Applying the SMED Methodology to Tire Calibration Procedures

Abstract

1. Introduction

1.1. State of the Art

1.2. Applying SMED to Preventive Maintenance Tasks

- By deciding between external and internal activities, it is possible to identify which tasks make it impossible to run the machine and which tasks can be performed during production.

- By reviewing each action at a practical level, it is possible to identify which tasks are essential, need to be improved, or can be removed.

2. Materials and Methods

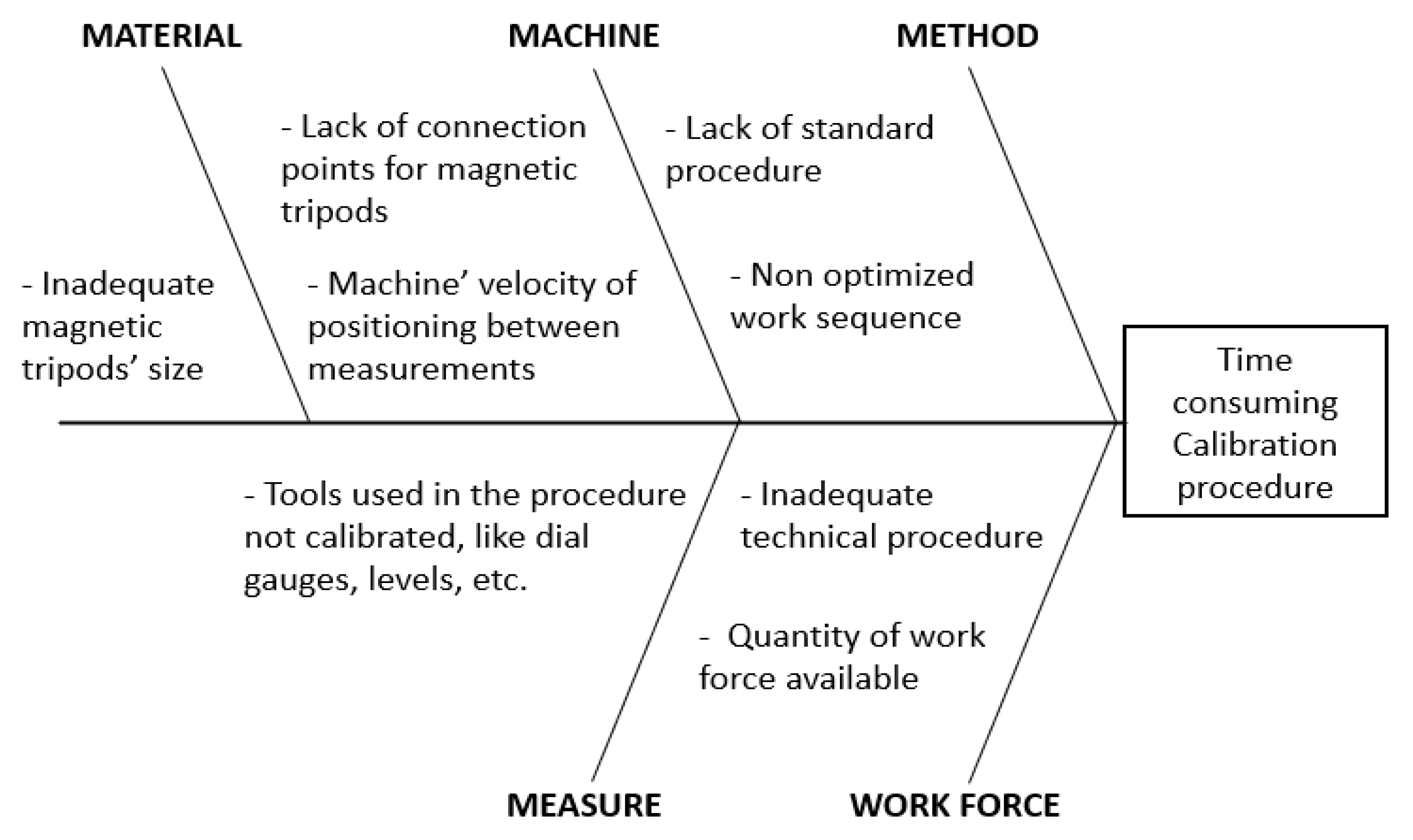

2.1. Problem Analysis

- Mixing, where all of the constituents (e.g., rubber, pigments, silica, etc.) are mixed;

- Preparation, where the different components of the tire (e.g., tire beads, steel belts, inner liner, etc.) are produced by cutting and calendaring;

- Construction, where all of the different components are put together in a precise manner;

- Vulcanisation, where a mould under high temperature and pressure gives the final shape to the tire;

- Final inspection, where the tires are inspected for misalignments of components, bubbles, and other possible defects.

