Abstract

To deal with environmental uncertainty, organizations need resilience to respond to disruptions, such as changing market conditions or variations in demand or supply, while avoiding large scale adjustments. The concept of resilience is ambiguous, often explained as the capability of an organization or a supply chain to recover its original state, within an appropriate time frame, after being disrupted. Resilient supply chains have event handling capabilities, can provide efficient responses, and can return to their normal operating performance, after the disruptive event. To increase their resilience, companies often make changes or adjustments to their internal IT infrastructure, which may temporarily disrupt their smooth operation. As a result, contemporary IT infrastructures are mixed and include varied systems or technologies. Although new technologies, including blockchain, IoT and cloud-based solutions, may facilitate the handling of changes by providing secure, low cost and scalable solutions, more traditional systems may hinder such changes. Therefore, the relationship between IT and supply chain resilience is still unclear. The paper intends to examine the above issues by adopting a socio-technical approach to explain the concept of supply chain resilience and investigate the role of IT. More specifically, based on previous literature and on the appreciative systems thinking theoretical perspective, the paper develops a theoretical framework to analyse the organisational and/or supply chain resilience. It then uses this framework to examine and explain the impact of IT, by identifying important characteristics of an IT infrastructure and examining whether they may support or hinder business resilience.

1. Introduction

The contemporary business environment is characterized by increased competition and disruptions caused by technological advancements, demand variations, and regulatory and socio-economic changes. All of these lead to unpredictability and increased market uncertainty [1,2], forcing firms to rethink, modify and redesign their business processes and strategy on a frequent basis. To survive in this turbulent environment, companies need to be agile and able to deal with changes [3,4].

To deal with environmental disturbances organisations need tools that will enable them to address the increasingly complex problems that arise [5]. A systems thinking perspective could enable them to see the world as a complex system, where everything is connected to everything else [6,7]. Therefore, ‘implementing a systemic thinking philosophy in real-life industrial operations is essential for companies to operate effectively and efficiently [5] (p. 995), as well as to deal with any changes.

To face unexpected situations and environmental changes, organizations additionally invest in new technologies enabling them to monitor and better manage the events of the external environment [8]. They also enable them to improve internal processes, increase their efficiency and improve their interaction with business partners.

Nowadays, complex systems are being developed aiming at facilitating and affecting business operations [5]. Therefore, contemporary IT infrastructures are mixed, including different types of technologies. As different information technologies have various characteristics, properties and limitations, their impact on resilience or on organisational changes is still debatable [9]. Older technologies are more rigid and inflexible, hindering change. Furthermore, major organizational changes are often time-consuming, costly and entail significant changes of the underlying IT infrastructure. These changes are even more difficult and complex when they affect cooperation and exchange of information with business partners.

To be able to confront environmental disturbances, while avoiding large scale changes, companies seek for resilience both internally and at their supply chain. Supply chain resilience is a relatively new term related to supply chain vulnerability [10]. Resilient supply chains demonstrate event readiness and are able to provide efficient responses. They are also often able to restore their primary state, or produce an even better one, after the disruptive event [11].

Although resilience is important for the survivability and efficient operation of companies, its meaning is still unclear and, as a result, different conceptualisations can be found in the literature [12,13]. Some researchers suggest that resilience is synonymous with flexibility [14], while others point out the differences between them. Some focus on the different dimensions of resilience, while others develop theoretical approaches to analyse the concept in depth [15,16,17]. Therefore, the main elements and dimensions of supply chain resilience, their interrelation, as well as their implications for supply chain management, are poorly analysed and understood [11]. Moreover, even though the use of IT supports the monitoring and handling of events, its impact on supply chain resilience needs to be further investigated and examined. Although previous research has focused on examining the impact of specific types of systems e.g., ERP [18] or blockchain technologies [19], on supply chain resilience, the impact of mixed IT infrastructures is still unclear. As varied IT implementations are context-dependent and existing IT infrastructures are complex, mixed and evolving, their results on resilience are diverse and dynamic (changing over time) and need to be further investigated. The aim of this paper is to address these issues and to:

- i.

- contribute to the definition and understanding of supply chain resilience as a multidimensional concept

- ii.

- develop a theoretical framework to analyse organisational and/or supply chain resilience

- iii.

- use the framework to analyse and explain the impact of IT on resilience

- iv.

- identify important characteristics of an IT infrastructure and examine whether they may support or hinder supply chain resilience.

This paper primarily analyses supply chain resilience based on an extensive literature review [20] and on the authors’ research experience [21]. Influenced by previous research, the paper recognizes different dimensions of resilience (focusing on the temporal, cost and range dimensions). It also adopts Vickers’s appreciative systems thinking theoretical perspective and suggests that resilience can be examined as the process through which organisations or supply chains “appreciate” an environmental disturbance (that has or is about to happen) and based on judgements (of facts and values) decide upon an action of response [22]. The paper argues that the ease of response can be specified by the time, cost and range of available options to respond. It also argues that the ease of response can be affected by the company’s IT infrastructure.

To analyse the role of IT on supply chain resilience, the paper identifies and examines specific characteristics of contemporary IT infrastructures (as mentioned in the literature). It then uses the framework to evaluate their impact (benefits or constraints) on supply chain resilience. Therefore, this is a conceptual paper aiming to contribute both to theory and practice.

The next section presents contemporary challenges of supply chain management, emphasizing on the problem of uncertainty. It discusses supply chain vulnerability and considers the importance of risk and event management. It then analyses supply chain resilience, putting an emphasis on its multidimensional nature. The third section takes into consideration previous research and Vickers’s theory of appreciative systems and proposes a conceptual framework for the analysis of resilience. Based on this framework, the fourth section discusses the impact of IT on the handling of environmental changes. It also examines important IT characteristics and analyses their impact on resilience. The discussion section compares the study’s results with those of previous studies. It also discusses the research limitations. The final section presents the contributions and concluding remarks of the study, as well as gives directions for future research.

2. Literature Review

The literature review enables us to better clarify and examine the main concepts addressed in this paper. It gives information about the papers published, and the theories related to the subject of study. It allows the identification of the main dimensions of supply chain resilience, as well as revealing the conceptual frameworks used. It also facilitates the analysis of the role of technology, supporting the paper’s argument, while allowing the provision of an original contribution [23].

The steps followed in this study include the search of articles based on keywords, the selection of articles based on their abstracts and content, their categorization, a clarification of the meanings of the main concepts and the identification of any relationships among them, as well as a discussion on the results of this study compared with previous literature.

The search was conducted mostly in the Scopus, ResearchGate and Google Scholar databases and the keywords or combination of keywords used included supply chain uncertainty, supply chain flexibility and resilience, IT infrastructure and new technologies, such as cloud-based solutions, IoT and blockchain technology.

2.1. Supply Chain Management and Uncertainty

Competitive intensity forces companies, of various industries, to try to enhance their operational efficiency, the effectiveness of their decisions, their products’ quality and their customers’ services. However, intense competition and market uncertainty complicate SCM and challenge the realization of its objectives [24]. In a competitive environment, the efficiency of operations is not sufficient for the survivability of companies [25]. To retain their market share or gain strategic advantage, organizations have to extend their ‘standalone’ business strategies to include strategies of their business partners [25]. According to Scholten and Schilder [26], effective collaboration among supply chain members can facilitate the provision of good quality products and inexpensive services, while ensuring that products and services are delivered at the right time and place. Therefore, effective supply chain management (SCM) and collaboration are key factors for enhancing not only organizational effectiveness, but also competitiveness.

