Research on Optimum Design of Waste Recycling Network for Agricultural Production

Abstract

1. Introduction

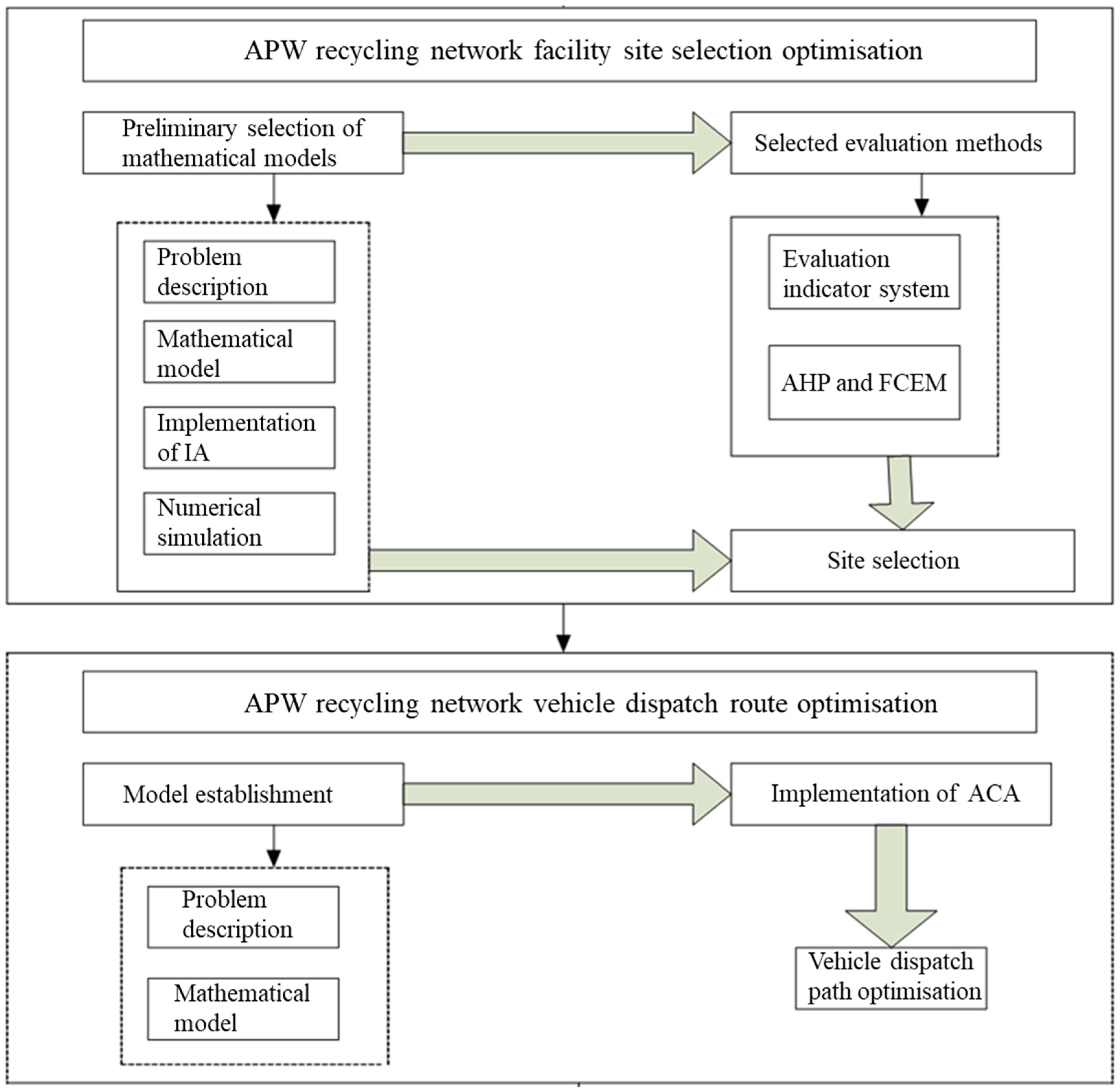

2. Methods

2.1. Model Formulation

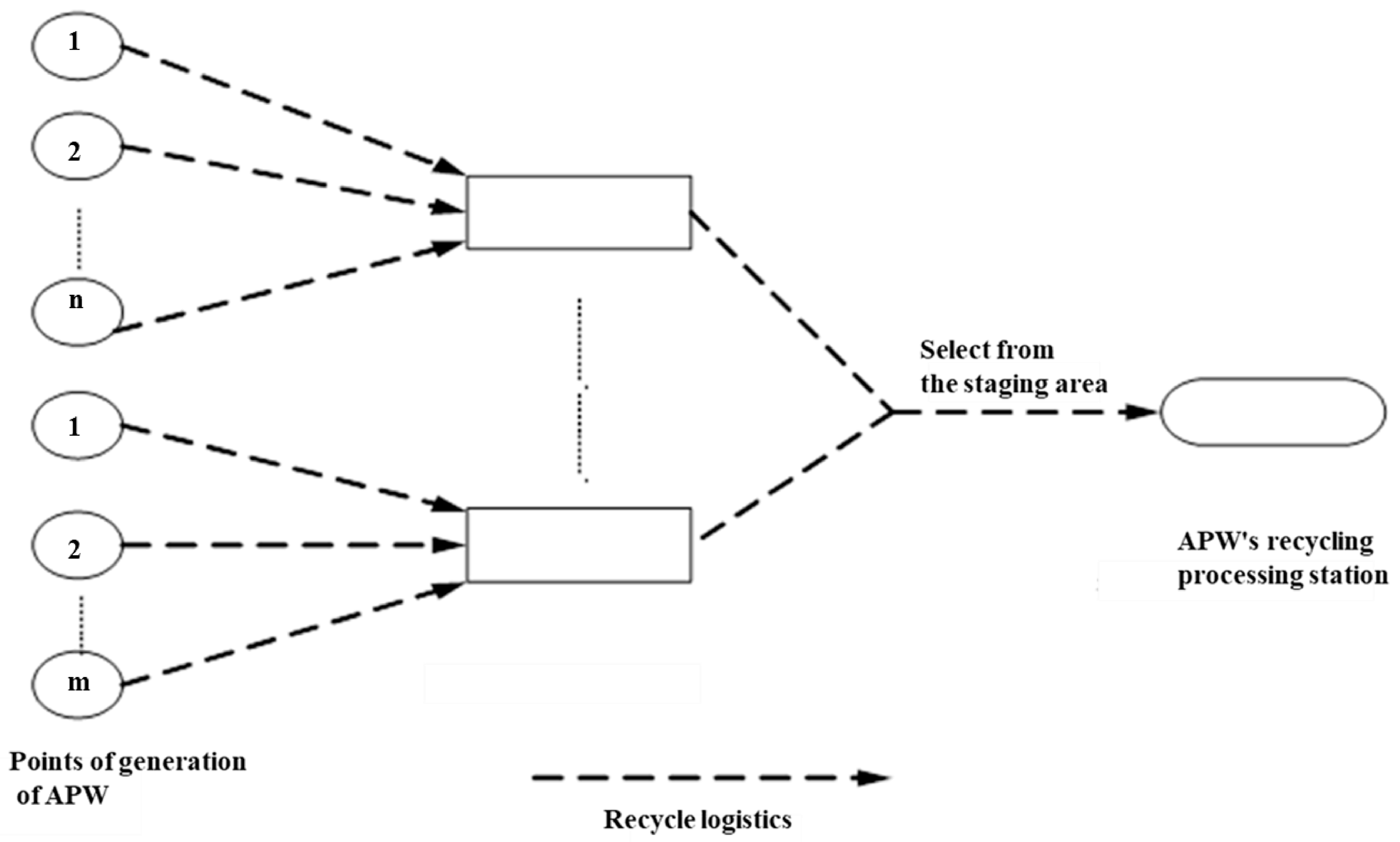

2.1.1. Construction of a Recycling Network for APW

2.1.2. Primary Model Building and Immunization Algorithm

Description of the Problem

Distance Calculations in Site Selection Models

- (1)

- Distance between two points on a plane

- (2)

- Distance between any two points on Earth

Discrete Point Ensemble Coverage Model

2.1.3. Establishment of Evaluation Indicators for Treatment Station Siting

2.1.4. Vehicle Dispatch Path Optimization Model

Basic Assumptions of the Model

Description of Parameters

- (1)

- Relevant parameters

- (2)

- Decision-making variables

- (3)

