Roadblocks in Integrating Lean Six Sigma and Industry 4.0 in Small and Medium Enterprises

Abstract

1. Introduction

2. Literature Review

2.1. Integrating LSS and I4.0 Practices

2.2. Barriers to Integrating LSS and I4.0

2.3. Research Gaps

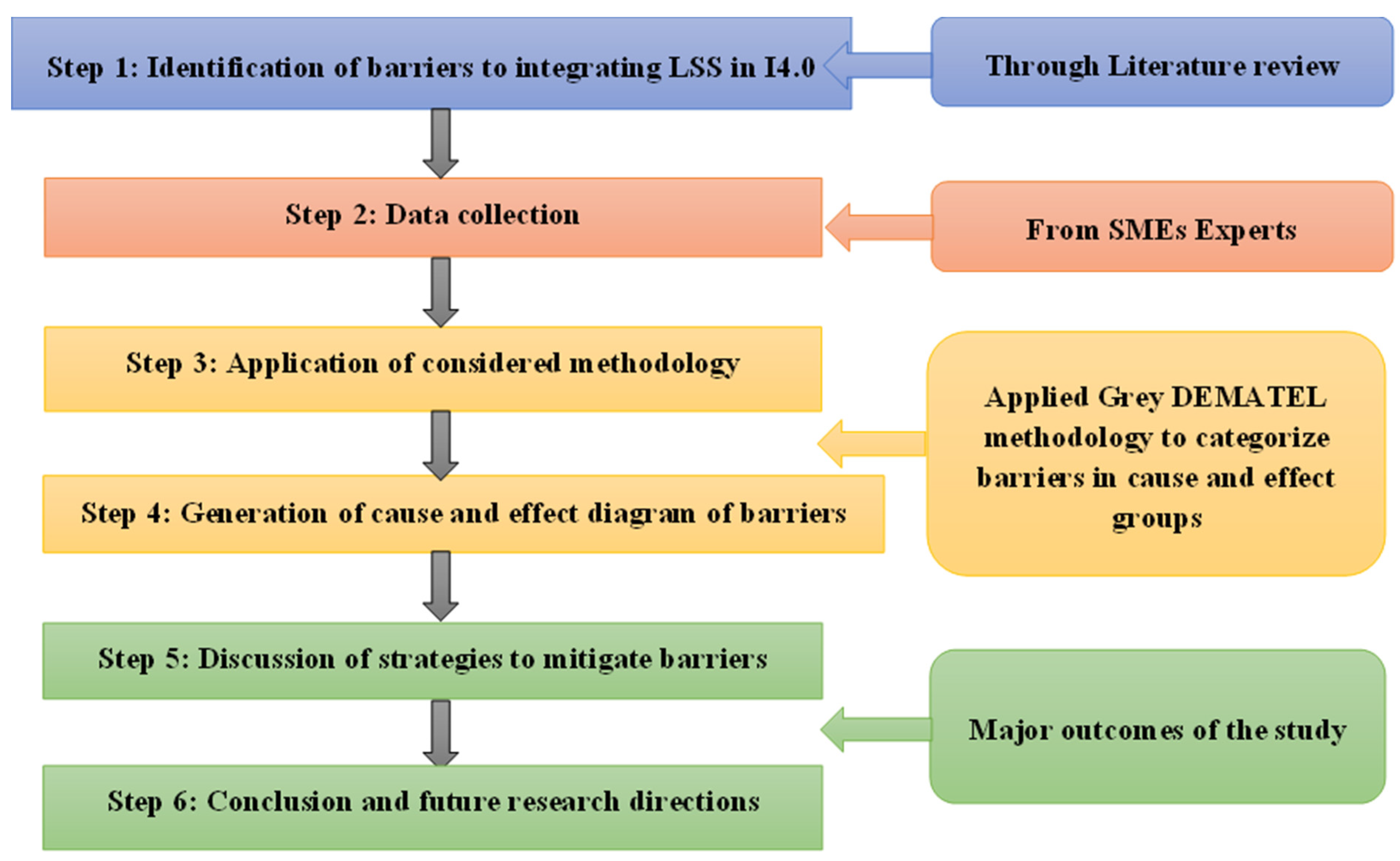

3. Research Methodology

3.1. Grey-DEMATEL Methodology

- Step 1: Preparation of direct relation matrix

- Step 2: Normalization of direct relation matrix

- Step 3: Development of total relation matrix

- Step 4: Identification of influential and prominent barriers

3.2. Grey Systems

4. Results and Discussions

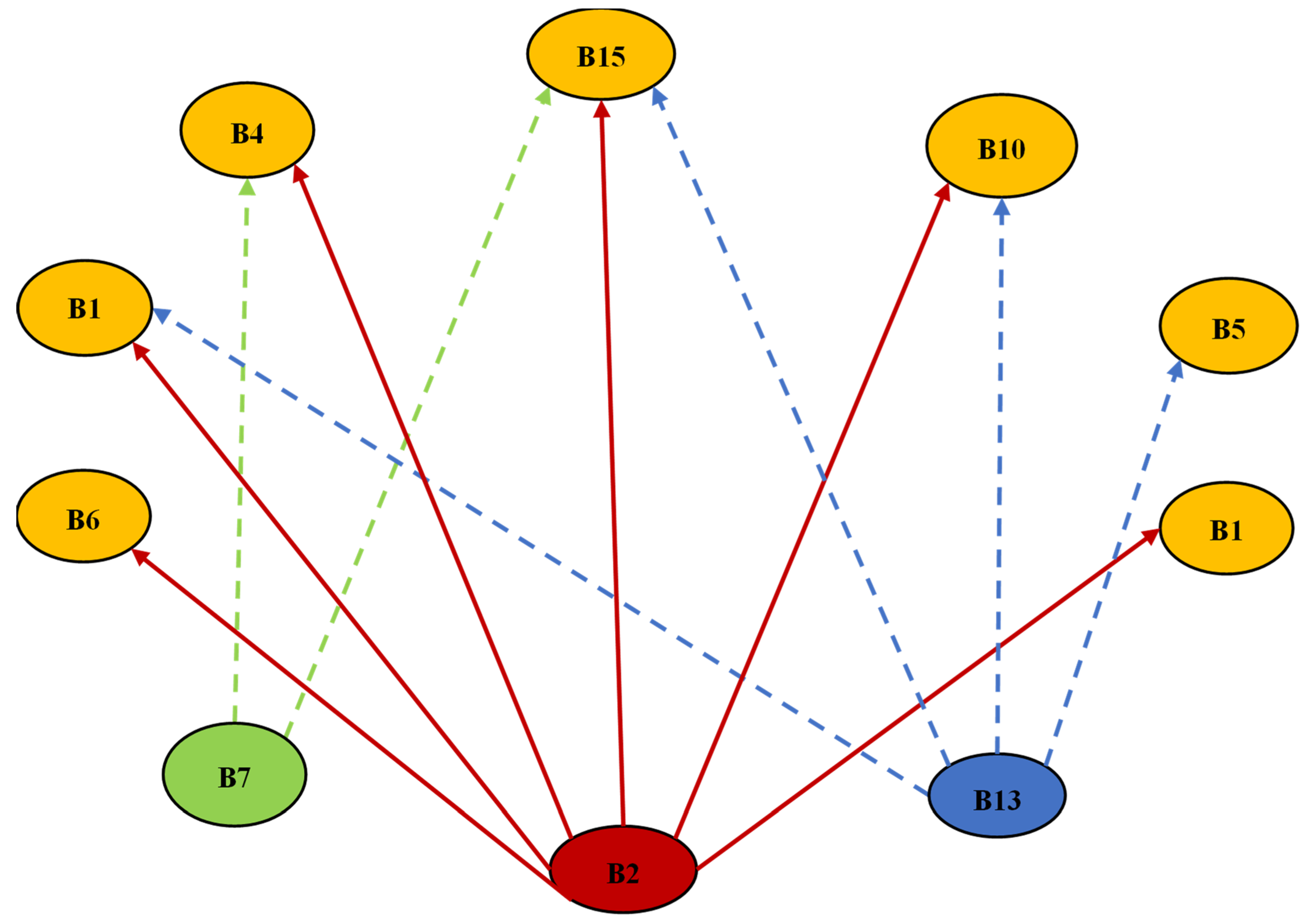

4.1. Prominent and Causal Barriers

4.2. Establishment of Strategy for Overcoming the Barriers to Integration

5. Implications

5.1. Theoretical Implications

5.2. Implications for Practitioners

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| “B1” | “B2” | “B3” | “B4” | “B5” | “B6” | “B7” | “B8” | “B9” | “B10” | “B11” | “B12” | “B13” | “B14” | “B15” | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| “B1” | (0, 0) | (0.313, 0.75) | (0.313, 0.75) | (0.375, 0.833) | (0.188, 0.583) | (0.5, 1) | (0.5, 1) | (0.313, 0.75) | (0.375, 0.833) | (0.688, 10.25) | (0.563, 10.083) | (0.688, 10.25) | (0.25, 0.667) | (0.188, 0.583) | (0.25, 0.667) |

