1. Introduction

The progressive, intensified and widespread adoption of management systems standards (MSSs) in organizations is a reality that is justified either by competitive factors, or by formal requirements of customers and other relevant stakeholders. The impact generated by MSSs, which cover a wide range of different management disciplines, objectives and activities of organizations, is demonstrated by their increasing importance around the world [

1]. Their development, diversification and operationalization have increased abruptly in recent years. This increase has supported more global and integrated management strategies in order to meet the reality of business globalization in a sustainable fashion [

2]. According to the ISO [

3], a common objective of MSSs is to assist organizations to manage the risks associated with providing products and services to customers and other stakeholders. There are examples of stakeholders identified in the model of Donaldson and Preston [

4], and in ISO 9004 [

5] which also have needs and expectations that, by themselves, require the existence in the organizations of a high diversity of MSSs and related individual management systems (MSs). Enhancing sustainable performance throughout the organizational structure should be the main focus of management in that it should act in a holistic and lean way to allow for increased efficiency, and therefore build the sustained success of organizations, promoting business excellence and value creation.

There are examples of MSSs: ISO 9001 for Quality Management Systems [

6]; ISO 14001 for Environmental Management Systems [

7]; OHSAS 18001 for Occupational Health and Safety Management Systems [

8]; ISO 22301 for Business Continuity Management Systems [

9]; ISO 31000 for Risk management [

10]; ISO/IEC 27001 for Information security Management Systems [

11]; NP 4457 for Research, Development and Innovation Management Systems [

12]; ISO 50001 for Energy Management Systems [

13]; and the ISO 55001 for Asset Management Systems [

14], among several other MSSs, as presented in the

Figure 1. This suggests a new framework regarding the implementation of multiple individualized MSs

versus an approach to the integrated implementation of these same systems.

According to ISO 9004 [

5], the sustained success of an organization is achieved through its ability to satisfy the needs and expectations of its customers and other stakeholders in the long term, and in a balanced way, and should be taken as referential of action the three pillars of sustainability—Economic, Environmental and Social—as well as the organizational and operational factors of competitiveness. Therefore, more than ever, business sustainability is rather more important than their sole financial results. These results will not verify if that focus does not prioritize also the satisfaction, in a balanced and integrated fashion, of the growing number of customers and others relevant stakeholders, that are clearly and objectively the employees, for example [

15].

The modern definition of Quality extends beyond traditional specifications of products and/or services to cover the requirements of a growing number of stakeholders. These requirements are varied, for example [

16]: ensure the health and safety of employees; to promote Sustainability; satisfy customers and transparency in organizational subjects for the execution of business processes, in an ethical and economic way as well as socially responsible. Therefore, Quality is not, as formerly, a reductive and restrictive concept and should be managed efficiently in a global perspective of integration and sustainability focused not only on the fulfillment of requirements of customers, but a whole range of relevant stakeholders [

17] that are determinants of the success of organizations within the context, internal and external, in which organizations are positioned and should be understand. According to Yang and Yang [

18], Quality is increasingly more entangled with business sustainability and hence customers are not the sole preoccupation. To be successful, an organization has to create value for customers, for their owners and also other relevant stakeholders.

Figure 1.

Proliferation and diversity of management system standards (MSSs)

versus management systems (MSs) [

2,

19,

20,

21].

Figure 1.

Proliferation and diversity of management system standards (MSSs)

versus management systems (MSs) [

2,

19,

20,

21].

As the number of MSSs increases their integration becomes a necessity [

22]. It is imperative, from our point of view, to promote sustained business success by adding value resulting from potential gains of efficiency. Organizations cannot remain indifferent to the unquestioned reality of growing proliferation of MSSs and the vital necessity for their integration into an holistic system of management [

23,

24]. The integration of MSs provides organizations with the infrastructure to manage the requirements of stakeholders [

25] and has been increasing the interest of organizations in adopting IMSs in the context of improving organizational efficiency in resource use and consequent satisfaction of stakeholders [

23,

26,

27]. Moreover, it is recognized as positive the balance of advantages in relation to disadvantages concerning the integration of MSs [

28]. According to [

29], it is increasing the number of organizations that are betting on the implementation and certification of MSs in order to meet the requirements of the stakeholders and achieve maximum efficiency. Maximize the integration is more and more a strategic priority, in that it is an opportunity to eliminate and/or reduce the potential factors of destruction of value in order to be possible for organizations to be more competitive and therefore promote their sustained success [

15].

