1. Introduction

In response to the numerous high-acceleration events recorded in recent earthquakes, there has been rising interest within the engineering community in understanding the seismic response of soil–structure systems under conditions that exceed conventional design limits. While performance-based design, which incorporates the nonlinear behavior of structural elements, has been a standard practice in superstructure design for years, the application of this concept in foundation design as a viable seismic retrofitting practice is commonly neglected [

1]. In this regard, innovative non-structural methods have been developed to control seismic responses, among which the rocking isolation design philosophy is becoming increasingly recognized as a promising concept in mitigating seismic forces on structures.

Previous observations have shown that the soil–foundation system can offer significant potential in seismic force control and energy dissipation through geometric nonlinearity (i.e., foundation uplift and sliding) and material nonlinearity (i.e., bearing capacity mobilization). Examples of high-rise structures supported by shallow foundations are abundant, with rocking and uplift effects extensively studied across various types, including bridges [

2,

3,

4], buildings [

5,

6,

7,

8,

9,

10,

11,

12], and wind turbine towers [

13,

14,

15].

As for bridge foundations, Deng et al. [

3] introduced a direct displacement-based design approach for the seismic design of rocking shallow foundations subjected to earthquake loading. Their method incorporates a multilinear model to represent the nonlinear moment–rotation behavior, along with a new empirical relationship that connects initial rotational stiffness with moment capacity. Antonellis et al. [

4] conducted large-scale shake table tests on bridge columns supported by two shallow foundations—one with aligned loading and the other skewed. Their findings showed that for peak drift ratios up to 6.9%, the rocking foundations performed well, with residual drift ratios of 0.5 to 0.9%, depending on backfill conditions, minimal settlement, and no structural damage.

In the context of building foundations, Gelagoti et al. [

10] compared conventional and rocking isolation designs through the numerical analysis of a one-bay, two-story reinforced concrete frame. They found that while both systems performed well under moderate seismic shaking, the rocking-isolated system was superior during very strong shaking, surviving with no column damage and non-negligible, repairable damage to beams and non-structural elements. Liu et al. [

11] and Liu [

12] investigated the performance of two-story-one-bay buildings in a series of centrifuge tests. They indicated that a balanced design, where the rocking foundation and structural fuse are intended to yield at approximately the same load, results in a well-controlled seismic-resisting system with much lower seismic ductility demands on structural components. Conversely, if the footing is restrained from rocking, the ductility demand on structural components is significantly higher than if the foundation were allowed to rock.

Ajaei and El Naggar [

13] explored using the rocking foundation concept to adapt shallow wind turbine foundations for higher-capacity turbines. They found that relaxing the no-uplift regulation during normal operations allows the installation of larger turbines on foundations initially designed for smaller ones, without compromising safety or serviceability. Ifeobu et al. [

14] investigated the long-term laterally cyclic behavior of onshore wind turbine foundations using Particle Image Velocimetry (PIV) through a series of centrifuge tests. They indicated that accumulated settlement and rotation can potentially reach the serviceability limit state (SLS) design limit outlined by current design guidelines. Wang and Ishihara [

15] compared two Winkler models to assess the impact of foundation uplift on wind turbine seismic loads. One model simulated foundation uplift, while the other did not. Their findings showed that including foundation uplift reduced the tower base moment but increased the bending moment in the foundation cross-section. In this context, common wind turbine support structure codes and guidelines address the potential for foundation uplift under specific loading conditions. DNVGL-ST-0126 [

16] requires that the foundation withstand repeated gapping cycles without negative effects, ensuring the stress state at the interface maintains soil plane shape stability beneath the foundation throughout its operational lifespan. DNV allows gapping up to the center of gravity of the foundation in some load cases. Meanwhile, IEC 61400-6 [

17] recommends a zero-gapping criterion to keep the foundation in full contact with the soil in certain load cases, preventing soil capacity or stiffness degradation, but does allow gapping under specific conditions if certain requirements are met.

Primary challenges in adopting the rocking isolation design philosophy include potential excessive rotation and settlement of the foundation, risk of structure overturning, and uncertainty in soil properties, which collectively limit its widespread use [

18]. Excessive deformation is a key concern, for which soil improvement techniques like shallow compaction [

1,

19,

20,

21,

22,

23,

24], geotextile reinforcement [

20,

25], unattached piles [

26,

27,

28], and soil–cement grids [

29] have been studied. Moreover, due to the kinematic and cyclic nature of earthquake loading, failures within the soil–foundation system and structural overturning are relatively rare. Finally, foundations with higher safety factors exhibit less sensitivity to subgrade characteristics, reducing concerns related to uncertainties in soil parameters. While most studies on rocking foundations focus on surface foundations, embedded foundations are more commonly used in practice for several reasons, including the weakness of surface soil layers, the need for greater bearing capacity, protection against scour, and avoiding interference at ground level. As a result, embedded foundations provide a more realistic representation of a rocking system’s behavior, influencing key performance aspects such as moment capacity and settlement.

Prior studies have shown that the performance of embedded rocking foundations is considerably different from that of surface foundations. Ko et al. [

30] found that side soil resistance in embedded foundations increases moment capacity, while Hakhamaneshi and Kutter [

31] noted that the uplift mechanism increases and settlement decreases with embedment. Sharma and Deng [

32] considered embedment depth as a part of their investigation in a series of field tests on cohesive soils. They observed that significant sliding in surface foundations was effectively mitigated by embedment, with embedded footings displaying increased uplift and reduced permanent settlement. Mousavi et al. (2022) [

33] investigated the rocking performance of embedded foundations using experimental testing and numerical modeling. They reported a reduction in the rotation and settlement of the foundation when subjected to rocking motions.

A deeper understanding of the factors influencing the performance of rocking foundations and their associated soil deformation mechanisms is essential for their reliable and broader application. Foundation embedment depth plays a crucial role in rocking behavior, yet research in this area remains limited [

34]. Notably, previous studies have not comprehensively characterized the soil–foundation behavior of embedded foundations in terms of key performance metrics alongside soil deformation mechanisms under varying loading and soil conditions. This gap highlights the need for a more focused and detailed investigation. This study aims to address this gap by investigating the effect of embedment depth on the rocking performance of shallow foundations under different subgrade relative densities and initial vertical factors of safety through a series of 1 g, slow cyclic loading experiments. First, a strip foundation with a PIV setup is used to examine the soil deformation mechanisms of rocking foundations with various embedment depths. Following this, a square foundation is tested to evaluate the embedment effects in terms of foundation moment capacity, damping ratio, settlement response, rotational stiffness, and recentering capability.

2. Physical Model Configuration and Test Program

This study explores the rocking behavior of a rigid single-degree-of-freedom (SDOF) structure placed on dry sand under slow cyclic lateral loading. This section details the components of the physical model, reviews the test preparation process, describes the loading procedure, and presents the test program.

2.1. Subgrade Properties and Preparation Procedure

Firouzkouh dry silica sand (code D1) was used to prepare the subgrade with the desired density, employing the sand raining technique.

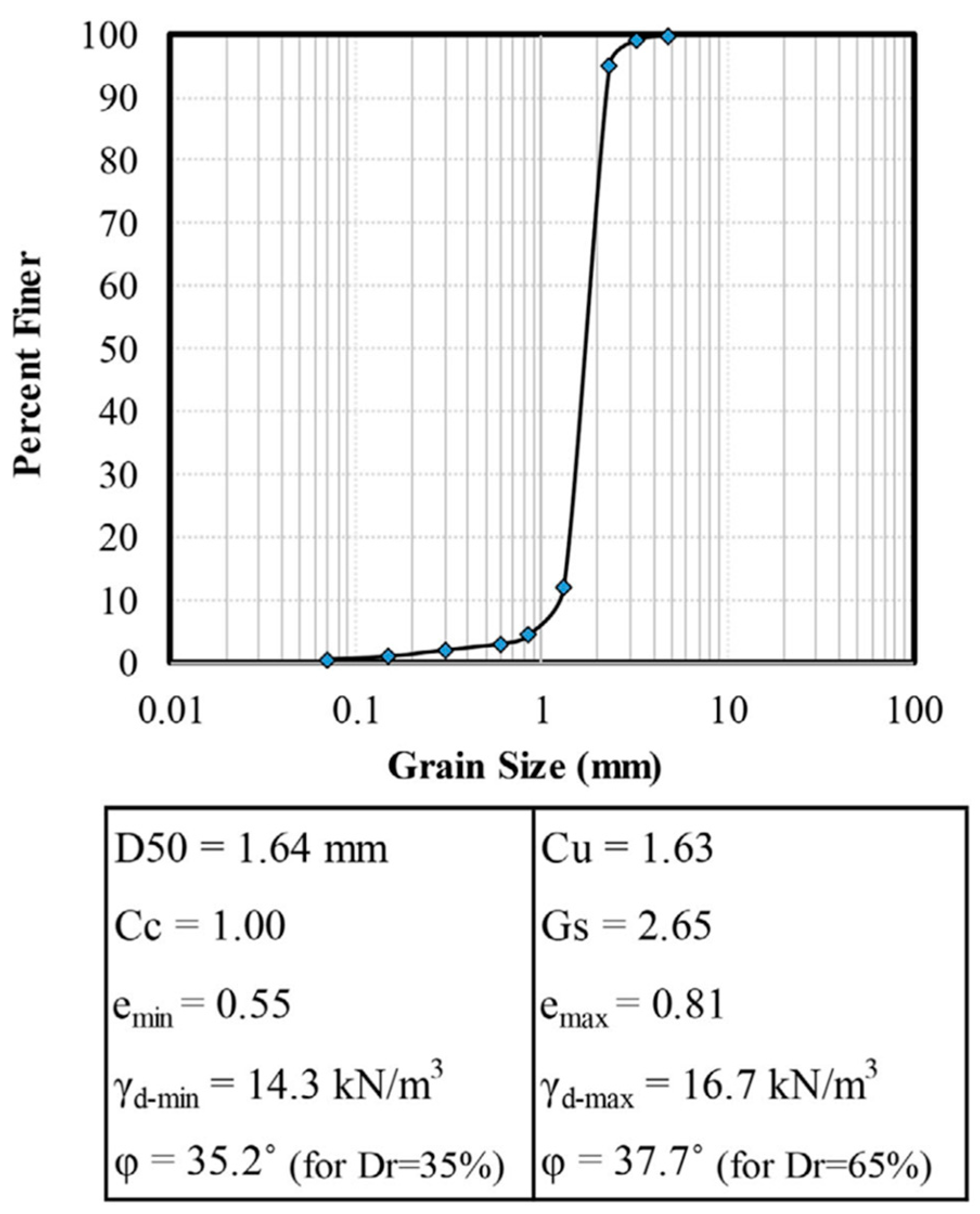

Figure 1 shows the grain size distribution and key characteristics of the sand. Minimum and maximum void ratios (e

min and e

max) were determined as per ASTM D-4253 and ASTM D-4254 [

35,

36]. The raining height and rate were adjusted to meet the target density, with the hopper covering the entire soil tank surface to ensure uniform density. Relative densities of 35% and 65% were targeted for loose and dense subgrades, corresponding to dry unit weights of 15.4 and 16.1 kN/m

3, achieved with raining heights of 10 cm and 60 cm, respectively. Uniformity was verified by measuring the density at multiple locations within the tank. This was undertaken by collecting sand in containers of known volume during the raining process and then weighing them.

