An Empirical Study of the Quality Governance Level of China’s Civil Aircraft Industry

Abstract

1. Introduction

- (1)

- It contributes to establishing a quality governance evaluation model for the CAIC for the first time, including an evaluation index system and the weights of each index.

- (2)

- It conducts a large-scale enterprise survey and empirical evaluation of the quality governance level of the CAIC, as well as qualitative and quantitative assessment.

- (3)

- It identifies the critical factors and bottleneck indices that restrict the quality governance level of the CAIC.

2. Literature Review

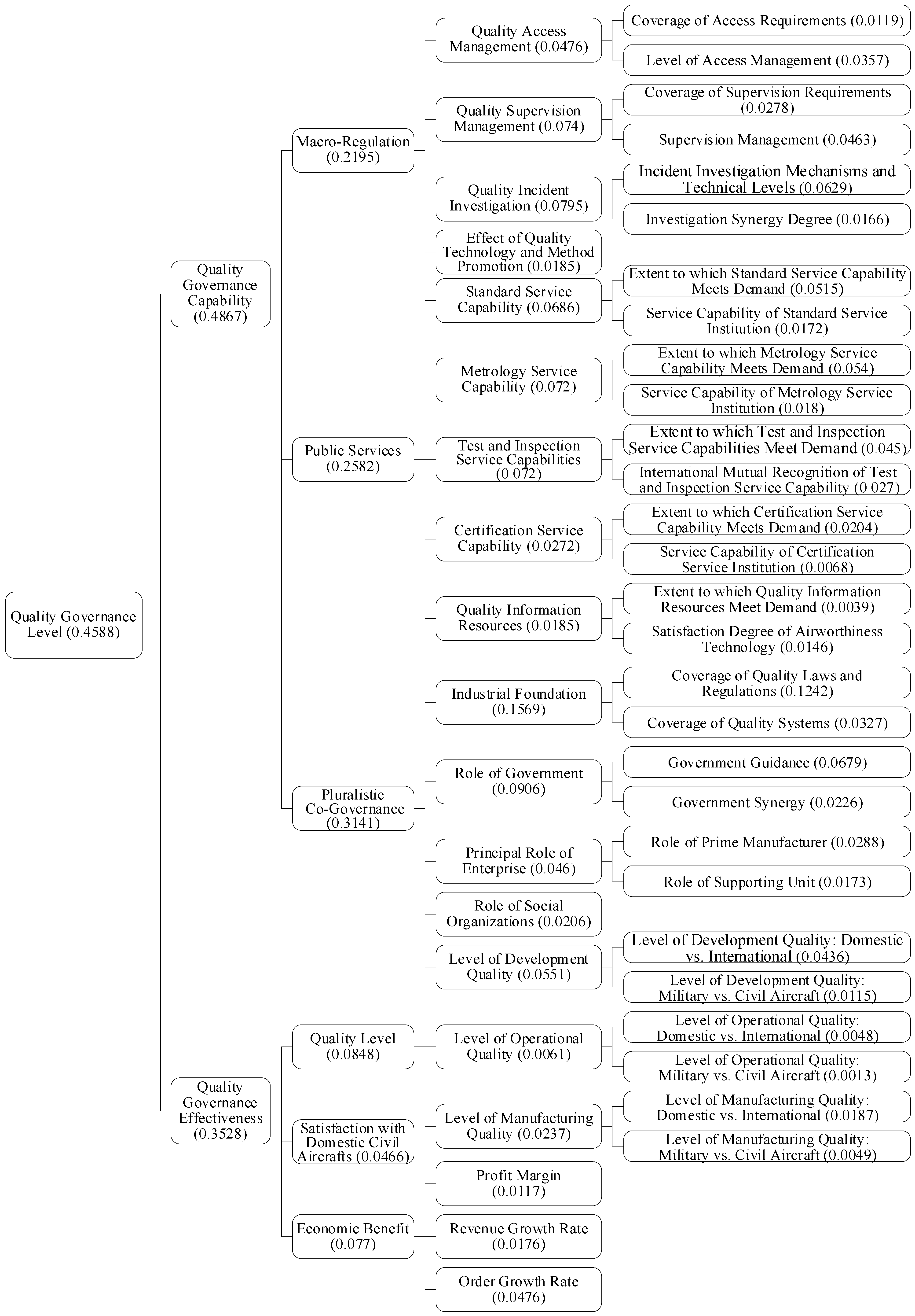

3. Construction of an Evaluation Index System

4. Setting Index Weights

- (1)

