Dynamic Railcar Flow Assignment of Railway Terminal with Multiple Marshalling Stations

Abstract

:1. Introduction

2. Literature Review

2.1. Railcar Flow Allocation of Marshalling Station

2.2. Optimization of Train Formation Plan

2.3. Research on Limitation for Full Workload of Outbound Trains

2.4. Research Gaps

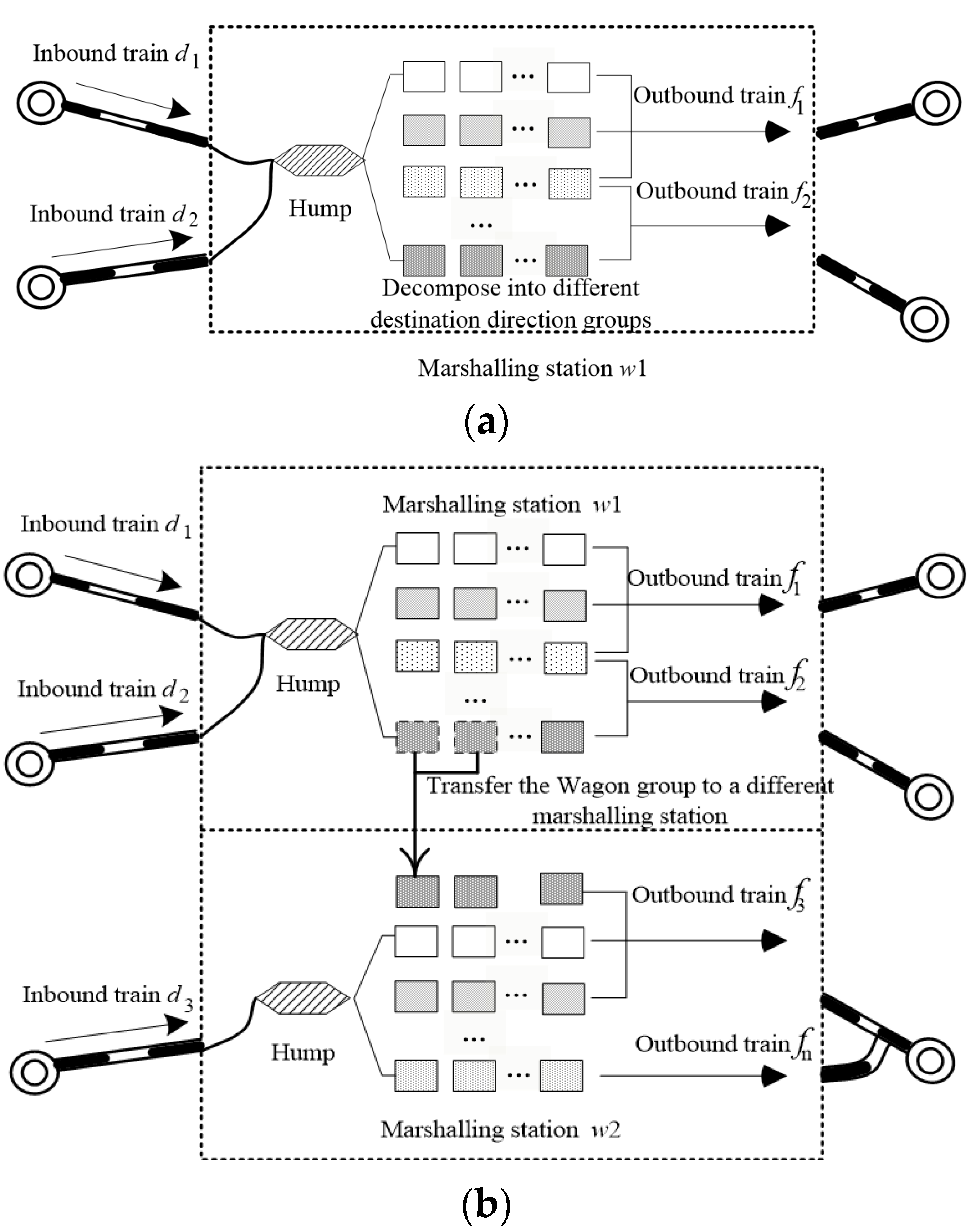

3. Problem Formulation

3.1. Problem Description

- (1)

- The railway terminal maintains a balance in the stage plan for arrival and departure railcar flows, which means that the quantity of arrival railcar flows is essentially equal to the quantity of railcar flows that should be dispatched according to the marshalling plan.

- (2)

- The division of labor among the marshalling stations within the railway terminal is predetermined; that is, the freight trains that are routed to or dispatched from a particular marshalling station are known.

- (3)

- There is an abundance of shunting locomotive resources at each marshalling station within the terminal, which is sufficient to satisfy the requirements of freight train break-up and make-up operations.

- (4)

- Freight trains arrive and depart from marshalling stations strictly according to the timetable, without additional consideration of the variability in train arrival or departure times.

- (5)

- The scope of this study is limited to arrival and break-up trains, self-assembled departure trains, and terminal short-haul trains, excluding other types of freight trains, such as non-marshaling transit trains and partially marshaling transit trains.

- (6)

- After accounting for the technical service capacity occupied by other types of trains (e.g., the technical service capacity occupied by non-marshaling transit trains and partially marshaling transit trains) and the necessary reserve capacity, the remaining capacity for receiving and dispatching trains at each station and the capacity for disassembly and assembly operations in the shunting yards meet the requirements. The technical service for freight trains can satisfy the requirement of immediate inspection upon arrival. Concurrently, the line section passing capacity is ample.

- (7)

- The sequence of train disassembly is determined by the order of arrival of the inbound trains, and the sequence of train marshalling is determined by the order of departure of the outbound trains.