Table 1 shows the relative density data for three points, confirming the sand raining system produced uniform density throughout the tank. The tank dimensions are sufficiently large to eliminate any boundary effects during modeling. Specifically, for the square foundation, the tank length exceeds 8 times the foundation width in the loading direction and 5 times the width perpendicular to the loading direction. Additionally, the tank depth extends to 5 times the foundation width.

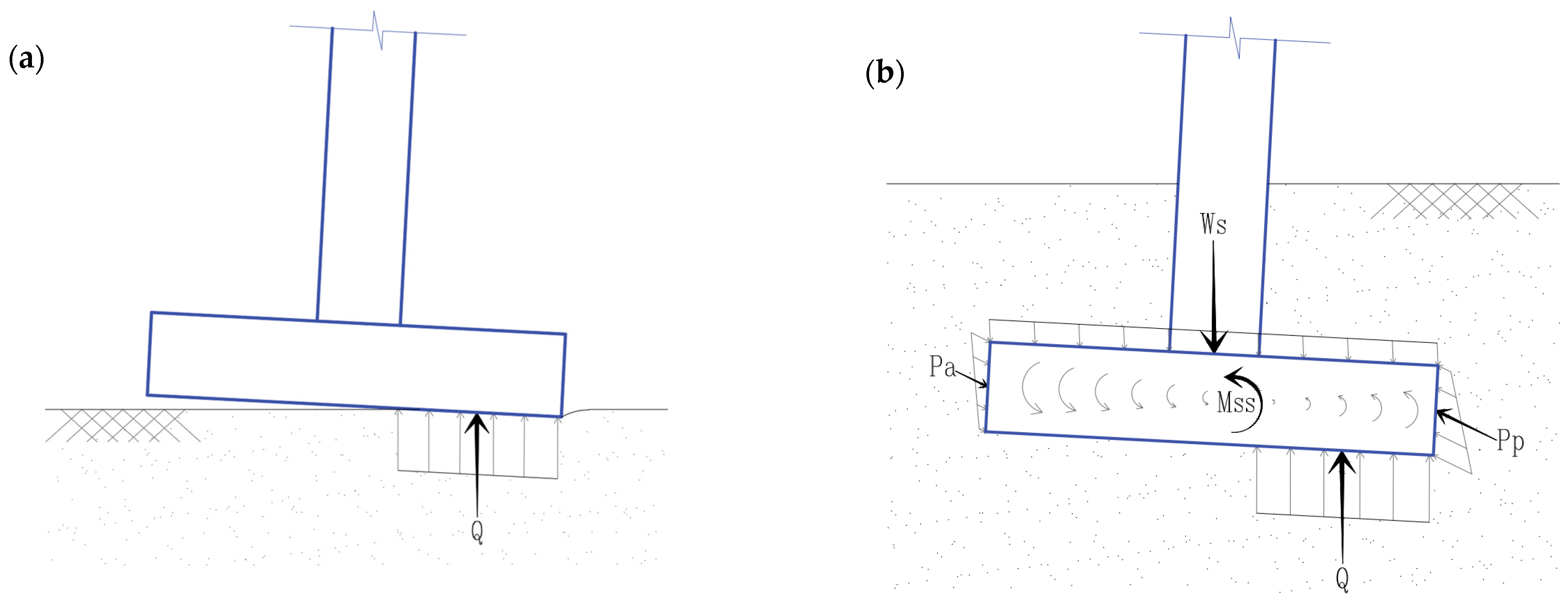

2.2. Physical Model

A soil tank with rigid walls, measuring 126 × 80 × 75 cm (length × width × height), was used to model the foundation subgrade. The structure, modeled as a single-degree-of-freedom (SDOF) system, includes a footing, a column, and a concentrated mass. These components are rigidly connected to ensure deformations occur only within the soil–foundation system. Steel plates, positioned 45 cm above the foundation base on either side of the column, provide the concentrated mass. The footings, designed in square and strip shapes, are fabricated using steel plates with a thickness of 2 cm. The column, a steel box profile 8 cm wide and 2 mm thick, is designed to behave rigidly for the loading range considered. To replicate concrete-to-subgrade friction, an abrasive sheet (sandpaper) was attached to the footing base. Direct shear tests showed friction angles between the sand and abrasive sheet of 33.6° and 35.3° for soil relative densities of 35% and 65%, respectively.

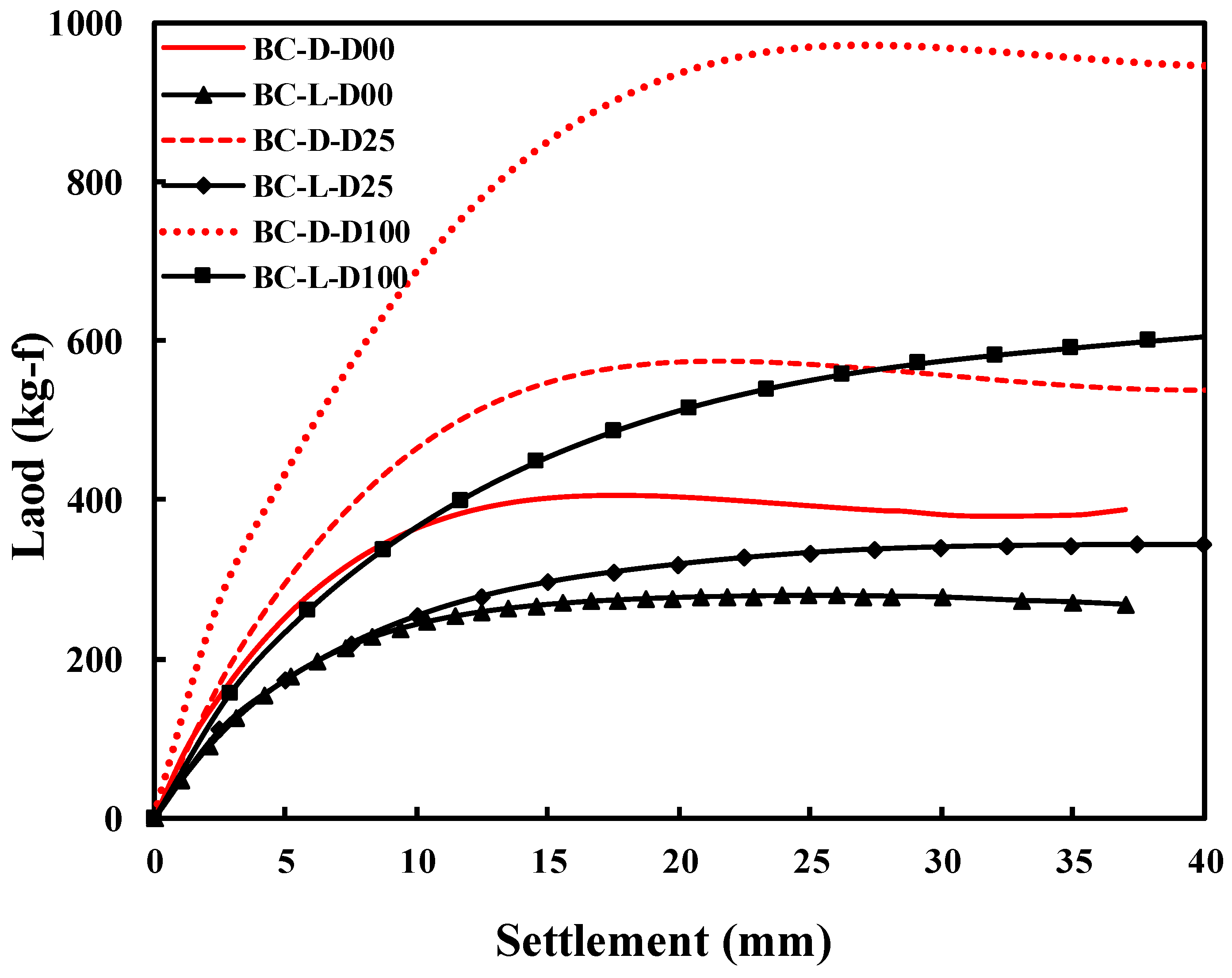

The initial vertical factor of safety (FSv) of the foundations was calculated by dividing the ultimate vertical bearing capacity of the foundation by the structure’s weight. The ultimate bearing capacity of the square foundation was determined using vertical bearing capacity tests with the vertical loading system, while the strip foundation’s capacity was obtained using the conventional bearing capacity equation and the back-calculated Nq from the square foundation bearing capacity tests. A pneumatic vertical loading system was used to conduct the bearing capacity tests, consisting of a pneumatic jack, load cell, loading shaft, and linear variable differential transformer (LVDT). The ultimate bearing capacity is defined as the load at which the load–settlement curve reaches its peak, or, if no peak is observed, the load at which the rate of change in vertical stiffness becomes constant [

1,

19,

30]. The corresponding values at these points and complete details of the tests are provided in

Table 2, while the bearing capacity test curves are shown in

Figure 2. The test naming convention in

Table 2 has three parts: “BC” for bearing capacity tests (constant in all related tests), “D” denotes a dense bed (Dr = 65%), “L” indicates a loose bed (Dr = 35%), and the third part indicates foundation embedment depth in millimeters.