- Coverage of Quality Laws and Regulations;

- (2)

- Government Guidance;

- (3)

- Incident Investigation Mechanisms and Technical Levels;

- (4)

- Extent to which Metrology Service Capability Meets Demand;

- (5)

- Extent to which Standard Service Capability Meets Demand;

- (6)

- Order Growth Rate;

- (7)

- Satisfaction with Domestic Civil Aircrafts;

- (8)

- Supervision Management;

- (9)

- Extent to which Test and Inspection Service Capabilities Meet Demand;

- (10)

- Level of Development Quality: Domestic vs. International;

- (11)

- Level of Access Management.

5. Empirical Evaluation of the Quality Governance Level

5.1. Data Sources

5.2. Index Quantification and Normalization

5.3. Evaluation Results and Analysis

- (1)

- Coverage of Quality Laws and Regulations;

- (2)

- Government Guidance;

- (3)

- Incident Investigation Mechanisms and Technical Levels;

- (4)

- Extent to which Standard Service Capability Meets Demand;

- (5)

- Order Growth Rate;

- (6)

- Satisfaction with Domestic Civil Aircrafts;

- (7)

- Level of Development Quality: Domestic vs. International.

6. Conclusions

- (1)

- Government departments should formulate targeted policies and measures to address the identified shortcomings, such as improving the relevant regulatory framework, strengthening the government’s macro-guidance, and optimizing the incident investigation mechanism.

- (2)

- The industry or academic community should actively organize workshops or forums, inviting enterprises, research institutions, and other relevant parties to engage in in-depth discussion on the root causes of these shortcomings and develop corresponding strategies. They can also conduct targeted in-depth research and analysis, such as examining the gaps between standard service capabilities and actual needs, thus providing more comprehensive policy recommendations for decision-makers.

- (1)

- Expand the scope of the industry survey, and employ statistical methods to improve and optimize the evaluation index system at the quality governance level. In addition, improving the gathering and processing methods for evaluation indices’ data may make the empirical evaluation results more objective and reasonable.

- (2)

- Introduce a metric that comprehensively represents the quality governance level of the CAIC, widely recognized by the industry, and conduct longitudinal dynamic-analysis-based annual metrics.

- (3)

- Compare horizontally the quality governance levels of the civil aircraft industry in aviation manufacturing between China and developed countries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Primary Index | Secondary Index | Tertiary Index | Quaternary Index | Measurement | Quantification |

|---|---|---|---|---|---|

| Quality Governance Capability | Macro-Regulation | Quality Access Management | Coverage of Access Requirements | Compared to the US and Europe, the quality access requirements for the civil aircraft industry stipulated by Chinese laws and regulations are ( ). A. more comprehensive and stricter; B. generally consistent; C. relatively lenient; D. unclear. | 1~3 (A = 3, B = 2, C = 1) |

| Level of Access Management | The implementation of quality access requirements for the civil aircraft industry by Chinese regulatory authorities is ( ). A. very well; B. well; C. average; D. poor; E. very poor; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Quality Supervision Management | Coverage of Supervision Requirements | Compared to the US and Europe, the quality supervision requirements for the aircraft industry stipulated by Chinese laws and regulations are ( ). A. more comprehensive and stricter; B. generally consistent; C. relatively lenient; D. unclear. | 1~3 (A = 3, B = 2, C = 1) | ||

| Level of Supervision Management | The implementation of quality supervision requirements for the civil aircraft industry by Chinese regulatory authorities is ( ). A. very well; B. well; C. average; D. poor; E. very poor; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Quality Incident Investigation | Incident Investigation Mechanisms and Technical Levels | Compared to foreign countries, the quality incident investigation processes and technical means in China’s civil aircraft industry are ( ). A. more advanced; B. generally consistent; C. Relatively backward; D. Unclear. | 1~3 (A = 3, B = 2, C = 1) | ||

| Investigation Synergy Degree | The synergy degree among quality incident investigation departments in China’s civil aircraft industry is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Effect of Quality Technology and Method Promotion | ∕ | Compared to foreign countries, the promotion and application of quality technology and method in China’s civil aircraft industry is ( ). A. more effective; B. generally consistent; C. ineffective; D. unclear. | 1~3 (A = 3, B = 2, C = 1) | ||

