The Evaluation Prediction System for Urban Advanced Manufacturing Development

Abstract

:1. Introduction

- (1)

- This article expands the evaluation indicators of UAM from the perspective of PPM theory. Specifically, we evaluate UAM from the perspectives of economy, technology, and environment, and adds some new indicators. Thus, a more scientific and comprehensive evaluation system has been established.

- (2)

- Using machine learning (ML) method to predict the evaluation results of other cities through a small amount of sample data. This extends the existing evaluation methods. Specifically, this allows for the evaluation of large sample data through a small amount of sample data, overcoming the problem of lacking sample indicators.

2. Literature Review

2.1. The Concept of Urban Advanced Manufacturing Development

- (1)

- Environmental regulations aim to reduce the negative impact of manufacturing development on the environment and promote itself transformation. Zhang et al. (2023) [10] found that environmental regulation accelerates the transfer of equipment manufacturing industry, but its impact on its international competitiveness presents a “U-shaped” pattern. Xie et al. (2023) [11] found technology innovation can be stimulated by combining environmental regulation and other policies to improve capacity utilization in moderate and severe pollution sectors. Wen et al. (2022) [12] found that environmental regulation can force manufacturing enterprises to transform and improve total factor productivity. Lena et al. (2022) [13] analyzed the impact of environmental policies on productivity in manufacturing industries in Italy. The result show that environmental regulation has no negative impact in most samples.

- (2)

- Economic development involves the overall development scale of large-scale manufacturing industry and the efficiency level of manufacturing enterprises. If the level of regional economic development is low, it will be difficult to attract a large number of manufacturing enterprises to gather and form a huge trade market. Popov et al. (2022) [14] evaluated the impact of regional economic diversification on the gross domestic product of the manufacturing industry. The results showed that regional economic diversification has a long-term impact on its stable economic development. Li et al. (2021) [15] found industrial agglomeration has a significant promoting effect on the improvement of the global value chain position of the manufacturing. Li et al. (2018) [16] found diversified agglomeration is more conducive to innovation for manufacturing enterprises than specialized agglomeration.

- (3)

- Only by continuously improving the level of intelligence in a region’s manufacturing industry can we effectively ensure the development advantages of the urban manufacturing. Lo et al. (2022) [17] found technology patents improve the total factor productivity of manufacturing enterprises by reducing operating costs, improving resource allocation efficiency, and enhancing innovation capabilities. Li et al. (2022) [18] believed that big data-driven analysis, as one of the key technologies of artificial intelligence, can improve the market competitiveness of the manufacturing and help business leaders make wise decisions. Von Joerg et al. (2022) [19] found that small and medium-sized manufacturing enterprises can create new business models by effectively utilizing AI resources. Wang et al. (2022) [20] found that artificial intelligence can significantly improve the total factor productivity of manufacturing enterprises. Specifically implemented from three aspects: technological innovation, human capital optimization, and market matching. Leoni et al. (2022) [21] found that manufacturing companies can deploy artificial intelligence to stimulate knowledge management processes and improve their supply chain resilience and performance.