According to Kopanaki [25], the most common SCM objectives, as identified in the literature, are improved demand planning, speed (reduction of lead time and speed of delivery), control and reliability, as well as reduction of costs (comprising production, transportation and purchasing costs, as well as inventory-driven costs). However, one of the main challenges that contemporary supply chains have to face is the uncertainty of the business environment [27]. In today’s business market, supply chains are exposed to frequent disturbances or disruptions [28]. Therefore, their ability to deal with changes needs to be reinforced.

According to Wang [29] uncertainty refers to the unpredictability of environmental or organizational issues or to the insufficient information regarding these issues that affect business performance. To analyse uncertainty, Liao et al. [30] focus on uncertainties related to production, quality, quantity, and market demand. Similarly, Davis [31] and Kopanaki [25] examine manufacturing uncertainty (e.g., machine failures, computer or software errors and ineffective design of products, which disrupt production and affect the products’ quality), demand uncertainty (variations in demand and erroneous orders that lead to inaccurate forecasts, out of stocks or excessive inventory) and supply uncertainty (inability to supply on time due to transportation problems or product returns due to defective products etc.).

Aiming to address one aspect of supply uncertainty, Ahmet et al. [32] handle the problem of backordering defective products. In their work they aim to measure the impact of reworking imperfect quality items and partially backordering them into the material flow and profit system. They propose a model that enables the identification and reparation of imperfect quality items, allowing partial backordering after rework. They follow an algebraic approach, based on the inventory theory, and develop an algorithm to also achieve a profit maximization objective.

Lee [33], focuses on demand uncertainty and argues that there are markets with high demand uncertainty (e.g., innovative services or products, clothing and music industry) and others with low demand uncertainty (e.g., utilities sector or basic groceries). Similarly, there are more stable processes (or with low uncertainty) (e.g., related to basic manufacturing) and processes of higher uncertainty (e.g., farming and agriculture affected by weather conditions).

Along with these uncertainties (related to supply or demand), companies must face competitive uncertainty, which related to their competitors’ strategies and responses to the firm’s actions. They also have to face physical disasters (e.g., a flood or fire in a warehouse or factory). Excessively lean or rigid supply chains with no slack, or ‘plan B’, may be unable to face such disasters, making the entire chain collapse.

The exposure to serious disturbances, occurring to supply chains either as internal or external risks, has led to the analysis of supply chain vulnerability. The notion of supply chain vulnerability has been examined by many researchers, giving various explanations [34]. Svensson [35] offered what became one of the most utilized definitions of supply chain vulnerability, explaining it as the existence of disturbances, with negative effects or consequences, which force companies to deviate from regular, expected or scheduled activities.

The effective response to these changes or disruptions is imperative, as they may significantly affect both the short-term performance [36] and the long-term strategies of a firm. The clothing industry is a good example of short-term changes as the demand is mostly subject to the fashion trends. In this industry, the life cycle of products is relatively short and highly uncertain. To deal with frequent changes in demand, supply chains have developed the “Quick Response” strategy to become more resilient and enhance their capability to quickly respond to fluctuations of sales related to varied styles, sizes and colours [25].

Therefore, changing market needs, varied supplier lead times, information asymmetry and dubious product quality are sources of uncertainty that create the need for business flexibility or resilience to disturbances [37]. Hence, to deal with vulnerability, everyday changes and more rare events, supply chains seek resilience [12,38].

2.2. Supply Chain Resilience

Resilience [38,39] is an evolving concept, which focuses on the capability of firms or of their supply chains to absorb or react to environmental disruptions, “with or without a limited decrease in their performance” [40] (p. 1). Pettit, et al. [12] state that a fundamental definition of resilience can be found in engineering, i.e., “the tendency of a material to return to its original shape after the removal of a stress that has produced elastic strain”. Evans [14] uses resilience as a synonym of elasticity and flexibility. Many researchers argue that the notion of resilience is related to that of flexibility, as both concepts refer to the ability of organisations or supply chains to handle environmental changes and unexpected events. Like flexibility, resilience is related to the variety of planned or unplanned organizational options to respond to disruptions.

Supply chain resilience includes the capability to adjust production capacity, make volume changes, do quick product design adjustments, incorporate a variety of promotional activities, as well as manage changes in deliveries. Resilient supply chains should be “market sensitive in terms of their ability to understand and respond to demand, while minimising the risks of supply shortages or disruptions” [22] (p. 337). Thus, a resilient supply chain must be capable of handling many expected or unexpected events, such as, production faults, machine breakdowns, truck accidents shipment delays and out-of-stocks. According to Ponomarov and Holcomb [11] (p. 124), “resilient supply chains incorporate event readiness, are capable of providing an efficient response”.

Wieland and Wallenburg [41] have argued that agility is a significant component of resilience. However, resilient supply chains are often capable of returning to their primary or improved state after the disrupting event [11,42]. Therefore, in contrast to agility or flexibility, resilience focuses on the capability of a supply chain to return to their regular business operation, within an appropriate time, after being disrupted [38,39]. However, sometimes it may be better for a supply chain to learn from the disruption and adapt into a new operational structure, instead of returning to its original state [12]. Thus, a supply chain is resilient when its primary business state is sustained or when a new stable situation is reached [41].

Acknowledging the fact that resilience and flexibility are related concepts, as well as that flexibility is an older concept with a much richer literature, this paper reviews conceptualizations of both concepts to propose a conceptual framework of supply chain resilience.

To explain the concepts of flexibility and resilience, many researchers have focused on identifying their different categories and classifications. Older research initiatives have focused on the examination of flexibility at the organizational level, while more recent initiatives have also analysed flexibility or resilience at an interorganizational or supply chain level.

Pettit et al. [12,13] argue that resilience can be defined as the desired balance between vulnerabilities and capabilities. Similarly, Kumar [43] argues that most descriptions and definitions of flexibility, which can equally apply to resilience, involve the notion of change (stimulus) and a response to this change. He thus proposes a stimulus–response framework to describe flexibility. He suggests that flexibility can be indicated by the ease of response. He further suggests that the ease of response (revealing the level of flexibility) can be specified by three related dimensions, comprising the time, cost and scope of response [22]. Similarly, Lucas and Olson [44] suggest that flexibility is related to the time, cost and effort to change workflow of processes and organisational structure.

Therefore, to explain flexibility, which is a resilience related concept, the majority of previous research has focused on its multidimensional nature [15], identifying the temporal and range dimensions as most fundamental [45,46,47]. Golden and Powell [48] state that the range dimension (indicated though the notions of robustness and versatility) demonstrates the variety of options (either planned or unplanned) to respond to events or disruptions from the environment. They further state that the temporal dimension demonstrates the length of time required to respond to these disturbances. It also demonstrates a company’s ability to adapt within an appropriate time frame and can be indicated/measured by responsiveness (revealing the time needed to adjust to a new situation/condition) and efficiency (showing the ability to quickly handle changes without excessive costs or downgrade of performance). Additional dimensions are suggested by Tan and Sia [49], who used ‘new capability’ and ‘ease of exit’ in their research [47].

As the aim of this research is to analyse resilience, it only focuses on the relevant dimensions and metrics. As previous research suggests that robustness plays an essential role in the attainment of resilience. This is related to the capability of an organization to deal with unforeseen environmental disturbances [48] and shows the ability of a company to react to changes that were not planned [50]. It also shows “the ability to absorb, deflect or endure the impacts of unanticipated contingency, so that a strategy can remain viable in spite of changes in the environment” [14] (p. 76). Finally, it is defined as “the ability to endure variations and perturbations, withstand pressures or tolerate external changes” [49] (p. 184). According to Wieland and Wallenburg [41] robustness involves the proactive realization of change, before its occurrence, and is a significant component of supply chain resilience.

