1. Introduction

The integration of Geomatics, Geographic Information Systems (GIS), and Remote Sensing into university courses within the mining industry is increasingly recognised as essential to prepare students for the multifaceted challenges of the sector. These technologies improve the management and environmental sustainability of mining activities, enabling students to gain directly applicable competences in the industry.

Plessis [

1] advocates the establishment of comprehensive educational frameworks that respond to industry needs, including certification and accreditation processes to ensure quality and relevance. This strategic educational design will ensure that graduating students have the competencies required in the mining industry.

The advancement of Remote Sensing technologies also provides significant benefits to the education of mining professionals. McKenna [

2] illustrates how remote sensing methodologies allow effective monitoring of mining impacts and landscape recovery, signaling that education in these areas is vital for sustainable operational management. With the growing prevalence of Earth observation tools, including UAVs and satellite systems, students trained in these technologies are better positioned for careers that demand proficiency in monitoring and managing environmental impacts.

Another trend observed in the modernisation of mining education is the expansion of sustainable development goals. This requires modernising the existing education system [

3]. It is also important to emphasise the need to consider the relationship between the mining plant and its social environment, that is, the local community, which experiences the benefits and problems associated with the existence and operation of the mining plant [

4]. In addition, there is a proposal to expand the competencies of the guidelines editor in the field of mining to include soft skills.

The accumulation of new requirements related to modernising mining personnel training, processing spatial data, achieving sustainable development goals, and assessing the impact of mining on society can cause students to have excessive hours studying at university. The study programme cannot be overloaded with classes. Simply defining new competencies is not enough to bring about modernisation. A decision must be made as to which classes should be reduced and shortened—this is a serious problem that needs to be addressed. Despite global advancement in education, there is still a gap in specialised programmes that address the evolving needs of industries such as mining.

According to the authors Nwaila et al. [

5], digital transformation in mining is an algorithmic and data driven change accompanying the fourth industrial revolution that encompasses automation (human–machine interaction), process digitisation and increased use of analytics, data science, and artificial intelligence throughout the entire chain from deposit to product.

Higher education does not offer a Master’s degree in digital transformation technologies in mining and entrepreneurship, which would allow the training of specialists needed by the mining industry to increase its competitiveness [

6]. Proposals will be made to expand the expertise of mining engineers to include new areas of knowledge and skills. Catalogues of skills necessary for the extraction of specific types of raw materials, such as rare earth metals, are being developed [

7].

The emergence of a new definition of mining geomatics [

8] as a distinct professional discipline enables the preparation of specialist mining personnel who are ready to carry out mining activities using the latest information, location and remote sensing technologies to their full potential. This involves not only acquiring and processing data, but also designing, managing, and strategically implementing a spatial data infrastructure that supports the near-real-time monitoring of mining operations and their environmental impact. This paves the way for the modelling of parallel mining operations and the prediction of their effects, enabling decisions to be made at the operational and strategic levels. This new profession lies at the intersection of geology, computer science, and industrial engineering. It responds to the industry’s growing demand for digital skills, regulatory compliance, and sustainable resource management.

An inherent feature of mining geomatics is the interoperability of spatial data, which has become crucial not only for the operation of mining plants but also for other businesses [

9]. Early mining IT systems relied on closed vector file formats and autonomous workspaces. This made it difficult to exchange and integrate spatial information between different systems. Overcoming this situation requires mining plants to acquire the knowledge and skills necessary to change their policies on the use of open data formats.

The primary objective of mining geomatics is to develop an extensive spatial data resource that includes the entire mining plant. This can only be achieved with the appropriate IT infrastructure to enable the sharing of spatial data within all technical departments and other departments within the plant. This system should provide location information and serve as the sole source of three-dimensional data on excavations, as well as the machinery, utilities, and other items installed within them. Implementing these measures should result in the creation of a spatial data infrastructure for the mining plant.

Managing spatial information in a mining plant already requires highly experienced staff with a wide range of skills and knowledge, including software automation and the use of the latest technologies at the intersection of data science and AI. The shift towards integrated spatial systems in mining has led to a new profession: mining geomatician [

8]. Located at the intersection of geoinformation technology and mining, this position involves managing spatial infrastructure in various departments of the company.