2.2. Evaluation Methods

3. Methodology

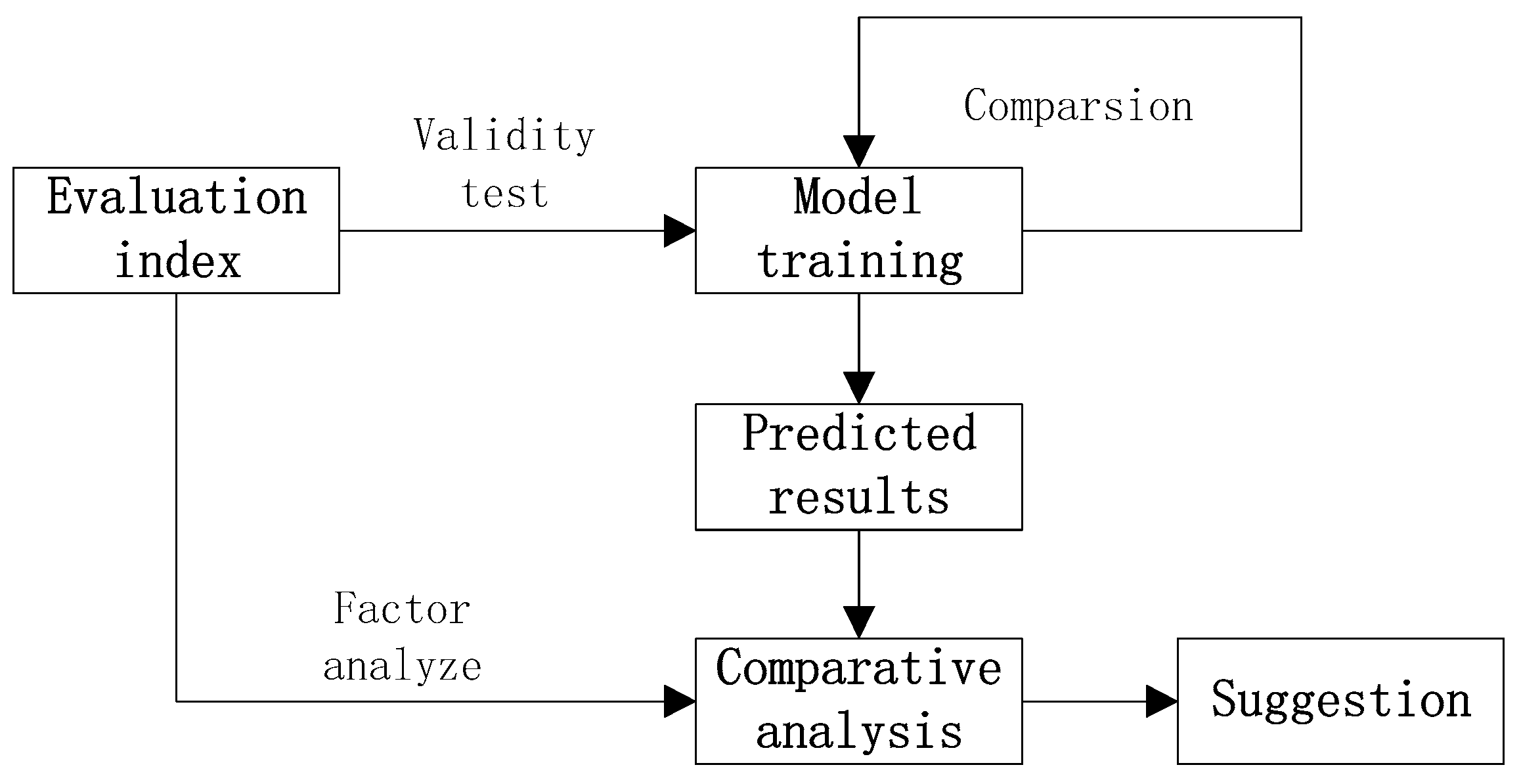

3.1. Research Framework

3.2. Sample Selection Basis

3.3. Evaluation Index

3.3.1. Theoretical Basis

3.3.2. Main Index

3.3.3. Mapping Index

3.4. Research Method

3.4.1. Data Processing Module

3.4.2. Factor Analysis Module

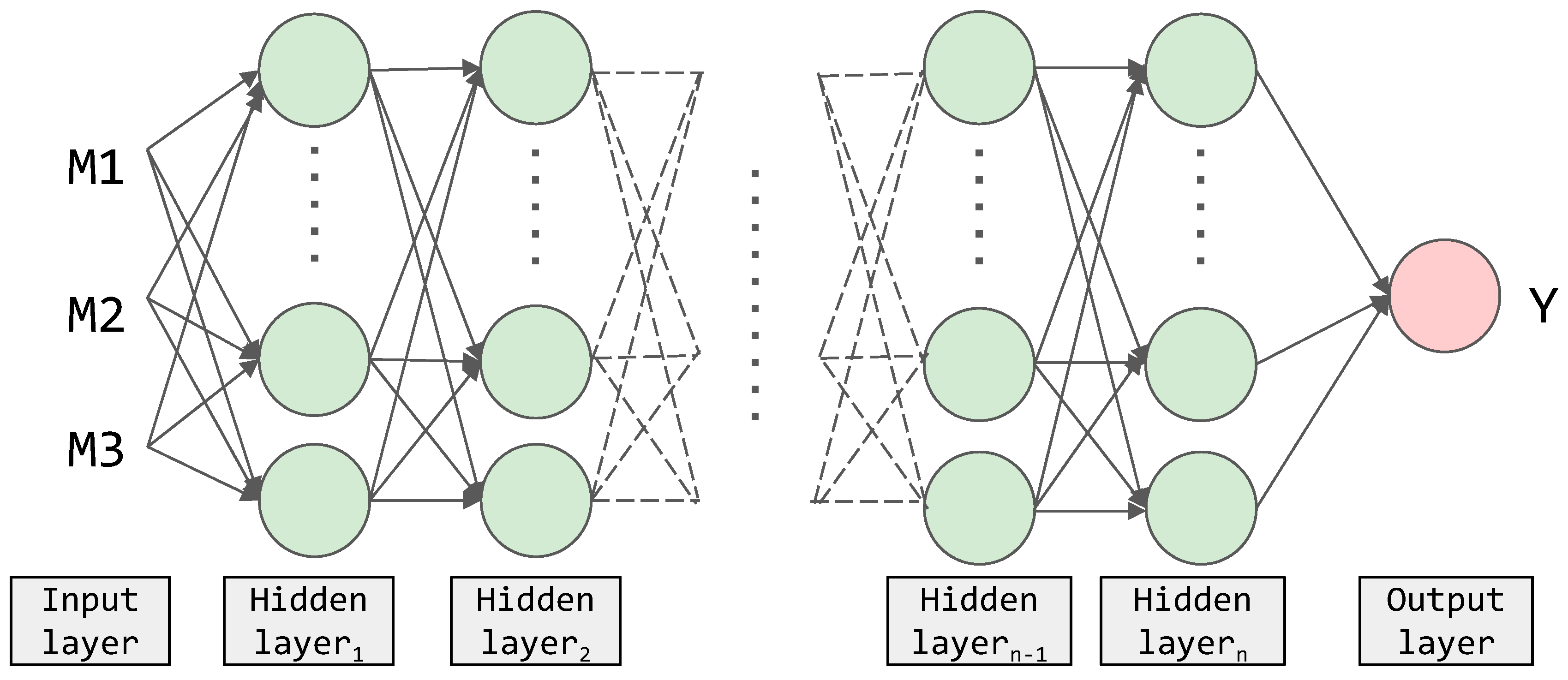

3.4.3. The Machine Learning Module

3.5. Evaluation Criterions Module

4. Experimental Results and Analysis

4.1. Factor Analysis Results

- (1)