The integration of different MSs into a single system, taking into account the correspondence and the level of compatibility between the several MSSs requirements and potential tangible and intangible gains resulting from this integration, results in added value for organizations [

2]. The challenge faced by organizations concerns with the maximization of compliance and consequent incorporation of requirements as well as demonstrate the ability of sustained and optimized compliance. Those organizations that have: (i) a structured model of flexibilization and systematization of the integration, with clear guidelines; (ii) methodologies to support the development of alignment and integration of the MSSs requirements and are faster and more efficient on the process of integration of the existing and future MSs will be on competitive advantage. The biggest difficulties that organizations are facing, in integrating their multiple MSs, is not having to implement an IMS model to support the integration process. Thus, the evaluation of the real situation, motivations, advantages, disadvantages, limitations, and models for implementation of MSs

versus IMS in real business context, is an area where research is needed [

15,

16,

17,

30,

31].The growing level of standardization

versus proliferation of MSS and its individual implementation, according to each Stakeholder requirements, might constitute a factor of destruction of value for organizations and, consequently, to the relevant stakeholders, robbing them competitiveness [

20].

2. Research Methodology

SMEs are the cornerstone of the Portuguese economy and make up to 75% of the total labor force in industry, services and trade. A research, supported on an empirical study using a questionnaire, was carried out in a business environment of a Portuguese company localized in the northern region of Portugal. Over the last two decades this Portuguese company has been gradually adopting, in whole or in part, individualized standards or specifications of different MSs. Particular relevance to the ISO 9001 (Quality Management Systems) [

6], ISO 14001 (Environmental Management Systems) [

7], OHSAS 18001 (Safety and Health Management Systems) [

8], among others. The idea behind the concept of an IMS is that an organization can manage its processes and associated risks

versus requirements of each internal and external stakeholder through only one MS instead of several individual MSs defined and implemented in an isolated way according to a specific MSS. The perceived integration level of the existing MSs is low. As result, several organizational and operational inefficiencies exist, both inside the company and in the context of its interfaces with external entities, namely in process management associated to certifications and accreditations of test laboratories.

