Abstract

Despite ongoing efforts to enhance coal rib stability, the underground coal mining sector continues to face incidents of rib failure, leading to injuries and fatalities. The development and validation of effective rib support systems are crucial for mitigating these risks. Unfortunately, a standardized design methodology that accommodates the diverse geological conditions of U.S. coal mines is missing. Current practices are often based on trial-and-error or outdated methods, yielding unreliable outcomes. This research aims to fill this gap by creating a comprehensive methodology for designing rib support systems suitable for U.S. underground mines. It encompasses in situ pull-out tests of coal rib bolts, numerical model validations, and parametric studies on variables affecting rib stability. A significant achievement of this study is the creation of the rib support recommendation tool (RSR), a user-friendly application that offers site-specific rib support advice. This tool leverages the results from parametric studies and improved Coal Pillar Rib Rating (CPRR) system values to recommend effective rib support. Validated by field data, the RSR tool promises to significantly improve mining safety and efficiency by providing a systematic and reliable method for rib support design, with ongoing efforts to further validate its effectiveness.

1. Introduction

Rib failures in underground coal mines pose a critical safety issue, leading to injuries, fatalities, and operational disruptions, emphasizing the need for immediate action to enhance rib stability. These failures not only endanger lives but also increase operational costs and legal risks, impacting the financial stability and productivity of mining operations. In the U.S., coal mines face diverse geological conditions, necessitating specialized support systems. However, the absence of a standardized design methodology for these systems leaves mining professionals with limited guidance, often resulting in reliance on inefficient, costly, and potentially dangerous trial-and-error methods. This underscores the importance of developing effective and reliable rib support solutions tailored to the specific challenges of each mining environment.

Different countries have varied methods for rib control and support in mining, but there is no universal standard for rib support design. In Australia, a common approach involves using two bolt rib support systems for mines with a height of 3 to 5 m, spacing them 1 to 1.5 m apart []. This method also incorporates wire meshes, face plates, and liners for additional support. The continuous monitoring of mining conditions ensures the effectiveness of these support designs, with immediate adjustments made in critical situations. For rib support systems, empirical design techniques like the Analysis of Longwall Tailgate Serviceability (ALTS) and the Analysis and Design of Rib Support (ADRS) have been introduced [], offering promising design strategies that, however, are not applicable to the U.S. mining sector due to its unique geological and geotechnical conditions. Rock bolt design strategies in China were presented by Kang and Wang [] based on the mining and geological conditions. In order to determine the bolt length for coal rib support applications, Xiangjun [] proposed an empirical approach. Similarly, primary supports in German and Polish coal mines are based on yieldable steel arches and rock bolting with additional roof supports. Coal ribs are typically strong and not cleated in South African mines, resulting in favorable mining conditions [].

The effectiveness of coal rib support systems is significantly influenced by the rock bolts’ anchor capacity and shear stiffness []. Given the absence of a standard rib support design method, it is crucial to comprehend how these support systems are installed. Standard pull-out tests are extensively utilized to assess the parameters of these support elements, providing insights into the interaction between coal ribs and rock bolts. These tests are vital for evaluating bolt performance, understanding the load transfer mechanism between the bolt and the surrounding rock strata [,], examining the interactions between rock bolts and the surrounding rock [], and identifying various failure mechanisms [].

U.S. coal mining primarily uses fully grouted, mechanical, and cuttable bolts for coal rib reinforcement [], with extensive research focusing on their efficacy, especially grouted bolts, through laboratory investigations [,,,,]. These studies assess the material properties of grout and the mechanical behavior of bolts under stress, revealing a spectrum of responses during pull-out tests. Significantly, experiments have demonstrated that the behavior of bolts can vary, and Han et al. [] observed a softening effect after the peak force levels were reached for both rebar and cuttable bolts. Beyond the laboratory, field-scale tests further enrich our understanding of bolt performance, particularly in terms of anchorage capacity and shear stiffness. Mohamed et al. [] identified a tri-linear pull-out behavior, using it to determine critical points related to bolt anchorage capacity and shear stiffness. Jin-feng and Peng-hao [] calibrated their models with data from fully grouted bolt pull-out tests. This comprehensive body of research underscores the importance of diverse testing methodologies in advancing our understanding of bolt technology and its application in enhancing the safety and efficiency of underground mining operations.

Since conducting extensive experiments is economically challenging, developing accurate numerical models is crucial as they provide a foundation for simulating real-world conditions. The data from these tests are instrumental in refining numerical models, ensuring they accurately reflect the complex dynamics of underground support systems. Understanding rock–bolt interactions primarily comes from studies using load-displacement curves derived from pull-out testing simulations [,,]. Recent research has focused on developing new constitutive models for analyzing the bond-slip behavior between bolt and grout materials [,,,,], highlighting the importance of numerical modeling in understanding bolt failure mechanisms and their impact on support design performance. Five main failure modes for grouted bolts have been identified: the yielding of rebar, failure of grout, failure at the bolt–grout interface, failure at the grout–rock interface, and failure of the surrounding rock material [], with the most dominant being the failure at the interfaces between grout and bolt [,,]. Nonetheless, a deeper exploration into the remaining failure modes, particularly across various grout levels, necessitates comprehensive field and numerical analyses. The ability of a system to transfer load is significantly impacted by the bond strengths at two critical interfaces: the bolt–grout and grout–rock interfaces, which display a tri-linear bond-slip behavior [,,,]. To accurately model these interactions, the rebar must be represented as a bilinear strain-hardening material, and a tri-linear bond-slip model should be applied to capture the bonding dynamics across the interfaces, a methodology supported by Ma et al. [] and Nie []. This model breaks down the bond stress versus slip displacement curve into three distinct linear phases, each representing different stiffness characteristics for the ascending, softening, and residual sections. Integrating these methodologies enables a comprehensive analysis of bolt failure modes, as evidenced by recent studies [,,]. This approach, integrating diverse models and tests, enables a comprehensive analysis of bolt failure modes and their implications for support design.

Hence, this study embarks on addressing the identified limitations and gaps in the research concerning rib support systems in underground coal mines. It aims to develop a specialized tool for mine operators and engineers to assess coal ribs, both supported and unsupported, and to select the most appropriate coal rib support across various geological and mining conditions. By incorporating experimental datasets and numerical results, this study seeks to deepen the understanding of failure mechanisms and enhance the efficiency of bolts used in underground coal mining. It intends to bridge the gap in the existing literature by providing field-scale data and calibrated numerical models that accurately reflect the complex interactions between coal ribs and support systems under different geological scenarios. This effort is complemented by a detailed quantitative analysis of how geological variations influence rib support system performance, focusing on critical bolt design parameters. Furthermore, this study plans to clarify the required anchorage levels and bolt performance through extensive testing, aiming to optimize rib support strategies by considering the complex failure mechanisms and specific anchorage needs. Lastly, it proposes developing a systematic methodology for designing rib support systems tailored to specific mining environments, moving beyond generic guidelines to offer mine professionals more reliable and effective support strategies, thereby enhancing safety and operational efficiency.

2. Materials and Methods

This study follows three primary stages of methodology, namely: a field test, a numerical model of bolts and their calibration, the implementation of bolt responses into coal rib model, a parametric study, and the development of a rib support recommendation (RSR) tool as discussed.

2.1. Laboratory Experiment and Field Testing

This study conducted pull-out tests in West Virginia, focusing on a coal pillar within a geological setting of layered sedimentary rocks, including coal seam and shales. The pillar featured a 2 ft thick shale layer at the top, a 1 ft thick shale at the base, and a 3 foot thick coal section in between. During our site visits, we collected multiple coal lump samples to conduct rock mechanics laboratory tests. We performed nine valid uniaxial compressive tests (UCT) to evaluate the uniaxial failure response of the samples under a constant axial displacement rate using the MTS 816 Rock Test System loading frame (Figure 1). The test samples were prepared in accordance with ISRM specifications for specimen dimensions and surface flatness, utilizing equipment in our rock mechanics laboratories. The loading rate was set at 0.127 mm/min for all specimens, ensuring failure occurred within a five-to-ten-minute period. Each test continued until the specimens reached their residual strength. The data acquisition unit continuously recorded the load, displacement, and test time at a rate of 8 Hz. A summary of the test results is provided in Table 1. The estimated uniaxial compressive strength (UCS) of the coal was around 20 MPa, categorizing it as medium-strength.