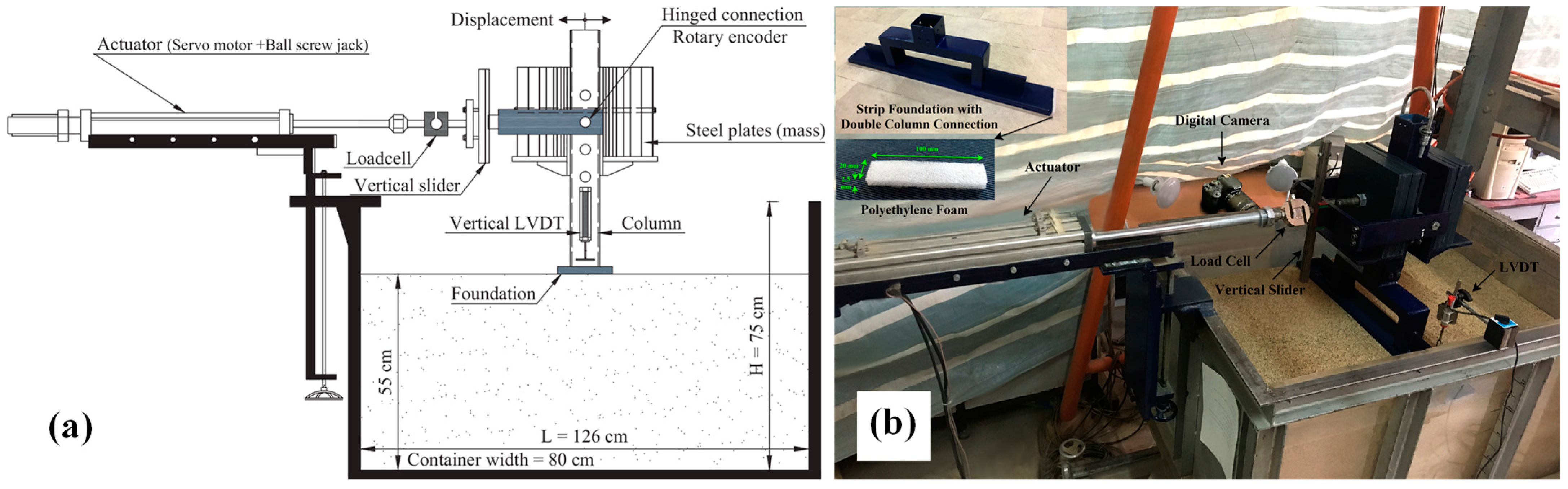

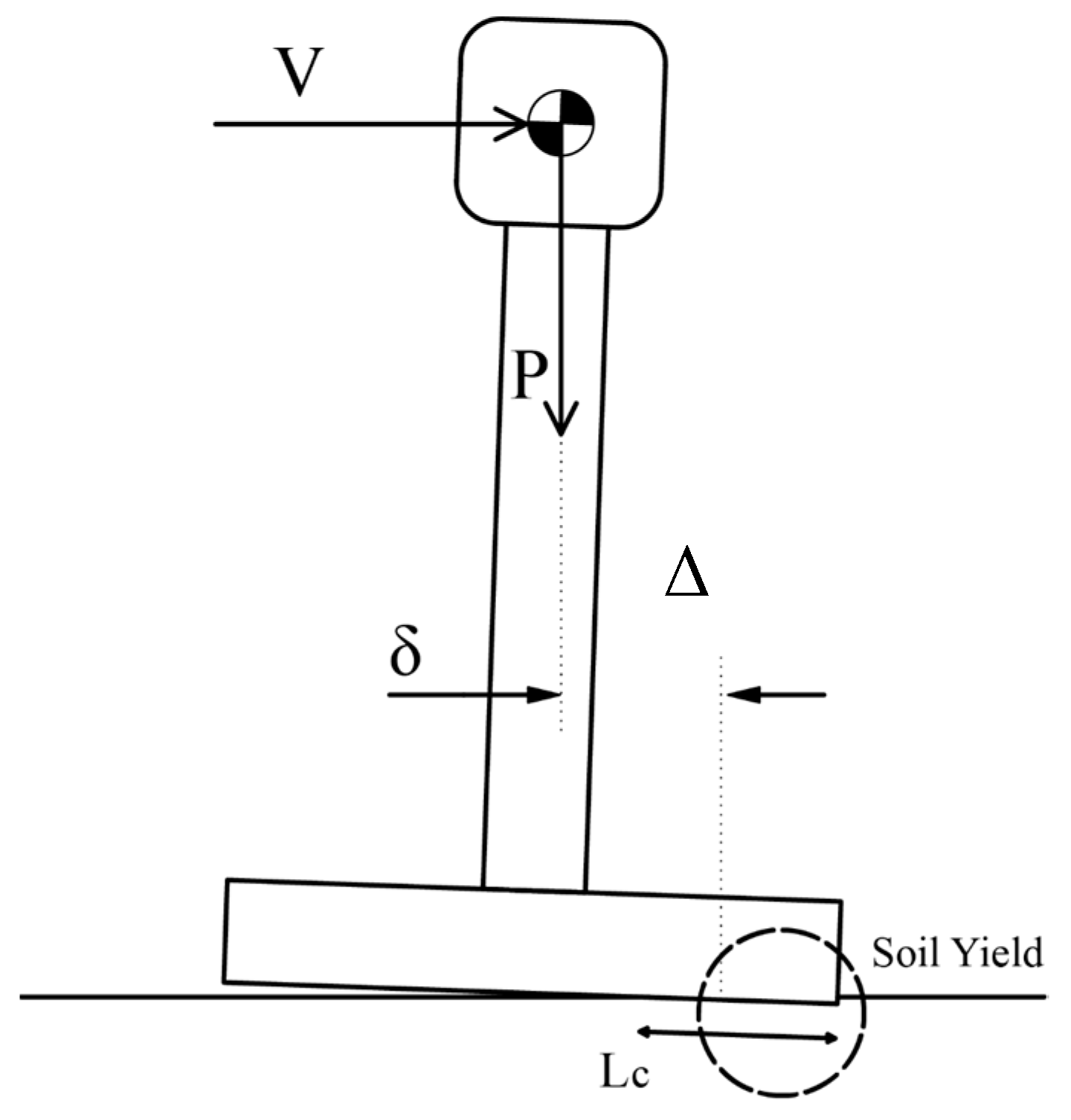

Figure 3a,b show the horizontal loading system and structural model. The center of mass of the structure is displaced horizontally by a displacement control actuator attached to the tank wall. As shown in

Figure 3a, the actuator connects to the structure through shear joints and pin connections, allowing for free rotation and settlement. The actuator’s height is adjustable to ensure precise displacement at the pin connection. The vertical load, reflecting different FSv values, is provided by the combined weight of the lumped mass and structural mass of the model. A load cell measures the load applied to the structure between the actuator and shear joint. Vertical displacements are monitored using an LVDT, while a rotary encoder tracks the structure’s rotation at the pin connection. These instruments feed data to a data logger, which continuously records and transmits the information to a computer.

In Test Series 1, a strip footing with dimensions of 10 cm (width) × 79.5 cm (length) × 2 cm (thickness) was placed transversely within the tank to simulate a 2D plane strain condition. This setup allowed for the clear visibility and detection of particle movement through the Plexiglas plate.

To prevent direct contact between the Plexiglas wall and the strip footing, the foundation was made 5 mm narrower than the tank’s width, allowing for free rotation and settlement during cyclic loading. A 2.5 mm gap on each side between the foundation and the Plexiglas plates was filled with polyethylene foam sheets (

Figure 3b), cut to match the foundation’s cross-sectional dimensions (2 × 10 cm) with a thickness of 2.5 mm. The foam sheets, glued to the foundation’s cross-section, prevent sand from entering the gap while still allowing the foundation to move freely. In Test Series 2, a square steel footing with a width of 15 cm and a thickness of 2 cm was used.

