Computationally Efficient Adaptive Type-2 Fuzzy Control of Flexible-Joint Manipulators

Abstract

:1. Introduction

2. Flexible-Joint Manipulator Dynamics

2.1. Modeling of a Flexible-Joint Manipulator

- (1)

- Positive Definite Symmetric (PDS), i.e., and for any non-null vector x.

- (2)

- Upper and lower bounded, i.e., there exist two scalars and such that , where I is the identity matrix.

- (1)

- Matrix is skew symmetric, i.e.,

- (2)

- is quadratic in and bounded, i.e., there exists a scalar such that .

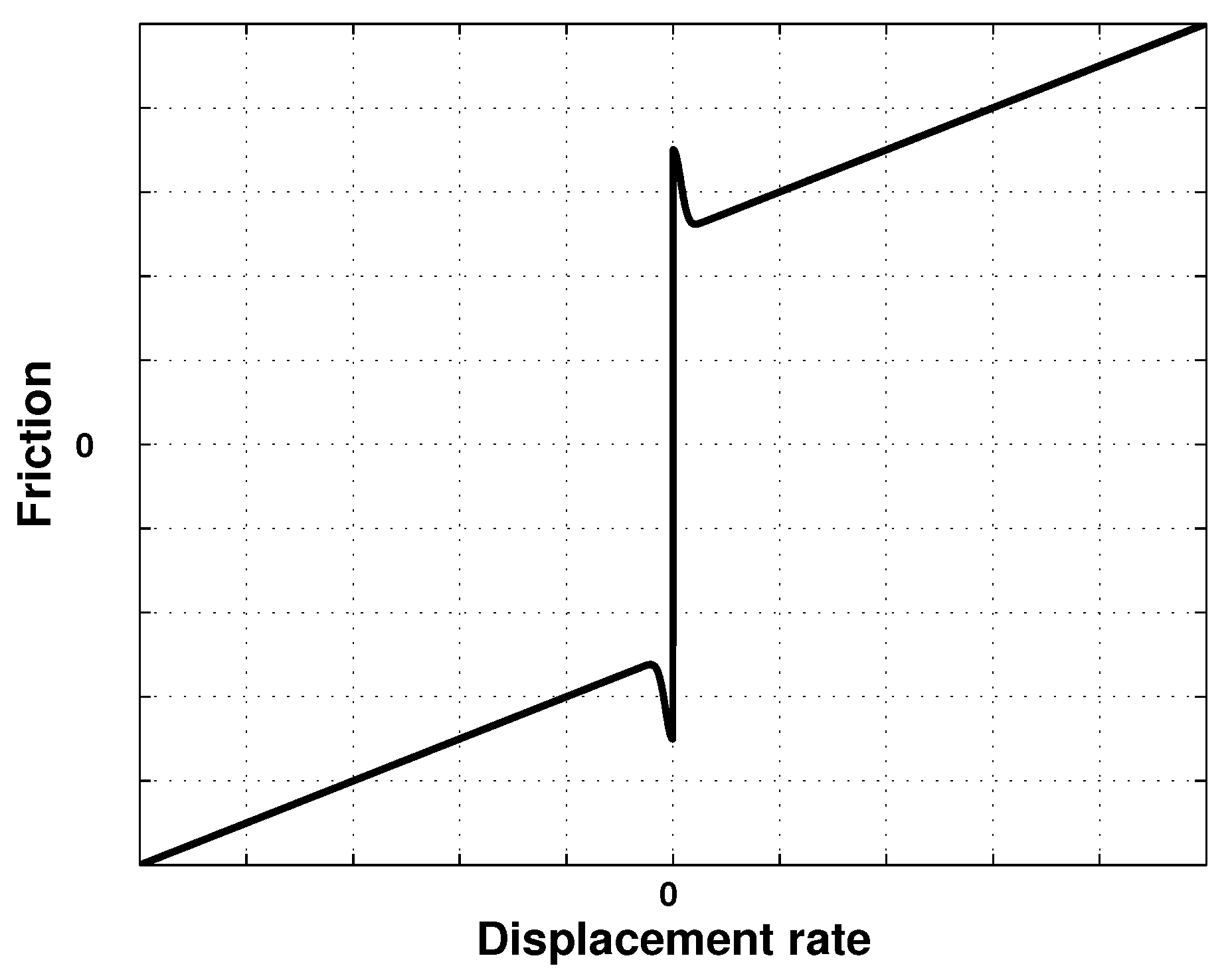

2.2. Friction Modeling

2.3. Problem Statement

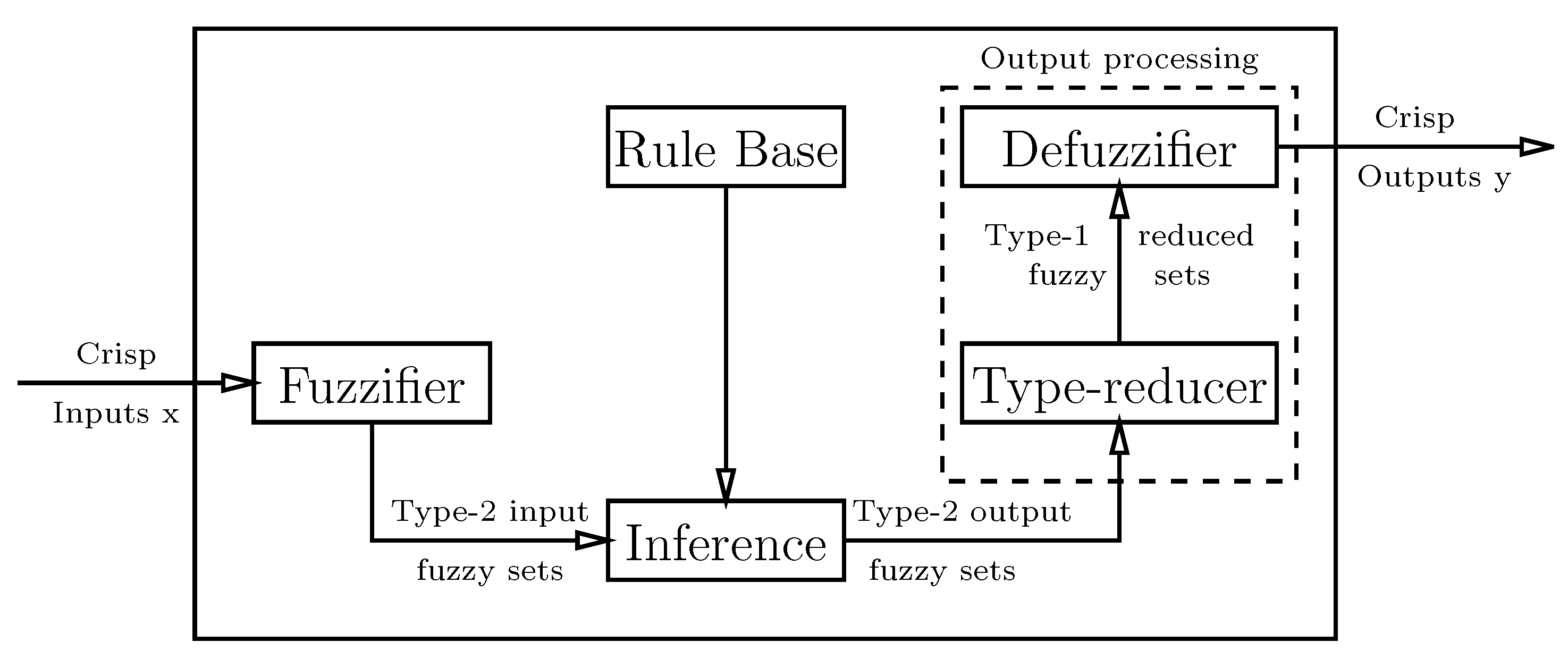

3. Type-2 FLSs

4. Interval Type-2 FLSs

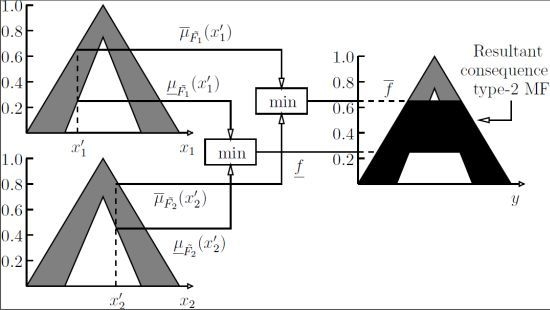

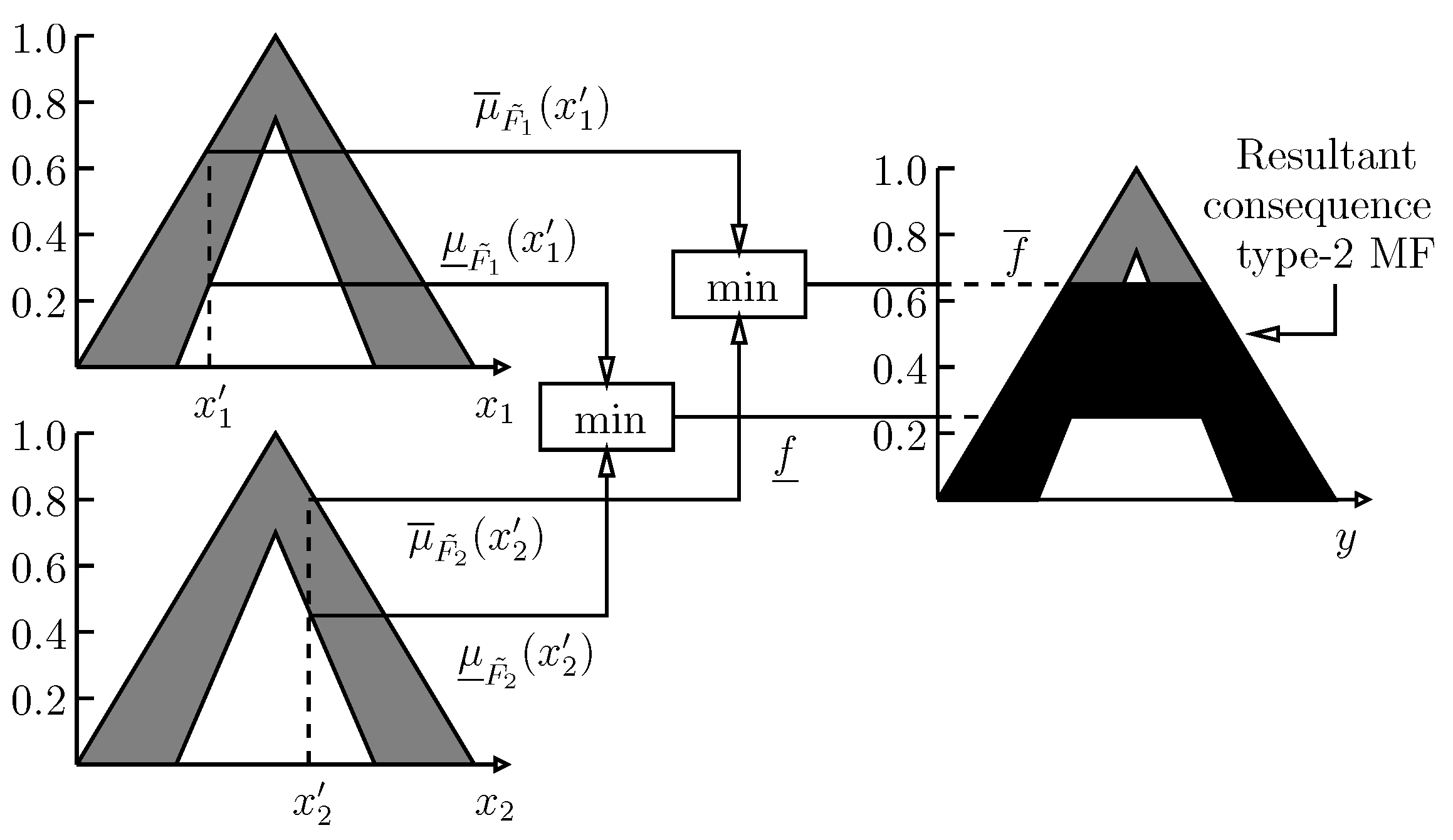

- the firing strength of the lth fuzzy rule is an interval type-1 fuzzy set defined aswherewith the t-norm operator denoted by “⋆”.

- the fired output consequent set of the lth rule is a type-1 fuzzy set characterized by a membership functionwith and being the lower and upper membership grades of .

- if N out of a total of L fuzzy rules in the FLS fire, where , then the overall aggregated output fuzzy set is defined by a type-1 membership function obtained by combining the fired output consequent sets into one. In other words, , where is defined in Equation (5).