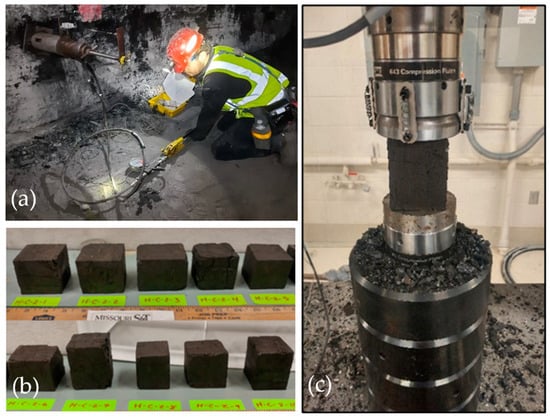

Figure 1.

Field and laboratory tests: (a) in situ pull-out test application [], (b) prepared coal samples, and (c) UCT on coal sample.

Table 1.

Uniaxial compressive test results for coal samples.

To compare the effectiveness of different bolt types, twenty in situ pull-out tests were performed on two neighboring pillars with identical geological features, using ten short-encapsulated (SEPT) bolts in one and ten mechanical bolts in the other. Both bolt types were tested in 4 ft and 5 ft lengths to evaluate the impact of the bolt length on the pull-out response. The key difference between the bolts is the inclusion of a resin cartridge in the SEPT bolts and a shell in the mechanical bolts that resists force application. A conventional pull gear, a pressure gauge, and a string pot were used for load-displacement monitoring, as shown in Figure 1a, with an intrinsically safe data acquisition system ensuring precise data collection according to MSHA standards.

The results of the mechanical bolt pull-out tests detailed in the study by Kirmaci et al. [] are tabulated in Table 2, while the outcomes for the short-encapsulated bolts and tests with varying grout levels are discussed subsequently, including references to Mohamed et al. [] for the latter.

Table 2.

In situ pull-out test results for mechanical bolts.

2.2. Numerical Model and Calibration

This section details the calibration of pull-out test models using both in situ data from an active coal mine and existing literature, initially focusing on calibrating bolt responses for use in parametric studies of supported coal ribs. The 3DEC numerical solver was used to simulate the pull-out test response of mechanical, short-encapsulation, partially grouted, and fully grouted bolts. The numerical model employed a cube block with 2 m length in each direction and a coal-mass constitutive model, developed by Mohamed et al. []. The pull-out test simulations were carried out for the banded bright coal lithotype (BBC). The model’s bottom and top were fixed in the Z direction, and the sides were fixed in the Y direction. The backside of the cube block was constrained in the X direction, while the face where the pull-out force was applied, remained free. The mesh size varied from 2.5 cm to 7.5 cm, enlarging from the center (around the rebar) to the edges of the block. The calibration process involves analyzing load-displacement data from pull-out tests and simulating supported coal rib models. Specifically, the calibration of mechanical bolts is discussed in Kirmaci et al. [], while the data for partially grouted (PGPT) and fully grouted bolts (FGPT) were derived from Mohamed et al. []. Figure 2 shows the calibrated SEPT and FGPT models.

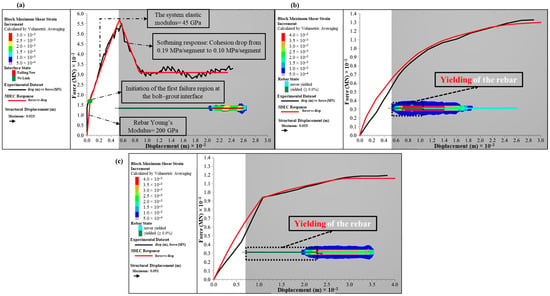

Figure 2.

Calibrated bolt models illustrating the variations in grout length and their respective calibration: (a) Short-Encapsulation Pull Test (SEPT) model with 1 ft grout, (b) Fully Grouted Pull Test (FGPT) model with 4 ft grout, and (c) Partially Grouted Pull Test (PGPT) model with 2 ft grout.

The SEPT results indicated that the rebar initially exhibited elastic behavior consistent with its Young’s modulus of 200 GPa. At a certain point, the behavior shifted to reflect the system’s elastic modulus, a combination of the rebar and grout responses. This shift, representing the onset of failure at the contacts, was calibrated in the numerical model. This behavior was also observed during field tests, where cracking noises indicated failure initiation at the contacts. In the numerical model, this behavior was implemented using a FISH code, which is a built-in scripting language that provides the 3DEC user with comprehensive control over nearly every aspect of program operation, identifying the first contact failure and immediately adjusting the elastic modulus to the system’s value (see Figure 2a). Consistent with field tests and observations of FGPTs, the dominant failure mode was rebar yielding. Additionally, the FGPT models exhibited partial interface failure, similar to the PGPT models. The FGPT model maintained a significantly higher number of stable contacts than the PGPT result. A noteworthy difference between the FGPT and the PGPT models is that the FGPT models achieved the bolt’s bearing capacity with a considerably lower structural displacement change (stiffer load-displacement curve), as illustrated in Figure 2b,c. Field test results corroborate these findings, indicating that increasing the grout level enhances the bolts’ bearing capacity.

2.3. Implementation of Bolt Responses into Coal Rib Model

This study employed a deformation-based criterion of 1 cm displacement within a 25 cm depth in the rib, informed by field observations and numerical simulations, to assess rib stability []. The coal mass constitutive model proposed by Mohamed et al. [] was applied to the coal rib. The coal mass scale value was set at 20, following recommendations by Rashed et al. [], and face cleats were integrated into the coal unit with properties calibrated by Guner et al. []. The model setup included fixed boundary conditions and calculated in situ stresses, considering coal density and overburden depth, with the roadway orientation and face cleats aligned to model the most unfavorable scenario. Horizontal stresses in coal were determined using methodologies proposed by Liu et al. [].

The following equations were employed to calculate the maximum and minimum horizontal stresses on the coal seam:

where and are the maximum and minimum horizontal stresses in MPa, and is the depth of the coal seam in meters.

The in situ horizontal stresses in the roof and floor rock units were calculated by the following equations []:

where and are the maximum and minimum horizontal stresses in MPa, is the Young’s modulus of rock strata in MPa, and is the depth of the rock strata in meters.

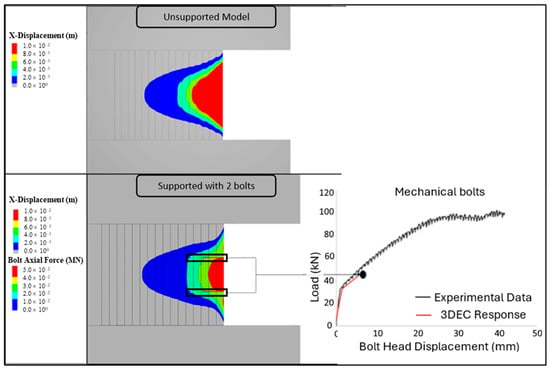

The model was first stabilized under given stress conditions before road excavation. Upon excavation, the reaction force around the opening was stored and applied to the excavation boundaries with the same magnitude. To simulate a more realistic softening response, the applied force was non-linearly decreased, based on a function of the step number (0.9step/1000), to gradually reduce the initial forces updated every 300 iteration steps. Rib bolts were added when the rib face softened by 65%. The coal matrix’s strength was adjusted using a Strength Reduction Factor (SRF), which was increased until the model became unstable, with the final SRF value indicating the Rib Factor-of-Safety (RibFOS). Figure 3 shows that the bolts significantly reduced the deformation, with the bolts reaching about 50 kN axial loads, aligning with the second portion of their load-displacement curve.

Figure 3.

Rib deformation plots illustrating the comparison between unsupported and supported coal rib models. The supported model incorporates the effect of an axial load acting on the mechanical bolt, complemented by the corresponding load-displacement plot.

2.4. Parametric Studies for Different Geological Conditions

This part of the research outlines the parametric studies conducted after calibrating the pull-out test models and base-supported coal rib models. The studies examined the effects of fully grouted and mechanical bolt parameters across various support densities and a broad spectrum of overburden depth and mining height conditions on coal ribs. Recognizing the variability in mining and geological conditions across U.S. coal mines, and sometimes within the same seam, these studies aimed to develop an appropriate support design system tailored to specific conditions. Comprehensive parametric studies leveraged 3DEC and considered a range of factors, including different coal lithotypes (dull coal, banded bright coal, and bright coal), mining heights, overburden depths, and the condition of roof and floor strata, among others, as outlined in Table 3. The selection of these parameters was informed by recent findings from NIOSH researchers, ensuring alignment with existing research in the field []. The overarching goal was to evaluate coal rib performance under diverse support conditions. To this end, the strength reduction method was employed to ascertain the RibFOS, or safety value factor, for both unsupported and supported coal ribs. A critical RibFOS value of 1.5 was identified, reflecting the threshold below which most coal mines would typically opt for rib support to ensure stability. Over 450 unstable, unsupported coal rib models were initially evaluated in this task for a wide range of support practices.

