Heat Losses in the Exhaust Manifold of a 4-Stoke DI Diesel Engine Subjected to Pulsating Flow

Abstract

1. Introduction

2. Heat Transfer Analysis in the Engine Exhaust

2.1. Phases of Engine Exhaust

2.2. Time Periodic Heat Conduction

2.3. Instantaneous and Mean Temperature and Heat Transfer Coefficient

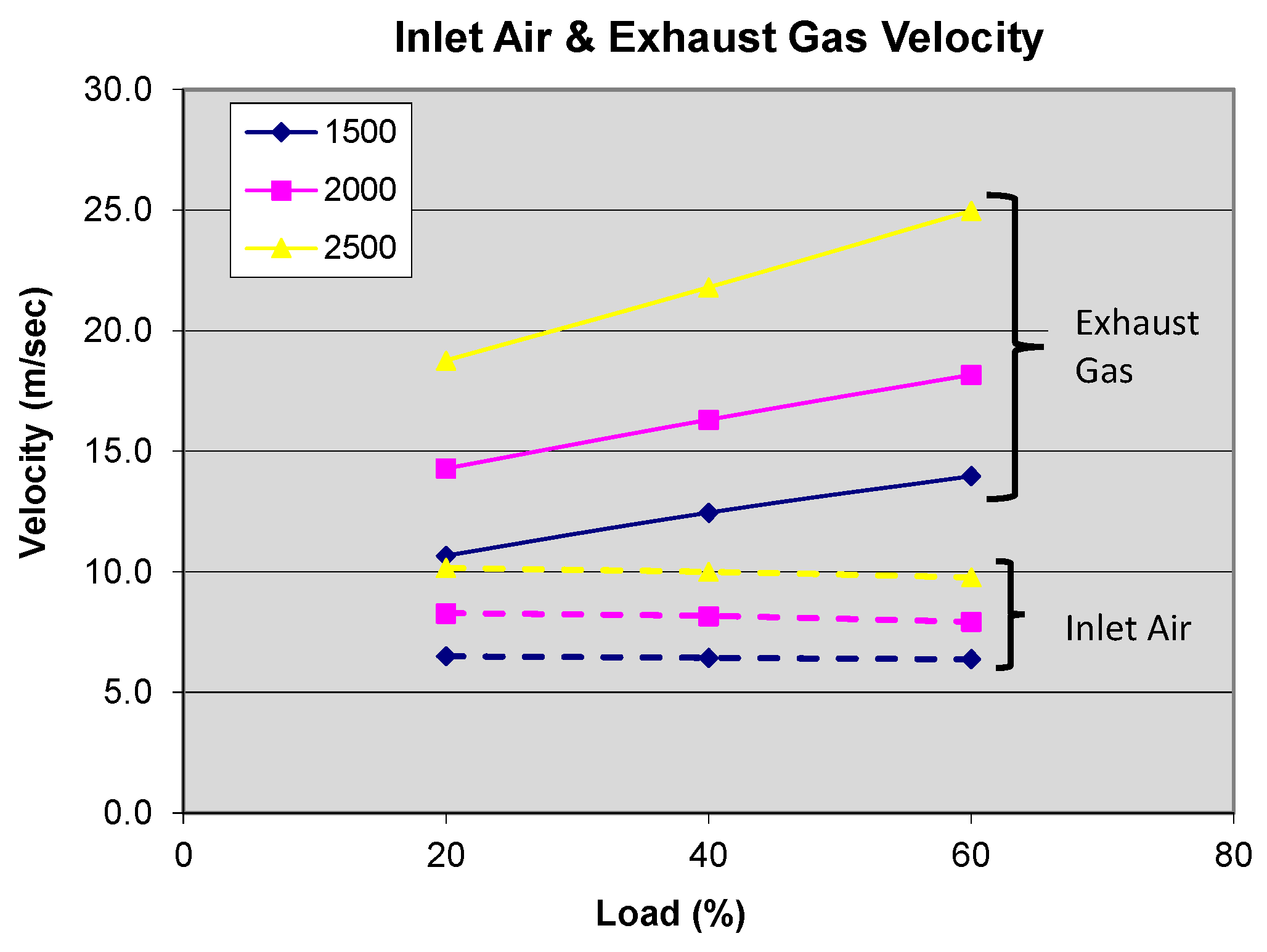

2.4. “Conventional” Heat Transfer Coefficient Estimation in the Engine Exhaust