| Public Services | Standard Service Capability | Extent to Which Standard Service Capability Meets Demand | The supporting role of existing standards for the development needs of the civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |

| Service Capability of Standard Service Institution | Your organization believes that the service level of domestic civil aircraft standard service institutions is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Metrology Service Capability | Extent to Which Metrology Service Capability Meets Demand | The supporting role of existing metrology standards for the development needs of the civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Service Capability of Metrology Service Institution | Your organization believes that the service level of domestic civil aircraft metrology service institutions is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Test and Inspection Service Capabilities | Extent to which Test and Inspection Service Capabilities Meet Demand | The supporting role of existing test and inspection capability for the development needs of the civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| International Mutual Recognition of Test and Inspection Service Capabilities | The international mutual recognition of China’s civil aircraft product test and inspection accounts for ( ). A. over 90%; B. 50–90%; C. 30–50%; D. less than 30%; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | |||

| Certification Service Capability | Extent to which Certification Service Capability Meets Demand | The supporting role of existing AS9100 certification service for the development needs of the civil aircraft industry ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Service Capability of Certification Service Institution | Compared to European and American certification institutions, the service of domestic civil aircraft industry certification institutions is ( ). A. better; B. generally consistent; C. relatively backward; D. unclear. | 1~3 (A = 3, B = 2, C = 1) | |||

| Quality Information Resources | Extent to which Quality Information Resources Meet Demand | The supporting role of existing quality and airworthiness information resources for the development needs of the civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Satisfaction Degree of Airworthiness Technology | The supporting role of existing airworthiness technology for the development needs of the civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Pluralistic Co-Governance | Industrial Foundation | Coverage of Quality Laws and Regulations | Your organization believes that the perfection degree of quality laws and regulations in China’s civil aircraft industry is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |

| Coverage of Quality Systems | Your organization believes that the perfection degree of quality governance mechanisms (policies, systems, etc.) in China’s civil aircraft industry is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Role of Government | Government Guidance | Your organization believes that the role of government departments in the quality governance of China’s civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Government Synergy | Your organization believes that the synergy of government departments in the quality governance of China’s civil aircraft industry is ( ). A. very high; B. high; C. average; D. low; E. very low; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Principal Role of Enterprise | Role of Prime Manufacturer | Your organization believes that the role of primary manufacturers in the quality governance of China’s civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Role of Supporting Unit | Your organization believes that the role of the supporting unit in the quality governance of China’s civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |||

| Role of Social Organizations | ∕ | Your organization believes that the role of social organizations (industrial associations) currently playing in the quality governance of China’s civil aircraft industry is ( ). A. very strong; B. strong; C. average; D. weak; E. very weak; F. unclear. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | ||

| Quality Governance Effectiveness | Quality Level | Level of Development Quality | Level of Development Quality: Domestic vs. International | Compared to the US and Europe, the development quality level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) |

| Level of Development Quality: Military vs. Civil Aircraft | Compared to military aircraft, the development quality level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | |||

| Level of Operational Quality | Level of Operational Quality: Domestic vs. International | Compared to the US and Europe, the operation and support level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | ||

| Level of Operational Quality: Military vs. Civil Aircraft | Compared to military aircraft, the operation and support level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | |||

| Level of Manufacturing Quality | Level of Manufacturing Quality: Domestic vs. International | Compared to the US and Europe, the manufacturing quality level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | ||

| Level of Manufacturing Quality: Military vs. Civil Aircraft | Compared to military aircraft, the manufacturing quality level of China’s civil aircraft products ( ). A. is higher; B. is basically the same; C. has a gap; D. has a significant gap; E. unclear. | 1~4 (A = 4, B = 3, C = 2, D = 1) | |||

| Satisfaction with Domestic Civil Aircrafts | ∕ | ∕ | As a member of the public, you believe that the role of news reporting in increasing your overall satisfaction with domestic civil aircraft brands is ( ). A. very significant; B. significant; C. average; D. minor; E. very minor. | 1~5 (A = 5, B = 4, C = 3, D = 2, E = 1) | |

| Economic Benefit | Profit Margin | ∕ | Using the “Operating Profit Margin of Civil Aviation Manufacturing Industry” index with data sourced from the statistical yearbook. | See Note 1 | |

| Revenue Growth Rate | ∕ | Using the “Revenue Growth Rate of Civil Aviation Manufacturing Industry” index with data sourced from the statistical yearbook. | See Note 2 | ||

| Order Growth Rate | ∕ | Using the index of “Growth Rate of New Subcontracting Orders of Civil Aviation Manufacturing Industry” with data sourced from the statistical yearbook. | See Note 3 |