- Vehicle transport cost

Model Construction

2.2. Algorithmic Methods

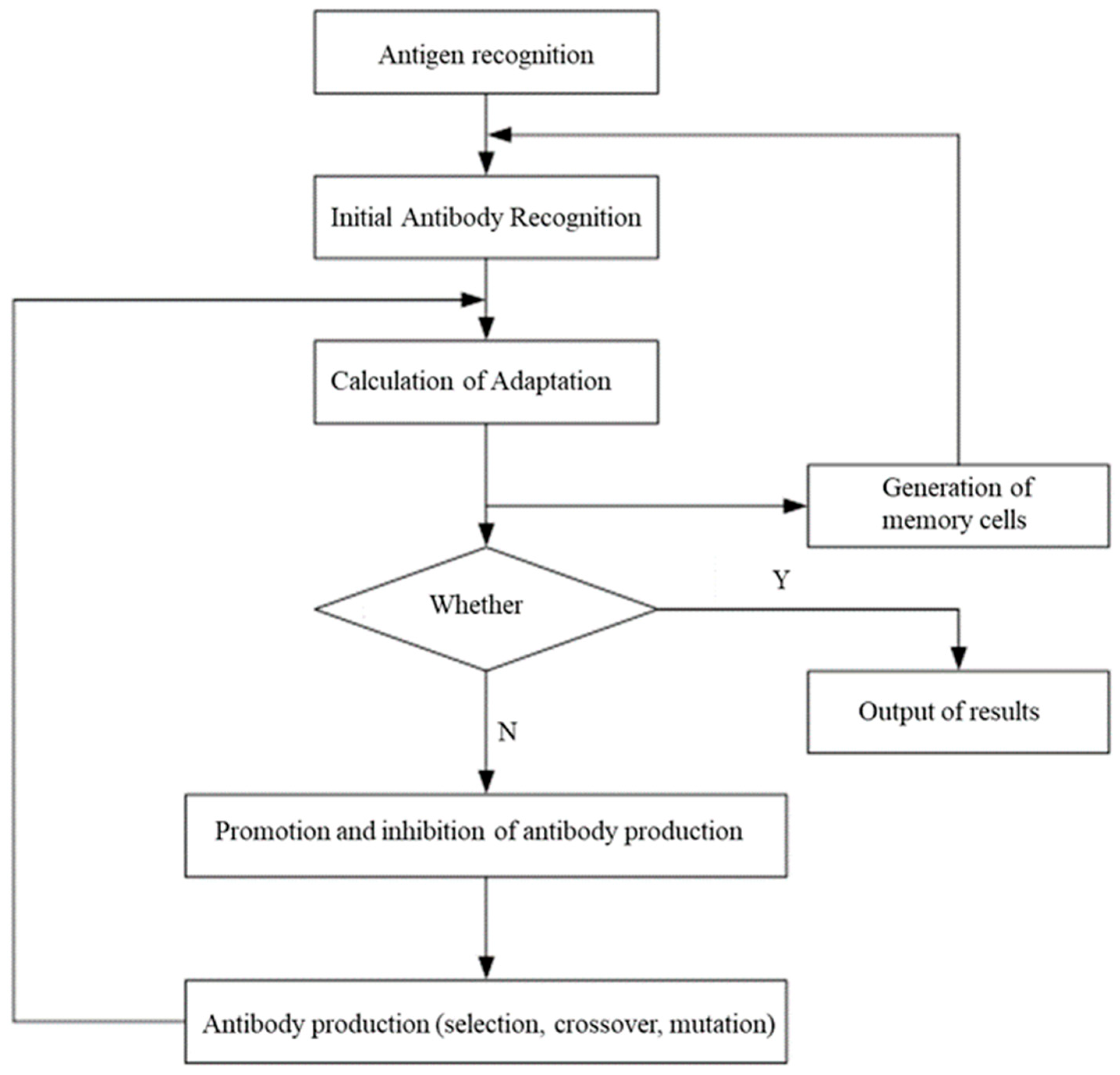

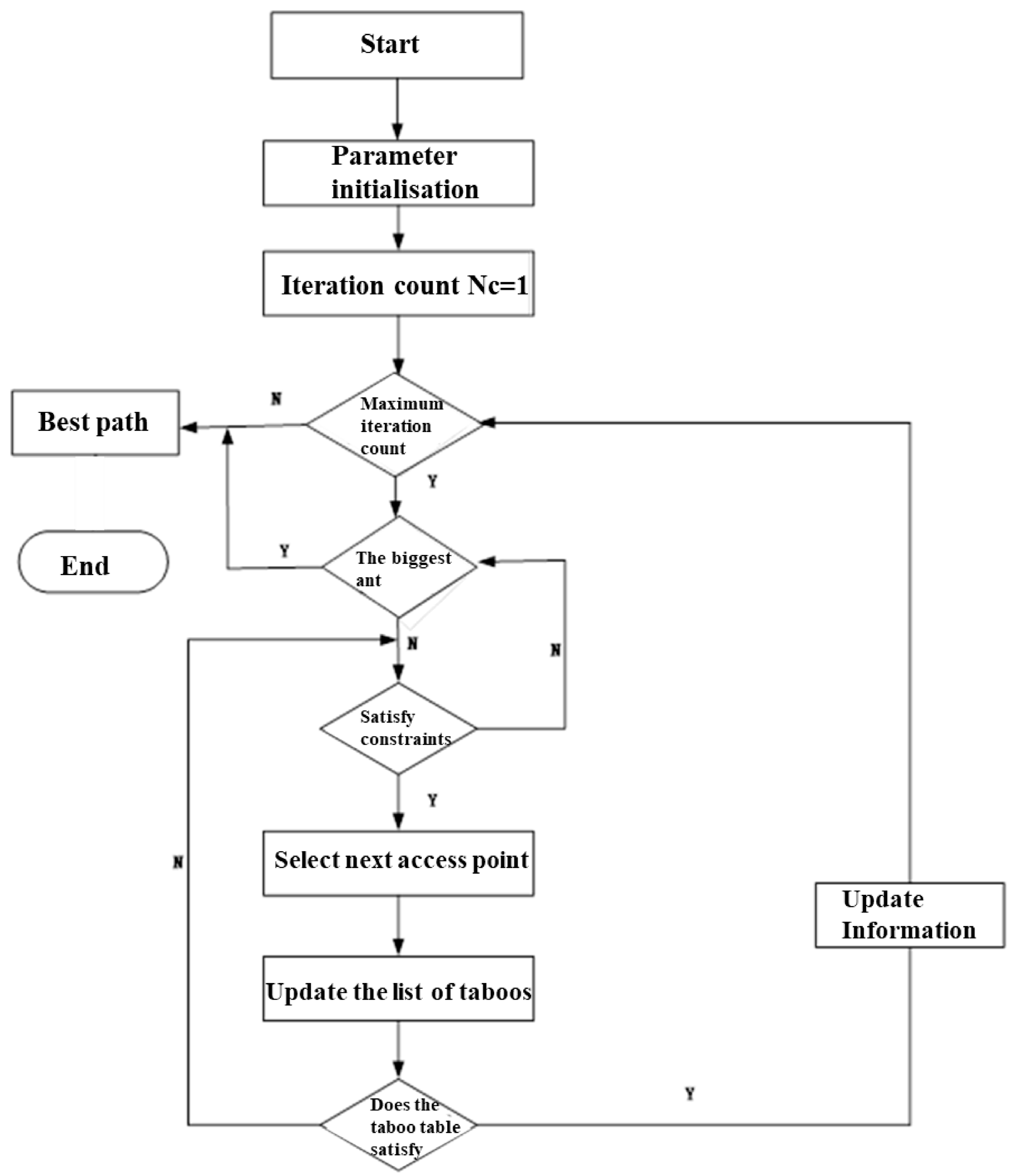

2.2.1. Immune Algorithm (IA)

- (1)

- Problem analysis: analyze the relevant problem and the properties of its solution, and devise a suitable expression for the solution.

- (2)

- Initial antibody population generation: individuals are extracted from randomly generated individuals to form the initial population ( is the number of individuals in the memory bank).

- (3)

- Antibody evaluation.

- (4)

- Parent population formation: the initial population generated earlier is arranged in the relevant descending order by a certain desired reproduction rate , where the parent population is composed of individuals randomly generated earlier, and m individuals are deposited in the memory bank.

- (5)

- Termination condition check: determine whether the end condition is satisfied; if so, end; otherwise, proceed to the next step.

- (6)

- New population generation: perform relevant operations on the antibody population to obtain a new population, extract the individuals from the memory, and constitute a new generation of the population.

- (7)

- Return to evaluation step: once a new population is generated, it is transferred to Step (3).

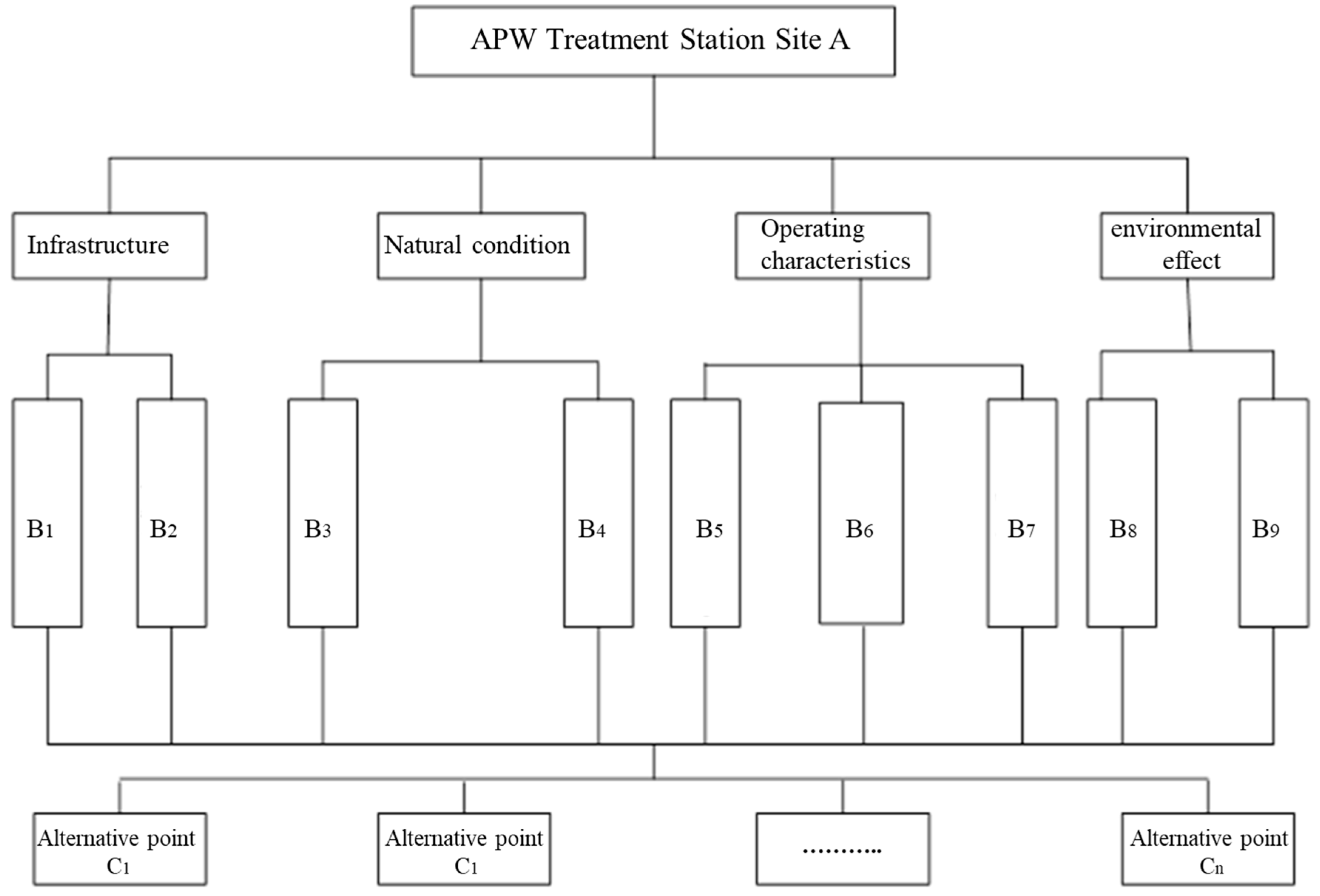

2.2.2. Methodology for Analyzing the Siting of Treatment Stations

Hierarchical Analysis (HA)

Fuzzy Integrated Evaluation Method (FIEM)

2.2.3. Evaluation System and Hierarchical Structure

2.2.4. Methods for Solving the Vehicle Scheduling Path Problem

- (1)

- In the first model, the formula is

- (2)

- In the second model, is calculated as

- (3)