Table 3.

Summary of the studied parameters along with their respective ranges.

Regarding the incorporation of bolt spacing effects, our approach involves scaling the bolt properties according to the spacing. All parametric models were initially configured with a 4 ft equivalent bolt spacing. Due to the computationally expensive nature of the simulations—characterized by very fine mesh sizes around the rib and a high element count—the research team determined that simulating the bolt spacing effect by increasing the model thickness was impractical. In our modeling approach, when considering the effect of bolt spacing (in the out-of-plane direction), it is necessary to decrease the bolt strength parameters appropriately rather than increasing the model thickness. According to Carranza-Torres [], if the bolt spacing deviates from the 1 m assumption used in plane strain analysis, several input parameters must be adjusted by a scaling factor . Specifically, this adjustment includes scaling the bolt’s Young’s modulus, and the yield limits of the bolt. Based on this, parametric models with 6 ft and 8 ft bolt spacing (which are reasonable intervals used in the field according to the study by Mohamed et al. []) were analyzed. All previous parametric models with a supported RibFOS value greater than 1.5 were rerun with 6 ft and 8 ft bolt spacing. It was evident that increasing the bolt spacing would result in lower supported RibFOS values, leading to outcomes below 1.5 and indicating instability.

3. Results

One of the significant observations made in the early stages of the parametric studies was that using rib support density (RSD) as a design variable might not be ideal. For example, the use of two 3-foot-long bolts and one 6-foot-long bolt results in the same RSD, but numerical simulations have demonstrated that the effectiveness of these bolt arrangements differs markedly. This variability in performance is also greatly influenced by factors such as the coal pillar rib rate (CPRR), the height of the mining operation, and the depth of the overburden. Therefore, it became evident that when evaluating the outcomes of parametric models, it is essential to offer specific support guidance. Moreover, the broad spectrum of RSD values recommended by researchers based on practical fieldwork further validates this research approach to provide detailed, situation-specific support advice instead of depending on generic RSD values. Hence, rib support recommendations were categorized as discussed.

3.1. Category 1—Coal Lithotypes with Varying Overburden Depths and Mining Heights for Single-Solid Coal Rib

In the first phase of the parametric studies, a range of support configurations was applied to simulate the behavior of unstable single-solid coal rib models under varying coal types, overburden depths, and mining heights. For all scenarios in this case, the roof and floor were characterized using elastic material parameters. Each model was first studied by applying a single bolt positioned at the center of the coal rib. If instability persisted, a multiple-bolt support system with various bolt lengths was implemented to enhance the rib stability. These simulations were conducted to systematically assess the impact of varying support densities and field conditions on rib performance.

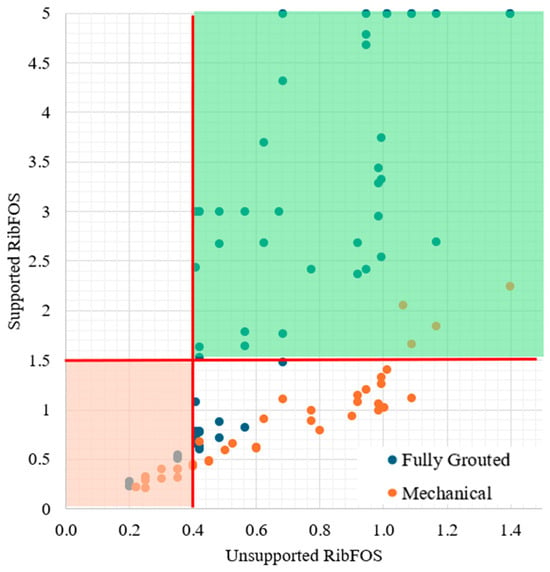

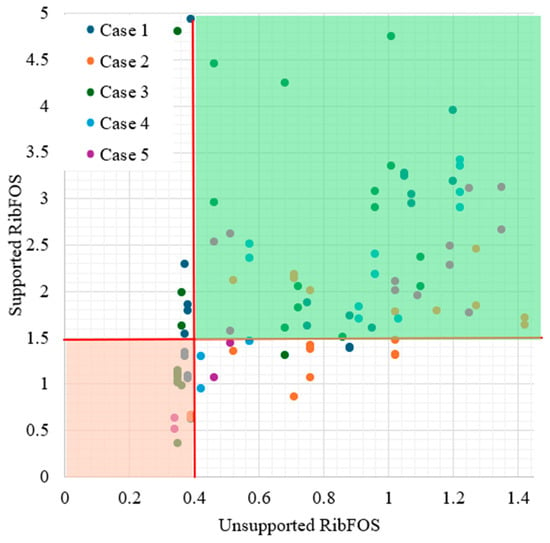

In the literature, the single-solid coal rib category has been the subject of extensive numerical modeling research despite its rarity in U.S. coal mines. This category holds significance primarily for evaluating the efficiency of bolting systems. Over 60 numerical models were conducted within this category, yielding valuable insights into the performance and effectiveness of rib support systems under varying conditions. Figure 4 shows the parametric model results for Category 1.

Figure 4.

Parametric model results for Category 1 (single-solid coal rib).

The Unsupported Rib Factor of Safety (RibFOS) is a dimensionless metric that can be quantitatively assessed through critical geological and operational parameters, including the Coal Pillar Rib Rating (CPRR), mining height, and overburden depth. Numerical modeling analyses have identified a pivotal threshold value for RibFOS, which represents the minimum criterion for rib support systems. The acceptable threshold value for supported RibFOS is established at 1.5, as per safety recommendations. Conversely, the threshold for unsupported RibFOS is defined in scenarios where RibFOS fails to achieve the value of 1.5, even with the implementation of support systems.

As depicted in Figure 4, a RibFOS value of 0.7 has been identified as a critical threshold, delineating the conditions under which primary rib support systems can effectively ensure rib stability versus scenarios that require additional stabilization measures. In this context, the unsupported RibFOS values for both fully grouted and mechanical bolts are observed to align at 0.7, with variations in RibFOS expected across different bolt types in subsequent analyses. When the unsupported RibFOS exceeds the value of 0.7, the rib can be stabilized through the application of standard primary support systems. Conversely, if the RibFOS is registered below this critical mark, the rib is increasingly prone to instability and potential failure. In such instances, it is imperative to integrate secondary support systems—such as wire mesh, ladder beams, or alternative reinforcement strategies—in conjunction with primary supports to ensure adequate stabilization. This multi-tiered approach is essential, particularly in mining operations that face adverse conditions, where elevated risks of rib sloughing or collapse arise due to significant stress factors or weak geological substrates. Further analysis of the model results revealed notable differences in the effectiveness of various bolt types under conditions where the unsupported RibFOS is below 0.7. Specifically, mechanical bolts demonstrated better performance compared to fully grouted bolts in maintaining rib stability in such cases. Models where the unsupported RibFOS is below 0.7 include scenarios with moderate and strong coal, a high overburden depth, and a significant mining height. The enhanced performance of mechanical bolts is largely attributed to the solid nature of the coal rib in Category 1 scenarios, which lacks interfaces or partings. This structural integrity enables a more efficient transfer of stress from the coal rib to the mechanical bolt shell, thereby enhancing stabilization.

Conversely, the superior performance of mechanical bolts was found to diminish when applied to weaker coal formations. In such cases, the lack of sufficient coal strength and structural cohesion rendered mechanical bolts less effective in providing the required rib support. This observation underscores the critical influence of geological conditions on the selection and effectiveness of rib support systems.

To address this variability, this study delves deeper into the parametric models to identify the minimum coal strength value necessary for the effective application of mechanical bolts. By analyzing the relationship between coal strength, mining conditions, and bolt performance, the subsequent sections of this study aim to establish guidelines for the deployment of mechanical bolts. This includes quantifying the threshold coal strength below which mechanical bolts lose their effectiveness and exploring alternative support strategies for weak or heavily fractured coal formations.

For Category 1, all models with an unsupported RibFOS above the 0.7 threshold, along with those from previously completed research, were individually analyzed. The analysis concluded that providing a statistically robust support recommendation was not feasible. Based on the reviewed model results, it was decided to utilize the unsupported RibFOS and mining height parameters in determining bolt recommendation classes. Since the unsupported RibFOS is a function of CPRR and overburden depth, the proposed support recommendation classes also account for coal integrity and field stress conditions. Upon analyzing the model results, two critical unsupported RibFOS values and two critical rib height values were observed. Based on the effective support densities applied in the models, six distinct support recommendation classes (from 1. A to 1. F) were proposed. The support recommendation classes for Category 1 are presented in Table 4.