References

- Hoyer, R.W.; Hoyer, B.B.; Crosby, P.B.; Deming, W.E. What Is Quality. Qual. Prog. 2001, 34, 53–62. [Google Scholar]

- De Feo, J.A. Juran’s Quality Handbook: The Complete Guide to Performance Excellence; McGraw-Hill Education: New York, NY, USA, 2017. [Google Scholar]

- Jochem, R. Quality Governance. Total Qual. Manag. 2009, 20, 777–785. [Google Scholar] [CrossRef]

- Akerlof, G.A. The Market for “Lemons”: Quality Uncertainty and the Market Mechanism. In Uncertainty in Economics; Academic Press: Oxford University, Oxford, UK, 1978; pp. 235–251. [Google Scholar]

- Roll, K.H. Measuring Performance, Development and Growth When Restricting Flexibility. J. Product. Anal. 2013, 39, 15–25. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Wang, L. A Study on the Quality Evaluation Index System of Smart Home Care for Older Adults in the Community—Based on Delphi and AHP. BMC Public Health 2023, 23, 411. [Google Scholar] [CrossRef]

- Baba Ali, E.; Radmehr, R.; Shayanmehr, S.; Gyamfi, B.A.; Anufriev, V.P. The Role of Technology Innovation, R&D, and Quality Governance in Pollution Mitigation for EU Economies: Fresh Evidence from Method of Moment Quantile Regression. Int. J. Sustain. Dev. World Ecol. 2023, 30, 244–261. [Google Scholar]

- Wang, L.; Pan, F.; Li, X. Compliance Relationship Analysis between Environmental Governance Attention and Environmental Quality in Beijing-Tianjin-Hebei Region. Front. Environ. Sci. 2023, 11, 1242971. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, H.; Wei, D.; Pu, C.; He, Z. Environmental Governance Capability and Water Quality: A Quasi-natural Experiment Based on the Ten-point Water Plan. Urban Clim. 2022, 41, 101050. [Google Scholar] [CrossRef]

- Jin, X.; Sumaila, U.R.; Yin, K.; Qi, Z. Evaluation of the Policy Effect of China’s Environmental Interview System for Effective Air Quality Governance. Int. J. Environ. Res. Public Health 2021, 18, 9006. [Google Scholar] [CrossRef]

- Cyrus, P. Communication and Urban Air Quality Governance in Germany: Discursive Framing by Selected National Environmental NGOs and the Automotive Industry Association (VDA) and its Potential Impacts. Environ. Policy Gov. 2023, 33, 561–576. [Google Scholar] [CrossRef]

- Walther, D.; Chou, K.T. Just Transition on Air Quality Governance: A Case Study of Heavy-duty Diesel Truck Protests in Taiwan. Sustain. Sci. 2023, 18, 2087–2105. [Google Scholar] [CrossRef]

- Mateus, C.; Valencia, M.; DiFrancesco, K.; Ochoa-Herrera, V.; Gartner, T.; Quiroga, D. Governance Mechanisms and Barriers for Achieving Water Quality Improvements in Galapagos. Sustainability 2020, 12, 8851. [Google Scholar] [CrossRef]

- Wuijts, S.; Rijswick, H.F.V.; Driessen, P.P. Achieving European Water Quality Ambitions: Governance Conditions for More Effective Approaches at the Local-Regional Scale. Sustainability 2021, 13, 681. [Google Scholar] [CrossRef]

- Namara, I.; Hartono, D.M.; Latief, Y.; Moersidik, S.S. Policy Development of River Water Quality Governance Toward Land Use Dynamics Through a Risk Management Approach. J. Ecol. Eng. 2022, 23, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Edelmann, H.; Quiñones-Ruiz, X.F.; Penker, M.; Scaramuzzi, S.; Broscha, K.; Jeanneaux, P.; Belletti, G.; Marescotti, A. Social Learning in Food Quality Governance–Evidences from Geographical Indications Amendments. Int. J. Commons 2020, 14, 108–122. [Google Scholar] [CrossRef]

