A Review on Qualitative Assessment of Natural Gas Utilisation Options for Eliminating Routine Nigerian Gas Flaring

Abstract

1. Introduction

2. Overview of Gas Flaring

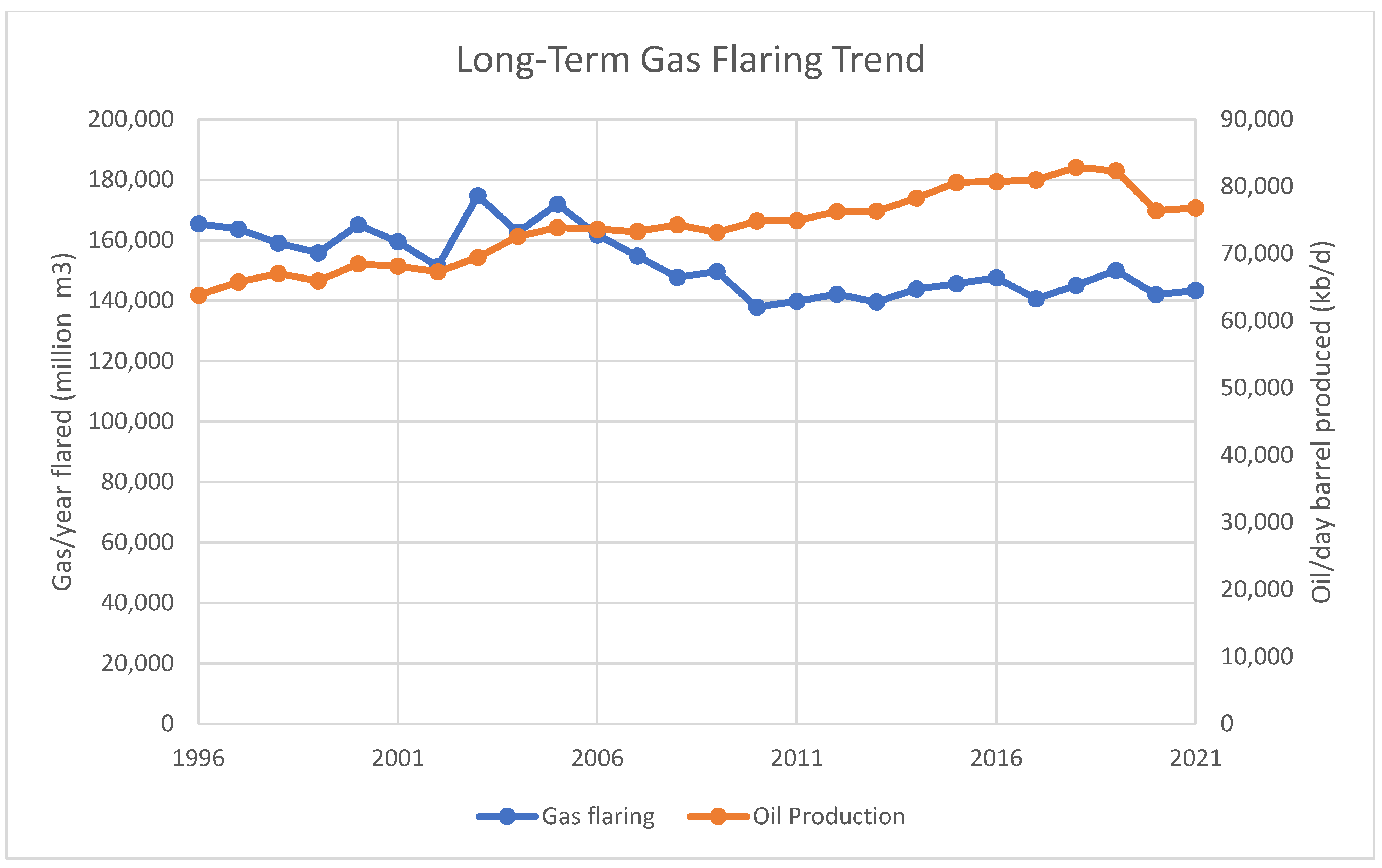

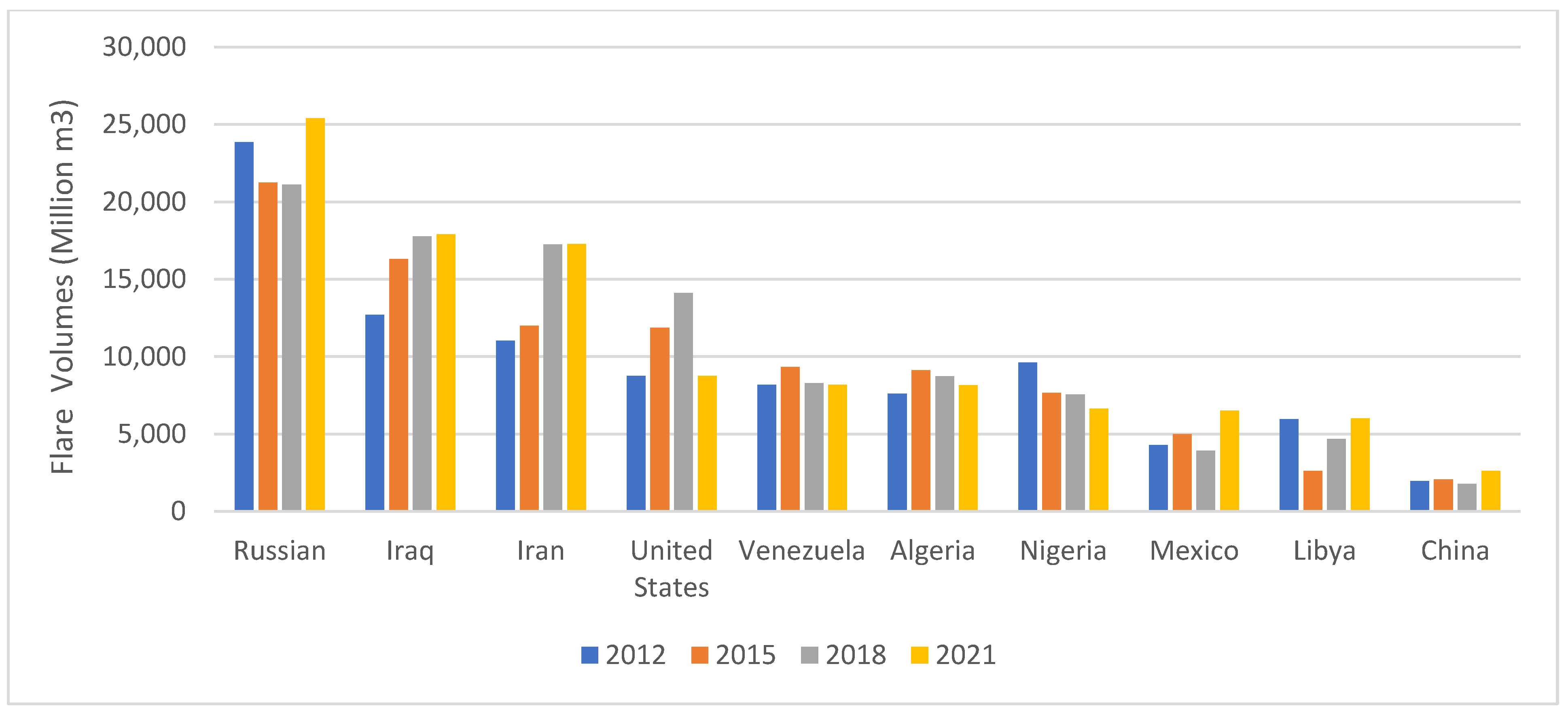

2.1. Global Gas Flaring

2.2. Gas Flaring in Nigeria and Efforts to Reduce Gas Flaring in Nigeria

3. Natural Gas Utilisation Methods

- I.

- Liquefied natural gas (LNG)

- II.

- Gas to liquid (GTL)

- III.

- Natural gas to methanol (GTM)

- IV.

- Natural gas to hydrogen (GTH)

- V.

- Gas to wire (GTW)

- VI.

- Compressed natural gas (CNG)

- VII.

- Gas to fertiliser (GTF)

- VIII.

- Gas re-injection process (GRP)

- IX.

- Gas to hydrates (NGH)

- X.

- Natural gas to pipelines (GTP)

- XI.

- Liquefied petroleum gas (LPG)

3.1. Liquefied Natural Gas (LNG)

3.2. Gas to Liquid (GTL)

3.3. Natural Gas to Methanol (GTM)

3.4. Natural Gas to Hydrogen (GTH)

3.5. Gas to Wire (GTW)

3.6. Compressed Natural Gas (CNG)

3.7. Natural Gas to Fertiliser (GTF)

3.8. Natural Gas Re-Injection Process (GRP)

3.9. Gas to Pipelines (GTP)

3.10. Natural Gas to Hydrate (NGH)

3.11. Liquefied Petroleum Gas (LPG)

3.12. Summary of Gas Utilisation in Nigeria

4. Results

Qualitative Assessment of Gas Flaring Utilisation Options against Various Key Decision Drivers

- Capital Costs (CAPEX)—This is the most crucial driver that determines the project’s practicability and viability. It is related to the netback value of the product depending on type of project.

- Maturity of technology—In terms of cost and reliability, the maturity of the deployed technology is equally crucial.

- Transportation to market—Products with a high energy density, such as liquids, are given precedence or have an advantage over gaseous products.

- Carbon and energy efficiency—Should be assessed on a well-to-wheel (WTW) basis (including all efficiencies associated to fuel production, processing, distribution, and consumption) where products may substitute greater carbon-intensive fuels.

- Revenue/Product uplift—CNG and LNG compete largely with fuels (such as oil and coal) for power production and residential heating, but GTL yields premium pricing by competing directly in the transportation sector.

- Gas composition including sensitivity to contaminants—This is also a major decision driver since the greater the levels of pollutants such as CO2 and H2S in gas composition, the higher the cost of treating gas and disposing of waste.