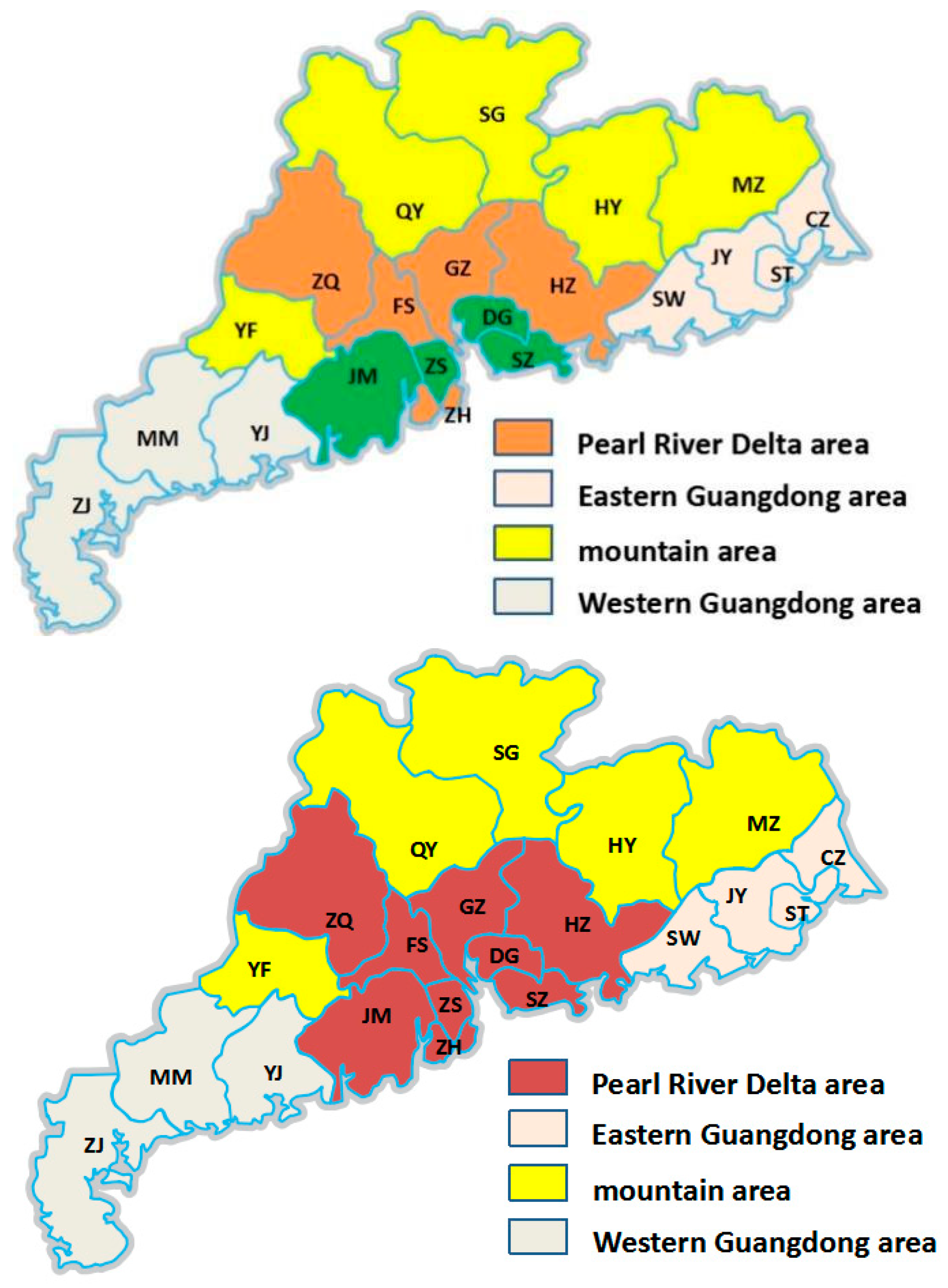

- The UAM in the Pearl River Delta region is generally in a leading position. SZ, GZ, FS, and DG have strong development, which is in line with the actual development situation. Based on Figure 3, it can be seen that these cities occupy the core position of GD and have the advantage of developing manufacturing. After years of development, both the manufacturing and information technology industries have dominated the local economy.

- (2)

- There is potential for the development of UAM in the eastern and western areas of GD. Based on Figure 3, JY is located in the central location of cities in the eastern GD area. It is in a leading position with overall strength still maintained, but its development potential is now relatively lower than that of ST. On the other hand, MM is located in the central area of three cities in the western GD area. Over time, the gap between its scores and those of the other two cities has gradually widened.

- (3)

- The overall development level of mountainous areas is not high, and it is necessary to increase the development of UAM. Based on Figure 3, it can be seen that cities in mountainous areas are relatively scattered and cannot form a central area for manufacturing factor resource aggregation like the other three areas. Compared to the other 16 cities, the 5 cities in this region are vast and sparsely populated and are located in a mountainous area to the north due to geographical limitations.

