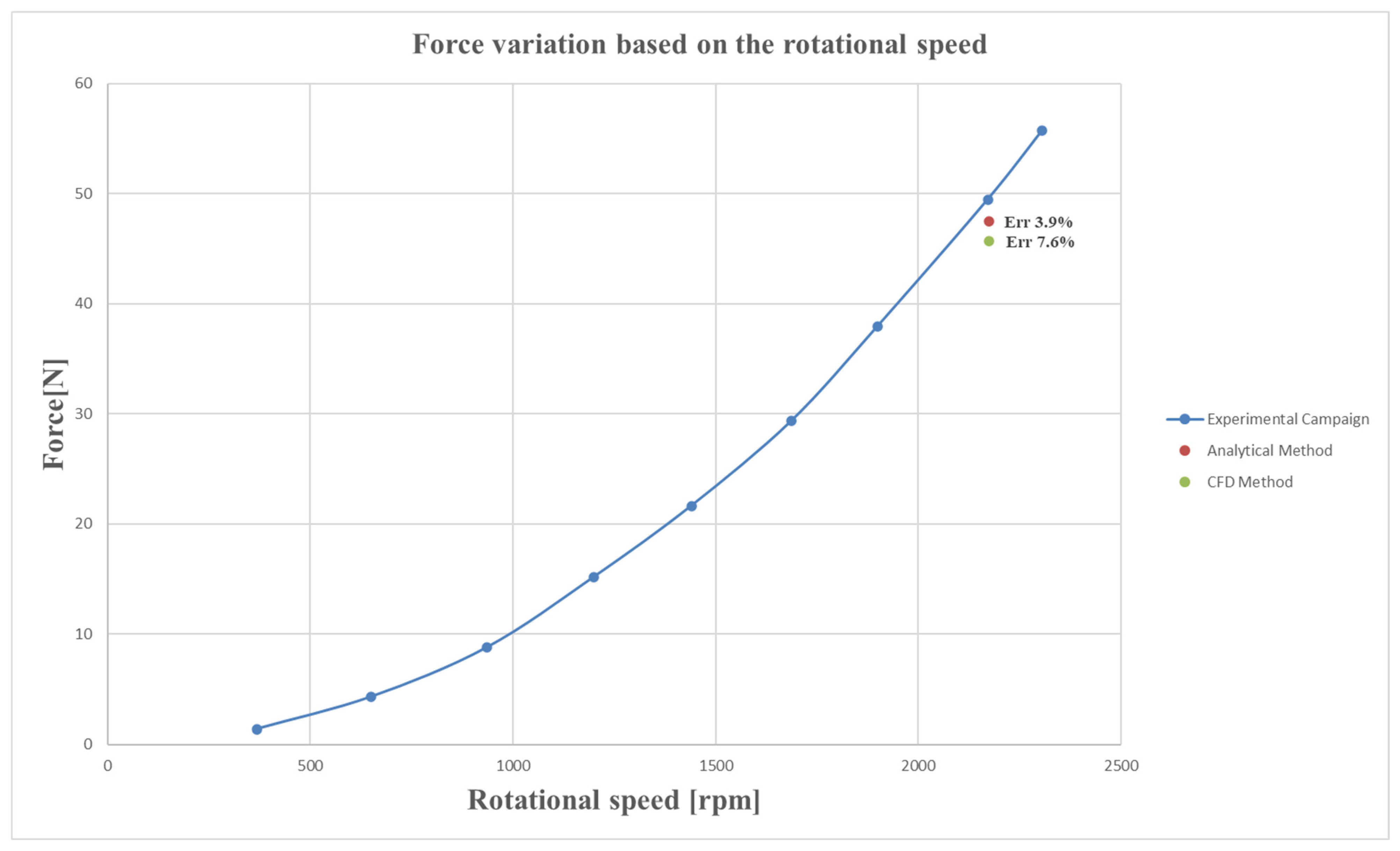

2.4. Experimental Testing Campaign

3. Results

4. Discussion

5. Conclusions

- Test bench design and validation—The stand was developed through an iterative design process, ensuring structural stability and measurement accuracy. Its modular architecture enabled reliable acquisition of thrust, torque, and rotational speed, establishing a robust platform for UAV propulsion research.