3.2. Parameters and Variables

| Sets | |

| M | Set of marshalling stations in the terminal. Define m = {m|m = I,II,···,},where is the total number of marshalling stations, and represents a marshalling station different from m. |

| R | Set of destination directions. Define R = { r|r = 1, 2, ···, }, where is the total number of destination directions. |

| K | Set of the railcar flow number stored at the initial station of the stage plan. Define K = {k|k = 1, 2, ···, }, where is the total number of railcar flows in the stations. Railcar-flow groups at different stations have different destinations. |

| A | Set of inbound trains in the stage plan. Define A = { a|a = 1, 2, ···, }, where is the total number of inbound trains. |

| D | Set of outbound trains within the stage plan. Define D = { d|d = 1, 2, ···, }, where is the total number of outbound trains. |

| Γ | Train type. Define Γ = {τ|τ = 0, 1}, At τ = 0, the trains are those that cannot be underloaded, such as district trains, through trains, and direct trains. At τ = 1, the trains are those that can be underloaded, such as pickup goods trains and district transfer trains. |

| H | Set of train technical operations. Define h = {h|h = 1, 2, 3, 4}, including arrival, disassembly, assembly, and departure operations. |

| Parameters | |

| ts | Stage plan start time. |

| te | Stage plan end time. |

| The actual arrival time of inbound train a (type τ) at marshalling station m in the stage plan. | |

| The actual departure time of outbound train d (type τ) departing from marshalling station m in the stage plan. | |

| The disassembly ability of marshalling station m. | |

| The assembly capacity of marshalling station m. | |

| The maximum number of transit railcars between marshalling stations m and where . | |

| The maximum transit time of railcars from marshalling station m to marshalling station . | |

| tm,h | The time it takes for trains to handle technical operations, h, at marshalling station m. |

| ma | The number of inbound trains at marshalling station m in the stage plan. |

| md | The number of outbound trains from marshalling station m in the stage plan. |

| mk | The number of station-stored railcar groups in marshalling station m at the beginning of the stage plan. |

| nmar | The number of railcars arriving at marshalling station m and going to r in train a. |

| nmkr | The number of railcars of station-stored railcar group k destined for r at marshalling station m. |

| lmar | The equivalent length of railcars destined for r in the inbound train a at marshalling station m. |

| lmkr | The equivalent length of the station-stored railcar group k destined for r at marshalling station m. |

| wmar | The weight of railcars arriving at marshalling station m and destined for r in inbound train a. |

| wmkr | The weight of the railcars destined for r in-station-stored railcar group k at marshalling station m. |

| The maximum equivalent length of outbound train d at marshalling station m, as specified in the assembly plan. | |

| The minimum equivalent length of outbound train d at marshalling station m, as specified in the assembly plan. | |

| The maximum weight of outbound train d at marshalling station m, as specified in the assembly plan. | |

| The minimum weight of outbound train d at marshalling station m, as specified in the assembly plan. | |

| Discriminant variables | |

| The discriminant variable of outbound trains with station-stored railcar group. = 1 means that the railcars destined for r in-station-stored railcars k at station provides the railcar-flow source for outbound train d departing from station m; otherwise, it is 0. = m means that the station-stored trains provide the railcar source for outbound trains departing from this station, and ≠ m means that the station-stored trains provide the railcar source across the stations. | |

| The number of railcars destined for r in-station-stored railcar group k at station is allocated to the number of outbound train d departing from station m. | |

| The discriminant variable for allocating the inbound trains to the outbound trains. = 1 means that the railcars destined for r in inbound train a arriving at station provides the railcar-flow source for outbound train d departing from the station m; otherwise, it is 0. = m means that the inbound train provides the railcar-flow source for the outbound train departing from this station, and ≠ m means that the inbound train provides the railcar-flow source across the stations. | |

| The number of railcars destined for r in train a arriving at station is allocated to train d departing from station . | |

| The discriminant variable for the length of the outbound train. = 1 means that outbound train d departing from station m meets the length requirement; otherwise, it is 0. | |

| The discriminant variable of outbound train weight. = 1 means that outbound train d departing from the station m meets the weight requirement; otherwise, it is 0. | |

3.3. Objective Function

- (1)

- Dwell time of on-time railcar flow

- (2)

- Dwell time of delayed railcar flow

3.4. Constraints

- (1)

- Destination direction of outbound train

- (2)

- In-station railcar flow connection time

- (3)

- Transit railcar flow connection time

- (4)

- Railcar transit constraint

- (5)

- Train full workload

3.5. Optimization Model

- st. Destination direction of outbound train: (3)–(6)

- In-station railcar-flow connection time: (7)–(8)

- Transit railcar-flow connection time: (9)–(10)

- Railcar transit constraint: (11)

- Train full workload: (12)–(14)

4. Case Study

4.1. Scenario Setting of the Experiments

4.2. Model Validation and Analysis

- (1)

- According to the solution results, considering different full workload constraint scenarios, the railcar-flow dwell time at the station was 19.48 railcar hours, the number of railcars in the station after the stage plan had ended was 67 railcars, and a total of two outbound trains were not dispatched owing to an insufficient traffic connection. Marshalling station I and station II each had one train;

- (2)

- Among the 22 outbound trains allocated on time within the stage plan, 17 trains could meet both the weight and length constraints. If only considering the train weight constraints, two additional outbound trains cannot be dispatched (the 11th and 18th trains). If only considering the train length constraints, three additional outbound trains cannot be dispatched (the 4th, 7th, and 10th trains). This result indicates that considering different full workload constraints reduces the occurrence of undispatched outbound trains.

4.3. Comparison of Railcar Flow Allocation Schemes Under Three Full Workload Constraints

- (1)

- According to Table 8, when only considering the train length constraint, the railcar flow stayed at the station for 19.9 railcar hours, the number of railcars in stock at the station after the stage plan had ended was 81 railcars, and a total of three outbound trains were not dispatched, owing to insufficient traffic connection. Marshalling station I had two trains, and marshalling station II had one train.

