Comparative Study on Phenolic Content and Antioxidant Activity of Different Malt Types

Abstract

:1. Introduction

2. Materials and Methods

2.1. Malt

2.2. Determination of the Main Characteristics of Malt and Wort

2.2.1. Mashing Method

2.2.2. Main Characteristics of Malt and Wort

2.3. Extraction and Determination of Phenolic Compounds

2.3.1. Extraction of Phenolic Compounds from Malt and Wort

2.3.2. Determination of Phenolic Compound Content in Malt and Wort

A. Content of Total Phenolic Compounds with FC-Reagent

B. Content of Phenolic Compounds by the Glories Method

2.3.3. Antioxidant Potential of Malt and Wort

A. Antioxidant Activity Against the DPPH (2,2′-Diphenyl-1-picrylhydrazyl) Radical

B. Antioxidant Activity by the FRAP (Ferric Reducing Ability of Plasma) Method

C. Antioxidant Activity by the ABTS (2,2′-Azinobis-(3-ethylbenzothiazoline-6-sulfonate)) Method

D. Antioxidant Activity by the CUPRAC (Cupric Reducing Antioxidant Capacity) Method

E. Antioxidant Activity by the ORAC (Oxygen Radical Absorbance Capacity) Method

2.4. Methods for Mathematical and Statistical Processing

3. Results

3.1. Main Brewing Characteristics of the Studied Malts

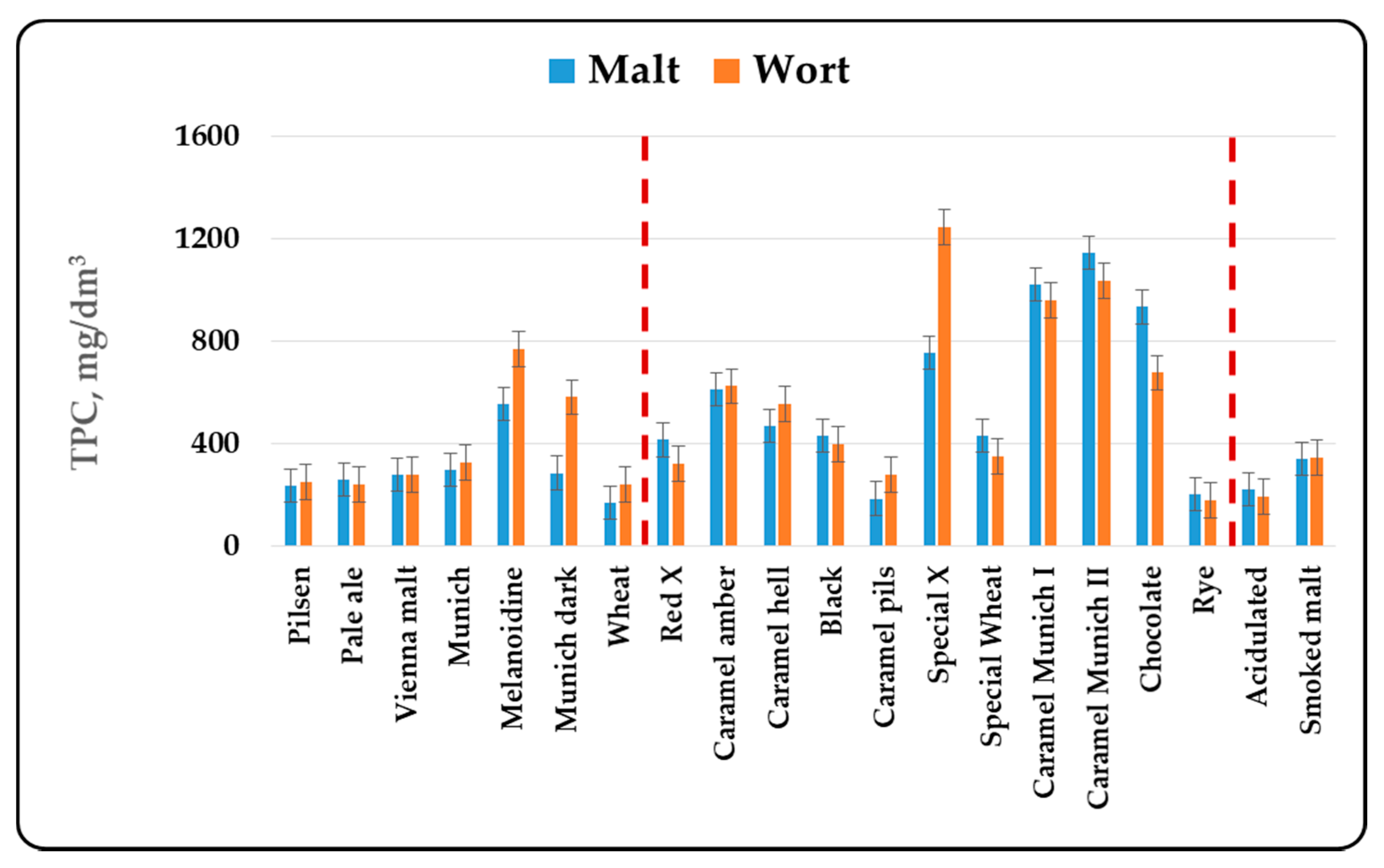

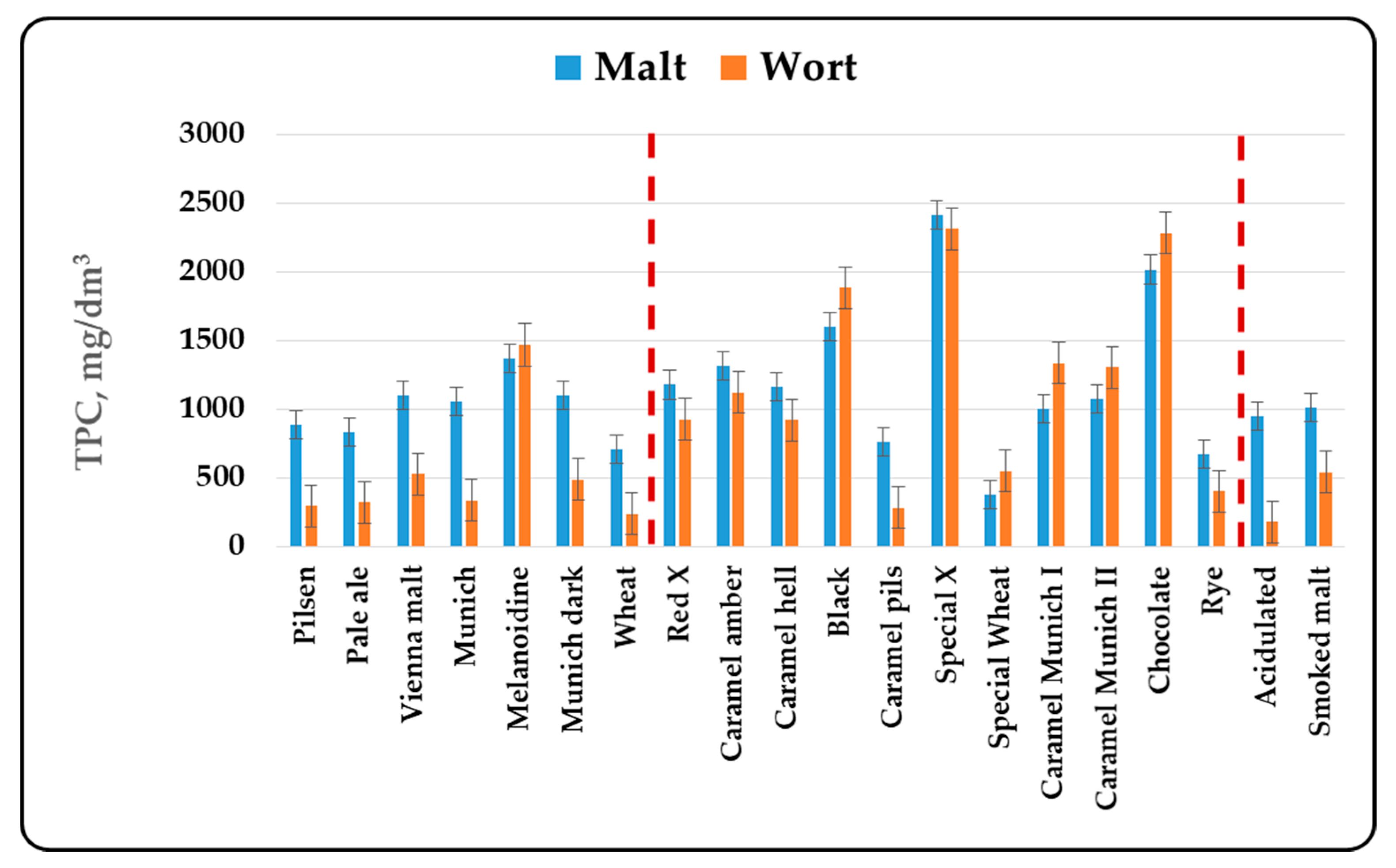

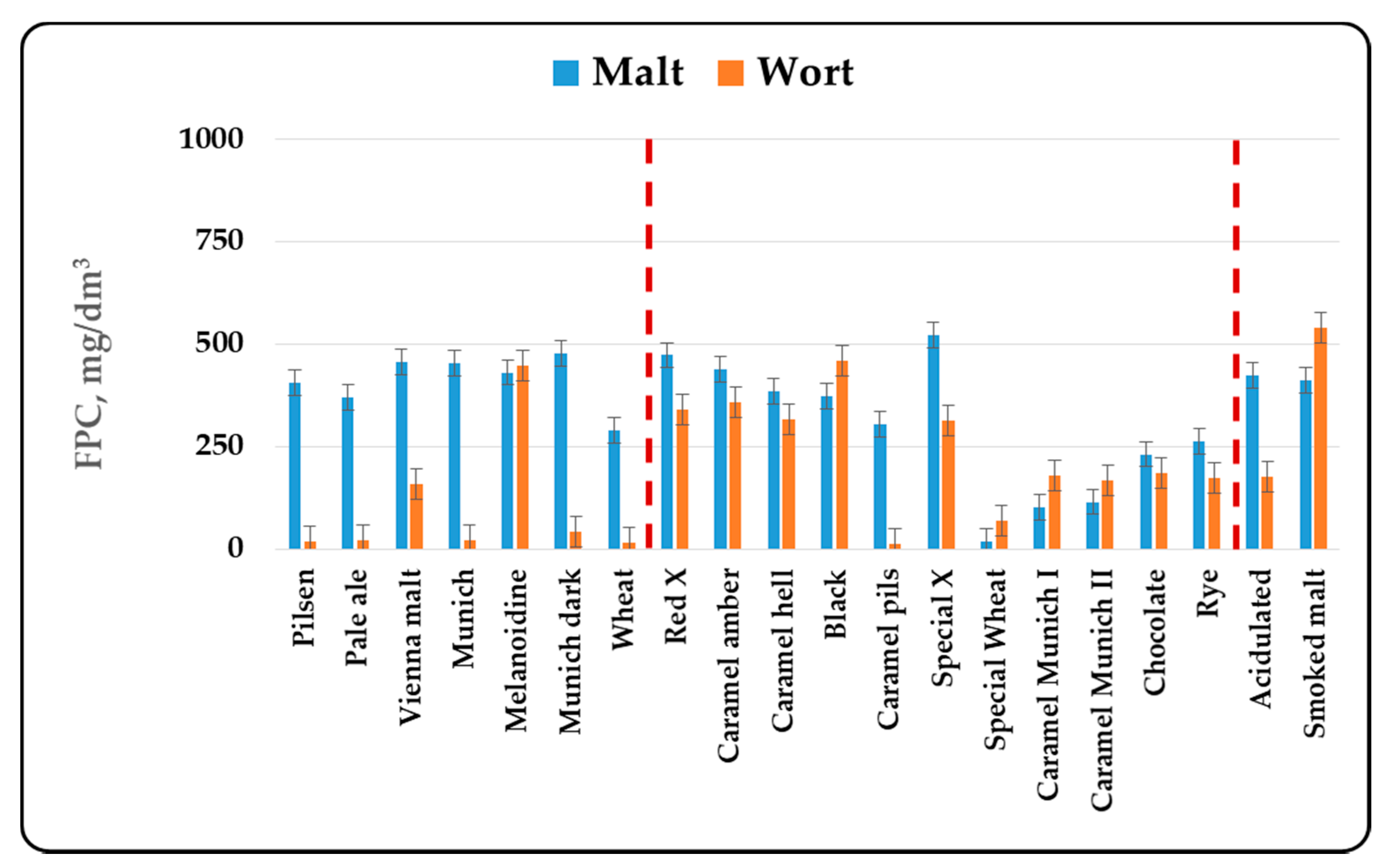

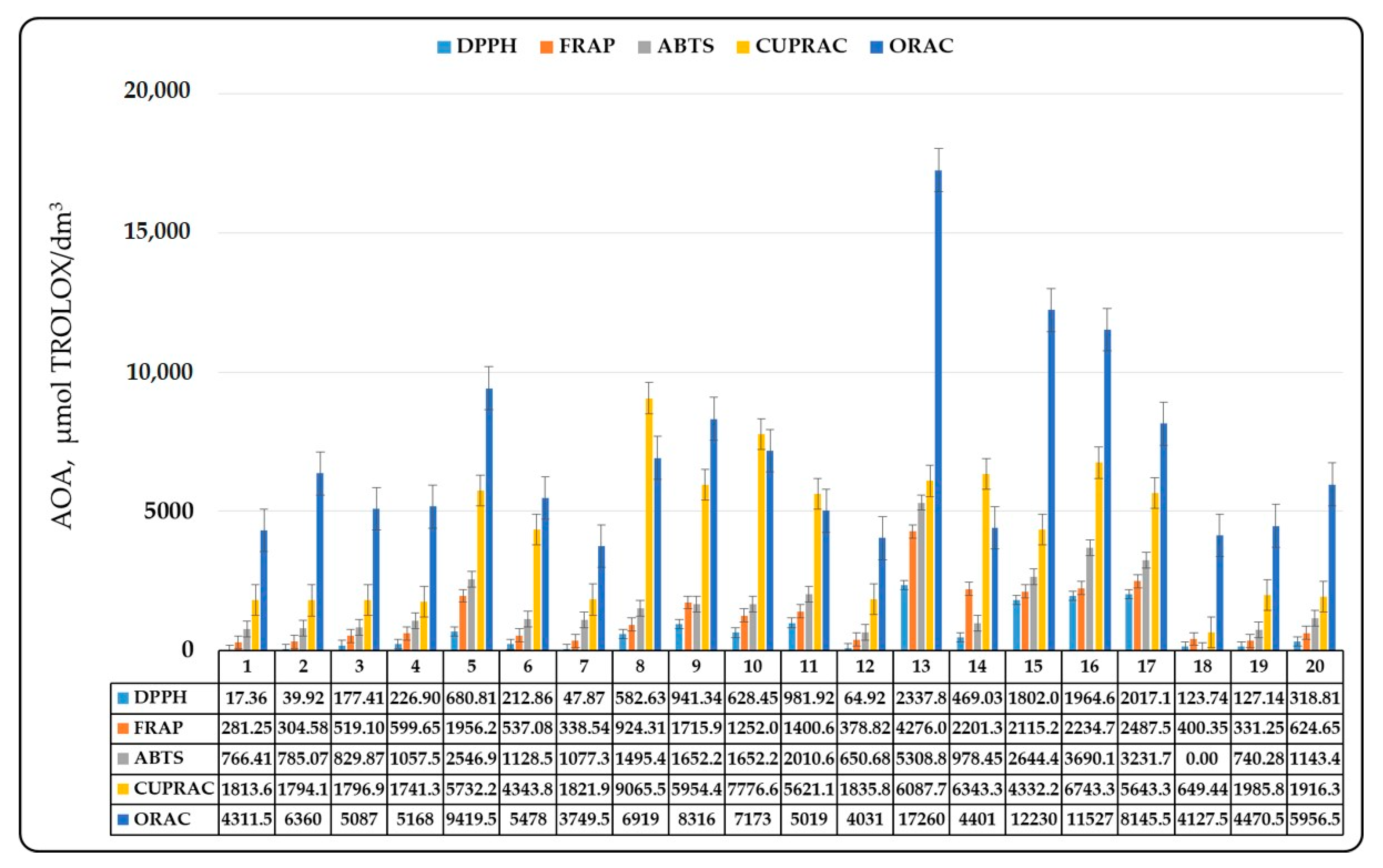

3.2. Phenolic Compound Content and Antioxidant Activity of the Malts