- The classical Blade Element Theory (BET) was employed for analytical predictions. To ensure comparability with experimental conditions, the model was refined by incorporating ground effect through a correction factor. This adaptation proved essential for realistic predictions under near-ground conditions, as confirmed by both CFD and experimental data.

- High-fidelity CFD simulations using ANSYS CFX and the k–ω SST turbulence model provided detailed insights into the aerodynamic field across three configurations (isolated propeller, propeller with motor, and full assembly with mounting plate). The results highlighted how installation effects, particularly the mounting plate, introduce local flow perturbations and significantly amplify thrust due to ground effect.

- A series of controlled tests were performed across nine operating points, yielding consistent measurements of thrust, electrical power, and rotational speed. The data demonstrated the quadratic dependency of thrust on rotational speed and confirmed the amplification induced by ground effect.

- When compared at the reference speed of ~2170 rpm, the analytically corrected method showed an error of only 3.9% relative to the experimental campaign, while CFD predictions deviated by 7.6%. This validates the analytical refinement as a reliable predictive tool and confirms the overall consistency of the three methodologies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frigioescu, T.-F.; Crunteanu, D.-E.; Căldărar, M.; Dombrovschi, M.; Badea, G.-P.; Nistor, A. Development and Implementation of an Autonomous Control System for a Micro-Turbogenerator Installed on an Unmanned Aerial Vehicle. Electronics 2025, 14, 1212. [Google Scholar] [CrossRef]

- Shakoor, S.; Kaleem, Z.; Baig, M.I.; Chughtai, O.; Duong, T.Q.; Nguyen, L.D. Role of UAVs in Public Safety Communications: Energy Efficiency Perspective. IEEE Access 2019, 7, 140665–140679. [Google Scholar] [CrossRef]

- Stone, Z.; Parker, K.A. Unmanned aerial vehicle (UAV) activity elicits little to no response from New Zealand forest birds during wildlife monitoring. Notornis 2022, 69, 25–119. [Google Scholar] [CrossRef]

- Dombrovschi, M.; Deaconu, M.; Cristea, L.; Frigioescu, T.-F.; Cican, G.; Badea, G.-P.; Totu, A.-G. Acoustic Analysis of a Hybrid Propulsion System for Drone Applications. Acoustics 2024, 6, 698–712. [Google Scholar] [CrossRef]

- Adoni, W.Y.H.; Lorenz, S.; Fareedh, J.S.; Gloaguen, R.; Bussmann, M. Investigation of Autonomous Multi-UAV Systems for Target Detection in Distributed Environment: Current Developments and Open Challenges. Drones 2023, 7, 263. [Google Scholar] [CrossRef]

- Badea, G.-P.; Frigioescu, T.-F.; Dombrovschi, M.; Cican, G.; Dima, M.; Anghel, V.; Crunteanu, D.-E. Innovative Hybrid UAV Design, Development, and Manufacture for Forest Preservation and Surveillance. Inventions 2023, 9, 39. [Google Scholar] [CrossRef]

- Brandt, J.; Selig, M. Propeller Performance Data at Low Reynolds Numbers. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Bohorquez, F.; Pines, D.; Samuel, P.D. Small Rotor Design Optimization Using Blade Element Momentum Theory and Hover Tests. J. Aircr. 2010, 1, 268–283. [Google Scholar] [CrossRef]