2.3. Loading Protocol and Testing Program

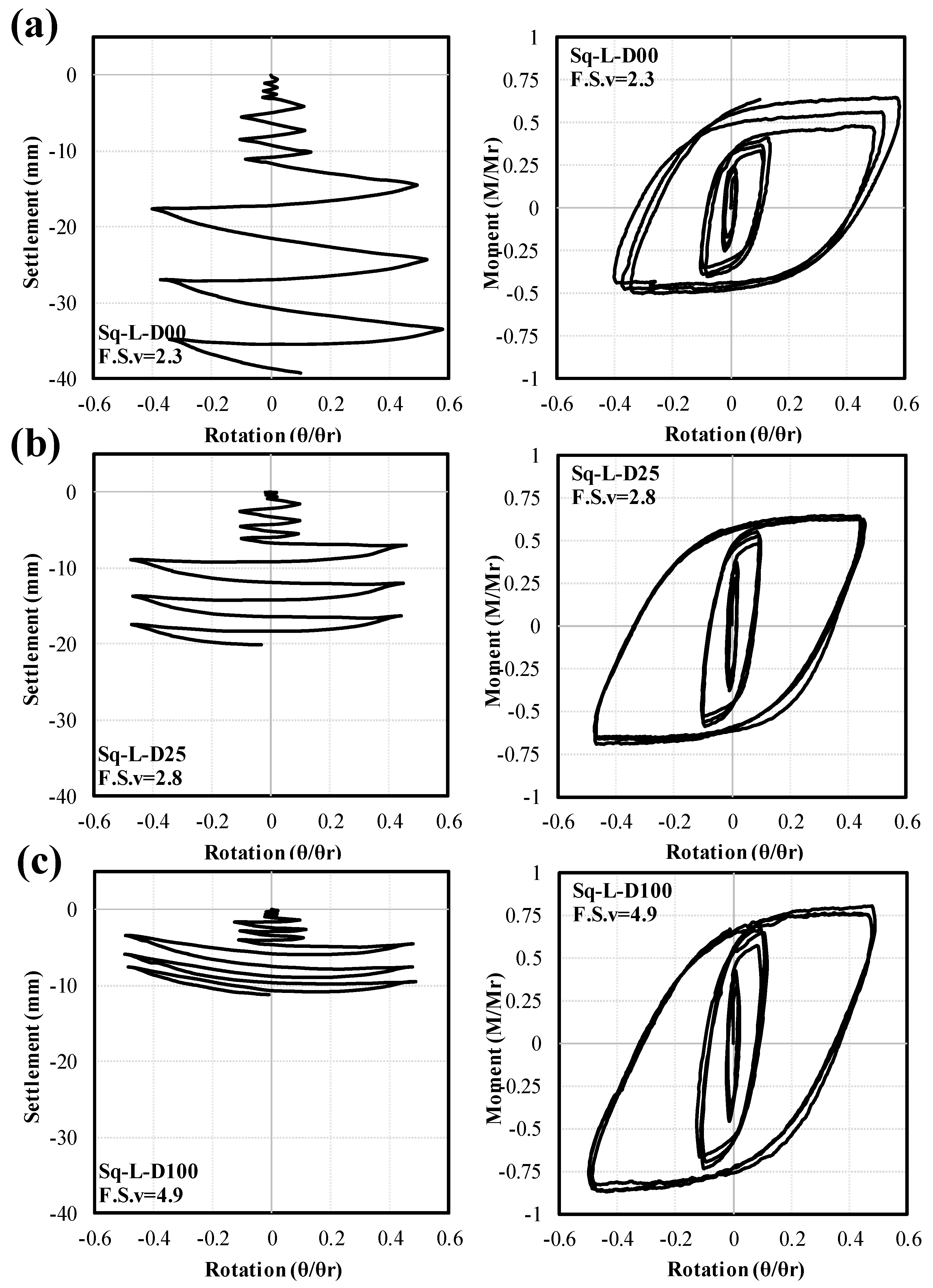

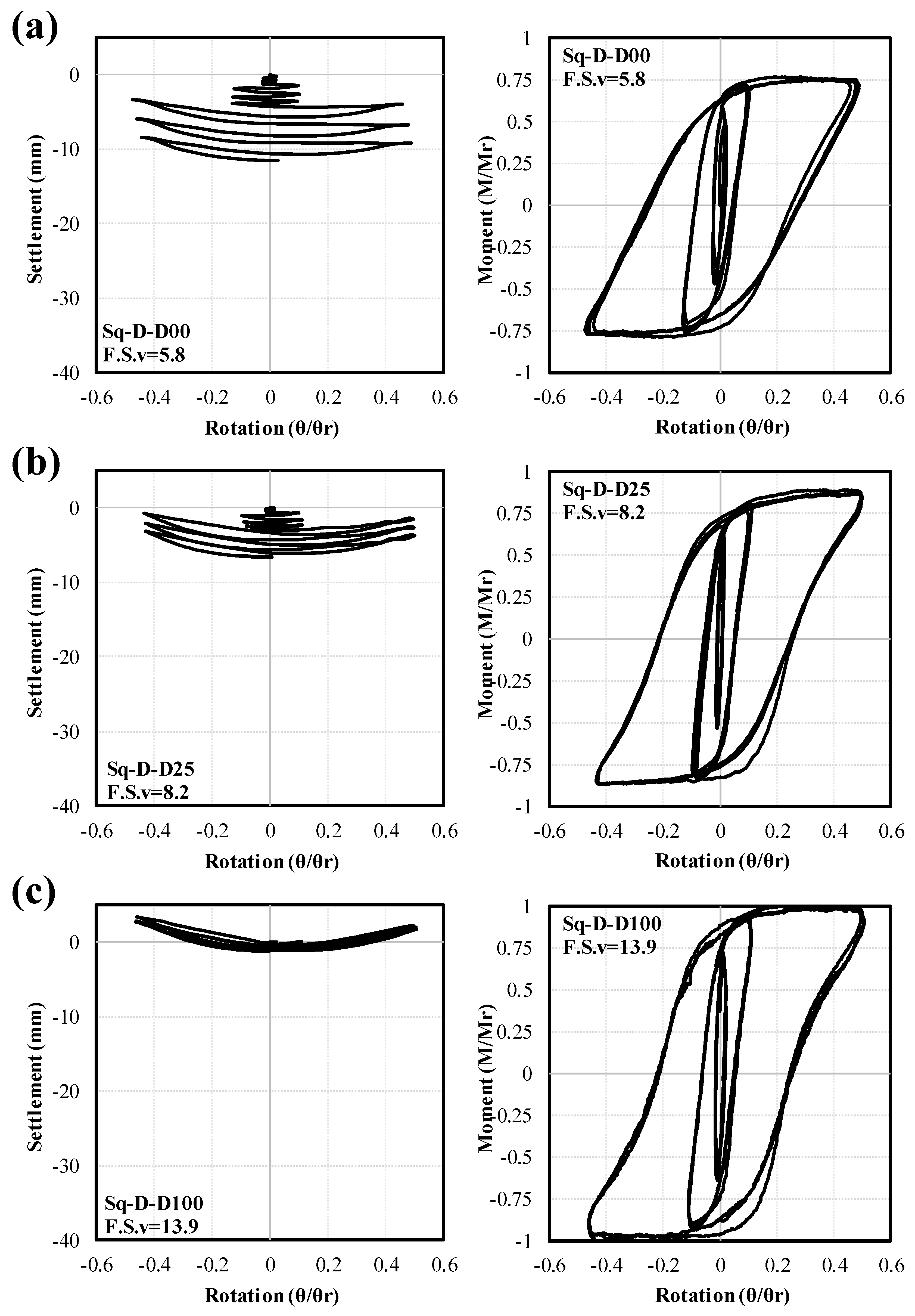

Slow cyclic lateral loading tests were conducted on strip and square foundations with the test specifications provided in

Table 3. The naming convention for the strip foundation tests consists of two parts: the first part represents the foundation shape (strip) and the second part indicates the depth of the foundation in millimeters. On the other hand, the naming convention for the square foundations includes three parts: the first part represents the foundation shape (square), the second part indicates the density state of the subgrade (dense or loose), and the third part specifies the depth of the foundation in millimeters.

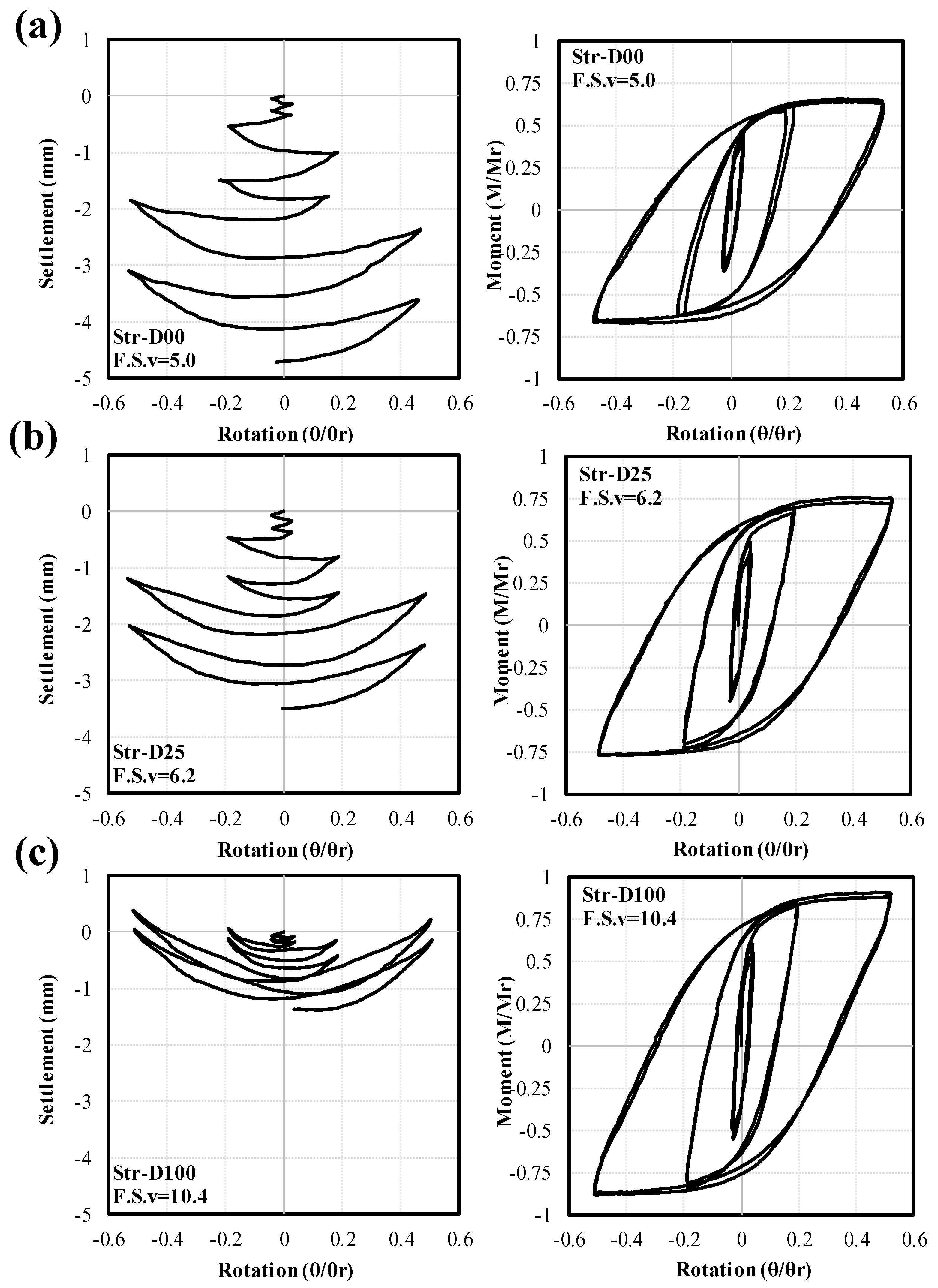

The aim of this study was to examine the rocking behavior of foundations with varying embedment depths and FSv values. To achieve this, different subgrade relative densities (35% for loose subgrade and 65% for dense subgrade) and different structural masses (70 kg, 120, and 300 kg) were used to create a range of FSv values. The effect of embedment depth was systematically studied by considering surface, slightly embedded (25 mm), and deeply embedded (100 mm) foundations. Based on these variables, nine tests were conducted with FSv values ranging from 2.3 to 13.9, and the test names and specifications are detailed in

Table 3.

In this research, the structure model underwent slow periodic displacements using a lateral loading system under 1 g conditions. Previous studies have examined the rocking behavior of foundations under four loading conditions: 1 and 2—scaled experiments under 1 g conditions with dynamic loading (shake table) or slow cyclic loading; 3 and 4—centrifuge testing (Ng acceleration) with dynamic loading (shake table) or slow cyclic loading.

Among these methods, centrifuge testing and shake table experiments are particularly beneficial. Centrifuge testing reduces scale effects and better simulates actual stress levels, while shake tables more accurately replicate seismic events and inertial loads. Both methods are ideal for studying how various factors affect stresses and deformations in the structure and subgrade soil. However, slow cyclic loading has its own advantages when examining the rocking behavior of soil–foundation systems. It generates clearer, more organized moment–rotation and settlement–rotation diagrams than dynamic loading, allowing for a more detailed understanding of the behavior. Additionally, under slow cyclic loading, soil deformations are solely due to foundation displacements, whereas dynamic loading introduces complexities from inertia due to imposed acceleration, making the results harder to interpret [

19,

37,

38].

The effectiveness of 1 g slow cyclic loading in studying rocking foundations is supported by prior research. Kokkali et al. [

39] found a strong correlation between the results under the 1 g and centrifuge conditions, particularly in behaviors like stiffness degradation, energy dissipation, and cyclic moment overstrength. They also observed similar moment–rotation and settlement–rotation diagrams, along with comparable rotational stiffness in both testing environments. Gajan et al. [

40] further demonstrated that the moment–rotation backbone curve of slow cyclic loading closely matches that of dynamic loading tests. They concluded that slow cyclic loading results can predict the performance of a soil–foundation system under dynamic loading, particularly for rigid structures [

41].

For structural materials, no scaling adjustments were applied due to the rigidity of the structure. Additionally, the tests were conducted at a sufficiently slow loading rate to simulate pseudo-dynamic conditions, effectively minimizing any potential inertial effects. Reduced-scale experiments inherently fail to replicate the exact stress conditions present in the supporting soil —a limitation addressed through centrifuge modeling. This limitation is particularly significant for sand, given its stress-dependent strength and stiffness. These discrepancies, known as scale effects, require the careful interpretation of experimental results. To mitigate these effects in this study, vertical push tests were conducted on a 15 cm square foundation to evaluate the soil’s bearing capacity under all conditions prior to the main tests.

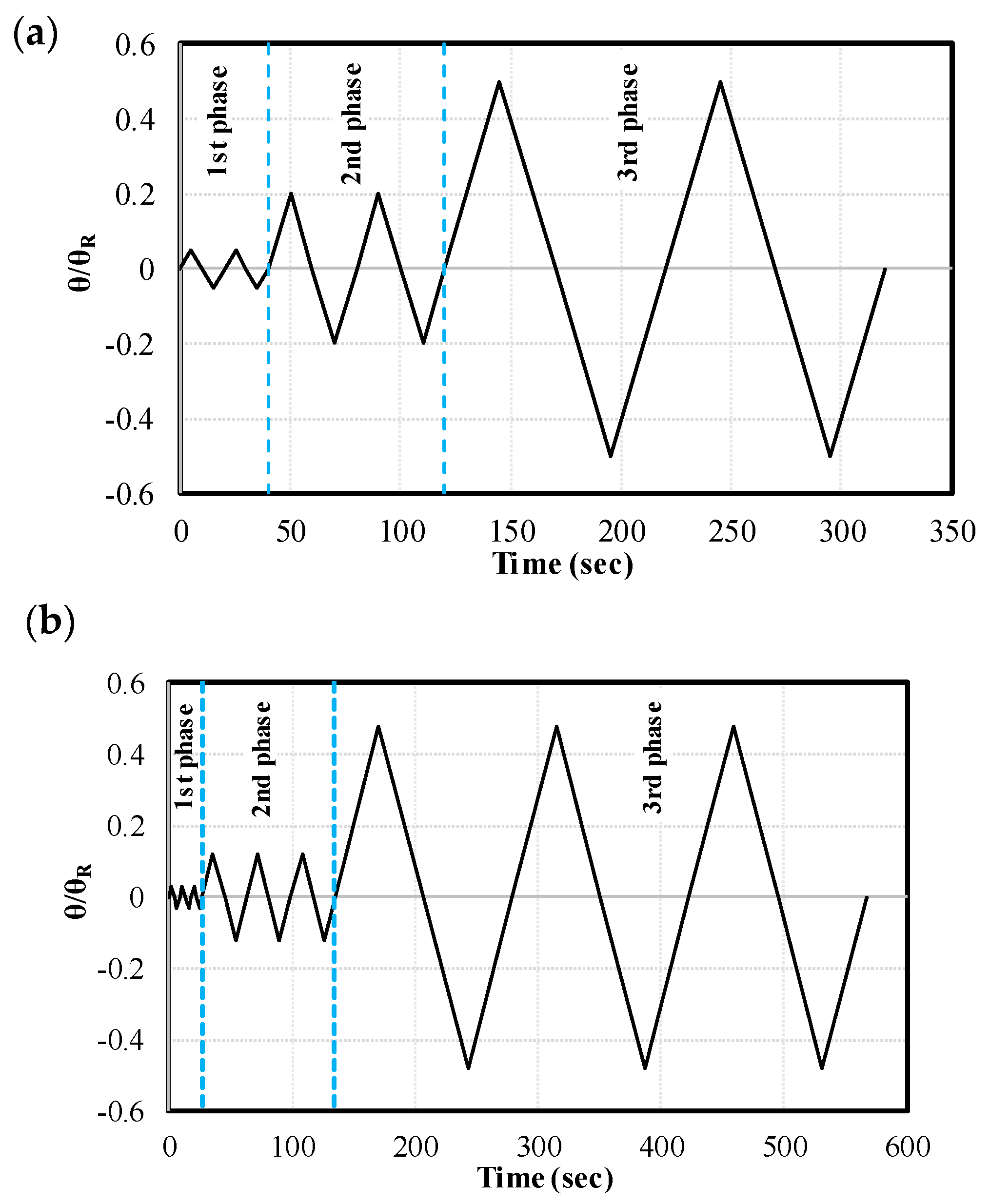

The lateral loading pattern applied to the strip footing is shown in

Figure 4a. It consists of three phases with displacement amplitudes of 2.5 mm, 10 mm, and 25 mm (equivalent to θ/θ