However, resilience also presupposes quick response to disturbances. Wieland and Wallenburg [41] argue that resilience also includes fast reaction to perceived changes. Therefore, responsiveness and efficiency are equally important factors of resilience. The distinction between responsiveness and efficiency is unclear, since the speed of response and the decrease in time delays indicate both responsiveness and efficiency. However, the concept of efficiency is additionally related to performance, effort or cost-effectiveness [47].

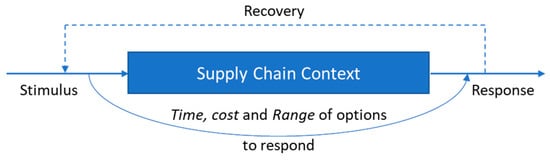

The analysis of the literature led to an initial representation of supply chain resilience as a stimulus–response conceptual framework (Figure 1), which is related to Kumar’s [43] conceptualisation of flexibility. Based on this framework, supply chain resilience can be considered as comprising three phases: initiation of a disruption (stimulus), response (reaction) and recovery (to the previous or a new stable state, after an event) [12,16,51].

Figure 1.

Initial framework of resilience.

Adobor and McMullen [15] and Scholten et al. [16] add an initial phase, which is related to the preparedness and the readiness of an organization to deal with an event. Finally, Ali et al. [51] (p. 23) add a final phase related to learning capabilities, enabling the supply chain “to understand what has happened and improve future performance based on the experience”.

Nevertheless, the identification of the different phases and dimensions of resilience is not sufficient for in-depth analysis of the concept. A more complete analysis requires an examination of the process through which organizations/supply chains realize environmental disruptions and take actions to respond.

To better explain or measure supply chain resilience, previous studies aimed to use and develop theoretical approaches. Chowdhury and Quaddus [17] used dynamic capability theory to analyse supply chain resilience and develop a measurement instrument for it. Vanpoucke and Ellis [52] focused on supply-side resilience to provide a behavioural perspective to analyse the influence of individuals to managerial decisions related to the resilience of the supply chain. Finally, based on the work of Zollo and Winter [53], Scholten et al. [16] (p. 432) have developed a framework to show the “pre-established relationship between learning mechanisms that shape operating routines directly (via knowledge creation and transfer) or by the intermediate step of dynamic capabilities (SCRes)”.

Table 1 summarizes the contribution of different studies aiming to conceptualize supply chain resilience. It also shows the difference of the proposed conceptual approach. The studies included in this table are compared based on the dimensions of resilience identified, the conceptual framework developed and the impact of ICT.

Table 1.

Summary of studies conceptualizing supply chain resilience.

The table demonstrates the breadth of supply chain resilience conceptualisations used in the literature. It shows that the meaning of supply chain resilience is still unclear, lacking a strong theoretical base.

3. Theoretical Development

This study argues that the concept of resilience, as a result of a firm’s interaction with the environment, can be analysed using a “systems thinking” theoretical approach. The core of systems thinking approaches is the notion of an entity/organism (as a whole), which can adapt (to a certain extent) to survive in a dynamic environment [55]. In such approaches organizations are considered as being greatly affected by their environment and interactions with other organizations. In situations of rapid changes only ‘learning’ organizations that are flexible and adaptive will excel [56]. Learning organizations are organizations where people continually expand their capacity to create desired results, expand their patterns of thinking and learn to see the ‘whole’ together [56].

Systems thinking approaches have been developed and used in different disciplines and strands of research [25]. In management science and information systems research, ‘hard’ systems thinking was for many years the prevalent systems approach [57]. ‘Hard’ systems thinking approaches follow an objective/positivistic scientific view, supposing that the world contains systems that can be ‘engineered’ [55,58] to achieve declared objectives.

According to Senge and Sterman [59] the development of models “creates a laboratory microworld in which hypotheses can be tested evaluated and revised”. However, this is not sufficient for an organization to develop the capability to learn effectively from experience. To address this need, Senge and Sterman [59] attempted to develop explicit learning processes to improve and alter managers’ mental models, making them more systemic and dynamic.

Their work is related to system dynamics (SD), which aims to improve the mental models that people use to represent the real world. According to Forrester [60] (p. 14) “for this to happen, individuals must be sufficiently involved in the modelling process to internalize lessons about dynamic feedback behaviour”.

Therefore, SD is a research approach “to identify structural causes for complex problems and find solutions to the structure’s problems” [61] (p. 2). It enables the production of rigorous models and the visualization of the causal linkages amongst variables. It is suitable to examine and simulate complex and dynamic systems, as well as support long-term strategic decision-making [7] It also enables understanding of a system’s structure that determines its “behaviour” [61].

We can find two different research streams in SD: the ‘hard’ and the ‘soft’ approach. In ‘hard’ system dynamics, description leads to the creation of a model, the simulation of which leads to an understanding of dynamic behaviour, evaluation of alternative policies and choice of a better policy and implementation [60]. In contrast, soft systems thinking approaches usually lack the discipline of explicit model creation and simulation. They take a process view of organisations [57], supporting the idea that reality is more complex than systems that can be engineered [58]. They regard the world as complex and problematic but accept that the process of inquiry into it can be organised as a learning system [55]. They thus shift systemicity from the world to the process of inquiry into the world [55]. Therefore, they put emphasis on eliciting information from real-world participants and contribute to useful insights [60].

Formulating a causal loop diagram (CLD) can be considered as part of a soft methodology [61], as it may support intuitive and qualitative analysis by enabling the visualization of complicated relationships between a system’s components. A CLD is a diagram, consisting of a set of nodes and edges, which illustrates how different variables in a system are interrelated [62]. The essence of CLD lies in the discovery and understanding of feedback loops, focusing on the ’structure’ that causes the ’phenomena’ [6]. Therefore, CLD is a modelling tool suitable for analysing the process through which companies perceive changes in the environment, identify different options and decide upon actions in response.

This paper follows a ‘soft systems thinking’ orientation, adopting a process view of companies [57]. Resilience can be seen as the capability of an organization to endure and handle disturbances without being significantly disorganized. In this context, the interaction between a firm and its environment can be explained by a sequence of stimulus processes of response and effect [47]. The paper focuses on Vickers’ [63,64,65,66] theory on appreciative systems, to explain the process though which organizations or supply chains realize a disturbance and take actions to respond. The theory focuses on the notion of ‘appreciation’, which, according to Checkland and Casar [67], can be structured as a system. It explains how individuals or groups of people in organizations realize changing situations and take actions to respond, either by maintaining or altering relationships [57]. Therefore, the theory explains the interaction of teams within an organization or between different organizations, which has an important effect on resilience [40]. It thus analyses the process by which people in organizations ‘appreciate’ disruptions, threats or opportunities and, make judgements to decide upon an action to respond.

Vickers [63] explains that the everyday operation of organizations is affected/influenced by an interplay (‘flux of interacting’) of events and/or ideas. He argues that the development of varied ideas is separate from the history of different events. The history of events and/or ideas affect attitudes [63], activities and business operations or decisions, and can be in turn changed through discussions and exchange of ideas with other people.