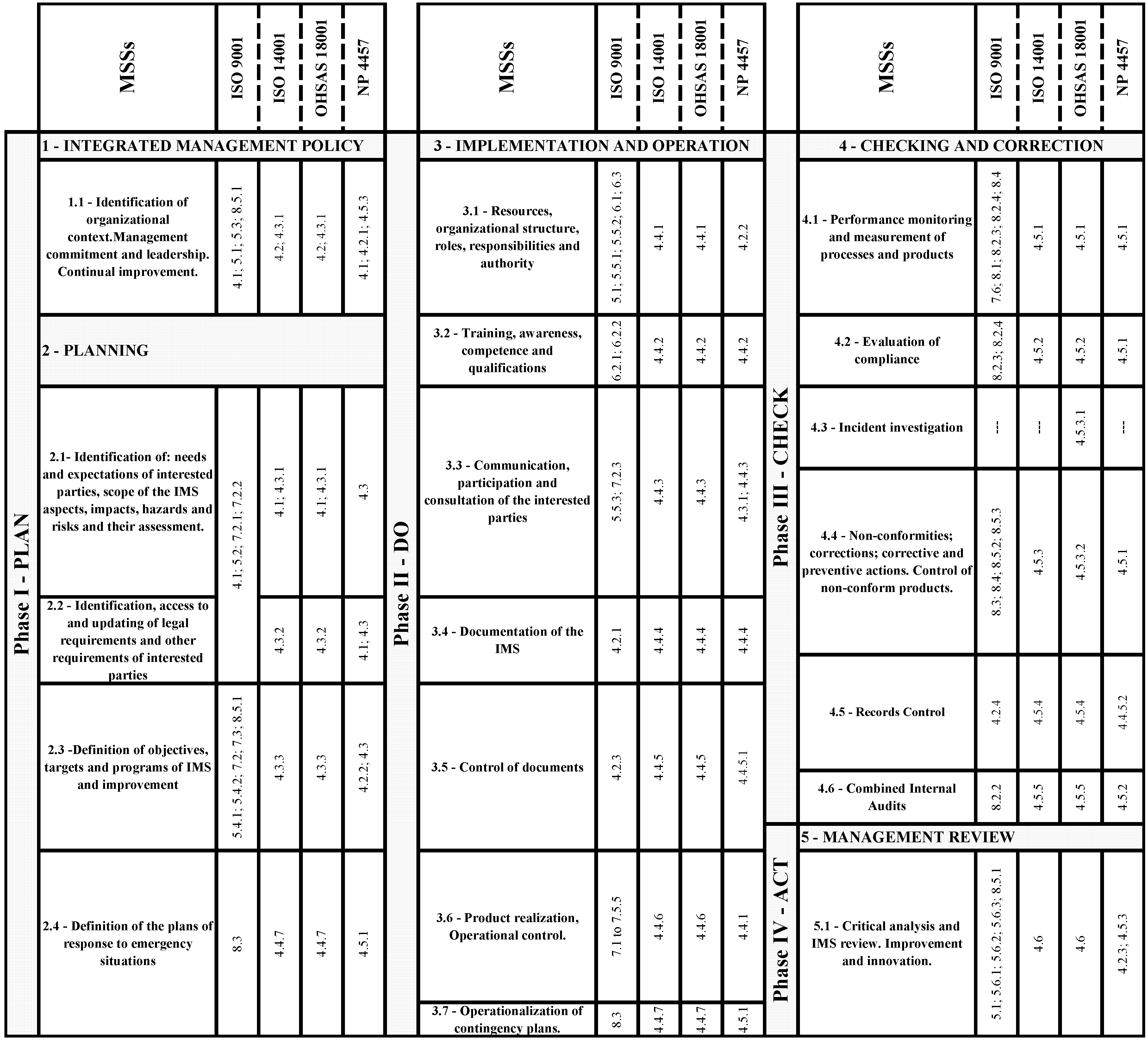

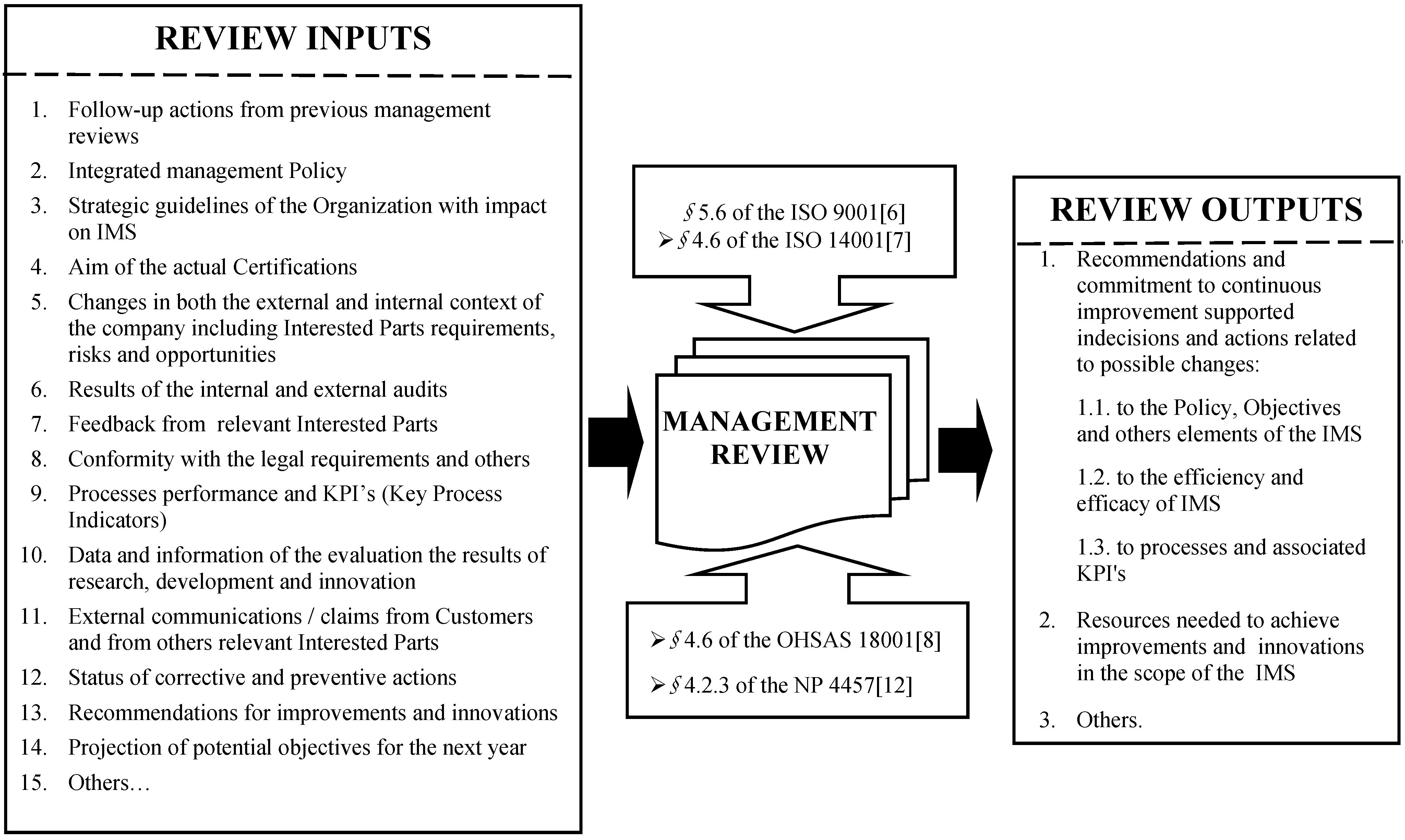

Given the underlying work environment it was imperative to assess the perception of collaborators within the company, including the top management leadership and commitment, pertaining to their approach concerning: (i) planning; (ii) implementation, checking and correcting; (iii) performance evaluation, and validation; and (iv) improvement of the IMS, supported on the matrix of

Figure 2. The conducted research is geared by a questionnaire—previously tested, improved and validated based on a small sample—delivered to a representative sample of internal collaborators from different departments and carefully selected by convenience, according to their position in the hierarchy. The sampled population was the total of the collaborators as distributed by the hierarchical levels of the organizational structure within the company: workers (97%–61%); intermediate staff (44%–28%); managers (12%–7%) and directors (7%–4%). A sample of 49 collaborators, representing 30.62% of the total––160 collaborators, was considered. The responses rate was 85.71%—42 collaborators. All received questionnaires were validated and consequently considered for the statistical analysis. The guidelines of the Portuguese standard NP 4463 [

32] were considered in the process of data collection, statistical analysis and presentation of results. The method employed for data collection, supporting this research, is based on an empirical study through questionnaire [

33]. This method has been applied by many researchers namely when conducting research in the domain of integrated management systems [

34].