- Production profile—Associated gas volumes typically vary over the field life. It is therefore important to note the production profile of an oil field.

- Community interdependency—May allow for interdependence/synergies with residents, which may minimise oil production risk from non-technical risk and develop a local market, reducing transportation costs.

- Operational Safety Considerations—These are steps made to guarantee that the ANG utilisation system operation is safe and not hazardous. The more complicated the ANG utilisation system, the higher the unjustifiable risk of hazard incidence and the lower the operational safety reported.

- Product Market size—This is another essential factor in determining the different ANG utilisation choices. It analyses the market’s volume and value, the various consumer categories and purchasing patterns, the competitiveness, and the economic environment in terms of entry obstacles and regulation.

- Plant Scale or Size (World scale)—This relates to the technical size range, which specifies the maximum natural gas throughput rate that each technology can realistically handle, or the production capacity range, which specifies the feasible plant’s overall output.

5. Discussion

| ANG Utilisation Technique | Technical Size Range in mmscfd | Production Size Range (Plant Size) | Typical Cost (USD m/mmscfd) |

|---|---|---|---|

| LNG | 170–1360 (per LNG train) | 1–8 Mtpa | 3.5–6.5 |

| GTL | 270–1400 | 27,000–140,000 bpd (1–5.5 Mtpa) | 6.5–10 |

| GTM | 75–317 | 1–4 Mtpa | 5.5 @ 5 mmscfd [46] |

| GTW * | 0.36–180 | 1–500 MW | 2.8–4.7 @ 0.36 mmscfd [46] |

| GTH | 20–200 | 22–224 kNm3/h | 2.2–3.2 @ 0.37 mmscfd [46] |

| GTP* | 30–3300 | - | Depends on size (in inch) per distance (mile) |

| CNG | 0.25–15 | - | 1.5–2.5 |

| GTF | 75–308 (per train) | 1–3 Mtpa | 2.2–4.6 |

| GRP * | 5–275 | - | 0.2 @ 5 mmscfd |

| NGH | >15 | >2 Mtpa | 120/ton @ 2 Mpta (peak shaving process) [134] |

| Mini GTL | 0.2–150 | 200–15,000 bpd (0.01–0.6 Mtpa) | 4.5 |

| Mini LNG | 0.4–50 | 0.002–0.3 Mtpa | 1.2 (+annual Opex at 4.5% of Capex) [46] |

| Mini GTM | 0.3–30 | 0.004–0.4 Mtpa | 15.1 @ 0.3 mmscfd [46] |

6. Conclusions

- Identifying distinct development phases and the necessary ANG utilisation solution (single or combined option),