| “B2” | (0.5, 1) | (0, 0) | (0.5, 1) | (0.5, 1) | (0.438, 0.917) | (0.625, 10.167) | (0.438, 0.917) | (0.438, 0.917) | (0.563, 10.083) | (0.625, 10.167) | (0.75, 10.333) | (0.625, 10.167) | (0.5, 1) | (0.375, 0.833) | (0.625, 10.167) |

| “B3” | (0.375, 0.833) | (0.25, 0.667) | (0, 0) | (0.625, 10.167) | (0.75, 10.333) | (0.375, 0.833) | (0.5, 1) | (0.188, 0.417) | (0, 0.167) | (0.5, 1) | (0.375, 0.833) | (0.5, 1) | (0.375, 0.833) | (0.5, 1) | (0.5, 1) |

| “B4” | (0.25, 0.667) | (0.375, 0.833) | (0.25, 0.5) | (0, 0) | (0.25, 0.5) | (0.5, 1) | (0.375, 0.833) | (0.25, 0.667) | (0.313, 0.75) | (0.625, 10.167) | (0.5, 1) | (0.5, 1) | (0.375, 0.833) | (0.375, 0.833) | (0.625, 10.167) |

| “B5” | (0.25, 0.667) | (0.375, 0.833) | (0.5, 1) | (0.5, 1) | (0, 0) | (0.625, 10.167) | (0.625, 10.167) | (0.125, 0.333) | (0.375, 0.667) | (0.5, 1) | (0.375, 0.833) | (0.5, 1) | (0.625, 10.167) | (0.5, 1) | (0.375, 0.833) |

| “B6” | (0.375, 0.833) | (0.25, 0.5) | (0.375, 0.833) | (0.5, 1) | (0.375, 0.833) | (0, 0) | (0.25, 0.667) | (0.25, 0.5) | (0.375, 0.833) | (0.5, 1) | (0.625, 10.167) | (0.25, 0.667) | (0.25, 0.5) | (0.25, 0.5) | (0.5, 1) |

| “B7” | (0.25, 0.667) | (0.375, 0.667) | (0.75, 10.333) | (0.75, 10.333) | (0.625, 10.167) | (0.5, 1) | (0, 0) | (0.5, 1) | (0.375, 0.667) | (0.5, 1) | (0.375, 0.833) | (0.5, 1) | (0.25, 0.5) | (0.5, 1) | (0.625, 10.167) |