Mining operations already require highly experienced personnel with a wide range of skills and knowledge in spatial information management, including software automation and the use of the latest technologies at the intersection of data science and artificial intelligence (AI) [

10]. Digital twin concepts and Internet of Things (IoT)-based monitoring are increasingly applied to optimise mine operations and improve safety [

11]. These developments indicate that the demand for mining professionals with expertise in artificial intelligence, automation, and data science is already evident in both industrial practice and academic research, rather than being just a theoretical projection.

The transition to integrated spatial systems in mining has led to the emergence of a new profession: the mining geomatician. This role, which sits at the intersection of geoinformation technology and mining, involves overseeing spatial infrastructure across different company departments. This specialist works at the intersection of geoinformation technology and mining engineering, combining spatial data analysis with information systems management across different departments. According to Estacio [

12], the work of a geomatics engineer aligns with the ’geomatics framework’ that encompasses data collection, spatial modelling, and forecasting change processes, a structure that is particularly important in dynamic mining environments. The process of developing spatial data processing skills of mining industry employees began several years ago, although it is not well documented scientifically.

As early as 1996 [

13], and later in 1999 [

14], scholars began to recognise the challenge of unifying the various GIS courses offered in different fields of study and specialisations into a single specialisation or even a field of study called Geomatics. In 2004, the concept of GIScience (GISc) [

15] was described as a theory of GIS systems, covering a wide range of topics recorded in the GIScience Book of Knowledge (GBoK) [

16]. Thanks to these efforts, numerous universities introduced new and innovative fields of study characterised by diverse names, e.g., GISc, geomatics, or geoinformatics and content, in the following years. This historical effort to unify geomatics education under GISc frameworks provides a relevant backdrop for assessing how such structures could support mining-specific adaptations.

Although numerous studies have examined the integration of GIS, geomatics, and geoinformatics into higher education [

13,

14,

17], their direct adaptation to mining remains limited and fragmented. The literature tends to emphasise general GIS education, while only rarely addresses mining-specific requirements such as spatial modelling of excavations, monitoring ground deformations, or integrating heterogeneous geospatial datasets. As noted by Hodza [

17], the lack of standardisation in geomatics curricula further hampers consistent implementation, which is particularly problematic for sectors demanding specialised applications such as mining. Earlier contributions on IT modernisation in mining companies [

18,

19] focused mainly on technical infrastructure, with little attention paid to the systematic development of human competencies. This exposes a clear research gap. Technological progress in mining has not been matched by an educational framework capable of preparing specialists to manage integrated spatial infrastructures.

In recent years, GIS&T, geomatics, and geoinformatics study programmes have gained popularity in numerous disciplines, including surveying, environmental engineering, forestry, computer science, and spatial planning. This expansion extends far beyond their original roots in geography. Although this interdisciplinary expansion is valuable, it has also resulted in highly diverse curricula emerging.

The blurred and undefined boundaries between new fields of spatial science and technology have led to the emergence of a wide range of knowledge and skills. This has made it impossible to create a uniform higher education programme. For example, studies labelled as Geomatics or GIS&T often differ substantially in their introductory curricula—even when offered under the same name—as noted by Hodza [

17]. This variation has made it difficult to standardise content across departments. This situation hinders the introduction of these technologies into mining education. Although geomatics is now an established academic discipline, its integration into the mining sector has been uneven and has been more influenced by local technical initiatives than by standardised educational standards. Meanwhile, in the last 20 years, there has been tremendous progress in the computerisation of technical departments in mining companies. For several years, lignite and copper ore mining companies have invested in geoinformation solutions, achieving very good results.

Before any privatisation, ’Kompania Węglowa’—then Europe’s largest hard coal company—made significant IT investments [

18]. LW Bogdanka SA also advanced the computerisation of its underground mines ahead of privatisation [

20]. In contrast, JSW SA broadened and upgraded its information systems in response to the global economic downturn [

19].