- Zawodny, N.; Haskin, H. Small Propeller and Rotor Testing Capabilities of the NASA Langley Low Speed Aeroacoustic Wind Tunnel. In Proceedings of the 23rd AIAA/CEAS Aeroacoustics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Guclu, G.; Tran, H.; Nguyen, E.; Singh, M.; Zaidi, S. Designing and Testing a Test Stand to Evaluate the Performance of a Custom-Built Drone. In Proceedings of the 2024 Regional Student Conferences, Santiago, Chile, 27 January 2024. [Google Scholar]

- Theyssen, J. The radiation from railway wheel modes and their effect on loudness, sharpness, and equivalent pressure level. Acta Acust. 2024, 8, 20. [Google Scholar] [CrossRef]

- Siddiqi, Z.; Lee, J.W. A computational and experimental study on aerodynamics of motor-driven propellers using thrust stand and rotating cup anemometer. Prog. Comput. Fluid Dyn. Int. J. 2022, 22, 23. [Google Scholar] [CrossRef]

- Tzomakas, M.K.; Peppa, V.; Alexiou, A.; Karakatsanis, G.; Episkopakis, A.; Michail, C.; Valais, I.; Fountos, G.; Kalyvas, N.; Kandarakis, I.S. A phantom based evaluation of the clinical imaging performance of electronic portal imaging devices. Heliyon 2023, 9, e21116. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, C.; Wang, W.; An, C. An Experimental and Numerical Evaluation of the Aerodynamic Performance of a UAV Propeller Considering Pitch Motion. Drones 2023, 7, 447. [Google Scholar] [CrossRef]

- Eldegwy, M.; Hetta, M.; Nabawy, M.; Mohamady, O. Experimental investigation into the performance of UAV propellers at low Reynolds numbers. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar] [CrossRef]

- Kan, X.; Thomas, J.; Teng, H.; Tanner, H.G.; Kumar, V.; Karydis, K. Analysis of Ground Effect for Small-Scale UAVs in Forward Flight. IEEE Robot. Autom. Lett. 2019, 4, 3860–3867. [Google Scholar] [CrossRef]

- Cai, J.; Gunasekaran, S.; Ol, M. Effect of Partial Ground and Partial Ceiling on Propeller Performance. J. Aircr. 2023, 3, 648–661. [Google Scholar] [CrossRef]

- Conyers, S.A. Empirical Evaluation of Ground, Ceiling, and Wall Effect for Small-Scale Rotorcraft. Ph.D. Thesis, University of Denver, Denver, CO, USA, 2019. [Google Scholar]

- Chiew, J.; Aftosmis, M.; Manies, K. Medium-Fidelity CFD Modeling of Multicopter Wakes for Airborne Sensor Measurements. In Proceedings of the Vertical Flight Society’s 78th Annual Forum & Technology Display, Fort Worth, TX, USA, 10–12 May 2022; pp. 1–13. [Google Scholar] [CrossRef]

- Sanchez-Cuevas, P.; Heredia, G.; Ollero, A. Characterization of the Aerodynamic Ground Effect and Its Influence in Multirotor Control. Int. J. Aerosp. Eng. 2017, 2017, 1823056. [Google Scholar] [CrossRef]

- Zhu, H.; Wei, S.; Nie, H.; Du, Y.; Wei, X. Ground Effect on the Thrust Performance of Staggered Rotor System. Drones 2024, 8, 118. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, T.; Tan, H.; Zhou, H.; Chen, W.; Xie, M. Hovering rotor aerodynamics in extreme ground effect. Chin. J. Aeronaut. 2024, 37, 204–219. [Google Scholar] [CrossRef]

- He, X.; Leang, K.K. Rotorcraft in-ground effect models in axial and forward flight. Aerosp. Sci. Technol. 2025, 156, 109748. [Google Scholar] [CrossRef]

- Jordan, W.A.; Narsipur, S.; Deters, R. Aerodynamic and Aeroacoustic Performance of Small UAV Propellers in Static Conditions. In Proceedings of the AIAA AVIATION 2020 FORUM, Online, 15–19 June 2020. [Google Scholar]