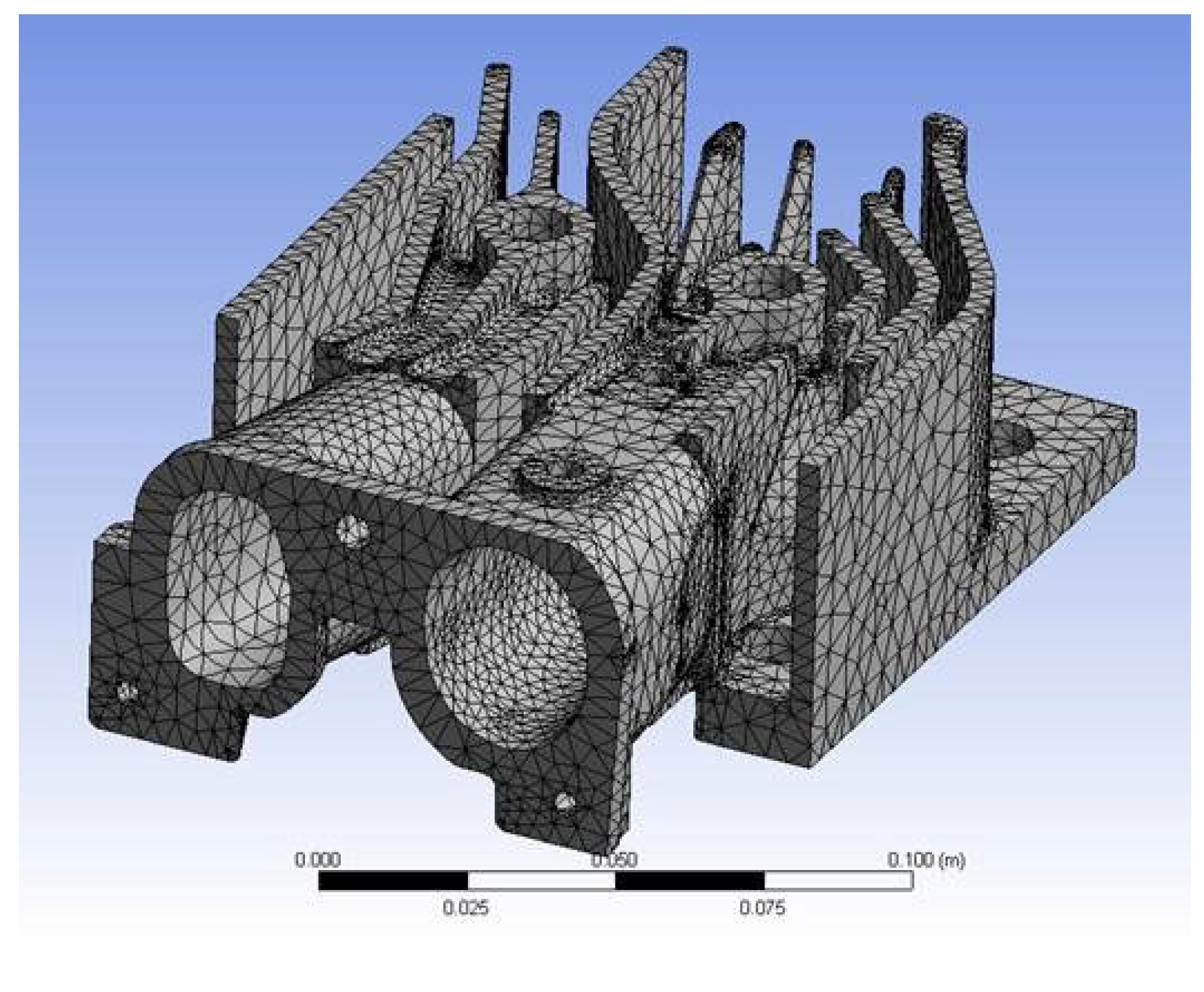

3. Simulation of Thermal Field in Engine Cylinder Head and Exhaust Manifold

3.1. The Use of the FEA Method in Engine Thermal Field Simulation

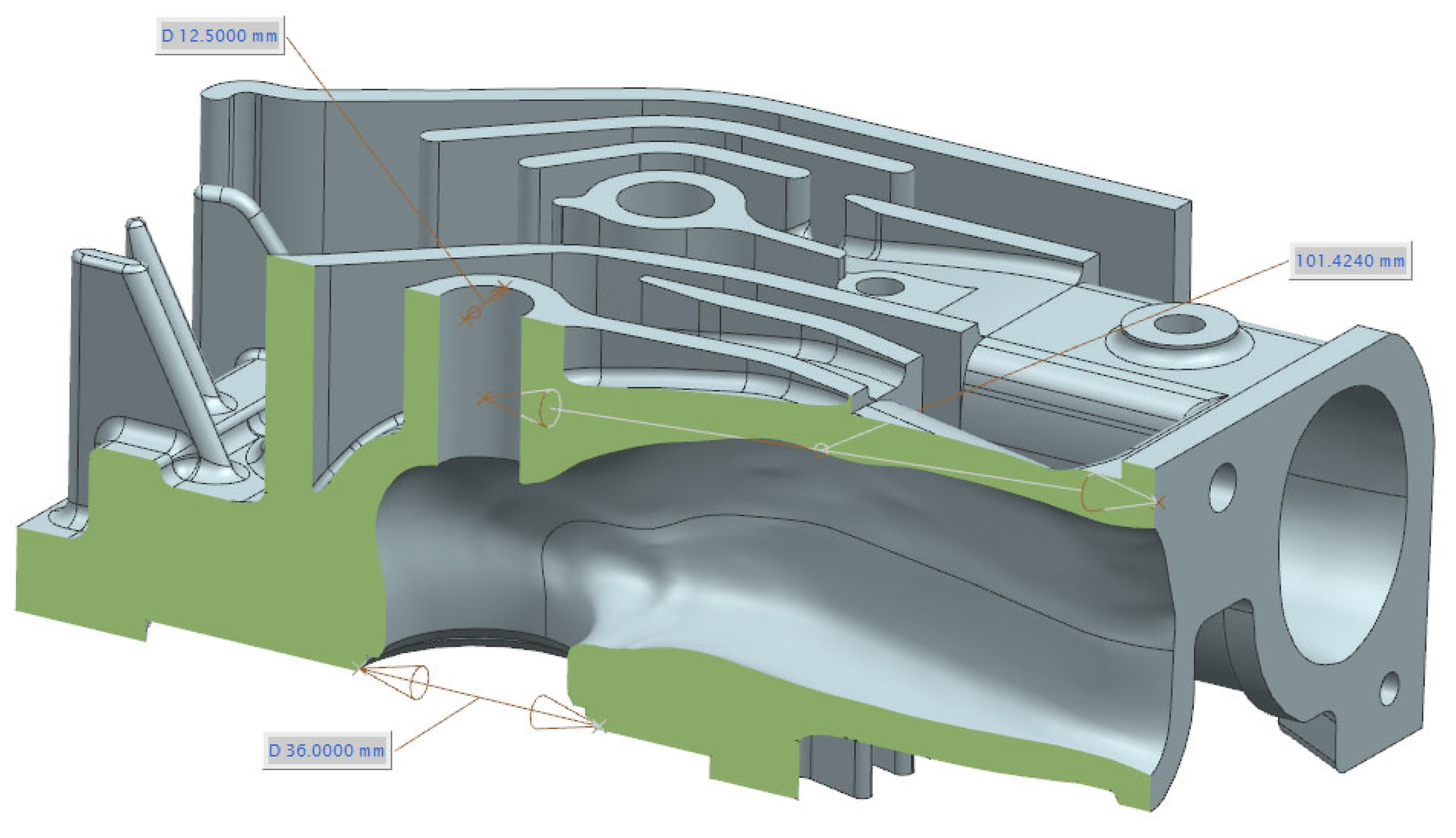

3.2. Mesh Development and Application of Boundary Conditions

3.3. Development of the Thermal Field for Steady-State Engine Operation

4. Test Engine and Experimental Installation

- Long-term response: the signals in this category present a non-periodic variation (or remain steady) over a large number of engine cycles. Therefore, the total period of acquisition is on the order of several minutes.

- Short-term response: the signals in this category vary within a period of one engine cycle (of the 2- or 4-stroke engine). Therefore, the total period of their acquisition is raised in several seconds (for the case of steady-state engine operation).