In light of these requirements, the question arises as to whether the combination of mining knowledge with geoinformatics/GIS&T knowledge and skills, which extend well beyond the capabilities characteristic of this industry, should now constitute a new educational challenge for universities training mining personnel. In response to the increasing use of geospatial technologies in mining, universities need to develop appropriate educational programmes. The skill gaps identified in

Section 2 provide the basis for the training proposal of the Mining Geomatician outlined in

Section 3.1,

Section 3.2 and

Section 3.3.

This article aims to define the competencies and propose a curriculum for the emerging profession of mining geomatician. To achieve this, we identified four research problems: (i) Recurring competency gaps in mining departments related to geospatial data processing and system implementation. (ii) Processes and organisational factors that hinder the successful implementation of software in mines. (iii) The scope and competencies of the emerging mining geomatics profession. (iv) Mapping these competencies to a coherent curriculum structure for second-cycle studies. These four problems allowed us to formulate three Research Questions (RQ).

RQ1 What recurring skill gaps and process patterns can be observed in the implementation of spatial data software in mining?

RQ2 Which technological and organisational constraints most significantly affect implementation outcomes in mining software projects?

RQ3 Which domains of competence are essential for a mining geomatician, and how can these be translated into programme-level learning objectives?

2. Materials and Methods

In software engineering, understood as a systematic and disciplined approach to the specification, design, implementation, and maintenance of software systems, the term “software development” denotes the process of creating or adapting software solutions for organisational IT infrastructures [

21]. Providing this conceptual framework at the outset is essential, since the following analysis concerns precisely such implementations in the mining industry.

The study used a qualitative research approach based on document analysis. This included analytical reports, project documents, and designs that were developed when the software was implemented in the technical departments of the mines. Scientific publications on spatial data processing, mining education, and the geomatics professional framework were also analysed. The documents were subjected to thematic analysis to identify recurring patterns in the implementation process and any skill gaps observed during multiple implementations in the mining sector.

The author was directly involved in the development of the SIoT system in KGHM “Polish Copper” SA (KGHM) [

22]. From 2002 to 2005, he worked on all phases of the project after being hired by Intergraph for a two-year term. In subsequent years, Intergraph provided maintenance and development services for the system. In 2021, due to problems with the SIoT system, KGHM commissioned the author to audit a subsystem that had ceased functioning properly due to successive upgrades. Thanks to his full-time employment at the AGH University of Krakow, the author participated in four other implementations of the GIS system in the Polish mining industry, either directly or indirectly. He systematically recorded and analysed the observations of these activities by topic to identify recurring educational gaps and emerging competency needs among mining industry employees. Interpretive findings are based on referenced sources and implementation artefacts rather than personal recollections.

Geospatial software implementations in mining are most often performed according to the classic waterfall paradigm [

23]. However, when viewed through the lens of software engineering theory, the ’Waterfall’ model is recognised as problematic in mining environments. The methodology is less effective in mining plants because it assumes stable and fully defined requirements and acceptance only at the end of the cycle. This makes it difficult to respond to changes resulting from production dynamics, equipment and software integration, or internal or external regulations. Particular emphasis is placed on problems such as “freezing” the scope of the project, difficulty introducing changes, and extensive documentation. These factors reduce the effectiveness of implementations under conditions of high complexity and uncertainty in the operation of a mining plant [

24].

Teams are often assembled under the assumption that the vendor provides IT professionals, analysts, and project managers who lack mining expertise. In contrast, the client provides mining specialists to define the scope of the project, but they typically have little knowledge about IT. This mismatch of competencies further explains why many implementations encounter difficulties, a pattern consistently observed in the analysed documents. Professional meetings are then held on both sides to determine the terms and conditions of the software project, which will be implemented or launched at the customer’s premises. Then, further stages of software implementation and training follow.

However, this was merely a theoretical proposition, as the model itself was found to be dysfunctional in practice. Despite considerable financial investments over a relatively brief period, the number of fully successful software implementations in the Polish mining industry remains low. The prevailing challenges encompass the following:

Interoperability between heterogeneous IT systems,

The absence of standard spatial data formats and management,

Organisational resistance to change,

A paucity of suitably trained personnel [

25],

The present article does not seek to provide a comprehensive discussion of digital transformation; instead, its focus is on defining competencies and proposing a course for mining geomatician engineers.