According to Vickers the process through which people interpret and respond to events or ideas can be called ‘appreciation’. Appreciation does not only refer to the process of realizing an event, but also to the observation of the ‘actual’ situation and its comparison with the ‘norm’ [63]. Therefore, it involves understanding or critical thinking, which may often produce an action. More specifically, the process of appreciation comprises reality, value and action judgements, which are interrelated [63,66]. ‘Reality’ judgements are judgements of facts related to a situation (what is or was the situation) and to its impact (what will, or might, the impact be under different hypotheses) [47,66]. ‘Value’ judgements refer to the importance and impact of those facts, while ‘action’ judgements refer to the way to respond to the situation (what to do in this specific situation).

Appreciation is continually “challenged or confirmed” by experience, referring to “the readiness to notice particular aspects of a specific situation, to distinguish them in particular ways and to measure them against standards, which have been built in similar ways” [64] (p. 102). The standards affecting the process of appreciation are altered or further enhanced through the same process as their application [47]. They can be modified through judgements influenced by business partners or other participants and/or through their application in a real or hypothetical situation “in a search for a better fit” [68] (p. 158). Therefore, they result from previous processes of appreciation and may be confirmed or altered through future processes [63].

The result of the process of appreciation may be an action or several actions taken. These actions may maintain or change relationships [57] and/or organizational arrangements. According to Vickers [66], relationship management involves changes which can, over time, directly or indirectly influence relationships between organizations or people, including modification of operations, changes of employees’ positions, use of human or other resources, etc. Therefore, interactions between teams within an organization or between different organizations have an important effect on resilience [40].

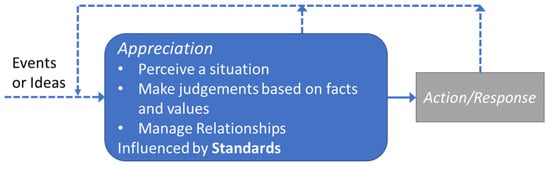

Checkland and Casar [67] developed a model of the process of appreciation, presenting it as a set of abstract entities, organized as a system. The emergent property of this system is its capability to carry out the process of appreciation. In this process, people in organizations perceive a situation, make judgments related to it, and often react [47]. The core of this model [67], presented in Figure 2, shows the main theoretical constructs each of which are connected by arrows which in turn carry the meaning of ‘leads to’. Based on the model, events and/or ideas, which unfold over time, initiate appreciation, which “perceives (some part of) reality, makes judgements about it, contributes to the ideas stream, and leads to actions that become part of the events stream” [58] (pp. 6–7).

Figure 2.

The structure of an appreciative system. Adapted from [67].

The perception of a situation leading to an action entails reality and value judgements, which are based on standards developed through responding to similar situations in the past [67]. Such standards also influence action judgements, which involve consideration of the relationships or the organizational arrangements that may be affected by the action. As Figure 2 shows, standards may be altered after being used in the process of appreciation. Consequently, the setting and context of an appreciative system changes and evolves over time [67].

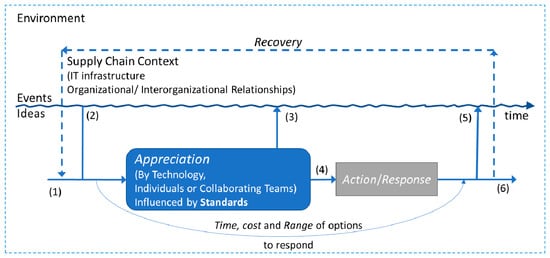

In this research, the model of an appreciative system is used as a conceptual base to examine the process through which organizations realize, assess, and respond to disruptions from their environment. The synthesis of these theoretical ideas, with the framework presented in Figure 1, enabled the development of a combined conceptual framework of resilience, shown in Figure 3.

Figure 3.

A synthesized framework of supply chain resilience. Arrows (1)–(5) have the meaning of ‘leads to’, while the arrow (6) shows the impact on the environment.

Based on this framework, a supply chain may respond to events or ideas generated either from the external environment (1) or from the supply chain context itself (2). The supply chain (business network) realizes the incoming events or reacts to them, as a result of the process of appreciation. The process of appreciation can generate another event or idea (3) or can lead to an action to respond (4). This action may affect the environment (6), can have an impact on the business network itself or provoke another event or idea (5), starting a new process of appreciation. A resilient supply chain also has the ability to recover to its original state or to a new stable state after responding to the disturbing events. Hence, through a recursive loop, events and/or ideas initiate appreciation, which may lead to further ideas or to actions, which may generate new events.

As mentioned before, this process is performed by people or groups of people (in one or different organizations) and may be supported by information systems and technological solutions with embedded business logic [47]. Therefore, people or systems (through appreciation) realize an occurring or forthcoming event, identify possible ways to react/respond and decide to take an action or actions. Both the process of appreciation and the choice of the actions to respond are affected by the IT infrastructure and influenced by the relationships/arrangements of people or organizations involved [47].

As demonstrated in the framework, the response capability (ease of response) is shown by the efficiency (time and cost) and/or responsiveness of both the appreciation and the resulting action, as well as by the range of planned or unplanned options to respond (robustness or versatility). Furthermore, both the process of appreciation and the selection of the action to respond are based on standards developed in previous cycles of appreciation. The efficiency of response increases, as organizations repetitively deal with comparable situations and follow known patterns of action (developed in the past, forming standards) [25].

Based on this framework, resilience can be seen as the ability of an organisation (or a supply chain) not only to respond to environmental events/changes, but also to return either to its original/normal operating state (after a cycle of appreciation/action) or to a new stable situation.

4. The Impact of IT Infrastructure on Supply Chain Resilience

To reduce and handle challenges, organisations and supply chains invest in new technologies and adopt information systems to support decision-making and improve business processes. Besides aiming to optimize their processes, organizations also try to ameliorate their cooperation and collaboration with business partners [26]. Hence, firms should choose technologies that not only facilitate the processing of information, but also enable the integration of business processes along the supply chain and allow the sharing of information and knowledge with business partners [69,70]. The use of suitable information systems, aligned with the supply chain management strategy, does not only increase the supply chain efficiency, but also improves the supply chain’s ability to handle uncertainty.

The use of IT is imperative to enable the sensing and responding capabilities of an organization (or a supply chain) [22]. It also facilitates and speeds up the processing of information, which frequently exceeds human capacity [1]. As a result, it increases the range of options that an organization or a supply chain has to respond to disturbances. Previous research suggests that IT is an important element of resilience, both at the level of the firm and of the supply chain [8,54]. However, IT infrastructures are not always flexible. Rigid or cumbersome IT infrastructures including legacy IT systems may hinder efficient organisational response to environmental disturbances [71]. They are usually rigid and do not support options to handle different or unexpected situations. Furthermore, complex IT infrastructures usually consist of different systems with varied characteristics, which may be unable to communicate or to provide the anticipated results on supply chain resilience.

As different types of systems or technologies have varied properties, they cannot provide similar advantages to different organisations or supply chains. These advantages are related to the specific characteristics of the IT infrastructure, the type of systems that it comprises and the specific context, in which it operates. To examine the role of technology on supply chain resilience, this section distinguishes between fundamental IT characteristics, analysed in the literature, and discusses whether they can enable or inhibit business resilience.