| “B8” | (0.438, 0.917) | (0.625, 10.167) | (0.188, 0.583) | (0.625, 10.167) | (0.5, 1) | (0.563, 10.083) | (0.25, 0.5) | (0, 0) | (0.625, 10.167) | (0.25, 0.667) | (0.625, 10.167) | (0.25, 0.5) | (0.25, 0.5) | (0.25, 0.5) | (0.375, 0.833) |

| “B9” | (0.5, 1) | (0.375, 0.667) | (0.25, 0.5) | (0.5, 1) | (0.5, 1) | (0.375, 0.833) | (0.375, 0.833) | (0.375, 0.833) | (0, 0) | (0.25, 0.5) | (0.625, 10.167) | (0.25, 0.667) | (0.375, 0.833) | (0.625, 10.167) | (0.75, 10.333) |

| “B10” | (0.375, 0.667) | (0.375, 0.833) | (0.5, 1) | (0.625, 10.167) | (0.375, 0.833) | (0.375, 0.833) | (0.75, 10.333) | (0.375, 0.833) | (0.375, 0.833) | (0, 0) | (0.375, 0.833) | (0.625, 10.167) | (0.375, 0.833) | (0.625, 10.167) | (0.375, 0.833) |

| “B11” | (0.375, 0.667) | (0.25, 0.667) | (0.375, 0.667) | (0.25, 0.5) | (0.375, 0.833) | (0.375, 0.833) | (0.5, 1) | (0.563, 10.083) | (0.625, 10.167) | (0.375, 0.833) | (0, 0) | (0.625, 10.167) | (0.625, 10.167) | (0.25, 0.5) | (0.625, 10.167) |

| “B12” | (0.25, 0.5) | (0.25, 0.5) | (0.25, 0.667) | (0.375, 0.833) | (0.5, 1) | (0.25, 0.667) | (0.25, 0.667) | (0.25, 0.5) | (0, 0) | (0.625, 10.167) | (0.25, 0.5) | (0, 0) | (0.375, 0.833) | (0.375, 0.833) | (0.5, 1) |

| “B13” | (0.25, 0.5) | (0.5, 1) | (0.375, 0.833) | (0.5, 1) | (0.75, 10.333) | (0.625, 10.167) | (0.625, 10.167) | (0.25, 0.667) | (0.25, 0.667) | (0.625, 10.167) | (0.5, 1) | (0.75, 10.333) | (0, 0) | (0.75, 10.333) | (0.5, 1) |

| “B14” | (0.25, 0.667) | (0.25, 0.667) | (0.375, 0.833) | (0.625, 10.167) | (0.5, 1) | (0.375, 0.833) | (0.25, 0.667) | (0.188, 0.417) | (0.25, 0.5) | (0.375, 0.833) | (0.375, 0.833) | (0.5, 1) | (0.625, 10.167) | (0, 0) | (0.625, 10.167) |

| “B15” | (0.25, 0.5) | (0.25, 0.667) | (0.25, 0.667) | (0.063, 0.417) | (0.438, 0.917) | (0.188, 0.417) | (0.313, 0.583) | (0.188, 0.417) | (0.25, 0.5) | (0.313, 0.75) | (0.375, 0.833) | (0.313, 0.75) | (0.438, 0.917) | (0.188, 0.583) | (0, 0) |

| “B1” | “B2” | “B3” | “B4” | “B5” | “B6” | “B7” | “B8” | “B9” | “B10” | “B11” | “B12” | “B13” | “B14” | “B15” | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| “B1” | 0 | 0.044 | 0.042 | 0.05 | 0.027 | 0.068 | 0.066 | 0.045 | 0.052 | 0.091 | 0.073 | 0.09 | 0.036 | 0.027 | 0.035 |

| “B2” | 0.071 | 0 | 0.066 | 0.066 | 0.058 | 0.084 | 0.058 | 0.061 | 0.076 | 0.083 | 0.098 | 0.082 | 0.068 | 0.05 | 0.082 |

| “B3” | 0.054 | 0.036 | 0 | 0.082 | 0.098 | 0.052 | 0.066 | 0.022 | 0.002 | 0.067 | 0.05 | 0.066 | 0.052 | 0.066 | 0.066 |

| “B4” | 0.038 | 0.052 | 0.028 | 0 | 0.028 | 0.068 | 0.05 | 0.037 | 0.044 | 0.083 | 0.066 | 0.066 | 0.052 | 0.05 | 0.082 |

| “B5” | 0.038 | 0.052 | 0.066 | 0.066 | 0 | 0.084 | 0.082 | 0.015 | 0.043 | 0.067 | 0.05 | 0.066 | 0.084 | 0.066 | 0.05 |

| “B6” | 0.054 | 0.029 | 0.05 | 0.066 | 0.05 | 0 | 0.035 | 0.029 | 0.052 | 0.067 | 0.082 | 0.035 | 0.029 | 0.028 | 0.066 |

| “B7” | 0.038 | 0.043 | 0.098 | 0.098 | 0.082 | 0.068 | 0 | 0.069 | 0.043 | 0.067 | 0.05 | 0.066 | 0.029 | 0.066 | 0.082 |

| “B8” | 0.062 | 0.084 | 0.027 | 0.082 | 0.066 | 0.076 | 0.028 | 0 | 0.084 | 0.035 | 0.082 | 0.028 | 0.029 | 0.028 | 0.05 |

| “B9” | 0.071 | 0.043 | 0.028 | 0.066 | 0.066 | 0.052 | 0.05 | 0.053 | 0 | 0.028 | 0.082 | 0.035 | 0.052 | 0.082 | 0.098 |

