Abstract

Supplier selection plays a pivotal role in the mining industry, forming a key component of the supply chain management. It has been established that the integration of sustainability and resilience into this process can significantly enhance the industry’s ability to withstand economic, environmental, and social shocks. Despite a large body of literature investigating supplier selection, there is a notable gap in research specifically addressing the incorporation of sustainability and resilience criteria in the mining industry. The objective of this research is to bridge this knowledge gap and contribute to the understanding of sustainable and resilient supplier selection in the mining industry. A constructive research approach was employed, identifying both practical and theoretical problems and proposing a construction—a mathematical model. This model was developed in collaboration with industry key actors, ensuring its practical applicability and validity. The main result of this research is an optimization mathematical programming model that allows practitioners to evaluate and select suppliers considering both sustainability and resilience criteria. The model facilitates a comprehensive assessment of suppliers, incorporating a wide range of factors beyond cost, including environmental impact, social responsibility, and the ability to maintain supply under various potential disruptions.

1. Introduction

Supplier selection (SS) plays a pivotal role in the operational efficiency and competitiveness of industries, particularly in the mining sector. The mining industry is a key component of the global economy, contributing significantly to employment, economic growth, and technological advancement. The selection of suppliers in this industry is often a complex and multi-criteria decision-making process, involving various economic, environmental, and social factors. The mining industry, known for its complex and dynamic supply chain, faces the crucial challenge of selecting suitable suppliers to meet its operational demands effectively. Supplier selection in this sector requires a comprehensive evaluation of various criteria, including qualitative and quantitative factors, to ensure the optimal choice that minimizes risks and maximizes overall value [1,2].

The incorporation of sustainability and resilience in the supplier selection process is a fundamental aspect of modern business strategy, particularly in the mining industry. Sustainability, as a concept, refers to the ability to maintain or improve standards of living without damaging or depleting natural resources for future generations. In the context of supplier selection, sustainability can be interpreted as the ability to maintain a steady supply chain while minimizing negative impacts on the environment, society, and economy [3]. The mining industry occupies a distinctive role in the incorporation of resilience and sustainability, owing to its inherent traits and external demands. This integration is vital because mining significantly contributes to global economic progress by supplying crucial raw materials for a variety of industries. Nevertheless, the sector encounters major challenges concerning environmental impact, social responsibility, and economic sustainability.

Moreover, according to the context–intervention–mechanism–outcome (CIMO) structure for the research questions proposed by Denyer, Tranfield, and van Aken [4], we propose, as the main focal research question of this paper, a newly developed optimization model for supplier selection in the mining industry considering sustainability and resilience aspects.

This research aims to address this gap by proposing a novel mathematical programming model for supplier selection in the mining industry. The model incorporates sustainability and resilience criteria, providing a comprehensive and practical tool for decision makers in the mining industry. The proposed model is validated with industry key actors, ensuring its practical applicability and effectiveness. This research contributes to the ongoing efforts to promote sustainable and resilient practices in the mining industry, offering valuable insights for academics, practitioners, and policymakers. The contribution to knowledge in this topic corresponds to the integration of variables not considered in previous models, such as resilience and sustainability, integrating it with production, location, inventory, and transport decisions, in an integrated way from a mathematical programming model.

The remainder of this paper is organized as follows. Section 2 describes the research methodology used in this paper. Section 3 summarizes relevant previous studies, focusing on the identified gap. Section 4 includes the formulation, objectives, and assumptions of the proposed model. Section 5 presents the results of a numerical example with different problem sizes to validate the model. Finally, Section 6 present the conclusions and the contributions of the study and guidelines for further research.

2. Research Methodology

The research methodology employed in this study is a constructive research approach, a paradigm particularly suited to the investigation of practical problems and the development of innovative solutions. This approach was chosen due to its ability to bridge the gap between theory and practice and its emphasis on the creation of novel constructions that can address real-world issues.