Table 4.

Support recommendations for category 1 (single-solid coal rib).

Similar responses were observed for both fully grouted and mechanical bolts in cases where the unsupported RibFOS values ranged between 0.7 and 1. In most cases where the rib height is above 7 ft, stability could not be achieved with a single bolt alone. These stability issues were addressed by installing additional bolts. The number of bolts required should be adjusted based on the rib height: For lower mining heights, such as 6 ft, stability can be achieved with a single bolt placed at the center of the rib. For rib heights between 7 ft and 10 ft, it is recommended to use at least two bolts. For rib heights greater than 10 ft, three bolts are recommended. In all cases, bolts of at least 4 to 5 ft in length with a spacing of 4 to 6 ft are recommended.

In cases where the unsupported RibFOS values fall between 1 and 1.25, the implementation of a single support significantly enhances the stability of the coal rib. A single bolt of 4 ft in length, placed at the center of the rib with a spacing of 4 to 6 ft, generally suffices for these conditions. Similar recommendations apply to cases with unsupported RibFOS values between 1.25 and 1.5. For these scenarios, shorter bolts, such as 3 ft, can be used, and the spacing can be increased to 6 to 8 ft.

In addition to the single-solid coal rib models, models incorporating soft in-seam bedding within the single-solid coal rib were also utilized. The presence of the in-seam bedding is assumed to divide the coal rib into multiple units, necessitating updates to the model code to account for the upper and lower unit ratios. These scenarios are included in the following section.

3.2. Categories 2 and 3—Coal Lithotypes with Varying Overburden Depths and Mining Heights for Multiple Coal Units

In addition to the single-solid coal rib models, two-unit and three-unit coal rib models were also examined as part of the parametric studies. A total of over 600 models were run in this section. These models were analyzed using the same methodology as the single-solid coal rib models. A general review of the model results revealed bolt performance variations based on the rib unit contacts’ characteristics. Consequently, this section classifies the results into two distinct categories: Category 2, representing multiple coal units with strong contacts, and Category 3, representing multiple coal units with weak contacts.

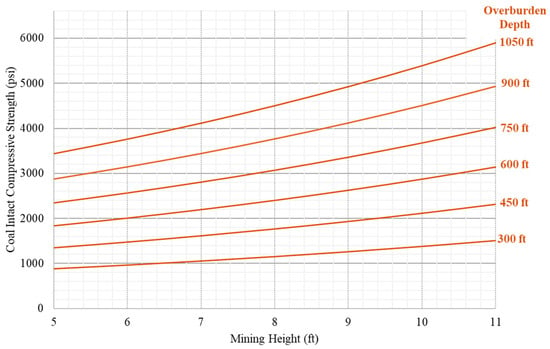

When evaluating these categories, a distinct parameter influencing bolt effectiveness was observed, particularly in the range where unsupported RibFOS values are between 0.4 and 0.7. This parameter is the thickness of the relatively weaker coal unit compared to other units in the rib. A new approach was proposed to quantify this relatively weaker coal unit: the critical coal strength (CCS) (See Equation (5)). This approach involves estimating the critical intact coal compressive strength, below which the coal unit may become susceptible to failure under certain overburden depth and mining height conditions. The easy-to-use graph was prepared by rearranging the unsupported RibFOS estimation equations presented in recently completed research [], resulting in the chart shown in Figure 5.

where CCS is the critical coal strength in psi, is the overburden depth in ft, and H is the mining height in ft.

Figure 5.

Proposed chart for estimating the critical coal strength (CCS).

Figure 5 illustrates the variability in the expected failure strength of coal units based on the mining height and overburden depth. For example, for a rib with a mining height of 6 ft and an overburden depth of 600 ft, coal units with a laboratory compressive strength below 2000 psi are anticipated to fail, with this value being estimated as the CCS. The chart aligns with numerical model results, except in conditions where the ratio of seam rock parting thickness (t) to mining height (H) exceeds 20%. In such cases, it is recommended to use the effective mining height as H-t.

For Categories 2 and 3, the proposed chart has been used to identify critical coal units where unsupported RibFOS values are between 0.4 and 0.7. It was observed that for support recommendations in these categories, having a thickness of 3 ft in the identified units is a critical threshold for a different support recommendation class.

Additionally, the chart can be utilized to determine bolt installation locations. In cases where the unsupported RibFOS falls below 1.5, the chart enables a quantitative prediction of which coal unit(s) should be targeted for bolting.

3.2.1. Parametric Model Results for Category 2

This category encompasses parametric model results for ribs composed of multiple units with strong contacts and bedding planes. The analysis of the model outcomes reveals that fully grouted bolts are significantly more efficient than mechanical bolts under the same conditions. The green region in Figure 6 shows models where the primary support systems effectively maintain rib stability. Below this region, most ineffective support configurations are associated with mechanical bolts, indicating their limited performance under these specific conditions. In cases where the unsupported RibFOS is below 1.0, mechanical bolts fail to achieve the desired support action, even at high bolt densities. The inefficiency of mechanical bolts in these scenarios can be attributed to two primary factors: (i) in weak coal units, the low coal stiffness prevents effective bolt–coal interaction, and (ii) when there is a sharp contrast in stiffness between coal units, mechanical bolts struggle to perform adequately.

Figure 6.

Parametric model results for Category 2 (multiple coal units with strong contact).

The parametric results clearly define an unsupported RibFOS of 0.4 as a critical threshold, marking a stability boundary for Category 2. This threshold distinguishes between scenarios where fully grouted bolts alone can effectively stabilize the rib and those where additional reinforcement is necessary. Specifically, if the Unsupported RibFOS falls below 0.4 within this category, secondary support systems must be implemented alongside primary supports to ensure rib stability.

In models where the unsupported RibFOS ranged between 0.4 and 0.7, it was observed that a single fully grouted bolt can function effectively in some cases. Upon further examination, it was concluded that a 5 ft long fully grouted bolt with a spacing of 4 ft or less is sufficient when the rib height is below 7 ft, and the critical coal unit (UCS < CCS) thickness is less than 3 ft. However, if the thickness of the critical coal unit exceeds 3 ft, the use of a second bolt becomes necessary. Additionally, for mining heights greater than 10 ft within the same unsupported RibFOS range, the application of a third bolt is required.

The model results for this category were thoroughly analyzed, leading to the development of eight distinct support recommendation classes. These classes were designed to ensure that the supported RibFOS exceeds 1.5 across all model results. The details of these support recommendation classes are presented in Table 5, which demonstrates their applicability across the different scenarios tested numerically.

Table 5.

Support recommendations for Category 2 (multiple coal units with strong contact).

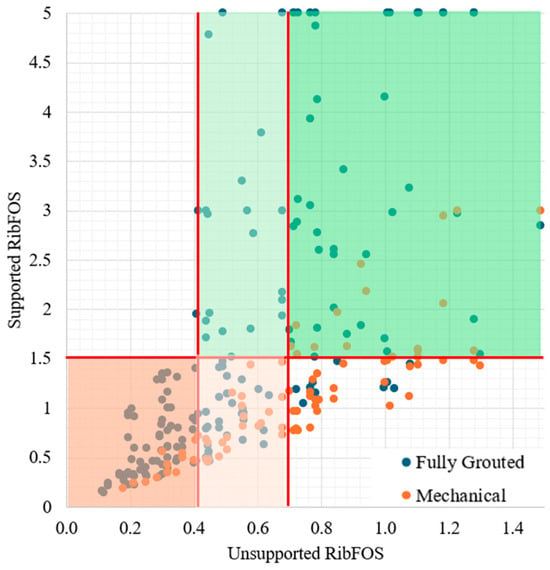

3.2.2. Parametric Model Results for Category 3

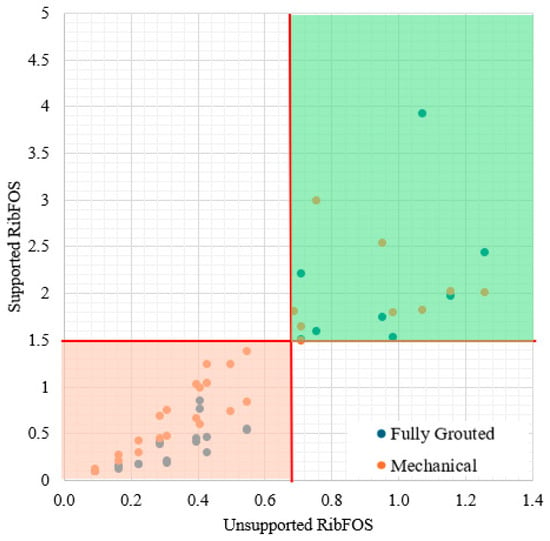

Category 3 covers the parametric models of ribs having multiple coal units with soft contacts. Given the variability in model outputs and the nonlinear dependencies between individual and interactive parameters affecting model behavior, it has been impractical to formulate deterministic equations for support recommendations using statistical techniques. The complexity of parameter interactions and their impact on the model’s response defies straightforward statistical analysis, necessitating a detailed evaluation of model results on a case-by-case basis and the categorization of models into multiple classes where similar bolt practices are effective. The model results for this category are illustrated in Figure 7.