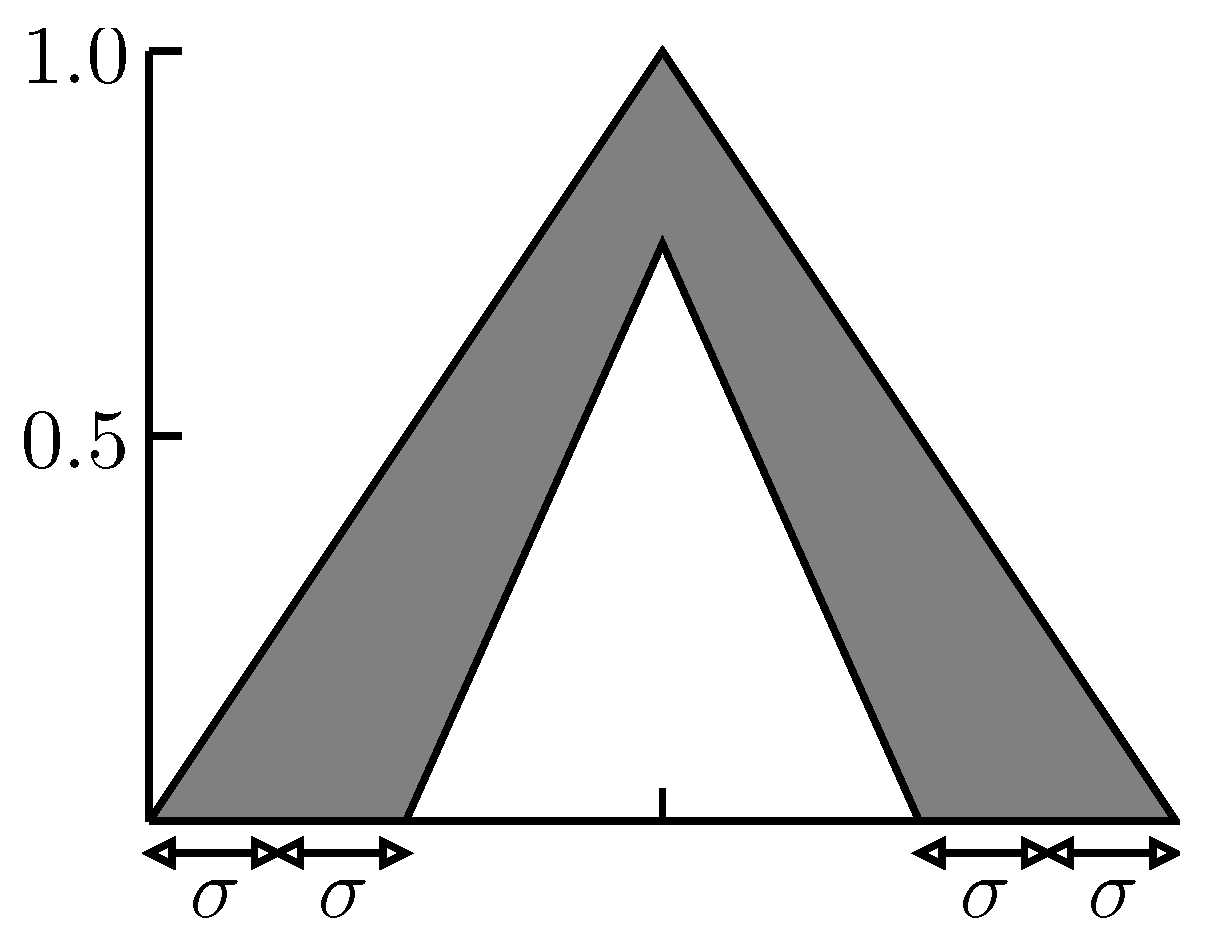

4.1. Type-2 Fuzzification

4.2. Type-2 Fuzzy Rule Base

4.3. Type-2 Fuzzy Inference Engine

4.4. Type Reduction

4.5. Calculation of the Type-Reduced Set

|

|

|

4.6. Type-2 Defuzzification

5. Control Strategy

| NL | NS | Z | PS | PL | |

| PL | Z | PL | PL | PL | PL |

| PS | NS | Z | PS | PS | PL |

| Z | NL | NS | Z | PS | PL |

| NS | NL | NS | NS | Z | PS |

| NL | NL | NL | NL | NL | Z |

5.1. Adaptive Type-2 FLC

6. Simulation Results and Discussion

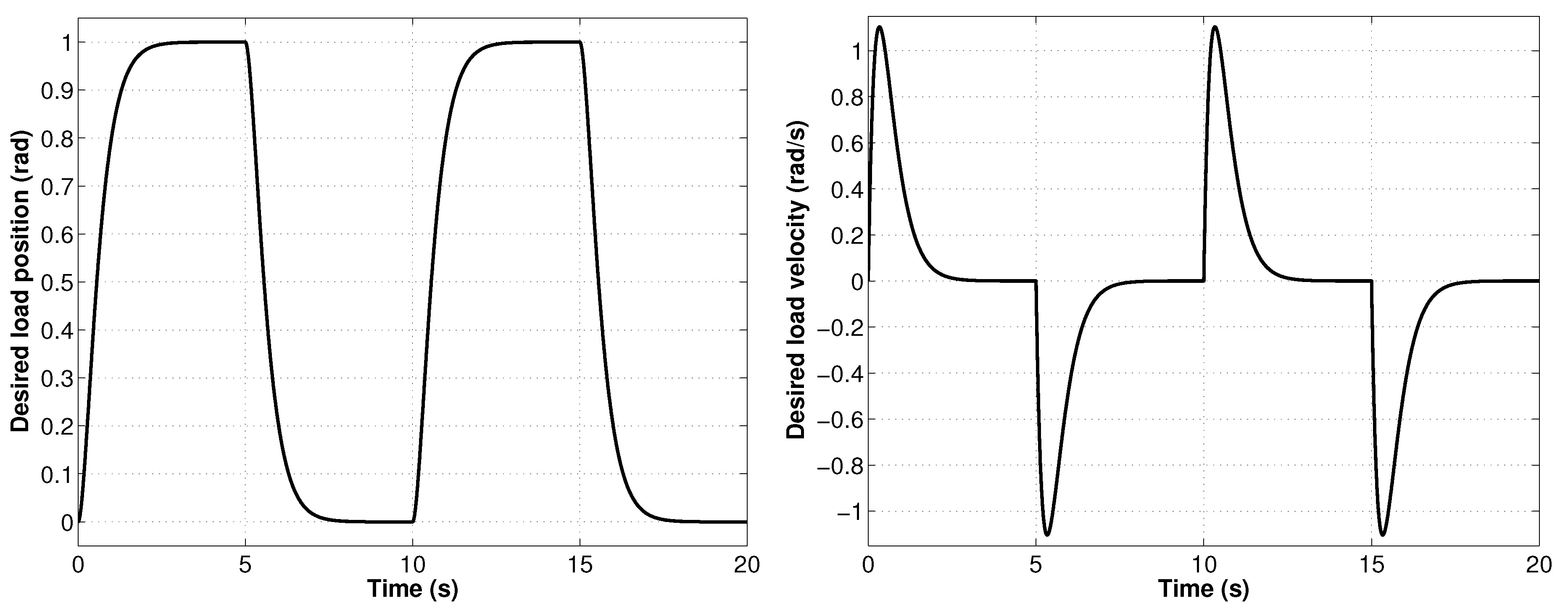

6.1. Simulation Setup