- In the third model, is calculated as

3. Example Description and Solution

3.1. Experimental Setup

3.1.1. Data and Parameters for Site Selection

3.1.2. Data and Parameters for Vehicle Routing

3.2. Results and Analysis

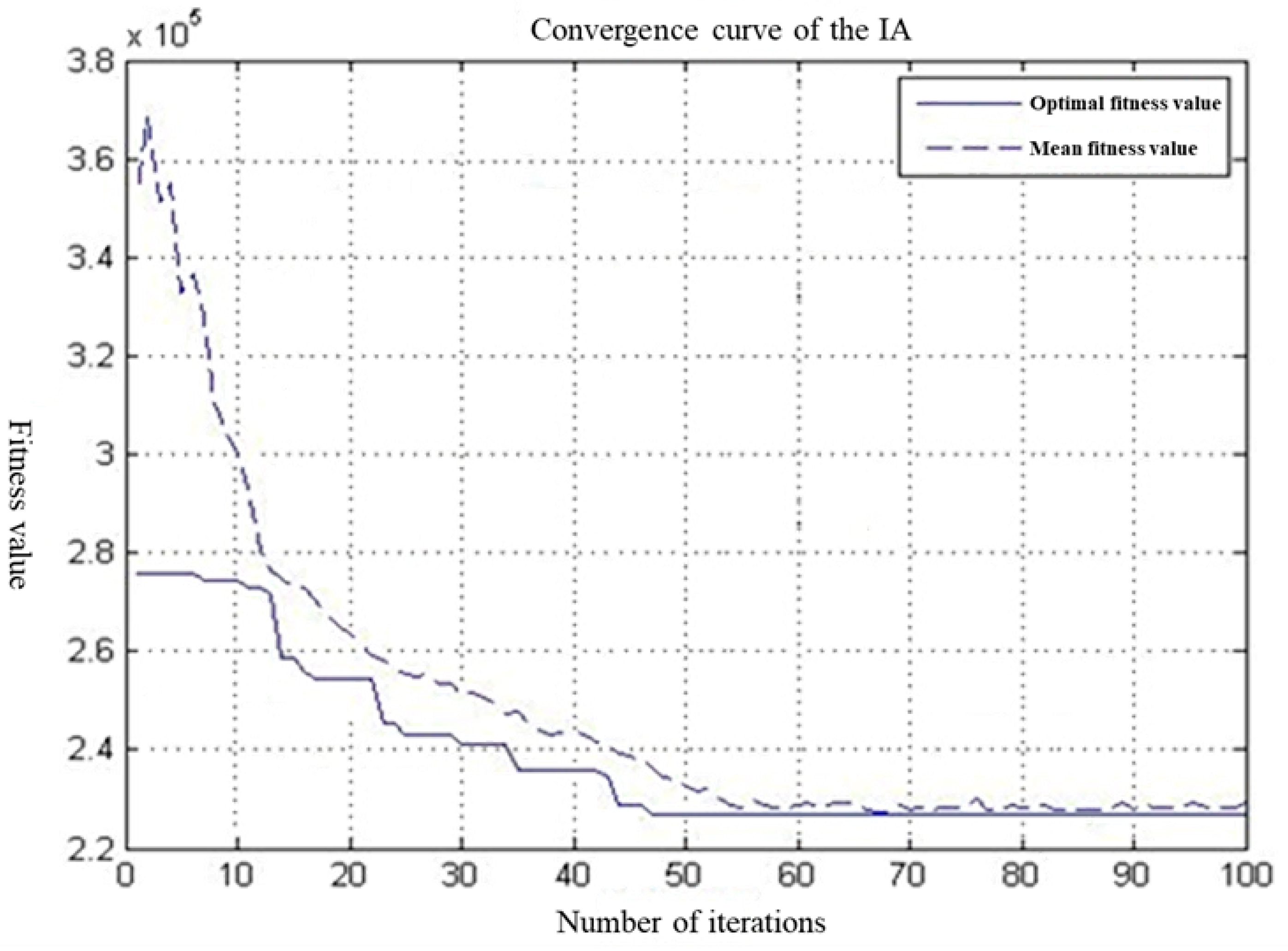

3.2.1. Site Selection Results

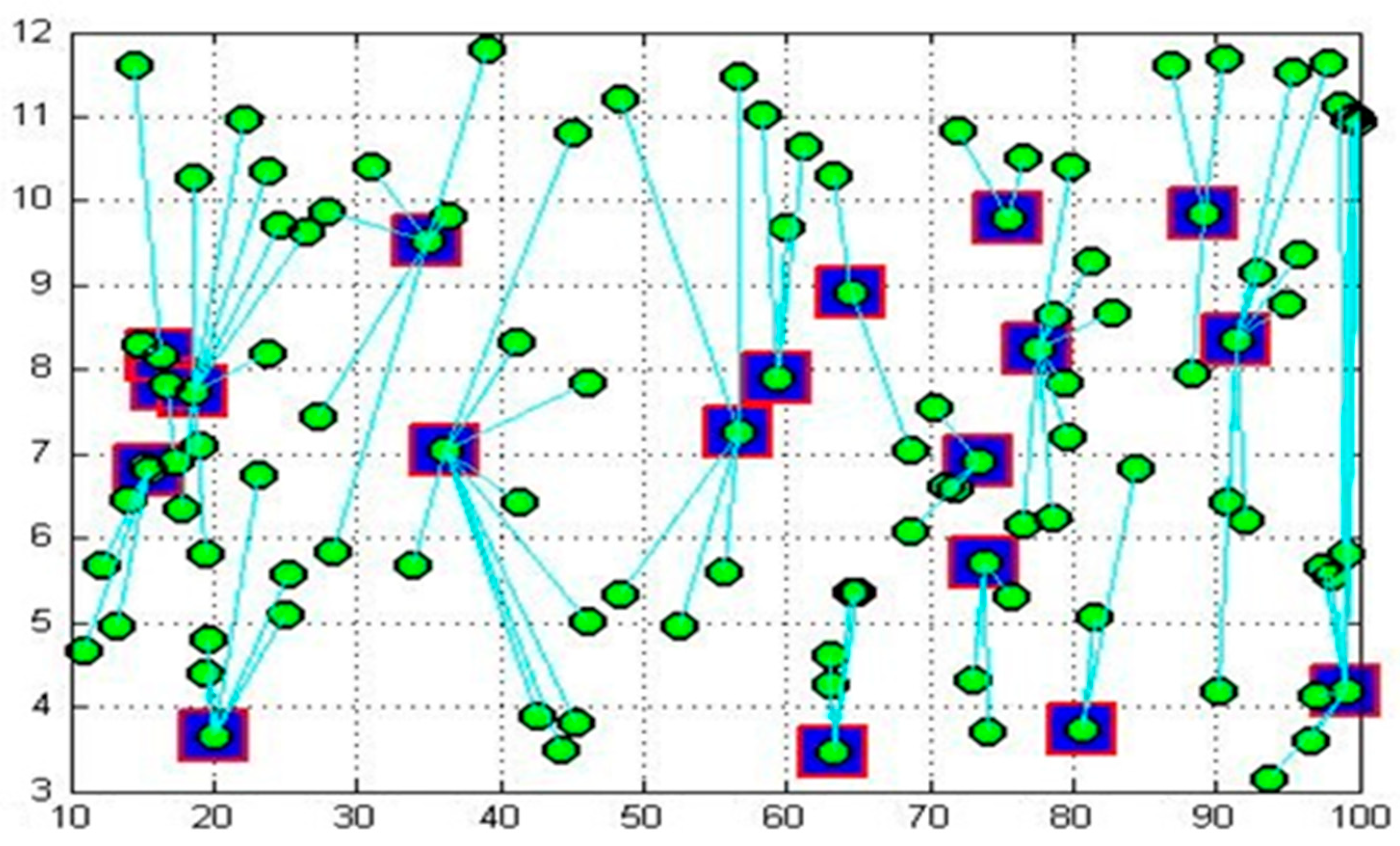

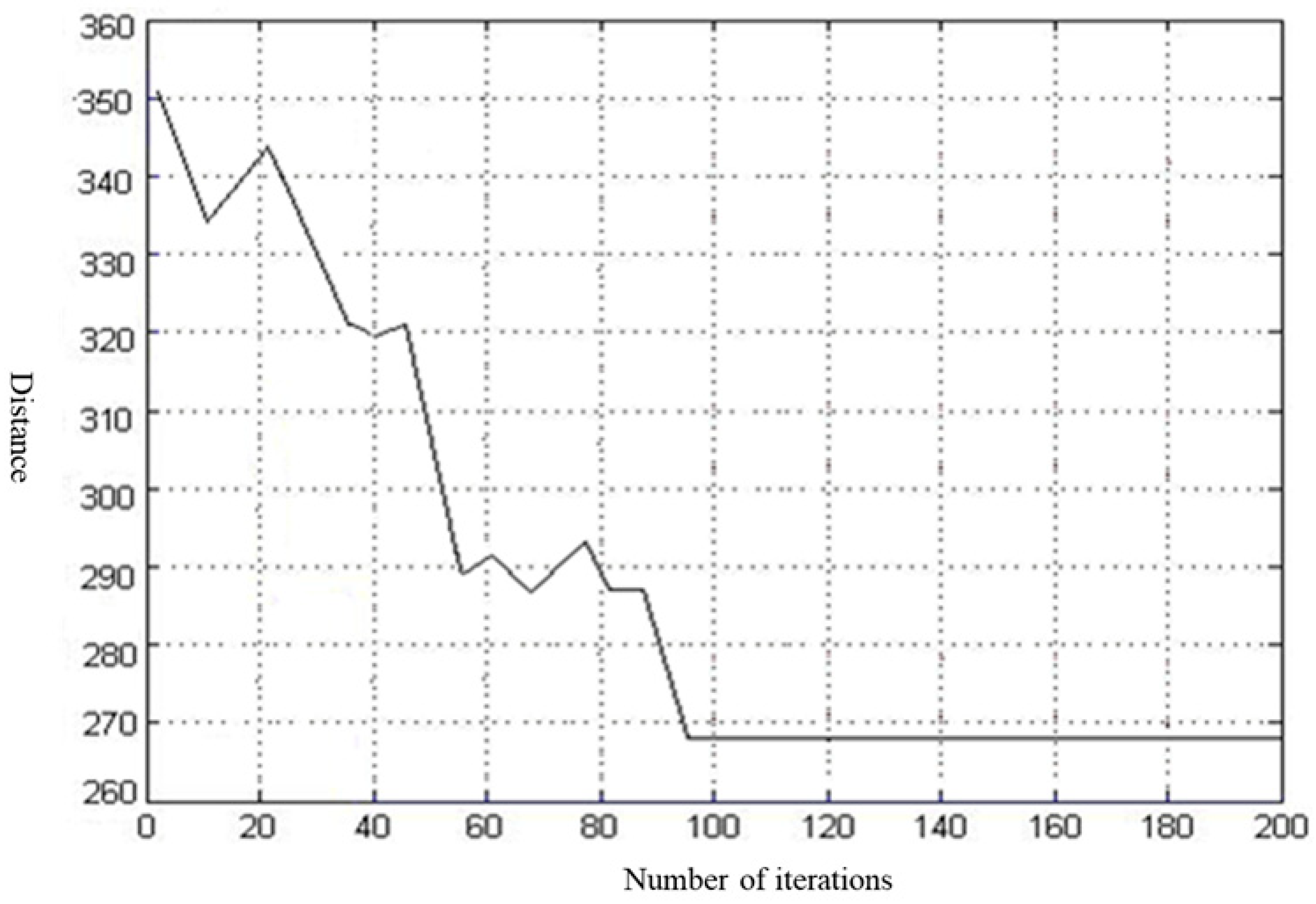

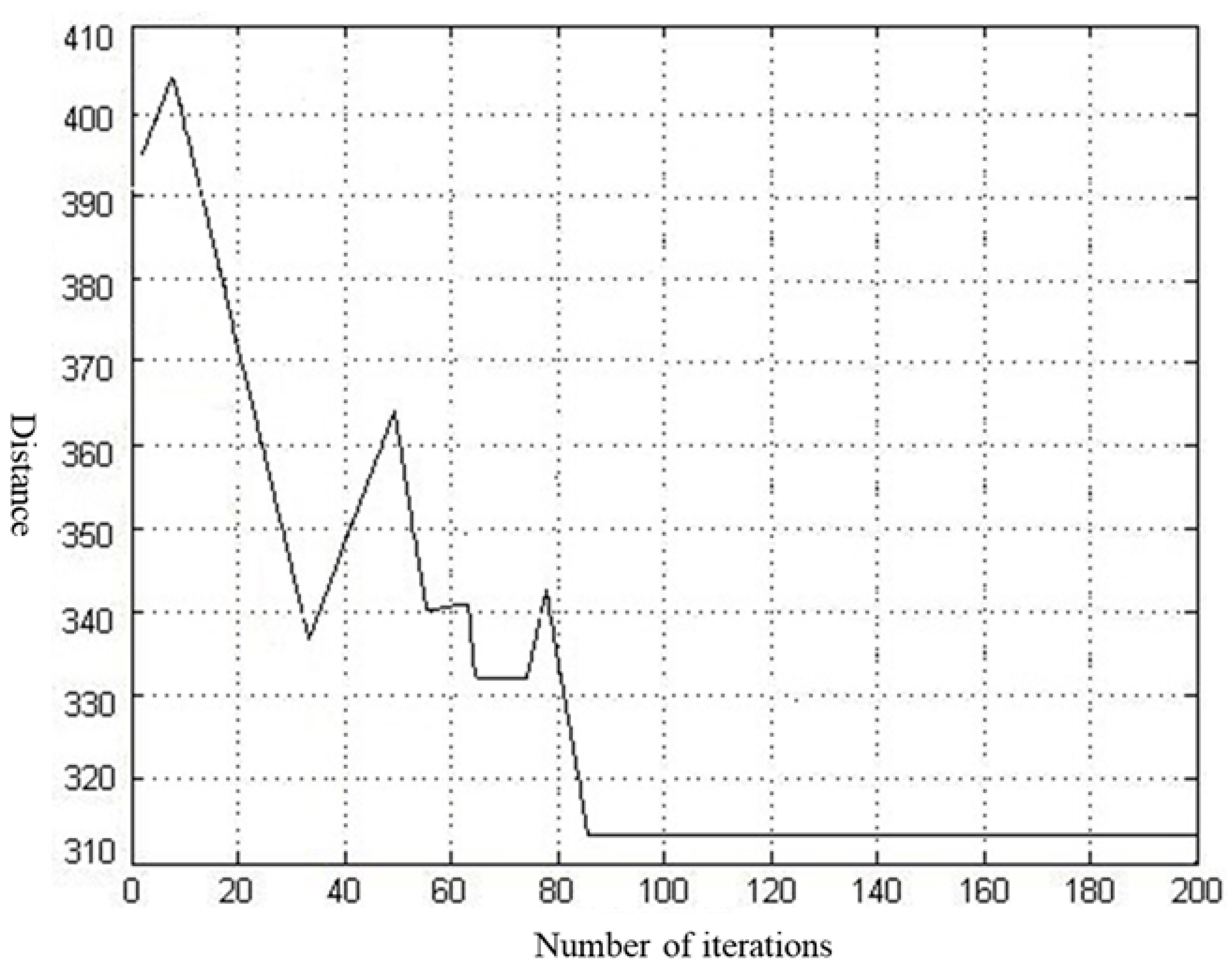

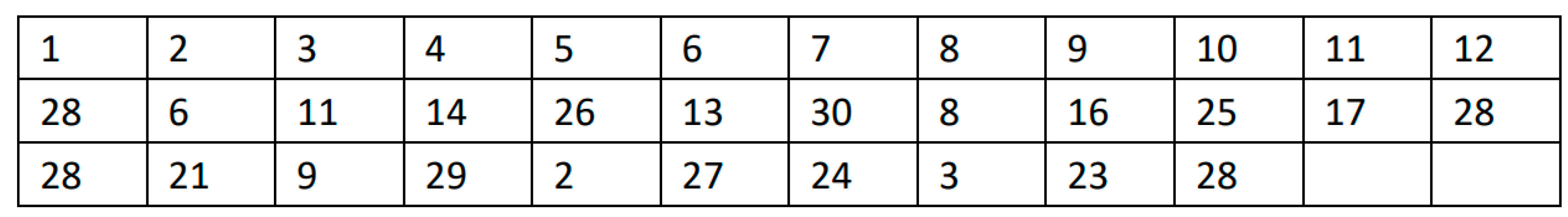

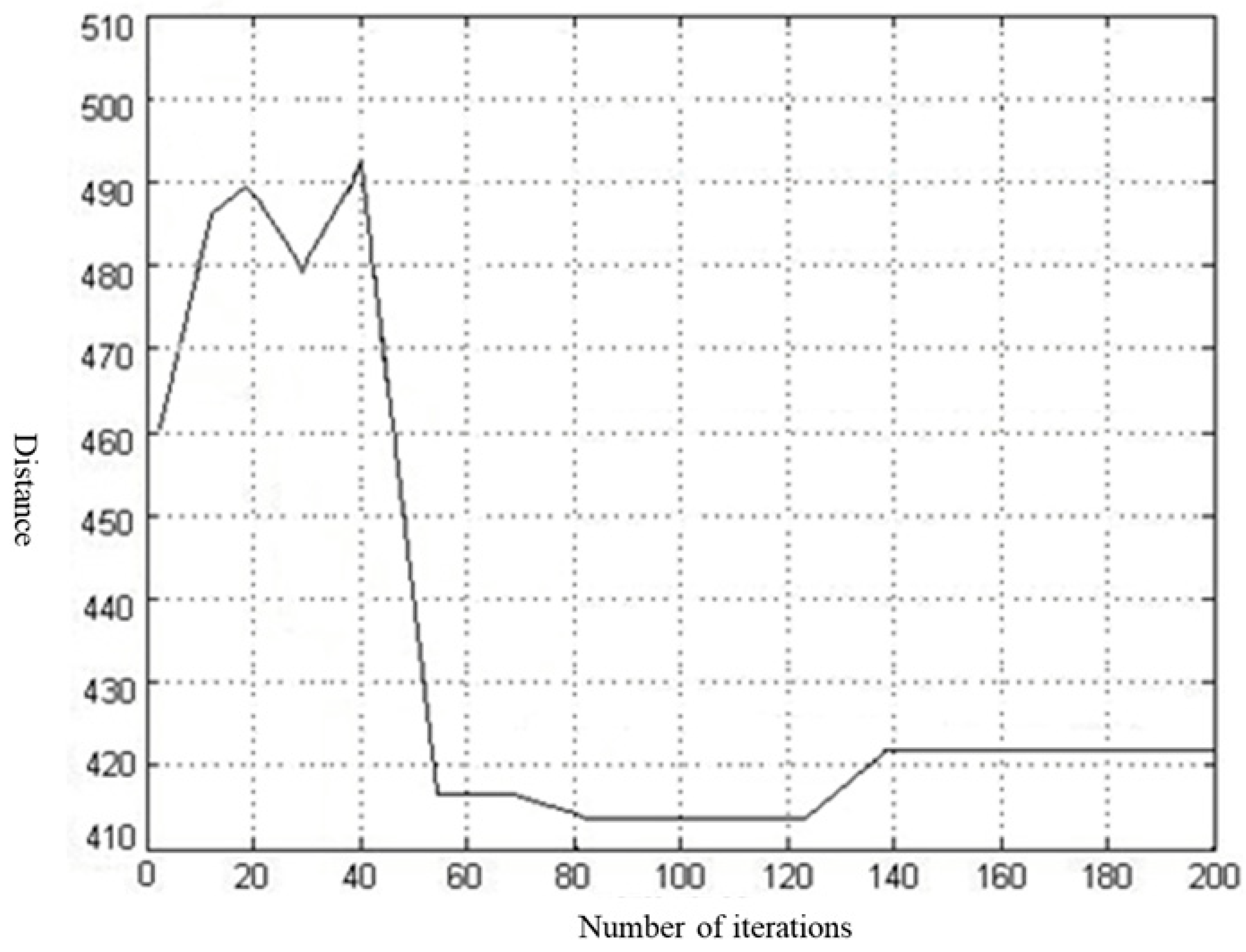

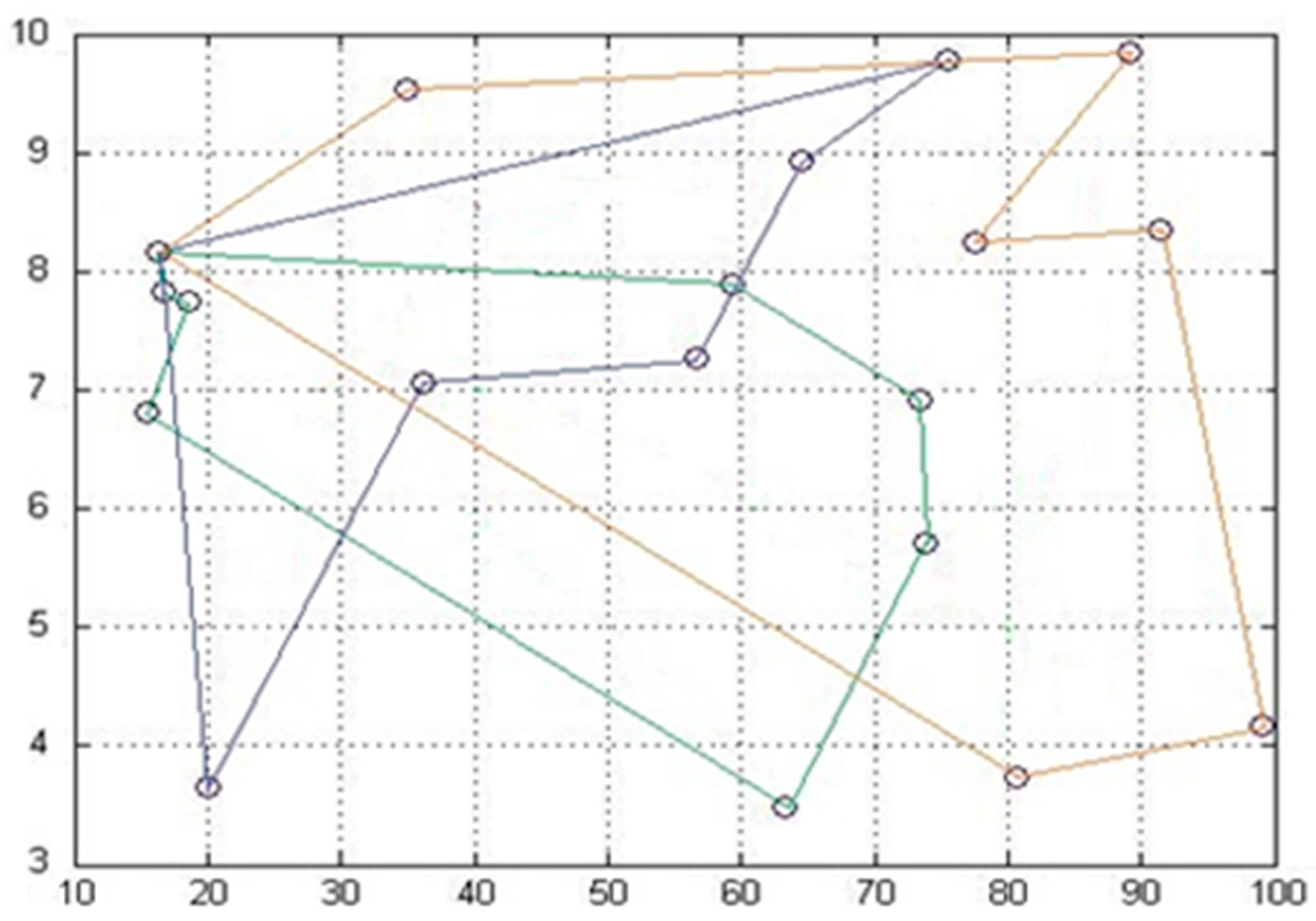

3.2.2. Vehicle Routing Results

4. Discussion

- (1)

- Selection of APW recycling temporary storage and processing stations: In constructing the set coverage model, this study assumes that the construction cost of APW recycling temporary storage sites is sufficiently large compared with other costs. Without this assumption, the constructed model may not be able to solve the selection problem of temporary storage sites for APW recycling. Additionally, for the selected evaluation indicator system constructed for processing station site selection, many qualitative factors need to be considered in real-world scenarios. This study selects four indicators: infrastructure, natural conditions, operational characteristics, and economic and environmental effects. Four core indicators were selected, primarily based on their systematic nature and suitability for the field. In terms of systematicity, the four categories of indicators cover the entire lifecycle of the recycling network: infrastructure (transportation conditions, land costs) forms the physical foundation for logistics efficiency; natural conditions (topography, weather) determine the feasibility of construction and operational stability; operational characteristics (matching degree of waste properties, service response speed, logistics costs) ensure the network aligns with the spatio-temporal characteristics of agricultural production; and economic and environmental effects (disruption to residents’ lives, ecological impact) ensure sustainable development. In terms of domain-specific relevance, the indicators are designed to align with the unique characteristics of agricultural production waste: infrastructure indicators address the current weaknesses in rural infrastructure (e.g., high-weight transportation assessments), natural condition indicators mitigate risks associated with agricultural environmental sensitivity (e.g., wind direction’s impact on pollution dispersion), operational characteristic indicators address the spatial and temporal dispersion of waste (e.g., seasonal recycling demands), and economic and environmental indicators balance costs with social acceptability. More indicators should be considered in future research.

- (2)

- Selection of optimization objectives: The model constructed for APW recycling and temporary storage sites only selected a single optimization objective and did not establish a multi-objective model. For example, the social and environmental impacts of temporary APW storage sites can also be considered.

- (3)

- Data acquisition: Because of the difficulty in obtaining data on APW generation points, a numerical simulation was used in this study. Although the effectiveness of the established model and algorithm was verified to a certain extent, efforts should be made to obtain and verify actual data.