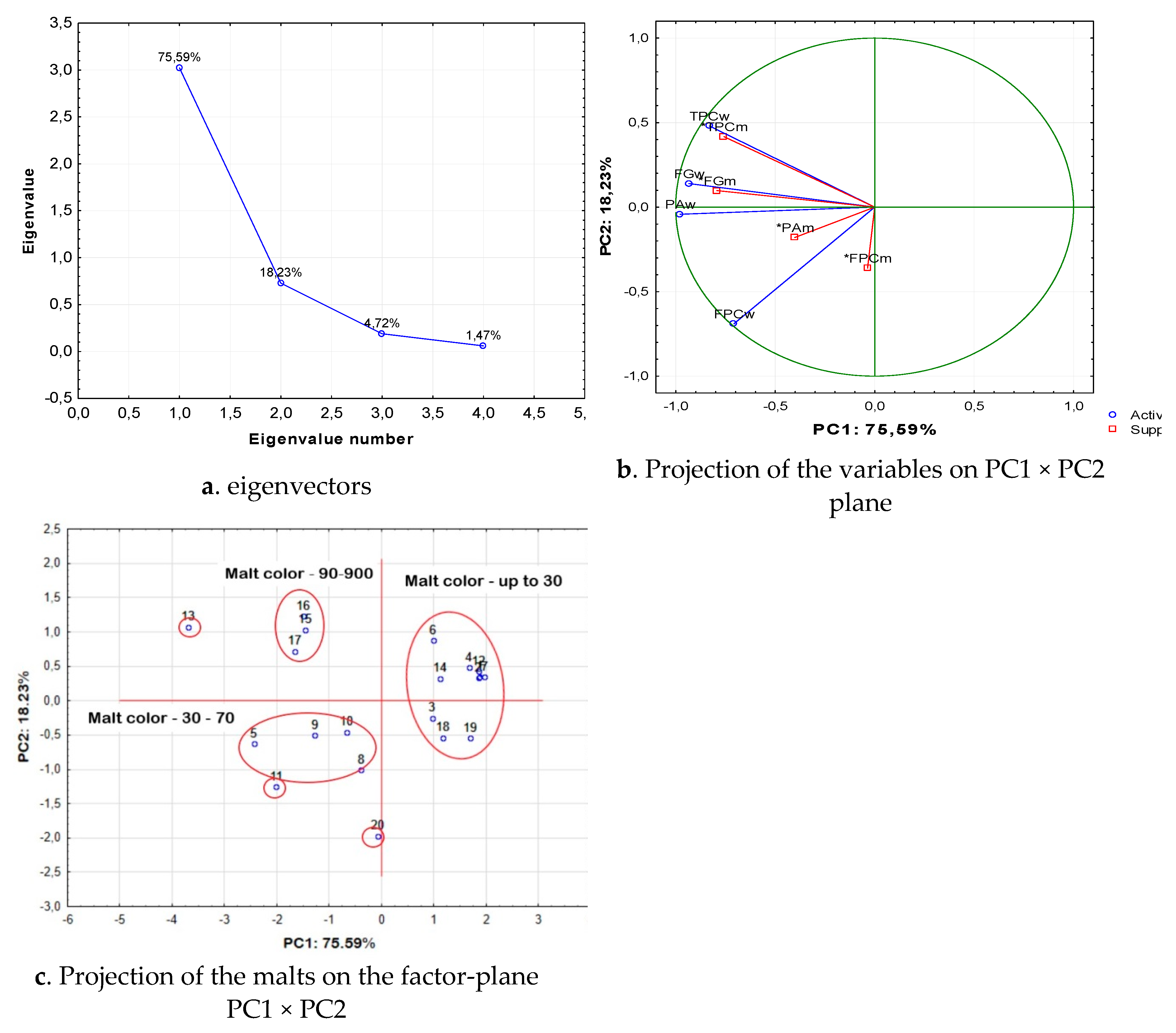

3.3. Statistical Analysis

3.4. Distribution of the Malts in Different Groups as a Beginning of the Optimization of the Wort Composition

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eaton, B. An overview of brewing. In Handbook of Brewing, 2nd ed.; Priest, D., Stewart, G., Eds.; CRC Press: Boca Raton, FL, USA, 2006; pp. 77–91. [Google Scholar] [CrossRef]

- Kunze, W. Technology of Brewing and Malting, 3rd ed.; VLB: Berlin, Germany, 2004. [Google Scholar]

- Carvalho, D.O.; Correia, E.; Lopes, L.; Guido, L.F. Further insights into the role of melanoidins on the antioxidant potential of barley malt. Food Chem. 2014, 160, 127–133. [Google Scholar] [CrossRef]

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- De Keukeleire, D. Fundamentals of beer and hop chemistry. Quim. Nova 2000, 23, 108–112. [Google Scholar] [CrossRef]

- Quifer-Rada, P.; Vallverdú-Queralt, A.; Martínez-Huélamo, M.; Chiva-Blanch, G.; Jáuregui, O.; Estruch, R.; Lamuela-Raventós, R. A comprehensive characterisation of beer polyphenols by high resolution mass spectrometry (LC–ESI-LTQ-Orbitrap-MS). Food Chem. 2015, 169, 336–343. [Google Scholar] [CrossRef]

- Čechovská, L.; Konečný, M.; Velíšek, J.; Cejpek, K. Effect of Maillard reaction on reducing power of malts and beers. Czech J. Food Sci. 2012, 30, 548–556. [Google Scholar] [CrossRef] [Green Version]