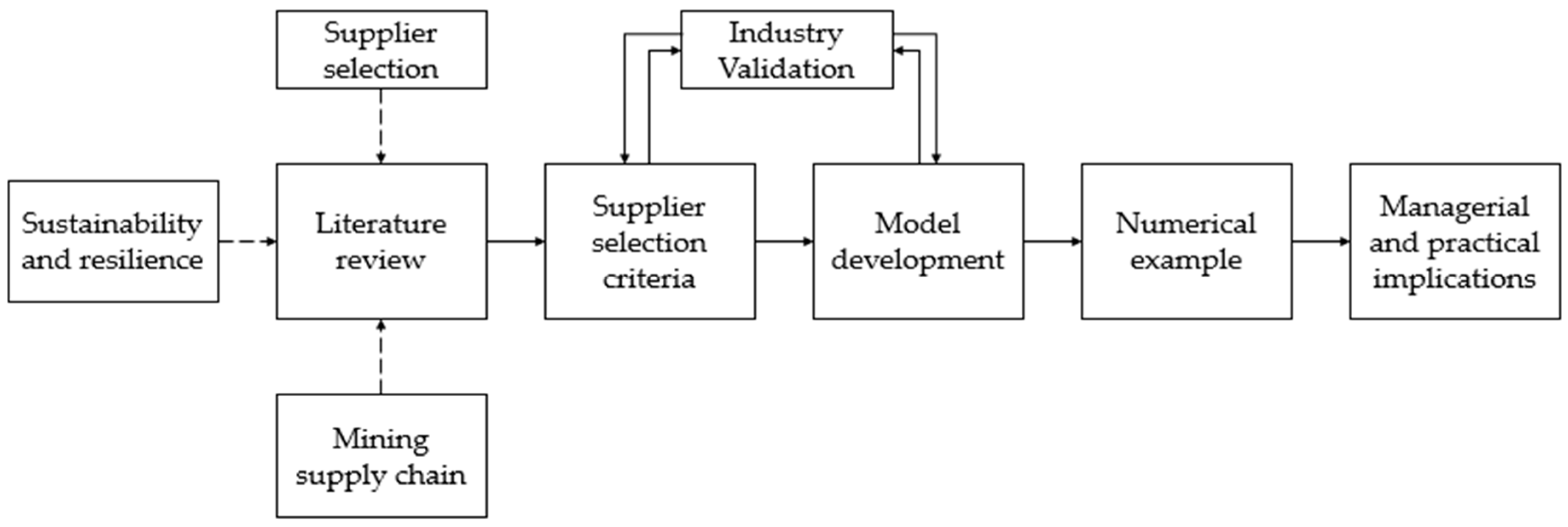

The first step in this process was the identification of the practical problem, namely the need for a more comprehensive supplier selection mechanism in the mining industry that incorporates sustainability and resilience criteria. The theoretical problem was identified as the lack of models that through optimization identify the best suppliers, considering inventory, production, location, and transport decisions in an integrated manner. Furthermore, decision making will not only consider economic criteria but also aspects of sustainability and resilience of the supply chain. Following the identification of these problems, the next phase was the development of a construction, in this case, a mathematical model. The model was designed to evaluate suppliers based on a range of criteria, including cost, environmental impact, social responsibility, and resilience to potential disruptions. The construction of the model involved the use of various mathematical programming techniques and was guided by the principles of multi-criteria decision making. To ensure the model’s validity and applicability in the mining industry, it was essential to involve industry key actors in the validation process. The followed methodology is found in Figure 1.

Figure 1.

Research methodology.

The methods employed in this study allowed for the development of a practical, industry-validated mathematical model for supplier selection in the mining industry. A concise outline of the research steps is presented below.

The first step entailed conducting a literature review, which was performed using the primary databases Scopus and Web of Science. This phase involved a systematic examination of articles pertaining to the concepts of resilience, sustainability, mining, and supplier selection. As a result, 38 articles were obtained, of which those that incorporated sustainability and/or resilience factors in the supplier selection criteria were selected. Finally, 12 articles were selected as reference models, leaving out repetitive articles, conference presentations, articles outside the scope of the research, and articles with access restrictions. In addition, the literature associated with SCM in the mining industry was reviewed under aspects of sustainability and resilience as well as the literature related to supplier selection models.

Subsequently, both the definition of the supplier selection criteria and the construction of the model were developed based on validation by supplier companies in the mining industry. A series of interviews were conducted with industry experts, including supply chain managers, sustainability officers, and procurement specialists. These sessions served to gather data on the practical realities of supplier selection in the mining industry and to refine and adjust the model based on this feedback.

Numerical examples were used to apply the model, based on instances of different sizes (small, medium, large), and approximate values for the parameters were derived from information obtained from the companies.

Finally, upon obtaining computational results, the managerial insights and practical implications of the model were defined and validated.

3. Literature Review

To identify the literature according to the problem addressed, a three-stage search was carried out with different search criteria. First, supply chain quantitative models for the mining industry were identified, then supplier selection models were studied in depth, and finally, the search was narrowed down to supplier selection optimization models in the mining industry.

3.1. Mining Supply Chain Models Considering Sustainability and Resilience Aspects

Regarding studies that aim to build quantitative models to design supply chains in mining industry, there are very few articles that address this problem. In this sense, the multi-objective mathematical programming (MP) models that address this problem are relevant. Here, Canales-Bustos et al. [5] proposed a multi-objective optimization model for the design of an effective decarbonized supply chain that considers decisions about the optimal localization of plants and the assignment of flows. Attari and Torkayesh [6] developed a multi-objective mixed integer programming (MIP) model in order to minimize the transportation costs, shortage costs, purchase costs, production costs, and CO2 emissions of vehicles. Soleimani [7] built a mathematical optimization approach including three aspects of sustainability considering fixed-charged transportation in travertine supply chain. Also, a resilient sustainable closed-loop supply chain (CLSC) for copper industry was proposed [8]. Becerra et al. [9] provided a multi-objective mixed integer nonlinear programming (MO-MINLP) model to incorporate the aspects of sustainability into a location, inventory, and transport optimization problem. Borji et al. [10] developed an MP model to optimize the sustainability of production and logistics operations in an iron supply chain. Valderrama et al. [11] proposed an MILP model that considers the location of capacitated facilities in the SC, addressing specific mining problems related to the ore grade and the customer demand satisfaction in terms of quality and quantity. Other authors have incorporated uncertainty in their proposals, e.g., Fattahi et al. [12] proposed a multi-stage stochastic program for the integrated strategic and tactical planning in mining SCs, including multiple mining sites. Furthermore, Gonela [13] presented a model that integrates various carbon emission schemes and considers uncertainties in coal mining, biomass yield, and electricity conversion rates to optimize the hybrid electricity supply chain.

3.2. Supplier Selection Problem

The selection of suitable suppliers is a critical decision for organizations, as it directly impacts the quality, cost, and timely delivery of goods and services. Supplier selection is a complex problem where decision makers must consider various factors, both qualitative and quantitative, to identify the most suitable supplier [14]. This type of problem is of strategic nature and is mostly conducted as an optimization problem [15].