4.1. Long-Term Response Installation

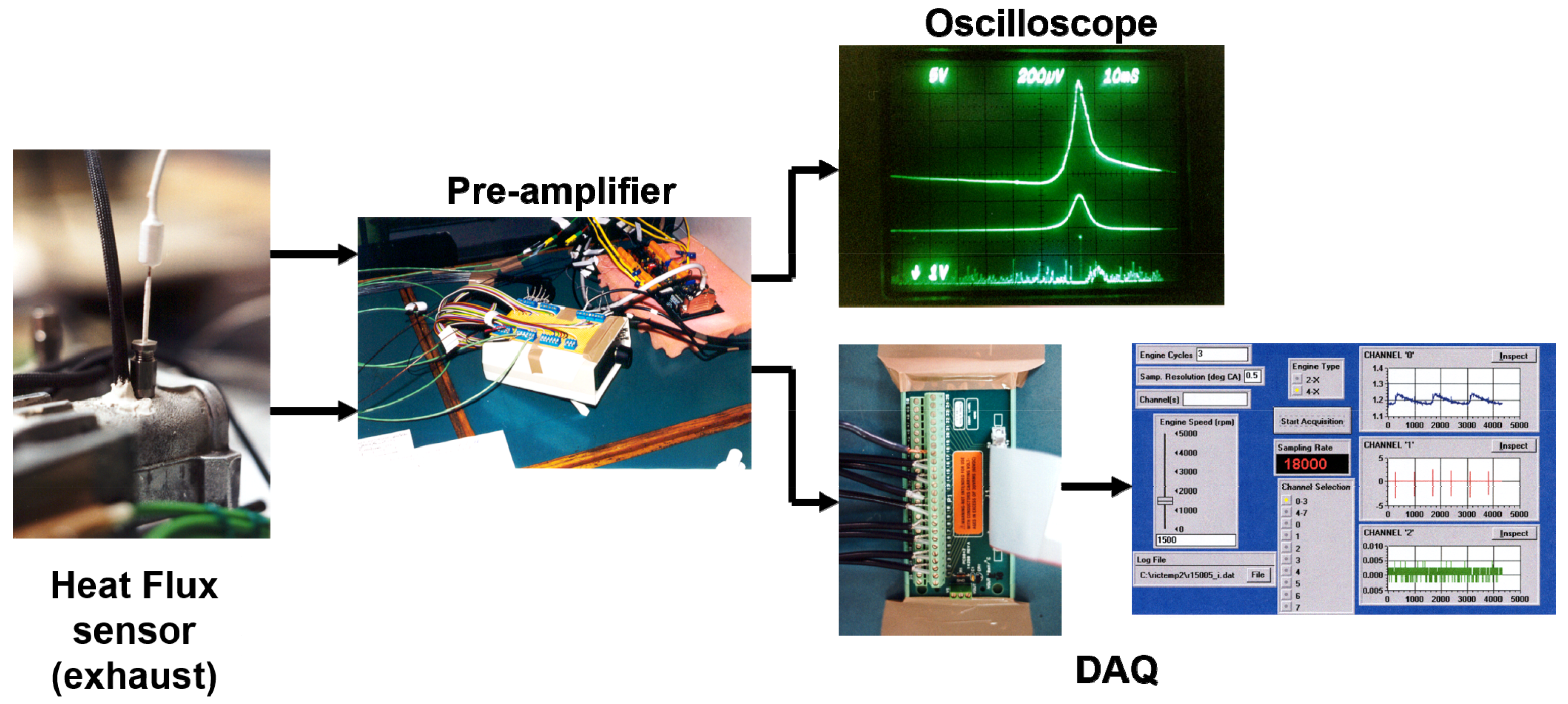

4.2. Short-Term Response Installation

4.2.1. Transducers and Heat Flux Probes

- “Tektronix” magnetic pick-up acting as TDC (Top Dead Center) marker

- Engine speed (rpm) counter and indicator (Tektronix, Beaverton, OR, USA).

- “Kistler” 6001 miniature piezoelectric transducer (Kistler Group, Winterthur, Switzerland) for measuring the cylinder pressure. The sensor was carefully mounted on the cylinder head surface. Its output is connected to a “Kistler” 5007 charge amplifier (Kistler Group, Winterthur, Switzerland).

- The heat flux sensors HT#1–3 in Figure 4a were installed on the cylinder head. Each of the sensors was based on a fast-response, K-type, flat-ribbon, ‘eroding’ thermocouple, which was custom-designed and manufactured for the needs of the present experimental installation [11]. This thermocouple was afterwards combined with a common K-type, in-depth thermocouple. The resulting heat flux sensor was finally fixed inside a compression fitting. The in-depth thermocouple was placed at a distance of 6 mm behind the fast-response one, inside the metal volume. The final result is shown in Figure 4.

- The heat flux sensor installed in the exhaust manifold (HT#4 in Figure 4a) was based on a fast response, J-type, ‘coaxial’ thermocouple. This was accompanied by a common J-type, in-depth thermocouple to form the corresponding heat flux sensor. The in-depth thermocouple was located inside the compression fitting at a distance of 6 mm behind the fast-response one. The sensor was flush-mounted on the exhaust manifold at a distance of 100 mm (when considered in a straight line) from the exhaust valve (Figure 6).