- (4)

- Algorithm selection: In this study, the IA was used to solve the treatment plant location problem, and the ACA was used to solve the vehicle scheduling path optimization model. These results indicate that the constructed model was effective and reasonable. However, whether other algorithms (such as genetic algorithms or simulated annealing algorithms) can solve the APW recycling temporary storage facility and vehicle scheduling path optimization models remains to be further studied. However, future research could systematically introduce other high-performance heuristic or meta-heuristic algorithms, such as genetic algorithms (GAs), simulated annealing (SA) algorithms, and particle swarm optimization (PSO), for comparative experiments. By designing a fair comparison environment, such as using the same dataset, parameter settings, and computational platform, and conducting a comprehensive evaluation of key metrics such as optimal solution quality, average solution quality, computation time, convergence speed, and algorithm stability, we can more objectively reveal the relative advantages and applicable scenarios of different algorithms in APW recycling network optimization problems, providing a more robust basis for algorithm selection in practice.

5. Conclusions

- (1)

- Given the characteristics of APW mentioned earlier, facility construction costs typically need to be considered during the site selection process. The objective was to minimize the number of facilities, and a set coverage site selection model was constructed. We randomly selected 110 APW generation points. These 110 APW generation points were used as the objects of the recycling temporary storage facility site selection study, and simulation research was conducted. The IA method was used to solve the constructed model, and based on the different quantities of APW generated, different numbers and locations of temporary storage facilities for APW recycling were selected.

- (2)

- The optimal location for the recycling treatment station was precisely selected from the selected temporary storage sites. During the precise site selection process, four key indicators were considered: infrastructure, the natural environment, operational characteristics, and economic and environmental impacts. An evaluation indicator system for the precise selection of APW treatment station locations was established, and the analytic hierarchy process (AHP) and fuzzy comprehensive evaluation method were employed to precisely select the optimal location for the recycling treatment station.

- (3)

- A scheduling and path optimization model suitable for APW recycling transport vehicles was constructed and solved using the ACA. Finally, the optimal recycling vehicle scheduling plan and detailed transport path plan for each vehicle were designed. Through this research, the infrastructure construction and transport costs of APW recycling were effectively reduced. For example, when the load capacity of the collected vehicle is 12 tons, the distance of the transportation route decreases from the initial 351.24 km to 268.17 km, a reduction of 23.65%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Agricultural Production Waste Generation Points | X-Coordinate | Y-Coordinate |