In this sense, the literature reviewed in this topic fluctuates between mathematical programming and multi-criteria decision making (MCDM) models. The most widely used modeling approach is mathematical programming. Ng [16] proposed a weighted linear model for the supplier selection problem with multiple criteria. Basnet and Weintraub [17] proposed a mixed integer programming (MIP) model that incorporates explicit recognition of the number of suppliers as an objective and solved it through a genetic algorithm. Guu et al. [18] developed a multi-objective optimization model through a portfolio approach that incorporates the benefits of supplier diversification arising from the management of trade-offs between price, quality, and delivery. Kuo et al. [19] modeled the route planning of the carbon dioxide emission inventory compilation based in the vehicle routing problem (VRP). Furthermore, several authors have considered uncertainty through stochastic models. Zhou et al. [20] proposed a stochastic dynamic program (SDP) integrating an order allocation problem with the assumption that the unsatisfied demand is fully reordered. Li and Zabinsky [21] proposed a two-stage stochastic programming (SP) model and a chance-constrained programming (CCP) model to determine an optimal set of suppliers and optimal order quantities. Fu et al. [22] built a robust optimization model to determine an optimal supplier selection and allocation scheme while better utilizing all suppliers’ capacities. Nguyen and Chen [23] proposed a two-stage SP model that involves decisions for the supplier selection and decisions for planning transportation, inventory, and production operations.

Moreover, many of the studies consider hybrid models. Firouz et al. [24] faced a multi-sourcing, supplier selection, and inventory problem with a heuristic algorithm powered with simulation. Also, papers were identified that combine MP models with MCDM models, specifically with Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) [25], fuzzy TOPSIS [26], and BSW-MARCOS [27] approaches. Kabadayi and Dehghanimohammadabadi [28] proposed a threefold integrated framework consisting of optimization, TOPSIS, and discrete-event simulation scheme.

On other hand, authors have used purely MCDM techniques such as AHP to distinguish the important supplier selection criteria but also to evaluate the most efficient supplier for sustainability in supply chain [29]. Additionally, a two-step hybrid MCDM solution method was proposed by Ada [30], where firstly, a set of criteria for supplier selection process was analyzed and built on Fuzzy Analytic Network Process (FANP), and the second step of the analysis was to design a model with multiple objectives for selection process of supplier using fuzzy VIKOR. On the other hand, artificial intelligence models are the least used. Of the studies reviewed, Golmohammadi et al. [31] used a neural network model to update provider scores. Islam et al. [32] developed a machine learning model to forecast demand and integrate it with supplier selection and order allocation decisions.

3.3. Sustainable and Resilient Supplier Selection Models in Mining Industry

From the literature review of supplier selection models and mining supply chains, a more specific review of supplier selection models in the mining industry that considers sustainability and resilience aspects was conducted. Thus, from the reviewed studies, it was observed that MCDM models are the most frequently used, such as Analytic Hierarchy Process (AHP) [33,34], fuzzy AHP [35], TOPSIS [36], and DEMATEL [37] approaches. A SMILP model was also developed [38]. In addition, hybrid models are very relevant; for example, there are studies that combine different MCDM approaches, such as AHP-TOPSIS [12], fuzzy AHP–fuzzy DEMATEL–TOPSIS [39], and fuzzy BWM-MULTIMOORA [40]. On the other hand, studies combining MP with MCDM, such as AHP-MINLP [41], or complementing MP models with discrete event simulation models [42] are less frequent.

Few studies incorporate the integration of other issues with supplier selection. Saputro et al. [42] integrated sourcing, inventory, and transportation decisions. Fattahi et al. [38] broadened the decision scope by incorporating inventory, transportation, and production issues. On the other hand, Ortiz-Barrios et al. [39] developed a model integrating transportation and production decisions, while Sarabi et al. [40] only incorporated the transportation decision.

Regarding the classic criteria for supplier selection, the most relevant among the selected studies is the quality of the product or service [33,36,39,40,41,42]. Similarly important, the criteria related to delivery times or service times are relevant in the research reviewed [33,36,39,40,42]. To a lesser extent, the technological capacity [35,40,41] and R&D [33,34,39] capacity of the supplier are considered. Other criteria of a subjective nature were identified, such as the company’s reputation [34,35], the level of compliance, and the previous relationship with the supplier [33].

According to the relevant literature search criteria, sustainability and resilience are an exclusion criterion for the development of our proposal. In this sense, it was identified that the economic aspect of sustainability is the most relevant, and it is mainly related to the price of the goods or service offered by the supplier. The environmental dimension is incorporated to a lesser extent and in different ways. Sivakumar et al. [34] considered the existence of environmental training for workers and environmental control activities as selection criteria. Ortiz-Barrios et al. [40] considered broader environmental aspects such as product design, manufacturing, and logistics from a green perspective. Environmental sustainability was also incorporated by measuring suppliers’ CO2 emissions [37]. Only two articles considered all three aspects of sustainability. Ramirez et al. [33] considered the company’s commitment to the environment and communities as criteria. On the other hand, Azimifard et al. [43], in environmental terms, considered water consumption, CO2 emissions, and energy consumption; in the social aspect, this incorporates the jobs generated. Resilience of SC is another key element in our research, Aldrighetti et al. [44] argued that the principles of recovery, robustness, and flexibility should be considered simultaneously to achieve efficient solutions against the risk of disruption. Of the studies reviewed, the flexibility principle is the most studied [14,34,38,41]; it aims to reduce the effects and consequences of disruptions by preparing more adaptable assets. Ortiz-Barrios et al. [39] considered the capacity to be flexible and recovery; this aims to adapt the system and its operating plan according to availability in order to successively restore the lost capacity as soon as possible. The robustness of the SC is associated with creating redundancies (i.e., new sites) and increasing the capacity of the network to protect against shortages. A summary of the literature review is presented in Table 1.

Table 1.

Review of the articles about sustainable and resilience SS model for mining industry.

Finally, the literature review revealed a lack of studies that integrate sustainability and resilience aspects in supplier selection models for the mining industry. While there are studies that address sustainability and resilience in the mining supply chain and supplier selection models, they often do not consider these aspects together. Furthermore, the literature review showed a preference for multi-criteria decision making (MCDM) models over mathematical programming (MP) models. However, hybrid models that combine MP and MCDM are also prevalent. Additionally, the review highlighted the importance of incorporating other issues such as sourcing, inventory, and transportation decisions in supplier selection models. Finally, the review identified the need for more research on the environmental and social aspects of sustainability in supplier selection as well as the principles of recovery, robustness, and flexibility in supply chain resilience.