- (2)

- According to Table 9, when only considering the train weight constraint, the railcar flow stayed at the station for 20.93 railcar hours, the number of railcars in the station after the end of the stage plan was 128 railcars, and a total of five outbound trains were not dispatched, owing to insufficient traffic connection. Marshalling stations I and II each had two trains, while Marshalling Station III had one train.

- (1)

- From the perspective of the CPU running time, for the three models, good solutions could be obtained within a reasonable time range, meeting real-world application requirements. The model that considers different full workload constraints took less time to run than the model that only considers the train length constraint and the one that only considers the train weight constraint.

- (2)

- Judging from the indicators of the number of station-stored railcars at the station and the number of undispatched outbound trains at the end of the stage plan, when considering different full workload constraints, we found that there were fewer station-stored railcars at the station at the end of the stage plan, and the undispatched outbound trains were also fewer.

4.4. Experimental Evaluation and Key Parameter Analysis Under Different Scales

- (1)

- As the problem size increases, at problem scale ③, CPLEX can only obtain satisfactory solutions within the specified time, whereas at problem scale ④, CPLEX is unable to find a feasible solution within the specified time. However, considering the Sujiatun Station, which has the strongest operational load capacity within the Shenyang railway hub, its current average daily number of arrival and departure trains is only over 400 (in an approximate conversion, equivalent to about 17 trains per hour), we believe that the performance of CPLEX in solving problems is sufficient to meet the daily operational needs.

- (2)

- The transit time between marshalling stations significantly affects the allocation outcomes. The solution results at problem scales ① and ② indicate that an increase in transit time leads to a corresponding increase in the number of trains not dispatched, with an average increase of one to two trains for every additional 20 min of transit time ( this value is subject to factors such as the structure of railcar flows). Concurrently, an increase in transit time also results in varying degrees of increase in the dwell time of railcar flows at stations and the number of unallocated railcars. Furthermore, the satisfactory solutions at problem scale ③ also validate this trend. We conclude that this is primarily because the increased transit time for railcar flows between stations encroaches on other technical operations, reducing the sources of railcar flows available for allocation to departing trains. Consequently, this leads to an increase in the number of trains not dispatched, the dwell time of railcar flows at stations, and the number of unallocated railcars.

5. Conclusions

- (1)

- Railcar flow organization optimization is characterized by its multi-objective nature, and the process of planning is a complex decision-making process. This paper only considers the continuity of railcar flows and different full workload constraints for outbound trains without taking into account the utilization of classification tracks, the arrangement of shunting resources, and the priority levels of railcar flow organization, which are influential factors. Therefore, comprehensive optimization considering all aspects of the station is a key direction for future research.

- (2)

- The information required for railcar flow organization in multiple marshalling stations often exhibits uncertainty in actual field compilation, and the on-site environment is prone to changes (such as changes in railcar flow information and equipment failures). Therefore, it is necessary to further enhance the robustness of the plan and design real-time adjustment strategies.

- (3)

- The existing railcar flow origins and quantities are based on the train arrival times confirmed by the stage plan, without additional consideration for the variability in train arrival times. However, in actual railway operations, the size of railcar flows exhibits more randomness. Future plans include incorporating other methods to determine the size of railcar flows, such as Fuzzy logic and neural networks.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- China Youth Network. The Ministry of Transport Released the 2023 Statistical Bulletin on the Development of the Transportation Industry [EB/OL]. 18 June 2024. Available online: https://baijiahao.baidu.com/s?id=1802162673518322571&wfr=spider&for=pc (accessed on 1 July 2024).

- Pineda-Jaramillo, J.; Viti, F. Identifying the Rail Operating Features Associated to Intermodal Freight Rail Operation Delays. Transp. Res. Part C Emerg. Technol. 2023, 147, 103993. [Google Scholar] [CrossRef]

- Zhao, J.; Xiang, J.; Peng, Q. Routing and Scheduling of Trains and Engines in a Railway Marshalling Station Yard. Transp. Res. Part C Emerg. Technol. 2024, 167, 104826. [Google Scholar] [CrossRef]

- Allafeepour, A.; Tavakoli, A.; Arvin, A. An Optimization Integrated Approach for Simultaneous Allocation of Railcars and Locomotives for Train Formation Based on a Pre-Designed Time Schedule. J. Rail Transp. Plan. Manag. 2023, 25, 100366. [Google Scholar] [CrossRef]

- Anghinolfi, D.; Paolucci, M.; Sacone, S.; Siri, S. Freight Transportation in Railway Networks with Automated Terminals: A Mathematical Model and MIP Heuristic Approaches. Eur. J. Oper. Res. 2011, 214, 588–594. [Google Scholar] [CrossRef]

- Schasfoort, B.; Gkiotsalitis, K.; Eikenbroek, O.; van Berkum, E. A dynamic model for real-time track assignment at railway yards. J. Rail Transp. Plan. Manag. 2020, 14, 100198. [Google Scholar] [CrossRef]

- Bruck, B.P.; Cordeau, J.-F.; Frejinger, E. Integrated inbound train split and load planning in an intermodal railway terminal. J. Transp. Res. Part B Methodol. 2021, 145, 270–289. [Google Scholar] [CrossRef]

- Haahr, J.T.; Lusby, R.M. A matheuristic approach to integrate humping and pullout sequencing operations at railroad hump yards. J. Netw. 2016, 67, 126–138. [Google Scholar] [CrossRef]

- Khadilkar, H.; Sinha, S.K. Rule-based discrete event simulation for optimising railway hump yard operations. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016; pp. 1151–1155. [Google Scholar] [CrossRef]