2.2. Solution Proposal

- Carcass unit (Machine Section 1);

- Belt unit (Machine Section 2);

- Shaping unit (Machine Section 3).

3. Results

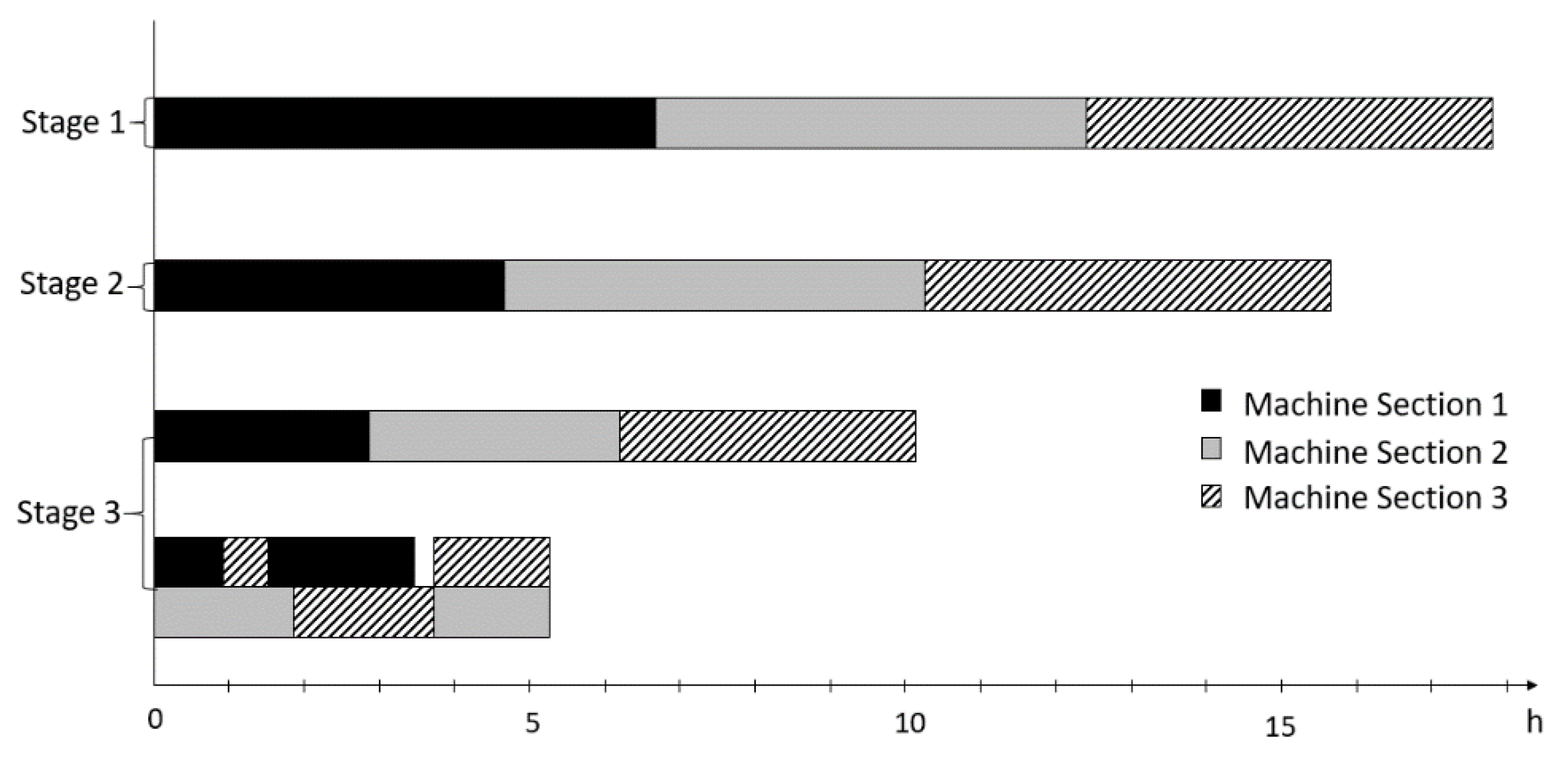

3.1. Step 1— Separation of Internal and External Activities

3.2. Step 2—Conversion of Internal Activities into External Activities

3.3. Step 3—General Improvements in All Activities (Streamlining)

- The laser spotlight check is an activity performed in five separate places and takes about 60 min for each place. The previous work method was non-intuitive and resulted in a lot of mistakes from workers (Figure 2a), involving the use of analogue equipment coupled with a complicated calibration procedure. The new proposal uses reference plates to rapidly check the alignment of the laser spotlight (Figure 2b). This implementation reduced the time required to perform this activity by about 50%.

