From Hop to Beer: Influence of Different Organic Foliar Fertilisation Treatments on Hop Oil Profile and Derived Beers’ Flavour

Abstract

1. Introduction

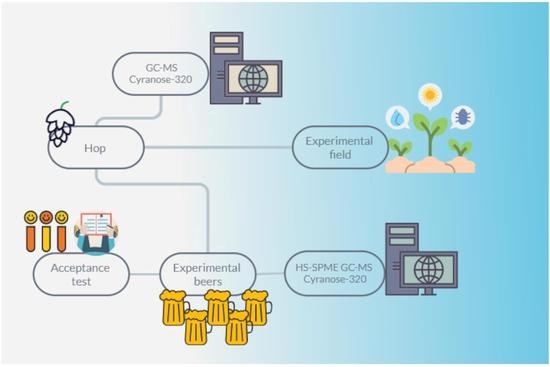

2. Results and Discussion

2.1. Fertilisation Experiment

2.2. Plant Material Characterisation

2.3. Hop Cone Analysis

2.3.1. GC-MS Hop Oil Analysis

2.3.2. Cyranose 320 Analysis on Hop Cones

2.4. Brewing Trial Analysis

2.4.1. HS/SPME/GC-MS Analysis of Conditioned Dry-Hopped Beers

2.4.2. Cyranose 320 Analysis on Dry-Hopped Beers

2.4.3. Sensory Analysis

3. Materials and Methods

3.1. Experimental Design and Hop Cone Sampling

3.2. Hop Cone Sampling

3.3. Hop Cone Analysis

3.3.1. Hop Oil GC-MS Analysis

3.3.2. Hop Cone Electronic Nose Analysis

3.4. Brewing Trials

Brewing Process

3.5. Single-Hopped Beer Analysis

3.5.1. Determination of Standard Quality Attributes

3.5.2. HS/SPME/GC-MS Analysis

3.5.3. Beer Electronic Nose Analysis

3.5.4. Sensory Analysis

3.6. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Turner, S.F.; Benedict, C.A.; Darby, H.; Hoagland, L.A.; Simonson, P.; Robert Sirrine, J.; Murphy, K.M. Challenges and Opportunities for Organic Hop Production in the United States. Agron. J. 2011, 103, 1645–1654. [Google Scholar] [CrossRef]

- Li, W.; Yang, M.; Wang, J.; Wang, Z.; Fan, Z.; Kang, F.; Wang, Y.; Luo, Y.; Kuang, D.; Chen, Z.; et al. Agronomic Responses of Major Fruit Crops to Fertilization in China: A Meta-Analysis. Agronomy 2020, 10, 15. [Google Scholar] [CrossRef]

- Wang, R.; Qi, Y.; Wu, J.; Shukla, M.K.; Sun, Q. Influence of the Application of Irrigated Water-Soluble Calcium Fertilizer on Wine Grape Properties. PLoS ONE 2019, 14, e0222104. [Google Scholar] [CrossRef]

- Osman Bursalioglu, E. The Effects of Fertilization on the Green Tea Elements. Environ. Res. Technol. 2019, 2, 98–102. [Google Scholar] [CrossRef]

- Webster, D.R.; Edwards, C.G.; Spayd, S.E.; Peterson, J.C.; Seymour, B.J. Influence of vineyard nitrogen fertilization on the concentrations of monoterpenes, higher alcohols, and esters in aged Riesling wines. AJEV 1993, 44, 275–284. [Google Scholar] [CrossRef]

- Liu, M.Y.; Burgos, A.; Ma, L.; Zhang, Q.; Tang, D.; Ruan, J. Lipidomics Analysis Unravels the Effect of Nitrogen Fertilization on Lipid Metabolism in Tea Plant (Camellia Sinensis L.). BMC Plant Biol. 2017, 17, 165. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.D.; Yang, M.S.; Renseigné, N.; Smith, D.L. Fertilizer Effect on the Yield and Terpene Components from the Flowerheads of Chrysanthemum Boreale M. (Compositae). Agron. Sustain. Dev. 2005, 25, 205. [Google Scholar] [CrossRef]

- Van Holle, A.; Van Landschoot, A.; Roldán-Ruiz, I.; Naudts, D.; De Keukeleire, D. The Brewing Value of Amarillo Hops (Humulus Lupulus L.) Grown in Northwestern USA: A Preliminary Study of Terroir Significance. J. Inst. Brew. 2017, 123, 312–318. [Google Scholar] [CrossRef]