R of 0.05, 0.2, and 0.5), representing small, medium, and large displacements (θ represents the rotation of the foundation relative to its initial position and θ

R denotes the threshold rotation for overturning the foundation resting on a rigid base). Each phase includes two similar cycles. To minimize structural inertia effects, the loading speed was set to 0.5 mm/s in the first phase and 1 mm/s in the next two phases, resulting in a total test time of 320

s. Due to the large volume of photos in the PIV tests (one image every two seconds), only two cycles were conducted per phase.

Moreover, the loading pattern applied to the square foundation is shown in

Figure 4b. It includes three phases with displacement amplitudes of 2.25 mm, 9 mm, and 36 mm (equivalent to θ/θ

R of 0.03, 0.12, and 0.48). Each phase consists of three similar cycles. Since repeating cycles with a constant rotation amplitude did not significantly affect behavior, further repetitions were omitted. The loading speed of 1 mm/s resulted in a total test time of 567

s.

3. Image Processing Using Particle Image Velocimetry (PIV) Technique

The Particle Image Velocimetry (PIV) method, also known as Digital Image Correlation (DIC), is a velocity measurement technique that tracks and analyzes the movement of particles in a moving medium by comparing images taken at specific time intervals. PIV evolved from the Laser Doppler Velocimetry (LDV) technique, originally developed for fluid mechanics experiments to study fluid flow mechanisms. In this method, laser pulses visualize particles added to a moving fluid at different time intervals, allowing for the evaluation of the fluid flow pattern at the particle locations, assuming the particles move with the flow. As soil displacement in phenomena like landslides, earthquakes, wave propagation, and pile penetration can be viewed as slow fluid flow, the PIV method was introduced by White et al. (1993) for studying soil deformation in geotechnical research [

42].

For PIV analysis, digital images can be extracted from video frames or captured directly with a digital camera. Digital cameras provide higher resolution and better image quality than video frames. Unlike fluid mechanics, where images are frequently taken from videos, the slow deformation rates of geotechnical phenomena typically permit direct image capture in geotechnical studies.

In PIV analysis, a certain level of contrast (texture) is necessary for reliable results. Fluids are typically textured with particles (colored powders) to enhance image distinction. In clay, this texture is artificially created by adding colored sand or other materials. However, sandy materials inherently possess texture due to the shape, color, and size of the sand particles, as well as the voids between them. This inherent texture is visible in

Figure 5. Therefore, given the high quality of the images obtained in this study, there is no need to add additional materials to the sand to enhance texture. Two 40-watt UFO LED lamps were installed on either side of the imaging plane at an angle of approximately 45 degrees so that the camera could capture a uniformly clear view of the soil in the tank. Using two light sources positioned at an angle and on both sides of the camera prevents light reflection and shadow formation in the imaging area.

In this study, a Canon EOS 700D digital camera (resolution: 5184 × 3456 pixels) was used to capture images continuously at 2

s intervals. The camera was positioned perpendicular to the plexiglass wall, covering a 48 × 32 cm field of view. This field of view was conservatively selected to include the soil area beneath the foundation that undergoes deformation due to its movements. Various software tools are available for PIV analysis; in this study, PIVlab software (Version 2.60), developed by Thielicke in 2014 within the MATLAB framework (Version 2015a) [

43], was utilized. This software analyzes particle flow by calculating displacement vectors across different frames. Each test, lasting 320

s (for strip footings), produced a total of 160 frames of the soil mass. The accuracy and precision of the PIV analyses were evaluated through repeated analyses and by comparing the displacement vector outputs for the foundation center with settlement values obtained from the LVDT sensor.

5. Conclusions

In recent years, severe earthquakes have driven researchers to seek methods that limit forces and deformations on structures, preserving their integrity during seismic events. One promising approach in foundation design is the rocking isolation method, where the foundation is allowed to uplift, mobilizing bearing capacity and triggering deformation mechanisms in the soil under intense shaking. While research has primarily focused on surface foundations, in practice, foundations are often embedded due to factors like weak surface soils, the need for greater bearing capacity, or scour protection. This study explores the distinct seismic behavior of embedded foundations compared to surface ones. In this study, the rocking behavior of foundations with varying embedment depths is investigated through physical modeling under 1 g conditions and slow cyclic loading. The key findings are as follows:

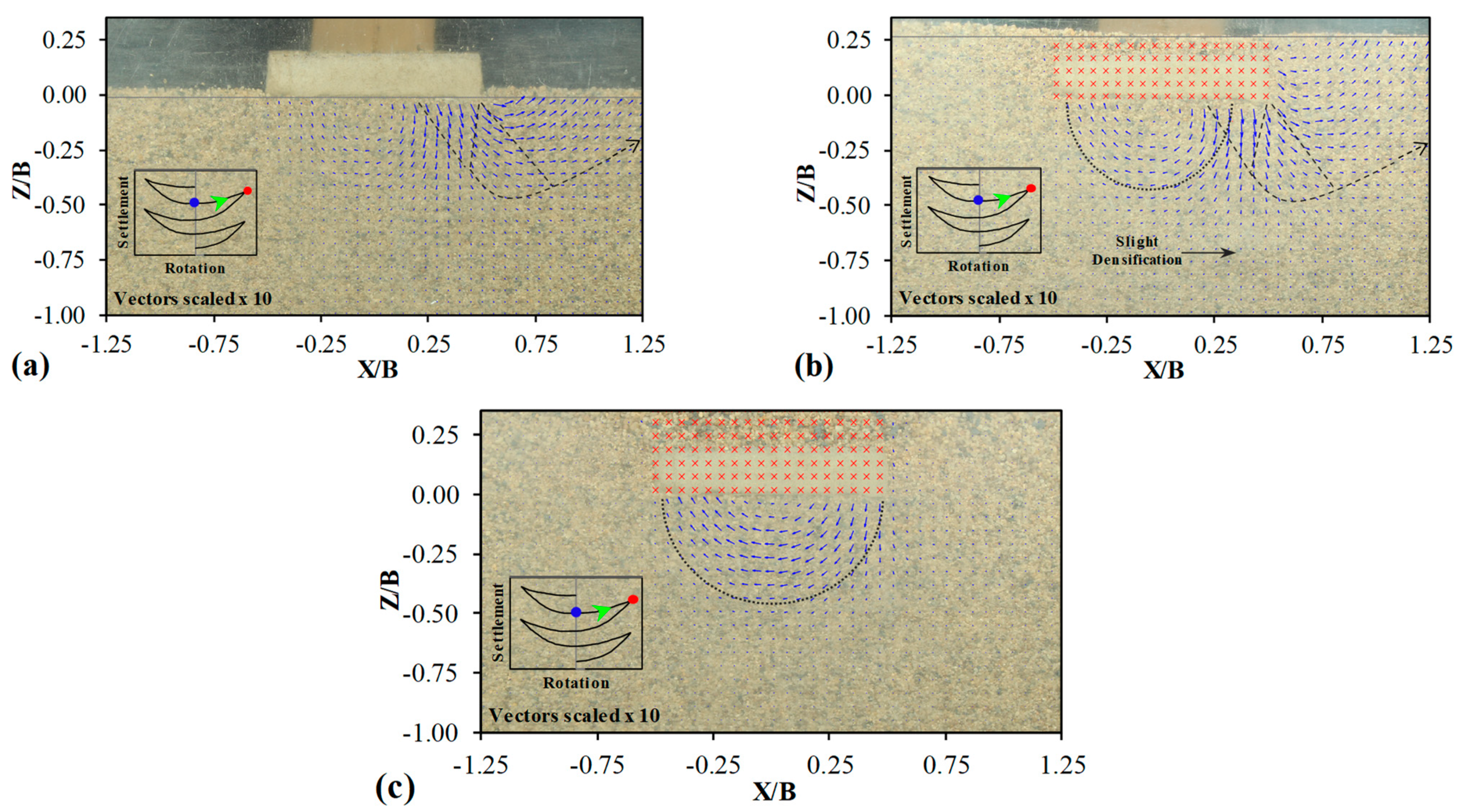

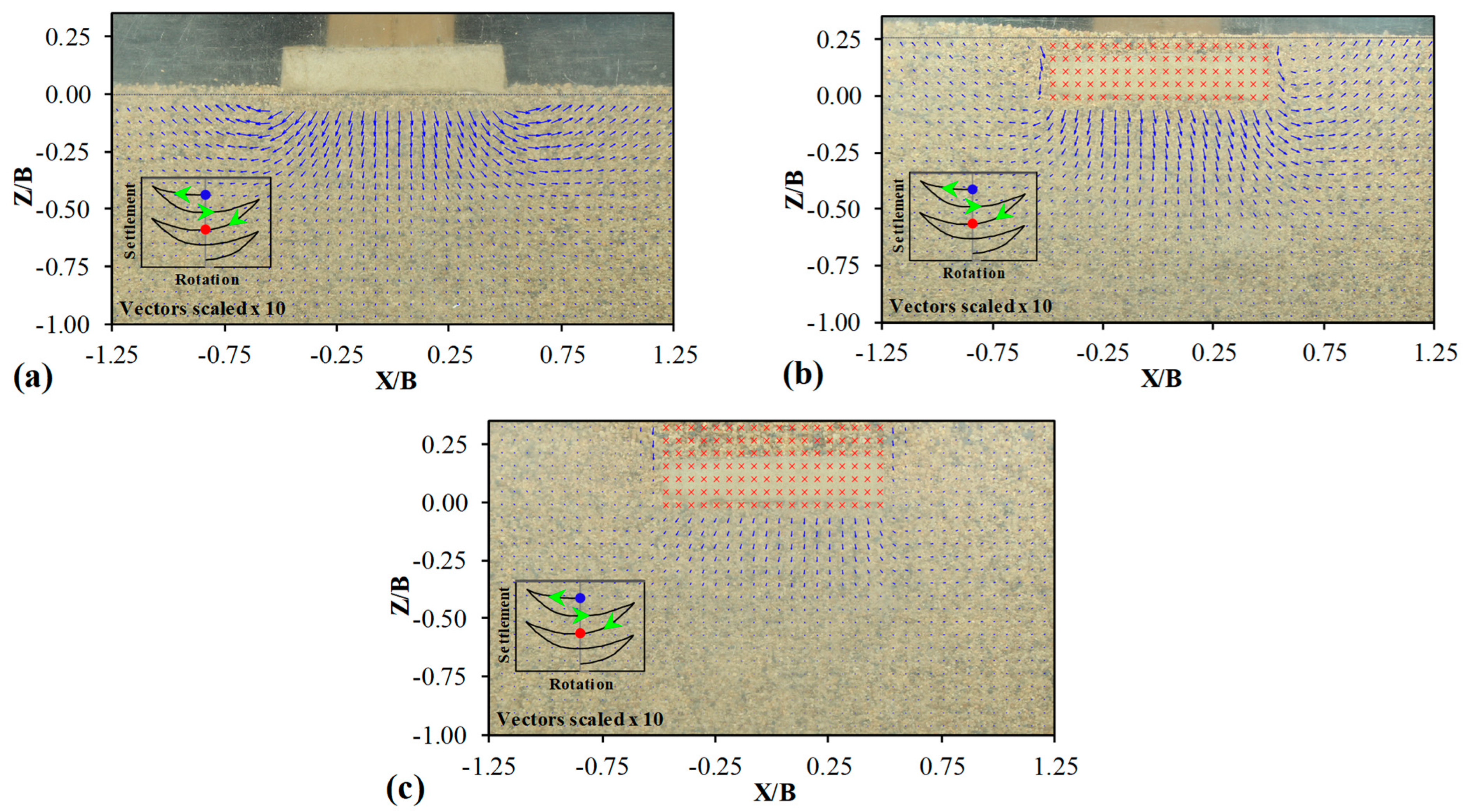

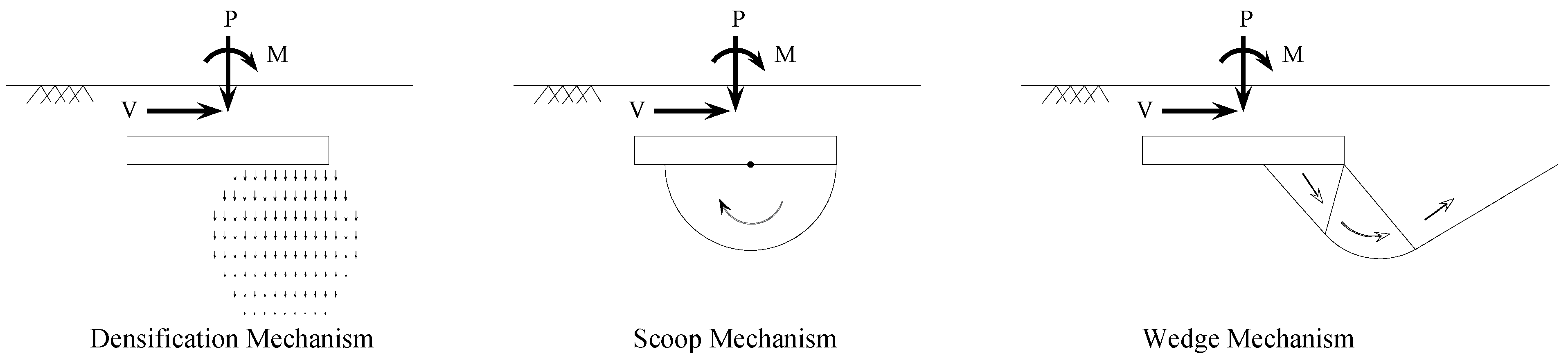

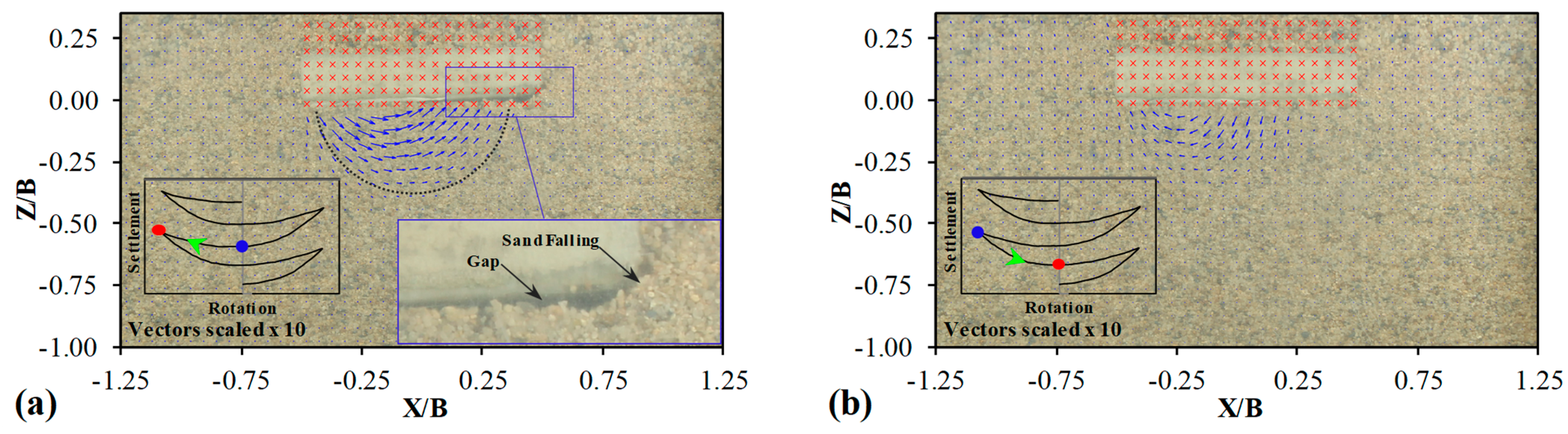

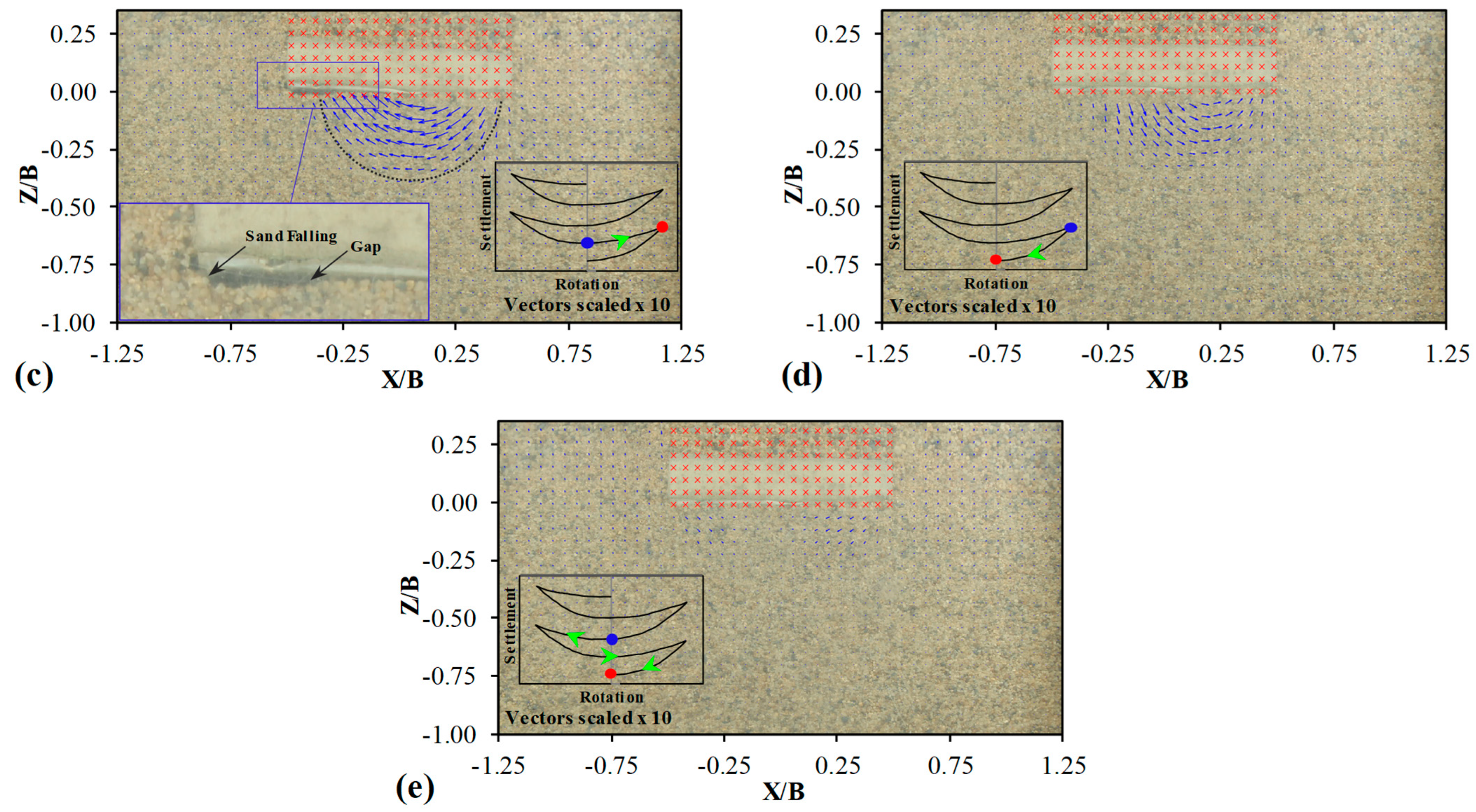

The soil deformation mechanisms during the quarter loading cycles include densification beneath the toe (loaded edge), outward wedge deformation, and scoop beneath the foundation.

As a foundation’s embedment depth increases, the outward wedge deformation mechanism becomes more restricted. In experiments with an embedment depth of B, soil movement from beneath the foundation is minimal. In contrast, for surface foundations, both outward wedge deformation and toe densification occur simultaneously, leading to greater foundation settlement.

The final settlement of the foundation stems from two mechanisms: soil densification beneath the foundation during loading and unloading quarter cycles, and soil escape from beneath the foundation during loading quarter cycles. As embedment depth increases, the influence of the soil escape mechanism diminishes. Although the scoop mechanism may fully develop, it does not significantly impact the final settlement. However, it can absorb considerable energy during rocking motions by creating a slip surface and inducing substantial soil displacement.

The moment capacity of the foundation increases with embedment depth due to passive and active soil pressure acting in front of and behind the foundation’s thickness, the weight of the overlying soil, and shear effects from the side faces in contact with the soil.