- Leitao, C.; Marchioni, E.; Bergaentzle, M.; Zhao, M.; Didierjean, L.; Miesch, L.; Holder, E.; Miesch, M.; Ennahar, S. Fate of polyphenols and antioxidant activity of barley throughout malting and brewing. J. Cereal Sci. 2012, 55, 318–322. [Google Scholar] [CrossRef]

- Holtekjølen, A.K.; Kinitz, C.; Knutsen, S.H. Flavanol and Bound Phenolic Acid Contents in Different Barley Varieties. J. Agric. Food Chem. 2006, 54, 2253–2260. [Google Scholar] [CrossRef] [PubMed]

- Madhujith, T.; Izydorczyk, A.M.; Shahidi, F. Antioxidant Properties of Pearled Barley Fractions. J. Agric. Food Chem. 2006, 54, 3283–3289. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Zhao, H.; Chen, J.; Fan, W.; Dong, J.; Kong, W.; Sun, J.; Cao, Y.; Cai, G. Evolution of Phenolic Compounds and Antioxidant Activity during Malting. J. Agric. Food Chem. 2007, 55, 10994–11001. [Google Scholar] [CrossRef] [PubMed]

- Dvořáková, M.; Guido, L.F.; Dostalek, P.; Skulilová, Z.; Moreira, M.M.; Barros, A.A. Antioxidant Properties of Free, Soluble Ester and Insoluble-Bound Phenolic Compounds in Different Barley Varieties and Corresponding Malts. J. Inst. Brew. 2008, 114, 27–33. [Google Scholar] [CrossRef]

- Dvorakova, M.; Moreira, M.M.; Dostalek, P.; Skulilova, Z.; Guido, L.F.; Barros, A.A. Characterization of monomeric and oligomeric flavan-3-ols from barley and malt by liquid chromatography–ultraviolet detection–electrospray ionization mass spectrometry. J. Chromatogr. A 2008, 1189, 398–405. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, P.J.; Almeida, S.M.; Carvalho, A.M.; Gonçalves, L.M.; Pacheco, J.G.; Cruz, J.M.; Guido, L.F.; Barros, A.A. Influence of malt on the xanthohumol and isoxanthohumol behavior in pale and dark beers: A micro-scale approach. Food Res. Int. 2011, 44, 351–359. [Google Scholar] [CrossRef]

- Goupy, P.; Hugues, M.; Boivin, P.; Amiot, M.J. Antioxidant composition and activity of barley (Hordeum vulgare) and malt extracts and of isolated phenolic compounds. J. Agric. Food Chem. 1999, 79, 1625–1634. [Google Scholar] [CrossRef]

- Samaras, T.S.; Camburn, P.A.; Chandra, S.X.; Gordon, M.H.; Ames, J.M. Antioxidant Properties of Kilned and Roasted Malts. J. Agric. Food Chem. 2005, 53, 8068–8074. [Google Scholar] [CrossRef] [PubMed]

- Inns, E.L.; Buggey, L.A.; Booer, C.; Nursten, H.E.; Ames, J.M. Effect of Heat Treatment on the Antioxidant Activity, Color, and Free Phenolic Acid Profile of Malt. J. Agric. Food Chem. 2007, 55, 6539–6546. [Google Scholar] [CrossRef]

- Inns, E.L.; Buggey, L.A.; Booer, C.; Nursten, H.E.; Ames, J.M. Effect of Modification of the Kilning Regimen on Levels of Free Ferulic Acid and Antioxidant Activity in Malt. J. Agric. Food Chem. 2011, 59, 9335–9343. [Google Scholar] [CrossRef] [PubMed]

- Maillard, M.-N.; Berset, C. Evolution of Antioxidant Activity during Kilning: Role of Insoluble Bound Phenolic Acids of Barley and Malt. J. Agric. Food Chem. 1995, 43, 1789–1793. [Google Scholar] [CrossRef]

- Coghe, S.; Adriaenssens, B.; Leonard, S.; Delvaux, F.R. Fractionation of Colored Maillard Reaction Products from Dark Specialty Malts. J. Am. Soc. Brew. Chem. 2004, 62, 79–86. [Google Scholar] [CrossRef]

- Coghe, S.; D’Hollander, H.; Verachtert, H.; Delvaux, F.R. Impact of Dark Specialty Malts on Extract Composition and Wort Fermentation. J. Inst. Brew. 2005, 111, 51–60. [Google Scholar] [CrossRef]

- Coghe, S.; Gheeraert, B.; Michiels, A.; Delvaux, F.R. Development of Maillard Reaction Related Characteristics During Malt Roasting. J. Inst. Brew. 2006, 112, 148–156. [Google Scholar] [CrossRef]

- Yahya, H.; Linforth, R.S.T.; Cook, D. Flavour generation during commercial barley and malt roasting operations: A time course study. Food Chem. 2014, 145, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Morales, F.J.; Fernandez-Fraguas, C.; Jimenez-Perez, S. Iron-binding ability of melanoidins from food and model systems? Food Chem. 2005, 90, 821–827. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Qian, H.; Yao, W.-R. Melanoidins produced by the Maillard reaction: Structure and biological activity. Food Chem. 2011, 128, 573–584. [Google Scholar] [CrossRef]

- Guido, L.F.; Fortunato, N.A.; Rodrigues, J.A.; Barros, A.A. Voltammetric Assay for the Aging of Beer. J. Agric. Food Chem. 2003, 51, 3911–3915. [Google Scholar] [CrossRef] [PubMed]

- Landete, J.M. Dietary Intake of Natural Antioxidants: Vitamins and Polyphenols. Crit. Rev. Food Sci. Nutr. 2013, 53, 706–721. [Google Scholar] [CrossRef] [PubMed]