A main and important characteristic of the IT infrastructure is information sharing:

- Information Sharing is related to the exchange of data and information between business partners. It contributes to the reduction of supply chain uncertainty and enables the increase of supply chain performance [72]. It enables the efficient monitoring of disturbances (e.g., changing consumer needs, problems of supply) and supports the understanding of possible changes (e.g., market conditions). Therefore, it supports the process of appreciation, as it enables companies to exchange information, to better realize an environmental disturbance and more efficiently decide upon an action to respond. Modern technologies facilitate the real-time exchange of information among different departments or organisations. Exchanged information may be related to production schedules, sales forecasts, promotions, deliveries, inventory, and sales data, etc. According to Kopanaki et al. [22], information sharing supports the effective coordination of supply chain operations and leads to improved forecasting, better production planning and more efficient replenishment of products. It also supports logistics and inventory management, as well as enables business partners to take effective decisions based on detailed information generated either in the internal or the external environment. However, information sharing can only be achieved if the different systems (of the same or different organizations) are integrated in an interconnected IT infrastructure.

- -

- Messaging standards: The efficient exchange of information and more specifically of electronic business documents, such as invoices, orders and catalogues of products, between different systems, presupposes the existence of messaging standards. The exchange of XML messages does not ensure the implementation of cross-platform applications [22]. Due to the immaturity and variety of existing XML standards, the diversity and adaptability of electronic messages and the widespread use of traditional EDI messages, a clear convergence of business messages standards has still not emerged [73].

- -

- Interconnection can be achieved through different technological solutions, such as ERP to ERP communication [74], exchange of data (e.g., via electronic messages or web services), uploading information on web-based platforms or typing in web-based forms [22]. Internet-based collaboration platforms may be used to support cooperation among different organizations in a supply chain, facilitating interconnection of different systems and supporting the exchange of data. Such interconnected IT infrastructures enable firms to share real-time information along the supply chain and facilitate cooperation with business partners [9].

- -

- Integration: The interconnection of all systems within a specific organization and between business partners leads to the development of an integrated infrastructure. Integration can also be achieved through the connection and linking of the companies’ internal IS with the supply chain’s collaboration platform. This may increase the efficiency of processes by leading to full automation and elimination of data entry. Nevertheless, the proliferation of technologies and the existence of different internet-based collaboration platforms may limit the integration capabilities of companies’ systems [75], especially if they are members of different supply chains.

- Event management capabilities: Supply chain event management (SCEM) approaches and systems introduce control mechanisms to handle events, especially exception events. “SCEM is reactive by its nature as event processing deals with the detection and notification upon undesired events that are already identified in the supply chain, taking action upon already known situations.” [76] (p. 29). Therefore, event handling presupposes situation awareness. “Situation awareness is based on the perception of the operational environment” [77] (p. 88). It involves awareness of what is happening and understanding of how information, events, and subsequent actions may affect the organization’s or the supply chain’s objectives [77]. Such capabilities support the process of appreciation in organisations, enabling them to perceive situations, efficiently realize changes and respond to them dynamically. According to Dießner and Rosemann [78] effective SCEM can only be developed if transparency, supply chain visibility and intensive information sharing are supported.

- Decision-making capabilities: The traditional configuration of a decision support system (DSS) (collecting information from the organization’s internal and external environment) should be extended to also monitor and manage events. Alternatively, a DSS could interact with an event management system to realize disruptions and suggest possible courses of actions.

- Proactive decision making is related to the ability to predict future and undesired events as well as to make decisions needed to mitigate the effects of the predicted events before their occurrence [76,79]. Consequently, proactive event processing must identify future events, predict event patterns and specify possible courses of action to take [80]. Therefore, proactive event management can support resilience, while substantially reducing supply-chain troubleshooting costs [81].

- Software scalability refers to a structural characteristic of a software and demonstrates its ability to incorporate new services or alter its functionality. It is related to the extent to which the software supporting business operations can tolerate or adapt to changes in the environment [22]. Therefore, scalability supports organizations’ resilience by enabling them to easily adjust their business processes and transactions, by quickly returning to a stable situation.

- Resource on demand refers to the dynamic allocation of resources, based on the computational or interaction requirements of firms. Depending on their needs, organizations can easily modify their computing and storage resources. For example, “if computational needs are increased in a particular time of the year (e.g., Christmas) then additional memory may be allocated or more servers may be used to support collaboration with multiple suppliers” [22] (p. 342). This property supports resilience as it enables the efficient adaptation to disturbances and the cost-effective adjustment to a scalable infrastructure, which can easily return to its original state.

- Pay-as-you-go solutions: Pay-as-you-go solutions enable companies to make temporary and low-cost changes to their IT infrastructures. To respond to changing market conditions, companies may often search for cost-effective and easy to implement solutions, such as web-based applications that can be used on a pay-per-use basis, for as long as the specific needs lasts.

These IT characteristics may generally support supply chain resilience. Specifically, information sharing, supported by systems’ interconnection, integration and messaging standards, is imperative to support the process of appreciation. As explained in the previous section, appreciation is a cyclic process, involving evaluation of events (e.g., a change in demand or a delay in deliveries) or ideas (e.g., a new promotion), based on standards (common/usual ways of responding in similar situations) formulated in previous history. It also involves handling of a situation, by making judgements of facts (reality judgements), evaluating their significance (value judgements), identifying possible responses (range of options) and deciding whether to take an action to respond [47]. This process includes intensive information sharing, especially at the supply chain level, where different companies may collaborate to realize and handle events, think of responses and decide upon actions to take. This process is further facilitated through more advanced systems, with embedded business logic either supporting event management or enabling decision making. These systems facilitate the monitoring of events, support situation awareness and quickly lead to a decision upon an action. Therefore, they increase the responsiveness of the supply chain and the efficiency of the process of appreciation.

Other IT characteristics support resilience, by facilitating the action of response. For example, the use of the same messaging standard increases the range of options for interconnection and enables companies to easily collaborate with additional partners to cover temporary demand or supply needs. Resource on demand supports robustness as it enhances the range of available ΙΤ resources and enables the efficient adaptation/adjustment of the resources used [1] when computational or interaction needs are altered. Similarly, scalability offers an enhanced range of functional/operational options, enabling firms to easily modify/adjust their business transactions based on changing business needs [82]. Finally, cloud-based and pay-as-you-go solutions enable companies to make quick changes with minimal cost and without changing their in-premises systems.

In the era of Industry 4.0 there are new technologies that can provide such characteristics and thus support supply chain resilience. These comprise:

- Cloud-based solutions: Cloud computing can be described as “a large pool of readily accessible virtualized resources, which can be transformed and adjusted to customer needs in a variable scale” [83] (p. 17). It offers scalable platforms, resource on demand and pay-as-you-go solutions [84].

- Blockchain technology can have a positive impact on supply chain management and on supply chain resilience [19]. It can be used to interconnect multiple trading partners, providing a secure platform for information sharing between authorized partners [85]. Any information related to a physical product can be stored in the blockchain, linking the product to its virtual identity [86]. As a result, products’ life cycle can be monitored from the first stages of the chain to the final consumer. The transparency of information achieved enables waste prevention, fraud detection, and quick realization of possible unethical practices. Therefore, though information recording, secure and transparent connections, blockchain enables supply chains to detect problematic situations, deal with unethical partners and counterfeit products.

- IoT may create new possibilities for companies, by linking digital with physical entities. By using sensor-based technology, IoT enables all supply chain partners to share information through the internet. IoT can be used to support transportation systems [87] and enable the tracking of goods along the supply chain. Therefore, it supports traceability inside the supply chain and efficient data sharing among different stakeholders [88]. By providing real-time information, while combined with cloud-based platforms or blockchain architectures, it facilitates situation awareness and supports the decision-making process of all stakeholders [88,89]. Therefore, it may support ‘autonomous and predictive capabilities of future supply chains’ [90] (p. 22).