- Gestrelius, S.; Aronsson, M.; Joborn, M.; Bohlin, M. Towards a comprehensive model for track allocation and roll-time scheduling at marshalling yards. J. Rail Transp. Plan. Manag. 2017, 7, 157–170. [Google Scholar] [CrossRef]

- Shi, Q.; Yagar, S. Case studies measuring the benefits of the HSS hump sequencing model. Can. J. Civ. Eng. 1983, 10, 36–47. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, X.; Qin, J.; Deng, L. Optimizing the long-term operating plan of railway marshalling station for capacity utilization analysis. J. Sci. World J. 2014, 2014, 251315. [Google Scholar] [CrossRef]

- Martinelli, D.R.; Teng, H. Optimization of railway operations using neural networks. J. Trans. Res.-C. 1995, 4, 33–49. [Google Scholar] [CrossRef]

- Shi, T.; Zhou, X. A mixed integer programming model for optimizing multi-level operations process in railroad yards. J. Transp. Res. Part B Methodol. 2015, 80, 19–39. [Google Scholar] [CrossRef]

- Raut, S.; Sinha, S.K.; Khadilkar, H.; Salsingikar, S. Rolling horizon optimisation model for consolidated hump yard operational planning. J. Rail Transp. Plan. Man 2019, 9, 3–21. [Google Scholar] [CrossRef]

- Qian, K.; Li, J.; Luo, M. Current Situation and Development of Comprehensive Automation Technology in Marshalling Station. J. IOP Conf. Ser. Mater. Sci. Eng. 2019, 688, 044028. [Google Scholar] [CrossRef]

- Lusby, R.M.; Larsen, J.; Bull, S. A Survey on Robustness in Railway Planning. J. Eur. J. Oper. Res. 2017, 266, 1–15. [Google Scholar] [CrossRef]

- Gulbrodsen, O. Optimal Planning of marshalling yard by operation research. J. Proc. 1963, 12, 226–233. [Google Scholar]

- Hein, O. A two-stage queuing model for a marshalling yard. Rail Int. 1972, 3, 249–259. [Google Scholar]

- Glover, F.; Karney, D.; Klingman, D.; Russell, R. Solving Singly Constrained Transshipment Problems. J. Transp. Sci. 1978, 12, 277–297. [Google Scholar] [CrossRef]

- Gupta, U.I.; Lee, D.T.; Leung, Y.T. An Optimal Solution for the Channel-Assignment Problem. J. IEEE Trans. Comput. 1979, C–28, 807–810. [Google Scholar] [CrossRef]

- Assad, A.A. Modelling of rail networks: Toward a routing/makeup model. J. Transp. Res. Part B 1980, 14, 101–114. [Google Scholar] [CrossRef]

- Bodin, L.D.; Golden, B.L.; Schuster, A.D.; Romig, W. A model for the blocking of trains. J.Transp. Res. Part B Methodol. 1980, 14, 115–120. [Google Scholar] [CrossRef]

- Crainic, T.; Ferland, J.-A.; Rousseau, J.-M. A Tactical Planning Model for Rail Freight Transportation. J. Transp. Sci. 1984, 18, 165–184. [Google Scholar] [CrossRef]

- Ferreira, L. Planning Australian freight rail operations: An overview. J. Transp. Res. Part A Policy Pract. 1997, 31, 335–348. [Google Scholar] [CrossRef]

- Marton, P.; Maue, J.; Nunkesser, M. An Improved Train Classification Procedure for the Hump Yard Lausanne Triage. In Proceedings of the ATMOS 2009—9th Workshop on Algorithmic Approaches for Transportation Modeling, Optimization, and Systems, Copenhagen, Denmark, 10 September 2009; DBLP: Trier, Germany, 2009. [Google Scholar]

- Bohlin, M.; Flier, H.; Maue, J.; Mihalák, M. Hump Yard Track Allocation with Temporary Car Storage. In Proceedings of the 4th International Seminar on Railway Operations Modelling and Analysis, Rome, Italy, 16–18 February 2011. [Google Scholar]

- Keaton, M.H. Designing optimal railroad operating plans: Lagrangian relaxation and heuristic approaches. J. Transp. Res. Part B 1989, 23, 415–431. [Google Scholar] [CrossRef]

- Keaton, M.H. Designing Railroad Operating Plans: A Dual Adjustment Method for Implementing Lagrangian Relaxation. Transp. Sci. 1992, 26, 263–279. [Google Scholar] [CrossRef]

- Peng, Q.; Zhao, J.; Han, X. Model and algorithm for the generalized wagon-flow allocation problem of railway technical station. J. China Railw. Sci. 2010, 31, 108–114. [Google Scholar]

- Wang, R.; Wang, C.; Jing, Y.; Feng, M. Study on the Minimum Number of Cars in Fixed-point Departure Mode. J. Railw. Transp. Econ. 2009, 31, 85–88. [Google Scholar]

- Wang, R.; Wang, C. Adaptability study of fixed-point departure mode of originated freight trains in railway marshalling stations. J. Beijing Univ. Technol. 2011, 37, 541–546. [Google Scholar] [CrossRef]

- Liu, C.; Sun, W.H. Research on optimization of sorting sequence of marshalling station trains in the time-fixed assembly mode with softened terms. J. China Railw. Soc. 2012, 34, 1–7. [Google Scholar] [CrossRef]

- Lin, F. The Theoretical Research Between Fixed-Time and Fixed Train Length of the Traffic Flows in Marshalling Yard. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2017. [Google Scholar]

- Li, J. Optimization of Fright Train Length in the Market Competition. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2020. [Google Scholar]

- Yan, L.; Lei, C.; Yu, C.; Zhang, D. A study of the overall reconstruction design of Shenyang North Railway Station and the station area. In Proceedings of the International Conference on Civil Engineering, Architecture and Building Materials, London, UK, 7–8 July 2012. [Google Scholar]