| “B10” | 0.045 | 0.052 | 0.066 | 0.082 | 0.05 | 0.052 | 0.098 | 0.053 | 0.052 | 0 | 0.05 | 0.082 | 0.052 | 0.082 | 0.05 |

| “B11” | 0.045 | 0.036 | 0.042 | 0.028 | 0.05 | 0.052 | 0.066 | 0.078 | 0.084 | 0.051 | 0 | 0.082 | 0.084 | 0.028 | 0.082 |

| “B12” | 0.03 | 0.029 | 0.035 | 0.05 | 0.066 | 0.036 | 0.035 | 0.029 | 0 | 0.083 | 0.028 | 0 | 0.052 | 0.05 | 0.066 |

| “B13” | 0.03 | 0.068 | 0.05 | 0.066 | 0.098 | 0.084 | 0.082 | 0.037 | 0.036 | 0.083 | 0.066 | 0.098 | 0 | 0.098 | 0.066 |

| “B14” | 0.038 | 0.036 | 0.05 | 0.082 | 0.066 | 0.052 | 0.035 | 0.022 | 0.029 | 0.051 | 0.05 | 0.066 | 0.084 | 0 | 0.082 |

| “B15” | 0.03 | 0.036 | 0.035 | 0.013 | 0.058 | 0.022 | 0.035 | 0.022 | 0.029 | 0.043 | 0.05 | 0.042 | 0.06 | 0.027 | 0 |

| “B1” | “B2” | “B3” | “B4” | “B5” | “B6” | “B7” | “B8” | “B9” | “B10” | “B11” | “B12” | “B13” | “B14” | “B15” | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| “B1” | 0.139 | 0.181 | 0.193 | 0.24 | 0.214 | 0.246 | 0.235 | 0.172 | 0.186 | 0.282 | 0.255 | 0.281 | 0.203 | 0.192 | 0.241 |

| “B2” | 0.25 | 0.184 | 0.261 | 0.313 | 0.301 | 0.319 | 0.283 | 0.225 | 0.252 | 0.337 | 0.337 | 0.336 | 0.287 | 0.264 | 0.349 |

| “B3” | 0.192 | 0.179 | 0.159 | 0.275 | 0.284 | 0.239 | 0.243 | 0.151 | 0.142 | 0.269 | 0.238 | 0.268 | 0.227 | 0.233 | 0.275 |

| “B4” | 0.173 | 0.187 | 0.177 | 0.188 | 0.212 | 0.242 | 0.218 | 0.161 | 0.177 | 0.271 | 0.246 | 0.256 | 0.217 | 0.209 | 0.281 |

| “B5” | 0.19 | 0.204 | 0.233 | 0.277 | 0.21 | 0.283 | 0.27 | 0.156 | 0.19 | 0.284 | 0.255 | 0.283 | 0.268 | 0.247 | 0.28 |

| “B6” | 0.176 | 0.153 | 0.183 | 0.231 | 0.213 | 0.163 | 0.19 | 0.143 | 0.172 | 0.239 | 0.243 | 0.211 | 0.181 | 0.174 | 0.247 |

| “B7” | 0.2 | 0.206 | 0.269 | 0.317 | 0.296 | 0.278 | 0.203 | 0.211 | 0.2 | 0.294 | 0.266 | 0.292 | 0.229 | 0.254 | 0.32 |

| “B8” | 0.204 | 0.223 | 0.181 | 0.271 | 0.251 | 0.261 | 0.205 | 0.132 | 0.224 | 0.237 | 0.273 | 0.23 | 0.204 | 0.194 | 0.262 |

| “B9” | 0.213 | 0.19 | 0.187 | 0.262 | 0.259 | 0.243 | 0.23 | 0.184 | 0.146 | 0.236 | 0.275 | 0.243 | 0.231 | 0.248 | 0.311 |

| “B10” | 0.202 | 0.21 | 0.238 | 0.299 | 0.264 | 0.26 | 0.289 | 0.196 | 0.204 | 0.228 | 0.262 | 0.303 | 0.244 | 0.266 | 0.288 |

| “B11” | 0.192 | 0.186 | 0.202 | 0.233 | 0.251 | 0.245 | 0.247 | 0.209 | 0.225 | 0.258 | 0.201 | 0.286 | 0.26 | 0.205 | 0.299 |

| “B12” | 0.137 | 0.14 | 0.156 | 0.2 | 0.21 | 0.18 | 0.173 | 0.127 | 0.108 | 0.235 | 0.174 | 0.158 | 0.185 | 0.18 | 0.225 |

| “B13” | 0.204 | 0.241 | 0.243 | 0.307 | 0.329 | 0.311 | 0.297 | 0.195 | 0.206 | 0.329 | 0.297 | 0.342 | 0.218 | 0.301 | 0.326 |

| “B14” | 0.171 | 0.173 | 0.197 | 0.263 | 0.247 | 0.229 | 0.205 | 0.145 | 0.16 | 0.245 | 0.23 | 0.258 | 0.248 | 0.163 | 0.28 |

| “B15” | 0.125 | 0.133 | 0.14 | 0.147 | 0.186 | 0.15 | 0.156 | 0.11 | 0.122 | 0.179 | 0.177 | 0.18 | 0.176 | 0.143 | 0.144 |

| “B1” | “B2” | “B3” | “B4” | “B5” | “B6” | “B7” | “B8” | “B9” | “B10” | “B11” | “B12” | “B13” | “B14” | “B15” | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| “B1” | 0.139 | 0.181 | 0.193 | 0.24 | 0.214 | 0.246 | 0.235 | 0.172 | 0.186 | 0.282 | 0.255 | 0.281 | 0.203 | 0.192 | 0.241 |