- Subba Rao, M.V.; Muralikrishna, G. Evaluation of the Antioxidant Properties of Free and Bound Phenolic Acids from Native and Malted Finger Millet (Ragi, Eleusine coracana Indaf-15). J. Agric. Food Chem. 2002, 50, 889–892. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Chen, W.; Lu, J.; Zhao, M. Phenolic profiles and antioxidant activities of commercial beers. Food Chem. 2010, 119, 1150–1158. [Google Scholar] [CrossRef]

- Leitao, C.; Marchioni, E.; Bergaentzlé, M.; Zhao, M.; Didierjean, L.; Taidi, B.; Ennahar, S. Effects of Processing Steps on the Phenolic Content and Antioxidant Activity of Beer. J. Agric. Food Chem. 2011, 59, 1249–1255. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef] [PubMed]

- Analytica (Version 2019)—European Brewing Convention. Available online: https://brewup.eu/ebcanalytica (accessed on 20 April 2021).

- Luckanov, N.; Ivanova, T.; Pishtiyski, I.; Koleva, A. Biochemistry (Laboratory Manual), 1st ed.; Academic Publisher of Higher Institute of Food and Flavour Industry: Plovdiv, Bulgaria, 1994. [Google Scholar]

- Mazza, G.; Fukumoto, L.; Delaquis, P.; Girard, B.; Ewert, B. Anthocyanins, Phenolics, and Color of Cabernet Franc, Merlot, and Pinot Noir Wines from British Columbia. J. Agric. Food Chem. 1999, 47, 4009–4017. [Google Scholar] [CrossRef] [PubMed]

- Dinkova, R.; Heffels, P.; Shikov, V.; Weber, F.; Schieber, A.; Mihalev, K. Effect of enzyme-assisted extraction on the chilled storage stability of bilberry (Vaccinium myrtillus L.) anthocyanins in skin extracts and freshly pressed juices. Food Res. Int. 2014, 65, 35–41. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, E.; Abu Salim, K.; Lim, L.B. Phytochemical screening, total phenolics and antioxidant activities of bark and leaf extracts of Goniothalamus velutinus (Airy Shaw) from Brunei Darussalam. J. King Saud Univ. Sci. 2015, 27, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Apak, R.; Güçlü, K.; Özyürek, M.; Karademir, S.E.; Erçağ, E. The cupric ion reducing antioxidant capacity and polyphenolic content of some herbal teas. Int. J. Food Sci. Nutr. 2006, 57, 292–304. [Google Scholar] [CrossRef] [PubMed]

- Ou, B.; Hampsch-Woodill, M.; Prior, R.L. Development and Validation of an Improved Oxygen Radical Absorbance Capacity Assay Using Fluorescein as the Fluorescent Probe. J. Agric. Food Chem. 2001, 49, 4619–4626. [Google Scholar] [CrossRef] [PubMed]

- Denev, P.; Ciz, M.; Ambrozova, G.; Lojek, A.; Yanakieva, I.; Kratchanova, M. Solid-phase extraction of berries’ anthocyanins and evaluation of their antioxidative properties. Food Chem. 2010, 123, 1055–1061. [Google Scholar] [CrossRef]

- BestMalz Catalog. Available online: https://bestmalz.de/ (accessed on 20 April 2021).

- Sharma, P.; Gujral, H.S. Antioxidant and polyphenol oxidase activity of germinated barley and its milling fractions. Food Chem. 2010, 120, 673–678. [Google Scholar] [CrossRef]

- Chandra, C.S.; Buggey, L.A.; Peters, S.; Cann, C.; Liegeois, C. Factors Affecting the Development of Antioxidant Properties of Malts during the Malting and Roasting Process; Project Report 2001, No. 2412, 242; B. R. International: Sydney, Australia, 2001. [Google Scholar]

- Piazzon, A.; Forte, M.; Nardini, M. Characterization of Phenolics Content and Antioxidant Activity of Different Beer Types. J. Agric. Food Chem. 2010, 58, 10677–10683. [Google Scholar] [CrossRef] [PubMed]

- Kunz, T.; Muller, C.; Mato-Gonzales, D.; Methner, F.-J. The influence of unmalted barley on the oxidative stability of wort and beer. J. Inst. Brew. 2012, 118, 32–39. [Google Scholar] [CrossRef]

- Szwajgier, D. Dry and Wet Milling of Malt. A Preliminary Study Comparing Fermentable Sugar, Total Protein, Total Phenolics and the Ferulic Acid Content in Non-Hopped Worts. J. Inst. Brew. 2011, 117, 569–577. [Google Scholar] [CrossRef]

- Vanbeneden, N.; Gils, F.; Delvaux, F.; Delvaux, F.R. Variability in the Release of Free and Bound Hydroxycinnamic Acids from Diverse Malted Barley (Hordeum vulgare L.) Cultivars during Wort Production. J. Agric. Food Chem. 2007, 55, 11002–11010. [Google Scholar] [CrossRef] [PubMed]

- Vanbeneden, N.; Van Roey, T.; Willems, F.; Delvaux, F.; Delvaux, F.R. Release of phenolic flavour precursors during wort production: Influence of process parameters and grist composition on ferulic acid release during brewing. Food Chem. 2008, 111, 83–91. [Google Scholar] [CrossRef]

- Bartolome, B.; Garcia-Conesa, M.T.; Williamson, G. Release of the bioactive compound, ferulic acid, from malt extracts. Biochem. Soc. Trans. 1996, 24, 379S. [Google Scholar] [CrossRef] [Green Version]

- Polak, J.; Bartoszek, M.; Stanimirova, I. A study of the antioxidant properties of beers using electron paramagnetic resonance. Food Chem. 2013, 141, 3042–3049. [Google Scholar] [CrossRef]