4. Problem Statement

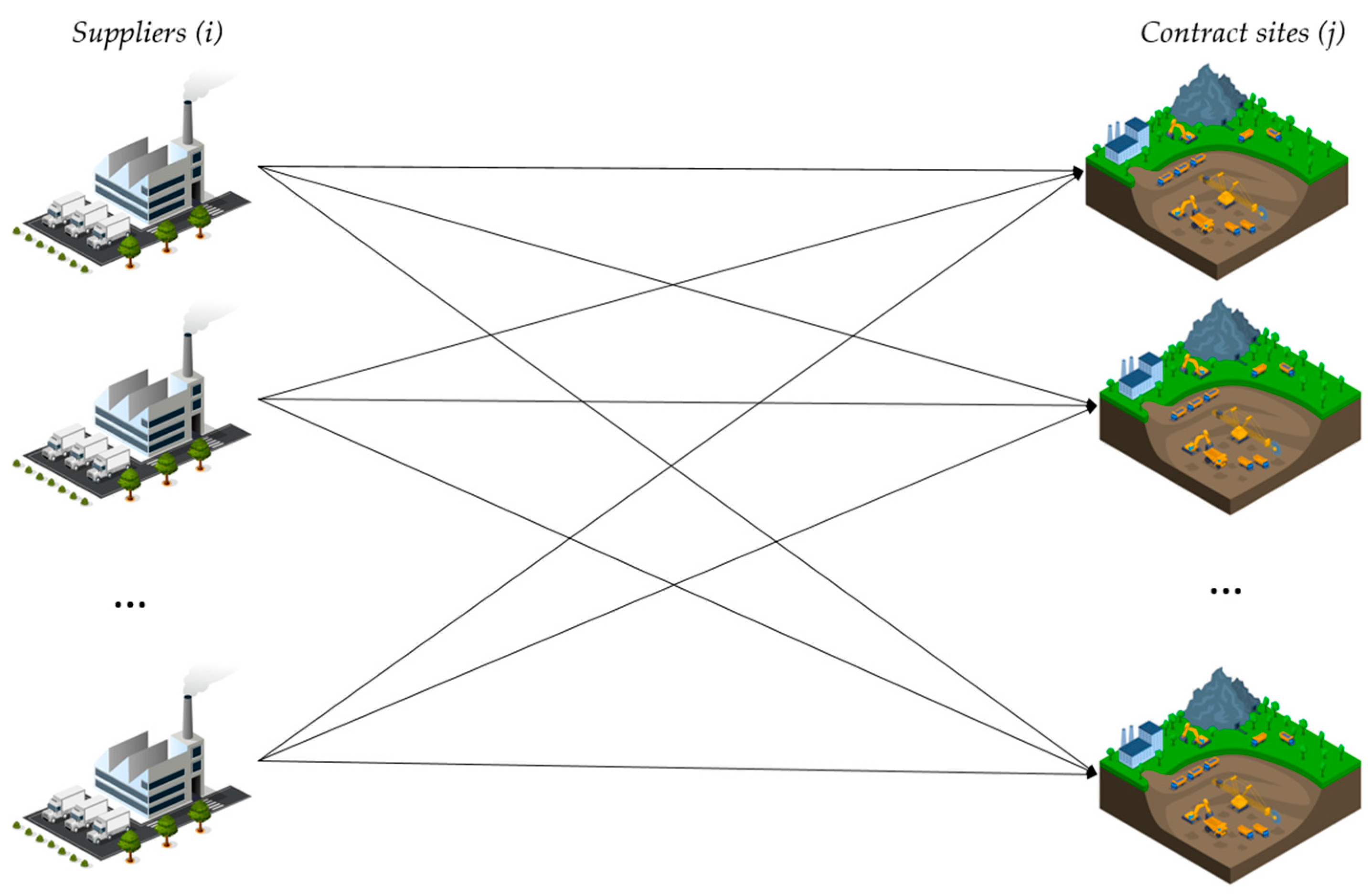

The problem under study is a supply chain management decision that concerns the selection of suppliers in the mining industry. Specifically, it focuses on the service providers of mining companies and their process of selecting suppliers of consumables or raw materials. In addition to the classic supplier selection criteria, sustainability and resilience aspects are incorporated. Another intention is to integrate inventory, location, and transport issues. This considers a set of potential suppliers that supply inputs to the different sites where the company has service contracts with the mining companies. Suppliers are selected, orders are assigned according to the needs of the contract, and these are transported to the sites where the service will be delivered. The material that arrives is stored until it is used. The costs of maintaining the inventory and the cost of shortages will be considered in the event of not being able to provide the service. Figure 2 depicts the supply chain between suppliers and contract sites. In this sense, the dyadic supply chain structure does not consider an intermediary distributor between suppliers and service delivery sites.

Figure 2.

Supply chain dyadic structure for supplier–site contract problem.

One of the criteria used to select suppliers is the quality of goods and delivery time, measured as a level of compliance on a scale of 0 to 1. Another criterion is the existence of resilience on the part of the supplier, where flexibility, resilience, and robustness are considered [43]. Sustainability is considered by incorporating the economic dimension through the costs associated with each supplier, the environmental dimension through carbon emissions, and the social aspect through jobs generated in the region where contracts are performed. The criteria used were validated through a questionnaire to managers, CEOs, procurement, environmental and quality professionals. Table 2 presents the model notations; indexes, parameters and variables.

Table 2.

Notation.

4.1. Assumptions and Model Description

- A supplier can serve more than one contract;

- The value of the carbon credit is considered to value carbon emissions;

- Capacity expansion is considered for suppliers that have this resilience capability;

- Shortages are considered as lost sales.