- Souza, O.D.; Machado, M.C.; Correa, V.S.; Telles, R. Influence of Governance Instruments on Supply Chain Quality: A Qualitative Investigation in the Dairy Industry. Benchmarking Int. J. 2023, 30, 2608–2633. [Google Scholar] [CrossRef]

- Tong, X.; Ding, W.; Huang, Z.; Gu, Y. Governance Mechanism of Quality and Safety of Imported Agricultural Products in China Based on Grounded Theory. Humanit. Soc. Sci. Commun. 2024, 11, 1–17. [Google Scholar]

- Li, T.; Hu, X.Q.; Pu, J.L.; Xu, H. Research on Developing Logistics Service Quality Evaluation Index System under Internet of Things Environment. In Proceedings of the 2015 International Conference on Industrial Technology and Management Science, Tianjin, China, 27–28 March 2015; pp. 499–502. [Google Scholar]

- Li, W.H. Study on Evaluation Index System of Product Quality Competence Based on Manufacturing Industry. Appl. Mech. Mater. 2012, 150, 227–234. [Google Scholar] [CrossRef]

- Zhao, L.; Lizhi, W.; Wu, T. Research on Macro-quality Evaluation Index System. In Proceedings of the 2010 IEEE International Conference on Software Engineering and Service Sciences, Beijing, China, 16–18 July 2010; pp. 608–611. [Google Scholar]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Wang, L.; He, F.; Zhang, Z. Uniformity and Comprehensive Quality Evaluation of Steel Product via Process Capability Index and TOPSIS. Ironmak. Steelmak. 2021, 48, 833–851. [Google Scholar] [CrossRef]

- Ferreira, F.A.; Santos, S.P. Comparing Trade-off Adjustments in Credit Risk Analysis of Mortgage Loans Using AHP, Delphi and MACBETH. Int. J. Strateg. Prop. Manag. 2016, 20, 44–63. [Google Scholar] [CrossRef]

- Dožić, S.; Lutovac, T.; Kalić, M. Fuzzy AHP Approach to Passenger Aircraft Type Selection. J. Air Transp. Manag. 2018, 68, 165–175. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, X.Y.; Yeh, I.C.; Chen, F.Y.; Bender, J.; Wang, T.N. Evaluating Competitiveness Using Fuzzy Analytic Hierarchy Process—A Case Study of Chinese Airlines. J. Adv. Transp. 2013, 47, 619–634. [Google Scholar] [CrossRef]

- Cui, Q.; Li, Y. The Change Trend and Influencing Factors of Civil Aviation Safety Efficiency: The Case of Chinese Airline Companies. Saf. Sci. 2015, 75, 56–63. [Google Scholar] [CrossRef]

- Bao, J.; Chen, Y.; Yin, J.; Chen, X.; Zhu, D. Exploring Topics and Trends in Chinese ATC Incident Reports Using a Domain-Knowledge Driven Topic Model. J. Air Transp. Manag. 2023, 108, 102374. [Google Scholar] [CrossRef]

- Kulkarni, P.L. Quality Governance for Developing High Reliable Satellite Systems. IETE Tech. Rev. 2001, 18, 229–235. [Google Scholar] [CrossRef]

| Primary Index | Weight (Global Weight) | Secondary Index | Weight (Global Weight) | Tertiary Index | Weight (Global Weight) | Quaternary Index | Weight (Global Weight) |

|---|---|---|---|---|---|---|---|

| Quality Governance Capability | 0.7917 (0.7917) | Macro-Regulation | 0.2773 (0.2195) | Quality Access Management | 0.2166 (0.0476) | Coverage of Access Requirements | 0.25 (0.0119) |

| Level of Access Management | 0.75 (0.0357) | ||||||

| Quality Supervision Management | 0.3372 (0.074) | Coverage of Supervision Requirements | 0.375 (0.0278) | ||||

| Supervision Management | 0.625 (0.0463) | ||||||

| Quality Incident Investigation | 0.3619 (0.0795) | Incident Investigation Mechanisms and Technical Levels | 0.7917 (0.0629) | ||||

| Investigation Synergy Degree | 0.2084 (0.0166) | ||||||

| Effect of Quality Technology and Method Promotion | 0.0844 (0.0185) | ||||||

| Public Services | 0.3261 (0.2582) | Standard Service Capability | 0.2658 (0.0686) | Extent to which Standard Service Capability Meets Demand | 0.75 (0.0515) | ||