- Obtaining high-quality input data from appropriate potential investment parties to conduct adequate analysis,

- Techno-economic modelling of various ANG utilisation options (single or combined option), including an examination of potential net positive values,

- Evaluating the net economic impact of the proposed ANG utilisation options (single or combined),

- Evaluating the sensitivity and risks of ANG utilisation option (single or combined option),

- Consider combining supplies from multiple fields (clustering) to enhance the profitability of ANG utilisation through economies of scale, better capacity utilisation, and increased gas value (via increased sustainability of supply).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shore, D. Making the flare safe. J. Loss Prev. Process Ind. 1996, 9, 363–381. [Google Scholar] [CrossRef]

- Akeredolu, F.A.; Sonibare, J.A. A review of the usefulness of gas flares in air pollution control. Manag. Environ. Qual. Int. J. 2004, 15, 574–583. [Google Scholar] [CrossRef]

- Generon. What Is Gas Flaring?—Why Is It Done and Viable Alternatives. 2019. Available online: https://www.generon.com/what-is-gas-flaring-why-is-it-done-alternatives/ (accessed on 20 August 2022).

- Emam, E.A. Gas Flaring in Industry: An Overview. Pet. Coal. 2015, 57, 532–555. [Google Scholar]

- Kearns, J.; Armstrong, K.; Shirvill, L.; Garland, E.; Simon, C.; Monopolis, J. Flaring and venting in the oil and gas exploration and production industry, international association of oil. Gas Prod. Rep. 2000, 2, 288. [Google Scholar]

- PriceWaterhouseCoopers (PwC). Assessing the Impact of Gas Flaring on the Nigerian Economy. 2019. Available online: https://www.pwc.com/ng/en/assets/pdf/gas-flaring-impact1.pdf (accessed on 7 July 2022).

- Ramanathan, V.; Yan, F. Air pollution, greenhouse gases and climate change: Global and regional perspectives. Atmos. Environ. 2009, 43, 37–50. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Oyewunmi, A.E. Managing gas flaring and allied issues in the oil and gas industry: Reflections on Nigeria. Mediterr. J. Soc. Sci. 2016, 7, 643. [Google Scholar] [CrossRef]

- The World Bank. Gas Flaring Explained. 2022. Available online: https://www.worldbank.org/en/programs/gasflaringreduction/technical-solutions (accessed on 24 August 2022).

- IEA. Flaring Emissions; IEA: Paris, France, 2021. Available online: https://www.iea.org/reports/flaring-emissions (accessed on 30 July 2022).

- Jacobs, T. Innovators Seek to Transform Flaring into Money and Power. J. Pet. Technol. 2020, 72, 24–29. Available online: https://jpt.spe.org/innovators-seek-transform-flaring-money-and-power (accessed on 20 August 2022).

- Thurber, M. Gas Flaring: Why Does It Happen and What Can Stop It. Energy Growth. 2019. Available online: https://www.energyforgrowth.org/wp-content/uploads/2019/02/Gas-Flaring.pdf (accessed on 20 August 2022).

- World Bank. Gas Flaring Explained. Global Gas Flaring Reduction Partnership (GGFR). 2021. Available online: https://www.worldbank.org/en/programs/gasflaringreduction/gas-flaring-explained (accessed on 22 July 2022).

- World Bank. Global Gas Flaring Tracker Report. Global Gas Flaring Reduction Partnership (GGFR). 2022. Available online: https://thedocs.worldbank.org/en/doc/1692f2ba2bd6408db82db9eb3894a789-0400072022/original/2022-Global-Gas-Flaring-Tracker-Report.pdf (accessed on 26 August 2022).

- EIA. How Much Carbon Dioxide Is Produced When Different Fuels Are Burned? Energy Information Administration. 2021. Available online: https://www.eia.gov/tools/faqs/faq.php?id=73&t=11 (accessed on 10 August 2022).

- IEA. Global Energy and CO2 Status Report 2019; International Energy Agency: Paris, France, 2019; Available online: https://www.iea.org/reports/global-energy-co2-status-report-2019 (accessed on 10 February 2022).

- Akhtar, A.; Krepl, V.; Ivanova, T. A combined overview of combustion, pyrolysis, and gasification of biomass. Energy Fuels 2018, 32, 7294–7318. [Google Scholar] [CrossRef]

- World Bank. Financing Solutions to Reduce Natural Gas Flaring and Methane Emissions. 2021. Available online: https://www.worldbank.org/en/topic/extractiveindustries/publication/financing-solutions-to-reduce-natural-gas-flaring-and-methane-emissions (accessed on 20 August 2022).

- IEA. Putting Gas Flaring in the Spotlight; IEA: Paris, France, 2020; Available online: https://www.iea.org/commentaries/putting-gas-flaring-in-the-spotlight (accessed on 20 August 2022).

- World Bank, Gas Flaring Data 2013–2018 for 85 Countries. 2019. Available online: http://pubdocs.worldbank.org/en/645771560185594790/pdf/New-ranking-Top-30-flaring-countries-2014-2018.pdf (accessed on 10 July 2022).

- Department of Petroleum Resources (DPR). Annual Oil and Gas Report; Ministry of Petroleum in Nigeria: Abuja, Nigeria, 2018.

- Orimoogunje, O.O.; Ayanlade, A.; Akinkuolie, T.A.; Odiong, A.U. Perception on effect of gas flaring on the environment. Res. J. Environ. Earth Sci. 2010, 2, 188–193. [Google Scholar]

- GAO, Natural Gas Flaring and Venting: Opportunities to Improve Data and Reduce Emissions. Retrieved 1 November 2017, from U.S. Government Accountability Office. 2004. Available online: http://www.gao.gov/assets/250/243433.pdf (accessed on 20 July 2022).

- Osuoka, A.; Roderick, P. Gas Flaring in Nigeria: A Human Rights, Environmental and Economic Monstrosity; Friends of the Earth International: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Niger Delta Environmental Survey (NDES). Environmental and Socio-Economic Characteristics; Environmental Resources Managers Ltd.: Lagos, Nigeria, 1997. [Google Scholar]

- Imevbore, V.; Imevbore, A.; Gundlach, E. Niger Delta Environmental Survey Final Report Phase I. Volume. I, Environmental and Socio-Economic Characteristics; Environmental Resources Managers Ltd.: Lagos, Nigeria, 1997; p. 301. [Google Scholar]

- Oil and Gas Journal (OGJ) Editors. 2019 Worldwide Reserves Survey (Table). Oil Gas J. 2020. Available online:https://www.ogj.com/ogj-survey-downloads/worldwide-production/document/14287591/worldwide-reserves-and-production (accessed on 15 August 2022).