- Rodolfi, M.; Chiancone, B.; Liberatore, C.M.; Fabbri, A.; Cirlini, M.; Ganino, T. Changes in Chemical Profile of Cascade Hop Cones According to the Growing Area. J. Sci. Food Agric. 2019, 99, 6011–6019. [Google Scholar] [CrossRef]

- Kishimoto, T.; Kobayashi, M.; Yako, N.; Iida, A.; Wanikawa, A. Comparison of 4-Mercapto-4-Methylpentan-2-One Contents in Hop Cultivars from Different Growing Regions. J. Agric. Food Chem. 2008, 56, 1051–1057. [Google Scholar] [CrossRef]

- Forster, A.; Gahr, A.; Schüll, F.; Bertazzoni, J. The Impact of Climatic Conditions on the Biogenesis of Various Compounds in Hops. BrewingScience 2021, 74, 160–171. [Google Scholar] [CrossRef]

- Ramakrishna, A.; Ravishankar, G.A. Influence of Abiotic Stress Signals on Secondary Metabolites in Plants. Plant Signal. Behav. 2011, 6, 1720–1731. [Google Scholar] [CrossRef]

- Iskra, A.E.; Lafontaine, S.R.; Trippe, K.M.; Massie, S.T.; Phillips, C.L.; Twomey, M.C.; Shellhammer, T.H.; Gent, D.H. Influence of Nitrogen Fertility Practices on Hop Cone Quality. J. Am. Soc. Brew. Chem. 2019, 77, 199–209. [Google Scholar] [CrossRef]

- De Keukeleire, J.; Janssens, I.; Heyerick, A.; Ghekiere, G.; Cambie, J.; Roldán-Ruiz, I.; Van Bockstaele, E.; De Keukeleire, D. Relevance of Organic Farming and Effect of Climatological Conditions on the Formation of α-Acids, β-Acids, Desmethylxanthohumol, and Xanthohumol in Hop (Humulus Lupulus L.). J. Agric. Food Chem. 2007, 55, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Brown, D. Fertilizers and Nutrient Management for Hops. Available online: https://www.canr.msu.edu/uploads/236/71516/fertilizer_and_nutrient_requirements_for_hops.pdf (accessed on 21 January 2023).

- Neve, R.A. Hops; Chapman and Hall: London, UK, 1991; p. 266. [Google Scholar]

- Greene, C.; Ferreira, G.; Carlson, A.; Cooke, B.; Waves, C.H.-A. Growing organic demand provides high-value opportunities for many types of producers. Amber Waves 2017. Available online: https://www.ers.usda.gov/amber-waves/2017/januaryfebruary/growing-organic-demand-provides-high-value-opportunities-for-many-types-of-producers/ (accessed on 10 April 2023).

- Rizzo, G.; Borrello, M.; Dara Guccione, G.; Schifani, G.; Cembalo, L. Organic food consumption: The relevance of the health attribute. Sustainability 2020, 12, 595. [Google Scholar] [CrossRef]

- Solarska, E.; Sosnowska, B. The Impact of Plant Protection and Fertilization on Content of Bioactive Substances in Organic Hops. Acta Sci. Pol.-Hortorum Cultus 2015, 14, 93–101. [Google Scholar]

- Rettberg, N.; Biendl, M.; Garbe, L.A. Hop Aroma and Hoppy Beer Flavor: Chemical Backgrounds and Analytical Tools—A Review. J. Am. Soc. Brew. Chem. 2018, 76, 1–20. [Google Scholar] [CrossRef]

- Gabrielyan, G.; Marsh, T.L.; McCluskey, J.J.; Ross, C.F. Hoppiness Is Happiness? Under-Fertilized Hop Treatments and Consumers’ Willingness to Pay for Beer. J. Wine Econ. 2018, 13, 160–181. [Google Scholar] [CrossRef]

- Rodolfi, M.; Barbanti, L.; Giordano, C.; Rinaldi, M.; Fabbri, A.; Pretti, L.; Casolari, R.; Beghé, D.; Petruccelli, R.; Ganino, T. The Effect of Different Organic Foliar Fertilization on Physiological and Chemical Characters in Hop (Humulus Lupulus L., Cv Cascade) Leaves and Cones. Appl. Sci. 2021, 11, 6778. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington DC, USA, 1995. [Google Scholar]

- NIST. Mass Spectral Library (NIST/EPA/NIH). 2005. Available online: https://chemdata.nist.gov/ (accessed on 15 April 2022).