|---|---|---|

| 1 | 90.77 | 6.431 |

| 2 | 89.1218 | 9.8461 |

| 3 | 73.4919 | 6.9218 |

| 4 | 23.8198 | 8.1872 |

| 5 | 99.0662 | 5.8295 |

| 6 | 16.6211 | 7.8272 |

| 7 | 30.9254 | 10.4122 |

| 8 | 99.0339 | 4.1811 |

| 9 | 64.4371 | 8.9227 |

| 10 | 36.3533 | 9.8352 |

| 11 | 18.5414 | 7.7495 |

| 12 | 11.0286 | 4.6616 |

| 13 | 63.3359 | 3.4798 |

| 14 | 15.5781 | 6.8121 |

| 15 | 97.9937 | 5.5561 |

| 16 | 73.7465 | 5.7014 |

| 17 | 36.075 | 7.0585 |

| 18 | 55.52 | 5.6032 |

| 19 | 81.3072 | 9.286 |

| 20 | 86.8865 | 11.6243 |

| 21 | 34.9283 | 9.5245 |

| 22 | 90.1438 | 4.1789 |

| 23 | 56.7005 | 7.2601 |

| 24 | 77.6402 | 8.2543 |

| 25 | 59.4368 | 7.8994 |

| 26 | 20.0632 | 3.6639 |

| 27 | 91.437 | 8.3471 |

| 28 | 16.38 | 8.1635 |

| 29 | 75.3796 | 9.7899 |

| 30 | 80.5606 | 3.7411 |

| 31 | 76.4872 | 6.1731 |

| 32 | 74.0645 | 3.7077 |

| 33 | 99.8923 | 10.9492 |

| 34 | 73.0712 | 4.31 |

| 35 | 76.4435 | 10.5247 |

| 36 | 19.427 | 5.828 |

| 37 | 68.7414 | 7.0373 |

| 38 | 92.8779 | 9.1576 |

| 39 | 71.9876 | 10.8339 |

| 40 | 25.1151 | 5.568 |

| 41 | 81.5091 | 5.0641 |

| 42 | 79.3334 | 7.8512 |

| 43 | 41.4377 | 6.4266 |

| 44 | 42.5662 | 3.9056 |

| 45 | 45.1168 | 10.8143 |

| 46 | 84.3256 | 6.8247 |

| 47 | 63.0825 | 4.2687 |

| 48 | 23.0896 | 6.7496 |

| 49 | 17.3896 | 6.9208 |

| 50 | 19.7123 | 4.8153 |

| 51 | 96.5951 | 3.6107 |

| 52 | 39.1349 | 11.8082 |

| 53 | 59.9453 | 9.7001 |

| 54 | 88.2986 | 7.9427 |

| 55 | 48.3369 | 11.2071 |

| 56 | 62.9742 | 4.6189 |

| 57 | 71.0542 | 6.6175 |

| 58 | 13.1093 | 4.9749 |

| 59 | 18.5405 | 10.2719 |

| 60 | 78.6087 | 6.2531 |

| 61 | 68.5732 | 6.0833 |

| 62 | 24.571 | 9.7217 |

| 63 | 95.8376 | 9.37 |

| 64 | 41.0821 | 8.3364 |

| 65 | 97.3575 | 5.657 |

| 66 | 15.261 | 6.851 |

| 67 | 24.9406 | 5.1054 |

| 68 | 12.2347 | 5.6765 |

| 69 | 71.6992 | 6.6026 |

| 70 | 56.6351 | 11.4682 |

| 71 | 82.7796 | 8.6852 |

| 72 | 98.6733 | 11.1401 |

| 73 | 79.7343 | 10.4018 |

| 74 | 75.7225 | 5.3034 |

| 75 | 14.1298 | 6.4712 |

| 76 | 96.9157 | 4.1266 |

| 77 | 63.2897 | 10.3026 |

| 78 | 97.7642 | 11.6348 |

| 79 | 27.3218 | 7.4599 |

| 80 | 93.6826 | 3.1585 |

| 81 | 58.3695 | 11.0162 |

| 82 | 90.5206 | 11.7034 |

| 83 | 78.6299 | 8.6446 |

| 84 | 19.0897 | 7.1032 |

| 85 | 46.0101 | 7.8427 |

| 86 | 17.6596 | 6.3649 |

| 87 | 22.0153 | 10.9827 |

| 88 | 14.4679 | 11.6186 |

| 89 | 61.1795 | 10.6628 |

| 90 | 23.7519 | 10.362 |

| 91 | 14.8938 | 8.3054 |

| 92 | 46.0485 | 5.022 |

| 93 | 52.4263 | 4.9701 |

| 94 | 28.3732 | 5.8438 |

| 95 | 26.4672 | 9.6484 |

| 96 | 79.6015 | 7.197 |

| 97 | 64.609 | 5.37 |

| 98 | 91.9884 | 6.2227 |

| 99 | 64.9253 | 5.3636 |

| 100 | 48.4028 | 5.3242 |

| 101 | 44.1651 | 3.4871 |

| 102 | 94.9766 | 8.7738 |

| 103 | 99.7626 | 11.009 |

| 104 | 27.8458 | 9.8763 |

| 105 | 99.2032 | 10.9694 |

| 106 | 95.3638 | 11.5266 |

| 107 | 33.985 | 5.6751 |

| 108 | 19.4501 | 4.3892 |

| 109 | 45.2444 | 3.8033 |

| 110 | 70.2901 | 7.5558 |

Appendix B

| Agricultural Production Waste Generation Points | Agricultural Production Waste Generation (kg) |