- Zhou, T.J. Further research on overall planning of Wuhan railway terminal. J. Railw. Stand. Des. 2014, 58, 1–4. [Google Scholar]

- Gao, M.M. Research on the arrangement planning for freighr traffic system of Beijing railway terminal. J. Railw. Eng. Soc. 2010, 27, 101–106. [Google Scholar]

- Marinov, M.; Di Giovanni, L.; Bellisai, G.; Clevermann, J.; Mastellou, A.; Victόria, D.; Deleva, L. Analysis of rail yard and terminal performances. J. Transp. Lit. 2014, 8, 178–200. [Google Scholar] [CrossRef]

| Marshalling Station | Coupling/Decoupling Capacity (Railcar) | The Transship Capacity (Railcar) | Trip Time Among Marshalling Stations (min) | |||||

|---|---|---|---|---|---|---|---|---|

| Break-Up | Make-UP | I | II | III | I | II | III | |

| I | 480 | 450 | - | 65 | 50 | - | 31 | 38 |

| II | 390 | 420 | - | - | 60 | - | - | 27 |

| III | 400 | 380 | - | - | - | - | - | - |

| Railcar-Flow Number | Marshalling Station | Destination Station Direction | Number of Railcars | Weight of Every Railcar (t) | Equivalent Length of Every Railcar |

|---|---|---|---|---|---|

| 1 | I | 2 | 3 | 58/65/66 | 1.3/1.3/1.3 |

| 2 | I | 4 | 8 | 54/54/54/58/58/60/59/60 | 1.1/1.1/1.2/1.2/1.2/1.2/1.2/1.2 |

| 3 | I | 6 | 5 | 58/57/62/65/63 | 1.3/1.4/1.4/1.4/1.4 |

| 4 | II | 5 | 6 | 54/52/65/53/56/64 | 1.2/1.1/1.4/1.1/1.2/1.3 |

| 5 | II | 7 | 8 | 52/53/54/54/53/52/55/56 | 1.1/1.1/1.2/1.2/1.1/1.2/1.2/1.2 |

| 6 | II | 1 | 4 | 63/58/60/65 | 1.4/1.4/1.4/1.4 |

| 7 | III | 3 | 3 | 60/67/65 | 1.3/1.4/1.3 |

| 8 | III | 8 | 5 | 66/63/60/52/65 | 1.4/1.4/1.3/1.3/1.4 |

| Inbound Trains | Arrival Marshalling Station | Time of Arrival at the Marshalling Station | Train Type | Inbound Trains | Arrival Marshalling Station | Time of Arrival at the Marshalling Station | Train Type |

|---|---|---|---|---|---|---|---|

| 1 | I | 9:05 | 0 | 13 | I | 9:56 | 0 |

| 2 | II | 9:09 | 0 | 14 | II | 9:59 | 0 |

| 3 | I | 9:15 | 0 | 15 | III | 10:03 | 0 |

| 4 | III | 9:18 | 1 | 16 | I | 10:06 | 1 |

| 5 | II | 9:21 | 0 | 17 | II | 10:17 | 0 |

| 6 | III | 9:32 | 0 | 18 | III | 10:21 | 1 |

| 7 | I | 9:32 | 0 | 19 | I | 10:25 | 0 |

| 8 | II | 9:39 | 0 | 20 | I | 10:31 | 0 |

| 9 | III | 9:45 | 1 | 21 | III | 10:37 | 0 |

| 10 | I | 9:47 | 0 | 22 | II | 10:45 | 0 |

| 11 | III | 9:52 | 0 | 23 | I | 10:52 | 0 |

| 12 | II | 9:55 | 0 | 24 | III | 10:56 | 0 |

| Inbound Trains | Destination Station Direction | Number of Railcars | Weight of Every Railcar (t) | Equivalent Length of Every Railcar |

|---|---|---|---|---|

| 1 | 2 | 8 | 58/65/72/65/48/52/54/55 | 1.2/1.4/1.5/1.2/1.3/1.3/1.2/1.2 |

| 1 | 4 | 14 | 52/54/58/60/54/55/52/53/55/ 52/52/53/54/54 | 1.1/1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/ 1.2/1.2/1.2/1.2/1.2 |

| 1 | 7 | 12 | 54/54/54/58/58/60/59/60/65/53/56/64 | 1.1/1.1/1.1/1.3/1.3/1.3/1.3/1.3/1.4/1.1/1.2/1.4 |

| 2 | 4 | 10 | 54/54/54/58/58/60/59/60/52/48 | 1.1/1.1/1.2/1.2/1.2/1.2/1.2/1.2/1.1/1.1 |

| 2 | 6 | 7 | 62/63/59/72/58/59/60 | 1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 2 | 7 | 8 | 52/53/54/54/53/52/55/56 | 1.1/1.1/1.2/1.2/1.1/1.2/1.2/1.2 |

| 2 | 8 | 10 | 52/54/58/60/54/55/52/53/55/52 | 1.1/1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/1.1 |

| 3 | 3 | 8 | 54/54/54/58/58/60/59/60 | 1.1/1.1/1.1/1.3/1.3/1.3/1.3/1.3 |

| 3 | 5 | 12 | 66/63/60/52/65/52/54/58/60/54/55/52 | 1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 3 | 7 | 12 | 64/62/59/54/60/51/56/57/60/54/54/54 | 1.3/1.4/1.3/1.4/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 4 | 4 | 12 | 66/61/60/55/65/52/53/58/60/53/54/53 | 1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 4 | 6 | 9 | 54/58/60/54/55/52/53/55/52 | 1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/1.1 |

| 5 | 1 | 12 | 54/54/54/58/58/60/59/60/65/53/56/64 | 1.1/1.1/1.1/1.3/1.3/1.3/1.3/1.3/1.4/1.1/1.2/1.4 |