- Adams, R.P. Identification of Essential Oil Components by Gas Chromatography/Mass Spectrometry; Allured Publishing Corporation, Pennsylvania State University: Carol Stream, PA, USA, 2007. [Google Scholar]

- Garcia, D.; Wu, Y.; Furlan, M.R.; Hassani, D.; Khalid, M.; Huang, D.; Ming, L.C. Dry Biomass and Volatile Oil Production of Achyrocline Satureioides Subjected to Agronomic Management Practices. Rev. Bras. Farmacogn. 2021, 31, 832–837. [Google Scholar] [CrossRef]

- Khammar, A.A.; Moghaddam, M.; Asgharzade, A.; Sourestani, M.M. Nutritive Composition, Growth, Biochemical Traits, Essential Oil Content and Compositions of Salvia Officinalis L. Grown in Different Nitrogen Levels in Soilless Culture. J. Soil Sci. Plant Nutr. 2021, 21, 3320–3332. [Google Scholar] [CrossRef]

- Vilanova, C.M.; Coelho, K.P.; Silva Araújo Luz, T.R.; Brandão Silveira, D.P.; Coutinho, D.F.; de Moura, E.G. Effect of Different Water Application Rates and Nitrogen Fertilisation on Growth and Essential Oil of Clove Basil (Ocimum Gratissimum L.). Ind. Crops Prod. 2018, 125, 186–197. [Google Scholar] [CrossRef]

- Ormeño, E.; Olivier, R.; Mévy, J.P.; Baldy, V.; Fernandez, C. Compost May Affect Volatile and Semi-Volatile Plant Emissions through Nitrogen Supply and Chlorophyll Fluorescence. Chemosphere 2009, 77, 94–104. [Google Scholar] [CrossRef]

- Peñuelas, J.; Estiarte, M. Can Elevated CO2 Affect Secondary Metabolism and Ecosystem Function? Trends Ecol. Evol. 1998, 13, 20–24. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Lai, Y.; He, G.; Wen, S.; He, H.; Li, Z.; Zhang, B.; Zhang, D. Transcriptomic Analysis Reveals the Significant Effects of Fertilization on the Biosynthesis of Sesquiterpenes in Phoebe Bournei. Genomics 2022, 114, 110375. [Google Scholar] [CrossRef]

- Lafontaine, S.; Varnum, S.; Roland, A.; Delpech, S.; Dagan, L.; Vollmer, D.; Kishimoto, T.; Shellhammer, T. Impact of Harvest Maturity on the Aroma Characteristics and Chemistry of Cascade Hops Used for Dry-Hopping. Food Chem. 2019, 278, 228–239. [Google Scholar] [CrossRef]

- Ordukaya, E.; Karlik, B. Fruit Juice–Alcohol Mixture Analysis Using Machine Learning and Electronic Nose. IEEJ Trans. Electr. Electron. Eng. 2016, 11, S171–S176. [Google Scholar] [CrossRef]

- Gardner, D.M.; Zoecklein, B.W.; Mallikarjunan, K. Electronic Nose Analysis of Cabernet Sauvignon (Vitis Vinifera L.) Grape and Wine Volatile Differences during Cold Soak and Postfermentation. Am. J. Enol. Vitic. 2011, 62, 81–90. [Google Scholar] [CrossRef]

- Mongelli, A.; Rodolfi, M.; Ganino, T.; Marieschi, M.; Dall’Asta, C.; Bruni, R. Italian Hop Germplasm: Characterization of Wild Humulus Lupulus L. Genotypes from Northern Italy by Means of Phytochemical, Morphological Traits and Multivariate Data Analysis. Ind. Crops Prod. 2015, 70, 16–27. [Google Scholar] [CrossRef]

- Montgomery, R.R.; Sauerwein, J.C. Standard Reference Materials Catalog-January 2007; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Zheng, X.Z.; Lan, Y.B.; Zhu, J.M.; Westbrook, J.; Hoffmann, W.C.; Lacey, R.E. Rapid Identification of Rice Samples Using an Electronic Nose. J. Bionic Eng. 2009, 6, 290–297. [Google Scholar] [CrossRef]