- Coghe, S.; Vanderhaegen, B.; Pelgrims, B.; Basteyns, A.-V.; Delvaux, F.R. Characterization of Dark Specialty Malts: New Insights in Color Evaluation and Pro- and Antioxidative Activity. J. Am. Soc. Brew. Chem. 2003, 61, 125–132. [Google Scholar] [CrossRef]

- Papetti, A.; Daglia, M.; Aceti, C.; Quaglia, M.; Gregotti, C.; Gazzani, G. Isolation of an in Vitro and ex Vivo Antiradical Melanoidin from Roasted Barley. J. Agric. Food Chem. 2006, 54, 1209–1216. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Gujral, H.S. Effect of sand roasting and microwave cooking on antioxidant activity of barley. Food Res. Int. 2011, 44, 235–240. [Google Scholar] [CrossRef]

- Spreng, S.; Hofmann, T. Activity-Guided Identification of in Vitro Antioxidants in Beer. J. Agric. Food Chem. 2018, 66, 720–731. [Google Scholar] [CrossRef]

| No. | Malt Type | Wort Extract, °P | Extract Yield, % | Malt Color, EBC Units * [40] | Moisture, % | Starch, % | |

|---|---|---|---|---|---|---|---|

| AirDW | AbsDW | ||||||

| Basic Malt Types | |||||||

| 1 | Pilsen | 8.22 ± 0.32 | 71.87 ± 0.58 | 75.66 ± 0.58 | 3–4.9 | 5.37 ± 0.14 | 66.64 ± 0.06 |

| 2 | Pale ale | 8.32 ± 0.25 | 72.80 ± 0.39 | 76.63 ± 0.39 | 5–7 | 5.12 ± 0.19 | 61.66 ± 0.59 |

| 3 | Vienna | 8.31 ± 0.12 | 72.68 ± 0.33 | 76.51 ± 0.33 | 8–10 | 5.78 ±0.23 | 65.47 ± 0.26 |

| 4 | Munich | 8.07 ± 0.21 | 70.45 ± 0.29 | 74.15 ± 0.29 | 11–20 | 5.30 ± 0.58 | 65.21 ± 0.17 |

| 5 | Melanoidin | 8.01 ± 0.16 | 69.90 ± 0.59 | 73.58 ± 0.59 | 61–80 | 4.75 ± 0.22 | 61.89 ± 0.66 |

| 6 | Munich dark | 8.63 ± 0.33 | 75.84 ± 0.63 | 79.83 ± 0.63 | 21–35 | 5.33 ± 0.13 | 60.59 ± 0.87 |

| 7 | Wheat | 7.39 ± 0.18 | 64.04 ± 0.68 | 67.41 ± 0.68 | 3.5–6 | 4.89 ± 0.34 | 73.67 ± 0.13 |

| Special Malt Types | |||||||

| 8 | Red X | 7.83 ± 0.22 | 68.15 ± 0.63 | 71.74 ± 0.63 | 28–32 | 5.57 ± 0.08 | 63.38 ± 0.28 |

| 9 | Caramel amber | 5.67 ± 0.14 | 48.21 ± 0.45 | 50.75 ± 0.45 | 61–80 | 5.78 ± 0.37 | 58.14 ± 0.55 |

| 10 | Caramel hell | 6.91 ± 0.37 | 59.52 ± 0.33 | 62.66 ± 0.33 | 20–40 | 4.37 ± 0.13 | 59.58 ± 0.99 |

| 11 | Black | 3.12 ± 0.08 | 25.83 ± 0.22 | 27.19 ± 0.22 | 1100–1200 | 4.13 ± 0.04 | 30.18 ± 2.42 |

| 12 | Caramel pils | 6.34 ± 0.18 | 54.32 ± 0.56 | 57.18 ± 0.56 | 3–7 | 5.53 ± 0.53 | 63.05 ± 0.83 |

| 13 | Special X | 4.09 ± 0.09 | 34.22 ± 0.48 | 36.02 ± 0.48 | 300–400 | 4.33 ± 0.26 | 17.19 ± 1.07 |

| 14 | Special Wheat | 7.54 ± 0.18 | 65.44 ± 0.58 | 68.89 ± 0.58 | 16–20 | 4.21 ± 0.15 | 66.68 ± 0.08 |

| 15 | Caramel Munich I | 6.73 ± 0.21 | 57.91 ± 0.59 | 60.95 ± 0.59 | 81–100 | 3.96 ± 0.10 | 53.24 ± 1.50 |

| 16 | Caramel Munich II | 5.67 ± 0.14 | 48.24 ± 0.65 | 50.78 ± 0.65 | 110–130 | 4.48 ± 0.43 | 15 ± 1.48 |

| 17 | Chocolate | 4.15 ± 0.07 | 34.75 ± 0.45 | 36.57 ± 0.45 | 800–1000 | 2.80 ± 0.11 | 7.08 ± 0.85 |

| 18 | Rye malt | 7.87 ± 0.21 | 68.50 ± 0.39 | 72.11 ± 0.39 | - | 5.90 ± 0.14 | 60.89 ± 0.82 |

| Functional Malt Types | |||||||

| 19 | Acidulated | 2.33 ± 0.09 | 18.8 ± 0.23 | 19.8±0.23 | 3–8 | 4.95 ± 0.67 | 61.85 ± 0.38 |

| 20 | Smoked | 8.42 ± 0.21 | 73.2 ± 0.45 | 77.0±0.45 | 3–8 | 5.99 ± 0.35 | 59.93 ± 0.71 |