| “B2” | 0.25 | 0.184 | 0.261 | 0.313 | 0.301 | 0.319 | 0.283 | 0.225 | 0.252 | 0.337 | 0.337 | 0.336 | 0.287 | 0.264 | 0.349 |

| “B3” | 0.192 | 0.179 | 0.159 | 0.275 | 0.284 | 0.239 | 0.243 | 0.151 | 0.142 | 0.269 | 0.238 | 0.268 | 0.227 | 0.233 | 0.275 |

| “B4” | 0.173 | 0.187 | 0.177 | 0.188 | 0.212 | 0.242 | 0.218 | 0.161 | 0.177 | 0.271 | 0.246 | 0.256 | 0.217 | 0.209 | 0.281 |

| “B5” | 0.19 | 0.204 | 0.233 | 0.277 | 0.21 | 0.283 | 0.27 | 0.156 | 0.19 | 0.284 | 0.255 | 0.283 | 0.268 | 0.247 | 0.28 |

| “B6” | 0.176 | 0.153 | 0.183 | 0.231 | 0.213 | 0.163 | 0.19 | 0.143 | 0.172 | 0.239 | 0.243 | 0.211 | 0.181 | 0.174 | 0.247 |

| “B7” | 0.2 | 0.206 | 0.269 | 0.317 | 0.296 | 0.278 | 0.203 | 0.211 | 0.2 | 0.294 | 0.266 | 0.292 | 0.229 | 0.254 | 0.32 |

| “B8” | 0.204 | 0.223 | 0.181 | 0.271 | 0.251 | 0.261 | 0.205 | 0.132 | 0.224 | 0.237 | 0.273 | 0.23 | 0.204 | 0.194 | 0.262 |

| “B9” | 0.213 | 0.19 | 0.187 | 0.262 | 0.259 | 0.243 | 0.23 | 0.184 | 0.146 | 0.236 | 0.275 | 0.243 | 0.231 | 0.248 | 0.311 |

| “B10” | 0.202 | 0.21 | 0.238 | 0.299 | 0.264 | 0.26 | 0.289 | 0.196 | 0.204 | 0.228 | 0.262 | 0.303 | 0.244 | 0.266 | 0.288 |

| “B11” | 0.192 | 0.186 | 0.202 | 0.233 | 0.251 | 0.245 | 0.247 | 0.209 | 0.225 | 0.258 | 0.201 | 0.286 | 0.26 | 0.205 | 0.299 |

| “B12” | 0.137 | 0.14 | 0.156 | 0.2 | 0.21 | 0.18 | 0.173 | 0.127 | 0.108 | 0.235 | 0.174 | 0.158 | 0.185 | 0.18 | 0.225 |

| “B13” | 0.204 | 0.241 | 0.243 | 0.307 | 0.329 | 0.311 | 0.297 | 0.195 | 0.206 | 0.329 | 0.297 | 0.342 | 0.218 | 0.301 | 0.326 |

| “B14” | 0.171 | 0.173 | 0.197 | 0.263 | 0.247 | 0.229 | 0.205 | 0.145 | 0.16 | 0.245 | 0.23 | 0.258 | 0.248 | 0.163 | 0.28 |

| “B15” | 0.125 | 0.133 | 0.14 | 0.147 | 0.186 | 0.15 | 0.156 | 0.11 | 0.122 | 0.179 | 0.177 | 0.18 | 0.176 | 0.143 | 0.144 |

References

- De la Vega, M.; Macias-Velasquez, S.; Baez-Lopez, Y.; Limon-Romero, J.; Tlapa, D.; Chávez-Moreno, E.A. Modeling Critical Success Factors of Lean Strategy in the Manufacturing Industry. Systems 2023, 11, 490. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.W.; Semini, M.; Strandhagen, J.O. The Digitalization of Manufacturing: Investigating the Impact of Production Environment and Company Size. J. Manuf. Technol. Manag. 2020, 32, 621–645. [Google Scholar] [CrossRef]

- Tissir, S.; Cherrafi, A.; Chiarini, A.; Elfezazi, S.; Bag, S. Lean Six Sigma and Industry 4.0 Combination: Scoping Review and Perspectives. Total Qual. Manag. Bus. Excell. 2022, 34, 261–290. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or Industry 4.0S? Introduction to Industry 4.0 and a Peek into the Prospective Industry 5.0 Technologies. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Sartal, A.; Ozcelik, N.; Rodríguez, M. Bringing the Circular Economy Closer to Small and Medium Enterprises: Improving Water Circularity without Damaging Plant Productivity. J. Clean. Prod. 2020, 256, 120363. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Kühl, A.; Grimm, S.; Erll, A.; Potzel, M.; Franke, J. Lean 4.0—A Conceptual Conjunction of Lean Management and Industry 4.0. Procedia CIRP 2018, 72, 622–628. [Google Scholar] [CrossRef]

- Pagliosa, M.; Tortorella, G.; Ferreira, J.C.E. Industry 4.0 and Lean Manufacturing. J. Manuf. Technol. Manag. 2019, 32, 543–569. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Staudacher, A.P.; Tortorella, G. Industry 4.0 and Lean Production: An Empirical Study. IFAC-Pap. 2019, 52, 42–47. [Google Scholar] [CrossRef]

- Tortorella, G.; Miorando, R.; Caiado, R.; Nascimento, D.; Portioli Staudacher, A. The Mediating Effect of Employees’ Involvement on the Relationship between Industry 4.0 and Operational Performance Improvement. Total Qual. Manag. Bus. Excell. 2021, 32, 119–133. [Google Scholar] [CrossRef]

- Dora, M.; Gellynck, X. House of Lean for Food Processing SMEs. Trends Food Sci. Technol. 2015, 44, 272–281. [Google Scholar] [CrossRef]

- Pearce, A.; Pons, D.; Neitzert, T. Implementing Lean—Outcomes from SME Case Studies. Oper. Res. Perspect. 2018, 5, 94–104. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of Critical Success Factors, Risks and Opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When Titans Meet—Can Industry 4.0 Revolutionise the Environmentally-Sustainable Manufacturing Wave? The Role of Critical Success Factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Pizoń, J.; Gola, A. The Meaning and Directions of Development of Personalized Production in the Era of Industry 4.0 and Industry 5.0. 2023; pp. 1–13. Available online: https://ouci.dntb.gov.ua/en/works/loXJAJQ9/ (accessed on 12 January 2024).