- Pathange, L.P.; Mallikarjunan, P.; Marini, R.P.; O’Keefe, S.; Vaughan, D. Non-Destructive Evaluation of Apple Maturity Using an Electronic Nose System. J. Food Eng. 2006, 77, 1018–1023. [Google Scholar] [CrossRef]

- Baietto, M.; Wilson, A.D. Electronic-Nose Applications for Fruit Identification, Ripeness and Quality Grading. Sensors 2015, 15, 899–931. [Google Scholar] [CrossRef]

- Castro, L.F.; Ross, C.F. Determination of Flavour Compounds in Beer Using Stir-Bar Sorptive Extraction and Solid-Phase Microextraction. J. Inst. Brew. 2015, 121, 197–203. [Google Scholar] [CrossRef]

- Lafontaine, S.R.; Shellhammer, T.H. Impact of Static Dry-Hopping Rate on the Sensory and Analytical Profiles of Beer. J. Inst. Brew. 2018, 124, 434–442. [Google Scholar] [CrossRef]

- Analytica, E.B.C. Hans Carl Getränke Fachverlag; Fachverlag Hans Carl: Nürenberg, Germany, 1998; Section: Method 7. [Google Scholar]

- Riu-Aumatell, M.; Miró, P.; Serra-Cayuela, A.; Buxaderas, S.; López-Tamames, E. Assessment of the Aroma Profiles of Low-Alcohol Beers Using HS-SPME-GC-MS. Food Res. Int. 2014, 57, 196–202. [Google Scholar] [CrossRef]

- Charry-Parra, G.; DeJesus-Echevarria, M.; Perez, F.J. Beer Volatile Analysis: Optimization of HS/SPME Coupled to GC/MS/FID. J. Food Sci. 2011, 76, C205–C211. [Google Scholar] [CrossRef] [PubMed]

- Aberl, A.; Coelhan, M. Determination of Volatile Compounds in Different Hop Varieties by Headspace-Trap GC/MS-in Comparison with Conventional Hop Essential Oil Analysis. J. Agric. Food Chem. 2012, 60, 2785–2792. [Google Scholar] [CrossRef]

- Ligor, M.; Stankevičius, M.; Wenda-Piesik, A.; Obelevičius, K.; Ragažinskiene, O.; Stanius, Ž.; Maruška, A.; Buszewski, B. Comparative Gas Chromatographic-Mass Spectrometric Evaluation of Hop (Humulus Lupulus L.) Essential Oils and Extracts Obtained Using Different Sample Preparation Methods. Food Anal. Methods 2014, 7, 1433–1442. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 1999; ISBN 978-1-00-304072-9. [Google Scholar]

- Aquilani, B.; Laureti, T.; Poponi, S.; Secondi, L. Beer Choice and Consumption Determinants When Craft Beers Are Tasted: An Exploratory Study of Consumer Preferences. Food Qual. Prefer. 2015, 41, 214–224. [Google Scholar] [CrossRef]

| Treatment | N Org. | P2O5 | K2O | Mg Chel | Zn Solub | Zn Chel | Mn Solub | Mn Chel | Fe Solub | Fe Chel. | Cu Solub | Cu Chel | B Solub | Mo Solub |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | 30 | 1125 | 2070 | 360 | 45 | 45 | 120 | 120 | 120 | 120 | 45 | 45 | 15 | 18 |