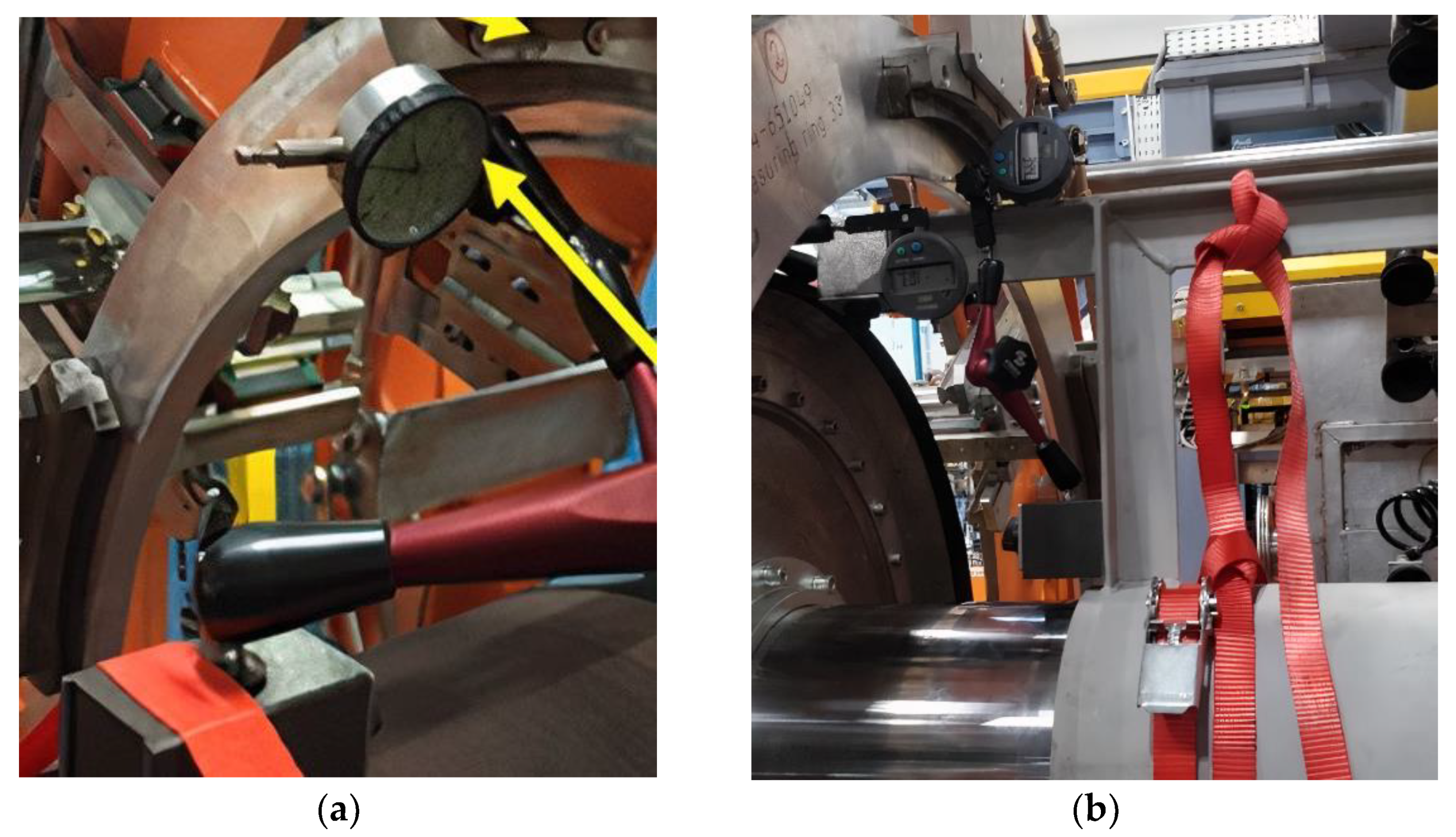

- Concentricity and parallelism verification between two subassemblies. One at a time, these two activities were performed with a dial gauge hooked to the machine with a strap (Figure 3a). The method represented a problem of measurement instability and loss of time. The proposed alternative was designing a tool fixture (Figure 3b) that simultaneously measured concentricity and parallelism, improving the measurement stability. Once again, the time reduction achieved was around 50%.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jeong, I.-J.; Leon, V.J.; Villalobos, J.R. Integrated decision-support system for diagnosis, maintenance planning, and scheduling of manufacturing systems. Int. J. Prod. Res. 2007, 45, 267–285. [Google Scholar] [CrossRef]