| Parameter | Link | Motor |

|---|---|---|

| rotational inertia (kg·m) | ||

| viscous friction coefficient (N·m·s/rad) | ||

| Coulomb friction coefficient (N·m) | ||

| static friction coefficient (N·m) | ||

| static friction decreasing rate (rad/s) |

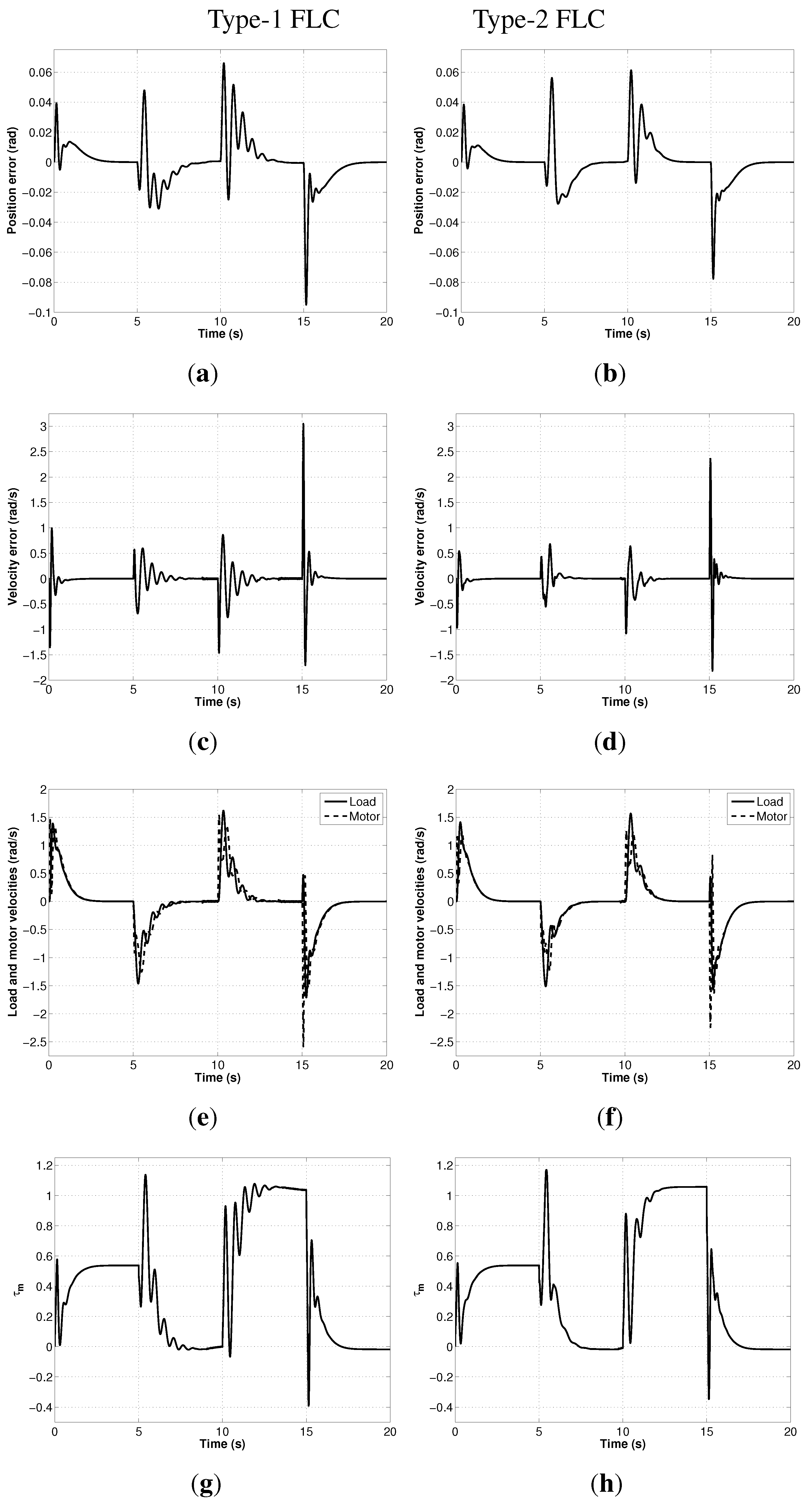

6.2. Numerical Simulations and Results

7. Conclusions

Acknowledgements

Conflict of Interest

References

- Olsson, H.; Astrom, K.; de Wit, C.C.; Gafvert, M.; Lischinsky, P. Friction models and friction compensation. Eur. J. Control 1998, 4, 176–195. [Google Scholar]