|---|---|

| 1 | 210.31 |

| 2 | 220.92 |

| 3 | 200.43 |

| 4 | 250.18 |

| 5 | 210.9 |

| 6 | 200.97 |

| 7 | 220.43 |

| 8 | 210.11 |

| 9 | 220.25 |

| 10 | 220.4 |

| 11 | 250.59 |

| 12 | 250.26 |

| 13 | 200.6 |

| 14 | 240.71 |

| 15 | 210.22 |

| 16 | 220.11 |

| 17 | 230.29 |

| 18 | 250.31 |

| 19 | 220.42 |

| 20 | 250.5 |

| 21 | 210.08 |

| 22 | 240.26 |

| 23 | 230.8 |

| 24 | 230.02 |

| 25 | 240.92 |

| 26 | 230.73 |

| 27 | 210.48 |

| 28 | 200.57 |

| 29 | 250.23 |

| 30 | 210.45 |

| 31 | 200.96 |

| 32 | 230.54 |

| 33 | 250.52 |

| 34 | 240.23 |

| 35 | 210.48 |

| 36 | 220.62 |

| 37 | 220.67 |

| 38 | 250.39 |

| 39 | 200.36 |

| 40 | 250.98 |

| 41 | 230.03 |

| 42 | 220.88 |

| 43 | 210.91 |

| 44 | 220.79 |

| 45 | 220.09 |

| 46 | 200.26 |

| 47 | 230.33 |

| 48 | 210.67 |

| 49 | 220.13 |

| 50 | 230.72 |

| 51 | 210.1 |

| 52 | 210.65 |

| 53 | 230.49 |

| 54 | 210.77 |

| 55 | 240.71 |

| 56 | 250.9 |

| 57 | 240.89 |

| 58 | 220.33 |

| 59 | 230.69 |

| 60 | 200.19 |

| 61 | 250.03 |

| 62 | 250.74 |

| 63 | 240.5 |

| 64 | 210.47 |

| 65 | 230.9 |

| 66 | 200.6 |

| 67 | 220.61 |

| 68 | 210.85 |

| 69 | 200.8 |

| 70 | 210.57 |

| 71 | 220.18 |

| 72 | 200.23 |

| 73 | 230.88 |

| 74 | 220.02 |

| 75 | 240.48 |

| 76 | 240.16 |

| 77 | 230.97 |

| 78 | 200.71 |

| 79 | 200.5 |

| 80 | 210.47 |

| 81 | 230.05 |

| 82 | 230.68 |

| 83 | 220.04 |

| 84 | 240.07 |

| 85 | 240.52 |

| 86 | 250.09 |

| 87 | 230.81 |

| 88 | 210.81 |

| 89 | 200.72 |

| 90 | 230.14 |

| 91 | 240.65 |

| 92 | 220.51 |

| 93 | 200.97 |

| 94 | 210.64 |

| 95 | 200.8 |

| 96 | 210.45 |

| 97 | 220.43 |

| 98 | 230.82 |

| 99 | 220.08 |

| 100 | 250.13 |

| 101 | 230.17 |

| 102 | 250.39 |

| 103 | 230.83 |

| 104 | 250.8 |

| 105 | 210.06 |

| 106 | 240.39 |

| 107 | 210.52 |

| 108 | 240.41 |

| 109 | 240.65 |

| 110 | 200.62 |

References

- Qu, L.; Li, Y.; Yang, F.; Ma, L.; Chen, Z. Assessing Sustainable Transformation and Development Strategies for Gully Agricultural Production: A Case Study in the Loess Plateau of China. Environ. Impact Assess. Rev. 2024, 104, 107325. [Google Scholar] [CrossRef]

- Babu, S.; Singh Rathore, S.; Singh, R.; Kumar, S.; Singh, V.K.; Yadav, S.K.; Yadav, V.; Raj, R.; Yadav, D.; Shekhawat, K.; et al. Exploring Agricultural Waste Biomass for Energy, Food and Feed Production and Pollution Mitigation: A Review. Bioresour. Technol. 2022, 360, 127566. [Google Scholar] [CrossRef]

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2022, 70, 6787–6804. [Google Scholar] [CrossRef] [PubMed]

- Sonu; Rani, G.M.; Pathania, D.; Abhimanyu; Umapathi, R.; Rustagi, S.; Huh, Y.S.; Gupta, V.K.; Kaushik, A.; Chaudhary, V. Agro-Waste to Sustainable Energy: A Green Strategy of Converting Agricultural Waste to Nano-Enabled Energy Applications. Sci. Total Environ. 2023, 875, 162667. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Liang, G.; Alex, J.; Zhang, T.; Ma, C. Research Progress of Energy Utilization of Agricultural Waste in China: Bibliometric Analysis by Citespace. Sustainability 2020, 12, 812. [Google Scholar] [CrossRef]

- Safieddin Ardebili, S.M. Green Electricity Generation Potential from Biogas Produced by Anaerobic Digestion of Farm Animal Waste and Agriculture Residues in Iran. Renew. Energy 2020, 154, 29–37. [Google Scholar] [CrossRef]

- Amen, R.; Hameed, J.; Albashar, G.; Kamran, H.W.; Hassan Shah, M.U.; Zaman, M.K.U.; Mukhtar, A.; Saqib, S.; Ch, S.I.; Ibrahim, M.; et al. Modelling the Higher Heating Value of Municipal Solid Waste for Assessment of Waste-to-Energy Potential: A Sustainable Case Study. J. Clean. Prod. 2021, 287, 125575. [Google Scholar] [CrossRef]

- Sharma, B.; Vaish, B.; Monika; Singh, U.K.; Singh, P.; Singh, R.P. Recycling of Organic Wastes in Agriculture: An Environmental Perspective. Int. J. Environ. Res. 2019, 13, 409–429. [Google Scholar] [CrossRef]

- Sarfaraz, Q.; da Silva, L.S.; Drescher, G.L.; Zafar, M.; Severo, F.F.; Kokkonen, A.; Dal Molin, G.; Shafi, M.I.; Shafique, Q.; Solaiman, Z.M. Characterization and Carbon Mineralization of Biochars Produced from Different Animal Manures and Plant Residues. Sci. Rep. 2020, 10, 955. [Google Scholar] [CrossRef]

- Shi, Q.; Ren, H.; Ma, X.; Xiao, Y. Site Selection of Construction Waste Recycling Plant. J. Clean. Prod. 2019, 227, 532–542. [Google Scholar] [CrossRef]

- Nuhu, S.K.; Manan, Z.A.; Wan Alwi, S.R.; Md Reba, M.N. Integrated Modelling Approach for an Eco-Industrial Park Site Selection. J. Clean. Prod. 2022, 368, 133141. [Google Scholar] [CrossRef]

- Liu, J.; Xiao, Y.; Wang, D.; Pang, Y. Optimization of Site Selection for Construction and Demolition Waste Recycling Plant Using Genetic Algorithm. Neural Comput. Appl. 2019, 31, 233–245. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Gamal, A.; Chakrabortty, R.K.; Ryan, M. A New Hybrid Multi-Criteria Decision-Making Approach for Location Selection of Sustainable Offshore Wind Energy Stations: A Case Study. J. Clean. Prod. 2021, 280, 124462. [Google Scholar] [CrossRef]

- Shao, M.; Han, Z.; Sun, J.; Xiao, C.; Zhang, S.; Zhao, Y. A Review of Multi-Criteria Decision Making Applications for Renewable Energy Site Selection. Renew. Energy 2020, 157, 377–403. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing Efficient Circularity for Construction and Demolition Waste Management in Fast Emerging Economies: Lessons Learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to Circular Construction: An Integrated Management of Construction and Demolition Waste for Resource Recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Mustafa, H.M.; Hayder, G. Recent Studies on Applications of Aquatic Weed Plants in Phytoremediation of Wastewater: A Review Article. Ain Shams Eng. J. 2021, 12, 355–365. [Google Scholar] [CrossRef]

- Attrah, M.; Elmanadely, A.; Akter, D.; Rene, E.R. A Review on Medical Waste Management: Treatment, Recycling, and Disposal Options. Environments 2022, 9, 146. [Google Scholar] [CrossRef]

- Mei, X.; Hao, H.; Sun, Y.; Wang, X.; Zhou, Y. Optimization of Medical Waste Recycling Network Considering Disposal Capacity Bottlenecks under a Novel Coronavirus Pneumonia Outbreak. Environ. Sci. Pollut. Res. 2022, 29, 79669–79687. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J.; Niu, B.; Liu, L.; He, X. A Novel Hybrid Multi-Criteria Group Decision-Making Approach with Intuitionistic Fuzzy Sets to Design Reverse Supply Chains for COVID-19 Medical Waste Recycling Channels. Comput. Ind. Eng. 2022, 169, 108228. [Google Scholar] [CrossRef]

- Liu, M.; Wen, J.; Feng, Y.; Zhang, L.; Wu, J.; Wang, J.; Yang, X. A Benefit Evaluation for Recycling Medical Plastic Waste in China Based on Material Flow Analysis and Life Cycle Assessment. J. Clean. Prod. 2022, 368, 133033. [Google Scholar] [CrossRef]

- Le, H.T.; Quoc, K.L.; Nguyen, T.A.; Dang, K.T.; Vo, H.K.; Luong, H.H.; Le Van, H.; Gia, K.H.; Cao Phu, L.V.; Nguyen Truong Quoc, D.; et al. Medical-Waste Chain: A Medical Waste Collection, Classification and Treatment Management by Blockchain Technology. Computers 2022, 11, 113. [Google Scholar] [CrossRef]

- Yoon, C.-W.; Kim, M.-J.; Park, Y.-S.; Jeon, T.-W.; Lee, M.-Y. A Review of Medical Waste Management Systems in the Republic of Korea for Hospital and Medical Waste Generated from the COVID-19 Pandemic. Sustainability 2022, 14, 3678. [Google Scholar] [CrossRef]