2.1. Case Studies of Spatial Information System Implementation

2.1.1. KGHM Land Information System—SIoT

The first implementation analysed is that conducted between 2003 and 2006 at the KGHM company, in which Intergraph conducted the implementation of the GIS software by building the KGHM SIoT system. The initial period of implementation of the spatial information system in KGHM was a relatively difficult period.

Numerous implementations of spatial information systems in the mining industry have faced the same problems. The key barrier was the lack of communication between IT personnel and specialists in the mining industry. The specialised vocabulary of both groups, coupled with differing industry expectations, resulted in frequent misunderstandings that affected the implementation schedule and acceptance of the system. The following case studies reflect these broader patterns within the specific organisational contexts of KGHM and LW Bogdanka.

The implementation of KGHM’s SIoT was planned for 2 years, which, given the huge number of areas of operation (five subsystems) and the high level of complexity of the system, caused some delays in the completion dates of the entire system. However, the most significant issue is the impact that this implementation has had. At the beginning of 2008, an additional Spatial Information Department was established in the KGHM Resources Management and Surface Protection Department, whose task is to develop and implement a coherent policy for spatial data processing and its coordination across the entire KGHM Group. Previously independent GIS systems at KGHM were integrated and fall within the sphere of interest of this Division, and their further development has been subordinated to the requirements stated at the level of the Management Board Office. Since the establishment of this division, the KGHM Management Office has ceased to be merely a ’buyer’ of the solutions offered and has become the manager of its own policy to build spatial data infrastructure. The employees of the KGHM survey departments were subjected to further changes. The new Department referred them to training courses. In the first place, training covered issues related to software engineering: object-orientated modelling in UML, spatial data management (structure, sources), and IT project management.

This change has meant that it is now possible to talk to trained people about designed applications not on the level of functions in individual windows of that application but can go straight to the level of the class diagram and activity diagram of an IT project. Multiple people associate the work of a surveyor with a measuring instrument at the bottom of a mine, who only sits down at a computer to chart a map. It is increasingly observed that this is not true. Some of them have less and less opportunity to go down the mine and spend more and more time on the computer organising the work of other surveyors. Currently, most of the surveying department managers at KGHM are therefore trying to have an employee with a broader range of geoinformatics knowledge on their team. There have been situations where an IT specialist was hired to learn geodesy on the job or surveyors were hired who had the advantage of an internship in geoinformatics companies. The following two examples can be pointed out here.

A former Intergraph employee, an analyst involved in the implementation of the SIoT spatial information system at KGHM, was employed in the surveying department of the KGHM Lubin Mine. In this particular instance, the individual’s educational background in Information Technology and Surveying, coupled with his extensive knowledge of the system, proved to be pivotal.

The surveying department at the KGHM Rudna Mine has appointed a person with extensive experience in the field of surveying and IT, with a particular focus on software development. It is important to note that this individual was selected to fill the position that had been vacated by an IT specialist who had previously been employed in this department. In such a scenario, IT proficiency was also found to be critical, as it was instrumental in the effective management of technology and the facilitation of seamless communication.

2.1.2. KGHM System of Mining Maps—MG

In 2010, KGHM implemented MG, a uniform system for maintaining mining maps that operates in the Bentley MicroStation Computer-Aided Design (CAD) environment. Although this solution ensured compliance with state standards for mining maps, it revealed serious analytical limitations. CAD drawings are composed mainly of geometric primitives and lack structured attribute data or semantic classification of objects. As a result, they contain hidden topological errors and do not allow reliable geospatial analysis. For example, it was not possible to calculate the excavation area or determine excavation lengths, since CAD lacks the GIS tools necessary to define axes or measure geometry consistently. Furthermore, geological and surveying data, such as deposit roof elevations, could only be visualised on CAD maps, without any possibility of systematic analysis.