4.2.2. Signal Pre-Amplification and Data Acquisition System

5. Results and Discussion on Heat Losses in the Exhaust Manifold

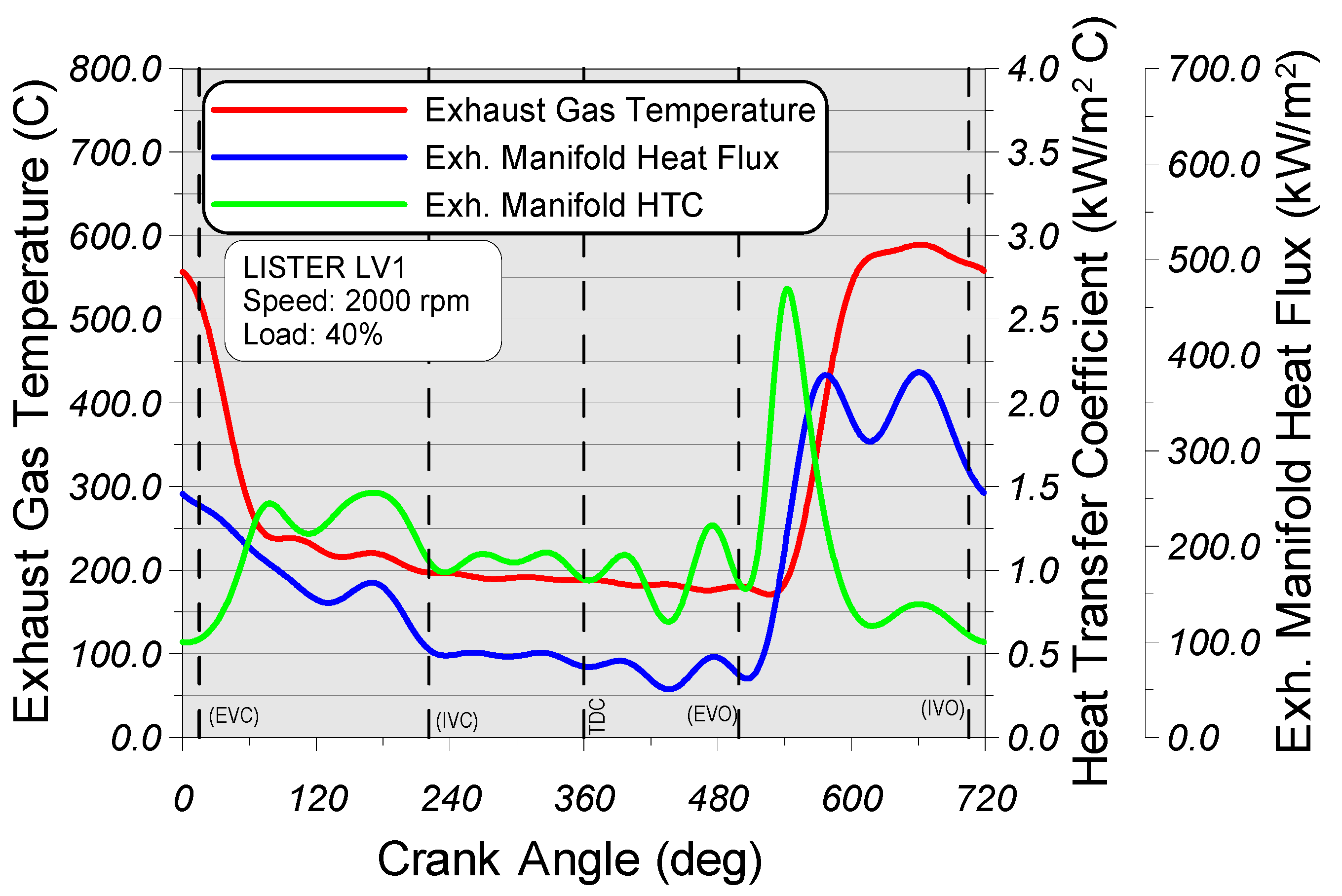

5.1. Instantaneous and Mean Heat Transfer on the Engine Exhaust

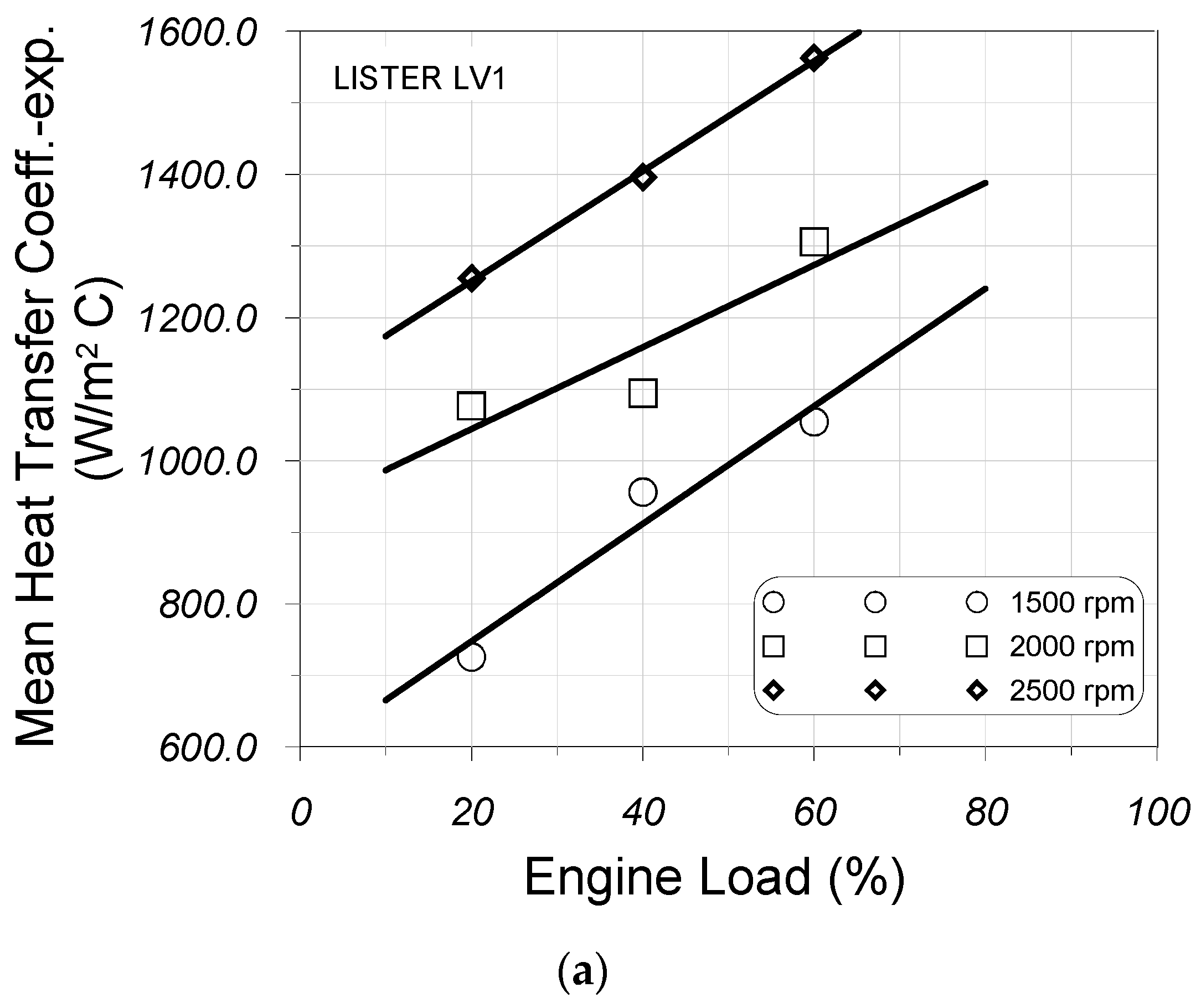

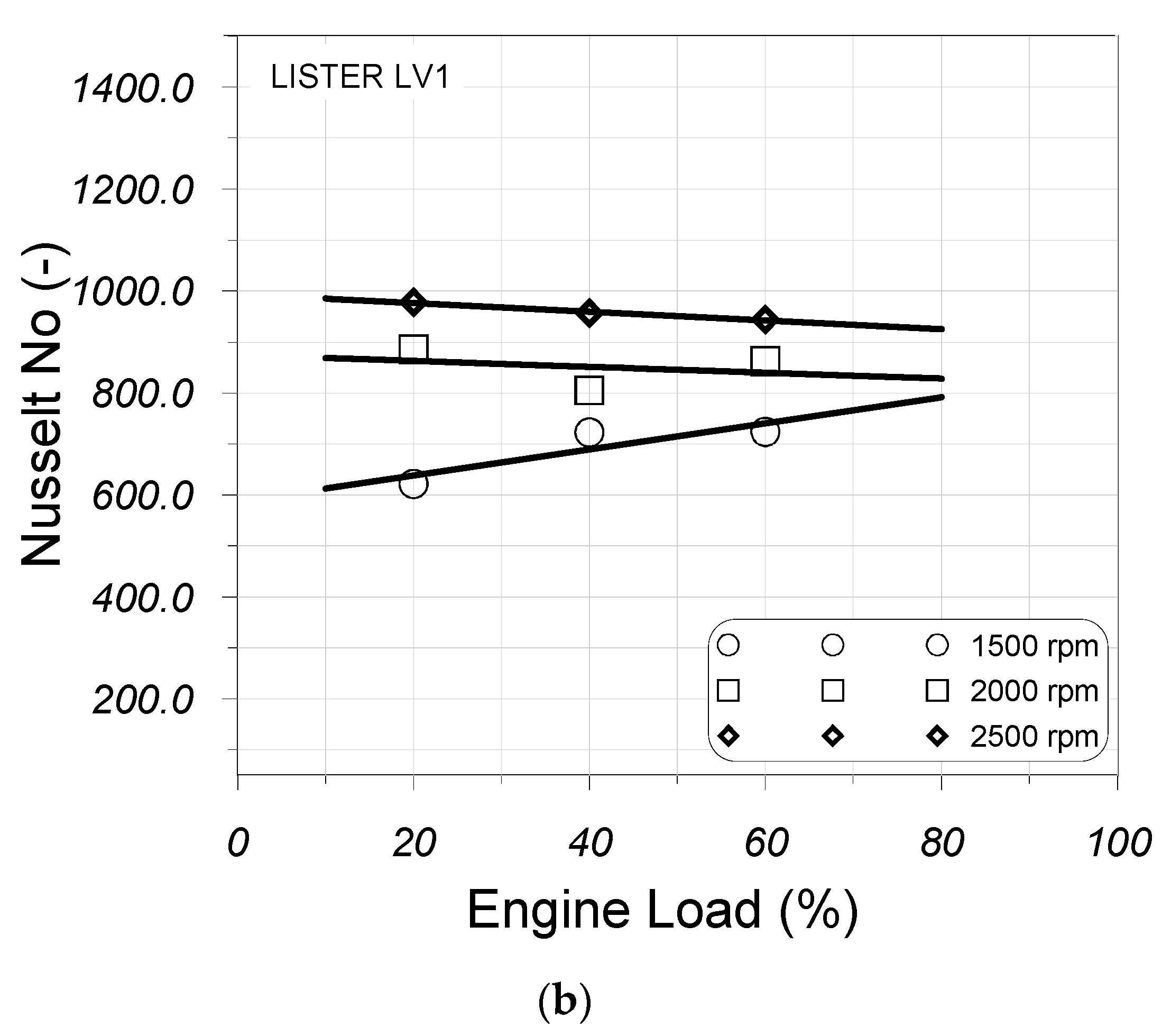

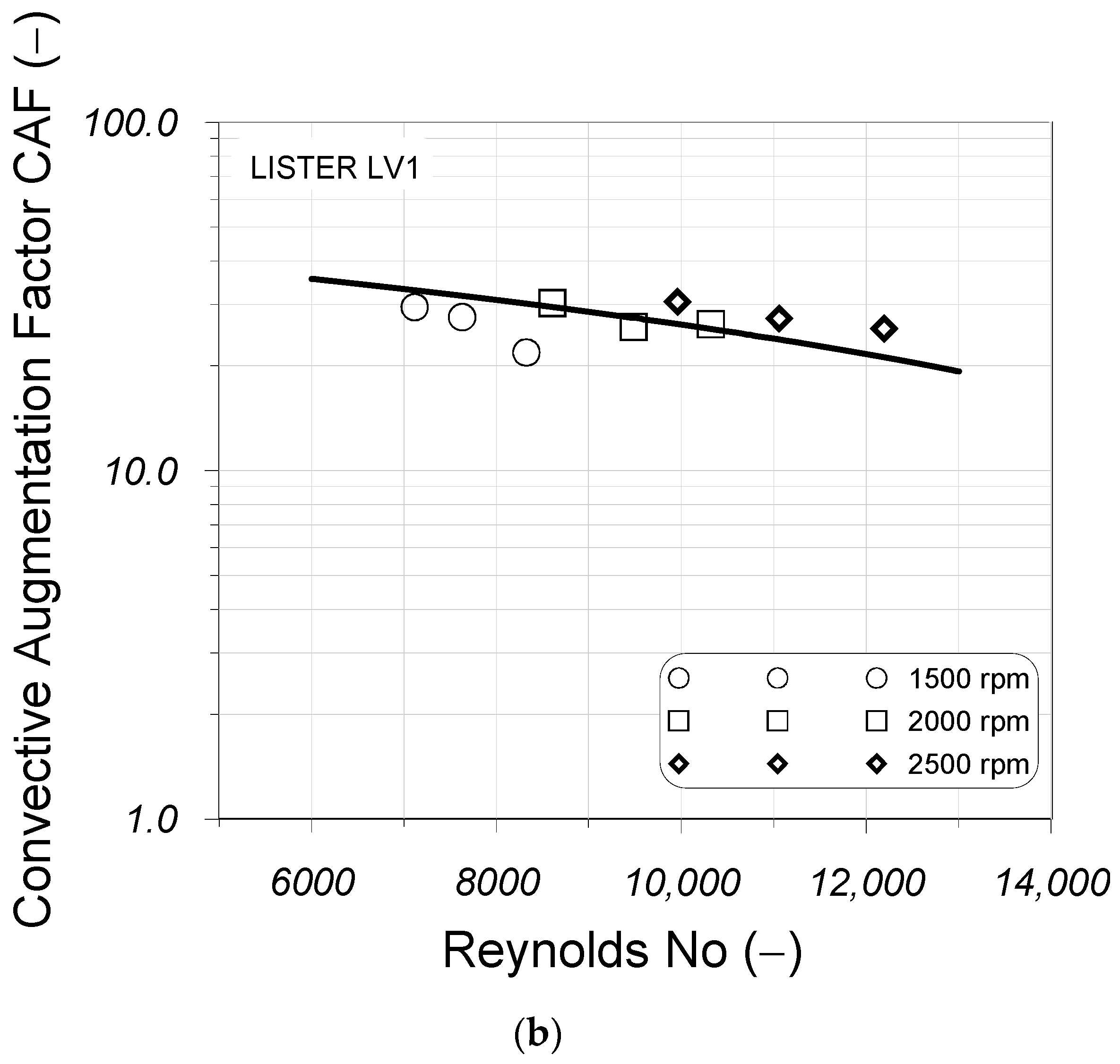

5.2. Development of a New Correlation for the Prediction of Heat Losses Inside the Engine Exhaust Manifold

- Application up to 100 mm downstream the exhaust valve;

- Engine speed: 1000 rpm < n < 3000 rpm.

5.3. Comparison of Theoretical Results with Experimental Measurements

6. Conclusions

- Perform a separation of the exhaust stroke into two different phases, namely the “blowdown” and the “displacement”. Due to the significant differences in the average velocity of the gases and the level of turbulence inside the exhaust port during these two phases, it is expected that eventually there will be two distinct expressions for the Heat Transfer Coefficient. These should then be connected to a common final heat loss evaluation model.

- Estimate the Heat Transfer Coefficient on the basis of operational variables and geometric parameters of the engine. Such variables are the gas mass flow rate, the curvature of the duct in the valve area, the “active” velocity of the pulsating flow, the pressure inside the cylinder at the point of the Exhaust Valve Opening, etc.