| 5 | 2 | 10 | 54/55/52/53/55/52/52/53/54/54 | 1.1/1.2/1.2/1.2/1.2/1.2/1.2/1.2/1.2/1.2 |

| 5 | 5 | 10 | 60/52/65/52/54/58/60/54/55/52 | 1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 5 | 8 | 9 | 54/60/51/56/57/60/54/54/54 | 1.4/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 6 | 3 | 12 | 55/57/52/56/60/62/63/59/72/58/59/60 | 1.1/1.1/1.2/1.2/1.1/1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 6 | 6 | 11 | 57/60/54/54/54/54/58/60/ 54/55/52 | 1.3/1.3/1.1/1.2/1.2/1.1/1.3/1.3/1.2/1.2/1.2 |

| 6 | 8 | 15 | 53/55/52/66/61/60/55/65/52/53/58/60/53/54/53 | 1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 7 | 1 | 8 | 68/60/54/55/52/53/65/72 | 1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 7 | 5 | 14 | 63/53/65/62/59/52/65/52/54/58/60/54/55/52 | 1.4/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 7 | 7 | 12 | 56/52/53/52/72/63/54/54/53/52/55/66 | 1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 8 | 4 | 8 | 60/51/56/57/60/54/54/54 | 1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 8 | 6 | 15 | 62/53/53/65/62/59/52/65/52/54/58/60/54/55/52 | 1.4/1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 8 | 7 | 12 | 64/62/59/54/60/51/56/57/60/54/54/54 | 1.3/1.4/1.3/1.4/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 9 | 5 | 12 | 56/56/52/56/60/62/63/59/72/58/59/60 | 1.2/1.2/1.1/1.2/1.1/1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 9 | 7 | 8 | 68/60/54/55/52/53/65/62 | 1.5/1.3/1.1/1.2/1.2/1.2/1.5/1.4 |

| 10 | 2 | 15 | 52/54/52/68/62/60/55/65/52/53/58/60/53/54/53 | 1.1/1.2/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 10 | 4 | 10 | 52/54/58/60/54/55/52/53/55/52 | 1.1/1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/1.1 |

| 10 | 8 | 15 | 54/54/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.2/1.2/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 11 | 3 | 6 | 60/54/58/52/53/67 | 1.3/1.1/1.4/1.2/1.2/1.5 |

| 11 | 5 | 14 | 53/52/65/63/60/52/65/52/54/58/60/54/55/52 | 1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 11 | 7 | 16 | 52/53/56/55/66/61/60/55/65/52/53/58/60/53/54/53 | 1.1/1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 12 | 2 | 12 | 66/63/60/52/65/52/54/58/60/54/55/52 | 1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 12 | 4 | 9 | 59/68/60/54/55/52/53/65/72 | 1.4/1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 12 | 7 | 15 | 52/56/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 13 | 4 | 14 | 52/54/66/62/59/52/65/52/54/58/60/54/55/52 | 1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 13 | 6 | 6 | 64/65/72/53/65/72 | 1.4/1.4/1.6/1.2/1.5/1.6 |

| 13 | 7 | 15 | 52/53/53/65/62/59/52/65/52/54/58/60/ 54/55/52 | 1.1/1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 14 | 4 | 15 | 53/55/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 14 | 5 | 8 | 61/68/60/54/58/52/53/67 | 1.4/1.6/1.3/1.1/1.4/1.2/1.2/1.5 |

| 14 | 7 | 14 | 53/53/65/62/59/52/65/52/54/58/60/54/55/52 | 1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 15 | 3 | 14 | 52/53/66/63/60/52/65/52/54/58/60/54/55/52 | 1.1/1.1/1.4/1.4/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.2/1.2/1.2 |

| 15 | 6 | 12 | 55/57/52/56/60/62/63/59/72/58/59/60 | 1.1/1.1/1.2/1.2/1.1/1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 15 | 7 | 8 | 59/68/60/54/58/52/53/65 | 1.4/1.6/1.3/1.1/1.4/1.2/1.2/1.5 |

| 15 | 8 | 5 | 65/72/53/65/72 | 1.4/1.6/1.2/1.5/1.6 |

| 16 | 5 | 12 | 56/52/53/52/72/63/54/54/53/52/55/66 | 1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 16 | 7 | 8 | 54/60/51/56/57/60/54/54 | 1.4/1.4/1.1/1.1/1.3/1.3/1.1/1.2 |

| 17 | 1 | 12 | 55/57/52/56/60/62/63/59/72/58/59/60 | 1.1/1.1/1.2/1.2/1.1/1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 17 | 5 | 5 | 68/59/68/60/54 | 1.5/1.4/1.6/1.3/1.1 |

| 17 | 7 | 12 | 57/52/53/52/72/63/54/54/53/52/55/66 | 1.3/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 17 | 8 | 9 | 66/68/60/54/55/52/53/65/72 | 1.5/1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 18 | 4 | 6 | 64/65/72/53/65/72 | 1.4/1.4/1.6/1.2/1.5/1.6 |

| 18 | 6 | 8 | 61/68/60/54/58/52/53/67 | 1.4/1.6/1.3/1.1/1.4/1.2/1.2/1.5 |

| 18 | 7 | 9 | 68/59/68/60/54/58/52/53/65 | 1.5/1.4/1.6/1.3/1.1/1.4/1.2/1.2/1.5 |

| 19 | 4 | 8 | 68/60/54/55/52/53/65/72 | 1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 19 | 5 | 16 | 51/53/55/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.1/1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 19 | 7 | 14 | 55/52/52/52/53/52/72/63/54/54/53/52/55/66 | 1.2/1.2/1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/ 1.2/1.2/1.4 |

| 20 | 3 | 8 | 68/60/54/55/52/53/65/72 | 1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 20 | 4 | 14 | 52/56/56/52/53/52/72/63/54/54/53/52/55/66 | 1.1/1.2/1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/ 1.2/1.2/1.4 |