Mathematical model

subject to

The proposed model corresponds to an MO-MINLP model, with two objective functions. The first Function (1) minimize the total costs of supplier selection. The first term corresponds to the fixed cost of selecting a supplier. The second term refers to the cost of purchasing the products. The third term consists of the cost of holding inventory. The fourth term represents the cost of shortages. The last term values the CO2 emissions generated by the supplier and by the transport of the products.

The second objective Function (2) maximizes other factors that are measured in relative terms. This function considers the resilience factor, quality measured as customer satisfaction, standardized lead time, and the percentage of the supplier’s workers who are from the geographical area where the contract is located.

Constraint (3) ensures that the products transported plus the shortage is greater than the demand for the product at each contract site. Constraint (4) guarantees that the quantity of products produced by each supplier does not exceed their capacity and additional capacity if they have any. Constraint (5) ensures that products produced and shipped are shipped to an allocated contract site. Constraint (6) calculates the remaining inventory between the product shipped to the contract site and the demand for that product. Constraint (7) ensures that the additional capacity used by the supplier is less than or equal to the extra capacity available. Constraints (8) and (9) define the domain of the decision variables.

4.2. Linearization of Objective Function

In order to increase computational efficiency, the MOMINLP is converted into an MO-MILP model by the following transformations. In the second objective function, specifically for the term related to employment, we find a non-linear term from the multiplication of the binary variables. According to Asghari et al. [45], auxiliary binary variables are proposed to linearize these terms. In this sense, the model is modified as follows:

where ijij is the auxiliary binary variable, to be restricted as follows:

4.3. Multi-Objective Solution

For our problem, we apply the lexicographic method [46,47,48]. As in Becerra et al. [8], the objective functions are ordered according to their importance or significance. Then each subproblem in that order is sequentially solved by considering only one objective at a time. The optimal value obtained in the first subproblem, is used as a reference as a constraint of the next subproblem.

5. Results and Discussions

To validate the model, numerical examples were applied considering three sizes, i.e., small, medium, and large, according to the number of suppliers, contracts, and products. To validate the model, random values for the parameters were generated so that no matter the size of the problem, the model will find an optimal value. The unit of currency used is the U.S. dollar (USD). The problem sizes for each index are presented in Table 3.

Table 3.

Problem Size.

Computational experimentation was carried out on a personal computer with 16 GB RAM and a 11th Gen Intel(R) Core(TM) i7-11800H processor, 2.30 GHz frequency, and a Windows 11 Home operating system. The mathematical model was modeled using Pyomo in the Python language and solved by solver Gurobi 11. Table 4 presents the computational results obtained.

Table 4.

Objective functions results and runtime by instance.

As expected, the total costs and factors of objective function 2 increased as the size of the model increased. However, computational times remained low despite the larger size.