Figure 7.

Parametric model results for Category 3 (multiple coal units with weak contact).

Similar to other categories, the approach applied here involves establishing a critical threshold for unsupported RibFOS, which is 0.4 for fully grouted bolt and 0.7 for any type (fully grouted or mechanical) bolt. Boundaries like those in Category 2 have been created. Observations from field surveys and parametric models have demonstrated that the presence of soft contacts adversely affects rib stability, leading to variable and non-uniform effects on bolt performance. As with Category 2, fully grouted bolts have proven more effective under high stability concerns (RibFOS < 1.0). Additionally, in cases where the unsupported RibFOS exceeds 1.0, stability can be achieved with a single bolt, aligning with observations from field investigations. Another key finding for this category pertains to the use of mechanical bolts. Even in conditions where the unsupported RibFOS exceeds 1.0, the effective performance of mechanical bolts is minimal in some cases. Mechanical bolt usage is not recommended for this category except in cases where the critical coal unit thickness (UCS < CCS) is less than 3 feet.

For specific scenarios, the CCS approach has been necessary when providing bolt recommendations. Detailed evaluations have led to the development of nine distinct support recommendation classes for this category (Table 6).

Table 6.

Support recommendations for Category 3 (multiple coal units with weak contact).

3.3. In-Seam Rock Parting (Category 4)

The presence of stronger rock partings has an effect on rib displacement distribution and minimizes overall coal rib displacement, which increases the coal rib stability []. However, there is no information on how the supported coal rib with an in-seam rock parting behaves; thus, rock partings with three different locations were investigated in our parametric studies. The rock parting material was simulated using the coal mass constitutive model. The parameters for the rock parting were derived from the study of NIOSH researchers, Xue and Mohamed [], who calibrated these parameters utilizing the coal mass constitutive model in their study. By adopting these calibrated rock parting parameters, the simulation ensured that the material behavior reflects realistic mechanical responses based on validated experimental and empirical data.

In this section, the effectiveness of the support systems in the ribs having a rock parting was systematically analyzed by introducing the parting at two distinct locations: (1) between two coal seams and (2) above or below a coal unit(s) with varying thicknesses. The findings revealed a marked improvement in bolt performance when the rock parting was between two coal seams, especially when located centrally within the rib.

Rock partings, generally more competent than coal units, are not typically expected to fail initially due to the absence of inherent vertical geological defects like face or butt cleats. In practice, the failure of the coal unit within the rib often precedes the eventual failure of the rock parting, a behavior frequently observed in field conditions. If a systematic and effective bolting system is implemented, stabilizing the coal units expected to fail first, even openings with mining heights of up to 10–11 feet can be stabilized with a single bolt, as noted during field inspections.

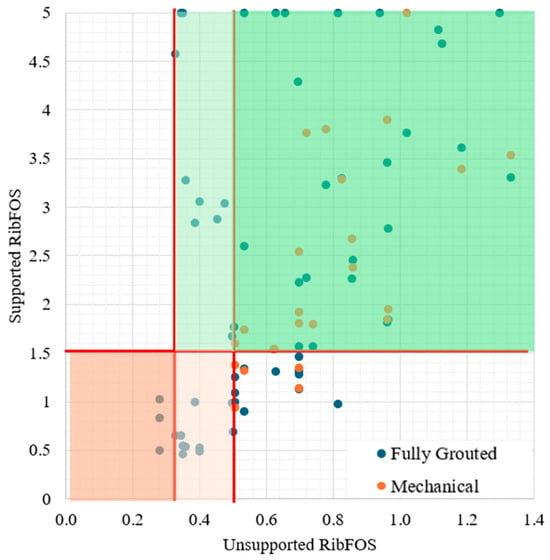

The primary reason for analyzing models with rock partings as a separate category is the distinct mechanical behavior of these systems. The model results clearly show that the performance and efficiency of support systems differ significantly in this category compared to those without rock parting. These variations in support system effectiveness underscore the need for tailored design approaches when dealing with ribs containing rock partings. The model results, presented in Figure 8, are provided in the same format as those for the other categories.

Figure 8.

Parametric model results for Category 4 (in-seam rock parting).

The dark-green region of Figure 8 represents models where primary support systems successfully maintain rib stability. Below this region, all the ineffective support configurations are linked to models with an unsupported RibFOS lower than 0.8. For all the models above the 0.8 threshold, stability was achieved on the first trial, indicating that a single bolt application is sufficient. The analysis identifies an unsupported RibFOS of 0.3 as a critical threshold, serving as a boundary for rib stability in Category 4. This boundary marks the transition between conditions where support systems alone can stabilize coal ribs with rock partings and conditions where additional measures are required. In other words, if the unsupported RibFOS falls below 0.3, secondary support systems should be considered alongside primary supports.

Another key takeaway from Figure 8 is that, in nearly all the models where the unsupported RibFOS exceeds 0.5, both mechanical bolts and fully grouted bolts exhibit similar performance efficiencies. For Category 4, each model with an unsupported RibFOS above 0.3 was analyzed individually, but providing a statistically robust support recommendation proved unfeasible. Based on the reviewed model results, it was determined that bolt recommendation classes should be developed using the unsupported RibFOS and mining height as key parameters. Since the unsupported RibFOS is a function of CPRR and overburden depth, the proposed support recommendation classes account for coal integrity and field stress conditions. Detailed evaluations have led to the development of seven distinct support recommendation classes for this category (Table 7).

Table 7.

Support recommendations for Category 4 (in-seam rock parting).

In recent field surveys conducted at active underground coal mines, it was observed in several mines that ribs with unsupported RibFOS values between 0.3 and 0.4 were stabilized using two 5-foot bolts, depending on site-specific conditions. Additionally, it was noted that ribs with heights of 10–11 feet could be stabilized with a single 4–5-foot bolt, depending on the thickness and position of the rock parting. While the recommendations presented in Table 7 were primarily based on numerical model results, they have also been validated by field experiences.

3.4. Weak and Moderate Roof and Floor Conditions:

In this research, the combined impact of various roof and weak floor conditions on rib stability was also analyzed. A new constitutive model, developed by Sherizadeh et al. [], was used to simulate the combined bedding-lamination representations. The Anisotropic Strain Softening Rock Mass (ANSSRM) constitutive model applies the strength anisotropy of laminated rocks and simultaneously integrates the elastic stiffness anisotropy.

The Coal Mine Roof Rating (CMRR) parameters of simulated roof strata are presented in Table 8. The roof was supported with fully grouted rock bolts, 6 ft long. The immediate roof (unit 1) was simulated for 5 ft thick laminated shale, and the rest of the roof above the bolting horizon was simulated with rock strata stronger than the bolted interval. The joints and rock matrices are modeled with a 90% reduction in cohesion and tensile strength after 0.5% strain (softening) is exceeded. To simulate weak floor conditions, a low stiffness value (3 GPa), 15 MPa rock matrix strength, and 2-inch-spaced weak clay beddings with 0.5 MPa cohesion and 20° friction angle were selected.

Table 8.

Roof properties for modeling weak and moderate cases (Sherizadeh et al. []).

The parametric studies were conducted to evaluate the impact of rib support under weak and moderate roof and floor conditions, considering five distinct scenarios. These scenarios are designed to capture a range of typical geotechnical conditions encountered in U.S. coal mines. The scenarios are as follows:

- Weak roof and strong floor: roof with CMRR 30 with an elastic, non-yielding floor;

- Moderate roof and strong floor: the roof is simulated with a CMRR value of 50, while the floor remains elastic;

- Weak roof and weak floor: both the roof (CMRR 30) and floor are simulated by weak material properties;

- Moderate roof and weak floor: the roof is simulated with a CMRR value of 50, while the floor is weak;

- Strong roof and weak floor: the roof is elastic, while the floor is modeled as weak and deformable.