- Govindan, K.; Nosrati-Abarghooee, S.; Nasiri, M.M.; Jolai, F. Green Reverse Logistics Network Design for Medical Waste Management: A Circular Economy Transition through Case Approach. J. Environ. Manag. 2022, 322, 115888. [Google Scholar] [CrossRef]

- Tushar, S.R.; Alam, M.D.F.B.; Bari, A.B.M.M.; Karmaker, C.L. Assessing the Challenges to Medical Waste Management during the COVID-19 Pandemic: Implications for the Environmental Sustainability in the Emerging Economies. Socioecon. Plann. Sci. 2023, 87, 101513. [Google Scholar] [CrossRef]

- Yu, H.; Sun, X.; Solvang, W.D.; Zhao, X. Reverse Logistics Network Design for Effective Management of Medical Waste in Epidemic Outbreaks: Insights from the Coronavirus Disease 2019 (COVID-19) Outbreak in Wuhan (China). Int. J. Environ. Res. Public. Health 2020, 17, 1770. [Google Scholar] [CrossRef]

- Aboelmaged, M. E-Waste Recycling Behaviour: An Integration of Recycling Habits into the Theory of Planned Behaviour. J. Clean. Prod. 2021, 278, 124182. [Google Scholar] [CrossRef]

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A Global Perspective on E-Waste Recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

- Vuppaladadiyam, S.S.V.; Thomas, B.S.; Kundu, C.; Vuppaladadiyam, A.K.; Duan, H.; Bhattacharya, S. Can E-Waste Recycling Provide a Solution to the Scarcity of Rare Earth Metals? An Overview of e-Waste Recycling Methods. Sci. Total Environ. 2024, 924, 171453. [Google Scholar] [CrossRef]

- Dhir, A.; Koshta, N.; Goyal, R.K.; Sakashita, M.; Almotairi, M. Behavioral Reasoning Theory (BRT) Perspectives on E-Waste Recycling and Management. J. Clean. Prod. 2021, 280, 124269. [Google Scholar] [CrossRef]

- Wang, Z.; Huo, J. Do Government Intervention Measures Promote E-Waste Recycling in China? J. Environ. Manag. 2023, 342, 118138. [Google Scholar] [CrossRef] [PubMed]

- Lovrak, A.; Pukšec, T.; Duić, N. A Geographical Information System (GIS) Based Approach for Assessing the Spatial Distribution and Seasonal Variation of Biogas Production Potential from Agricultural Residues and Municipal Biowaste. Appl. Energy 2020, 267, 115010. [Google Scholar] [CrossRef]

- Yan, B.; Li, Y.; Qin, Y.; Shi, W.; Yan, J. Spatial-Temporal Distribution of Biogas Production from Agricultural Waste per Capita in Rural China and Its Correlation with Ground Temperature. Sci. Total Environ. 2022, 817, 152987. [Google Scholar] [CrossRef]

- Cowie, P.; Townsend, L.; Salemink, K. Smart Rural Futures: Will Rural Areas Be Left behind in the 4th Industrial Revolution? J. Rural Stud. 2020, 79, 169–176. [Google Scholar] [CrossRef] [PubMed]

- Prus, P.; Sikora, M. The Impact of Transport Infrastructure on the Sustainable Development of the Region—Case Study. Agriculture 2021, 11, 279. [Google Scholar] [CrossRef]

- Xiao, D.; An, S.; Cai, H.; Wang, J.; Cai, H. An Optimization Model for Electric Vehicle Charging Infrastructure Planning Considering Queuing Behavior with Finite Queue Length. J. Energy Storage 2020, 29, 101317. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Q.; Ma, L.; Zhang, Z.; Liu, Y. A Hybrid Ant Colony Optimization Algorithm for a Multi-Objective Vehicle Routing Problem with Flexible Time Windows. Inf. Sci. 2019, 490, 166–190. [Google Scholar] [CrossRef]

- Fu, Y.; Li, H.; Huang, M.; Xiao, H. Bi-Objective Modeling and Optimization for Stochastic Two-Stage Open Shop Scheduling Problems in the Sharing Economy. IEEE Trans. Eng. Manag. 2023, 70, 3395–3409. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.-S. Recycling Municipal, Agricultural and Industrial Waste into Energy, Fertilizers, Food and Construction Materials, and Economic Feasibility: A Review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Sikiru, S.; Abioye, K.J.; Adedayo, H.B.; Adebukola, S.Y.; Soleimani, H.; Anar, M. Technology Projection in Biofuel Production Using Agricultural Waste Materials as a Source of Energy Sustainability: A Comprehensive Review. Renew. Sustain. Energy Rev. 2024, 200, 114535. [Google Scholar] [CrossRef]

- Damian, C.S.; Devarajan, Y.; Jayabal, R. A Comprehensive Review of the Resource Efficiency and Sustainability in Biofuel Production from Industrial and Agricultural Waste. J. Mater. Cycles Waste Manag. 2024, 26, 1264–1276. [Google Scholar] [CrossRef]

- Ufitikirezi, J.D.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Atinkut, H.B.; Yan, T.; Zhang, F.; Qin, S.; Gai, H.; Liu, Q. Cognition of Agriculture Waste and Payments for a Circular Agriculture Model in Central China. Sci. Rep. 2020, 10, 10826. [Google Scholar] [CrossRef]

- Zhang, H.G.; Tang, X.Y. Study on Optimized Combination and Utilization Model of Agricultural and Animal Husbandry Resources in Mountain Ecotone. IOP Conf. Ser. Earth Environ. Sci. 2019, 346, 012031. [Google Scholar] [CrossRef]

- Han, R.; Huo-Gen, W. N2N Regional Circular Agriculture Model in China: A Case Study of Luofang Biogas Project. Cogent Food Agric. 2023, 9, 2222563. [Google Scholar] [CrossRef]

- Zhou, K.; Li, Y.; Tang, Y.; Yang, Y.; Tian, G.; Liu, B.; Bian, B.; He, C. A New Scheme for Low-Carbon Recycling of Urban and Rural Organic Waste Based on Carbon Footprint Assessment: A Case Study in China. Npj Sustain. Agric. 2024, 2, 9. [Google Scholar] [CrossRef]

- Chen, L.; Dong, T.; Peng, J.; Ralescu, D. Uncertainty Analysis and Optimization Modeling with Application to Supply Chain Management: A Systematic Review. Mathematics 2023, 11, 2530. [Google Scholar] [CrossRef]

- Rokbani, N.; Kumar, R.; Abraham, A.; Alimi, A.M.; Long, H.V.; Priyadarshini, I.; Son, L.H. Bi-Heuristic Ant Colony Optimization-Based Approaches for Traveling Salesman Problem. Soft Comput. 2021, 25, 3775–3794. [Google Scholar] [CrossRef]

- Wang, Y.; Han, Z. Ant Colony Optimization for Traveling Salesman Problem Based on Parameters Optimization. Appl. Soft Comput. 2021, 107, 107439. [Google Scholar] [CrossRef]

- Wu, L.; Huang, X.; Cui, J.; Liu, C.; Xiao, W. Modified Adaptive Ant Colony Optimization Algorithm and Its Application for Solving Path Planning of Mobile Robot. Expert Syst. Appl. 2023, 215, 119410. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural Waste Management Strategies for Environmental Sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef]

- Agapkin, A.M.; Makhotina, I.A.; Ibragimova, N.A.; Goryunova, O.B.; Izembayeva, A.K.; Kalachev, S.L. The Problem of Agricultural Waste and Ways to Solve It. IOP Conf. Ser. Earth Environ. Sci. 2022, 981, 022009. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Jeong, J.S.; García-Moruno, L.; Hernández-Blanco, J. A Site Planning Approach for Rural Buildings into a Landscape Using a Spatial Multi-Criteria Decision Analysis Methodology. Land Use Policy 2013, 32, 108–118. [Google Scholar] [CrossRef]

- Agramanisti Azdy, R.; Darnis, F. Use of Haversine Formula in Finding Distance Between Temporary Shelter and Waste End Processing Sites. J. Phys. Conf. Ser. 2020, 1500, 012104. [Google Scholar] [CrossRef]

- Albahri, O.S.; Zaidan, A.A.; Zaidan, B.B.; Albahri, A.S.; Mohsin, A.H.; Mohammed, K.I.; Alsalem, M.A. New mHealth Hospital Selection Framework Supporting Decentralised Telemedicine Architecture for Outpatient Cardiovascular Disease-Based Integrated Techniques: Haversine-GPS and AHP-VIKOR. J. Ambient Intell. Humaniz. Comput. 2022, 13, 219–239. [Google Scholar] [CrossRef]

- Zhang, Y.; Schaap, M.G.; Wei, Z. Development of Hierarchical Ensemble Model and Estimates of Soil Water Retention with Global Coverage. Geophys. Res. Lett. 2020, 47, e2020GL088819. [Google Scholar] [CrossRef]

- Li, L.; Lin, Q.; Li, K.; Ming, Z. Vertical Distance-Based Clonal Selection Mechanism for the Multiobjective Immune Algorithm. Swarm Evol. Comput. 2021, 63, 100886. [Google Scholar] [CrossRef]

- Yu, X.; Tian, X. A Fault Detection Algorithm for Pipeline Insulation Layer Based on Immune Neural Network. Int. J. Press. Vessels Pip. 2022, 196, 104611. [Google Scholar] [CrossRef]

- Aslan, S.; Rohacs, D.; Yıldız, M.; Kale, U. A Three-Dimensional UCAV Path Planning Approach Based on Immune Plasma Algorithm. Int. J. Comput. Intell. Syst. 2023, 16, 112. [Google Scholar] [CrossRef]

- Tang, C.; Todo, Y.; Ji, J.; Lin, Q.; Tang, Z. Artificial Immune System Training Algorithm for a Dendritic Neuron Model. Knowl.-Based Syst. 2021, 233, 107509. [Google Scholar] [CrossRef]

- Kuikka, V.; Aalto, H.; Ijäs, M.; Kaski, K.K. Efficiency of Algorithms for Computing Influence and Information Spreading on Social Networks. Algorithms 2022, 15, 262. [Google Scholar] [CrossRef]

- Forestal, R.L.; Pi, S.-M. A Hybrid Approach Based on ELECTRE III-Genetic Algorithm and TOPSIS Method for Selection of Optimal COVID-19 Vaccines. J. Multi-Criteria Decis. Anal. 2022, 29, 80–91. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Luo, J.; Hu, Y.; Li, S. A Novel Multi-Strategy DE Algorithm for Parameter Optimization in Support Vector Machine. J. Intell. Inf. Syst. 2020, 54, 527–543. [Google Scholar] [CrossRef]