| 20 | 6 | 16 | 52/52/56/54/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.1/1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 21 | 4 | 8 | 72/63/54/54/53/52/55/66 | 1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 21 | 7 | 15 | 53/55/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 21 | 8 | 12 | 55/52/53/52/72/63/54/54/53/52/55/66 | 1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 22 | 5 | 12 | 55/57/52/56/60/62/63/59/72/58/59/60 | 1.1/1.1/1.2/1.2/1.1/1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 22 | 6 | 7 | 60/54/55/52/53/65/72 | 1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 22 | 7 | 14 | 51/56/55/52/53/52/72/63/54/54/53/52/55/66 | 1.1/1.2/1.2/1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| 23 | 4 | 15 | 55/53/54/57/60/54/55/52/53/55/53/53/52/55/54 | 1.3/1.1/1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/ 1.2/1.2/1.2/1.2/1.2 |

| 23 | 5 | 15 | 56/52/54/58/60/54/55/52/53/55/ 52/52/53/54/54 | 1.3/1.1/1.1/1.3/1.3/1.1/1.2/1.2/1.2/1.2/ 1.2/1.2/1.2/1.2/1.2 |

| 23 | 6 | 7 | 62/63/59/72/58/59/60 | 1.4/1.4/1.3/1.6/1.4/1.4/1.4 |

| 24 | 4 | 9 | 59/68/60/54/55/52/53/65/72 | 1.6/1.3/1.1/1.2/1.2/1.2/1.5/1.6 |

| 24 | 6 | 16 | 51/53/55/52/66/61/60/55/65/52/53/58/60/ 53/54/53 | 1.1/1.2/1.2/1.1/1.4/1.3/1.3/1.3/1.4/1.1/1.1/1.3/1.3/1.1/1.2/1.2 |

| 24 | 7 | 11 | 52/53/52/72/63/54/54/53/52/55/66 | 1.1/1.1/1.2/1.6/1.4/1.2/1.2/1.1/1.2/1.2/1.4 |

| Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Train Type | Destination Station Direction | Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Train Type | Destination Station Direction |

|---|---|---|---|---|---|---|---|---|---|

| 1 | I | 11:00 | 0 | 4,6 | 13 | I | 11:58 | 0 | 4,7,8 |

| 2 | II | 11:03 | 1 | 1 | 14 | III | 12:02 | 0 | 5,7 |

| 3 | I | 11:07 | 1 | 2,3 | 15 | II | 12:07 | 0 | 4,6,7 |

| 4 | III | 11:18 | 0 | 6,8 | 16 | II | 12:15 | 0 | 4,5,7 |

| 5 | I | 11:17 | 0 | 4,7 | 17 | III | 12:20 | 1 | 3 |

| 6 | III | 11:18 | 0 | 2,3 | 18 | II | 12:23 | 0 | 5,6 |

| 7 | II | 11:26 | 0 | 5,7,8 | 19 | I | 12:28 | 0 | 4,5,6 |

| 8 | I | 11:28 | 0 | 4,5,6 | 20 | I | 12:34 | 0 | 4,5,7 |

| 9 | II | 11:37 | 0 | 4,6,7 | 21 | III | 12:38 | 0 | 6,7 |

| 10 | I | 11:45 | 0 | 4,6 | 22 | I | 12:44 | 0 | 4,5,7 |

| 11 | III | 11:48 | 0 | 4,5 | 23 | III | 12:46 | 0 | 4,6,7 |

| 12 | II | 11:50 | 1 | 2,3 | 24 | II | 12:56 | 0 | 5,7,8 |

| Outbound Trains | Train Weight Range (t) | Train Length Range | Outbound Trains | Train Weight Range (t) | Train Length Range |

|---|---|---|---|---|---|

| 1 | [1550,1820] | [35,42] | 13 | [1750,2100] | [38,48] |

| 2 | [1320,2100] | [28,40] | 14 | [1120,1560] | [28,38] |

| 3 | [1550,1860] | [28,48] | 15 | [1350,2200] | [35,48] |

| 4 | [1560,2100] | [35,42] | 16 | [1360,1820] | [31,42] |

| 5 | [1320,1820] | [28,42] | 17 | [1420,1860] | [31,42] |

| 6 | [1350,2100] | [28,48] | 18 | [1520,1820] | [31,42] |

| 7 | [1760,2400] | [35,48] | 19 | [1500,1860] | [31,38] |

| 8 | [1360,1820] | [28,42] | 20 | [1420,1860] | [31,38] |

| 9 | [1360,1820] | [31,40] | 21 | [1320,1820] | [31,38] |

| 10 | [1320,1800] | [31,38] | 22 | [1520,1800] | [31,42] |

| 11 | [1550,1800] | [28,42] | 23 | [1360,1800] | [28,38] |

| 12 | [1420,1800] | [31,48] | 24 | [1750,1820] | [35,42] |

| Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length | Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length |

|---|---|---|---|---|---|---|---|---|---|

| 1 | I | 11:00 | - | - | 13 | I | 11:58 | 1839 | 40 |

| 2 | II | 11:03 | 1337 | 30 | 14 | III | 12:02 | 1198 | 30.1 |

| 3 | I | 11:07 | 1999 | 45.5 | 15 | II | 12:07 | 2081 | 46.6 |

| 4 | III | 11:18 | 2006 | 46.4 | 16 | II | 12:15 | 1734 | 40.5 |

| 5 | I | 11:17 | 1444 | 30.7 | 17 | III | 12:20 | 1426 | 32.6 |

| 6 | III | 11:18 | 1815 | 40 | 18 | II | 12:23 | 1304 | 33.8 |

| 7 | II | 11:26 | 2282 | 50.9 | 19 | I | 12:28 | 1530 | 36.8 |

| 8 | I | 11:28 | 1642 | 39.1 | 20 | I | 12:34 | 1468 | 35.9 |

| 9 | II | 11:37 | 1730 | 38.9 | 21 | III | 12:38 | 1347 | 32.7 |

| 10 | I | 11:45 | 1479 | 30.3 | 22 | I | 12:44 | 1561 | 34.9 |

| 11 | III | 11:48 | 1292 | 30.4 | 23 | III | 12:46 | 1388 | 30 |

| 12 | II | 11:50 | 1726 | 40 | 24 | II | 12:56 | - | - |

| Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length | Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length |