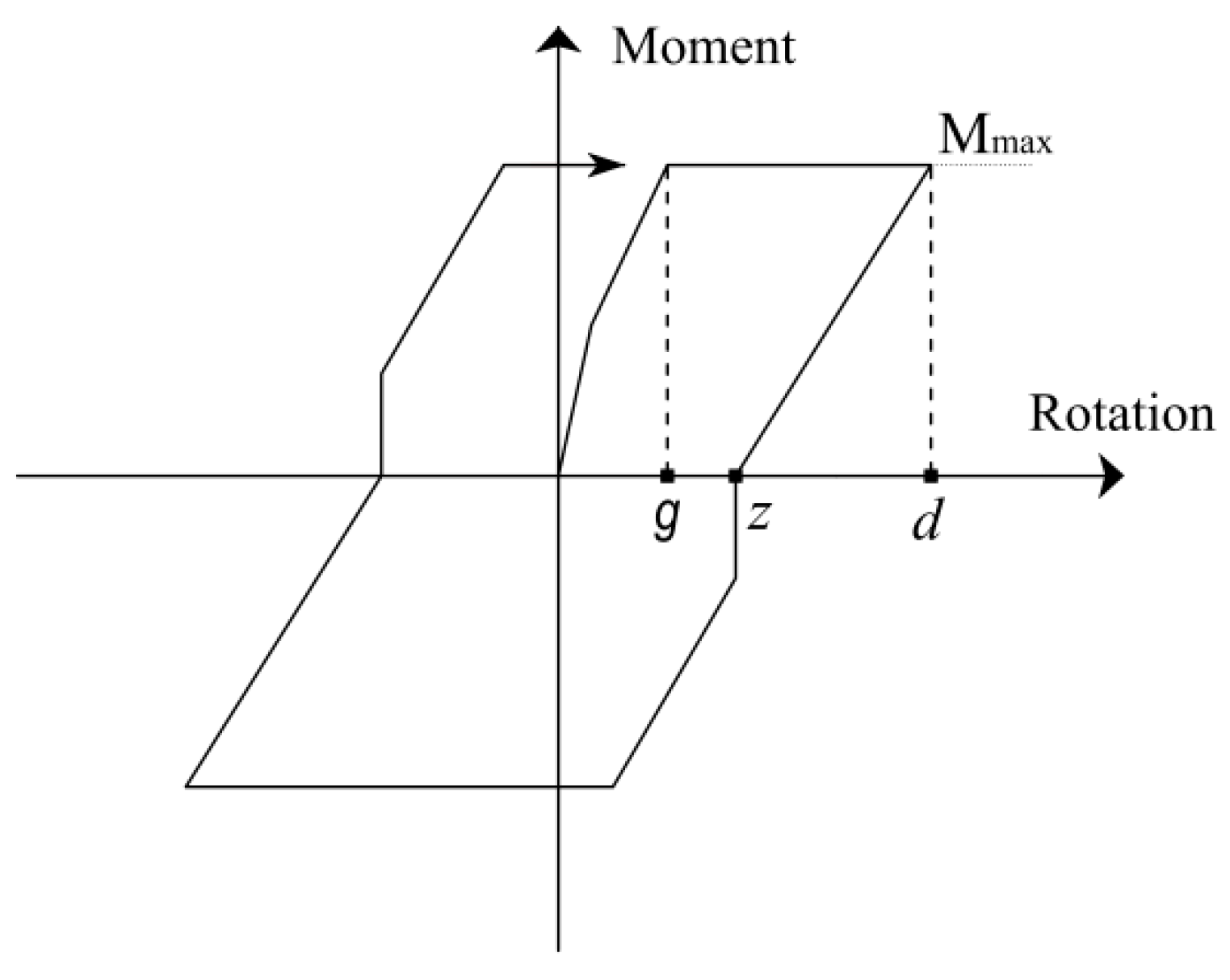

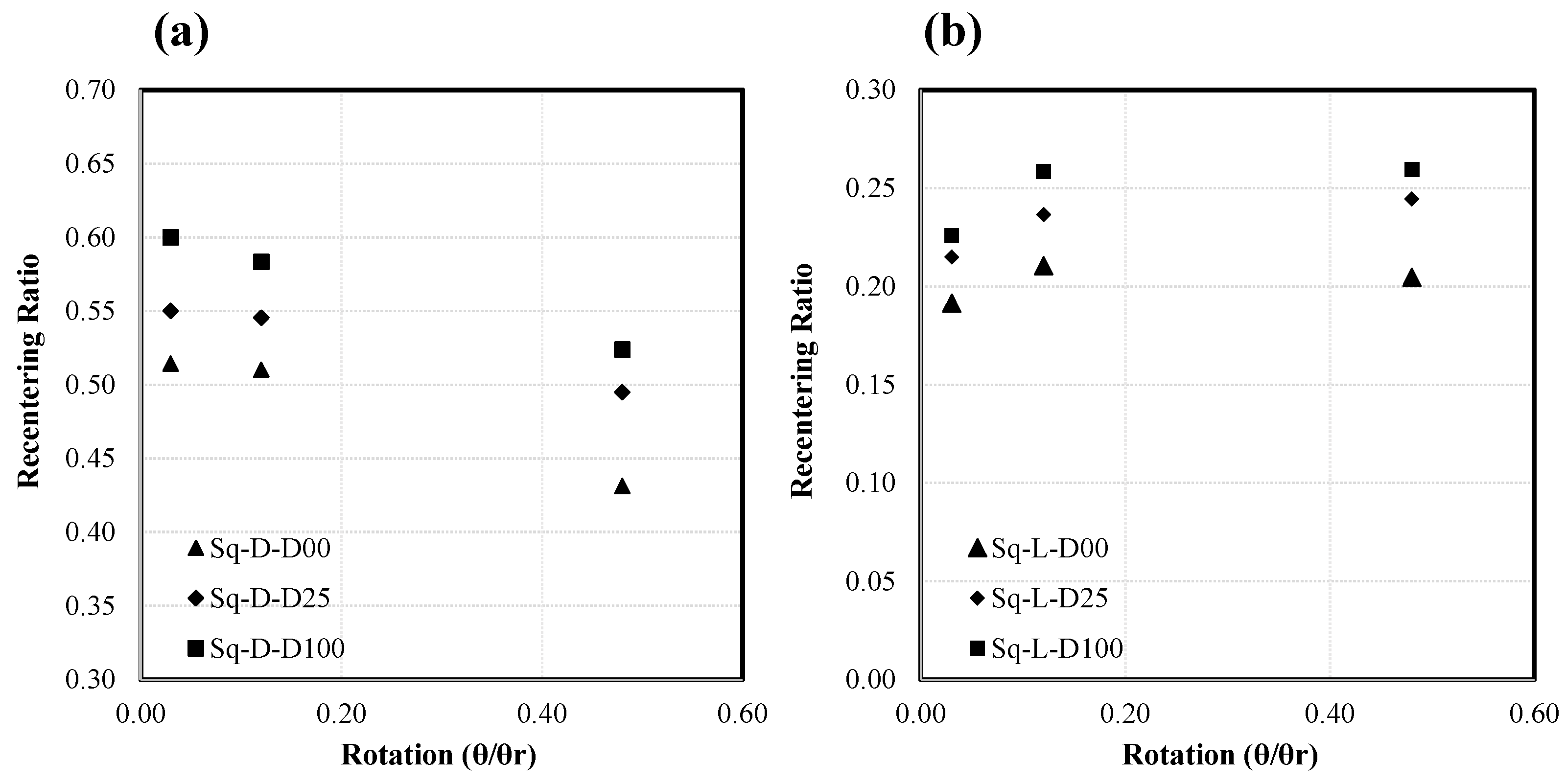

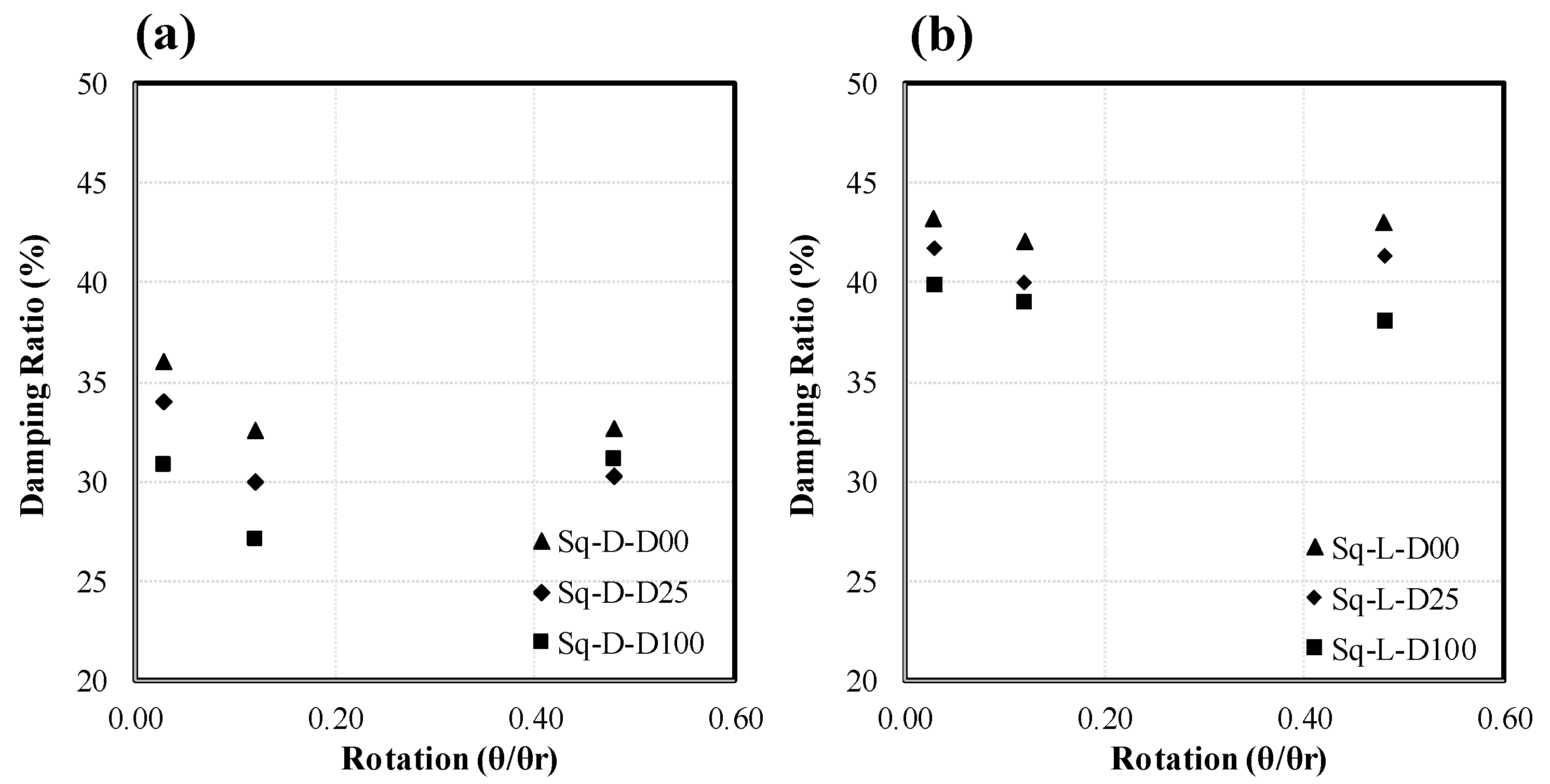

As the foundation’s factor of safety and embedment depth increase, the moment–rotation curves become narrower and more S-shaped, resulting in greater recentering and reduced damping.