To overcome these limitations, a geoinformatics specialist designed an automated, server-based ETL (extract, transform, load) workflow that converts CAD files in DGN format into GPKG files on a daily basis. Subsequent processes automatically generate thematic maps from these datasets, including a deposit roof elevation map and several others in GPKG format. The implementation of this solution, carried out by an IT specialist with more than 25 years of mining measurement experience, exemplifies the emerging professional role of the ’mining geomatician’.

2.1.3. KHW System of Mining Maps

Numerical map research has been done in the surveying and geological departments of Katowicki Holding Węglowy S.A. (KHW), and people with extensive geoinformatics competencies have been employed there. For example, an employee of PRGW S.A., a company that has specialised in information technology for the mining industry for 20 years, has been employed in one of them. These examples clearly indicate the need for an employee with a high IT level in the surveying and geological departments. In this case, our graduates do not guarantee a sufficient level of IT knowledge and are not likely to be considered worthy of employment in this type of specific position, i.e., one for IT special tasks.

2.1.4. LW ’Bogdanka’ System of Mining Maps

During the implementation of an IT System of Mining Maps at the LW ’Bogdanka’ Mine, a graduate of our Faculty was accepted to work in the geological and surveying department; one of its tasks was to operate the system. However, the student deserved this distinction, among other things, thanks to his hard work in the WGGiIŚ Computer Graphics Student Association, where he learnt how to work in the 3D environment and became familiar with the software used in the implementation of the system. One of his first assignments was the manual preparation of three-dimensional excavation axes, essential for 3D exploitation planning and ventilation design. Later, tasks related to automating routine CAD operations through programming were assigned to him. Therefore, it is evident that it is necessary to separate from the mining surveyor’s education process a profile of education that would guarantee an appropriate level of geoinformatics competencies for the graduate.

Another identified problem was the lack of management of the three-dimensional model of the mining plant. The mining surveyors provide a 2D map of the mining excavations. Other technical departments then create their own versions of the 3D data based on this map. For example, geologists create their own model, miners have their own 3D model to design operations, and the ventilation department has its own 3D model of mining excavations. The person responsible for organising the infrastructure of a 3D object map of a mining plant is the mining geomatician. This situation illustrates a broader pattern: Polish mining companies generally lack a systematic approach to managing three-dimensional vector spatial data. To date, no mine has introduced a coordinated transition to 3D work across all technical departments, which continue to maintain their own separate models.

2.1.5. Observations from Software Implementations

Based on the observations described above and information on other implementation work by mine surveyors and geologists, as well as reviewing the tasks currently executed by the surveying and geological departments of some mining companies, several conclusions can be drawn:

The size of the investment justifies the need for intensive further training of currently employed staff, and the emergence at this point of a graduate ready to carry out these tasks, a “mining geomatician” could significantly increase the efficiency of implementation.

The stage of completing the implementation of the software only opens the chapter related to the problems of operating quite complex software and the problem of managing mining data and maintaining the system.

Staging implementations can increase their effectiveness. However, this requires the technical departments of the mine staff who can define the order terms so that the whole system can be implemented in stages, possibly by different companies at different stages.

The processing of 3D vector data within the mining technical departments should be better coordinated and standardised, thus facilitating consistent data exchange and integration between units.

The findings confirm the RQ2 research question: The key technological constraints are interoperability and 3D integration issues, while the main organisational barriers include resistance to change, lack of standardisation, and limited internal capacity to manage staged implementations. Another important aspect is the necessity for employers to invest in new software functions or in human resources. However, there is currently a shortage of specialists with adequate training in mining spatial data processing. Currently, recent graduates cannot fill this gap as no educational programmes provide the required competencies.

The analysis performed allows a statement about the requirements for a new professional profile, which will allow the education of employees with the desired knowledge and skills in spatial data processing in information systems. These recurring problems provide evidence to support the RQ1 research question. They show that repeated deficiencies persist across software implementations, particularly in IT–mining communication, geoinformatics skills, and systematic management of 3D spatial data.