The same parametric mining conditions, specifically the overburden depth and mining height, were applied across all five scenarios to ensure the consistency and comparability of the results. Around 200 model runs have been completed for five different scenarios and various bolt types/densities.

In the parametric models, despite the consistent selection of bolt installation locations throughout the research (positioned at the center of the weakest unit), a different approach was adopted for inelastic roof and floor conditions. Our approach is explained in the illustrative case below.

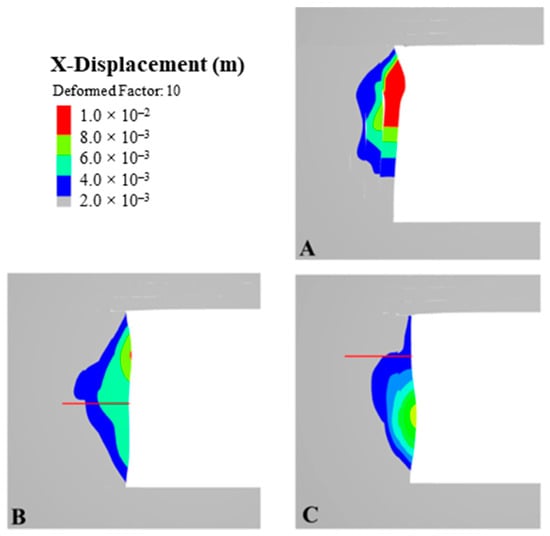

Figure 9 illustrates the deformation plots for both unsupported and supported ribs in the case of solid banded bright coal (medium strength), buried at a depth of 600 ft, with a mining height of 11 ft. In the unsupported case (Figure 9A), the deformation is primarily concentrated in the upper half of the rib due to weak and incompetent roof conditions. This concentration of deformation indicates instability. In the case where a bolt is applied to the center of the seam (Figure 9B), the deformation, although it is halted, remains concentrated in the upper half of the rib. The axial load on the bolt in this configuration is around 40 kN. While the rib achieves stability under this condition, the location of the bolt is not appropriate.

Figure 9.

Representative rib deformation plots for (A) unsupported, (B) supported at the middle of the rib, and (C) supported at the anticipated highly deformed point scenarios under weak roof conditions, highlighting different bolt installation locations and their effects on rib deformation behavior.

On the other hand, when the bolt is installed in the upper half of the rib, as indicated by the unsupported rib deformation plot, the bolt is observed to perform more effectively, with an axial load of approximately 48 kN (Figure 9C). This configuration significantly enhances the rib stability, as the bolt is better positioned to resist concentrated deformation, leading to an improved load distribution and overall rib integrity. Moreover, should a second bolt installation be required for this specific case, the optimal location for the second bolt can be inferred based on the deformation plots of this case. This example provides insight into the most effective bolting location, allowing for enhanced rib support in incompetent surrounding strata conditions.

The bolting strategy applied in this study aligns with observations from supported rib field surveys, where a similar bolt installation was shown to be effective. Discussions with mining professionals further validated this approach, concluding that installing the bolt at the location of maximum observed rib deformation—rather than the center—enhances the overall stability and support effectiveness. This conclusion was reached through both empirical field data and feedback from industry experts, underscoring the need for adaptable support systems in response to varying geotechnical conditions.

All single-solid coal models in which the unsupported RibFOS was estimated to be less than 1.5 were analyzed in this section. Initially, a single bolt was applied, and if the supported RibFOS did not reach the target value of 1.5, the bolt density was increased accordingly.

When evaluating the model results for the single-solid coal rib, it was observed that both mechanical and fully grouted bolts exhibited similar behavior and effectiveness, similar to what we observed in cases with strong roof and floor conditions. The primary distinction, when compared to strong roof and floor cases, lies in the significance of the bolt installation location. Even in scenarios where the unsupported RibFOS was as low as 0.4, the application of bolts in the optimal location generated effective support results.

The results of all models conducted under inelastic roof and floor conditions are presented in Figure 10. The figure is divided into four distinct zones. The orange-shaded region represents cases where increasing the support density was insufficient to stabilize the rib. The green region corresponds to models where the supported RibFOS exceeded the target value. Despite being marked as ineffective in terms of support practice, cases located just below the green region achieved stability through an increase in bolt density.

Figure 10.

Parametric model results for weak and moderate roof and floor conditions.

Following a detailed evaluation of each model, a rib support recommendation guideline was developed for inelastic roof and floor conditions. Since the guideline closely mirrors the one created for the single-solid coal model, no separate support recommendations were proposed for inelastic roof and floor conditions in this study.

In this study, it was observed that mechanical bolts were more effective than grouted bolts only in the specific case of ribs with solid and not weak coal. Under conditions outside this specific scenario, grouted bolts were found to perform similarly to or, in many cases, better than mechanical bolts. This difference in performance can be attributed to the distinct load transfer mechanisms of the two bolt types. Mechanical bolts primarily rely on friction and mechanical interlock at the bolt ends, which restricts their load-bearing capacity to specific points along the bolt length. In contrast, grouted bolts distribute loads uniformly along their entire length via the grout–rock interface, enabling a more consistent and effective stress distribution. Furthermore, the doweling effect created by fully grouted bolts resists coal cleat separation, thereby contributing to their superior performance, particularly in highly cleated coal seams.

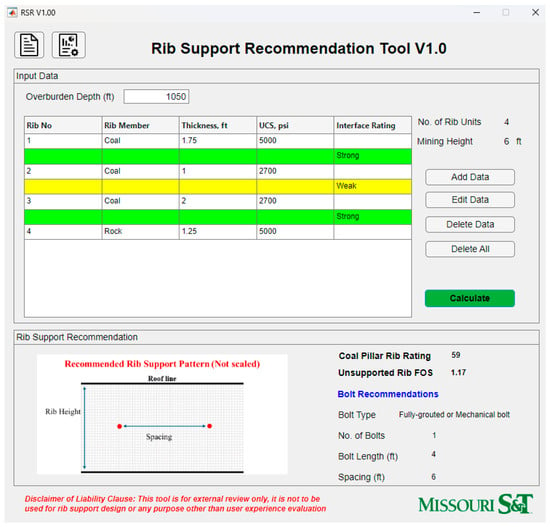

4. Development of Rib Support Recommendation (RSR) Tool

The parametric study results observed in this study were implemented into the current CPRR system. The integration of parametric study results into the CPRR system is a critical step toward refining rib support recommendations based on the inherent stability of the coal ribs. In line with the objectives, the parametric model results have been correlated with the unsupported RibFOS values predicted by the CPRR system. A comprehensive analysis of the parametric results has categorized the models into four distinct groups, with support recommendation tables created for each category. Although the goal of these tables is to assist mine professionals in making informed decisions, they encompass nearly 30 different support classes, reflecting the complexity of the problem. Due to the wide variability in the parametric results and the numerous factors considered in the models, it was not feasible to create easy-to-use support design charts. Instead, the research team has developed a user-friendly standalone application named the rib support recommendation tool (RSR) to streamline the process of determining optimal support recommendations based on site-specific conditions and model inputs. The tool can be downloaded at https://github.com/Sherizadeh/RSRV (accessed on 7 January 2025). Figure 11 shows the interface of the developed RSR tool and the user input fields.

Figure 11.

The interface of the developed RSR tool displaying the user input and the output section.

Application of Developed Rib Support Recommendations

In this section, the support practices implemented at two active mining sites are compared with the support systems recommended by the developed RSR tool.

Case A:

In the first case study, the coal seam being mined has a thickness of 78 inches at a depth of 1025 feet. The mining height for this operation is 94 inches. The rib consists of five units, with the primary thick coal units directly overlain and underlain by competent shale formations. Three distinct coal units were identified within this rib. Details regarding the rib composition, including the unit thicknesses, material strengths, and interface conditions, are summarized in Table 9. The strengths of these units were determined through both direct laboratory tests and indirect assessments using Schmidt hammer measurements (Kirmaci et al. []). During the development phase, the rib was supported with two rows of 5-foot-long, fully grouted Grade 60 bolts, with a measured spacing of 4 feet between bolts.

Table 9.

Details of the two cases with recommended support system classes.

The rib composition data presented in Table 9 were input into the RSR tool, resulting in a CPRR value of 36 and an unsupported RibFOS value of 0.37. Based on the parametric studies and the support recommendation table developed, this case falls into Category 4.B. According to this category, the recommended support system consists of two fully grouted bolts, each 5 feet in length, with a spacing of 4 feet, and mechanical bolts are not recommended for such conditions.