- Seidl, D.R.; Lam, S.L.; Putman, J.A.; Lorenz, R.D. Neural network compensation of gear backlash hysteresis in position-controlled mechanisms. IEEE Trans. Ind. Appl. 1995, 31, 1475–1483. [Google Scholar] [CrossRef]

- Sweet, L.; Good, M. Redefinition of the robot motion-control problem. Control Syst. Mag. IEEE 1985, 5, 18–25. [Google Scholar] [CrossRef]

- Armstrong, B.; de Wit, C.C. Friction modeling and compensation. Control Handb. 1996, 77, 1369–1382. [Google Scholar]

- Ghorbel, F.; Hung, J.; Spong, M. Adaptive control of flexible-joint manipulators. Control Syst. Mag. IEEE 1989, 9, 9–13. [Google Scholar] [CrossRef]

- Seidl, D.; Lam, S.L.; Putman, J.; Lorenz, R. Neural network compensation of gear backlash hysteresis in position-controlled mechanisms. IEEE Trans. Ind. Appl. 1995, 31, 1475–1483. [Google Scholar] [CrossRef]

- Seidl, D.; Reineking, T.; Lorenz, R. Neural Network Compensation of Gear Backlash Hysteresis in Position-Controlled Mechanisms. In Proceedings of Conference Record of the IEEE Industry Applications Society Annual Meeting, Houston, TX, USA, October 1992; Volume 2, pp. 1937–1944.

- Benosman, M.; Vey, G.L. Control of flexible manipulators: A survey. Robotica 2004, 22, 533–545. [Google Scholar] [CrossRef]

- Chaoui, H.; Gueaieb, W. Type-2 fuzzy logic control of a flexible-joint manipulator. J. Intell. Robot. Syst. 2008, 51, 159–186. [Google Scholar] [CrossRef]

- Chaoui, H.; Sicard, P.; Gueaieb, W. ANN-based adaptive control of robotic manipulators with friction and joint elasticity. IEEE Trans. Ind. Electron. 2009, 56, 3174–3187. [Google Scholar] [CrossRef]

- Luca, A.D.; Isidori, A.; Nicolo, F. Control of Robot Arm with Elastic Joints via Nonlinear Dynamic Feedback. In Proceedings of the IEEE Conference on Decision and Control Including the Symposium on Adaptive Processes, Ft. Lauderdale, FL, USA, 11–13 December 1985; pp. 1671–1679.

- Khorasani, K. Nonlinear feedback control of flexible joint manipulators: A single link case study. IEEE Trans. Autom. Control 1990, 35, 1145–1149. [Google Scholar] [CrossRef]

- De Wit, C. Robust control for servo-mechanisms under inexact friction compensation. Automatica 1993, 29, 757–761. [Google Scholar] [CrossRef]

- Ott, C.; Albu-Schaffer, A.; Hirzinger, G. Comparison of Adaptive and Nonadaptive Tracking Control Laws for a Flexible Joint Manipulator. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; Volume 2, pp. 2018–2024.

- Al-Ashoor, R.; Patel, R.; Khorasani, K. Robust adaptive controller design and stability analysis for flexible-joint manipulators. IEEE Trans. Syst. Man Cybern. 1993, 23, 589–602. [Google Scholar] [CrossRef]

- Ghorbel, F.; Spong, M.W. Adaptive Integral Manifold Control of Flexible Joint Robot Manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, Nice, France, 12–14 May 1992; Volume 1, pp. 707–714.

- Spong, M.W. Modeling AND control of elastic joint robots. J. Dyn. Syst. Meas. Control 1987, 109, 310–319. [Google Scholar] [CrossRef]

- Ge, S.S.; Postlethwaite, I. Adaptive neural network controller design for flexible joint robots using singular perturbation technique. Trans. Inst. Meas. Control 1995, 17, 120–131. [Google Scholar]

- Taghirad, H.; Khosravi, M. Design and Simulation of Robust Composite Controllers for Flexible Joint Robots. In Proceedings of the IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 14–19 September 2003; Volume 3, pp. 3108–3113.

- Huang, L.; Ge, S.; Lee, T. Adaptive Position/force Control of an Uncertain Constrained Flexible Joint Robots-Singular Perturbation Approach. In Proceedings of the SICE Annual Conference, Sapporo, Japan, 4–6 August 2004; pp. 1693–1698.

- Spong, M. Modeling and control of elastic joint robots. J. Dyn. Syst. Meas. Control 1987, 109, 310–319. [Google Scholar] [CrossRef]

- Khorasani, K. Adaptive control of flexible joint robots. IEEE Trans. Robot. Autom. 1992, 8, 250–267. [Google Scholar] [CrossRef]

- Ott, C.; Albu-Schaffer, A.; Kugi, A.; Stramigioli, S.; Hirzinger, G. A Passivity Based Cartesian Impedance Controller for Flexible Joint Robots-Part I: Torque Feedback and Gravity Compensation. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 2659–2665.