- Pinto, V.M. Gestão da Manutenção; IAPMEI: Lisboa, Portugal, 1994; ISBN 972-9205-57-4. (In Portuguese)

- Ahuja, S.; Khamba, K. Total productive maintenance: Literature review and directions. Int. J. Qual. Reliab. Manag. 2008, 25, 709–756. [Google Scholar] [CrossRef]

- Silva, I.B.; Filho, M.G. Single-minute exchange of die (SMED): A state-of-the-art literature review. Int. J. Adv. Manuf. Technol. 2019, 102, 4289–4307. [Google Scholar] [CrossRef]

- Patrik, J.; Magnus, L. Evaluation and improvement of manufacturing performance measurement systems–the role of OEE. Int. J. Oper. Prod. Manag. 1999, 19, 55–78. [Google Scholar]

- Farinha, J.T.; Galar, D.; Shagluf, A.; Longstaff, A.P. Maintenance strategies to reduce downtime due to machine positional errors. In Proceedings of the Maintenance, Performance, Measurement and Management Conference, Coimbra, Portugal, 4–5 September 2014; pp. 111–118, ISBN 978-972-8954-42-0. [Google Scholar]

- Dillon, A.P.; Shingo, S. A Revolution in Manufacturing: The SMED System; CRC Press: Boca Raton, FL, USA, 1985; ISBN 9780915299034. [Google Scholar]

- Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. A Structural Literature Review of the Single Minute Exchange of Die: The Latest Trends. Procedia Manuf. 2018, 17, 783–790. [Google Scholar] [CrossRef]

- Monteiro, C.; Ferreira, L.P.; Fernandes, N.O.; Sá, J.C.; Ribeiro, M.T.; Silva, F.J.G. Improving the machining process of the metalworking industry using the lean tool SMED. Procedia Manuf. 2019, 41, 555–562. [Google Scholar] [CrossRef]

- Sousa, E.; Silva, F.J.G.; Ferreira, L.P.; Pereira, M.T.; Gouveia, R.; Silva, R.P. Applying SMED methodology in cork stoppers production. Procedia Manuf. 2018, 17, 611–622. [Google Scholar] [CrossRef]

- Ferreira, C.; Sá, J.C.; Ferreira, L.P.; Lopes, M.P.; Pereira, T.; Silva, F.J.G. ILeanDMAIC—A methodology for implementing the lean tools. Procedia Manuf. 2019, 41, 1095–1102. [Google Scholar] [CrossRef]

- Pinto, G.F.L.; Silva, F.J.G.; Campilho, R.D.S.G.; Casais, R.B.; Fernandes, A.J.; Baptista, A. Continuous improvement in maintenance: A case study in the automotive industry involving Lean tools. Procedia Manuf. 2019, 38, 1582–1591. [Google Scholar] [CrossRef]

- Méndez, J.D.M.; Rodríguez, R.S. Set-up reduction in an interconnection axle manufacturing cell using SMED. Int. J. Adv. Manuf. Technol. 2016, 84, 1907–1916. [Google Scholar] [CrossRef]

- Brito, M.; Ramos, A.L.; Carneiro, P.; Gonçalves, M.A. Combining SMED methodology and ergonomics for reduction of setup in a turning production area. Procedia Manuf. 2017, 13, 1112–1119. [Google Scholar] [CrossRef]

- Boran, S.; Ekincioğlu, C. A novel integrated SMED approach for reducing setup time. Int. J. Adv. Manuf. Technol. 2017, 92, 3941–3951. [Google Scholar] [CrossRef]

- Braglia, M.; Frosolini, M.; Gallo, M. SMED enhanced with 5-Whys Analysis to improve set-upreduction programs: The SWAN approach. Int. J. Adv. Manuf. Technol. 2017, 90, 1845–1855. [Google Scholar] [CrossRef]