2.2. Integration of Geomatic Engineering in the Mining Sector

Geomatic engineering plays a crucial role in modern spatial data acquisition, integrating various technologies and methods to analyse and process data efficiently. It involves the application of surveying techniques to ensure precision and accuracy in data collection [

26]. Geomatics has also been increasingly integrated into the mining sector, providing essential tools to measure, monitor, and analyse mining activities and infrastructure. Terrestrial laser scanning is used to invent the mine infrastructure [

27,

28], measuring the volume of work and landfills in underground and open-pit mining operations [

29]. Aerial laser scanning, on the other hand, has found use in measuring changes in the surface of the terrain within mining areas [

30]. Infrared remote sensing should also be mentioned, which allows the monitoring of waste piles in coal mining [

31]. InSAR (Interferometry Synthetic Aperture Radar) satellite interferometry has also been widely used in the mining industry to measure ground deformation [

32,

33]. Equally attractive data acquisition tools are UAV platforms, which are increasingly being used in mining to achieve comprehensive topographic analysis [

34].

Data acquired through geomatic engineering require specialised knowledge and skills in gathering and analysing information in the context of the mining situation and other data collected during exploitation. The authors of the publication [

35] clearly emphasise that data acquisition technologies alone are not sufficient. It is also necessary to create an integrated digital model of the mine in which the data will be collected and analysed.

Professionals in the field must understand a range of technologies and methods to handle and interpret spatial data effectively, including knowledge of their integration with spatial databases to manage geospatial information efficiently.

2.3. Thematic Identifications and Analysis

In summary, I conducted a two-stage thematic analysis. During the first stage, I developed preliminary identifiers that were consistent with the research objective and preliminary framework. The framework included stages of the implementation process, three areas of specialisation (geoinformatics, mining technologies, and software engineering), and types of barriers (professional, institutional, and educational). In the inductive phase, I refined and expanded these identifiers to recognise emerging patterns in the research materials (e.g., interoperability issues, spatial data management, and training bottlenecks). The unit of analysis was a document fragment, such as a paragraph, a note in a table, or an implementation record. All sources described in

Section 2 (implementation artefacts and scientific/programmatic literature) were coded, and this activity was repeated until no new higher-order themes emerged (thematic saturation). To ensure traceability, I kept an analytical journal in which I recorded decisions regarding the identification, merging, and splitting of themes.

3. Results

3.1. Professional Role and Functions

The recently redefined concept of “Mining Geomatics” could be the core to defining a new type of profession within mining, one that combines basic mining and geological knowledge with IT skills to maximise the use of hardware and software to effectively manage mining processes. The market economy forces production volumes to become more flexible, allowing them to adapt to the changing level of demand. It also forces the shaping of the quality parameters of the raw material, the final product of the mining plant [

36].

The mapping of data structures in IT systems and the cooperation with specialised personnel from other technical departments should lead to the integration of sectoral analyses of the planned exploitation. This integration helps balance the drive for profit maximisation with social and environmental expectations to minimise mining impacts, allowing the preservation and revitalisation of surface objects [

37]. Their tasks are also related to the economic context and the building of relationships with the local community. The third training objective is the operation of information systems, which determines the good performance of any information system.

A mining geomatician is responsible for managing the IT infrastructure at a mining site, ensuring the compatibility and security of the hardware and software. This involves configuring networks, supervising operating environments, and ensuring system reliability. They also oversee the structure, availability, and long-term compatibility of spatial data, as well as managing data security protocols and staff access. Geomaticians should also support the professional development of staff in geoinformation technologies.

In more technical roles, they apply advanced spatial analytics, contribute to the development of data integration software, and lead recovery efforts in the event of IT failures or data loss. They also monitor seismic activity [

38], water inflows, and other hazards. Finally, geomaticians act as managers of spatial systems, overseeing purchases and maintenance, designing long-term solutions, and applying artificial intelligence [

10] and data mining techniques to extract knowledge from complex geospatial datasets.