Four main parts were considered on the questionnaire: Part 1—Importance of the twelve factors identified as motivation for the implementation of the IMS for Quality, Environment and Safety (IMS-QES); Part 2—Influence of the nine identified stakeholders on the performance and evolution of the IMS-QES; Part 3—Seven main difficulties in the context of the development and implementation of a model for IMS-QES; and, Part 4—Eleven potential benefits, with the implementation of the IMS. The twelve identified factors on Part 1 of the questionnaire were to: (i) improve the company’s image, near its customers and other stakeholders; (ii) rationalize and optimize management of different resources; (iii) facilitate management of the three sustainable components; (iv) company versus business development; (v) increased requirements of customers and other stakeholders; (vi) competitive advantage; (vii) strategic vision of the business; (viii) natural evolution of the MSs in the company; (ix) continuous improvement of the QMS, EMS, and others MSs through integration; (x) having the MSs implemented separately results in additional costs, creating unnecessary bureaucracy, and an organizational structure less efficient and less lean; (xi) growing appreciation of the IMSs by major customers; and, (xii) as a result from globalization and the growing business requirements. The nine identified stakeholders on Part 2 of the questionnaire were: (i) guidelines, policies, and objectives of the international group in which the company is inserted; (ii) customers; (iii) competitors; (iv) insurers; (v) suppliers; (vi) official entities related to the issues of Quality, Environment, Occupational Health, and Safety; (vii) workers and/or their representatives; (viii) financial institutions; and, (ix) group of directors and managers of the company. The seven identified difficulties on Part 3 of the questionnaire were: (i) deficit of human and material resources due to the strongly competitive environment and costs reduction; (ii) resistance to change; (iii) organizational structure; (iv) diversity of products and services vis-a-vis the customer’s requirements, and legal and other requirements; (v) not explicit, as an objective of the company, the integration of the individual MSs; (vi) lack of internal competences on IMSs; and (vii) lack of an international standard for IMSs. Lastly the eleven identified benefits on Part 4 of the questionnaire were: (i) better and greater visibility of operation of the company concerning MSs; (ii) elimination of conflicts between individual MSs, and consequent resources optimization, namely human resources; (iii) elimination of several organizational and operational waste, resulting from an individual implementation of each MSs; (iv) common management policies, objectives, goals and key process indicators (KPIs) related to the performance of the concerned MSs; (v) improvement of the internal and external image and credibility of the company with focus in the areas of Quality, Environment, Occupational Health and Safety; (vi) involvement and consolidation, by all collaborators, of a culture of continuous improvement, attitudes and values in the scope of the concerned MSs; (vii) reduction of the number of internal and/or external audits; (viii) improvement at the level of the risk management through an integrated and systematized approach; (ix) greater employee valorization and motivation as a result of greater scope of its competencies, tasks and responsibilities with consequent “empowerment”; (x) integrated management of the several components of sustainability; and, (xi) improvement of the partnership relationships with suppliers and of dialogue and compromise with others relevant stakeholders, contributing to the competitiveness of the company. It was considered a Likert scale on the questionnaire: level 1—irrelevant; level 2—not so relevant; level 3—relevant; level 4—very relevant; and level 5—determinant.

One of the main objectives was to contribute to the implementation of a structured integration of individual MSs in a specific business context of a given Portuguese company, considering the choice between two options Top Management has to embrace: (1) to continue with the implementation of individualized MSs; or (2) integrate them into an efficient IMS.