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the Driving and Dependence Power of Barriers to Adopt Industry 4.0 in Indian Manufacturing Industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Pozzi, R.; Cannas, V.G.; Rossi, T. Data Science Supporting Lean Production: Evidence from Manufacturing Companies. Systems 2024, 12, 100. [Google Scholar] [CrossRef]

- Kolla, S.; Minufekr, M.; Plapper, P. Deriving Essential Components of Lean and Industry 4.0 Assessment Model for Manufacturing SMEs. Procedia CIRP 2019, 81, 753–758. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; van Dun, D.H. Industry 4.0 Adoption as a Moderator of the Impact of Lean Production Practices on Operational Performance Improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Khanchanapong, T.; Prajogo, D.; Sohal, A.S.; Cooper, B.K.; Yeung, A.C.L.; Cheng, T.C.E. The Unique and Complementary Effects of Manufacturing Technologies and Lean Practices on Manufacturing Operational Performance. Int. J. Prod. Econ. 2014, 153, 191–203. [Google Scholar] [CrossRef]

- Satoglu, S.; Ustundag, A.; Cevikcan, E.; Durmusoglu, M.B. Lean Transformation Integrated with Industry 4.0 Implementation Methodology. 2018, pp. 97–107. Available online: https://www.semanticscholar.org/paper/Lean-Transformation-Integrated-with-Industry-4.0-Satoglu-Ustundag/1cca0c23cac80f2cbb12b55051df56325f982c91 (accessed on 12 January 2024).

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 Implies Lean Manufacturing: Research Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. J. Ind. Eng. Manag. 2016, 9, 811. [Google Scholar] [CrossRef]

- Skorupińska, E.; Hitka, M.; Sydor, M. Surveying Quality Management Methodologies in Wooden Furniture Production. Systems 2024, 12, 51. [Google Scholar] [CrossRef]

- Kumar, P.; Bhadu, J.; Singh, D.; Bhamu, J. Integration between Lean, Six Sigma and Industry 4.0 Technologies. Int. J. Six Sigma Compet. Advant. 2021, 13, 19. [Google Scholar] [CrossRef]

- Arcidiacono, G.; Pieroni, A. The Revolution Lean Six Sigma 4.0. Int. J. Adv. Sci. Eng. Inf. Technol. 2018, 8, 141. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Gunasekaran, A. Big Data in Lean Six Sigma: A Review and Further Research Directions. Int. J. Prod. Res. 2020, 58, 947–969. [Google Scholar] [CrossRef]

- Henao, R.; Sarache, W.; Gómez, I. Lean Manufacturing and Sustainable Performance: Trends and Future Challenges. J. Clean. Prod. 2019, 208, 99–116. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A Comprehensive Review of Big Data Analytics throughout Product Lifecycle to Support Sustainable Smart Manufacturing: A Framework, Challenges and Future Research Directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Lopes de Sousa Jabbour, A.B.; Rajak, S. Barriers to the Adoption of Industry 4.0 Technologies in the Manufacturing Sector: An Inter-Country Comparative Perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A Framework to Achieve Sustainability in Manufacturing Organisations of Developing Economies Using Industry 4.0 Technologies’ Enablers. Comput. Ind. 2020, 122, 103280. [Google Scholar] [CrossRef]

- Ali, I.; Aboelmaged, M.G.S. Implementation of Supply Chain 4.0 in the Food and Beverage Industry: Perceived Drivers and Barriers. Int. J. Product. Perform. Manag. 2022, 71, 1426–1443. [Google Scholar] [CrossRef]

- Bag, S.; Sahu, A.K.; Kilbourn, P.; Pisa, N.; Dhamija, P.; Sahu, A.K. Modeling Barriers of Digital Manufacturing in a Circular Economy for Enhancing Sustainability. Int. J. Product. Perform. Manag. 2022, 71, 833–869. [Google Scholar] [CrossRef]

- Khanzode, A.G.; Sarma, P.R.S.; Mangla, S.K.; Yuan, H. Modeling the Industry 4.0 Adoption for Sustainable Production in Micro, Small & Medium Enterprises. J. Clean. Prod. 2021, 279, 123489. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing Challenges for Implementing Industry 4.0: Implications for Process Safety and Environmental Protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- Yadav, G.; Seth, D.; Desai, T.N. Prioritising Solutions for Lean Six Sigma Adoption Barriers through Fuzzy AHP-Modified TOPSIS Framework. Int. J. Lean Six Sigma 2018, 9, 270–300. [Google Scholar] [CrossRef]

- Nagy, J.; Oláh, J.; Erdei, E.; Máté, D.; Popp, J. The Role and Impact of Industry 4.0 and the Internet of Things on the Business Strategy of the Value Chain—The Case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V. Modeling Enablers of Supply Chain Risk Mitigation in Electronic Supply Chains: A Grey–DEMATEL Approach. Comput. Ind. Eng. 2015, 87, 126–139. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Social Expectations and Market Changes in the Context of Developing the Industry 4.0 Concept. Sustainability 2020, 12, 1362. [Google Scholar] [CrossRef]

- Aggarwal, A.; Gupta, S.; Ojha, M.K. Evaluation of Key Challenges to Industry 4.0 in Indian Context: A DEMATEL Approach. 2019, pp. 387–396. Available online: https://link.springer.com/chapter/10.1007/978-981-13-6412-9_37 (accessed on 12 January 2024).