- U.S. Energy Information Administration (EIA). Nigeria: The Overview. Indep. Stat. Anal. 2020. Available online: https://www.eia.gov/international/analysis/country/NGA (accessed on 10 August 2022).

- National Oil Spill Response and Detection Agency (NOSDRA). Nigeria Gas Flare Tracker: Satellite Gas Flaring Tracking from NOSDRA. 2021. Available online: https://nosdra.gasflaretracker.ng/ (accessed on 28 July 2022).

- Bassey, N. Gas flaring: Assaulting communities, jeopardizing the world. In Proceedings of the a Paper Presented at the National Environmental Consultation Hosted by the Environmental Rights Action in Conjunction with the Federal Ministry of Environment at Reiz Hotel, Abuja, Nigeria, 10 December 2008; pp. 10–11. [Google Scholar]

- Environmental Right Action. Shell’s Devastation in Nigeria. The Case Against Shell. 2009. Available online: http://wiwavshell.org/shell%E2%80%99s-environmental-devastation-in-nigeria (accessed on 20 July 2022).

- Hassan, A.; Kouhy, R. Gas flaring in Nigeria: Analysis of Changes in Its Consequent Carbon Emission and Reporting; Accounting Forum; Taylor & Francis: Oxfordshire, UK, 2013; Volume 37, pp. 124–134. [Google Scholar] [CrossRef]

- Jaillet, A.; Laurent, J. Outlook for Flare Reduction in Nigeria; Technical Reports No. 34; Agence Française de Développement (AFD): Paris, France, 2013. [Google Scholar]

- Nigeria Gas Flare Commercialization Programme (NGFCP). The Flare Gas (Prevention of Waste and Pollution) Regulations; Nigerian Upstream Petroleum Regulatory Commission: Abuja, Nigeria, 2018.

- Hedley, T. Nigeria Takes Aim against Gas Flaring in 2020. Africa Oil and Power. 4 September 2020. Available online: https://www.africaoilandpower.com/2020/09/04/nigeria-takes-aim-against-gasflaring-in-2020 (accessed on 17 May 2022).

- Malumfashi, G.I. Phase-Out of Gas Flaring in Nigeria by 2008: The Prospects of a Multi-Win Project; Centre for Energy Petroleum and Mineral Law and Policy (CEPMLP), University of Dundee: Scotland, UK, 2007. [Google Scholar]

- Stanley, I.O. Gas-to-Liquid technology: Prospect for natural gas utilisation in Nigeria. J. Nat. Gas Sci. Eng. 2009, 1, 190–194. [Google Scholar] [CrossRef]

- Panagiotidis, D. A Global Perspective of Liquefied Natural Gas Vessels Capacity. Mater’s Thesis, Erasmus University Rotherdam, Rotherdam, The Netherlands, 2013. Available online: https://thesis.eur.nl/pub/41240/Panagiotidis-D.-A-global-perspective-of-Liquefied-Natural-Gas-vessels-capacity.pdf (accessed on 20 July 2022).

- Strozek, A. Fuel Distribution Networks; Diplom. De: Hamburg, Germany, 8 October 2009; ISBN 978-3-8366-3654-4. [Google Scholar]

- Shi, G.H.; Jing, Y.Y.; Wang, S.L.; Zhang, X.T. Development status of liquefied natural gas industry in China. Energy Policy 2010, 38, 7457–7465. [Google Scholar] [CrossRef]

- Bahadori, A. Natural Gas Processing: Technology and Engineering Design; Gulf Professional Publishing: Houston, TX, USA, 2014; ISBN 978-0080999715. [Google Scholar]

- Indonesia Climate Change Sectoral Roadmap (ICCSR). Energy Sector Part 3 (Gas Flaring Reduction). 2010. Available online: https://perpustakaan.bappenas.go.id/e-library/file_upload/koleksi/migrasi-data-publikasi/file/Policy_Paper/energy-sector-part-3-gas-flaring-reduction__20110217185935__0.pdf (accessed on 23 August 2022).

- Elengy LNG: An Energy of the Future. 2020. Available online: https://www.elengy.com/en/lng/lng-an-energy-of-the-future.html (accessed on 24 May 2022).

- Prima LNG. Benefits of LNG 2020. Available online: https://www.primalng.com/about-lng/benefits-of-lng (accessed on 20 May 2022).

- Romsom, E.; McPhail, K. The Energy Transition in Asia: The Role of Liquefied Natural Gas and Implications for East African Producers. In WIDER Working Paper 2020/80; UNU-WIDER: Helsinki, Finland, 2020; ISBN 978-92-9256-837-5. [Google Scholar] [CrossRef]

- Romsom, E.; McPhail, K. Capturing economic and social value from hydrocarbon gas flaring and venting: Solutions and actions. In WIDER Working Paper 2021/6; UNU-WIDER: Helsinki, Finland, 2021; ISBN 978-92-9256-940-2. [Google Scholar] [CrossRef]

- GGFR. GGFR Technology Overview: Utilization of Small-Scale Associated Gas; World Bank: Washington, DC, USA, 2018; Available online: http://pubdocs.worldbank.org/en/801871519953431815/GGFR-TechnologyMASTER-February-2018.pdf (accessed on 12 June 2021).

- Songhurst, B. LNG Plant Cost Reduction 2014–2018. In OIES Paper NG137; Oxford Institute for Energy Studies: Oxford, UK, 2018. [Google Scholar] [CrossRef]

- International Gas Union (IGU). World Liquefied Natural Gas (LNG) Annual Report; International Gas Union (IGU): London, UK, 2020. [Google Scholar]

- Yep, E. Commodities 2021: Global LNG to Continue Growth Trajectory in 2021 but at Slower Pace. S&P Global Commodity Insights, 2020. Available online: https://www.spglobal.com/platts/en/market-insights/latest-news/natural-gas/123020-commodities-2021-global-lng-to-continue-growth-trajectory-in-2021-but-at-slower-pace (accessed on 15 August 2022).