- (4)

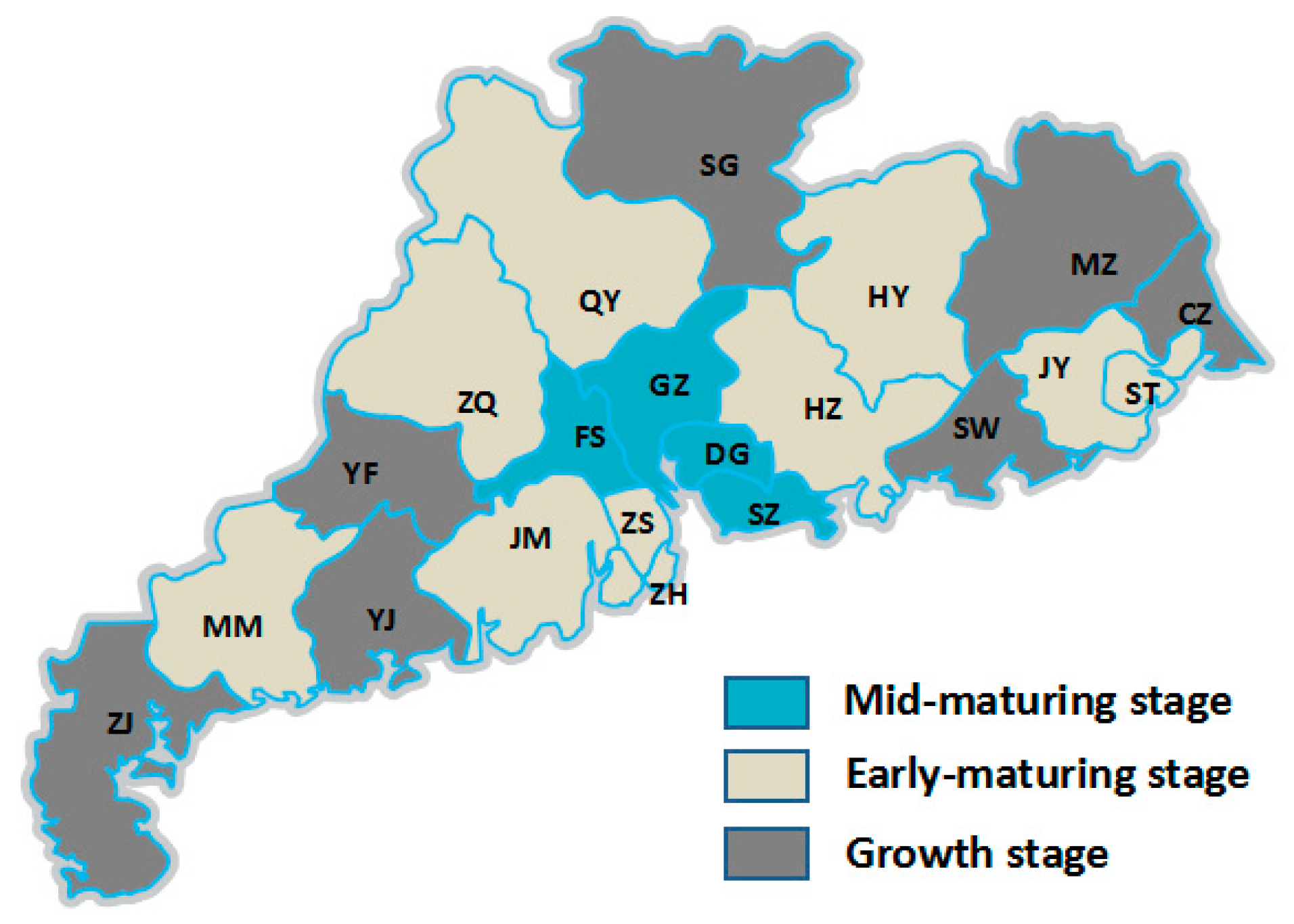

- In terms of the overall development level of GD, first, each area has its own cities with good development levels. Cities with higher levels of development in these regions have a demonstrative role and can lead the development of the region. Second, the scores of these cities have obvious periodicity. Even if leading cities in other regions have a lower level of development than the four leading cities in the Pearl River Delta, they are in the same stage of development as the remaining five cities. According to the life cycle theory, the four leading cities in the Pearl River Delta, GZ, SZ, FS, and DG, belong to the mid-maturing stage. Leading cities in other regions, such as MM, JY, ST, QY, and HY as well as the remaining five cities in the Pearl River Delta, are in the early-maturity stage. The remaining cities in GD belong to the growth stage. In the mid-maturing stage, cities not only have a spillover effect on the early-maturing stage, but also have a demonstrative effect on them. Similarly, cities in the early-maturing stage will also enable cities in the growth stage to learn and imitate them. Cities with different life cycles are shown in Figure 4.

4.2. Model Training

4.3. Model Comparison Results

4.4. Prediction Results

4.5. Analysis

4.5.1. The Development Path of the Mid-Maturing Cities

4.5.2. The Development Path of the Early-Maturing Cities

4.5.3. The Development Path of the Growth Cities

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, K.; Peng, J. The Manufacturing Sector’s strategic Position and Role in China’s New Stage of Development. Soc. Sci. China 2021, 5, 128–149+207. [Google Scholar]

- Li, B.; Liu, Z. Measurement and Evolution of High-quality Development Level of Marine Fishery in China. Chin. Geogr. Sci. 2022, 32, 251–267. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.Q.; Jin, T.; Liu, Y. Effects of environmental regulation on the upgrading of Chinese manufacturing industry. Environ. Sci. Pollut. Res. 2019, 26, 27087–27099. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Zhang, W.M.; Zhang, Y.L. Carbon Performance Evaluation of Automobile Manufacturing Industry in Green Supply Chain. In Proceedings of the International Conference on Robots and Intelligent System (ICRIS), Haikou, China, 15–16 June 2019; pp. 405–408. [Google Scholar]