- Ahmad, R.; Soberi, M.S.F. Changeover process improvement based on modified SMED method and other process improvement tools application: An improvement project of 5-axis CNC machine operation in advanced composite manufacturing industry. Int. J. Adv. Manuf. Technol. 2018, 94, 433–450. [Google Scholar] [CrossRef]

- Guariente, P.; Antoniolli, I.; Ferreira, L.P.; Pereira, T.; Silva, F.J.G. Implementing autonomous maintenance in an automotive components manufacturer. Procedia Manuf. 2017, 13, 1128–1134. [Google Scholar] [CrossRef]

- Ribeiro, I.M.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. Implementing TPM supported by 5S to improve the availability of an automotive production line. Procedia Manuf. 2019, 38, 1574–1581. [Google Scholar] [CrossRef]

- Borris, S. Total Productive Maintenance; McGraw-Hill: New York, NY, USA, 2006; ISBN 978-0071467339. [Google Scholar]

- Rosa, C.; Silva, F.J.G.; Ferreira, L.P.; Campilho, R. SMED methodology: The reduction of setup times for Steel Wire-Rope assembly lines in the automotive industry. Procedia Manuf. 2017, 13, 1034–1042. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Petridis, D.; Stavropoulos, P. Experimental Investigation of rubber extrusion process through vibrational testing. Procedia CIRP 2020, 93, 1236–1240. [Google Scholar] [CrossRef]

- Martins, M.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. A Practical Study of the Application of SMED to Electron-beam Machining in Automotive Industry. Procedia Manuf. 2018, 17, 647–654. [Google Scholar] [CrossRef]

- Vieira, A.M.; Silva, F.J.G.; Campilho, R.D.S.G.; Ferreira, L.P.; Sá, J.C.; Pereira, T. SMED methodology applied to the deep drawing process in the automotive industry. Procedia Manuf. 2020, 51, 1416–1422. [Google Scholar] [CrossRef]

- Vieira, T.; Sá, J.C.; Lopes, M.P.; Santos, G.; Félix, M.J.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T. Optimization of the cold profiling process through SMED. Procedia Manuf. 2019, 38, 892–899. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Tzimanis, K.; Sabatakakis, K.; Stavropoulos, P. Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase. Sensors 2020, 20, 5481. [Google Scholar] [CrossRef] [PubMed]

| Problem Category | Description |

|---|---|

| Problems related to the machine | Lack of magnetic tripod attachment points to assemble dial gauges and movement of the machine concerning the positioning of its components for measurement. |

| Problems related to material availability | Causes that are related to the available materials. Available tools prove to be impractical due to the dimensions of the machine. |

| Problems related to labour | The number of maintenance technicians who perform the procedure affects the number of tasks that can be overlapped. Moreover, the lack of training and standard procedures of these professionals makes the procedure less effective. |

| Step | Method |

|---|---|

| 1—Separation of internal and external activities | Selection of the procedure to improve, selection of work team, measuring the execution time of the activities, and identification of internal and external activities. |

| 2—Conversion of internal activities into external activities | Converting all activities that can be performed during production into external ones or developing conditions to convert activities into external activities. |

| 3—General improvements in all activities (streamlining) | Reduction in time by improving, eliminating, converting, combining, or simplifying activities. |

| Sequence of Activities | Time Sum(Minutes) | Time of Activities (Minutes) | Internal Activity | External Activity |

|---|---|---|---|---|

| 1—Radial run-out | 90 | 90 | X | |

| 2—Drum circumference verification | 95 | 5 | X | |

| 3—Bead loader outsider check | 100 | 5 | X | |

| 4—Bead loader inside diameter and gap between fingers | 110 | 10 | X | |

| 5—Verification of concentricity of CTU over carcass drum | 170 | 60 | X | |

| 6—Verification of parallelism of CTU over carcass drum | X | |||

| 7—Verification of centring of CTU to drum | 180 | 10 | X | |

| 8—Verification of tangency ply to drum | 185 | 5 | X | |

| 9—Verification of centre of the drum to the servicer | 190 | 5 | X | |

| 10—Laser vertical check of inner liner | 210 | 20 | X | |

| 11—Laser spotlight rotation position check | 230 | 20 | X | |

| 12—Laser spotlight centre position check | 250 | 20 | X | |

| 13—Verification of tangency ply to drum | 255 | 5 | X | |

| 14—Verification of centre of the drum to the servicer | 260 | 5 | X | |

| 15—Laser vertical check (1st ply) | 280 | 20 | X | |

| 16—Laser spotlight rotation position check (1st ply) | 300 | 20 | X | |

| 17—Laser spotlight centre position check (1st ply) | 320 | 20 | X | |

| 18—Centring of the 1st ply stitcher rollers check | 380 | 60 | X | |

| 19—Centring profile servicer to drum check | 395 | 15 | X | |

| Total time of activity (min) | 280 | 115 | ||

| Sequence of Activities | Time Sum(min) | Time of Activities (min) | Internal Activity | External Activity |