Figure 12 provides a screenshot of the support recommendation given by the RSR tool for this case. The figure demonstrates that the recommended support system is directly aligned with the active support practices currently implemented in the mine, identical to the predicted recommendations for Support Class 4. B.

Figure 12.

Output of the RSR tool support recommendation for Case A.

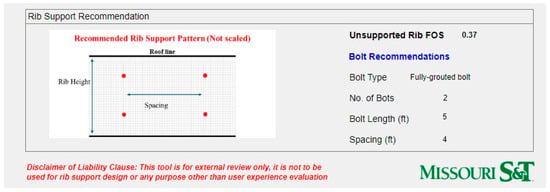

Case B:

In the second case, the mined coal seam has a thickness of 36 inches at a depth of 1050 feet, with a mining height of 72 inches. The rib comprises four units, with the major coal units bounded by massive shale layers both above and below. Within this rib, two distinct coal units have been identified. Details of the rib’s composition are provided in Table 9. During the development phase, the rib was supported using a single 5-foot-long, fully grouted Grade 60 bolt, with a spacing of 6 feet.

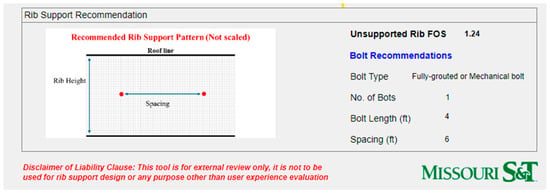

For this case, the RSR tool provided a CPRR value of 61 and an unsupported RibFOS value of 1.24. According to the parametric analyses and the support recommendation table, this case falls under Category 4. G. For this category, the recommended support system includes either one fully grouted or mechanical bolt, 4 feet in length, with a spacing of 6 feet. Figure 13 presents a screenshot of the RSR tool’s support recommendation for this case. This figure illustrates that the recommended support system closely aligns with the active support practices employed in the mine, with only a 1-foot difference in bolt length.

Figure 13.

Output of the RSR tool support recommendation for Case B.

5. Conclusions

This study presented contributes significantly to advancing health and safety in mining, with a particular focus on coal rib control. By combining field tests, numerical modeling, and a case-specific analysis, it provides a robust framework for designing effective rib support systems. Below, the key outputs of this study are summarized:

- Field pull-out tests were conducted on various bolt types, generating complex response data. These data were used to calibrate bolt parameters in numerical models, enhancing their accuracy and realism, particularly in simulating the interaction between bolts and coal ribs. The calibrated models were validated against field observations to ensure realistic support performance, which then informed more accurate parametric modeling;

- This study identifies that the Rib Support Density (RSD) alone is inadequate as a design parameter. It does not account for the effectiveness of different bolt configurations under varying conditions such as the Coal Pillar Rib Rating (CPRR), mining height, and overburden depth. This finding challenges the traditional reliance on RSD and underscores the need for tailored, case-specific support recommendations to ensure safety and efficiency in mining operations;

- A detailed case-by-case evaluation of the parametric models led to the categorization of rib support systems into four distinct groups, each associated with specific support recommendation tables. Minimum threshold values of the Unsupported Rib Factor of Safety (RibFOS) were established, marking the operational limits for rib support systems. For example, a RibFOS of 0.7 was set as a critical threshold for solid coal ribs, while a value of 0.3 was identified for ribs with rock partings;

- Over 30 distinct rib support recommendation classes were identified, primarily determined by the mining height and unsupported RibFOS, which depend on factors like CPRR and overburden depth. In more complex scenarios, this study introduced the critical coal strength (CCS) concept to refine the classification accuracy. CCS estimates the compressive strength of coal below which failure is likely to occur under certain conditions, integrating the overburden depth and mining height into the analysis;

- Mechanical bolts were found effective under certain adverse conditions, such as high mining heights and significant overburden depth, particularly in strong solid coal ribs without interfaces or partings. However, their performance was limited in weaker or thinner coal units. This study incorporates CCS and critical coal unit thickness into support recommendation classifications to better address these limitations. It suggests that mechanical bolts can be effective if the coal strength exceeds 1750–2000 psi in conditions with rock partings;

- Recognizing the complexity of rib support classifications, this study developed the rib support recommendation tool (RSR), a standalone application designed to simplify the process of determining optimal rib support strategies. The RSR tool integrates the extensive rib support recommendation classes derived from parametric models and accounts for a wide range of scenarios and influencing factors;

- In two applied cases, the rib support recommendations provided by the RSR tool showed significant potential. However, this study emphasizes that the widespread adoption of this methodology among mining professionals will require extensive validation across a broad spectrum of real-world cases.

This study lays the foundation for a more precise and effective approach to coal rib control by challenging traditional methods, and creating a user-friendly tool for rib support recommendations. By addressing the complexities of rib stability through rigorous modeling, field validation, and tailored support recommendations, this research offers significant potential for improving safety and operational efficiency in coal mining. Future work will focus on validating these findings across diverse mining conditions to ensure the robustness and adaptability of the proposed methodology.

Author Contributions

Conceptualization, A.K., D.G. and T.S.; methodology, A.K., D.G. and T.S.; software analysis, A.K., D.G. and T.S.; validation, A.K., D.G., D.R.W. and T.S.; investigation, A.K., D.G. and T.S.; data curation, A.K., D.G., D.R.W. and T.S., writing—original draft, A.K., D.G., K.E.K. and C.M.; writing, A.K., D.G., D.R.W. and T.S.; review, D.G., K.E.K., C.M., D.R.W. and T.S. visualization, A.K., D.G. and T.S.; supervision, D.G., D.R.W. and T.S.; project administration, T.S.; and funding acquisition, T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was sponsored by the Alpha Foundation for the Improvement of Mine Safety and Health, Inc. (ALPHA FOUNDATION) (Grant AFCTG22-152). The views, opinions, and recommendations expressed herein are solely those of the authors and do not imply any endorsement by the ALPHA FOUNDATION, its Directors, and staff.

Data Availability Statement

All data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Heritage, Y. Mechanics of rib deformation—Observations and monitoring in Australian coal mines. Int. J. Min. Sci. Technol. 2019, 29, 119–129. [Google Scholar] [CrossRef]

- Colwell, M.; Frith, R. ALTS 2009-a Ten Year Journey; University of Wollongong: Wollongong, Australia, 2009. [Google Scholar]

- Kang, H.; Wang, J. Rock Bolting Theory and Complete Technology for Coal Roadways; China Coal Industry Publishing House: Beijing, China, 2007. [Google Scholar]

- Xiangjun, M. Solid coal rib support technology of fully-mechanized mining along gob-side entry driving based on main roof fracture location. Coal Sci. Technol. 2020, 48, 61–67. [Google Scholar]

- Mark, C. Ground control in South African coal mines—A US perspective. In Proceedings of the Proceedings, 18th International Conference on Ground Control in Mining, Morgantown, WV, USA, 3–5 August 1999; pp. 186–193. [Google Scholar]

- Bastami, M.; Shahriar, K.; Ghadimi, M. Verification of the analytical model for fully grouted rock bolts based on pull-out test (Case study: Tabas coal mine). In Proceedings of the ISRM European Rock Mechanics Symposium—EUROCK 2017, Ostrava, Czech Republic, 20–22 June 2017. [Google Scholar]

- Cox, R.H.; Fuller, P. Load Transfer Behaviour Between Steel Reinforcement and Cement Based Grout; National Library of Australia: Canberra, Australia, 1977. [Google Scholar]

- Schmuck, C. Cable bolting at the Homestake gold mine. Min. Eng. 1979, 31, 1677–1681. [Google Scholar]

- Jin-feng, Z.; Peng-hao, Z. Analytical model of fully grouted bolts in pull-out tests and in situ rock masses. Int. J. Rock Mech. Min. Sci. 2019, 113, 278–294. [Google Scholar] [CrossRef]

- Li, X.; Aziz, N.; Mirzaghorbanali, A.; Nemcik, J. Behavior of fiber glass bolts, rock bolts and cable bolts in shear. Rock Mech. Rock Eng. 2016, 49, 2723–2735. [Google Scholar] [CrossRef]

- Mohamed, K.M.; Murphy, M.M.; Lawson, H.E.; Klemetti, T. Analysis of the current rib support practices and techniques in U.S. coal mines. Int. J. Min. Sci. Technol. 2016, 26, 77–87. [Google Scholar] [CrossRef] [PubMed]

- Kılıc, A.; Yasar, E.; Celik, A.G. Effect of grout properties on the pull-out load capacity of fully grouted rock bolt. Tunn. Undergr. Space Technol. 2002, 17, 355–362. [Google Scholar] [CrossRef]