4. Empirical Study—Results from the Questionnaire

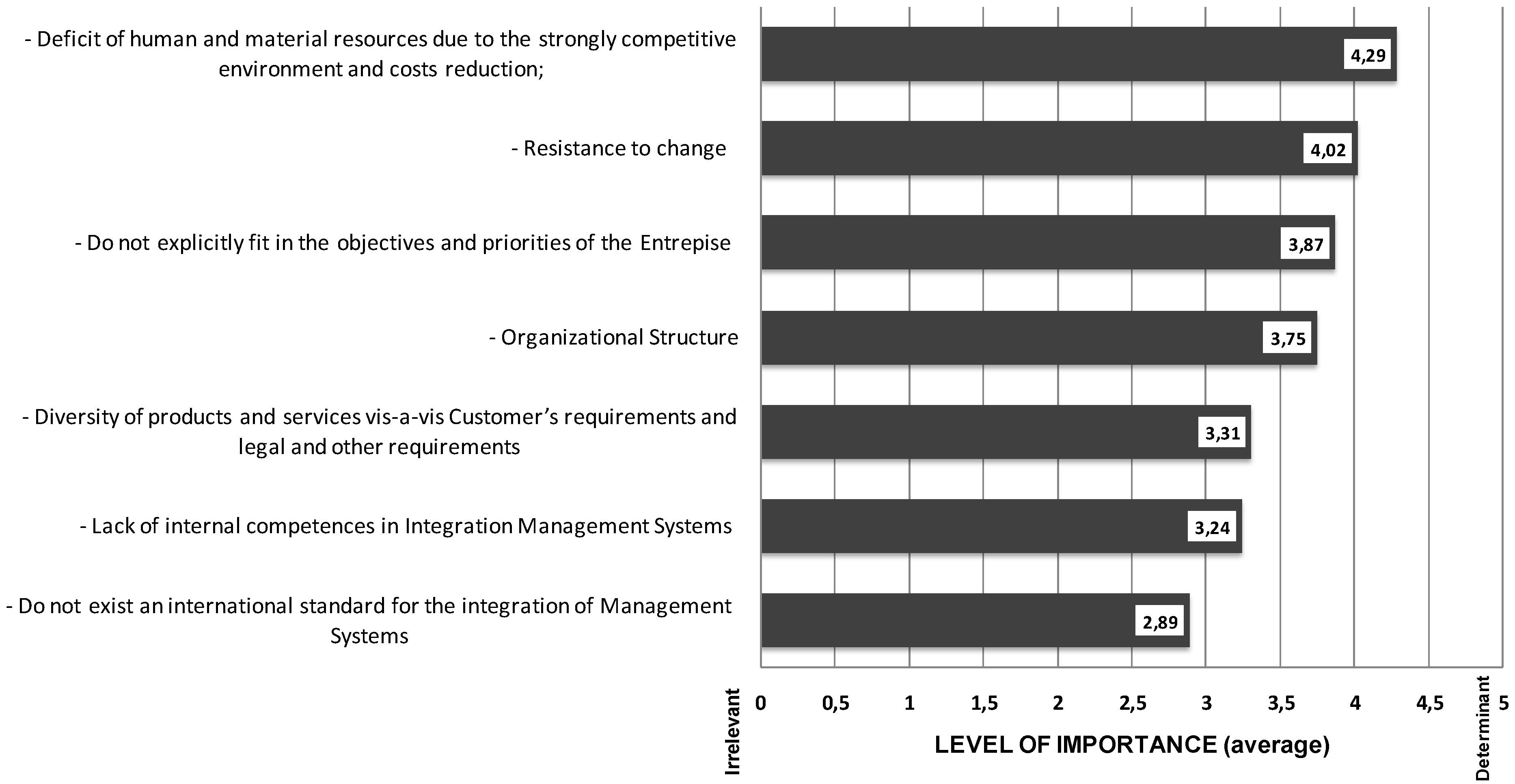

Gathered information, including questionnaire based analysis, was performed both quantitatively, given the previously obtained mean values from the established scaling, as well as qualitatively, through evidences pertaining to the certification of MSs. Survey data created in an Excel spreadsheet was then exported to SPSS (Statistical Package for Social Sciences). The analysis of the survey was directed to the most relevant items of the questionnaire. Regarding the main difficulties associated to the development and implementation of the IMS–QES, the results are presented in

Figure 5. Regarding the main benefits resulting from the implementation of the IMS–QES the results are presented in

Figure 6.

Figure 5.

Main difficulties associated to the development and implementation of the IMS–QES [

2,

14].

Figure 5.

Main difficulties associated to the development and implementation of the IMS–QES [

2,

14].

Figure 6.

Main benefits resulting from the implementation of an IMS–QES [

14,

20].

Figure 6.

Main benefits resulting from the implementation of an IMS–QES [

14,

20].