Hence, as shown in the above description, new technologies are able to provide properties and characteristics enabling supply chain resilience.

5. Discussion

The notion of supply chain resilience is analysed by many researchers, and different conceptualizations are identified in the literature [12,13]. Many researchers focus on examining the multidimensional nature of resilience [15,41], while others aim at developing theoretical approaches to analyse the concept of resilience in depth [16,17,52]. The paper aims to clarify the concept of supply chain resilience by providing a framework and an approach based on appreciative systems thinking theory [57,63]. It argues that resilience can be examined by the process though which organisations appreciate a situation, realize an environmental disturbance, and decide upon an action to respond [47]. It also argues that the ease of response can be indicated by the time and range of options (available to an organisation/supply chain) to respond [48]. It finally argues that resilience is associated with the ability of an organization/supply chain to recover to its original state or to a new stable state after being disturbed [11,42].

The paper further suggests that this framework can be used as a base to evaluate the impact of IT on supply chain resilience. As previous research shows, the use of IT may facilitate business collaboration, support information sharing [69,70] and to a certain extent increase business or supply chain resilience [8,54]. However different types of systems have varied results, and do not provide similar benefits to all organisations.

Previous research focused on examining the impact of specific types of systems e.g., ERP [18], interorganizational systems [47], cloud-based solutions [22] or blockchain technologies [19] on supply chain resilience. This paper acknowledges that modern technological infrastructures are mixed, complex and evolving, they may include different technologies with varied characteristics, providing different results, which may change over time. Therefore, it argues that the analysis of the impact of complex IT infrastructures on business resilience can be conducted through the identification and evaluation of its different systems and IT characteristics. Based on the literature the paper identifies important IT characteristics, such as information sharing [72], interconnection [9], similar messaging standards, event management [77], proactive decision-making capabilities [76,79], software scalability and resource on demand [22].

Supported by key characteristics and developments of ICT, the supply chain of the future will be autonomous and have predictive capabilities that will ensure their efficient operation in an increasingly complex and uncertain environment [90]. Such ‘self-thinking’ supply chains will be more responsive through their ability to act autonomously and quickly.

Nevertheless, the IT infrastructure (comprising new technologies, specific IT solutions or characteristics) is not the only factor influencing supply chain resilience. Resilience is further affected by the supply chain context in which it is embedded [22]. It is influenced by specific organisational and interorganisational arrangements. It is also influenced by the people involved in the main business processes, their relationships and collaboration [25]. Therefore, the creation of agile teams [91], or of agile partnerships, as well as the alignment of business strategies are equally important factors for the attainment of resilience. However, examining the context-dependent nature and social aspect of resilience was out of the scope of this research and forms the main limitation of this study.

6. Managerial Insights

This study provides insight to practitioners and managers, by explaining supply chain resilience as a multidimensional concept and providing a conceptual framework for its analysis. This framework can be used as a base for the evaluation of resilience, by enabling managers to examine the process though which their organisation, as part of a supply chain, realize environmental disturbances, appreciate their importance and potential impact (by making judgements of facts and values), identify the available planned or unplanned options and decide upon an action to respond. The range of options and the time needed to respond shows them the ease of response, that is the degree of business resilience.

The proposed framework can be further used by managers to evaluate the impact of IT on the resilience of their company or supply chain. As the paper suggests, complex IT infrastructures need to be analysed based on their important IT characteristics (such as information sharing capabilities, messaging standards, level of integration, event management capabilities, proactive or reactive decision-making capabilities, software scalability, resource on demand features and pay-as-you-go solutions). Although this list is not exhaustive it provides managers with a set of important features that can be assessed based on the extent to which they support:

- the ability of the organisation/supply chain to perceive environmental disturbances and appreciate the current situation,

- the range of available options to respond

- the decision upon an action to respond

- the time, cost, or effort to respond

- the ability of an organisation to return to its original state or to a new stable state after responding to the disturbing events

7. Conclusions

The paper aimed at clarifying the notion of supply chain resilience, based on an extensive literature review. It explained resilience as a multidimensional concept (focusing on the temporal, cost and range dimensions). It also adopted a soft systems thinking approach to develop a conceptual framework for the analysis of resilience. It then identified and examined specific characteristics of contemporary IT infrastructures (as mentioned in the literature) and evaluated their impact (benefits or constraints) on supply chain resilience.

The conceptual framework of supply chain resilience, based on previous research and on appreciative systems thinking theoretical approach, forms the main theoretical contribution of the paper. It can be used to analyse the process through which organisations or supply chains “appreciate” an environmental disturbance and, based on judgements, decide upon an action to respond. The paper further suggests that the proposed framework can be used by researchers and/or practitioners to examine specific information systems (or IT infrastructures), identify their characteristics, and evaluate the extent to which they support supply chain resilience. The proposed approach of IT infrastructures’ evaluation, based on the analysis of different IT characteristics, forms the paper’s main contribution to practice.

The analysis shows that IT infrastructures comprising modern technologies, such as cloud-based solutions, blockchain and IoT, may support supply chain resilience by facilitating the exchange of real-time data, enabling situation awareness, providing scalable solutions, supporting collaborative practices and facilitating decision making. However, it should be stated that these results are influenced by the wider organizational and supply chain context, leading to or hindering supply chain resilience. The application of the proposed framework in specific business contexts and the examination of the different characteristics of their IT infrastructures, will be subject of future research.

Funding

This work has been partly supported by the University of Piraeus Research Center.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Overby, E.; Bharadwaj, A.; Sambamurthy, V. Enterprise agility and the enabling role of information technology. Eur. J. Inf. Syst. 2006, 15, 120–131. [Google Scholar] [CrossRef]

- Ngai, E.W.; Chau, D.C.; Chan, T. Information technology, operational, and management competencies for supply chain agility: Findings from case studies. J. Strateg. Inf. Syst. 2011, 20, 232–249. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Nevo, S.; Jin, J.; Wang, L.; Chow, W.S. IT capability and organisational performance: The roles of business process agility and environmental factors. Eur. J. Inf. Syst. 2013, 23, 326–342. [Google Scholar] [CrossRef]

- DeGroote, S.E.; Marx, T.G. The impact of IT on supply chain agility and firm performance: An empirical investigation. Int. J. Inf. Manag. 2013, 33, 909–916. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Miloulis, D.M.; Chatzistelios, G.; Gayialis, S.P.; Papadopoulos, G.A. Applying a system dynamics approach for the pharmaceutical industry: Simulation and optimization of the quality control process. WSEAS Trans. Environ. Dev. 2021, 17, 983–996. [Google Scholar] [CrossRef]

- Sterman, J. Business Dynamics; McGraw-Hill, Inc.: New York, NY, USA, 2000. [Google Scholar]

- Rebs, T.; Brandenburg, M.; Seuring, S. System dynamics modelling for sustainable supply chain management: A literature review and systems thinking approach. J. Clean. Prod. 2019, 208, 1265–1280. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. Achieving supply chain agility through IT integration and flexibility. Int. J. Prod. Econ. 2008, 116, 288–297. [Google Scholar] [CrossRef]

- Bi, R.; Davidson, R.; Kam, B.; Smyrnios, K. Developing organisational agility through IT and supply chain capability. J. Glob. Inf. Manag. 2013, 21, 38–55. [Google Scholar] [CrossRef]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The evolution of resilience in supply chain management: A retrospective on ensuring supply chain resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Evans, S. Strategic Flexibility For High Technology Manoeuvres. J. Manag. Stud. 1991, 28, 69–89. [Google Scholar] [CrossRef]