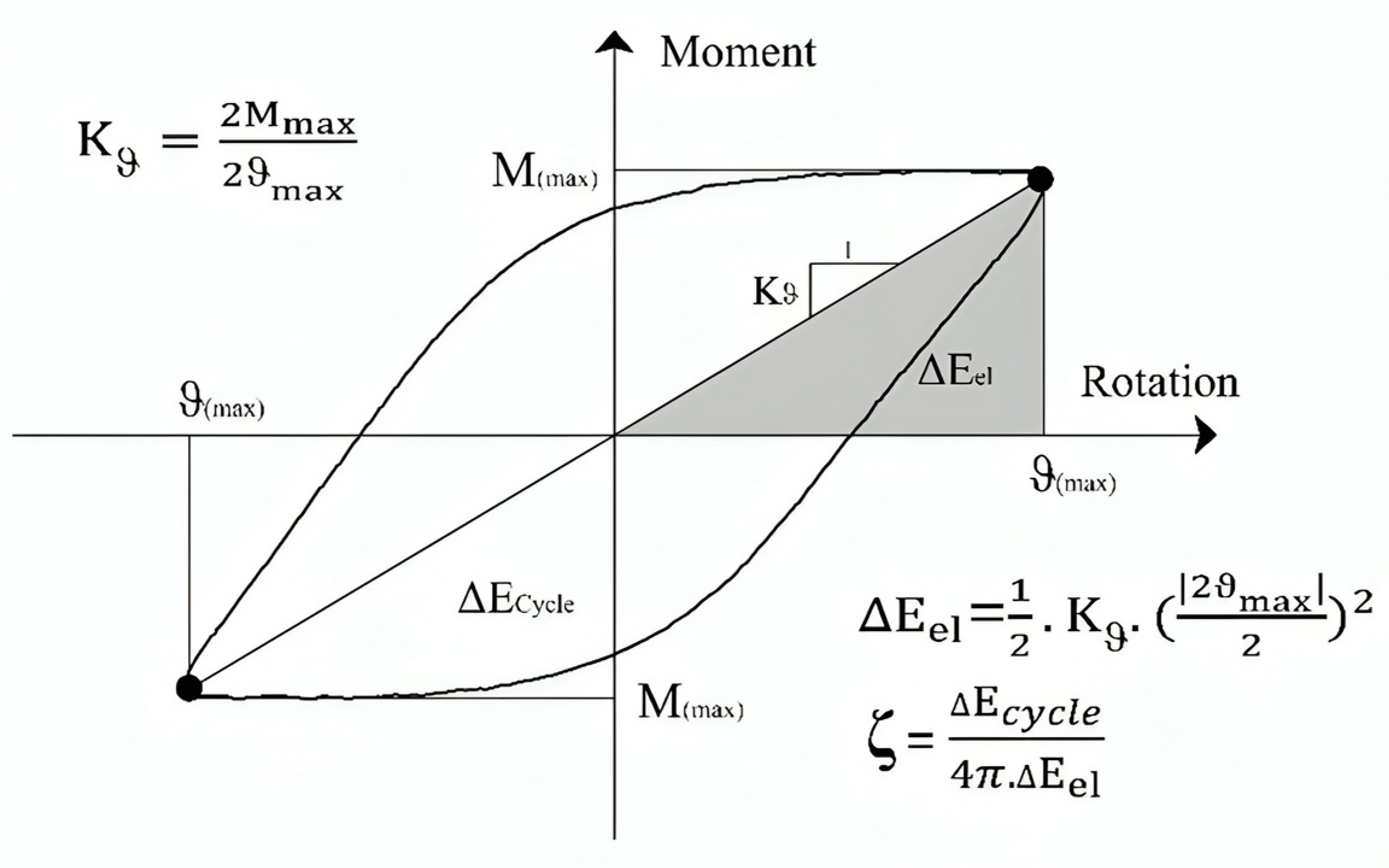

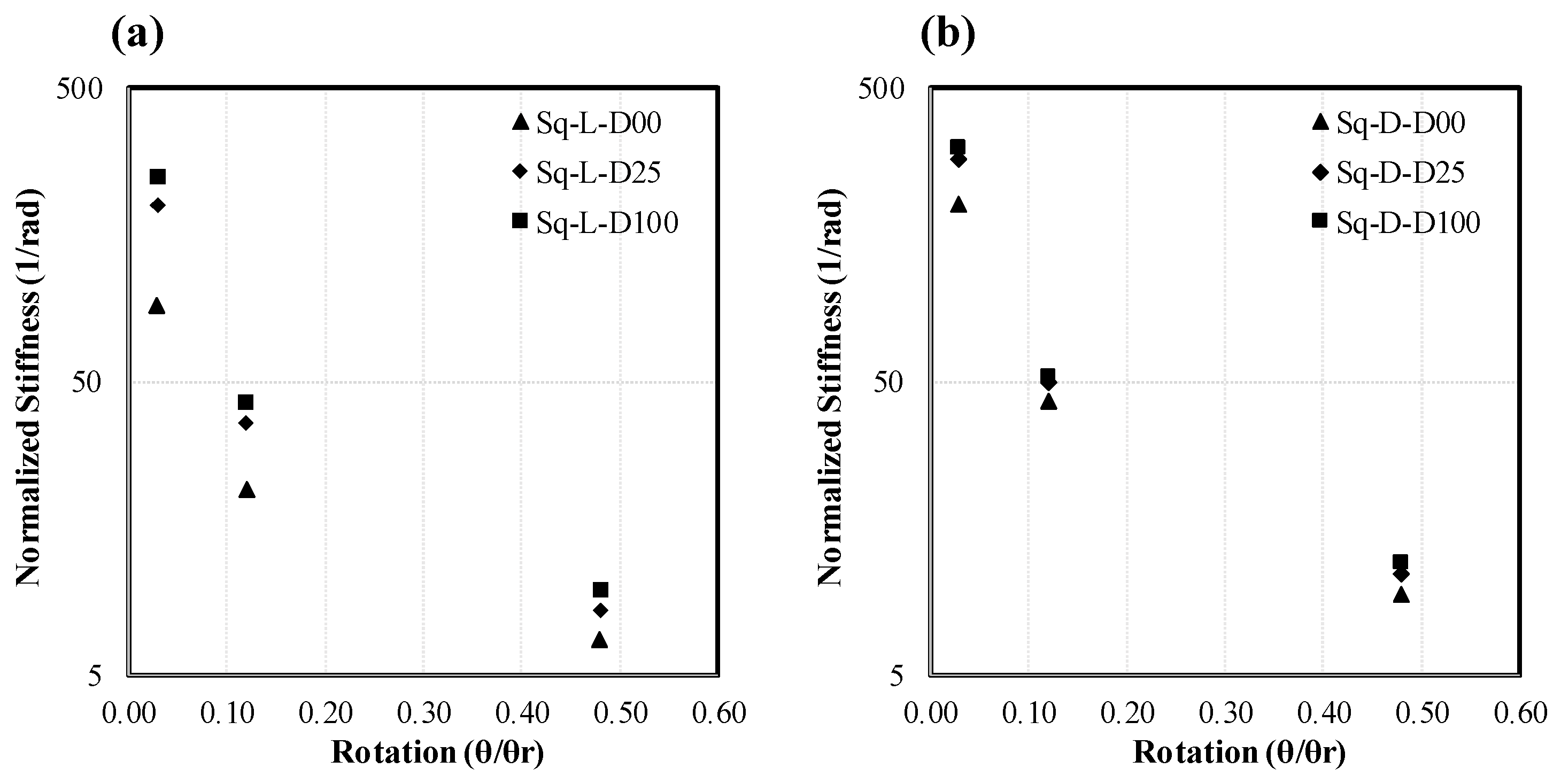

As the foundation’s factor of safety and embedment depth increase, the rocking stiffness of the foundation also rises, attributed to the enhanced moment capacity.

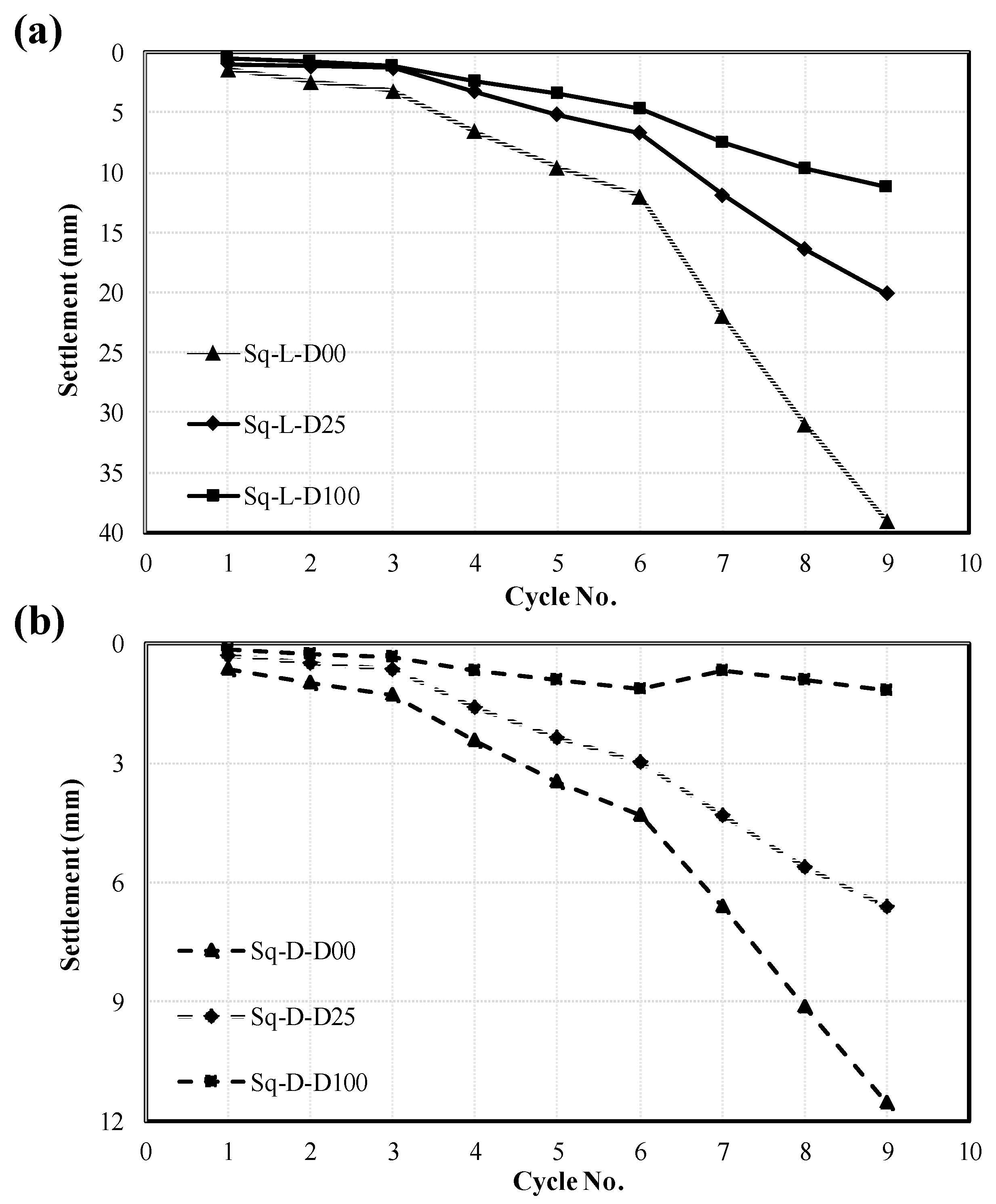

As the foundation’s factor of safety and embedment depth increase, settlement during loading cycles decreases. This reduction is primarily due to the restriction of the outward wedge deformation mechanism of the soil mass.