- Mordor Intelligence. LNG Market—Growth, Trends, COVID-19 Impact, and Forecasts (2022–2027). 2021. Available online: https://www.mordorintelligence.com/industry-reports/global-lng-market-industry (accessed on 15 August 2022).

- Shell, R.D. Shell LNG Outlook 2021; Royal Dutch Shell: London, UK, 2021; pp. 1–31. Available online: https://www.shell.com/promos/energy-and-innovation/download-the-shell-lng-outlook-2021/_jcr_cotent.stream/1614823770264/2b5b3fdaa9feba85dadc9b3408c200f26eadf85f/lng-outlook-2021-final-pack-updated.pdf (accessed on 15 August 2022).

- GlobalData Energy. GTL Process: An Excellent Alternative to Reduce Gas Flaring. Offshore Technology, 2020. Available online: https://www.offshore-technology.com/comment/gas-to-liquid-gtl-process/ (accessed on 30 August 2022).

- Keshav, T.R.; Basu, S. Gas-to-liquid technologies: India’s perspective. Fuel Process. Technol. 2007, 88, 493–500. [Google Scholar] [CrossRef]

- Visiongain. Gas to Liquids (GTL) Market Forecast 2020–2030. Market Research. February, 2020. Available online: https://www.marketresearch.com/Visiongain-v1531/Gas-Liquids-GTL-Forecast-13241729/ (accessed on 20 August 2022).

- Dalena, F.; Senatore, A.; Marino, A.; Gordano, A.; Basile, M.; Basile, A. Methanol production and applications: An overview. Methanol 2018, 3–28. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety and Health (NIOSH). The Emergency Response Safety and Health Database: Methanol. 2008. Available online: https://www.cdc.gov/niosh/ershdb/EmergencyResponseCard_29750029.html (accessed on 17 March 2022).

- Bromberg, L.; Cheng, W.K. Methanol as an Alternative Transportation Fuel in the US: Options for Sustainable and/or Energy-Secure Transportation; Sloan Automotive Laboratory, Massachusetts Institute of Technology: Cambridge, MA, USA, 2020. Available online: https://afdc.energy.gov/files/pdfs/mit_methanol_white_paper.pdf (accessed on 10 August 2022).

- Ott, J.; Gronemann, V.; Pontzen, F.; Fiedler, E.; Grossmann, G.; Kersebohm, D.B.; Weiss, G.; Witte, C. Methanol. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; pp. 1–27. ISBN 978-3527306732. [Google Scholar] [CrossRef]

- Mäyrä, O.; Kauko, L. “Modeling in Methanol Synthesis.” Methanol.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 475–492. [Google Scholar]

- Kim, W.S.; Yang, D.R.; Moon, D.J.; Ahn, B.S. The process design and simulation for the methanol production on the FPSO (floating production, storage and off-loading) system. Chem. Eng. Res. Des. 2014, 92, 931–940. [Google Scholar] [CrossRef]

- Alternative Fuels Data Center (AFDC). Methanol. 2020. Available online: https://afdc.energy.gov/fuels/emerging_methanol.html (accessed on 29 May 2022).

- Research and Markets. Methanol Market Forecast to 2028—COVID-19 Impact and Global Analysis by Derivative End-User Industry (Report ID number-5557886). In Research and Markets Reports; Research and Markets: Dublin, Ireland, 2022; 174p, Available online: https://www.researchandmarkets.com/reports/5557886/methanol-market-forecast-to-2028-covid-19?utm_source=GNOM&utm_medium=PressRelease&utm_code=lv2z6s&utm_campaign=1676009+-+The+Worldwide+Methanol+Industry+is+Expected+to+Reach+%2441.9+Billion+by+2028&utm_exec=jamu273prd (accessed on 17 August 2022).

- IEA. The Future of Hydrogen; IEA: Paris, France, 2019. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 30 August 2022).

- Liu, K.; Song, C.; Subramani, V. Hydrogen and Syngas Production and Purification Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-471-71975-5. [Google Scholar] [CrossRef]

- IEA. Hydrogen; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/hydrogen (accessed on 30 August 2022).

- Collins, L. A net-zero world ‘Would Require 306 Million Tonnes of Green Hydrogen per Year by 2050’: IEA. In Recharge-Latest Renewable Energy News; International Energy Agency: Paris, France, 2021; Available online: https://www.rechargenews.com/energy-transition/a-net-zero-world-would-require-306-million-tonnes-of-green-hydrogen-per-year-by-2050-iea/2-1-1011920 (accessed on 20 July 2022).

- Santhanam, K.S.; Press, R.J.; Miri, M.J.; Alla, V.B.; Gerald, A.T. Introduction to Hydrogen Technology; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Sonibare, J.A.; Akeredolu, F.A. Natural gas domestic market development for total elimination of routine flares in Nigeria’s upstream petroleum operations. Energy Policy 2006, 34, 743–753. [Google Scholar] [CrossRef]

- Indriani, G. Gas Flaring Reduction in the Indonesian Oil and Gas Sector: Technical and Economic Potential of Clean Development Mechanism (CDM) Projects; HWWA-Report 253, Hamburg Institute of International Economics (HWWA): Hamburg, Germany, 2005. [Google Scholar]

- GGFR. Flared gas utilisation strategy opportunities for small scale uses of gas. In Global Gas Flaring Reduction Report No. 4; World Bank Group: Geneva, Switzerland, 2004. [Google Scholar]

- Anosike, N.; El-Suleiman, A.; Pilidis, P. Associated gas utilization using gas turbine engine, performance implication—Nigerian case study. Energy Power Eng. 2016, 8, 137–145. [Google Scholar] [CrossRef]

- Lammey, M. Gas to Wire Could Hold the Key to Further Cost Cuts, OGA Says. Energy Voice. 2018. Available online: https://www.energyvoice.com/otherenergy/181878/gas-to-wire-concept-could-hold-key-to-further-cost-cuts-oga-says/ (accessed on 20 May 2022).

- Nigerian Electricity Regulation Commission (NERC). Generation: Power Generation in Nigeria NERC. 2020. Available online: https://nerc.gov.ng/index.php/home/nesi/403-generation (accessed on 20 August 2022).