- Adobor, H.; McMullen, R.S. Supply chain resilience: A dynamic and multidimensional approach. Int. J. Logist. Manag. 2018, 29, 1451–1471. [Google Scholar] [CrossRef]

- Scholten, K.; Scott, P.S.; Fynes, B. Building routines for non-routine events: Supply chain resilience learning mechanisms and their antecedents. Supply Chain Manag. Int. J. 2019, 24, 430–442. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain resilience: Conceptualization and scale development using dynamic capability theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Börekçi, D.Y.; Kiriş, S.B.; Batmaca, S. Analysis of enterprise resource planning (ERP) system workarounds with a resilience perspective. Contin. Resil. Rev. 2020, 2, 131–148. [Google Scholar] [CrossRef]

- Min, H. Blockchain technology for enhancing supply chain resilience. Bus. Horiz. 2019, 62, 35–45. [Google Scholar] [CrossRef]

- Gastel, B.; Day, R.A. How to Write and Publish a Scientific Paper; ABC-CLIO: Santa Barbara, CA, USA, 2016; Volume 103, pp. b1–b3. [Google Scholar] [CrossRef][Green Version]

- Mayer, P. Guidelines for Writing a Review Article. Zurich-Basel Plant Sci. Cent. 2009, 82, 443–446. [Google Scholar]

- Kopanaki, E.; Karvela, P.; Georgopoulos, N. From traditional interorganisational systems to cloud-based solutions: The impact on supply chain flexibility. J. Organ. Comput. Electron. Commer. 2018, 28, 334–353. [Google Scholar] [CrossRef]

- Pozzebon, M.; Petrini, M.; de Mello, R.B.; Garreau, L. Unpacking researchers’ creativity and imagination in grounded theorizing: An exemplar from IS research. Inf. Organ. 2011, 21, 177–193. [Google Scholar] [CrossRef]

- Fayezi, S.; Zutshi, A.; O’Loughlin, A. Developing an analytical framework to assess the uncertainty and flexibility mismatches across the supply chain. Bus. Process Manag. J. 2014, 20, 362–391. [Google Scholar] [CrossRef]

- Kopanaki, E. Examining Organisational Flexibility in an Interorganisational Context: A Case Study of a Grocery Retail Supply Chain. Ph.D. Thesis, London School of Economics and Political Science, London, UK, 2008. [Google Scholar]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Vilko, J.; Ritala, P.; Edelmann, J. On uncertainty in supply chain risk management. Int. J. Logist. Manag. 2014, 25, 3–19. [Google Scholar] [CrossRef]

- Christopher, M.; Lee, H.L. Mitigating supply chain risk through improved confidence. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 388–396. [Google Scholar] [CrossRef]

- Wang, M. Impacts of supply chain uncertainty and risk on the logistics performance. Asia Pac. J. Mark. Logist. 2018, 30, 689–704. [Google Scholar] [CrossRef]

- Liao, H.; Deng, Q.; Shen, N. Optimal remanufacture-up-to strategy with uncertainties in acquisition quality, quantity, and market demand. J. Clean. Prod. 2019, 206, 987–1003. [Google Scholar] [CrossRef]

- Davis, T. Effective supply chain management. Sloan Manag. Rev. 1993, 34, 35–46. [Google Scholar]

- Ahmed, W.; Moazzam, M.; Sarkar, B.; Rehman, S.U. Synergic effect of reworking for imperfect quality items with the integration of multi-period delay-in-payment and partial backordering in global supply chains. Engineering 2021, 7, 260–271. [Google Scholar] [CrossRef]

- Lee, H.L. Aligning Supply Chain Strategies with Product Uncertainties. Calif. Manag. Rev. 2002, 44, 105–119. [Google Scholar] [CrossRef]

- Lahmar, A.; Galasso, F.; Chabchoub, H.; Lamothe, J. Conceptual Framework of Supply Chain Vulnerability. In Proceedings of the 6th International Conference on Information Systems, Logistics and Supply Chain (ILS Conference), Bordeaux, France, 1–4 June 2016. [Google Scholar]

- Svensson, G. A Conceptual Framework for the Analysis of Vulnerability in Supply Chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–749. [Google Scholar] [CrossRef]

- Tang, C.S. Perspectives in supply chain risk management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Manders, J.H.; Caniëls, M.C.; Ghijsen, P.W.T. Supply chain flexibility: A systematic literature review and identification of directions for future research. Int. J. Logist. Manag. 2017, 28, 964–1026. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A contingent resource-based perspective of supply chain resilience and robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–13. [Google Scholar] [CrossRef]

- Scholten, K.; Stevenson, M.; van Donk, D.P. Dealing with the unpredictable: Supply chain resilience. Int. J. Oper. Prod. Manag. 2020, 40, 1–10. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Tukamuhabwa, R.B.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Kumar, R. Understanding the Business Value of Information Systems: A Flexibility-Based Perspective. In Measuring Information Technology Investment Payoff: Contemporary Approaches; Mahmood, M.A., Szewczak, E.J., Eds.; IGI Global: Hershey, PA, USA, 1998; pp. 301–320. [Google Scholar]

- Lucas, H.; Olson, M. The Impact of Information Technology on Organisational Flexibility. J. Organ. Comput. 1994, 4, 155–175. [Google Scholar]

- Volberda, H.W. Toward the flexible form: How to remain vital in hypercompetitive environments. Organ. Sci. 1996, 7, 359–374. [Google Scholar] [CrossRef]

- Martínez Sánchez, A.; Pérez Pérez, M. Supply chain flexibility and firm performance: A conceptual model and empirical study in the automotive industry. Int. J. Oper. Prod. Manag. 2005, 25, 681–700. [Google Scholar] [CrossRef]

- Kopanaki, E.; Smithson, S. The issue of flexibility in inter-organisational collaboration: An appreciative systems thinking perspective. Int. J. Appl. Syst. Stud. 2013, 5, 92–113. [Google Scholar] [CrossRef]

- Golden, W.; Powell, P. Towards a definition of flexibility: In search of the Holy Grail? Omega 2000, 28, 373–384. [Google Scholar] [CrossRef]

- Tan, C.; Sia, S.K. Managing Flexibility in Outsourcing. J. Assoc. Inf. Syst. 2006, 7, 179–206. [Google Scholar] [CrossRef]

- Rosenhead, J. Rational Analysis for a Problematic World: Problem Structuring Methods for Complexity, Uncertainty and Conflict; Wiley: Chichester, UK, 1989; Volume 26, pp. 117–131. [Google Scholar]

- Ali, A.; Mahfouz, A.; Arisha, A. Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 16–39. [Google Scholar] [CrossRef]

- Vanpoucke, E.; Ellis, S.C. Building supply-side resilience—A behavioural view. Int. J. Oper. Prod. Manag. 2020, 40, 11–33. [Google Scholar] [CrossRef]

- Zollo, M.; Winter, S.G. Deliberate learning and the evolution of dynamic capabilities. Organ. Sci. 2002, 13, 339–351. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef] [PubMed]

- Checkland, P. Systems Thinking. In Rethinking Management Information Systems: An Interdisciplinary Perspective; Oxford University Press: Oxford, NY, USA, 1999; pp. 45–56. [Google Scholar]

- Senge, P.M. The Fifth Discipline: The Art & Practice of The Learning Organization; Paperback–Deckle Edge: Cape Town, South Africa, 2006. [Google Scholar]