- Yan, Y.; Chu, D.J. Evaluation of Enterprise Management Innovation in Manufacturing Industry Using Fuzzy Multicriteria Decision-Making under the Background of Big Data. Math. Probl. Eng. 2021, 3, 2163–2190. [Google Scholar] [CrossRef]

- Zheng, W.; Tian, X.; Yang, B.; Liu, S.; Ding, Y.; Tian, J.; Yin, L. A Few Shot Classification Methods Based on Multiscale Relational Networks. Appl. Sci. 2022, 12, 4059. [Google Scholar] [CrossRef]

- Jia, F.; Ma, X.; Xu, X. The Differential Role of Manufacturing and Non-manufacturing TFP Growth in Economic Growth. Struct. Change Econ. Dyn. 2019, 52, 174–183. [Google Scholar] [CrossRef]

- Xin, G.B. Promote high-quality development of manufacturing industry. Macroecon. Manag. 2019, 2, 5–7. [Google Scholar]

- Liu, G.X.; Wang, J.; Jiang, L.W. Theoretical mechanism and evaluation analysis of high-quality development of China’s manufacturing industry. Ind. Econ. 2020, 3, 20–24. [Google Scholar]

- Zhang, X.F.; Fan, D.C. Research on the influence mechanism of heterogeneous environmental regulation on the manufacturing equipment industry in Asia-Pacific countries. Clean Technol. Environ. Policy 2023, 25, 1737–1752. [Google Scholar] [CrossRef]

- Xie, B.; Yang, C.; Song, W.; Song, L.; Wang, H. The impact of environmental regulation on capacity utilization of China’s manufacturing industry: An empirical research based on the sector level. Ecol. Indic. 2023, 148, 110085. [Google Scholar] [CrossRef]

- Wen, H.W.; Wen, C.Y.; Lee, C.C. Impact of digitalization and environmental regulation on total factor productivity. Inf. Econ. Policy 2022, 61, 101007. [Google Scholar] [CrossRef]

- Lena, D.; Pasurka, C.A.; Cucculelli, M. Environmental regulation and green productivity growth: Evidence from Italian manufacturing industries. Technol. Forecast. Soc. Chang. 2022, 184, 121993. [Google Scholar] [CrossRef]

- Popov, A.A.; Karataeva, T.A.; Danilova, E.V.; Myreev, A.N.; Sergeeva, V.V. Diversification as a factor in the efficient economic development of the republic of Sakha (Yakutia), Russia. J. East. Eur. Cent. Asian Res. 2022, 9, 183–193. [Google Scholar] [CrossRef]

- Li, N.; Yang, R. Industrial Agglomeration and Upgrading of Manufacturing Global Value Chain Status: Impact Mechanism and Empirical Test. J. Nanjing Univ. Financ. Econ. 2021, 9, 87–97. [Google Scholar]

- Li, S.; You, W. Can Industrial Agglomeration Promote Innovation in Manufacturing Enterprises. Res. Financ. Econ. Issues 2018, 4, 30–38. [Google Scholar]

- Lo, K.L.; Zhang, J.J.; Xia, F. Does digital technology innovation work better for industrial upgrading? An empirical analysis of listed Chinese manufacturing firms. Appl. Econ. Lett. 2022. [Google Scholar] [CrossRef]

- Li, C.Q.; Chen, Y.Q.; Shang, Y.L. A review of industrial big data for decision making in intelligent manufacturing. Eng. Sci. Technol.-Int. J.-Jestech 2022, 29, 101021. [Google Scholar] [CrossRef]

- Von Joerg, G.; Carlos, J. Design Framework for the Implementation of AI-based (Service) Business Models for Small and Medium-sized Manufacturing Enterprises. J. Knowl. Econ. 2022. [Google Scholar]

- Wang, K.L.; Sun, T.T.; Xu, R.Y. The impact of artificial intelligence on total factor productivity: Empirical evidence from China’s manufacturing enterprises. Econ. Change Restruct. 2022, 56, 1113–1146. [Google Scholar] [CrossRef]

- Leoni, L.; Ardolino, M.; El Baz, J.; Gueli, G.; Bacchetti, A. The mediating role of knowledge management processes in the effective use of artificial intelligence in manufacturing firms. Int. J. Oper. Prod. Manag. 2022, 42, 411–437. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Zhang, Y.; Wu, T. Evaluation of Factors Influencing the Sustainable Development of the Marine Equipment Manufacturing Industry Cluster. J. Coast. Res. 2020, 106, 440–444. [Google Scholar] [CrossRef]

- Yin, J.Y.; Wang, D. Dynamic evaluation of green innovation efficiency of patent-intensive industries: Evidence from the new equipment manufacturing. Technol. Anal. Strateg. Manag. 2021. [Google Scholar] [CrossRef]

- Singh, A.; Askary, Z.; Gupta, S.; Sharma, A.K.; Shrivastava, P. AHP Based Model for Evaluation of Sustainable Manufacturing Enablers in Indian Manufacturing Companies. Adv. Ind. Prod. Eng. 2018, 2019, 397–403. [Google Scholar]

- Patalas-Maliszewska, J.; Losyk, H.; Jasiulewicz-Kaczmarek, M. A Sustainable Development Evaluation Card for a Manufacturing Company. Ifac Pap. 2020, 53, 10468–10473. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Wang, W.; Gong, Z. Behavioral DEA model and its application to the efficiency evaluation of manufacturing transformation and upgrading in the Yangtze River Delta. Soft Comput. 2020, 24, 10721–10738. [Google Scholar] [CrossRef]