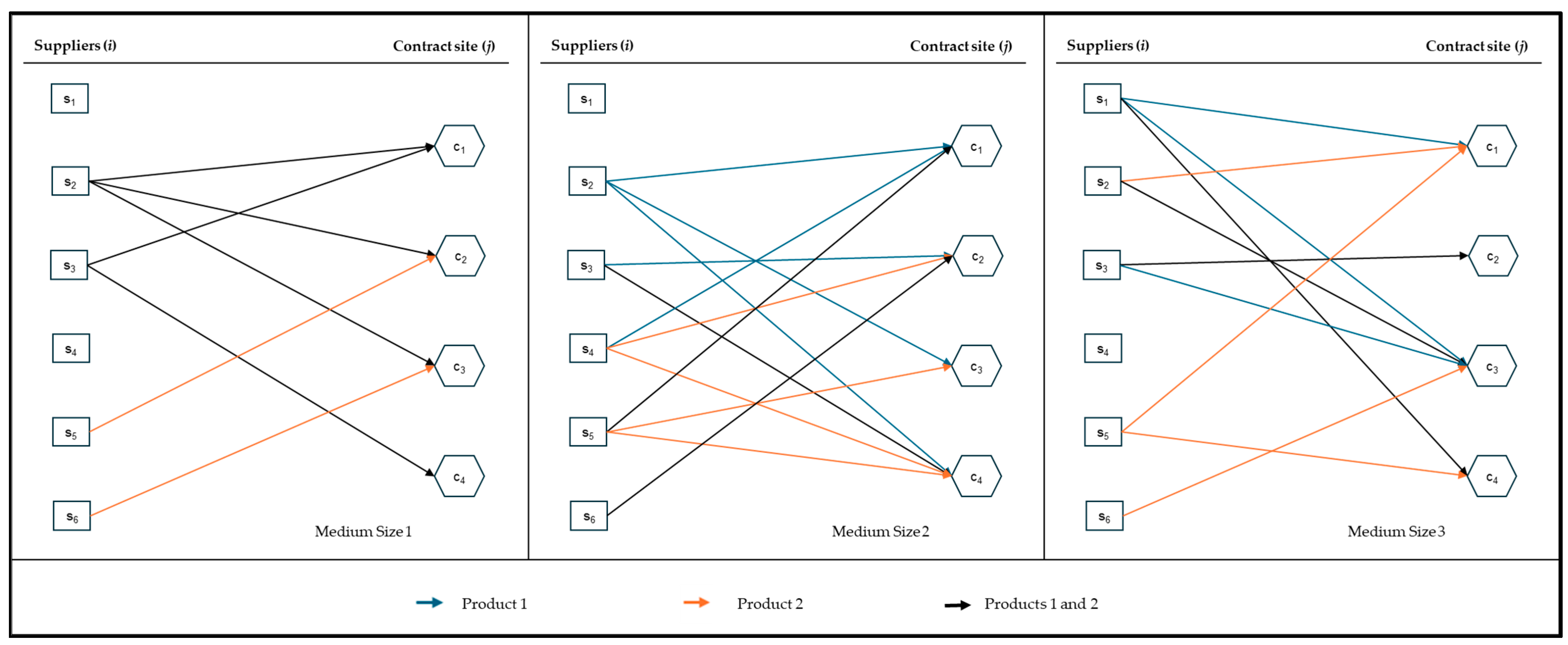

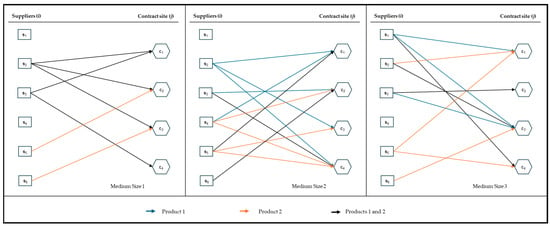

To illustrate, medium-sized instances were considered. Figure 3 shows the selected suppliers and the allocation of the products to the different contract sites.

Figure 3.

Selection and allocation of suppliers (i) to contract sites (j) for each product in medium-size instances.

From the results found, along with minimizing costs and emissions, we sought to maximize factors that incorporate the resilience capabilities of suppliers. Table 5 presents the suppliers selected in each instance, the resilience factor associated with each one, the emissions generated by each supplier and each product produced, and the social impact measured as the portion of workers assigned to each contract that belong to the locality where the service is carried out.

Table 5.

Resilience and sustainability factors of selected suppliers.

The results show that in some instances all suppliers are selected, but in others, only those that are necessary to meet the demand and that reduce the overall emissions and costs of the system are selected. Likewise, the allocation of products to contracts is made according to the suppliers’ capacities and the needs of the contracts, considering minimizing transport costs, suppliers’ fixed costs, and the emissions generated both by product transportation and by their production.

Studies on sustainability and resilience in supply chain management represent a growing field. Considering the resilience capacities described by Aldrighetti et al. [44] and as mentioned in the literature review, there are few studies that incorporate any of these capabilities in their studies. Furthermore, these studies are limited to flexibility [34,38,39,41,42] and recovery [39] capabilities. Compared to the present study, most previous studies did not incorporate three dimensions of sustainability in their decisions [41,43]. In this sense, previous studies incorporate the environmental factor in a more generalized way, but there is a difficulty in incorporating the social dimension [5].

The generalizability of these findings is limited by data access. The results allow us to validate the usability of the model in different instances or problem sizes but do not allow us to provide a solution to a company or a set of companies without compromising the confidentiality of the information.

To the best of our knowledge, this is a novel model that integrates considerations of sustainability aspects and resilience capabilities into decisions regarding location, production, inventory, and transportation decision in a supplier selection model into supply chain management context. The computational results indicate that the model can be solved within reasonable timeframes, even with varying dataset sizes. As anticipated, the outcomes display logical behavior; specifically, larger dataset sizes lead to increased costs and more significant impacts.

6. Conclusions

Focusing on the mining industry, cost reduction as a strategy is relevant, as companies maximize their profit at a commodity price set by the market. Therefore, a model that allows the selection of efficient suppliers, which also considers elements of sustainability and resilience, is a strong contribution. In these sense, this research developed a supplier selection model considering sustainability factors such as CO2 emissions and local employment development and resilience factors such as robustness, recovery, and flexibility.

The main results of our proposal are oriented as follows:

- We sought to provide a novel MO-MINLP model for selecting suppliers in the mining industry, considering sustainability and resilience factors;

- The validation of the model presented to the companies made it possible to identify the relevant criteria to be considered in the selection of suppliers, discarding some that were considered relevant in the literature;

- We validated the model using datasets of three different sizes (small, medium, and large) to obtain an expected behavior of the total costs and sustainability and resilience factors, which increase as the size of the problem grows. The most efficient suppliers were selected and assigned contracts to meet demand.

The implications for logistics and the procurement of professionals and managers are related to providing an analytical decision tool to select suppliers considering sustainability aspects and resilience capabilities. Our proposal can help supply managers to address sustainability challenges and also be able to face uncertainty in the supply of inputs required for an efficient operation. When using this model, decision makers consider that costs are still the most important criteria when ranking the criteria. However, elements of social sustainability and resilience are incorporated into the decision that could increase costs. As a multi-objective model, the outcomes are within the Pareto frontier, where the weighting of each objective is given by the decision maker. Therefore, a universal method has not yet been established for selecting the optimal solution according to the different weights of the objective functions on the Pareto frontier.

The main limitation of the research is the access to real data; therefore, generic and approximate industry data were used. Companies within the mining sector develop their strategy based on minimizing costs, and these data are highly strategic and therefore difficult to access. In this paper, the lexicographic method was used, emphasizing costs, so resilience factors did not have an impact on the decision to select a supplier; future research could consider a different method, e.g., normalizing and weighting each objective. Finally, using other modeling approaches to solve the supplier selection problem, considering stochastic optimization or other solution methods such as heuristics or metaheuristics, is a future guideline for research.