- Checkland, P.; Holwell, S. Information, Systems and Information Systems: Making Sense of the Field; Wiley: Chichester, UK; New York, NY, USA, 1998. [Google Scholar]

- Checkland, P. Systems Theory and Management Thinking. In Critical Issues in Systems Theory and Practice; Ellis, K., Gregory, A., Mears-Young, B.R., Ragsdell, G., Eds.; Plenum Press: New York, NY, USA; London, UK, 1995; Volume 38, pp. 75–91. [Google Scholar] [CrossRef]

- Senge, P.M.; Sterman, J.D. Systems thinking and organizational learning: Acting locally and thinking globally in the organization of the future. Eur. J. Oper. Res. 1992, 59, 137–150. [Google Scholar] [CrossRef]

- Forrester, J.W. System dynamics, systems thinking, and soft OR. Syst. Dyn. Rev. 1994, 10, 245–256. [Google Scholar] [CrossRef]

- Kim, S.; Connerton, T.P.; Park, C. Exploring the impact of technological disruptions in the automotive retail: A futures studies and systems thinking approach based on causal layered analysis and causal loop diagram. Technol. Forecast. Soc. Chang. 2021, 172, 121024. [Google Scholar] [CrossRef]

- Roxas, F.M.Y.; Rivera, J.P.R.; Gutierrez, E.L.M. Locating potential leverage points in a systems thinking causal loop diagram toward policy intervention. World Futures 2019, 75, 609–631. [Google Scholar] [CrossRef]

- Vickers, G. Value Systems and Social Process; Travistock: London, UK, 1968. [Google Scholar]

- Vickers, G. Freedom in a Rocking Boat; Pellican Books: London, UK, 1972. [Google Scholar]

- Vickers, G. Human Systems Are different; Harper & Row: London, UK, 1983. [Google Scholar]

- Vickers, G. The Art of Judgement; Harper & Row: London, UK, 1983. [Google Scholar]

- Checkland, P.; Casar, A. Vickers’ Concept of an Appreciative System: A Systemic Account. J. Appl. Syst. Anal. 1986, 13, 3–17. [Google Scholar]

- Vickers, G. The Vickers Papers; Harper & Row: London, UK, 1984; pp. 230–245. [Google Scholar]

- Malhotra, A.; Gosain, S.; El Sawy, O.A. Absorptive Capacity Configurations in Supply Chains: Gearing for Partner-Enabled Market Knowledge Creation. MIS Q. 2005, 29, 145–187. [Google Scholar] [CrossRef]

- Premkumar, G.P. Inter-Organizational Systems and Supply Chain Management—An Information Processing Perspective. In Proceedings of the Eighth European Conference on Information Systems, Vienna, Austria, 3–5 July 2000; pp. 1017–1028. [Google Scholar]

- van Oosterhout, M.; Waarts, E.; van Hillegesberg, J. Change factors requiring agility and implications for IT. Eur. J. Inf. Syst. 2006, 15, 132–145. [Google Scholar] [CrossRef]

- Hung, W.H.; Ho, C.F.; Jou, J.J.; Tai, Y.M. Sharing information strategically in a supply chain: Antecedents, content and impact. Int. J. Logist. Res. Appl. 2011, 14, 111–133. [Google Scholar] [CrossRef]

- Angeles, R.; Corritore, C.L.; Basu, S.C.; Nath, R. Success factors for domestic and international electronic data interchange (EDI) implementation for US firms. Int. J. Inf. Manag. 2001, 21, 329–347. [Google Scholar] [CrossRef]

- Kähkönen, T.; Smolander, K. ERP Integration—A Systematic Mapping Study. In Proceedings of the 15th International Conference on Enterprise Information Systems (ICEIS-2013), Angers, France, 4–7 July 2013; pp. 23–35. [Google Scholar] [CrossRef]

- Fliedner, G. CPFR: An emerging supply chain tool. Ind. Manag. Data Syst. 2003, 103, 14–21. [Google Scholar] [CrossRef]

- Vlahakis, G.; Kopanaki, E.; Apostolou, D. Proactive decision making in supply chain procurement. J. Organ. Comput. Electron. Commer. 2020, 30, 28–50. [Google Scholar] [CrossRef]

- Vlahakis, G.; Apostolou, D.; Kopanaki, E. 2018. Enabling situation awareness with supply chain event management. Expert Syst. Appl. 2018, 93, 86–103. [Google Scholar] [CrossRef]

- Dießner, P.; Rosemann, M. Supply Chain Event Management: Managing Risk by Creating Visibility. Strategies and Tactics in Supply Chain Event Management; Springer: Berlin, Germany, 2008; Volume 368, pp. 83–98. [Google Scholar] [CrossRef]

- Bousdekis, A.; Papageorgiou, N.; Magoutas, B.; Apostolou, D.; Mentzas, G. A Probabilistic model for context-aware proactive decision making. In Proceedings of the 7th International Conference on Information, Intelligence, Systems & Applications (IISA), Chalkidiki, Greece, 13–15 July 2016; pp. 1–6. [Google Scholar]

- Engel, Y.; Etzion, O.; Feldman, Z. A basic model for proactive event-driven computing. In Proceedings of the 6th ACM International Conference on Distributed Event-Based Systems, Berlin, Germany, 16–20 July 2012; pp. 107–118. [Google Scholar] [CrossRef]

- Bodendorf, F.; Zimmermann, R. Proactive supply-chain event management with agent technology. Int. J. Electron. Commer. 2005, 9, 58–89. [Google Scholar] [CrossRef]

- Heisterberg, R.; Verma, A. Creating Business Agility: How Convergence of Cloud, Social, Mobile, Video, and Big Data Enables Competitive Advantage; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Leukel, J.; Kirn, S.; Schlegel, T. Supply Chain as a Service: A Cloud Perspective on Supply Chain Systems. Syst. J. IEEE 2011, 5, 16–27. [Google Scholar] [CrossRef]

- Haag, S.; Cummings, M. Information Systems Essentials; McGraw Hill Higher Education: New York, NY, USA, 2008. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Abeyratne, S.A.; Monfared, R.P. Blockchain ready manufacturing supply chain using distributed ledger. Int. J. Res. Eng. Technol. 2016, 5, 1–10. [Google Scholar]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system–Part 1: Modeling IoT-based manufacturing supply chain. Ind. Manag. Data Syst. 2018, 118, 65–95. [Google Scholar] [CrossRef]

- Chi, J.; Li, Y.; Huang, J.; Liu, J.; Jin, Y.; Chen, C.; Qiu, T. A secure and efficient data sharing scheme based on blockchain in industrial Internet of Things. J. Netw. Comput. Appl. 2020, 167, 102710. [Google Scholar] [CrossRef]

- Rezaei, M.; Shirazi, M.A.; Karimi, B. IoT-based framework for performance measurement: A real-time supply chain decision alignment. Ind. Manag. Data Syst. 2017, 117, 688–712. [Google Scholar] [CrossRef]

- Calatayud, A.; Mangan, J.; Christopher, M. The self-thinking supply chain. Supply Chain. Manag. Int. J. 2018, 24, 22–38. [Google Scholar] [CrossRef]

- Schaveling, J.; Stob, A. Leadership that Supports Agile Team Behavior in Gaining Resilience, a Team Study. In Academy of Management Proceedings, 10510; Academy of Management: Briarcliff Manor, NY, USA, 2018; p. 13196. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).