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar] [CrossRef]

- Kumar, P.; Brar, P.S.; Singh, D.; Bhamu, J. Fuzzy AHP Approach for Barriers to Implement LSS in the Context of Industry 4.0. Int. J. Product. Perform. Manag. 2022, 72, 2559–2583. [Google Scholar] [CrossRef]

- Singh, R.; Bhanot, N. An Integrated DEMATEL-MMDE-ISM Based Approach for Analysing the Barriers of IoT Implementation in the Manufacturing Industry. Int. J. Prod. Res. 2020, 58, 2454–2476. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 Integration for Operational Excellence: Evidence from Italian Manufacturing Companies. Prod. Plan. Control 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Kumar, A.; Agrawal, R.; Wankhede, V.A.; Sharma, M.; Mulat-weldemeskel, E. A Framework for Assessing Social Acceptability of Industry 4.0 Technologies for the Development of Digital Manufacturing. Technol. Forecast. Soc. Chang. 2022, 174, 121217. [Google Scholar] [CrossRef]

- Zheng, P.; wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart Manufacturing Systems for Industry 4.0: Conceptual Framework, Scenarios, and Future Perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Psarommatis, F.; Prouvost, S.; May, G.; Kiritsis, D. Product Quality Improvement Policies in Industry 4.0: Characteristics, Enabling Factors, Barriers, and Evolution Toward Zero Defect Manufacturing. Front. Comput. Sci. 2020, 2, 26. [Google Scholar] [CrossRef]

- Yadav, N.; Shankar, R.; Singh, S.P. Hierarchy of Critical Success Factors (CSF) for Lean Six Sigma (LSS) in Quality 4.0. Int. J. Glob. Bus. Compet. 2021, 16, 1–14. [Google Scholar] [CrossRef]

- Butt, J. A Strategic Roadmap for the Manufacturing Industry to Implement Industry 4.0. Designs 2020, 4, 11. [Google Scholar] [CrossRef]

- Titmarsh, R.; Assad, F.; Harrison, R. Contributions of Lean Six Sigma to Sustainable Manufacturing Requirements: An Industry 4.0 Perspective. Procedia CIRP 2020, 90, 589–593. [Google Scholar] [CrossRef]

- Raval, S.J.; Kant, R. Study on Lean Six Sigma Frameworks: A Critical Literature Review. Int. J. Lean Six Sigma 2017, 8, 275–334. [Google Scholar] [CrossRef]

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Modern Divulge in Production Optimization: An Implementation Framework of LARG Manufacturing with Industry 4.0. Int. J. Lean Six Sigma 2021, 12, 992–1016. [Google Scholar] [CrossRef]

- Reyes, J.; Mula, J.; Díaz-Madroñero, M. Development of a Conceptual Model for Lean Supply Chain Planning in Industry 4.0: Multidimensional Analysis for Operations Management. Prod. Plan. Control 2023, 34, 1209–1224. [Google Scholar] [CrossRef]

- Güçdemir, H.; Selim, H. Integrating Multi-Criteria Decision Making and Clustering for Business Customer Segmentation. Ind. Manag. Data Syst. 2015, 115, 1022–1040. [Google Scholar] [CrossRef]

- Ordoobadi, S.M. Application of AHP and Taguchi Loss Functions in Supply Chain. Ind. Manag. Data Syst. 2010, 110, 1251–1269. [Google Scholar] [CrossRef]

- Yu, P.; Hee Lee, J. Optimal Technology Selection Considering Input Levels of Resource. Ind. Manag. Data Syst. 2013, 113, 57–76. [Google Scholar] [CrossRef]

- Yang, C.-C.; Chen, B.-S. Key quality performance evaluation using fuzzy AHP. J. Chin. Inst. Ind. Eng. 2004, 21, 543–550. [Google Scholar] [CrossRef]

- Raval, S.J.; Kant, R.; Shankar, R. Analyzing the Critical Success Factors Influencing Lean Six Sigma Implementation: Fuzzy DEMATEL Approach. J. Model. Manag. 2021, 16, 728–764. [Google Scholar] [CrossRef]

- Belhadi, A.; Touriki, F.E.; El fezazi, S. Prioritizing the Solutions of Lean Implementation in SMEs to Overcome Its Barriers. J. Manuf. Technol. Manag. 2017, 28, 1115–1139. [Google Scholar] [CrossRef]

- Govindan, K.; Madan Shankar, K.; Kannan, D. Application of Fuzzy Analytic Network Process for Barrier Evaluation in Automotive Parts Remanufacturing towards Cleaner Production—A Study in an Indian Scenario. J. Clean. Prod. 2016, 114, 199–213. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Mangla, S.K. Structural Model for Sustainable Consumption and Production Adoption—A Grey-DEMATEL Based Approach. Resour. Conserv. Recycl. 2017, 125, 198–207. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Shaik, M.N.; Abdul-Kader, W. Comprehensive Performance Measurement and Causal-Effect Decision Making Model for Reverse Logistics Enterprise. Comput. Ind. Eng. 2014, 68, 87–103. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, G. An Analysis of Barriers Affecting the Implementation of E-Waste Management Practices in India: A Novel ISM-DEMATEL Approach. Sustain. Prod. Consum. 2018, 14, 36–52. [Google Scholar] [CrossRef]