- The previous estimations could eventually be combined with a Computational Fluid Dynamics (CFD) model to lead to an interconnected model (Conjugate Heat Transfer, CHT), which will allow a more accurate calculation of the heat losses and the thermal exchange between the solid wall and the mass of hot gases inside the exhaust manifold.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wendland, D.W. Automobile Exhaust-System Steady-State Heat Transfer. In 1993 Vehicle Thermal Management Systems Conference Proceedings (VTMS1); SAE: Columbus, OH, USA, 1993; SAE Paper 931085. [Google Scholar] [CrossRef]

- Malchow, G.L.; Sorenson, S.C.; Buckius, R.O. Heat Transfer in the Straight Section of an Exhaust Port of a Spark Ignition Engine. In Proceedings of the SAE Automotive Engineering Congress and Exposition, Detroit, MI, USA, 26 February–2 March 1979. SAE Paper 790309. [Google Scholar] [CrossRef]

- Farrugia, M.; Alkidas, A.C.; Sangeorzan, B.P. Cycle-averaged heat flux measurements in a straight-pipe extension of the exhaust port of a SI engine. SAE Trans. J. Engines 2006, 115, 565–575, SAE Paper 2006-01-1033. [Google Scholar] [CrossRef]

- Heller, S.; Wachtmeister, G. Analysis and Modeling of Heat Transfer in the SI Engine Exhaust System During Warm-Up. SAE Trans. J. Engines 2007, 116, 673–686, SAE Paper 2007-01-1092. [Google Scholar] [CrossRef]

- Kar, K.; Roberts, S.; Stone, R.; Oldfield, M.; French, B. Instantaneous Exhaust Temperature Measurements Using Thermocouple Compensation Techniques. SAE Trans. J. Fuels Lubr.-V113-4 2004, 113, 652–673, SAE Paper 2004-01-1418. [Google Scholar] [CrossRef]

- Depcik, C.; Assanis, D. A Universal Heat Transfer Correlation for Intake and Exhaust Flows in an Spark-Ignition Internal Combustion Engine. SAE Trans. J. Engines 2002, 111, 734–740, SAE Paper 2002-01-0372. [Google Scholar] [CrossRef]

- Ranganathan, R.P.; Turner, D.W.; Franchett, M.E. Exhaust Manifold Gas Temperature Predictions using System Level Data Driven Modelling. In Proceedings of the SAE 2005 World Congress & Exhibition, Detroit, MI, USA, 11–14 April 2005. SAE Paper 2005-01-0698, 2005. [Google Scholar] [CrossRef]

- Balzan, N.; Sangeorzan, B.P.; Alkidas, A.C. Steady-State Local Heat Flux Measurements in a Straight Pipe Extension of an Exhaust Port of a Spark Ignition Engine. SAE Trans. J. Engines 2007, 116, 1154–1163, SAE Paper 2007-01-3990, 2007. [Google Scholar] [CrossRef]

- Haehndel, K.; Frank, T.; Christel, F.; Spengler, C.; Suck, G.; Abanteriba, S. The Development of Exhaust Surface Temperature Models for 3D CFD Vehicle Thermal Management Simulations Part 1-General Exhaust Configurations. SAE Int. J. Passeng. Cars-Mech. Syst. 2013, 6, 847–858. [Google Scholar] [CrossRef]

- Zhien, L.; Wang, X.; Yan, Z.; Li, X. Study on the Unsteady Heat Transfer of Engine Exhaust Manifold Based on the Analysis Method of Serial. SAE Int. J. Engines 2014, 7, 1547–1554. [Google Scholar] [CrossRef]

- Mavropoulos, G.C.; Rakopoulos, C.D.; Hountalas, D.T. Experimental Assessment of Instantaneous Heat Transfer in the Combustion Chamber and Exhaust Manifold Walls of Air-Cooled Direct Injection Diesel Engine. SAE Int. J. Engines 2008, 1, 888–912. [Google Scholar] [CrossRef]

- Mavropoulos, G.C.; Hountalas, D.T. Exhaust Phases in a DI Diesel Engine Based on Instantaneous Cyclic Heat Transfer Experimental Data. In Proceedings of the SAE 2013 World Congress & Exhibition, Detroit, MI, USA, 16–18 April 2013. SAE Paper 2013-01-1646. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Mavropoulos, G.C.; Hountalas, D.T. Modeling the Structural Thermal Response of an Air-Cooled Diesel Engine under Transient Operation Including a Detailed Thermodynamic Description of Boundary Conditions. In Proceedings of the SAE 1998 International Congress and Exposition, Detroit, MI, USA, 23–26 February 1998. SAE Paper 981024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyrounakos, G.; Mavropoulos, G. Heat Losses in the Exhaust Manifold of a 4-Stoke DI Diesel Engine Subjected to Pulsating Flow. Computation 2025, 13, 223. https://doi.org/10.3390/computation13090223

Spyrounakos G, Mavropoulos G. Heat Losses in the Exhaust Manifold of a 4-Stoke DI Diesel Engine Subjected to Pulsating Flow. Computation. 2025; 13(9):223. https://doi.org/10.3390/computation13090223

Chicago/Turabian StyleSpyrounakos, Grigorios, and Georgios Mavropoulos. 2025. "Heat Losses in the Exhaust Manifold of a 4-Stoke DI Diesel Engine Subjected to Pulsating Flow" Computation 13, no. 9: 223. https://doi.org/10.3390/computation13090223

APA StyleSpyrounakos, G., & Mavropoulos, G. (2025). Heat Losses in the Exhaust Manifold of a 4-Stoke DI Diesel Engine Subjected to Pulsating Flow. Computation, 13(9), 223. https://doi.org/10.3390/computation13090223