- Tian, L.; Goldenberg, A. Robust Adaptive Control of Flexible Joint Robots with Joint Torque Feedback. In Proceedings of the IEEE International Conference on Robotics and Automation, Nagoya, Japan, May 1995; Volume 1, pp. 1229–1234.

- Sun, T.; Pei, H.; Pan, Y.; Zhou, H.; Zhang, C. Neural network-based sliding mode adaptive control for robot manipulators. Neurocomputing 2011, 74, 2377–2384. [Google Scholar] [CrossRef]

- Li, Y.; Tong, S.; Li, T. Adaptive fuzzy output feedback control for a single-link flexible robot manipulator driven DC motor via backstepping. Nonlinear Anal. R. World Appl. 2013, 14, 483–494. [Google Scholar] [CrossRef]

- Yen, H.M.; Li, T.H.S.; Chang, Y.C. Adaptive neural network based tracking control for electrically driven flexible-joint robots without velocity measurements. Comput. Math. Appl. 2012, 64, 1022–1032. [Google Scholar] [CrossRef]

- Lopez-Araujo, D.J.; Zavala-Rio, A.; Santibanez, V.; Reyes, F. Output-feedback adaptive control for the global regulation of robot manipulators with bounded inputs. Int. J. Control Autom. Syst. 2013, 11, 816–822. [Google Scholar] [CrossRef]

- Fateh, M.M. Nonlinear control of electrical flexible-joint robots. Nonlinear Dyn. 2011, 67, 2549–2559. [Google Scholar] [CrossRef]

- Fateh, M.M.; Khorashadizadeh, S. Robust control of electrically driven robots by adaptive fuzzy estimation of uncertainty. Nonlinear Dyn. 2012, 69, 1465–1477. [Google Scholar] [CrossRef]

- Islam, S.; Liu, P.X. Robust sliding mode control for robot manipulators. IEEE Trans. Ind. Electron. 2011, 58, 2444–2453. [Google Scholar] [CrossRef]

- Corradini, M.L.; Fossi, V.; Giantomassi, A.; Ippoliti, G.; Longhi, S.; Orlando, G. Discrete time sliding mode control of robotic manipulators: Development and experimental validation. Control Eng. Pract. 2012, 20, 816–822. [Google Scholar] [CrossRef]

- Islam, S.; Liu, P.X. Robust adaptive fuzzy output feedback control system for robot manipulators. ASME/IEEE Trans. Mechatron. 2011, 16, 288–296. [Google Scholar] [CrossRef]

- Karray, F.; Gueaieb, W.; Al-Sharhan, S. The hierarchical expert tuning of PID controllers using tools of soft computing. IEEE Trans. Syst. Man Cybern. 2002, 32, 77–90. [Google Scholar] [CrossRef] [PubMed]

- De Silva, C.W. Intelligent Control Fuzzy Logic Applications; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Kim, E. Output feedback tracking control of robot manipulators with model uncertainty via adaptive fuzzy logic. IEEE Trans. Fuzzy Syst. 2004, 12, 368–378. [Google Scholar] [CrossRef]

- Gueaieb, W.; Karray, F.; Al-Sharhan, S. A robust adaptive fuzzy position/force control scheme for cooperative manipulators. IEEE Trans. Control Syst. Technol. 2003, 11, 516–528. [Google Scholar] [CrossRef]

- Chaoui, H.; Sicard, P.; Lakhsasi, A.; Schwartz, H. Neural Network Based Model Reference Adaptive Control Structure for a Flexible Joint with Hard Nonlinearities. In Proceedings of the IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004; Volume 1, pp. 271–276.

- Chaoui, H.; Sicard, P.; Lakhsasi, A. Reference Model Supervisory Loop for Neural Network Based Adaptive Control of a Flexible Joint with Hard Nonlinearities. In Proceedings of the IEEE Canadian Conference on Electrical and Computer Engineering, Niagara Falls, ON, Canada, 2–5 May 2004; Volume 4, pp. 2029–2034.

- Chaoui, H.; Gueaieb, W.; Yagoub, M.; Sicard, P. Hybrid Neural Fuzzy Sliding Mode Control of Flexible-Joint Manipulators with Unknown Dynamics. In Proceedings of the 32nd Annual Conference of the IEEE Industrial Electronics Society (IECON-2006), Paris, France, 6–10 November 2006; pp. 4082–4087.

- Chaoui, H.; Gueaieb, W.; Yagoub, M.C. Artificial Neural Network Control of a Flexible-Joint Manipulator under Unstructured Dynamic Uncertainties. In Proceedings of the IEEE International Workshop on Robotic and Sensors Environments, Ottawa, ON, Canada, 12–13 October 2007.