- Blanco Martín, L.; Tijani, M.; Hadj-Hassen, F.; Noiret, A. Assessment of the bolt-grout interface behaviour of fully grouted rockbolts from laboratory experiments under axial loads. Int. J. Rock Mech. Min. Sci. 2013, 63, 50–61. [Google Scholar] [CrossRef]

- Chen, J.; Hagan, P.C.; Saydam, S. Parametric study on the axial performance of a fully grouted cable bolt with a new pull-out test. Int. J. Min. Sci. Technol. 2016, 26, 53–58. [Google Scholar] [CrossRef]

- Du, Y.-l.; Feng, G.-r.; Kang, H.-p.; Zhang, Y.-j.; Zhang, X.-h. Effects of different pull-out loading rates on mechanical behaviors and acoustic emission responses of fully grouted bolts. J. Cent. South Univ. 2021, 28, 2052–2066. [Google Scholar] [CrossRef]

- Thenevin, I.; Blanco-Martín, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Han, J.; Bi, Z.; Liang, B.; Cao, C.; Ma, S. Anchorage performance of large-diameter FRP bolts and their application in large deformation roadway. Int. J. Min. Sci. Technol. 2023, 33, 1037–1043. [Google Scholar] [CrossRef]

- Mohamed, K.; Rashed, G.; Radakovic-Guzina, Z. Loading characteristics of mechanical rib bolts determined through testing and numerical modeling. Int. J. Min. Sci. Technol. 2020, 30, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Saydam, S.; Hagan, P.C. Numerical simulation of the pull-out behaviour of fully grouted cable bolts. Constr. Build. Mater. 2018, 191, 1148–1158. [Google Scholar] [CrossRef]

- Chen, J.; Li, D. Numerical simulation of fully encapsulated rock bolts with a tri-linear constitutive relation. Tunn. Undergr. Space Technol. 2022, 120, 104265. [Google Scholar] [CrossRef]

- Saadat, M.; Taheri, A. Effect of contributing parameters on the behaviour of a bolted rock joint subjected to combined pull-and-shear loading: A DEM approach. Rock Mech. Rock Eng. 2020, 53, 383–409. [Google Scholar] [CrossRef]

- Chen, J.; Liu, L.; Zeng, B.; Tao, K.; Zhang, C.; Zhao, H.; Li, D.; Zhang, J. A constitutive model to reveal the anchorage mechanism of fully bonded bolts. Rock Mech. Rock Eng. 2023, 56, 1739–1757. [Google Scholar] [CrossRef]

- Jahangir, E.; Blanco-Martín, L.; Hadj-Hassen, F.; Tijani, M. Development and application of an interface constitutive model for fully grouted rock-bolts and cable-bolts. J. Rock Mech. Geotech. Eng. 2021, 13, 811–819. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, Z.; Nie, W.; Gui, Y. A numerical model of fully grouted bolts considering the tri-linear shear bond–slip model. Tunn. Undergr. Space Technol. 2016, 54, 73–80. [Google Scholar] [CrossRef]

- Nemcik, J.; Ma, S.; Aziz, N.; Ren, T.; Geng, X. Numerical modelling of failure propagation in fully grouted rock bolts subjected to tensile load. Int. J. Rock Mech. Min. Sci. 2014, 71, 293–300. [Google Scholar] [CrossRef]

- Hyett, A.J.; Bawden, W.F.; Reichert, R.D. The effect of rock mass confinement on the bond strength of fully grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 503–524. [Google Scholar] [CrossRef]

- Xu, C.; Li, Z.; Wang, S.; Wang, S.; Fu, L.; Tang, C. Pullout performances of grouted rockbolt systems with bond defects. Rock Mech. Rock Eng. 2018, 51, 861–871. [Google Scholar] [CrossRef]

- Nie, W.; Guo, W.; Ma, S.; Zhao, Z. Numerical modelling of fully grouted rockbolts subjected to shear load. Rock Mech. Rock Eng. 2020, 53, 2493–2503. [Google Scholar] [CrossRef]

- Luga, E.; Periku, E. A pioneer in-situ investigation on the bearing capacity and failure causes of real scale fully grouted rockbolts. Constr. Build. Mater. 2021, 310, 124826. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, Z.; Nie, W.; Zhu, X. An analytical model for fully grouted rockbolts with consideration of the pre- and post-yielding behavior. Rock Mech. Rock Eng. 2017, 50, 3019–3028. [Google Scholar] [CrossRef]

- Nie, W. Reinforcement Mechanism of Rockbolt System for Underground Excavation. Doctoral Thesis, Nanyang Technological University, Singapore, 2019. [Google Scholar]

- Giot, R.; Auvray, C.; Raude, S.; Giraud, A. Experimental and numerical analysis of in situ pull-out tests on rock bolts in claystones. Eur. J. Environ. Civ. Eng. 2021, 25, 2277–2300. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, H.; He, F.; Zhang, J.; Tao, K. Studying the performance of fully encapsulated rock bolts with modified structural elements. Int. J. Coal Sci. Technol. 2021, 8, 64–76. [Google Scholar] [CrossRef]

- Tulu, I.B.; Esterhuizen, G.S.; Heasley, K.A. Calibration of FLAC3D to simulate the shear resistance of fully grouted rock bolts. In Proceedings of the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012. [Google Scholar]

- Kirmaci, A.; Guner, D.; Karadeniz, K.E.; Wijesinghe, D.R.; Sherizadeh, T. Examining coal rib stability using mechanical bolts: An experimental and numerical study. Int. J. Geomech. 2024. accepted. [Google Scholar]

- Mohamed, K.; Xue, Y.; Guner, D.; Kirmaci, A.; Sherizadeh, T. Examining pull-out tests for grouted rib bolts: A comprehensive analysis. In Proceedings of the SME Annual Conference & EXPO, Phoenix, AZ, USA, 25–28 February 2024. [Google Scholar]

- Mohamed, K.M.; Tulu, I.B.; Klemetti, T. Numerical simulation of deformation and failure process of coal-mass. In Proceedings of the 49th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 29 June–1 July 2015. [Google Scholar]

- Guner, D.; Sherizadeh, T.; Nowak, S.; Karadeniz, K.E.; Sunkpal, M. Distinct element analysis for the effectiveness of preliminary coal pillar rib support systems based on the strength reduction method using coal mass constitutive model. Min. Metall. Explor. 2023, 40, 1535–1546. [Google Scholar] [CrossRef]

- Rashed, G.; Sears, M.; Addis, J.; Mohamed, K.; Wickline, J. A case-study of roof support alternatives for deep cover room-and-pillar retreat mining using in-situ monitoring and numerical modeling. In Proceedings of the SME Annual Meeting, Denver, CO, USA, 24–27 February 2019; pp. 25–28. [Google Scholar]

- Liu, H.; Sang, S.; Xue, J.; Wang, G.; Xu, H.; Ren, B.; Liu, C.; Liu, S. Characteristics of an in situ stress field and its control on coal fractures and coal permeability in the Gucheng block, Southern Qinshui basin, China. J. Nat. Gas Sci. Eng. 2016, 36, 1130–1139. [Google Scholar] [CrossRef]

- Esterhuizen, G.S. (National Institute for Occupational Safety and Health, Pittsburgh Mining Research Division, Pittsburgh, USA). Personal communication, 2017.

- Xue, Y.; Mohamed, K.M. Stability analysis of coal rib with rock parting based on the strength reduction of the coal mass model. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Online, 18–25 June 2021. [Google Scholar]

- Carranza-Torres, C. Analytical and numerical study of the mechanics of rockbolt reinforcement around tunnels in rock masses. Rock Mech. Rock Eng. 2009, 42, 175–228. [Google Scholar] [CrossRef]

- Sherizadeh, T. Reducing Rib Hazards in Underground Coal Mines by Improvement of the Coal Pillar Rib Rating (CPRR) System. 2023. Alpha Foundation for the Improvement of Mine Safety and Health, Final Technical Report (AFCRFP20 -112). Available online: https://www.alpha-foundation.org/wp-content/uploads/2023/07/AFCRFP20-112_MST_FinalRpt.pdf (accessed on 7 January 2025).

- Sherizadeh, T.; Dogukan, G.; Kutay, E.K.; Samuel, N.; Alper, K. A New Strain-Softening Anisotropic Constitutive Model for Coal Mine Roof Simulation. In Proceedings of the 42nd International Conference on Ground Control in Mining, Canonsburg, PA, USA, 24–27 July 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).