- Statista. Electricity Generation in Nigeria in 2020 and 2021. Statista Energy and Environment. 2022. Available online: https://www.statista.com/statistics/1294835/annual-electrical-energy-generation-in-nigeria/ (accessed on 20 August 2022).

- Ediri, E. Power Generation: Nigeria’s Average Unutilized Power Rises 291% to 3008.1MW in 8 Years. Vanguard Nigeria. 2021. Available online: https://www.vanguardngr.com/2021/11/power-generation-nigerias-average-unutilized-power-rises-291-to-3008-1mw-in-8-years/ (accessed on 20 August 2022).

- Soltanieh, M.; Zohrabian, A.; Gholipour, M.J.; Kalnay, E. A review of global gas flaring and venting and impact on the environment: Case study of Iran. Int. J. Greenh. Gas Control 2016, 49, 488–509. [Google Scholar] [CrossRef]

- Odumugbo, C.A. Natural gas utilisation in Nigeria: Challenges and opportunities. J. Nat. Gas Sci. Eng. 2010, 2, 310–316. [Google Scholar] [CrossRef]

- Alternative Fuels Data Centre (AFDC) U.S. Department of Energy, United States of America. 2004. Available online: http://www.eere.energy.gov/afdc/altfuel/whatis_gas.html (accessed on 17 February 2022).

- Wong, W.L. Compressed Natural Gas as an Alternative Fuel in Diesel Engines; University of South Queensland: Queensland, Australia, 2005; pp. 1–118. Available online: https://eprints.usq.edu.au/532/1/WONGWeiLoon-2005.pdf (accessed on 10 September 2022).

- Venkateswarlu, K.; Murthy, B.S.R. Alternative Fuels and Advanced Vehicle Technologies; PHI Learning Pvt. Ltd.: Delhi, India, 2020; ISBN 978-81-94685-16-6. [Google Scholar]

- United States Environmental Protection Agency. Clean Alternative Fuels: Compressed Natural Gas. 2002. Available online: http://www.epa.gov/otaq/consumer/fuels/altfuels/420f00033.pdf (accessed on 2 June 2022).

- Saurabh, D.; Yerukula, E.P. Compressed Natural Gas Market Research. In Allied Market Research; Allied Market: Portland, OR, USA, 2022; Available online: https://www.alliedmarketresearch.com/compressed-natural-gas-market#:~:text=Compressed%20Natural%20Gas%20Market%20Research,8.2%25%20from%202021%20to%202030 (accessed on 12 July 2022).

- Tractebel Engineering SA. CNG for Commercialization of Small Volumes of Associated Gas; GGFR and World Bank Group: Washington, DC, USA, 2015; Available online: https://openknowledge.worldbank.org/handle/10986/25918 (accessed on 12 June 2022).

- Stenning, D.; Fitzpatrick, J. ABS Approves New CNG Carrier: The CNG Optimum 200. Gastech Insights, 2020. Available online: https://gastechinsights.com/node/5287 (accessed on 6 July 2022).

- Research Dive. Global Fertilizer Market Analysis. 2021. Available online: https://www.researchdive.com/press-release/fertilizer-market.html (accessed on 20 July 2022).

- Nelson, K.; Scharf, P.; Burdick, B.; Stevens, G. Rescue N Applications for Corn: Yield Response, Leaf Burn, and Yield Loss; University of Missouri: Columbia, MO, USA, 2004; p. 59. [Google Scholar]

- The International Plant Nutrition Institute (IPNI). Nutrient Source Specifics. IPNI Canada. 2019. Available online: http://www.ipni.net/specifics-en (accessed on 19 July 2022).

- Havlin, J.L.; Tisdale, S.L.; Nelson, W.L.; Beaton, J.D. Soil Fertility and Fertilizers: An Introduction to Nutrient Management, 6th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Medeiros, J.A. Management Alternatives for Urea Use in Corn and Wheat Production. Ph.D. Thesis, University of Missouri, Columbia, MO, USA, 2006. [Google Scholar]

- IHS Markit. Urea Fertilizer Market and Price Analysis. S&P Global. 2022. Available online: https://ihsmarkit.com/products/fertilizers-urea.html#:~:text=Urea%20is%20the%20most%20widely%20used%20nitrogen%20fertilizer,tonnes%20of%20urea%20are%20produced%20and%20consumed%20annually (accessed on 14 July 2022).

- Wigmoretrading. How to Export Nitrogenous Fertilizers From Nigeria: The Complete Guide. 2021. Available online: https://wigmoretrading.com/how-to-export-nitrogenous-fertilizers-from-nigeria-the-complete-guide/ (accessed on 23 August 2022).

- Lyons, W.C.; Plisga, G.J. Standard Handbook of Petroleum and Natural Gas Engineering; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Alvarado, V.; Manrique, E. Enhanced oil recovery: An update review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Speight, J.G. Introduction to Enhanced Recovery Methods for Heavy Oil and Tar Sands; Gulf Professional Publishing: Houston, TX, USA, 2016; ISBN ISBN: 9780128499061. [Google Scholar]

- Schmidt, V.A. Social contracts under siege: National responses to globalized and Europeanized production in Europe. In Global Capitalism Unbound; Palgrave Macmillan: New York, NY, USA, 2007; pp. 113–129. [Google Scholar]

- Ojijiagwo, E.; Oduoza, C.F.; Emekwuru, N. Economics of gas to wire technology applied in gas flare management. Eng. Sci. Technol. Int. J. 2016, 19, 2109–2118. [Google Scholar] [CrossRef]

- Hughes, R. Processing of natural gas offshore. In A Paper Presented in a Symposium on Production and Processing of Natural Gas; King Saud University: Riyadh, Saudi Arabia, 1992. [Google Scholar]

- EIA. Natural gas processing: The crucial link between natural gas production and its transportation to market. In Energy Information Administration, Office of Oil and Gas; Energy Information Administration: Washington, DC, USA, 2006. [Google Scholar]

- Adegoke, A.A. Utilising the Heat Content of Gas-to-Liquids by-Product Streams for Commercial Power Generation. Master’s Thesis, Texas A & M University, College Station, TX, USA, 2006. [Google Scholar]

- Research and Markets. Pipeline Transport Global Market Report 2022. In Cision PR Newswire; Research and Markets: Dublin, Ireland, 2022; 20p, Available online: https://www.prnewswire.com/news-releases/pipeline-transport-global-market-report-2022-301523838.html#:~:text=The%20global%20pipeline%20transport%20market%20is%20expected%20to%20grow%20from,(CAGR)%20of%207.7%25 (accessed on 29 June 2022).