- Dou, Z.; Sun, Y.; Wang, T.; Wan, H.; Fan, S. Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong-Hong Kong-Macao Greater Bay Area. Int. J. Environ. Res. Public Health 2021, 18, 5800. [Google Scholar] [CrossRef]

- Zhen, Z. Competitiveness Model of Chinese Port Manufacturing Industry Based on Global Value Chain. J. Coast. Res. 2020, 103, 701–704. [Google Scholar] [CrossRef]

- Jin, Q. Measurement and Promotion of the Transformation and Upgrading Effect of Marine Manufacturing Industry. J. Coast. Res. 2020, 81–84. [Google Scholar] [CrossRef]

- Sun, X.D.; Jia, X.F.; Rong, Y.F. Maturity evaluation in China’s low carbon energy industry. Clean. Energy Clean. Cities 2018, 152, 709–714. [Google Scholar] [CrossRef]

- Liu, X.L.; Xu, Y. Progressiveness status, problems and countermeasures of equipment manufacturing industry on the west bank of the Pearl River. Sci. Technol. Prog. Policy 2018, 35, 48–53. [Google Scholar]

- Li, L.S.; Yang, C.H.; Liu, J. Evaluation of the Comprehensive Development Capability of Regional Manufacturing Industry in China: An Empirical Analysis Based on Manufacturing Industries in the East, Central, and West Regions. China Soft Sci. 2014, 2, 121–129. [Google Scholar] [CrossRef]

- Yang, F.; Sun, Y.; Zhang, Y.; Wang, T. Factors Affecting the Manufacturing Industry Transformation and Upgrading: A Case Study of Guangdong-Hong Kong-Macao Greater Bay Area. Int. J. Environ. Res. Public Health 2021, 18, 7157. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.H.; Wang, Z.; Ma, Y.T. Does environmental regulation promote the high-quality development of manufacturing? A quasi-natural experiment based on China’s carbon emission trading pilot scheme. Socio-Econ. Plan. Sci. 2022, 81, 101216. [Google Scholar] [CrossRef]

- Su, Y.W. Evaluation of High Quality Development of Manufacturing Industry in Central China: Analysis from 2007 to 2018. Econ. Probl. 2020, 9, 85–91+117. [Google Scholar]

- Avenyo, E.K.; Tregenna, F. Greening manufacturing: Technology intensity and carbon dioxide emissions in developing countries. Appl. Energy 2022, 324, 119726. [Google Scholar] [CrossRef]

- Li, C.; Xia, W.J.; Wang, L.P. Synergies of green policies and their pollution reduction effects: Quantitative analysis of China’s green policy texts. J. Clean. Prod. 2023, 412, 137360. [Google Scholar] [CrossRef]

- Dou, Z.X.; Sun, Y.M. Situation Analysis and Development Strategy of Advanced Manufacturing Industry in Regional Cities: Based on 9 cities in the Pearl River Delta of Guangdong–Hong Kong–Macao Greater Bay Area. Sci. Technol. Manag. Res. 2020, 40, 68–74. [Google Scholar]

- Fu, W.Z.; Chu, L.P. Evaluation of High Quality Development of Manufacturing Industry from the Perspective of Yangtze River Delta Integration: Topsis Evaluation Model Based on Improved CRITIC Entropy Weight Combination Weights. J. Ind. Technol. Econ. 2020, 39, 145–152. [Google Scholar]

- Liu, J.; Yang, Y.J.; Cao, Y.R. Forrest Jeffrey Yi-Lin. Stimulating effects of intelligent policy on the performance of listed manufacturing companies in China. J. Policy Model. 2021, 43, 558–573. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X. Industrial agglomeration, technological innovation and carbon productivity: Evidence from China. Resour. Conserv. Recycl. 2021, 166, 105330. [Google Scholar] [CrossRef]

- Li, G.; Fang, C.; He, S. The influence of environmental efficiency on PM2.5 pollution: Evidence from 283 Chinese prefecture-level cities. Sci. Total Environ. 2020, 748, 141549. [Google Scholar] [CrossRef] [PubMed]

- Dou, Z.; Sun, Y.; Zhang, Y.; Wang, T.; Wu, C.; Fan, S. Regional industry demand forecasting: A deep learning approach. Appl. Sci. 2021, 11, 6199. [Google Scholar] [CrossRef]

- Zhang, W.F. MATLABneural Network Programming; Chemical Industry Press: Beijing, China, 2011. [Google Scholar]

- Qiu, S.B.; Liu, Y.; Ye, Y. Analyzing the Sustainability of Water-Cultural Industry and Their Influencing Factors in China. J. Interconnect. Netw. 2022, 22, 2144001. [Google Scholar] [CrossRef]

- Khatami, F.; Ricciardi, F.; Cavallo, A.; Cantino, V. Effects of globalization on food production in five European countries. Br. Food J. 2022, 124, 1569–1589. [Google Scholar] [CrossRef]

- Beraud, J.; Zhao, X.; Wu, J. Revitalization of Chinese’s manufacturing industry under the carbon neutral goal. Environ. Sci. Pollut. Res. 2022, 29, 66462–66478. [Google Scholar] [CrossRef]

- Wu, B.; Young-Myung, Y. A Study on Enhancing National Competitiveness of China’s Eco-friendly Automobile Industry: Focusing on the Porter’s Diamond Model. J. Econ. Stud. 2022, 40, 149–168. [Google Scholar] [CrossRef]