3.2. Identification of Educational Objectives by Competency Mapping

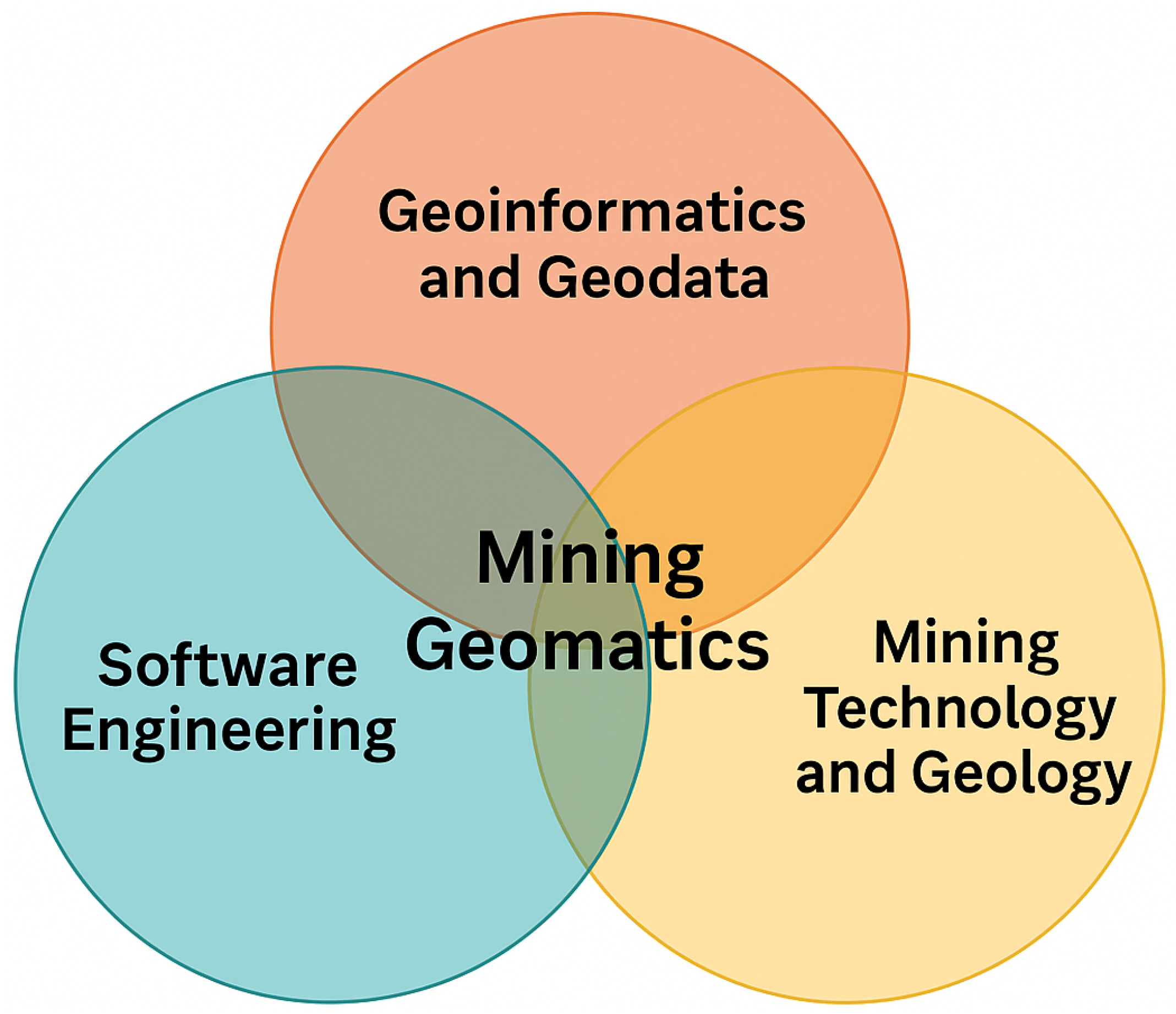

Competences in mining geomatics emerge at the intersection of three fundamental fields: geoinformatics, software engineering, geology, and mining technologies.

Figure 1 illustrates this convergence, showing how these fields interact to support mining spatial data processing tasks and form the core of the proposed curriculum structure.

To translate these professional requirements into educational objectives, they must first be formulated as specific elements of the curriculum. These elements should reflect the diverse range of responsibilities of a mining geomatics engineer by combining technical, geospatial, and IT competencies.