|---|---|---|---|---|

| 1—Centring of belt drum | 60 | 60 | X | |

| 2—Vertical alignment of belt drum | X | |||

| 3—Centring of belt drum | 65 | 5 | X | |

| 4—Centring of guides in the tire belt zone | 95 | 30 | X | |

| 5—Centring of feeders in the tire belt zone | 155 | 60 | X | |

| 6—Vertical alignment of the feeder laser | 215 | 60 | X | |

| 7—Laser rotation in the belt feeder | 275 | 60 | X | |

| 8—Laser centring on the belt feeder | 335 | 5 | X | |

| 9—Verification of centre of the drum to the servicer | 345 | 10 | X | |

| Total time of activity (min) | 335 | 10 | ||

| Sequence of Activities | Time Sum(min) | Time of Activities (min) | Internal Activity | External Activity |

|---|---|---|---|---|

| 1—Circumference check of CTU over the shaping head | 60 | 60 | X | |

| 2—Parallelism check of CTU over the shaping head | X | |||

| 3—Centring of CTU over the shaping head | 65 | 6 | X | |

| 4—Centring of BTR over the shaping head | 70 | 5 | X | |

| 5—Circumference check of BTR over the shaping head | 140 | 70 | X | |

| 6—Parallelism check of BTR over the shaping head | X | |||

| 7—Check shaping head unit | 150 | 10 | X | |

| 8—Centring of shaping heads | 155 | 5 | X | |

| 9—Centring of guides of the shaping head | 175 | 20 | X | |

| 10—Laser vertical alignment of the shaping head | 195 | 20 | X | |

| 11—Laser rotation of the shaping head | 215 | 20 | X | |

| 12—Laser centring in the shaping unit | 235 | 20 | X | |

| 13—Check tolerances of the shaping unit’s applicator arm | 265 | 30 | X | |

| 14—Perpendicularity check of the applicator arm | X | |||

| 15—Centring of the applicator arm | X | |||

| 16—Verification of the shaping unit’s sensor | X | |||

| 17—Check extrusion rolls pressure | 295 | 30 | X | |

| 18—Check extrusion machine’s tolerances | 325 | 30 | X | |

| Total time of activity (min) | 325 | 0 | ||

| Type of Activity | Before Improvements | After Improvements | |||

|---|---|---|---|---|---|

| Percentage (%) | Time (min) | Percentage (%) | Time (min) | ||

| Machine Section 1 | External | 0% | 0 | 16% | 115 |

| Internal | 37% | 395 | 23% | 170 | |

| Machine Section 2 | External | 0% | 0 | 1% | 10 |

| Internal | 32% | 345 | 27% | 200 | |

| Machine Section 3 | External | 0% | 0 | 0% | 0 |

| Internal | 31% | 325 | 32% | 235 | |

| Total | 100% | 1065 | 100% | 730 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, V.; Sousa, V.F.C.; Silva, F.J.G.; Matias, J.C.O.; Costa, R.D.; Pinto, A.G.; Campilho, R.D.S.G. Applying the SMED Methodology to Tire Calibration Procedures. Systems 2022, 10, 239. https://doi.org/10.3390/systems10060239

Santos V, Sousa VFC, Silva FJG, Matias JCO, Costa RD, Pinto AG, Campilho RDSG. Applying the SMED Methodology to Tire Calibration Procedures. Systems. 2022; 10(6):239. https://doi.org/10.3390/systems10060239

Chicago/Turabian StyleSantos, Vitor, Vitor F. C. Sousa, Francisco J. G. Silva, João C. O. Matias, Rúben D. Costa, Arnaldo G. Pinto, and Raul D. S. G. Campilho. 2022. "Applying the SMED Methodology to Tire Calibration Procedures" Systems 10, no. 6: 239. https://doi.org/10.3390/systems10060239

APA StyleSantos, V., Sousa, V. F. C., Silva, F. J. G., Matias, J. C. O., Costa, R. D., Pinto, A. G., & Campilho, R. D. S. G. (2022). Applying the SMED Methodology to Tire Calibration Procedures. Systems, 10(6), 239. https://doi.org/10.3390/systems10060239