- Spampinato, A.G.; Scollo, R.A.; Cutello, V.; Pavone, M. Random Search Immune Algorithm for Community Detection. Soft Comput. 2023, 27, 8061–8090. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; The MIT Press: Cambridge, MA, USA, 1992; ISBN 978-0-262-27555-2. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by Simulated Annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Zhang, Y.; Shang, K. Evaluation of Mine Ecological Environment Based on Fuzzy Hierarchical Analysis and Grey Relational Degree. Environ. Res. 2024, 257, 119370. [Google Scholar] [CrossRef]

- Wu, X.; Hu, F. Analysis of Ecological Carrying Capacity Using a Fuzzy Comprehensive Evaluation Method. Ecol. Indic. 2020, 113, 106243. [Google Scholar] [CrossRef]

- Wu, H.; Sun, X.; Li, D.; Zhao, Y. Research on Learning Evaluation of College Students Based on AHP and Fuzzy Comprehensive Evaluation. Comput. Intell. Neurosci. 2022, 2022, 9160695. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, H.; Zheng, Y.; He, J. Research on Path Planning of Mobile Robot Based on Improved Ant Colony Algorithm. Neural Comput. Appl. 2020, 32, 1555–1566. [Google Scholar] [CrossRef]

- Miao, C.; Chen, G.; Yan, C.; Wu, Y. Path Planning Optimization of Indoor Mobile Robot Based on Adaptive Ant Colony Algorithm. Comput. Ind. Eng. 2021, 156, 107230. [Google Scholar] [CrossRef]

- Yi, N.; Xu, J.; Yan, L.; Huang, L. Task Optimization and Scheduling of Distributed Cyber–Physical System Based on Improved Ant Colony Algorithm. Future Gener. Comput. Syst. 2020, 109, 134–148. [Google Scholar] [CrossRef]

- Hou, W.; Xiong, Z.; Wang, C.; Chen, H. Enhanced Ant Colony Algorithm with Communication Mechanism for Mobile Robot Path Planning. Robot. Auton. Syst. 2022, 148, 103949. [Google Scholar] [CrossRef]

- Ataei, P.; Karimi, H.; Hallaj, Z.; Menatizadeh, M. Agricultural Waste Recycling by Farmers: A Behavioral Study. Sustain. Futur. 2025, 9, 100443. [Google Scholar] [CrossRef]

- Zhang, H.; Ren, Z.; Xin, S.; Liu, S.; Lan, C.; Sun, X. A Scale-Adaptive Positive Selection Algorithm Based on B-Cell Immune Mechanisms for Anomaly Detection. Eng. Appl. Artif. Intell. 2020, 94, 103805. [Google Scholar] [CrossRef]

- Magalhães, M.T. Spatial Coverage Index for Assessing National and Regional Transportation Infrastructures. J. Transp. Geogr. 2016, 56, 53–61. [Google Scholar] [CrossRef]

- Wang, J.; Hou, D.; Liu, Z.; Tao, J.; Yan, B.; Liu, Z.; Yang, T.; Su, H.; Tahir, M.H.; Chen, G. Emergy Analysis of Agricultural Waste Biomass for Energy-Oriented Utilization in China: Current Situation and Perspectives. Sci. Total Environ. 2022, 849, 157798. [Google Scholar] [CrossRef]

- Ayyildiz, E.; Erdogan, M. Literature Analysis of the Location Selection Studies Related to the Waste Facilities within MCDM Approaches. Environ. Sci. Pollut. Res. 2024. [Google Scholar] [CrossRef]

- Feiz, R.; Metson, G.S.; Wretman, J.; Ammenberg, J. Key Factors for Site-Selection of Biogas Plants in Sweden. J. Clean. Prod. 2022, 354, 131671. [Google Scholar] [CrossRef]

| A | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 | B9 |

|---|---|---|---|---|---|---|---|---|---|

| B1 | 1 | 3 | 5 | 9 | 2 | 7 | 1/4 | 1/7 | 3 |

| B2 | 1/3 | 1 | 2 | 5 | 3 | 6 | 1/3 | 1/7 | 5 |

| B3 | 1/5 | 1/2 | 1 | 1/2 | 3 | 5 | 1/5 | 1/9 | 2 |

| B4 | 1/9 | 1/5 | 2 | 1 | 2 | 7 | 1/5 | 1/9 | 2 |

| B5 | 1/2 | 1/3 | 1/3 | 1/2 | 1 | 1/3 | 1/5 | 1/9 | 3 |

| B6 | 1/7 | 1/6 | 1/5 | 1/7 | 3 | 1 | 3 | 1/7 | 7 |

| B7 | 4 | 3 | 5 | 5 | 5 | 3 | 1 | 1/5 | 5 |

| B8 | 7 | 7 | 9 | 9 | 9 | 7 | 5 | 1 | 9 |

| B9 | 1/3 | 1/5 | 1/2 | 1/2 | 1/3 | 1/7 | 1/5 | 1/9 | 1 |

| APW Recycling Drop-Off Locations | APW Recycling Drop-Off Location Coordinates () |

|---|---|

| 30 | (80.5606, 3.7411) |

| 6 | (16.6211, 7.8272) |

| 17 | (36.0750, 7.0585) |

| 25 | (59.4368, 7.8994) |

| 3 | (73.4919, 6.9218) |

| 2 | (89.1218, 9.8461) |

| 28 | (16.3800, 8.1635) |

| 13 | (63.3359, 3.4798) |

| 29 | (75.3796, 9.7899) |

| 27 | (91.4370, 8.3471) |

| 11 | (18.5414, 7.7495) |

| 26 | (20.0632, 3.6639) |

| 23 | (56.7005, 7.2601) |

| 24 | (77.6402, 8.2543) |

| 14 | (15.5781, 6.8121) |

| 21 | (34.9283, 9.5245) |

| 8 | (99.0339, 4.1811) |

| 16 | (73.7465, 5.7014) |

| 9 | (64.4371, 8.9227) |

| Temporary Storage Area | APW Generation Point | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 19 | 42 | 46 | 71 | 73 | 83 | 96 | ||||||||

| 23 | 18 | 23 | 55 | 70 | 85 | 92 | 93 | 100 | |||||||

| 26 | 26 | 40 | 48 | 50 | 67 | 108 | |||||||||

| 9 | 9 | 13 | 37 | 47 | 56 | 77 | 97 | 99 | |||||||

| 30 | 30 | 41 | 60 | ||||||||||||

| 2 | 1 | 2 | 20 | 22 | 27 | 38 | 54 | 82 | 98 | 102 | 106 | ||||

| 12 | 12 | 58 | 68 | ||||||||||||

| 8 | 5 | 8 | 15 | 33 | 51 | 63 | 65 | 72 | 76 | 78 | 80 | 103 | 105 | ||

| 16 | 16 | 31 | 32 | 34 | 74 | ||||||||||

| 29 | 24 | 29 | 35 | 39 | |||||||||||

| 28 | 28 | 75 | 88 | 91 | |||||||||||

| 3 | 3 | 57 | 61 | 69 | 110 | ||||||||||

| 25 | 25 | 53 | 81 | 89 | |||||||||||

| 6 | 6 | 14 | 49 | 66 | |||||||||||

| 21 | 7 | 10 | 17 | 21 | 43 | 44 | 45 | 52 | 64 | 79 | 94 | 101 | 104 | 107 | 109 |

| 11 | 4 | 11 | 36 | 59 | 62 | 84 | 86 | 87 | 90 | 95 | |||||

| Temporary Storage Area | APW Generation Point | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 30 | 41 | 46 | ||||||||

| 6 | 6 | 49 | |||||||||

| 17 | 17 | 43 | 44 | 45 | 64 | 85 | 92 | 101 | 107 | 109 | |

| 25 | 25 | 53 | 81 | 89 | |||||||

| 3 | 3 | 57 | 61 | 69 | 110 | ||||||

| 2 | 2 | 20 | 54 | 82 | |||||||

| 28 | 28 | 88 | 91 | ||||||||

| 13 | 13 | 47 | 56 | 97 | 99 | ||||||

| 29 | 29 | 35 | 39 | ||||||||

| 27 | 1 | 22 | 27 | 38 | 63 | 78 | 98 | 102 | 106 | ||

| 11 | 4 | 11 | 36 | 59 | 62 | 84 | 86 | 87 | 90 | 95 | |

| 26 | 26 | 40 | 48 | 50 | 67 | 108 | |||||

| 23 | 18 | 23 | 55 | 70 | 93 | 100 | |||||

| 24 | 19 | 24 | 31 | 42 | 60 | 71 | 73 | 83 | 96 | ||

| 14 | 12 | 14 | 58 | 66 | 68 | 75 | |||||

| 21 | 7 | 10 | 21 | 52 | 79 | 94 | 104 | ||||

| 8 | 5 | 8 | 15 | 33 | 51 | 65 | 72 | 76 | 80 | 103 | 105 |

| 16 | 16 | 32 | 34 | 74 | |||||||

| 9 | 9 | 37 | 77 | ||||||||

| Vehicle Load Capacity (t) | Number of Vehicles | Distance Before Optimization (km) | Optimized Optimal Distance (km) | Cost Before Optimization (CNY) | Optimized Cost (CNY) |

|---|---|---|---|---|---|

| 12 | 2 | 351.24 | 268.17 | 1013.1 | 798.4 |

| 13 | 2 | 395.72 | 312.10 | 1137.4 | 983.5 |

| 10 | 3 | 461.28 | 422.73 | 1404.8 | 1147.8 |

| Research Module | Research Methods | Research Content |

|---|---|---|

| Temporary Storage Site Selection | Immune Algorithm (IA) and Set Covering Model | With the goal of minimizing the number of facilities, input 110 production point coordinates and yields, and output 16–19 candidate temporary storage points |

| Treatment Plant Site Selection | AHP and FCEM | Screen the optimal sites from the candidate sites, input geographical/economic/environmental constraints, and output the coordinates of the processing stations |

| Path Optimization | Ant Colony Algorithm (ACA) and Vehicle Scheduling Model | Plan transportation routes based on site distribution, input load/distance costs, and output the lowest-cost vehicle route plan |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Zhang, J.; Ji, Y.; Su, Y.; Shu, S. Research on Optimum Design of Waste Recycling Network for Agricultural Production. Systems 2025, 13, 570. https://doi.org/10.3390/systems13070570

Wu H, Zhang J, Ji Y, Su Y, Shu S. Research on Optimum Design of Waste Recycling Network for Agricultural Production. Systems. 2025; 13(7):570. https://doi.org/10.3390/systems13070570

Chicago/Turabian StyleWu, Huabin, Jing Zhang, Yanshu Ji, Yuelong Su, and Shumiao Shu. 2025. "Research on Optimum Design of Waste Recycling Network for Agricultural Production" Systems 13, no. 7: 570. https://doi.org/10.3390/systems13070570

APA StyleWu, H., Zhang, J., Ji, Y., Su, Y., & Shu, S. (2025). Research on Optimum Design of Waste Recycling Network for Agricultural Production. Systems, 13(7), 570. https://doi.org/10.3390/systems13070570