Table 1 summarises the identified professional requirements and their corresponding academic course topics, demonstrating how structured training can support the development of these key skills.

This mapping directly addresses the RQ3 research question by showing how professional requirements are operationalised into programme-level learning objectives. The identified domains—geoinformatics, IT systems, hazard monitoring, and intelligent analytics—are aligned with specific academic course topics. This alignment ensures that the curriculum reflects industry needs in a systematic and verifiable manner, while also providing a clear framework for evaluating the adequacy of training against professional expectations.

Based on a comparison of professional requirements and academic content, several key educational objectives have been identified. The most important objective is to master the use of spatial data infrastructure. This includes organising, managing, and securely accessing three-dimensional geospatial data used in mining, as well as optimising resource use.

The second objective is to become proficient in modelling mining processes and their impacts on technical, economic, social, and environmental aspects of mining, with a particular focus on spatial simulations and forecasts of future changes.

A third objective is to develop analytical and predictive reasoning skills, such as evaluating mining results within a broader socioeconomic and geospatial context and using advanced tools (e.g., AI, ML and data exploration) to predict spatial changes.

The final objective is to develop communication and coordination skills, including the ability to work across departments, manage system development, and collaborate with stakeholders, including local communities.

3.3. Role Comparison with Traditional Surveyor

Table 2 provides a comparative overview of the knowledge and skills expected from two distinct but related professional profiles in the mining sector: the traditional mining surveyor and the newly emerging mining geomatician. The comparison is based on selected topics and issues that reflect the core and complementary areas of competence. The descriptions follow a simplified scheme that indicates whether the knowledge or skills in a given area are basic, intermediate, or advanced. This comparison highlights the growing demand for geoinformatics, data transmission, and digital modelling competencies in modern mining education.

The functions and tasks of the new profession, as described above, together with the resulting educational objectives, form the core of the professional profile and academic training pathway for mining geomaticians. However, translating these findings into an institutional framework also reveals broader challenges within their environment. These include systemic institutional constraints, professional regulations related to the practice of the profession, and problems with the implementation of the new educational profile. These three aspects form a closed circle that is difficult to break.

5. Conclusions

Based on the analyses and discussion conducted, it is evident that there is a pressing need for training programmes tailored to the new profession—the mining geomatician. The development of this specialised role is driven by the increasing demand for precise geospatial data in modern mining operations. This training should focus on equipping professionals with advanced skills in geomatics technologies and their application in the mining industry. This initiative aligns with the growing emphasis on efficiency, sustainability, and safety in mining practices.

The analysis presented in this study confirms the clear need for a formalised educational pathway that considers the interdisciplinary requirements of mining geomatics. This role requires knowledge of both mining and geology, as well as skills in geoinformatics and software engineering. It enables specialists to manage complex spatial data infrastructure and support digitally integrated mining operations. The curriculum framework in

Table 1 reflects this convergence, aligning key professional requirements with the targeted academic content. Implementing it could establish a foundation for future educational standards in this sector. Further work should include piloting this curriculum and evaluating its effectiveness in improving workers’ adaptability, facilitating innovation transfer, and promoting interdisciplinary cooperation in the mining context.

The number of educational objectives collected provides the foundation for proposing a conceptual syllabus for a 1.5-year second cycle (master’s level) programme. This academic pathway is envisioned as aligning, at least in principle, with the learning outcomes defined at Level 7 of the European Qualifications Framework (EQF), subject to further development, validation and institutional accreditation of the curriculum. Finally, state professional qualifications could be established (similar to those of a mining surveyor), which would be awarded upon completion of professional training and passing an exam before the relevant public institution. Designed in this way, a multistage accreditation model would combine flexibility with formal recognition, responding to the needs of the labour market and administration.

In conclusion, the introduction of the profile of the ’mining geomatician’ can contribute significantly to the development of the mining industry, making it more modern and adapted to the requirements of a modern knowledge and technology-based economy. A pilot educational programme jointly developed by academic and industry stakeholders could be a practical next step to validate this proposed professional profile.