- Chen, W.; Yan, Y. New components and combinations: The perspective of the internal collaboration networks of scientific teams. J. Informetr. 2023, 17, 101407. [Google Scholar] [CrossRef]

| Specific Indicators | Indicator Direction | References | |

|---|---|---|---|

| Economics index | Value-add of industrial enterprises above designated size (X1) | Positive | Liu et al. (2018) [31] Li et al. (2014) [32] Yang et al. (2021) [33] Wang et al. (2022) [34] |

| Total profits of industrial enterprises above designated size (X2) | Positive | ||

| Overall labor productivity of industrial enterprises above designated size (X3) | Positive | ||

| Investment in fixed assets by manufacturing (X4) | Positive | ||

| Industrial structure sophistication (X5) | Positive | ||

| Environmental index | Discharge of industrial waste water (X6) | Negative | Su et al. (2020) [35] Dou et al. (2021) [27] Avenyo et al. (2022) [36] Li et al. (2023) [37] |

| Discharge of industrial solid waste produced (X7) | Negative | ||

| Discharge of industrial waste gas (X8) | Negative | ||

| Low carbon policy text (X9) | Positive | ||

| CO2 emissions from industrial production processes (X10) | Negative | ||

| Technical index | Value added of advanced manufacturing industry (X11) | Positive | Dou et al. (2020) [38] Fu et al. (2020) [39] Liu et al. (2021) [40] |

| Value added of high-tech industry (X12) | Positive | ||

| Internal expenditure on R&D by industrial enterprises (X13) | Positive | ||

| Sale revenue of new products by industrial enterprises (X14) | Positive | ||

| Intelligent manufacturing policy text (X15) | Positive | ||

| Scientific collaboration network (X16) | Positive |

| Guangzhou (GZ) | Shenzhen (SZ) | Zhuhai (ZH) | Shantou (ST) | Foshan (FS) | Shaoguan (SG) | Heyuan (HY) | |

| 2011 | 0.2686 | 0.3098 | 0.0910 | 0.0630 | 0.1858 | −0.0001 | 0.0557 |

| 2012 | 0.2619 | 0.3267 | 0.0932 | 0.0895 | 0.1898 | 0.0014 | 0.0576 |

| 2013 | 0.2873 | 0.3564 | 0.0995 | 0.0868 | 0.2108 | 0.0287 | 0.0805 |

| 2014 | 0.2777 | 0.3858 | 0.1170 | 0.0999 | 0.2426 | 0.0354 | 0.0956 |

| 2015 | 0.2986 | 0.4268 | 0.1249 | 0.1151 | 0.2752 | 0.0310 | 0.0996 |

| 2016 | 0.3215 | 0.4697 | 0.1528 | 0.1187 | 0.2937 | 0.0242 | 0.1203 |

| 2017 | 0.3372 | 0.5242 | 0.1550 | 0.1476 | 0.2900 | 0.0467 | 0.1112 |

| 2018 | 0.3587 | 0.5573 | 0.1427 | 0.1545 | 0.2953 | 0.0492 | 0.1172 |

| 2019 | 0.3886 | 0.5714 | 0.1560 | 0.1651 | 0.3121 | 0.0583 | 0.1158 |

| 2020 | 0.4237 | 0.5948 | 0.1681 | 0.1451 | 0.2946 | 0.0550 | 0.1411 |

| Meizhou (MZ) | Huizhou (HZ) | Shanwei (SW) | Dongguan (DG) | Zhongshan (ZS) | Jiangmen (JM) | Yan jiang (YJ) | |

| 2011 | −0.0054 | 0.1185 | 0.0739 | 0.1057 | 0.1098 | 0.0844 | 0.0598 |

| 2012 | 0.0078 | 0.1153 | 0.0540 | 0.1204 | 0.1100 | 0.0718 | 0.0776 |

| 2013 | 0.0294 | 0.1373 | 0.0741 | 0.1521 | 0.1081 | 0.0947 | 0.0808 |

| 2014 | 0.0383 | 0.1428 | 0.0777 | 0.1430 | 0.1251 | 0.0945 | 0.0791 |

| 2015 | 0.0339 | 0.1511 | 0.0851 | 0.1705 | 0.1200 | 0.1257 | 0.0871 |

| 2016 | 0.0683 | 0.1727 | 0.0822 | 0.2008 | 0.1490 | 0.1428 | 0.0922 |

| 2017 | 0.0737 | 0.1871 | 0.0931 | 0.2462 | 0.1413 | 0.1313 | 0.0872 |

| 2018 | 0.0841 | 0.1729 | 0.1031 | 0.2624 | 0.1364 | 0.1430 | 0.0829 |

| 2019 | 0.0895 | 0.1718 | 0.0805 | 0.2630 | 0.1238 | 0.1407 | 0.1001 |

| 2020 | 0.1141 | 0.1742 | 0.0875 | 0.2870 | 0.1335 | 0.1524 | 0.1001 |

| Zhanjiang (ZJ) | Maoming (MM) | Zhaoqing (ZQ) | Qingyuan (QY) | Chaozhou (CZ) | Jieyang (JY) | Yunfu (YF) | |