| T2 | 16,230 | - | 570 | 270 | 45 | 45 | 120 | 120 | 120 | 120 | 45 | 45 | 15 | 3 |

| T3 | 16,080 | 3600 | 19,170 | 180 | 21 | 21 | - | - | 1950 | 1950 | - | - | - | - |

| T4 | 16,080 | - | 16,770 | - | 66 | 66 | 120 | 120 | 2070 | 2070 | 45 | 45 | 345 | 3 |

| Treatment | α-Acids % | β-Acids % | COH % | Ess. Oil Yield % | Moisture % |

|---|---|---|---|---|---|

| C | 4.3 ± 0.3 c | 5.3 ± 0.2 b | 26.2 ± 0.5 a | 1.1 ± 0.1 c | 11.1 ± 0.1 a |

| T1 | 5.8 ± 0.4 b | 4.9 ± 0.5 b | 26.7 ± 0.5 a | 1.4 ± 0.1 b | 10.0 ± 0.1 a |

| T2 | 7.0 ± 0.3 a | 6.4 ± 0.1 a | 26.8 ± 0.1 a | 1.8 ± 0.1 a | 10.1 ± 0.2 a |

| T3 | 5.8 ± 0.6 b | 5.3 ± 0.2 b | 26.1 ± 0.4 a | 1.5 ± 0.2 b | 10.5 ± 0.2 a |

| T4 | 5.1 ± 0.1 bc | 5.05 ± 0.2 b | 26.2 ± 0.4 a | 1.3 ± 0.1 b | 10.1 ± 0.1 a |

| Terpenes | C | T1 | T2 | T3 | T4 | RI Calc * |

|---|---|---|---|---|---|---|

| α-Pinene | 0.1 ± 0.03 a | 0.2 ± 0.01 a | 0.3 ± 0.00 a | 0.2 ± 0.05 a | 0.3 ± 0.01 a | 1028 |

| β-Pinene | 1.3 ± 0.22 b | 1.8 ± 0.02 ab | 1.9 ± 0.02 ab | 1.8 ± 0.20 ab | 2.0 ± 0.00 a | 1039 |

| β-Myrcene | 47.3 ± 3.01 b | 58.5 ± 1.73 a | 57.9 ± 1.36 ab | 57.4 ± 1.39 ab | 56.5 ± 1.10 ab | 1173 |

| Limonene | 1.0 ± 0.07 a | 1.2 ± 0.05 a | 1.1 ± 0.04 a | 12 ± 0.06 a | 1.2 ± 0.06 a | 1185 |

| β-Linalool | 0.7 ± 0.19 a | 0.7 ± 0.03 a | 0.8 ± 0.03 a | 0.7 ± 0.03 a | 0.7 ± 0.01 a | 1544 |

| β-Caryophyllene | 6.5 ± 1.08 a | 4.8 ± 0.60 ab | 4.3 ± 0.04 b | 4.6 ± 0.24 ab | 5.2 ± 0.60 ab | 1577 |

| trans-Bergamotene | 0.7 ± 0.14 a | 0.4 ± 0.07 a | 0.5 ± 0.04 a | 0.5 ± 0.04 a | 0.5 ± 0.07 a | 1581 |

| trans- β- Farnesene | 6.3 ± 0.60 a | 4.6 ± 0.63 a | 4.6 ± 0.41 a | 4.7 ± 0.14 a | 4.9 ± 0.23 a | 1645 |

| α-Humulene | 15.2 ± 2.25 a | 9.6 ± 0.96 ab | 9.0 ± 0.57 b | 10.0 ± 1.08 ab | 11.6 ± 2.06 ab | 1658 |

| Muurolene | 1.1 ± 0.13 a | 1.1 ± 0.29 a | 0.8 ± 0.04 b | 0.7 ± 0.00 b | 0.8 ± 0.04 ab | 1684 |

| Methyl geranate | 0.8 ± 0.20 a | 0.7 ± 0.01 a | 0.7 ± 0.08 a | 0.7 ± 0.00 a | 0.7 ± 0.06 a | 1688 |

| β-Selinene | 2.1 ± 0.21 a | 1.3 ± 0.79 ab | 1.8 ± 0.03 ab | 1.7 ± 0.08 ab | 1.7 ± 0.06 b | 1714 |

| α-Selinene | 3.4 ± 0.11 a | 2.6 ± 1.13 ab | 2.9 ± 0.01 ab | 2.7 ± 0.04 b | 2.9 ± 0.05 ab | 1718 |

| τ-Cadinene | 0.9 ± 0.11 a | 0.9 ± 0.61 ab | 0.6 ± 0.04 b | 0.6 ± 0.03 b | 0.7 ± 0.02 ab | 1755 |

| δ-Cadinene | 1.5 ± 0.22 a | 0.9 ± 0.38 a | 0.9 ± 0.08 a | 0.9 ± 0.01 a | 1.0 ± 0.07 a | 1763 |

| trans-1,4-Cadina diene | 0.1 ± 0.03 a | 0.5 ± 0.62 a | 0.1 ± 0.01 a | 0.1 ± 0.00 a | 0.1 ± 0.03 a | 1769 |

| Terpenes | BC | BT1 | BT2 | BT3 | BT4 | RI Calc * |

|---|---|---|---|---|---|---|

| β-Myrcene | 0.4 ± 0.19 a | 0.6 ± 0.09 a | 0.3 ± 0.08 a | 0.3 ± 0.12 a | 0.2 ± 0.03 a | 991 |