- Zhang, T.; Qiao, G.; Smith, D.; Barakos, G.; Kusyumov, A. Parametric study of aerodynamic performance of equivalent ducted/un-ducted rotors. Aerosp. Sci. Technol. 2021, 117, 106984. [Google Scholar] [CrossRef]

- Yilmaz, S.; Erdem, D.; Kavsaoglu, M.S. Performance of a ducted propeller designed for UAV applications at zero angle of attack flight: An experimental study. Aerosp. Sci. Technol. 2015, 45, 376–386. [Google Scholar] [CrossRef]

- de Pierrepont Franzetti, I.D.D.M.; Parin, R.; Capello, E.; Rutherford, M.J.; Valavanis, K.P. Ground, Ceiling and Wall Effect Evaluation of Small Quadcopters in Pressure-controlled Environments. J. Intell. Robot. Syst. 2024, 110, 125. [Google Scholar] [CrossRef]

- Carter, D.; Zhong, Q.; Quinn, D. Using ground effect to model the performance of small near-water rotors. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar]

- Zhang, G.; Xing, Y.; Zhang, W.; Li, J. Prescribed Performance Control for USV-UAV via a Robust Bounded Compensating Technique. IEEE Trans. Control. Netw. Syst. 2025, 12, 2289–2299. [Google Scholar] [CrossRef]

- Hanson, L.; Jawahar, H.K.; Vemuri, S.S.; Azarpeyvand, M. Experimental investigation of propeller noise in ground effect. J. Sound Vib. 2023, 559, 117751. [Google Scholar] [CrossRef]

- PA1 Miniature Single Point Load Cell|Flintec. Available online: https://www.flintec.com/weight-sensors/load-cells/single-point/pa1 (accessed on 26 September 2025).

- Tahometru cu Senzor Hall Maxim 9999 RPM. Available online: https://www.optimusdigital.ro/ro/senzori-senzori-hall/4490-tahometru-cu-senzor-hall-maxim-9999-rpm.html?srsltid=AfmBOoo5yKCV7fCn1jF7QihVJbyr7OsmGtN8MurBAzh3WUJQlzyeBOLZ (accessed on 26 September 2025).

- Hassan, T.; Islam, M.; Mizanur Rahman, M.; Ali, A.; Ziyan, A. 180-Evaluation of Different Turbulence Models at Low Reynolds Number for the Flow over Symmetric and Cambered Airfoils. J. Eng. Adv. 2022, 3, 12–22. [Google Scholar] [CrossRef]

- Sun, W. Assessment of advanced RANS turbulence models for prediction of complex flows in compressors. Chin. J. Aeronaut. 2023, 36, 162–177. [Google Scholar] [CrossRef]

- Newman, S.J. Principles of Helicopter Aerodynamics, 2nd ed.; Leishmann, J.G., Ed.; Cambridge University Press: Cambridge, UK, 2006; 826p, ISBN 0-521-85860-7. [Google Scholar]

- McCormick, B.W. Aerodynamics, Aeronautics, and Flight Mechanics, 2nd ed.; Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Cai, J.; Gunasekaran, S. Propeller Ground Effect in Forward Flight. AIAA J. 2023, 61, 4378–4390. [Google Scholar] [CrossRef]

- Prouty, R. Helicopter Aerodynamics; Phillips Business Information, Inc.: Lebanon, OH, USA, 2009; Volume I, 592p, ISBN 978-0557089918. [Google Scholar]

| Name | Description | Value | Unit of Measure | |

|---|---|---|---|---|

| Manufacturer Details (Propeller + Motor) | Force generated by the propeller | 200 | N | |

| Generated momentum by the electric motor | 25 | Nm | ||

| Bolt Circle Radius of the Motor Mounting Screws | 0.025 | m | ||

| Geometric parameters | Height from the Stand Base to the Motor Center | 0.898 | m | |