| Service Capability of Standard Service Institution | 0.25 (0.0172) | ||||||

| Metrology Service Capability | 0.2788 (0.072) | Extent to which Metrology Service Capability Meets Demand | 0.75 (0.054) | ||||

| Service Capability of Metrology Service Institution | 0.25 (0.018) | ||||||

| Test and Inspection Service Capabilities | 0.2788 (0.072) | Extent to which Test and Inspection Service Capabilities Meet Demand (0.045) | 0.625 (0.045) | ||||

| International Mutual Recognition of Test and Inspection Service Capabilities | 0.375 (0.027) | ||||||

| Certification Service Capability | 0.1052 (0.0272) | Extent to which Certification Service Capability Meets Demand | 0.75 (0.0204) | ||||

| Service Capability of Certification Service Institution | 0.25 (0.0068) | ||||||

| Quality Information Resources | 0.0716 (0.0185) | Extent to which Quality Information Resources Meet Demand | 0.2084 (0.0039) | ||||

| Satisfaction Degree of Airworthiness Technology | 0.7917 (0.0146) | ||||||

| Pluralistic Co-Governance | 0.3967 (0.3141) | Industrial Foundation | 0.4995 (0.1569) | Coverage of Quality Laws and Regulations | 0.7917 (0.1242) | ||

| Coverage of Quality Systems | 0.2084 (0.0327) | ||||||

| Role of Government | 0.2884 (0.0906) | Government Guidance | 0.75 (0.0679) | ||||

| Government Synergy | 0.25 (0.0226) | ||||||

| Principal Role of Enterprise | 0.1465 (0.046) | Role of Prime Manufacturer | 0.625 (0.0288) | ||||

| Role of Supporting Unit | 0.375 (0.0173) | ||||||

| Role of Social Organizations | 0.0656 (0.0206) | ||||||

| Quality Governance Effectiveness | 0.2084 (0.2084) | Quality Level | 0.4070 (0.0848) | Level of Development Quality | 0.6491 (0.0551) | Level of Development Quality: Domestic vs. International | 0.7917 (0.0436) |

| Level of Development Quality: Military vs. Civil Aircraft | 0.2084 (0.0115) | ||||||

| Level of Operational Quality | 0.0719 (0.0061) | Level of Operational Quality: Domestic vs. International | 0.7917 (0.0048) | ||||

| Level of Operational Quality: Military vs. Civil Aircraft | 0.2084 (0.0013) | ||||||

| Level of Manufacturing Quality | 0.2790 (0.0237) | Level of Manufacturing Quality: Domestic vs. International | 0.7917 (0.0187) | ||||

| Level of Manufacturing Quality: Military vs. Civil Aircraft | 0.2084 (0.0049) | ||||||

| Satisfaction with Domestic Civil Aircrafts | 0.2237 (0.0466) | ||||||

| Economic Benefit | 0.3694 (0.077) | Profit Margin | 0.1524 (0.0117) | ||||

| Revenue Growth Rate | 0.2292 (0.0176) | ||||||

| Order Growth Rate | 0.6185 (0.0476) | ||||||

| Grade | Very low | Low | Medium | High | Very high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, T.; Liu, H.; Shi, X.; Meng, P.; Wang, J.; Fang, W. An Empirical Study of the Quality Governance Level of China’s Civil Aircraft Industry. Systems 2024, 12, 247. https://doi.org/10.3390/systems12070247

Luo T, Liu H, Shi X, Meng P, Wang J, Fang W. An Empirical Study of the Quality Governance Level of China’s Civil Aircraft Industry. Systems. 2024; 12(7):247. https://doi.org/10.3390/systems12070247

Chicago/Turabian StyleLuo, Tingyu, Hongde Liu, Xiang Shi, Peng Meng, Jun Wang, and Weiguo Fang. 2024. "An Empirical Study of the Quality Governance Level of China’s Civil Aircraft Industry" Systems 12, no. 7: 247. https://doi.org/10.3390/systems12070247

APA StyleLuo, T., Liu, H., Shi, X., Meng, P., Wang, J., & Fang, W. (2024). An Empirical Study of the Quality Governance Level of China’s Civil Aircraft Industry. Systems, 12(7), 247. https://doi.org/10.3390/systems12070247