| 2011 | 0.0890 | 0.0970 | 0.0746 | 0.0459 | 0.0573 | 0.0922 | 0.0091 |

| 2012 | 0.0864 | 0.1095 | 0.0862 | 0.0670 | 0.0633 | 0.1105 | 0.0462 |

| 2013 | 0.0987 | 0.1241 | 0.1014 | 0.0726 | 0.0639 | 0.0947 | 0.0771 |

| 2014 | 0.1302 | 0.1352 | 0.1226 | 0.0797 | 0.0788 | 0.1241 | 0.0860 |

| 2015 | 0.1214 | 0.1441 | 0.1408 | 0.0848 | 0.0766 | 0.1212 | 0.0901 |

| 2016 | 0.1151 | 0.1603 | 0.1378 | 0.1034 | 0.0943 | 0.1467 | 0.0876 |

| 2017 | 0.1170 | 0.1656 | 0.1273 | 0.1077 | 0.0944 | 0.1464 | 0.0568 |

| 2018 | 0.1286 | 0.1507 | 0.1059 | 0.0934 | 0.0887 | 0.1387 | 0.0608 |

| 2019 | 0.1233 | 0.1528 | 0.1221 | 0.1276 | 0.0919 | 0.1525 | 0.0513 |

| 2020 | 0.1047 | 0.1542 | 0.1244 | 0.1296 | 0.0855 | 0.1518 | 0.0792 |

| The Number of Hidden Layers | The Number of Hidden Layer Neurons | MAE | MSE | RMSE | R2 |

|---|---|---|---|---|---|

| 1 | 2 | 0.038 | 0.002 | 0.049 | 0.757 |

| 2 | 2 | 0.032 | 0.002 | 0.047 | 0.782 |

| 3 | 2 | 0.042 | 0.003 | 0.055 | 0.701 |

| 4 | 2 | 0.032 | 0.002 | 0.045 | 0.802 |

| 5 | 2 | 0.041 | 0.003 | 0.054 | 0.711 |

| The Number of Hidden Layers | The Number of Hidden Layer Neurons | MAE | MSE | RMSE | R2 |

|---|---|---|---|---|---|

| 1 | 3 | 0.038 | 0.002 | 0.049 | 0.757 |

| 2 | 3 | 0.032 | 0.002 | 0.047 | 0.782 |

| 3 | 3 | 0.042 | 0.003 | 0.055 | 0.701 |

| 4 | 3 | 0.032 | 0.002 | 0.045 | 0.802 |

| 5 | 3 | 0.041 | 0.003 | 0.054 | 0.711 |

| The Number of Hidden Layers | The Number of Hidden Layer Neurons | MAE | MSE | RMSE | R2 |

|---|---|---|---|---|---|

| 1 | 6 | 0.026 | 0.001 | 0.034 | 0.884 |

| 2 | 6 | 0.034 | 0.002 | 0.046 | 0.792 |

| 3 | 6 | 0.038 | 0.002 | 0.046 | 0.786 |

| 4 | 6 | 0.032 | 0.002 | 0.044 | 0.811 |

| 5 | 6 | 0.027 | 0.001 | 0.038 | 0.859 |

| Model | MAE | MSE | RMSE | R2 |

|---|---|---|---|---|

| Our model | 0.026 | 0.001 | 0.034 | 0.884 |

| SVR | 0.045 | 0.003 | 0.057 | 0.673 |

| KNN | 0.042 | 0.004 | 0.067 | 0.551 |

| Xgboost | 0.041 | 0.006 | 0.077 | 0.473 |

| LSTM | 0.029 | 0.002 | 0.041 | 0.830 |

| Mean | Minimum | Maximum | 25 Percentile | 50 Percentile | 75 Percentile | |

|---|---|---|---|---|---|---|

| M1 | 7.2384 | 2.5255 | 16.5851 | 4.5727 | 6.3599 | 8.6616 |

| M2 | 9.0902 | 0.3786 | 51.7768 | 2.3708 | 5.2856 | 11.6949 |

| M3 | 29.9974 | 14.5226 | 50.7973 | 23.7548 | 29.3574 | 35.2565 |

| Score | 0.1748 | 0.0771 | 0.4636 | 0.1278 | 0.1438 | 0.1834 |

| Mean | Minimum | Maximum | 25 Percentile | 50 Percentile | 75 Percentile | |

|---|---|---|---|---|---|---|

| M1 | 6.8439 | 3.1011 | 15.9309 | 4.2326 | 5.2357 | 8.1827 |

| M2 | 10.8876 | 0.6000 | 61.1900 | 1.6350 | 3.6900 | 15.0900 |

| M3 | 21.4643 | 19.0600 | 24.9600 | 20.2100 | 21.4700 | 22.5700 |

| Score | 0.1762 | 0.0550 | 0.5948 | 0.1024 | 0.1411 | 0.1712 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Sun, Y.; Zhu, J.; Zhou, Z. The Evaluation Prediction System for Urban Advanced Manufacturing Development. Systems 2023, 11, 392. https://doi.org/10.3390/systems11080392

Dou Z, Sun Y, Zhu J, Zhou Z. The Evaluation Prediction System for Urban Advanced Manufacturing Development. Systems. 2023; 11(8):392. https://doi.org/10.3390/systems11080392

Chicago/Turabian StyleDou, Zixin, Yanming Sun, Jianhua Zhu, and Zijia Zhou. 2023. "The Evaluation Prediction System for Urban Advanced Manufacturing Development" Systems 11, no. 8: 392. https://doi.org/10.3390/systems11080392

APA StyleDou, Z., Sun, Y., Zhu, J., & Zhou, Z. (2023). The Evaluation Prediction System for Urban Advanced Manufacturing Development. Systems, 11(8), 392. https://doi.org/10.3390/systems11080392