| Distance from the Center of Mass to the Overturning Edge | 0.36 | m | ||

| Test bench Weight | 700 | N | ||

| Physical Characteristics | Friction coefficient | 0.8 | N/A |

| Parameter | Description | Value | Unit of Measurement |

|---|---|---|---|

| Propeller Diameter | 0.76 | m | |

| Propeller Radius | 0.38 | m | |

| Hub Diameter | 0.08 | m | |

| Non-dimensional Radius | 0.10526 | N/A | |

| N | Number of Blades | 2 | N/A |

| n | Propeller Rotational Speed | 2174 | Rot/min |

| Ω | Angular Velocity | 227.7 | Rev/min |

| b | Blade chord | 0.07 | m |

| Non-dimensional chord with respect to propeller diameter | 0.18421 | N/A | |

| τ | Blade Profile camber Angle | −0.02 | rad |

| ρ | Air density | 1.225 | |

| Reference Angle for Establishing the blade pitch angle | 9.3 | ° | |

| Radial Increment Step | 0.02 | N/A |

| Manufacturer Force: 38.72 [N] | |||

|---|---|---|---|

| Case No. | Force CFD [N] | Deviation from Analytic [%] | Deviation from Producer [%] |

| 1 | 36.63 | 0.5% | 5% |

| 2 | 37.43 | 2.4% | 3% |

| 3 | 45.7 | 21% | 15% |

| Configuration | Thrust [N] | ΔThrust [%] vs. Isolated |

|---|---|---|

| Isolated propeller | 36.63 | N/A |

| Propeller + motor | 37.43 | +2.2% |

| Propeller + motor + plate | 45.7 | +24.7% |

| Case No. | Rotational Speed [rpm] | Voltage [V] | Current [A] | Force [N] | Power [W] |

|---|---|---|---|---|---|

| 1 | 368 | 46.23 | 0.4 | 1.38 | 18.49 |

| 2 | 650 | 46.2 | 0.7 | 4.3 | 3234 |

| 3 | 935 | 46.1 | 1.3 | 8.76 | 59.93 |

| 4 | 1200 | 46 | 2.2 | 15.18 | 101.2 |

| 5 | 1440 | 46 | 3.2 | 21.63 | 147.2 |

| 6 | 1686 | 45.85 | 4.6 | 29.31 | 210.91 |

| 7 | 1900 | 45.7 | 6.4 | 37.96 | 292.48 |

| 8 | 2171 | 45.55 | 9.2 | 49.44 | 419.06 |

| 9 | 2305 | 45.35 | 11 | 55.68 | 498.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dombrovschi, M.; Badea, G.-P.; Frigioescu, T.-F.; Căldărar, M.; Crunțeanu, D.-E. Ground Effect Influence on UAV Propeller Thrust: Experimental and CFD Validation. Technologies 2025, 13, 542. https://doi.org/10.3390/technologies13120542

Dombrovschi M, Badea G-P, Frigioescu T-F, Căldărar M, Crunțeanu D-E. Ground Effect Influence on UAV Propeller Thrust: Experimental and CFD Validation. Technologies. 2025; 13(12):542. https://doi.org/10.3390/technologies13120542

Chicago/Turabian StyleDombrovschi, Mădălin, Gabriel-Petre Badea, Tiberius-Florian Frigioescu, Maria Căldărar, and Daniel-Eugeniu Crunțeanu. 2025. "Ground Effect Influence on UAV Propeller Thrust: Experimental and CFD Validation" Technologies 13, no. 12: 542. https://doi.org/10.3390/technologies13120542

APA StyleDombrovschi, M., Badea, G.-P., Frigioescu, T.-F., Căldărar, M., & Crunțeanu, D.-E. (2025). Ground Effect Influence on UAV Propeller Thrust: Experimental and CFD Validation. Technologies, 13(12), 542. https://doi.org/10.3390/technologies13120542