Author Contributions

Conceptualization, P.B. and J.D.; methodology, P.B.; software, P.B.; validation, P.B. and J.D.; formal analysis, P.B.; investigation, P.B.; resources, P.B. and J.D.; data curation, P.B. and J.D.; writing—original draft preparation, P.B.; writing—review and editing, P.B.; visualization, P.B. and J.D.; supervision, P.B.; project administration, P.B.; funding acquisition, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

Acknowledgement of the DIUDA Regular 88231R17 project of the Universidad de Atacama for funding this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data presented in the study are openly available in Zenodo at https://doi.org/10.5281/zenodo.14500518.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pal, O.; Kumar Gupta, A.; Garg, R.K. Supplier Selection Criteria and Methods in Supply Chains: A Review. Int. J. Econ. Manag. Eng. 2013, 7, 2667–2673. [Google Scholar] [CrossRef]

- Wang, C.-N.; Tsai, H.-T.; Ho, T.-P.; Nguyen, V.-T.; Huang, Y.-F. Multi-Criteria Decision Making (MCDM) Model for Supplier Evaluation and Selection for Oil Production Projects in Vietnam. Processes 2020, 8, 134. [Google Scholar] [CrossRef]

- Singh, G.; Pandey, A. Environmental Sustainability Integrated Supplier Selection in Electric Vehicle Supply Chains: A Grey Relational Analysis Approach. Env. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D.; van Aken, J.E. Developing Design Propositions through Research Synthesis. Organ. Stud. 2008, 29, 393–413. [Google Scholar] [CrossRef]

- Canales-Bustos, L.; Santibañez-González, E.; Candia-Véjar, A. A Multi-Objective Optimization Model for the Design of an Effective Decarbonized Supply Chain in Mining. Int. J. Prod. Econ. 2017, 193, 449–464. [Google Scholar] [CrossRef]

- Attari, M.Y.N.; Torkayesh, A.E. Developing Benders Decomposition Algorithm for a Green Supply Chain Network of Mine Industry: Case of Iranian Mine Industry. Oper. Res. Perspect. 2018, 5, 371–382. [Google Scholar] [CrossRef]

- Soleimani, H. A New Sustainable Closed-Loop Supply Chain Model for Mining Industry Considering Fixed-Charged Transportation: A Case Study in a Travertine Quarry. Resour. Policy 2021, 74, 101230. [Google Scholar] [CrossRef]

- Akbari-Kasgari, M.; Khademi-Zare, H.; Fakhrzad, M.B.; Hajiaghaei-Keshteli, M.; Honarvar, M. Designing a Resilient and Sustainable Closed-Loop Supply Chain Network in Copper Industry. Clean. Technol. Env. Policy 2022, 24, 1553–1580. [Google Scholar] [CrossRef]

- Becerra, P.; Mula, J.; Sanchis, R. Optimising Location, Inventory and Transportation in a Sustainable Closed-Loop Supply Chain. Int. J. Prod. Res. 2023, 62, 1609–1632. [Google Scholar] [CrossRef]

- Borji, M.K.; Sayadi, A.R.; Nikbakhsh, E. A Novel Sustainable Multi-Objective Optimization Model for Steel Supply Chain Design Considering Technical and Managerial Issues: A Case Study. J. Min. Environ. 2023, 14, 295–319. [Google Scholar] [CrossRef]

- Valderrama, C.V.; Santibanez-González, E.; Pimentel, B.; Candia-Véjar, A.; Canales-Bustos, L. Designing an Environmental Supply Chain Network in the Mining Industry to Reduce Carbon Emissions. J. Clean. Prod. 2020, 254, 119688. [Google Scholar] [CrossRef]

- Fattahi, M.; Mosadegh, H.; Hasani, A. Sustainable Planning in Mining Supply Chains with Renewable Energy Integration: A Real-Life Case Study. Resour. Policy 2021, 74, 101296. [Google Scholar] [CrossRef]

- Gonela, V. Stochastic Optimization of Hybrid Electricity Supply Chain Considering Carbon Emission Schemes. Sustain. Prod. Consum. 2018, 14, 136–151. [Google Scholar] [CrossRef]

- Saputro, T.E.; Figueira, G.; Almada-Lobo, B. A Comprehensive Framework and Literature Review of Supplier Selection under Different Purchasing Strategies. Comput. Ind. Eng. 2022, 167, 108010. [Google Scholar] [CrossRef]

- Huang, S.H.; Keskar, H. Comprehensive and Configurable Metrics for Supplier Selection. Int. J. Prod. Econ. 2007, 105, 510–523. [Google Scholar] [CrossRef]

- Ng, W.L. An Efficient and Simple Model for Multiple Criteria Supplier Selection Problem. Eur. J. Oper. Res. 2008, 186, 1059–1067. [Google Scholar] [CrossRef]

- Basnet, C.; Weintraub, A. A Genetic Algorithm for a Bicriteria Supplier Selection Problem. Int. Trans. Oper. Res. 2009, 16, 173–187. [Google Scholar] [CrossRef]

- Guu, S.M.; Mehlawat, M.; Kumar, S. A Multiobjective Optimization Framework for Optimal Selection of Supplier Portfolio. Optimization 2014, 63, 1491–1512. [Google Scholar] [CrossRef]

- Kuo, T.C.; Chen, G.Y.H.; Wang, M.L.; Ho, M.W. Carbon Footprint Inventory Route Planning and Selection of Hot Spot Suppliers. Int. J. Prod. Econ. 2014, 150, 125–139. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, L.; Zhao, X.; Jiang, J. A Supplier Selection and Order Allocation Problem with Stochastic Demands. Proc. Int. J. Syst. Sci. 2011, 42, 1323–1338. [Google Scholar] [CrossRef]

- Li, L.; Zabinsky, Z.B. Incorporating Uncertainty into a Supplier Selection Problem. Int. J. Prod. Econ. 2011, 134, 344–356. [Google Scholar] [CrossRef]

- Fu, Y.; Lai, K.K.; Liang, L. A Robust Optimisation Approach to the Problem of Supplier Selection and Allocation in Outsourcing. Int. J. Syst. Sci. 2016, 47, 913–918. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Chen, H. Supplier Selection and Operation Planning in Biomass Supply Chains with Supply Uncertainty. Comput. Chem. Eng. 2018, 118, 103–117. [Google Scholar] [CrossRef]

- Firouz, M.; Keskin, B.B.; Melouk, S.H. An Integrated Supplier Selection and Inventory Problem with Multi-Sourcing and Lateral Transshipments. Omega 2017, 70, 77–93. [Google Scholar] [CrossRef]