- Singh, C.; Singh, D.; Khamba, J.S. Analyzing Barriers of Green Lean Practices in Manufacturing Industries by DEMATEL Approach. J. Manuf. Technol. Manag. 2020, 32, 176–198. [Google Scholar] [CrossRef]

- Liu, S.; Fang, Z.; Yang, Y.; Forrest, J. General Grey Numbers and Their Operations. Grey Syst. Theory Appl. 2012, 2, 341–349. [Google Scholar] [CrossRef]

- Javanmardi, E.; Liu, S.; Xie, N. Exploring the Philosophical Foundations of Grey Systems Theory: Subjective Processes, Information Extraction and Knowledge Formation. Found. Sci. 2021, 26, 371–404. [Google Scholar] [CrossRef]

- Toan, P.N.; Dang, T.-T.; Hong, L.T.T. Evaluating Video Conferencing Software for Remote Working Using Two-Stage Grey MCDM: A Case Study from Vietnam. Mathematics 2022, 10, 946. [Google Scholar] [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing Internal Barriers for Automotive Parts Remanufacturers in China Using Grey-DEMATEL Approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. A Grey DEMATEL Approach to Develop Third-Party Logistics Provider Selection Criteria. Ind. Manag. Data Syst. 2016, 116, 690–722. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Srivastava, R.K. Analysis of External Barriers to Remanufacturing Using Grey-DEMATEL Approach: An Indian Perspective. Resour. Conserv. Recycl. 2018, 136, 79–87. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M.I. Enablers to Implement Circular Initiatives in the Supply Chain: A Grey DEMATEL Method. Glob. Bus. Rev. 2020, 097215092092948. [Google Scholar] [CrossRef]

- Majumdar, A.; Ali, S.M.; Agrawal, R.; Srivastava, S. A Triple Helix Framework for Strategy Development in Circular Textile and Clothing Supply Chain: An Indian Perspective. J. Clean. Prod. 2022, 367, 132954. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and Retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

| Barriers | References | |

|---|---|---|

| B1 | “High initial investment cost” | [15,30] |

| B2 | “Lack of available infrastructure” | [40,41] |

| B3 | “Lack of skilled workforce” | [34,37] |

| B4 | “Lack of coordination in supply chain” | [42] |

| B5 | “Lack of understanding of I4.0” | [42,43] |

| B6 | “Lack of standardization” | [30,44] |

| B7 | “Lack of training on LSS” | [43,45] |

| B8 | “Lack of database management system” | [29,46] |

| B9 | “Lack of available data for data analytics” | [43] |

| B10 | “Lack of top management commitment” | [47,48] |

| B11 | “Risk of security breaches” | [45,49] |

| B12 | “Resistance to change” | [44,50] |

| B13 | “Lack of consultant in the field” | [44,51] |

| B14 | “Lack of clarity among different functional group” | [48,52] |

| B15 | “Risk of disruption” | [53] |

| Linguistic Terms | Grey Number |

|---|---|

| “No impact (NO)” | (0, 0) |

| “Very low impact (VL)” | (0, 0.25) |

| “Low impact (L)” | (0.25, 0.5) |

| “High impact (H)” | (0.5, 0.75) |

| “Very high impact (VH)” | (0.75, 1) |

| Barriers | R | C | Prominence Score (R+C) | Relation Score (R-C) | Prominence Rank | Cause/Effect |

|---|---|---|---|---|---|---|

| B1 | 3.261 | 2.767 | 6.028 | 0.494 | 14 | Cause |

| B2 | 4.298 | 2.788 | 7.086 | 1.509 | 6 | Cause |

| B3 | 3.375 | 3.019 | 6.394 | 0.355 | 12 | Cause |

| B4 | 3.216 | 3.824 | 7.04 | −0.608 | 7 | Effect |

| B5 | 3.63 | 3.726 | 7.357 | −0.096 | 3 | Effect |

| B6 | 2.919 | 3.649 | 6.568 | −0.729 | 8 | Effect |

| B7 | 3.834 | 3.446 | 7.28 | 0.388 | 4 | Cause |

| B8 | 3.351 | 2.516 | 5.867 | 0.834 | 15 | Cause |

| B9 | 3.46 | 2.715 | 6.175 | 0.745 | 13 | Cause |

| B10 | 3.752 | 3.924 | 7.676 | −0.172 | 1 | Effect |

| B11 | 3.498 | 3.73 | 7.228 | −0.232 | 5 | Effect |

| B12 | 2.589 | 3.928 | 6.517 | −1.339 | 9 | Effect |

| B13 | 4.148 | 3.378 | 7.526 | 0.77 | 2 | Cause |

| B14 | 3.213 | 3.275 | 6.488 | −0.062 | 10 | Effect |

| B15 | 2.269 | 4.128 | 6.398 | −1.859 | 11 | Effect |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaadi, N. Roadblocks in Integrating Lean Six Sigma and Industry 4.0 in Small and Medium Enterprises. Systems 2024, 12, 125. https://doi.org/10.3390/systems12040125

Alsaadi N. Roadblocks in Integrating Lean Six Sigma and Industry 4.0 in Small and Medium Enterprises. Systems. 2024; 12(4):125. https://doi.org/10.3390/systems12040125

Chicago/Turabian StyleAlsaadi, Naif. 2024. "Roadblocks in Integrating Lean Six Sigma and Industry 4.0 in Small and Medium Enterprises" Systems 12, no. 4: 125. https://doi.org/10.3390/systems12040125

APA StyleAlsaadi, N. (2024). Roadblocks in Integrating Lean Six Sigma and Industry 4.0 in Small and Medium Enterprises. Systems, 12(4), 125. https://doi.org/10.3390/systems12040125