- Ajagbe, O. Natural Gas Utilization: A Case Study of GTW and GTL Technologies; University of Oklahoma: Norman, OK, USA, 2019; Available online: https://shareok.org/bitstream/handle/11244/321400/2019_Olwatobi_Ajagbe_Publication.pdf?sequence=1 (accessed on 15 September 2022).

- Sloan, E.D. Natural gas hydrates. J. Pet. Technol. 1991, 43, 1414–1417. [Google Scholar] [CrossRef]

- Wilson, A. Comparison of Various Offshore Industrial Gas Technologies. J. Pet. Technol. 2018, 70, 73–75. [Google Scholar] [CrossRef]

- Hancock, S.; Boswell, R.; Collett, T. Development of deepwater natural gas hydrates. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar]

- Boswell, R.; Collett, T.S. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Gudmundsson, J.S. Method and Equipment for Production of Gas Hydrates. Norwegian Patent No. 172080, 1990. [Google Scholar]

- Gudmundsson, J.S.; Parlaktuna, M. Storage of natural gas hydrate at refrigerated conditions. In Proceedings of the AICHE Spring National Meeting, New Orleans, LA, USA, 1992; p. 27. [Google Scholar]

- Gudmundsson, J.S.; Parlaktuna, M.; Khokhar, A.A. Storage of natural gas as frozen hydrate. SPE Prod. Facil. 1994, 9, 69–73. [Google Scholar] [CrossRef]

- Visiongain Ltd. Global Liquefied Petroleum Gas Market. In GlobeNewswire; Visiongain: London, UK, 2022; Available online: https://www.globenewswire.com/en/news-release/2022/04/05/2416842/0/en/Global-Liquefied-Petroleum-Gas-market-is-projected-to-grow-at-a-CAGR-of-5-02-By-2032-Visiongain-Research-Inc.html (accessed on 19 July 2022).

- Akpan, S.E. Production and Utilization of Natural Gas Resources in Nigeria-A Review. In Nigeria Annual International Conference and Exhibition; OnePetro: Abuja, Nigeria, 2009. [Google Scholar]

- Emmanuel, E.O.; Yusuf, F.A.; Caleb, N.S. Towards Effective Domestic Natural Gas Utilisation in Nigeria. Int. J. Eng. Mod. Technol. 2018, 4, 2504–8856. [Google Scholar]

- Texas Comptroller of Public Accounts (TCPA). Liquefied Petroleum Gas (LPG). In The Energy Report Q. 2008; TCPA: Crockett, TX, USA, 2008. [Google Scholar]

- Oyekale, A.S.; Dare, A.M.; Olugbire, O.O. Assessment of rural households cooking energy choice during kerosene subsidy in Nigeria: A case study of Oluyole Local Government Area of Oyo State. Afr. J. Agric. Res. 2012, 7, 5405–5411. [Google Scholar]

- Bamiro, O.M.; Ogunjobi, J.O. Determinants of household energy consumption in Nigeria: Evidence from Ogun State. Res. J. Soc. Sci. Manag. 2015, 4, 35–41. [Google Scholar]

- Akpan, U. NLPGA Commends NLNG as It Sets out to Supply 100% LPG Output to Domestic Market. Vanguard Energy. 2022. Available online: https://www.vanguardngr.com/2022/02/nlpga-commends-nlng-as-it-sets-out-to-supply-100-lpg-output-to-domestic-market/ (accessed on 23 August 2022).

- National Petroleum Investment Management Services (NAPIMS). Gas Operations: Gas Utilisation Projects. NNPC Group. 2021. Available online: https://napims.nnpcgroup.com/ourservices/Pages/Gas-Operations.aspx (accessed on 18 July 2022).

- Svensson, B. Best practices for Evaluating and Reducing Emissions from Oil and Gas Production: An Evaluation of Flare Gas Reduction Opportunities. Methane Expo 2013-Global Methane Initiative. GGFR. 2013. Available online: https://www.globalmethane.org/expo-docs/canada13/og_12_Svennson.pdf (accessed on 28 June 2022).

- Haugland, T.; Saunier, S.; Pederstad, A.; Holm, T.; Darani, H.; Kertesheva, A. Associated Petroleum Gas Flaring Study for Russia, Kazakhstan, Turkmenistan and Azerbaijan. 2013. Available online: https://www.ebrd.com/downloads/sector/sei/ap-gas-flaringstudy-final-report.pdf (accessed on 20 August 2022).

- Nwaoha, C.; Wood, D.A. A review of the utilization and monetization of Nigeria’s natural gas resources: Current realities. J. Nat. Gas Sci. Eng. 2014, 18, 412–432. [Google Scholar] [CrossRef]

- Mokhatab, S.; Mak, J.Y.; Valappil, J.V.; Wood, D.A. Handbook of Liquefied Natural Gas; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Rodgers, R.E.; Zbong, Y.; Arunkumar, R.; Etheridge, J.A.; Pearson, L.E.; Cown, J.M.; Hogancamp, K. Gas hydrate storage process for natural gas. GasTIPS Winter 2005, 12, 34–39. [Google Scholar]

- Shekhar, C. Methanol: The New Hydrogen. Technol. Rev. 2006, 109, 55–72. [Google Scholar]

- Dong, L.; Wei, S.A.; Tan, S.; Zhang, H. GTL or LNG: Which is the best way to monetize “stranded” natural gas? Pet. Sci. 2008, 5, 388–394. [Google Scholar] [CrossRef]

- Berg, H. Natural Gas Takes the Role as Backup Fuel. Wärtsilä: Helsinki, Finland. 2018. Available online: https://www.wartsila.com/twentyfour7/in-detail/natural-gas-takes-the-role-as-backup-fuel (accessed on 17 July 2022).