- Hamdan, S.; Cheaitou, A. Dynamic Green Supplier Selection and Order Allocation with Quantity Discounts and Varying Supplier Availability. Comput. Ind. Eng. 2017, 110, 573–589. [Google Scholar] [CrossRef]

- Yadavalli, V.S.; Darbari, J.D.; Bhayana, N.; Jha, P.C.; Agarwal, V. An Integrated Optimization Model for Selection of Sustainable Suppliers Based on Customers’ Expectations. Oper. Res. Perspect. 2019, 6, 100113. [Google Scholar] [CrossRef]

- Aditi; Kannan, D.; Darbari, J.D.; Jha, P.C. Sustainable Supplier Selection Model with a Trade-off between Supplier Development and Supplier Switching. Ann. Oper. Res. 2023, 331, 351–392. [Google Scholar] [CrossRef]

- Kabadayi, N.; Dehghanimohammadabadi, M. Multi-Objective Supplier Selection Process: A Simulation–Optimization Framework Integrated with MCDM. Ann. Oper. Res. 2022, 319, 1607–1629. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An Integrated Framework for Sustainable Supplier Selection and Evaluation in Supply Chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Ada, N. Sustainable Supplier Selection in Agri-Food Supply Chain Management. Int. J. Math. Eng. Manag. Sci. 2022, 7, 115–130. [Google Scholar] [CrossRef]

- Golmohammadi, D.; Creese, R.C.; Valian, H.; Kolassa, J. Supplier Selection Based on a Neural Network Model Using Genetic Algorithm. IEEE Trans. Neural Netw. 2009, 20, 1504–1519. [Google Scholar] [CrossRef] [PubMed]

- Islam, S.; Amin, S.H.; Wardley, L.J. Machine Learning and Optimization Models for Supplier Selection and Order Allocation Planning. Int. J. Prod. Econ. 2021, 242, 108315. [Google Scholar] [CrossRef]

- Ramírez Olivares, E.; Castillo-Vergara, M. Analytical Hierarchical Process to Establish the Criteria for Choosing Explosives Suppliers in Small and Medium Mining Companies. Eng 2023, 4, 2407–2420. [Google Scholar] [CrossRef]

- Sivakumar, R.; Kannan, D.; Murugesan, P. Green Vendor Evaluation and Selection Using AHP and Taguchi Loss Functions in Production Outsourcing in Mining Industry. Resour. Policy 2015, 46, 64–75. [Google Scholar] [CrossRef]

- Hu, X.; Sun, B.; Chen, X. Double Quantitative Fuzzy Rough Set-Based Improved AHP Method and Application to Supplier Selection Decision Making. Int. J. Mach. Learn. Cybern. 2020, 11, 153–167. [Google Scholar] [CrossRef]

- Bouhedja, S.; Boukhaled, A.; Bouhedja, A.; Benselhoub, A. Use of the Topsis Technique to Choose the Best Supplier of Quarry Natural Aggregate. Min. Miner. Depos. 2020, 14, 11–18. [Google Scholar] [CrossRef]

- Azimifard, A.; Moosavirad, S.H.; Ariafar, S. Designing Steel Supply Chain and Assessing the Embedded CO2 Emission Based on the Input-Output Table by Using DEMATEL Method. Manag. Decis. 2018, 56, 757–776. [Google Scholar] [CrossRef]

- Fattahi, M. Resilient Procurement Planning for Supply Chains: A Case Study for Sourcing a Critical Mineral Material. Resour. Policy 2021, 74, 101093. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; Cabarcas-Reyes, J.; Ishizaka, A.; Barbati, M.; Jaramillo-Rueda, N.; de Jesús Carrascal-Zambrano, G. A Hybrid Fuzzy Multi-Criteria Decision Making Model for Selecting a Sustainable Supplier of Forklift Filters: A Case Study from the Mining Industry. Ann. Oper. Res. 2021, 307, 443–481. [Google Scholar] [CrossRef]

- Sarabi, E.P.; Darestani, S.A. Developing a Decision Support System for Logistics Service Provider Selection Employing Fuzzy MULTIMOORA & BWM in Mining Equipment Manufacturing. Appl. Soft Comput. 2021, 98, 106849. [Google Scholar] [CrossRef]

- Ahmad, M.T.; Mondal, S. Dynamic Supplier Selection Approach for Mining Equipment Company. J. Model. Manag. 2018, 14, 77–105. [Google Scholar] [CrossRef]

- Saputro, T.E.; Figueira, G.; Almada-Lobo, B. Integrating Supplier Selection with Inventory Management under Supply Disruptions. Int. J. Prod. Res. 2021, 59, 3304–3322. [Google Scholar] [CrossRef]

- Azimifard, A.; Moosavirad, S.H.; Ariafar, S. Selecting Sustainable Supplier Countries for Iran’s Steel Industry at Three Levels by Using AHP and TOPSIS Methods. Resour. Policy 2018, 57, 30–44. [Google Scholar] [CrossRef]

- Aldrighetti, R.; Calzavara, M.; Zennaro, I.; Battini, D.; Ivanov, D. A Methodological Framework for Efficient and Resilient Supply Network Design. IFAC-PapersOnLine 2022, 55, 2840–2845. [Google Scholar] [CrossRef]

- Asghari, M.; Fathollahi-Fard, A.M.; Mirzapour Al-E-Hashem, S.M.J.; Dulebenets, M.A. Transformation and Linearization Techniques in Optimization: A State-of-the-Art Survey. Mathematics 2022, 10, 283. [Google Scholar] [CrossRef]

- Arora, J.S. Multi-objective Optimum Design Concepts and Methods. In Introduction to Optimum Design, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 771–794. [Google Scholar] [CrossRef]

- Gunantara, N. A review of multi-objective optimization: Methods and its applications. Cogent Eng. 2018, 5, 1502242. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 2004, 26, 369–395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).