|---|---|---|---|---|---|---|---|---|---|

| 1 | I | 11:00 | - | - | 13 | I | 11:58 | 2021 | 44.1 |

| 2 | II | 11:03 | 1650 | 37 | 14 | III | 12:02 | 1536 | 37.2 |

| 3 | I | 11:07 | 1587 | 37 | 15 | II | 12:07 | 1706 | 37.6 |

| 4 | III | 11:18 | 1745 | 39.6 | 16 | II | 12:15 | 1578 | 37 |

| 5 | I | 11:17 | - | - | 17 | III | 12:20 | 1606 | 37.1 |

| 6 | III | 11:18 | 2031 | 45.2 | 18 | II | 12:23 | 1420 | 37 |

| 7 | II | 11:26 | 1993 | 44.3 | 19 | I | 12:28 | 1482 | 37.2 |

| 8 | I | 11:28 | 1655 | 38.5 | 20 | I | 12:34 | 1575 | 37.1 |

| 9 | II | 11:37 | 1741 | 38.2 | 21 | III | 12:38 | 1547 | 37.2 |

| 10 | I | 11:45 | 1710 | 37 | 22 | I | 12:44 | 1656 | 37.6 |

| 11 | III | 11:48 | 1580 | 37.1 | 23 | III | 12:46 | 1785 | 37.7 |

| 12 | II | 11:50 | 2004 | 46 | 24 | II | 12:56 | - | - |

| Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length | Outbound Trains | Departure Marshalling Station | Time of Departure at the Marshalling Station | Hauling Weight (t) | Equivalent Length |

|---|---|---|---|---|---|---|---|---|---|

| 1 | I | 11:00 | - | - | 13 | I | 11:58 | 1983 | 61.1 |

| 2 | II | 11:03 | 1752 | 39.3 | 14 | III | 12:02 | - | - |

| 3 | I | 11:07 | 1753 | 40.4 | 15 | II | 12:07 | 2171 | 48 |

| 4 | III | 11:18 | 1817 | 40.9 | 16 | II | 12:15 | 1784 | 41.3 |

| 5 | I | 11:17 | - | - | 17 | III | 12:20 | 1770 | 40.6 |

| 6 | III | 11:18 | 1986 | 44.1 | 18 | II | 12:23 | 1751 | 44.9 |

| 7 | II | 11:26 | 2065 | 45.6 | 19 | I | 12:28 | 1770 | 43.9 |

| 8 | I | 11:28 | 1775 | 41.4 | 20 | I | 12:34 | 1806 | 43.5 |

| 9 | II | 11:37 | 1782 | 39.7 | 21 | III | 12:38 | 1785 | 43.6 |

| 10 | I | 11:45 | 1751 | 35.5 | 22 | I | 12:44 | 1774 | 38.8 |

| 11 | III | 11:48 | 1751 | 41.1 | 23 | III | 12:46 | - | - |

| 12 | II | 11:50 | 1783 | 41.5 | 24 | II | 12:56 | - | - |

| Comparative Indicators | Comparative models | ||

|---|---|---|---|

| Different Full Workload | Equivalent Length Limitation | Hauling Weight Limitation | |

| CPU running time (s) | 322 | 376 | 451 |

| Dwell time of terminal railcar flow (h) | 1169 | 1194 | 1256 |

| Railcars unallocated into the outbound trains (railcar) | 67 | 81 | 128 |

| Outbound trains not dispatched within the time range of the stage plan (train) | 2 | 3 | 5 |

| Comparative Indicators | Scenario Configuration | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scale ① | Scale ② | Scale ③ | Scale ④ | |||||||||

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | |

| CPU running time (s) | 316 | 356 | 374 | 896 | 966 | 1120 | 3600 | 3600 | 3600 | # | # | # |

| Dwell time of terminal railcar flow (h) | 1178 | 1189 | 1232 | 1312 | 1346 | 1425 | 1620 * | 1677 * | 1783 * | # | # | # |

| Railcars unallocated into the outbound trains (railcar) | 47 | 61 | 117 | 103 | 131 | 147 | 137 * | 151 * | 226 * | # | # | # |

| Outbound trains not dispatched within time range of the stage plan (train) | 2 | 2 | 4 | 4 | 5 | 6 | 5 * | 5 * | 8 * | # | # | # |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Li, B.; Ren, Z.; Cao, Z. Dynamic Railcar Flow Assignment of Railway Terminal with Multiple Marshalling Stations. Systems 2024, 12, 514. https://doi.org/10.3390/systems12120514

Zhou X, Li B, Ren Z, Cao Z. Dynamic Railcar Flow Assignment of Railway Terminal with Multiple Marshalling Stations. Systems. 2024; 12(12):514. https://doi.org/10.3390/systems12120514

Chicago/Turabian StyleZhou, Xiaoqian, Bing Li, Zeqiang Ren, and Ziao Cao. 2024. "Dynamic Railcar Flow Assignment of Railway Terminal with Multiple Marshalling Stations" Systems 12, no. 12: 514. https://doi.org/10.3390/systems12120514

APA StyleZhou, X., Li, B., Ren, Z., & Cao, Z. (2024). Dynamic Railcar Flow Assignment of Railway Terminal with Multiple Marshalling Stations. Systems, 12(12), 514. https://doi.org/10.3390/systems12120514