| Linalool | 1.3 ± 0.15 a | 0.9 ± 0.06 bc | 0.9 ± 0.00 c | 0.9 ± 0.01 abc | 1.1 ± 0.01 ab | 1099 |

| Terpineol | 0.2 ± 0.05 a | 0.1 ± 0.00 b | 0.1 ± 0.00 b | 0.1 ± 0.00 b | 0.1 ± 0.00 b | 1188 |

| Citronellol | 1.1 ± 0.08 a | 07 ± 0.07 ab | 0.6 ± 0.04 b | 0.7 ± 0.02 ab | 0.6 ± 0.02 ab | 1228 |

| Geraniol | 0.2 ± 0.02 b | 0.3 ± 0.04 a,b | 0.4 ± 0.05 a | 0.4 ± 0.05 a | 0.4 ± 0.01 a | 1255 |

| Methyl geranate | 0.1 ± 0.02 b | 0.4 ± 0.01 a | 0.3 ± 0.01 ab | 0.4 ± 0.00 a | 0.4 ± 0.01 a | 1302 |

| Hedonic Score for Beer Samples | |||||

|---|---|---|---|---|---|

| Sensory Attribute | BC | BT1 | BT2 | BT3 | BT4 |

| Appearance | 5.6 ± 1.5 a | 5.8 ± 1.3 a | 5.7 ± 1.2 a | 5.7 ± 1.1 a | 5.8 ± 1.3 a |

| Odour | 6.1 ± 1.2 b | 6.0 ± 1.3 b | 5.1 ± 1.3 ab | 5.4 ± 1.3 ab | 5.2 ± 1.0 a |

| Flavour/aroma | 5.7 ± 1.3 b | 5.8 ± 1.3 b | 5.1 ± 1.2 a | 5.3 ± 1.3 ab | 5.1 ± 1.3 a |

| Taste | 5.3 ± 1.3 a | 5.4 ± 1.3 a | 5.3 ± 1.3 a | 5.2 ± 1.3 a | 5.4 ± 1.3 a |

| Overall Acceptability | 6.0 ± 1.2 a | 6.1 ± 0.9 a | 5.7 ± 1.1 a | 5.8 ± 1.4 a | 5.8 ± 1.3 a |

| Preference + | 166 | 164 | 174 | 174 | 172 |

| Parameter | Value | Unit |

| pH | 7.33 | |

| EC | 264 | µS/cm |

| CEC | 30.86 | cmolc/Kg |

| Element | Value | Unit |

| (N) tot | 2 | g/Kg |

| Organic matter | 3.1 | % w/w |

| (P) available | 17.8 | mg/kg |

| (P2O5) available | 40.9 | mg/kg |

| Ca | 13.65 | mmol/L |

| Mg | 1.1 | mmol/L |

| K | 1.23 | mmol/L |

| Na | 0.22 | mmol/L |

| Zn | 41 | mg/kg |

| Fe | 17.4 | g/kg |

| B | 11 | mg/kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodolfi, M.; Valentoni, A.; Pretti, L.; Sanna, M.; Guidotti, S.; Marchioni, I.; Ganino, T. From Hop to Beer: Influence of Different Organic Foliar Fertilisation Treatments on Hop Oil Profile and Derived Beers’ Flavour. Plants 2023, 12, 1861. https://doi.org/10.3390/plants12091861

Rodolfi M, Valentoni A, Pretti L, Sanna M, Guidotti S, Marchioni I, Ganino T. From Hop to Beer: Influence of Different Organic Foliar Fertilisation Treatments on Hop Oil Profile and Derived Beers’ Flavour. Plants. 2023; 12(9):1861. https://doi.org/10.3390/plants12091861

Chicago/Turabian StyleRodolfi, Margherita, Antonio Valentoni, Luca Pretti, Manuela Sanna, Simone Guidotti, Ilaria Marchioni, and Tommaso Ganino. 2023. "From Hop to Beer: Influence of Different Organic Foliar Fertilisation Treatments on Hop Oil Profile and Derived Beers’ Flavour" Plants 12, no. 9: 1861. https://doi.org/10.3390/plants12091861

APA StyleRodolfi, M., Valentoni, A., Pretti, L., Sanna, M., Guidotti, S., Marchioni, I., & Ganino, T. (2023). From Hop to Beer: Influence of Different Organic Foliar Fertilisation Treatments on Hop Oil Profile and Derived Beers’ Flavour. Plants, 12(9), 1861. https://doi.org/10.3390/plants12091861