- Hui, D.; Fuchun, S.; Zengqi, S. Observer-based adaptive controller design of flexible manipulators using time-delay neuro-fuzzy networks. J. Intell. Robot. Syst. Theory Appl. 2002, 34, 453–466. [Google Scholar] [CrossRef]

- Subudhi, B.; Morris, A. Singular perturbation based neuro-H infinity control scheme for a manipulator with flexible links and joints. Robotica 2006, 24, 151–161. [Google Scholar] [CrossRef]

- Park, C.W. Robust stable fuzzy control via fuzzy modeling and feedback linearization with its applications to controlling uncertain single-link flexible joint manipulators. J. Intell. Robot. Syst. Theory Appl. 2004, 39, 131–147. [Google Scholar] [CrossRef]

- Li, T.H.S.; Huang, Y.C. MIMO adaptive fuzzy terminal sliding-mode controller for robotic manipulators. Inform. Sci. 2011, 180, 4641–4660. [Google Scholar] [CrossRef]

- Cazarez-Castro, N.R.; Aguilar, L.T.; Castillo, O. Designing type-1 and type-2 fuzzy logic controllers via fuzzy lyapunov synthesis for nonsmooth mechanical systems. Eng. Appl. Artif. Intell. 2012, 25, 971–979. [Google Scholar] [CrossRef]

- Castillo, O.; Melin, P. Optimization of type-2 fuzzy systems based on bio-inspired methods: A concise review. Inform. Sci. 2012, 205, 1–19. [Google Scholar] [CrossRef]

- Castillo, O.; Martinez-Marroquin, R.; Melin, P.; Valdez, F.; Soria, J. Comparative study of bio-inspired algorithms applied to the optimization of type-1 and type-2 fuzzy controllers for an autonomous mobile robot. Eng. Appl. Artif. Intell. 2012, 192, 19–38. [Google Scholar] [CrossRef]

- Melin, P.; Astudillo, L.; Castillo, O.; Valdez, F.; Garcia, M. Optimal design of type-2 and type-1 fuzzy tracking controllers for autonomous mobile robots under perturbed torques using a new chemical optimization paradigm. Expert Syst. Appl. 2013, 40, 3185–3195. [Google Scholar] [CrossRef]

- Feng, G. A survey on analysis and design of model-based fuzzy control systems. IEEE Trans. Fuzzy Sets Syst. 2006, 14, 676–697. [Google Scholar] [CrossRef]

- Chen, C.S. Supervisory adaptive tracking control of robot manipulators using interval type-2 TSK fuzzy logic system. IET Control Theory Appl. 2011, 5, 1796–1807. [Google Scholar] [CrossRef]

- Linda, O.; Manic, M. Uncertainty-robust design of interval type-2 fuzzy logic controller for delta parallel robot. IEEE Trans. Ind. Inf. 2011, 57, 661–670. [Google Scholar] [CrossRef]

- Biglarbegian, M.; Melek, W.W.; Mendel, J.M. Design of novel interval type-2 fuzzy controllers for modular and reconfigurable robots: Theory and experiments. IEEE Trans. Ind. Electron. 2011, 58, 1371–1384. [Google Scholar] [CrossRef]

- Hagras, H.A. A hierarchical type-2 fuzzy logic control architecture for autonomous mobile robots. IEEE Trans. Fuzzy Syst. 2004, 12, 524–539. [Google Scholar] [CrossRef]

- Sicard, P. Trajectory Tracking of Flexible Joint Manipulators with Passivity Based Controller. Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, USA, 1993. [Google Scholar]

- Liang, Q.; Mendel, J.M. Interval type-2 fuzzy logic systems: Theory and design. IEEE Trans. Fuzzy Syst. 2000, 8, 535–550. [Google Scholar] [CrossRef]

- Mendel, J.M. Uncertain Rule-Based Fuzzy Logic Systems: Introduction and New Directions; Prentice-Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Pedryez, W. Why triangular membership functions? Fuzzy Sets Syst. 1994, 64, 21–30. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chaoui, H.; Gueaieb, W.; Biglarbegian, M.; Yagoub, M.C.E. Computationally Efficient Adaptive Type-2 Fuzzy Control of Flexible-Joint Manipulators. Robotics 2013, 2, 66-91. https://doi.org/10.3390/robotics2020066

Chaoui H, Gueaieb W, Biglarbegian M, Yagoub MCE. Computationally Efficient Adaptive Type-2 Fuzzy Control of Flexible-Joint Manipulators. Robotics. 2013; 2(2):66-91. https://doi.org/10.3390/robotics2020066

Chicago/Turabian StyleChaoui, Hicham, Wail Gueaieb, Mohammad Biglarbegian, and Mustapha C. E. Yagoub. 2013. "Computationally Efficient Adaptive Type-2 Fuzzy Control of Flexible-Joint Manipulators" Robotics 2, no. 2: 66-91. https://doi.org/10.3390/robotics2020066

APA StyleChaoui, H., Gueaieb, W., Biglarbegian, M., & Yagoub, M. C. E. (2013). Computationally Efficient Adaptive Type-2 Fuzzy Control of Flexible-Joint Manipulators. Robotics, 2(2), 66-91. https://doi.org/10.3390/robotics2020066