The statistical analyses of questionnaires has shown a set of conclusions: (i) revealed the importance, in the present and for the future, of all the twelve identified “motivating factors” to implement an IMS; (ii) identified the relative position of nine relevant stakeholders, in terms of their influences on the performance and evolution of the IMS; (iii) revealed the main difficulties and associated critical success factors related to the context of development and implementation of the IMS; (iv) revealed the main potential benefits for the Company resulting from the implementation of the IMS; and, (v) alone justifies and validates the proposed approach to develop and to structure the integration process of the existing individualized MSs in the Company. From the motivating factors it can be depicted: “the continuous improvement of the MSs of Quality; Environment and Occupational Health and Safety implies its integration”; “the improvement of the image of the Company near customers and others stakeholders”; “rationalize and optimize the management of financial, material and human resources”. From the influences of the stakeholders on the performance and evolution of the IMS it can be highlighted: “the customers” as the most influent stakeholder and the “financial institutions” as the less influent stakeholder. Related to the main difficulties associated to the development and implementation of the IMS (

Figure 5) it is highlighted: “deficit of human and material resources in the context of its rationalization”; “resistance to change”; “lack of internal competencies about IMSs”.

Lastly, the main potential benefits for companies, resulting from the implementation of the IMS (

Figure 6), can be highlighted as: “the elimination of conflicts between individual systems”; “the integrated management of sustainability components in a global market, where Quality no longer makes a competitive difference and is now just a starting point for a business”; “the improvement of partnerships with suppliers of goods and services”; “dialogue with the main stakeholders and commitment to their ongoing satisfaction and increased contribution to the Company’s competitiveness”; “common management policy, objectives, targets and key process indicators (KPIs) related to QES performance”; “the creation of added value for the business through the elimination of waste, especially that of bureaucracy associated with independent MSs and their certifications”; “improvement to the Company’s internal and external image and to its credibility in QES areas, specifically in relationships with customers, official entities and other stakeholders”; “improvements to the coordinated and integrated management of risks to the safety of people and assets, the environment and the Quality of products along the supply chain”; “reduction of the number of internal and/or external audits and audits of suppliers and the consequential amount of time taken and associated costs”; “greater valuation and motivation of collaborators as a result of the expansion of their skill base, actions and responsibilities, with consequent empowerment”; and, “the integrated management of sustainability components”.

The survey results, on their own, strongly justify, validate and prioritize the proposed methodological approach in developing and structuring the integration process of the existing individualized MSs.

5. Conclusions

With the growing proliferation and diversity of MSSs, there emerges in organizations threats and opportunities, and thus several problems that are generators of inefficiencies, value destruction and consequently loss of competitiveness. In this scenario, organizations are faced with a dilemma—to integrate the MSSs versus related MSs into an IMS or to continue with the individualized implementations. Organizations have to understand its context, internal and external, the needs and expectations of stakeholders and consequently determine the requirements to be satisfied, and correspondent MSSs versus MSs to be implemented, considering the two possible options. The continuous improvement of global performance of organizations must always be a present goal in a perspective of sustainability. The presented guidelines regarding the integration of various individual MSs, supported on the Matrix of compatibilities shown for MSSs requirements and based on the model to support the development of the IMS presented, should therefore potentiate, for each phase: Plan, Do, Check, Act, a careful and methodical analysis of the differences that are effectively observed at the level of MSSs requirements under the equivalent clauses and for each step of their development. Compatibly studies should be the starting point for subsequent activities of integration, simplification and optimization, to a level of the strictly necessary and consequent integration maximized as desired for the individual MSs.

The integration of different MSs represent added value both in the present and, fundamentally, for the future, not only for the company, as well as for a whole range of stakeholders allowing for the enhancement of sustainable development of organizations. The advantages highlighted in this study are summarized hereby: (i) the elimination of conflicts between individual MSs with the optimization of resources; (ii) the improvement at the level of the coordinated and integrated management of the risk associated to the occupational health and safety regarding collaborators; (iii) the safety of Company assets; (iv) the Environment protection; (v) the Quality of products; (vi) the reduction on the number of internal and/or external audits and audits to Suppliers as well as spent time versus associated costs; and, (vii) the creation of added value for the business through the elimination of several types of waste.