- Kezirian, M.T.; Phoenix, S.L. Natural gas hydrate as a storage mechanism for safe, sustainable and economical production from offshore petroleum reserves. Energies 2017, 10, 828. [Google Scholar] [CrossRef]

- Speight, J.G. Natural Gas: A Basic Handbook; Gulf Professional Publishing: Houston, TX, USA, 2018. [Google Scholar]

- Saavedra, C.G. Application of Gas Industrial Technologies Offshore. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4 May 2017. [Google Scholar]

- Bechtold, R.L.; Goodman, M.B.; Timbario, T.A. Use of Methanol as a Transportation Fuel; Methanol Institute: Charleston, WV, USA, 2007. [Google Scholar]

- Walker, I.; Madden, B.; Tahir, F. Hydrogen Supply Chain Evidence Base; Element Energy Ltd.: Cambridge, UK, 2018. [Google Scholar]

- Joshi, S.; Hussain, H.; Tiwari, P.; Rahman, D.; Aldajani, T. Improve Gas Turbine/Engine Performance and Reduce Maintenance Using Membranes for Fuel Gas Conditioning; Membrane Technology and Research: Newark, CA, USA, 2015; Available online: https://www.mtrinc.com/wpcontent/uploads/2018/09/NG08-MTR-Power-Gen-NG-2015.pdf (accessed on 29 June 2022).

- Basye, L.; Swaminathan, S. Hydrogen Production Costs—A Survey (No. DOE/GO/10170-T18); Sentech, Inc.: Bethesda, MD, USA, 1997. [Google Scholar]

- Ahmadi, M.A.; Zeinali Hasanvand, M.; Shokrolahzadeh, S. Technical and economic feasibility study of flue gas injection in an Iranian oil field. Petroleum 2015, 1, 217–222. [Google Scholar] [CrossRef]

- Mannel, D.; Puckett, D. Transportation and Storage of Natural Gas Hydrates; University of Oklahoma: Norman, OK, USA, 2008; Available online: https://ou.edu/class/che-design/a-design/projects-2008/Gas%20Hydrate%20Transportation.pdf. (accessed on 22 August 2022).

| Name of Technology | Usage in Nigeria | Limitations in Nigeria | Existing Projects in Nigeria |

|---|---|---|---|

| LNG | Nigeria LNG currently delivers around 40% of Nigeria’s annual domestic cooking gas or LPG consumption needs and LNG sale or export | Limited advances are made to secure small to medium scale LNG projects for increased output and variability of ANG supplies | On Bonny Island in Nigeria, Nigeria LNG runs a six-train LNG facility capable of producing 22 Mtpa of LNG and 5 Mtpa of NGLs (LPG and condensate) from 3.5 billion standard cubic feet per day (bscfd) of natural gas intake [117]. |

| GTL | Production of liquid fuels and chemicals | Small to medium scale GTL projects are yet to commence in stranded gas areas with minimum supply and Inconsistent supply of ANG | The Escravos gas-to-liquid (EGTL) plant (100 km south-east of Lagos) is the first project in Nigeria to use GTL technology. EGTL is a two-train plant designed to convert 330 MMscfd of natural gas into 34,000 barrels per day (bpd) of acceptable products. 1000 bpd of LPG [117]. |

| LPG/NGL | Cooking gas | Limited supply to rural areas of Nigeria because of transportation costs, lack of gas processing facilities and availability of fuel | A two-train NGL plant with 550 mmscfd capacity (that converts ANG into NGLs which includes LPGs) located at its Oso field (offshore) in the south-eastern region of Nigeria. It started production for export in 1998 and produces about 50,000 bpd of NGL [117]. |

| GTW | Electricity and heat generation | Fluctuating or limited supply of ANG, Scarcity of new power investments, poor maintenance of power plant | The Okpai power plant in Okpai community (Delta state, Nigeria) uses combined cycle technology. It has a 480 MW installed capacity and uses 120 mmscfd of gas [117]. |

| Gas re-injection | Enhanced oil recovery and storage | Limited to onsite use, economic unattractiveness to investors and limitation to certain type of reservoirs | A USD 1.3 billion gas reinjection project offshore Nigeria is being operated by a joint venture between NNPC (60%) and Mobil Producing Nigeria (40%) in the Ebok and Amenam-kpono fields. The project is expected to generate 530 million barrels of extra oil at a peak output of 120,000 bpd [117]. |

| GTH | Transport fuel, applied in fuel cell for electricity generation, fertiliser production and petroleum refining | Difficulty in storing and transporting hydrogen and limited market size | Non-existing now. |

| NGH | Transportation of ANG and storage | Immature technology, no commercial application yet | Non-existing now. |

| CNG | Transport fuel, cooking fuel and power generation | Transportation limitation, limited availability | Powergas Africa limited operates four CNG plants in Nigeria, with a combined capacity of around 720,000 standard cubic metre per day [117]. |

| GTF | To boost crop output and nutrient content in agriculture | Limited availability of product, high cost of product | 1.5 Mtpa Dangote fertiliser plant in Lagos state. |

| ANG Utilisation Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Decision Drivers | LNG * | GTL * | GTM * | GTH | GTW * | CNG | GTF | NGH | GRP | GTP | LPG |

| Gas composition | |||||||||||

| Production profile | |||||||||||

| Revenue/Product uplift | |||||||||||

| Capex | |||||||||||

| Technology maturity | |||||||||||

| Transport to market | |||||||||||

| Energy and carbon efficiency | |||||||||||

| Operational safety considerations | |||||||||||

| Community interdependency | |||||||||||

| Product market size | |||||||||||

| Plant size (world scale) ** | |||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu, R.; Patchigolla, K.; Simms, N. A Review on Qualitative Assessment of Natural Gas Utilisation Options for Eliminating Routine Nigerian Gas Flaring. Gases 2023, 3, 1-24. https://doi.org/10.3390/gases3010001

Abu R, Patchigolla K, Simms N. A Review on Qualitative Assessment of Natural Gas Utilisation Options for Eliminating Routine Nigerian Gas Flaring. Gases. 2023; 3(1):1-24. https://doi.org/10.3390/gases3010001

Chicago/Turabian StyleAbu, Robin, Kumar Patchigolla, and Nigel Simms. 2023. "A Review on Qualitative Assessment of Natural Gas Utilisation Options for Eliminating Routine Nigerian Gas Flaring" Gases 3, no. 1: 1-24. https://doi.org/10.3390/gases3010001

APA StyleAbu, R., Patchigolla, K., & Simms, N. (2023). A Review on Qualitative Assessment of Natural Gas Utilisation Options for Eliminating Routine Nigerian Gas Flaring. Gases, 3(1), 1-24. https://doi.org/10.3390/gases3010001