| Analysis of Variance Marked Effects are Significant at p < 0.05000 | ||||||||

|---|---|---|---|---|---|---|---|---|

| SS Effect | df Effect | MS Effect | SS Error | df Error | MS Error | F | p | |

| TPCm | 1078156 | 10 | 107816 | 2726 | 2 | 1363 | 79.11 | 0.012545 |

| TPCw | 1251217 | 10 | 125122 | 27260 | 2 | 13630 | 9.18 | 0.102161 |

| FGm | 3699327 | 10 | 369933 | 8485 | 2 | 4242 | 87.20 | 0.011389 |

| FGw | 6763666 | 10 | 676367 | 96 | 2 | 48 | 14026.40 | 0.000071 |

| PAm | 207003 | 10 | 20700 | 4218 | 2 | 2109 | 9.81 | |

| PAw | 289436 | 10 | 28944 | 9 | 2 | 5 | 6261.14 | 0.000160 |

| FPCm | 254477 | 10 | 25448 | 8758 | 2 | 4379 | 5.81 | 0.155646 |

| FPCw | 249845 | 10 | 24985 | 347 | 2 | 173 | 144.15 | 0.006908 |

| DPPHm | 2000181 | 10 | 200018 | 43389 | 2 | 21694 | 9.22 | 0.101746 |

| DPPHw | 8293012 | 10 | 829301 | 2181 | 2 | 1090 | 760.49 | 0.001314 |

| FRAPm | 7486926 | 10 | 748693 | 34781 | 2 | 17391 | 43.05 | 0.022908 |

| FRAPw | 16919969 | 10 | 1691997 | 58479 | 2 | 29240 | 57.87 | 0.017103 |

| ABTSm | 5007264 | 10 | 500726 | 118931 | 2 | 59466 | 8.42 | 0.110744 |

| ABTSw | 26742097 | 10 | 2674210 | 18987 | 2 | 9494 | 281.69 | 0.003543 |

| CUPRACm | 9604245 | 10 | 960424 | 165115 | 2 | 82558 | 11.63 | 0.081698 |

| CUPRACw | 87979953 | 10 | 8797995 | 830864 | 2 | 415432 | 21.18 | 0.045910 |

| ORACm | 40018408 | 10 | 4001841 | 8359008 | 2 | 4179504 | 0.96 | 0.612666 |

| ORACw | 168293859 | 10 | 16829386 | 71598 | 2 | 35799 | 470.11 | 0.002124 |

| Spearman Rank Order Correlations Marked Correlations are Significant at p < 0.05000 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Color | TPCm | FGm | PAm | FPCm | DPPHm | FRAPm | ABTSm | CUPRACm | ORACm | |

| Color | 1.000000 | 0.879097 | 0.754519 | 0.199548 | −0.003012 | 0.568525 | 0.853164 | 0.454820 | 0.597892 | 0.483434 |

| TPCm | - | 1.000000 | - | - | - | 0.337721 | 0.916134 | 0.422715 | 0.713802 | 0.641595 |

| FGm | 0.754519 | - | 1.000000 | - | - | 0.551880 | 0.807519 | 0.374436 | 0.622556 | 0.427068 |

| PAm | 0.199548 | - | - | 1.000000 | 0.345865 | 0.312782 | 0.233083 | 0.433083 | 0.192481 | |

| FPCm | −0.003012 | - | - | - | 1.000000 | 0.275188 | 0.109774 | 0.157895 | 0.287218 | 0.066165 |

| Spearman Rank Order Correlations Marked Correlations Are Significant at p < 0.05000 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Color | TPCw | FGw | PAw | FPCw | DPPHw | FRAPw | ABTSw | CUPRACw | ORACw | |

| Color | 1.000000 | 0.816266 | 0.932230 | 0.893826 | 0.612199 | 0.925453 | 0.860694 | 0.839925 | 0.631778 | 0.740212 |

| TPCw | - | 1.000000 | - | - | - | 0.893233 | 0.890226 | 0.913125 | 0.669173 | 0.822556 |

| FGw | - | - | 1.000000 | - | - | 0.933835 | 0.908271 | 0.883039 | 0.648120 | 0.769925 |

| PAw | - | - | - | 1.000000 | - | 0.873684 | 0821053 | 0.796540 | 0.574436 | 0.760902 |

| FPCw | - | - | - | - | 1.000000 | 0.675188 | 0.559398 | 0.591200 | 0.529323 | 0.560902 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shopska, V.; Denkova-Kostova, R.; Dzhivoderova-Zarcheva, M.; Teneva, D.; Denev, P.; Kostov, G. Comparative Study on Phenolic Content and Antioxidant Activity of Different Malt Types. Antioxidants 2021, 10, 1124. https://doi.org/10.3390/antiox10071124

Shopska V, Denkova-Kostova R, Dzhivoderova-Zarcheva M, Teneva D, Denev P, Kostov G. Comparative Study on Phenolic Content and Antioxidant Activity of Different Malt Types. Antioxidants. 2021; 10(7):1124. https://doi.org/10.3390/antiox10071124

Chicago/Turabian StyleShopska, Vesela, Rositsa Denkova-Kostova, Mina Dzhivoderova-Zarcheva, Desislava Teneva, Petko Denev, and Georgi Kostov. 2021. "Comparative Study on Phenolic Content and Antioxidant Activity of Different Malt Types" Antioxidants 10, no. 7: 1124. https://doi.org/10.3390/antiox10071124

APA StyleShopska, V., Denkova-Kostova, R., Dzhivoderova-Zarcheva, M., Teneva, D., Denev, P., & Kostov, G. (2021). Comparative Study on Phenolic Content and Antioxidant Activity of Different Malt Types. Antioxidants, 10(7), 1124. https://doi.org/10.3390/antiox10071124